®

®

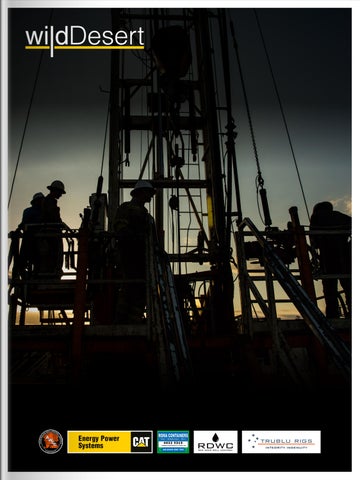

As a community-centric company, Wild Desert’s values are deeply embedded in its locally focused approach. COO, Mark Tonin, discusses how commitment to safety and innovative solutions has positioned it as a leader in the oil and gas industry

Writer: Rachel Carr | Project Manager: Eddie Clinton

“AS WE CONTINUE TO GROW, OUR FOUNDING PRINCIPLES – FAMILY VALUES, COMMUNITY SUPPORT, AND A RELENTLESS FOCUS ON SAFETY – GUIDE OUR OPERATIONS AND LONG-TERM PARTNERSHIPS”

– MARK TONIN, COO, WILD DESERT

Established in 2005 in the charming town of Roma, Queensland (QLD), Wild Desert is a dedicated, family-owned Australian enterprise driven by a clear vision – to deliver exceptional oil and gas field services built on safety, efficiency, and a can-do attitude.

Since its inception, the company has focused on supporting regional communities and local suppliers whilst maintaining strong partnerships with major energy operators.

This commitment to quality and reliability has shaped Wild Desert’s reputation as a trusted name in the industry.

“Today, we employ more than 450 people and remain deeply connected to our roots. In fact, Founders, David Whiley and Gina Tedford, still live in Roma and are active members of the local community,” introduces Mark Tonin, COO.

“Our core expertise lies in well servicing and integrated field support. We operate a fleet of well servicing rigs and provide comprehensive solutions, including well interventions, transport and logistics, mobile camps, equipment hire, maintenance, and fabrication.”

Wild Desert invests in innovation through its in-house design and engineering capabilities, ensuring customised solutions for complex field challenges.

“Safety and operational excellence remain at the heart of everything we do, supported by rigorous standards and continuous workforce development,” he notes.

Furthermore, with its headquarters in Roma and a corporate office in Brisbane, QLD, Wild Desert maintains a strong presence across the Surat and Cooper Basins, significant geological formations known for their large resources and economic importance.

“Our clients include leading oil and gas operators who value our responsiveness, flexibility, and proactive problem-solving.

“As we continue to grow, our founding principles – family values, community support, and a relentless focus on safety – guide our operations and long-term partnerships,” Tonin impassions.

Over the past 20 years, Wild Desert has navigated multiple industry challenges, including sharp downturns in oil and gas activity and the liquified natural gas (LNG) investment cycle, as well as the unprecedented disruption caused by global events.

Each downturn brought reduced rig utilisation, project deferrals, and significant workforce pressures and reductions, whilst the COVID-19 pandemic added supply chain delays, border restrictions, and heightened health and safety requirements.

These cycles tested the resilience of service providers across Australia, particularly those operating in remote regions.

However, what sets Wild Desert apart is its ability to adapt and maintain stability through these volatile periods.

“As a family-owned company, we’ve built a reputation for reliability by offering integrated solutions – well servicing, logistics, mobile camps, maintenance, and in-house design and fabrication – under one roof.

“Our ‘local-first’ approach strengthens supply chains and supports regional communities,

whilst our unwavering focus on safety and operational excellence ensures continuity even in challenging conditions,” Tonin prides.

Meanwhile, Whiley and Tedford remain active in Roma, reinforcing a culture of trust, accountability, and long-term partnership that competitors often struggle to match.

AWCC prepares new entrants for safe industry access through Preferred Provider delivery of the Industry Safety Induction. Turbo Certificate II gives a fast, nationally recognised pathway into the field, supported by weekly face-to-face and online well control training options.

