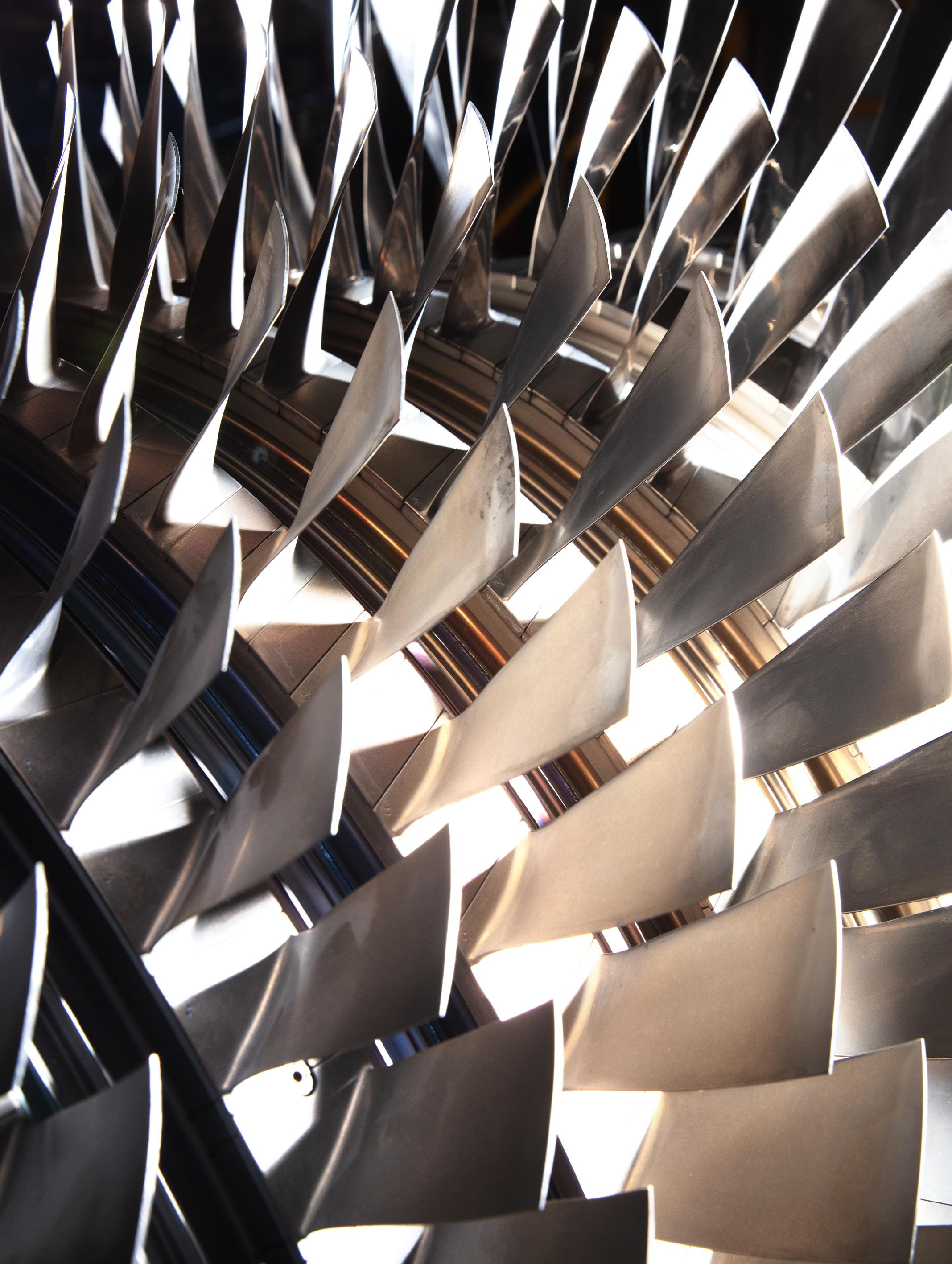

WORLD-CLASS AERO ENGINE AND COMPONENT REPAIR SERVICES

Providing world-class aero engine and component repair services to some of the most respected airlines, Hong Kong Aero Engine Services Limited is a global name in engineering. George Edmunds, CEO, tells us more about the company and its plans for a high-flying future

