Founded on principles of safety, honesty, and integrity, Richard offers complete solutions for its customers across the industrial and energy industries, managing projects with seamless efficiency, every time

Writer: Lily Sawyer | Project Manager: Scarlett Burke

Afull-service engineering, procurement, and construction (EPC) firm in the petrochemical and refining sectors, Richard utilizes its unique combination of capabilities to deliver innovative services and solutions to its clients, from concept to completion.

The family-owned business is built on fundamental principles of integrity, safety, and reliability, while its vision centers around prioritizing the needs of its clients.

Supported by over 2,000 talented employees, the company is proud to offer some of the industry’s best and most experienced talent.

Headquartered in Beaumont, Texas, Richard also has offices across the state in Corpus Christi, Huffman, and Houston; Lake Charles and Giesmer in neighboring Louisiana; and an international facility in Kolkata, India.

The company is committed to further growing local economies in the communities in which it operates and proudly sponsors many regional charities thanks to its strong corporate social responsibility (CSR) principles.

Richard’s utmost priority is to execute all projects safely, on time, and within budget – all while maintaining the company’s core values.

With vast experience, expertise, and award-winning safety programs under its belt, Richard has earned its reputation for producing outstanding outcomes without compromise, providing reliable results.

Bringing customers’ visions to life through its long-standing expertise in EPC, Richard is committed to excellence and innovation, delivering turnkey solutions that exceed expectations.

A tight-knit family company on a mission to provide tailored EPC solutions to the refining and petrochemical industries, Richard sets itself apart from the competition.

In partnership with its dedicated team of employees, the company approaches each project with a personal touch, driven by its passion for excellence.

Richard’s unwavering commitment to honesty, integrity and safety ensures it delivers innovative solutions and best-in-class service, no matter the project’s complexity or size.

As a company committed to leveraging innovative solutions to deliver exceptional value and quality to its clients, last year Richard enhanced its engineering services with state-of-the-art 3D laser scanning technology.

The advancement has enabled the company to create highly accurate, detailed models of existing process units, streamlining facility surveys and significantly reducing the potential for errors.

Key benefits of the 3D laser scanning include:

PRECISION AND ACCURACY – The company’s cutting-edge technology captures intricate details, ensuring precise models that reflect the exact specifications of each client’s process units.

EFFICIENCY – By utilizing 3D laser scanning, Richard expedites the surveying process, saving both time and resources.

ERROR REDUCTION – The detailed models produced through the technology minimize the likelihood of errors during project execution, enhancing overall quality.

INTEGRATION WITH LEADING SOFTWARE – Richard works with industry-leading programs to ensure seamless integration and optimal results, such as:

• CADWorx® Plant Professional – A powerful and versatile solution designed by Hexagon offering unmatched flexibility and scalability to streamline the entire plant design process.

• CADWorx® Equipment – A module within Hexagon’s CADWorx® Plant Professional software that provides tools for creating and designing 3D equipment models.

• AutoCAD – A leading computer-aided design (CAD) software developed by Autodesk used for precise 2D and 3D drafting, design, and modeling in industries like architecture, engineering, and construction

• Isogen® – A leading solution for the total automation of piping isometric drawing production from CADWorx®, Isogen® reduces errors and improves consistency, while being fully customizable to meet users specific drawing standards.

On a mission to become the industry’s contractor of choice for EPC work, Richard vows to pursue success without compromising on its core values and strives to cultivate and maintain long-term relationships with its clients.