AWCC builds practical competence through weekly short courses and ongoing compliance refreshers in Brisbane and Toowoomba, including Common Industry Competency training. AWCCs exclusive Turbo Certificate III accelerates progression through a fasttracked pathway designed for real-world advancement.

Capability under pressure demands deeper technical skill. AWCCs Certificate IV, seamless RPL via online portals and interview access, IWCF Level 3 and Level 4, and online well control training, develop rig-side decision making, pressure awareness, and operational integrity, available face-to-face or remotely for operational flexibility.

Leadership underpins safe operations and performance. AWCC advances future supervisors and OCRs through Diploma pathways, seamless RPL via online portals and interview access, and IWCF Level 4. AWCC Access provides skilled labour supply to support operational needs, completing the workforce cycle.

Australian Well Control Centre congratulates our partner, Wild Desert on its 20-year milestone, a testament to capability, resilience, and leadership within Australia’s oil and gas sector. Since AWCCs inception, our organisations have worked side-byside, delivering IWCF well control training, short courses, ISI induction, and compliance refreshers that support Wild Desert’s operational success. AWCCs exclusive Turbo Certificate pathways, can benefit Wild Desert from fast-tracked, industryready personnel who arrive trained, vetted, and prepared for safe deployment, reducing disruption and lowering workforce mobilisation costs. We are proud to support Wild Desert in developing a skilled workforce and look forward to strengthening our partnership into the future, extending capability across Australia and the wider APAC region.

“AS A FAMILY-OWNED COMPANY, WE’VE BUILT A REPUTATION FOR RELIABILITY BY OFFERING INTEGRATED SOLUTIONS – WELL SERVICING, LOGISTICS, MOBILE CAMPS, MAINTENANCE, AND IN-HOUSE DESIGN AND FABRICATION – UNDER ONE ROOF”

– MARK TONIN, COO, WILD DESERT

“A key differentiator for us is our Australian-only focus and local ownership. Unlike global service providers, which often face delays due to overseas decision-making or competing international priorities, Wild Desert operates without influence from foreign markets or global headquarters,” he explains.

“This independence allows us to respond quickly to clients’ needs, adapt to local conditions, and maintain operational certainty –critical advantages in an industry

where timing and reliability are everything.”

This combination of scale, flexibility, innovation, and community commitment has allowed Wild Desert to not only survive industry downturns but also emerge stronger, with a proven track record of delivering safe, efficient, and responsive services when clients need them most.