Writer: Lauren Kania | Project Manager: Josh Whiteside

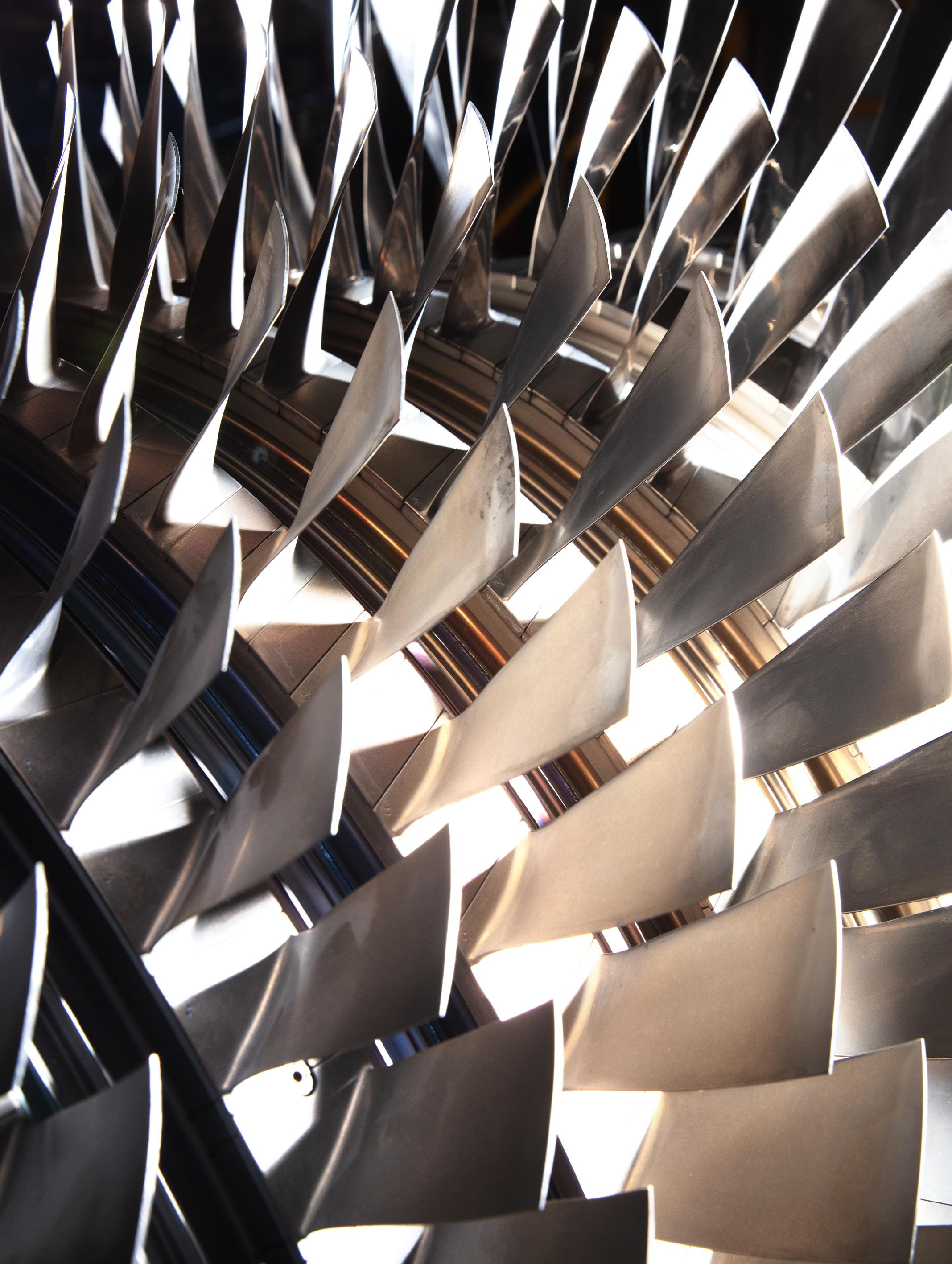

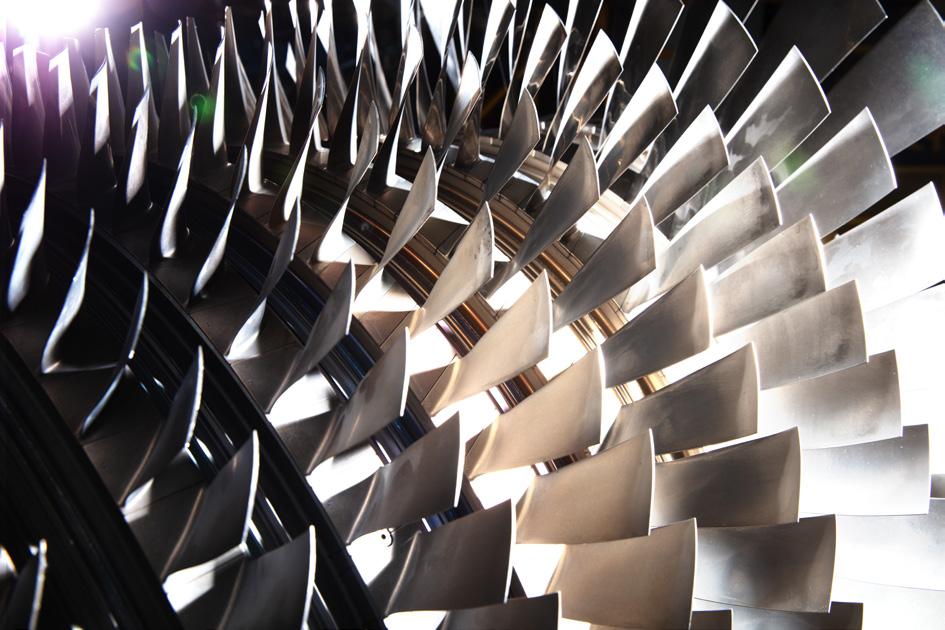

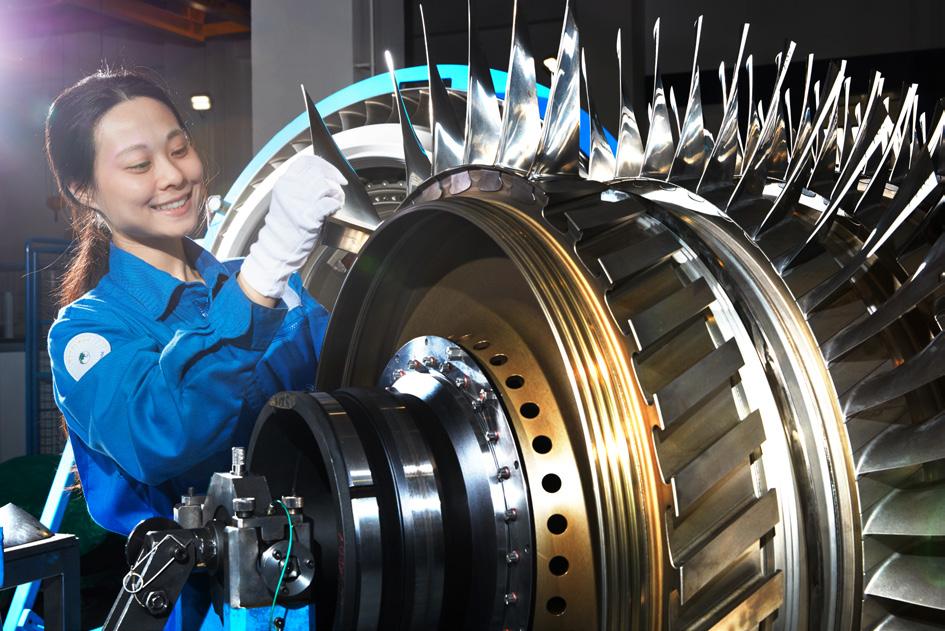

Established in 1997 as a joint venture between Hong Kong Aircraft Engineering Company Limited (HAECO) and Rolls-Royce, Hong Kong Aero Engine Services Limited (HAESL) has established itself as a globally recognised maintenance, repair, and overhaul (MRO) provider specialising in Rolls-Royce Trent engines.