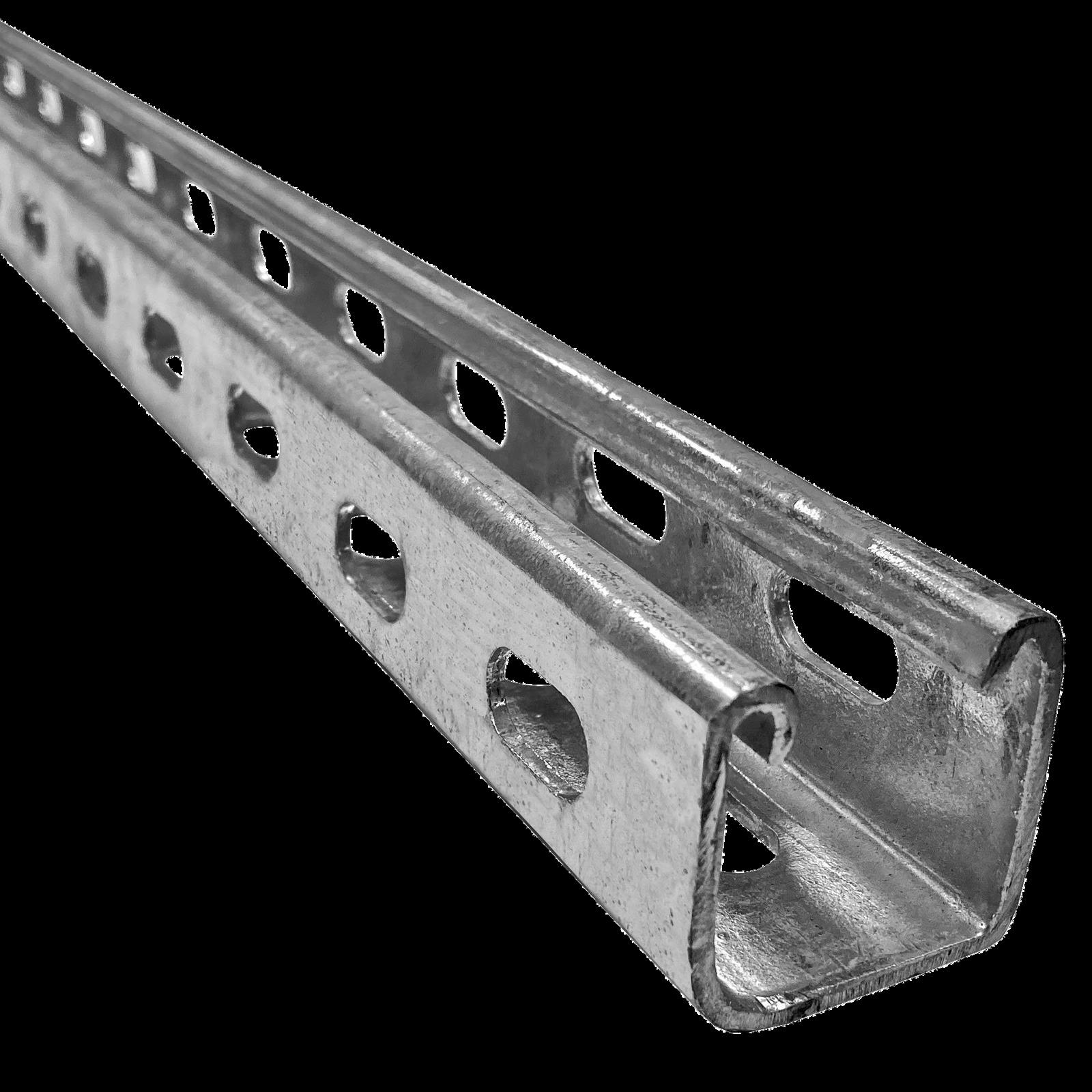

Known for operating one of the largest pipe fabrication facilities between Houston and Baton Rouge, Louisiana – totaling 85,000 square feet of dedicated shop space – Richard is substantiating how it is built to deliver and engineered for precision.

Featuring a segregated shop space for carbon steels and alloys, and capacity to produce over 1,000 spools per month, the company’s fabrication facility is truly advanced.

Richard is proud of its less than one percent weld rejection rate here, which reflects its commitment to reducing operational waste, while full spool traceability is available from material receipt to shipment, providing customers with peace of mind.

Further to this, clients have access to quality assurance and spool tracking via Bluebeam – an industry-standard and state-of-the-art construction site logistics and planning solution.

Over the years, Richard has carved out a reputation for executing projects successfully time and again, while building meaningful relationships with its customers.

As such, the company has developed a comprehensive understanding of each client’s culture, plant environment, and preferred project execution standards, procedures, and practices.

Richard’s ability to offer either a single specialized service or utilize its vast portfolio of turnkey project execution capabilities – from routine plant maintenance to large-scale capital projects – differentiates it.

Its full-service capabilities for all disciplines, meanwhile, include process, civil, structural, mechanical, piping, electrical, instrument, automation, fabrication, and construction.

Richard, armed with over 30 years’ experience, provides its clients with accurate estimate development.

With top-level managers directly involved in each project, the company also provides integrated services for improved accuracy, efficiency, productivity, and accountability.

Not only building superior infrastructure, Richard also builds momentum for a renewable future.

From leading the first large-scale renewable diesel project in the US back in 2009, to continuing to drive innovation today, the company is proud to be fueling a cleaner, greener tomorrow.

As a company that values both teamwork and partnerships, Richard is able to leverage its diverse range of integrated capabilities to execute any project.

No matter its size or scope, the company is prepared to ensure each project’s success while continuing to prioritize quality and safety.

Richard understands that all projects are unique – its

Richard was proud to announce it had received the Highwire Platinum Safety Award 2025 in April this year.

The prestigious recognition is generally bestowed upon companies who achieve a safety score of 95 or more in Highwire’s rigorous safety assessment program.

Receiving this award demonstrates Richard’s deep dedication to safety and reflects the high standards it practices as part of its core values.

It speaks volumes about the unwavering dedication of the company’s teams, who consistently uphold exemplary levels of safety on every project, time and again.

As such, safety emerges as a truly shared responsibility among Richard’s workforce, and a true part of its culture.

extensive and diverse portfolio therefore demonstrates its ability to customize solutions to meet each client’s specific needs.

Equipped with such comprehensive capabilities, the company sees itself as more than just a contractor, but a committed partner, dedicated to delivering exceptional results every time.

Projects of note include the Naphtha Splitter in Port Arthur, Texas, a refining operation where Richard performed the second and third stages of front-end loading (FEL2/3), detailed engineering, and provided procurement assistance for a grassroots unit integrated with a new delayed coking unit.

The design emphasized maximum modularization, allowing the field contractor to achieve nearly 100 percent fit-up of all process modules on-site.

This approach also significantly reduced field labor hours, optimizing both cost and schedule.

The process unit, meanwhile, featured a dual-column split tower, overhead condenser/receiver, reboilers, heat exchangers, and more.

Additionally, all electrical systems, as well as the safety instrumented system (SIS) and distributed control system (DCS) equipment, were seamlessly integrated with the infrastructure supporting the new delayed coking unit.