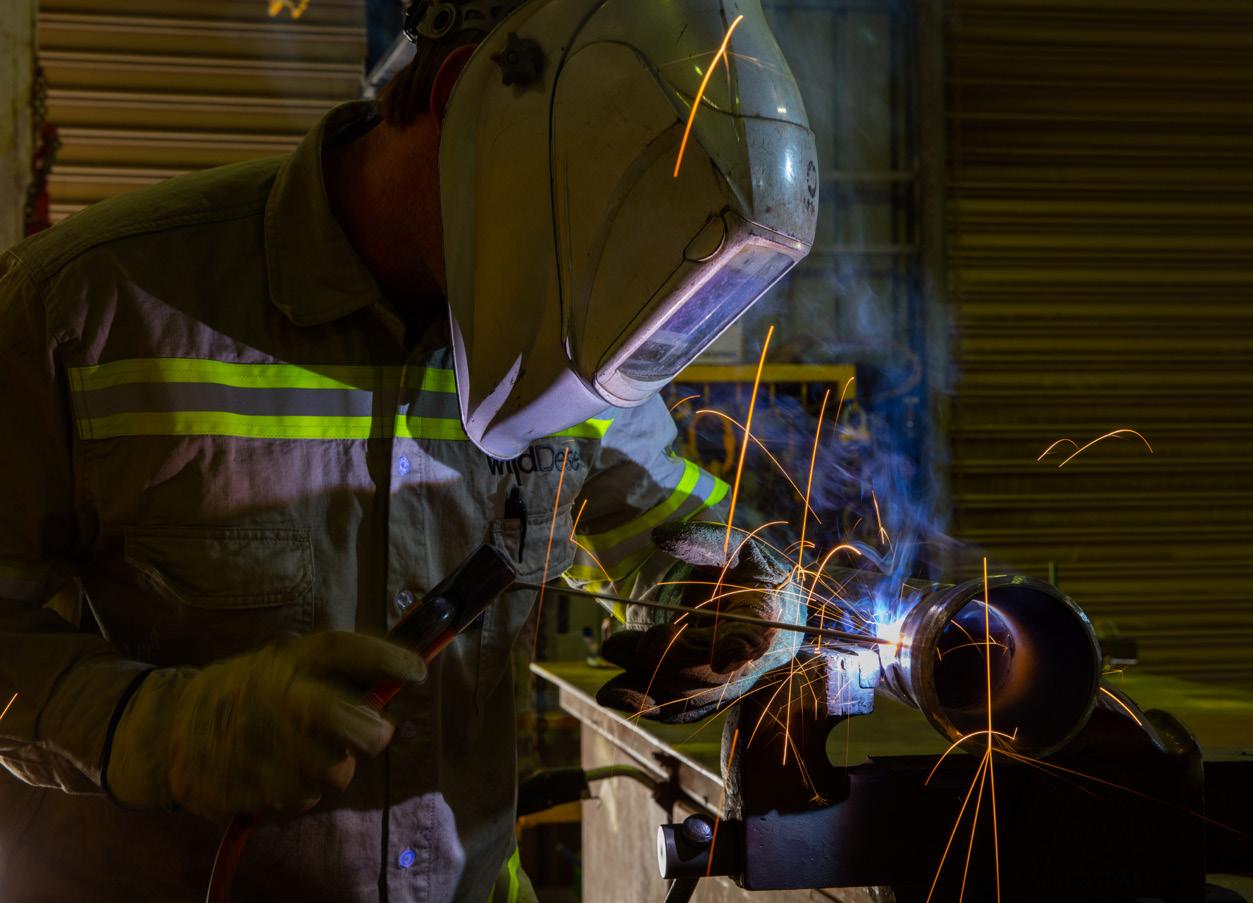

Wild Desert’s local manufacturing,

maintenance, and fabrication facility contributes to its overall efficiency and service capabilities.

“Our local manufacturing facility is a major contributor to our efficiency and service capability. Having in-house engineering, maintenance, and fabrication means we can handle repairs, modifications, and equipment builds without relying on external vendors,” imparts Tonin.

This approach reduces downtime, quickens turnarounds, and keeps operations running smoothly by ensuring equipment is fit for purpose and withstands the harsh conditions the Australian landscape demands.

“Our rigs operate in isolated locations, with the Cooper Basin specifically being an extremely demanding and challenging environment. The remoteness of well sites requires robust equipment that is durable and can support 24/7 operations, as clients demand and expect,” he outlines.

“The ability to fabricate and assemble ancillary equipment, from trailered mud tanks and mud pump and generator trailers to office shacks, bespoke skids, and support equipment, gives us the flexibility to meet specific customer needs quickly and cost-effectively.”

Ultimately, this self-sufficiency enables Wild Desert to maintain high standards, respond more quickly to challenges, and deliver reliable field services.

A new hybrid-electric rig, meanwhile, is expected to bring several improvements to the company’s operations, such as lower noise levels that will enhance safety and comfort for crews and reduce disturbances for landholders.

The rig’s lower fuel consumption will also mean fewer emissions, less fuel transport, and improved safety through reduced travel to fuel resupply points.

Local sourcing is key to Wild Desert’s supply chain strategy and directly impacts its operational efficiency.

“As a locally owned Roma company, we understand that the strength of our operations lies in our community,” Tonin smiles.

“By prioritising local, regional, and Indigenous participation, we ensure our supply chain remains responsive and resilient in the demanding oil and gas industry, reducing the impact of international market pressures where possible.”

The company actively recruits personnel from Roma and the surrounding areas for field, office, and workshop roles, and aims to source at least 50 percent of its procurement from the Maranoa region, including engaging local suppliers for freight, accommodation, catering, maintenance, and consumables.