With its headquarters based in Tseung Kwan O Industrial Estate, the company offers a full suite of services, including engine overhaul, testing, and component

repair. Since its inception, HAESL has proudly serviced over 5,500 engines and is set to achieve a record engine throughput of between 360 and 375 engines in 2025.

The company serves over 35 global airline customers, with strong representation in Hong Kong, the Chinese mainland, Asia Pacific (APAC), the Middle East, Europe, and North America. With growing demand from across the globe, as reflected in this year’s record engine overhaul volumes, HAESL has seen significant growth in its staff numbers, which now stands at over 1,650.

CAN YOU TELL US MORE ABOUT HOW YOU OVERHAUL ENGINES FROM ACROSS THE GLOBE, WITH THE UNITED ARAB EMIRATES BEING A MASSIVE PART OF YOUR CUSTOMER CHAIN?

George Edmunds, CEO: “HAESL’s customer base spans global airlines, original equipment manufacturers (OEMs), and strategic partners, with a strong presence in the APAC region.

“Within the region, we provide overhaul services to major carriers, including Cathay Pacific, Hong Kong Express (HK Express), Hong Kong Airlines, Singapore Airlines, AirAsia X Berhad (AirAsia X), All Nippon Airways (ANA), Japan Airlines, and major operators from the Chinese Mainland. In the EMEA region, Qatar Airways, Etihad Airways, and British Airways are also significant contributors to HAESL’s workload.”

“Managing this remarkable growth is a testament to our collaborative spirit and commitment to excellence,” introduces George Edmunds, CEO.

“To support this growth, we have actively looked to widen the talent pool we recruit from, moving from a

traditional male-centric workforce to a more diverse one. For success, it is essential that our people feel supported and know that our dedication to diversity and inclusion is unwavering. To ensure this, we have active internal networks that

foster a sense of belonging and ensure everyone’s voice is heard. Regular health checks and well-being workshops further demonstrate our commitment to creating an inclusive and supportive workplace for all.”

Safety is also an area in which HAESL has made significant strides. It achieved record-low lost-time injuries, which speaks volumes about the company’s robust approach to ensuring workplace safety. This starts with a proactive safety risk identification system, where crossfunctional engagement reflects the sense of shared responsibility in maintaining a safe environment – a feature of the company’s culture.

Equally, community engagement is a cornerstone of HAESL’s culture. It has collectively volunteered over 4,000 hours this year and made significant donations to local causes, reflecting a deep-rooted commitment to giving back and making a positive impact.

Since our establishment in 2012, SAMWO (CHINA & HK) CO., LIMITED, along with several packaging product manufacturers, jointly initiated a unified overseas sales strategy to achieve mutual development and win-win cooperation.

Since its establishment, our company has fulfilled its blueprint for exporting its products to various parts of the world. We have also become a designated supplier of materials to the Hong Kong SAR government.

Our main products include:

• Carton box (Material H838Y carton box) (Size: according to customer request.)

• Bearing box (Size: according to customer request.)

• NGV carton box with foam.

• 15 or 70 lattice box with foam.

• Carton paper (Size: according to customer request.)

We solemnly promise:

Guaranteed product quality and on-time delivery.

If you have special packaging requirements, our engineering term are happy to cooperate and provide samples until your satisfaction is achieved.

• Fan blade protective band.

• Plastic pallet size: (Size: 1200x800x145mm, load capacity 1.5 tonnes.)

• Freezer bag (Size:150x215mm.)

• Moisture barrier shielding bag (Size: according to customer request.)

• EPE foam sheet (Size: according to customer request.)

We welcome all businesses to contact us about using our packaging products.

Tel: (852) 3563 0980 FAX: (852)3616 6257 E-mail:info@samwoltd.com Website:samwoltd.com

“THE AIRCRAFT MAINTENANCE INDUSTRY IN HONG KONG IS CURRENTLY EXPERIENCING A DYNAMIC AND PROMISING PHASE, MAKING IT AN EXCITING SPACE TO BE WORKING IN”

– GEORGE EDMUNDS, CEO, HONG KONG AERO ENGINE SERVICES LIMITED

“These accomplishments are a testament to the strength of our culture and the incredible people who make up our team. We continue to build on this momentum and strive for even greater heights,” notes Edmunds.