“Our partnerships with Indigenous businesses such as Waddi Springs further reinforce our commitment to inclusive economic growth.”

This approach delivers measurable outcomes – 42 percent of Wild Desert’s total spend is local, and 82 percent is within QLD.

“Beyond numbers, local sourcing reduces lead times, improves reliability, and strengthens relationships, enabling us to adapt quickly to changing operational needs. It also supports community development through employment, apprenticeships, and sponsorship of regional initiatives.

“For Wild Desert, procuring locally is not just a policy – it’s a strategic imperative. It enables us to remain agile and flexible, ensuring we meet the challenges of the oil and gas industry whilst creating lasting benefits for the communities we call home,” assures Tonin.

In regional Australia, where infrastructure is scarce and working conditions are tough, energy reliability is critical. Energy Power Systems Australia (EPSA) is proud to support Wild Desert – one of the nation’s leading providers of well servicing rigs – with a fully integrated hybrid energy solution designed to meet the unique demands of remote oil and gas operations.

Established in Roma, Queensland in 2005, Wild Desert has grown into a trusted partner to the oil and gas sector, delivering well servicing, transport, and mobile camp operations across regional Australia. These environments demand energy systems that are mobile, durable and increasingly low-emission.

EPSA’s recent delivery includes a combination of diesel and battery systems, a complete hybrid package engineered and integrated to deliver high performance, lower fuel consumption and reduced environmental impact.

EPSA specialises in engineered energy systems across industries, with a particular focus on tailored solutions for oil and gas. From hazardous zone compliance to mobile generator configurations, the company’s ability to design for specific customer needs is a core strength.

For Wild Desert, the hybrid system was designed with remote reliability and efficiency in mind. The project scope included:

• 2 x Cat® C18 770kVA prime-rated generator sets, with custom control systems, air shut-off valves, sparkarrested exhaust systems, and additional local upfit to suit site requirements

• 1 x Cat® PGS1260 BESS with custom controls, featuring the Cat® BDP1000 bidirectional inverter. This unit provides 1000kW of continuous power with a 1260kW overload capacity

• Full integration and testing of the BESS and generator systems to ensure seamless operation and optimised load management

“We’ve worked with many oil and gas operators to develop customised builds to suit their environment,” said Scott Bennett, General Manager Engine Solutions.

“With Wild Desert, we delivered a complete hybrid system that supports energy security, reduces fuel use, and helps them meet carbon goals.”

EPSA’s approach goes beyond simply delivering equipment. With technical depth and hands-on project experience, the team plays an active role in helping customers transition to new energy models.

“Many of our customers are actively looking for ways to lower their carbon footprint, without compromising operational performance,” said Bennett.

“Hybrid systems like this give them that flexibility. They’re clean, scalable, and designed to run reliably even in Australia’s harshest conditions.”

EPSA’s integrated solutions are already being adopted across remote and regional operations, and the Wild Desert project is a benchmark example of innovation tailored for real-world performance.

As the authorised Cat® power systems dealer for Australia, Papua New Guinea and the Solomon Islands, EPSA brings together global product innovation and national delivery capability. It operates a vast dealer network, ensuring service and support coverage for even the most isolated customer sites.

“No other provider has the national footprint we do,” said Bennett. “That means better uptime, faster support, and ultimately less risk for the customer.”

EPSA’s energy portfolio is one of the broadest in the region, including diesel and gas generators, industrial engines, marine engines, hybrid systems, and BESS, all backed by technical specialists and project managers who understand industry challenges across sectors like mining, oil and gas, construction and agriculture.

Customers are facing growing pressure from investors, regulators, and communities to reduce emissions. For many, hybrid systems are a practical step forward, blending traditional power with clean energy storage to reduce fuel consumption and lower environmental impact.

“This isn’t about ticking a box, it’s about practical sustainability,” said Bennett. “Our solutions help customers meet their operational needs whilst making meaningful progress towards lower emissions.”

EPSA is continuing to invest in battery and hybrid energy systems that help customers stay ahead of compliance requirements and operational risk.

EPSA’s customer research shows that whilst product performance and technology are important, customers place the greatest value on ease of doing business, responsive support, and relationships built on trust.

“We know that our customers value having someone who understands their environment and can help solve complex problems,” said Bennett.

“That’s where we add the most value, not just by delivering the hardware, but by being a reliable partner in their long-term success.”

EPSA’s hybrid project with Wild Desert demonstrates what’s possible when technology, customer understanding, and reliable delivery come together. As more businesses in remote and industrial sectors look to clean and flexible power options, EPSA is well positioned to lead that transition.

From Roma to the Pilbara, EPSA is powering progress, one integrated energy system at a time.

Energy Power Systems Australia (EPSA) sell, rent, design, engineer and commission Cat® engines, generators and custom-built power solutions – from individual units to multi-megawatt power stations – to customers in every industr y.

Whatever your energy and power requires, EPSA’s has the power you need.

“Moving away from hydraulic systems reduces the risk of oil leaks, which is a huge environmental win.

Additionally, improved remote diagnostics and real-time monitoring via variable-frequency drives (VFDs) will help minimise downtime and increase overall efficiency.

“Since this is the first rig of its kind in the workover space, we expect

even more benefits to emerge once it is fully operational and has completed several work scopes,” Tonin affirms.

Reflecting Wild Desert’s commitment to innovation and efficiency in the drilling and completions industry, the company recently completed

an advantageous project that showcases its adoption of autonomous technology.

“One of our most significant initiatives in 2024 has been the complete refurbishment and upgrade of two conventional workover rigs, transforming them into highly automated, integrated systems.

Established in 1997, Roma Containers has grown into a trusted name in the sale and hire of shipping containers throughout regional Queensland. With a team of experienced sales professionals and skilled boilermakers, the company delivers tailored solutions that combine quality craftsmanship with practical design.

Our Core Values

Our Story

• Safety First • Customer Satisfaction • Professionalism • Strong Work Ethic

• Dependability and Responsibility • Continuous Learning • Pride in Workmanship

What We Offer

Standard and Custom Containers:

From 6ft to 40ft, we supply and modify containers for hire or purchase.

Tier 1 Modifications:

• Dangerous goods storage

• Office blocks

• Refrigerated units

• Workshops and shelters

• Flat racks

• Certified sea-worthy containers

Tier 2 Modifications:

• Air conditioning

• Lighting and power

• Doors and windows

• Shelving and workbenches

• Vents and whirlybirds

For over 25 years, Roma Containers has provided cost-effective, reliable container solutions for businesses big and small. From standard units to custom-built designs, we pride ourselves on delivering products that meet the unique needs of every client. Phone: 0746225315 / 0409696703

Strategic Locations

Our main yard in Roma sits at the heart of Australia’s CSG operations, complemented by a Brisbane yard for efficient distribution. With IVMS tracking, site induction compliance, and environmental standards like ‘weed-free’ certification, we guarantee safe and timely delivery.

Why Choose Roma Containers?

• Over 25 years of proven reliability

• Competitive pricing and on-time delivery

• Exclusive distributor in Western Downs and Maranoa

• Capacity to stock 300 containers

• Direct sourcing from overseas suppliers

• Strong partnerships along the eastern seaboard

Roma Containers is your one-stop solution for container sales, hire, and modifications. We combine innovation, reliability, and exceptional service to help businesses thrive.

Email: info@romacontainers.com.au

Website: www.romacontainers.com.au

Facebook: Roma Container Sales and Hire

Instagram: romacontainers_sheahanbuilt

“This project was executed entirely in-house at our Roma maintenance facility and workshops, where we stripped the rigs back to their chassis and rebuilt them to deliver a modernised design that combines the robustness of conventional rigs with advanced automation and electronic controls,” details Tonin.