Hong Kong is situated as a key hub for aviation. This position is built on a combination of geographic, economic, infrastructural, and strategic advantages that make it uniquely competitive both locally and internationally.

The region is the aviation gateway to the Greater Bay Area (GBA), consisting of 86 million people and a gross domestic product (GDP) of USD$1.9 trillion.

“Hong Kong’s aviation hub status is not just about location – it’s about connectivity, capability, and strategic foresight. With its infrastructure upgrades, integration into the GBA, and strong cargo and MRO capabilities, it remains a critical node in global aviation,” insights Edmunds.

Located in the heart of Asia, within a five-hour flight radius of half the world’s population, Hong

Kong is a truly ideal transit point for both passenger and cargo traffic, efficiently connecting the East and West.

Additionally, Hong Kong International Airport (HKG) is consistently ranked amongst the world’s best, with over 220 destinations served globally, alongside being the busiest international cargo airport, handling over 4.3 million tonnes of cargo annually.

Despite the setbacks caused by the COVID-19 pandemic, HKIA has recovered to 80 percent of prepandemic passenger levels, whilst cargo operations remained strong throughout.

This resurgence after the pandemic is fuelling demand for MRO services across all categories, including engine, airframe, components, and interiors. The Hong Kong aircraft maintenance market is projected to grow steadily through to 2031, driven by increasing air traffic in the APAC

BRIDGING CUSTOMER NEEDS WITH TECHNOLOGY AND EXPERTISE

At Jebsen & Jessen Technology – Industrial Services Division, we are dedicated to supporting the aerospace industry in Singapore, Malaysia, Thailand, Indonesia, and Hong Kong with advanced technical solutions.

True to our mission of “Bridging customer needs with technology and expertise”, we believe the best results come from working hand in hand with our customers. By taking the time to understand their needs, operations, and delivery timelines, we build relationships that go beyond transactions — relationships founded on partnership.

Guided by our corporate values of trust, entrepreneurship, prudence, commitment, and partnership, we have earned the confidence of many long-term customers. Amongst them is HAESL, with whom we are proud to share a strong and enduring partnership.

in HAESL over

Over the past 20 years, PORTS Connection Cargo (HK) Ltd has become an important player in the global aerospace supply chain, streamlining the flow of parts, developing relationships with component vendors, and providing comprehensive AOG services. Extensive experience and in-depth knowledge allow us to assist clients with this challenge and achieve excellence.

region, technological advancements in aircraft systems, and government investment in aviation infrastructure.

“The government is actively investing in aviation talent, smart airport technologies, and crossboundary cooperation to future-proof the sector,” details Edmunds.

“Whilst the outlook is positive, there are also some challenges. These include availability of talent, increasing regulatory complexity and compliance demands, and, more recently, increasing geopolitical tensions and economic fluctuations. It is essential that we have strategies in place to navigate these challenges to ensure we can be confident to continue to make investments in the long term.”