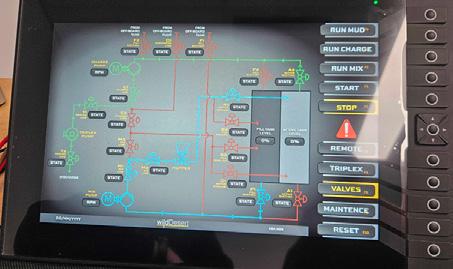

Key enhancements include an enclosed, air-conditioned driller’s cabin for improved safety and comfort and a fully integrated driller’s console featuring touchscreen readouts and joystick controls, enabling remote operation of mud pumps, air compressors, and booster packages.

These benefits are complemented by other advantages, including remote monitoring of all critical parameters, automated workover functions, including a weight-on-bit calculator and digital indicators, and safety integrations, such as floor- and crown-saver functions.

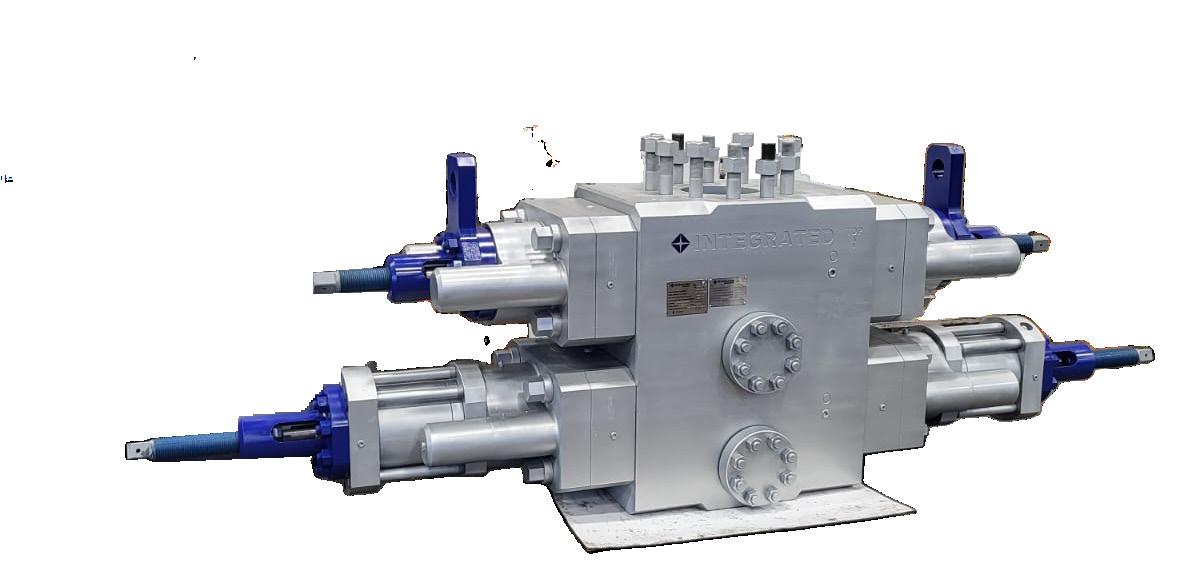

For over a decade, has supported the oilfield with dependable BOP and valve recertification services, competitive pricing, and unmatched product knowledge. Whether your operation involves drilling, snubbing, or well servicing, we have the equipment, expertise, and turnaround times to keep you moving.

From certification and testing to new and re-manufactured equipment sales, RDWC is your single-source solution for well-control reliability.

• 3-Year and 5-Year Certifications with Reseal and Testing

• Authorised Repair Facility for Integrated Equipment (Canada)

• New and Re-Manufactured Well Control Equipment

• Elastomers: Ram Rubbers, Packing Elements, Seal Kits and Dampeners

• Complete Ram Assemblies (Type 70, VBR, Type 81, HS, 88, U and Shearing)

• Pressure Testing, Torquing and On-Site Field Service

It also has hands-free rig-up and rigdown capabilities via remote control and hydraulic guy lines, with pressure monitoring, for enhanced stability.

This is a crucial development because integrated design delivers a fast, agile, and purpose-built QLD coal seam gas package, ensuring operational efficiency through automation and remote functionality. Moreover, safety is enhanced with advanced monitoring and handsfree processes, alongside long-term

durability and reduced downtime, thanks to modern joystick controls, digital readouts, and real-time data monitoring.

“To complement the rig refurbishment programme, we designed, fabricated, and assembled new mud pump and tank trailers entirely in-house. These were engineered with a strong focus on human factors and operational efficiency, incorporating advanced features such as next-generation

Skill shortages have long been a challenge for the oil and gas sector, particularly in Australia, where Wild Desert competes with mining, construction, and other heavy industries for talent.

Recognising this, the company launched its in-house mature-age

and school-based apprenticeship programme several years ago to develop local capability and secure the skills the industry needs.

This initiative reflects the passion of Whiley and Tedford, who are committed to creating opportunities for young people whilst addressing current and future workforce gaps.

By investing in apprenticeships, the company is building a strong pipeline of skilled professionals who will

acoustic panelling for superior sound attenuation and remote monitoring functions.

“This investment significantly enhances rig performance and delivers faster, more efficient rig-up and rig-down operations. By integrating these purpose-built trailers, we have strengthened the overall capability of our workover packages, ensuring greater reliability and productivity in the field,” he elaborates.

sustain the industry for years to come.

Furthermore, Wild Desert is proud to support the next generation and will continue expanding the programme, with plans to recruit additional school-based apprentices throughout 2026.

This initiative is crucial given the current large infrastructure projects underway in QLD, namely Cross River Rail and the upcoming 2032 Summer Olympic and Paralympic Games.

TruBlu Rigs is redefining what Australian operators can expect from rigs and their support equipment. Established in 2023 and driven by the principles of integrity and ingenuity, we design, manufacture and support advanced equipment solutions purpose-built for the demands of the Australian market.

Our mission is simple: deliver high-quality, fit-for-purpose rigs and equipment — on time, on budget and engineered for long-term field performance.

Operating from our Acacia Ridge facility in Queensland, TruBlu Rigs provides a fully integrated design and manufacturing capability, from electrical control cabins and rig control systems to complete rig solutions. Our team continues to expand the facility’s capacity, investing in systems and tooling that refine production efficiency and elevate product quality. Backed by a robust ERP platform and a trusted supplier network across South East Queensland, we ensure efficient procurement, traceability and quality control — essential for mission-critical equipment.

Unmatched Engineering Expertise

Our engineers bring deep industry experience, having designed multiple new rigs, upgraded existing rigs, and delivered key components such as pipe handlers, automated storage systems, drill heads, mud pump systems and API 4F-compliant masts.

With in-house mechanical, structural, hydraulic, electrical and PLC design capability, TruBlu Rigs offers a fully integrated engineering solution, eliminating the need for third-party component integration and reducing project complexity.

TruBlu Rigs has earned its reputation through committed aftersales service. We provide round-the-clock field support, including remote diagnostics, rapid troubleshooting and onsite technical assistance. For every new rig deployed, a senior technician remains onsite for the first two weeks to ensure smooth commissioning, operator training and optimal early-life performance — protecting both your investment and operational uptime.

+61 7 3640 5080 Sales Service Manager joshua@trublurigs.com

Our recent project portfolio includes:

• PLC Safety System upgrade for an existing workover rig.

• Offshore-rated hydraulic power pack design (800 hp, 2000 L/min).

• Airpack trailers, control systems and remote monitoring solutions.

• 235-kip hydraulic snubbing rig design for the Middle East.

• Generator, pipe bin and fuel distribution trailers.

• Jib winches and remote rig-up control systems.

— plus continuous site support, part sales and certification services.

Whether you are upgrading an existing fleet or seeking a fully engineered new rig package, TruBlu Rigs delivers reliable Australian capability backed by deep technical expertise and genuine service commitment.

TruBlu Rigs — Australian ingenuity. Proven engineering. Reliable support.

With the global shift towards net zero emissions, Wild Desert is pursuing innovations in battery-operated rigs and ancillary products.

“Our company is actively investing in innovations that reduce environmental impact whilst maintaining operational efficiency. A key focus has been on electrification and hybrid technologies; for example, we have deployed solar-powered remote office shacks on-site, reducing fuel use for auxiliary power.

“Future projects include solarpowered remote camps and we are currently looking into the feasibility of larger-scale hybrid support equipment, including remote camps. We are finalising the precommissioning of our hybrid-electric workover rig, supported by a battery trailer with generator back-up. This system allows us to perform an entire well workover on battery power alone,” Tonin specifies.

The benefits are substantial –reduced emissions, fuel consumption,

and spill risk, for instance, align with sustainability targets and enhance environmental outcomes, whilst lower noise levels improve crew working conditions and enable operations in noise-sensitive receptors.

A reduction in fuel burn requirements and fuel deliveries is also critical because driving remains one of the riskiest activities in Australia’s onshore oil and gas industry. Distances will be similar for trips, but overall kilometres driven will be lower because fewer trips are required.

Roma Wire and Steel are proud to be part of their local community and believe in giving back to those who support them.

They are sponsors of many local events from rodeos and campdrafts to children’s sport.

Roma Wire and Steel: 20 years strong - One of South West Queensland’s largest independent suppliers of steel products.

Locals Jamie and Natalie Dingle have been at the helm of the Roma-based steel business for the last 20 years during which time they have experienced substantial growth.

Ask them what the strength is behind their successful business and the answer will always be “customer service and experienced staff”.

Jamie is well-known throughout western Queensland, having spent 32 years in the steel and fabrication industry.

He comes from a rural background and has a vast knowledge of the local area which ensures he understands the needs of all facets of industry from gas to graziers, builders and fabricators.

From building sheds to designing cattle yards, Jamie will give you the right advice.

Roma Wire and Steel provides a wide range of steel supplies and are happy to source less popular items – “if you want it, we can get it” is their catchcry.

The business specialises in cattle handling equipment and will make “anything to your specifications”.

They offer an all day delivery service both in town and surrounding areas.

“These innovations not only help us achieve sustainability goals but also support our clients in meeting their own net zero commitments whilst delivering tangible safety and operational benefits,” emphasises Tonin.

“At Wild Desert, we pride ourselves on our innovation, agility, and flexibility – adapting quickly to client priorities and operational challenges. By integrating solutions like hybridelectric rigs, battery-powered systems, and solar infrastructure, we deliver practical, environmentally responsible outcomes without compromising performance.”

In the coming year, Wild Desert aspires to accomplish a multitude of ambitious goals.

“Our primary objective for the next 12 months is to sustain the highest standards of service quality whilst continuing to support our key strategic clients in delivering reliable and affordable energy.

“At the same time, we remain committed to strengthening

relationships with local suppliers and communities that have been integral to our success since the company began,” Tonin sets out.

As Wild Desert moves towards achieving its goals, the company is also focused on innovation and operational efficiency.

Robust processes position it well as the annual outlook appears promising and is characterised by consistency.

“In 2026, we anticipate operating 14 rigs, fully supported by our internal business units and divisions to ensure seamless execution. Based on current forecasts and global energy demand, the outlook for 2026-27 appears steady and stable.”

To complete these objectives, Wild Desert will implement strategic initiatives that promote collaboration and innovation across all teams, ensuring every member is aligned with its vision for sustainable growth.

“Future growth will largely depend on industry activity levels and market dynamics over the next few years. A major focus will be on developing and retaining top talent, enhancing crew expertise, and investing in training

programmes to maintain unparalleled excellence in service delivery.

“Safety and operational efficiency will remain at the core of everything we do as these are fundamental to our reputation and long-term success,” Tonin emphatically concludes.

Through an unwavering commitment to these principles, Wild Desert strives to uphold its high industry standards and build a brighter future for all involved.

Tel: (07) 4622 6004

www.wilddesert.com.au

PETRO Industrial delivers world-class fuel farm & lubrication storage with dispensing solutions, engineered for the rigorous demands of major mining operations. From in-house engineering and design, through to manufacture, installation, commissioning, and ongoing service, we provide true turnkey systems backed by advanced fuel management technology and secure cloud-based data storage. Talk to the team about your next bulk fluid project.