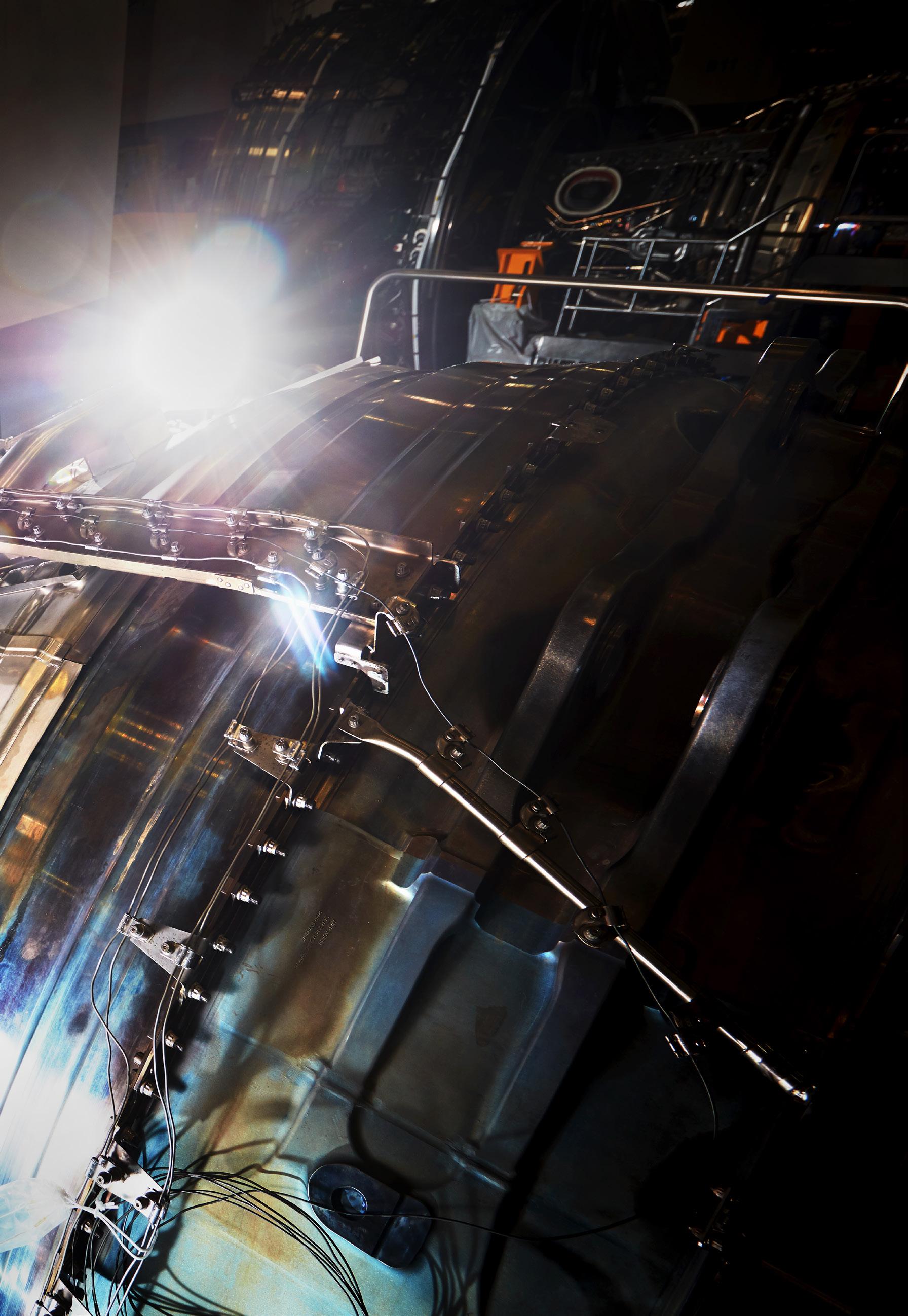

George Edmunds, CEO: “HAESL’s supply chain operations are tightly integrated with Rolls-Royce through a multi-tiered governance framework that ensures alignment across delivery, cost, quality, and risk management.

“Regular business reviews are jointly conducted by HAESL and Rolls-Royce stakeholders, covering critical areas such as parts input, kitting issues, turnaround time deviations, and subcontract repair delivery. A shared MRO performance scorecard tracks key performance indicators (KPIs) over time.

“Strategic planning is supported by sales and operations planning (SOP) processes that synchronise engine induction volumes and parts forecasting. Joint workshops, such as the SAP S/4HANA transition sessions, have produced actionable outputs around data exchange policies, inventory catalogue control, and governance mechanisms. These efforts are designed to modernise HAESL’s digital infrastructure whilst maintaining seamless integration with Rolls-Royce systems.

“Component repair development is another area of collaboration, with RollsRoyce supporting HAESL’s repair capability expansion through fair approvals and proprietary process sharing. Risk management is embedded into our supply chain strategy, with HAESL identifying over-reliance on Rolls-Royce and regulatory delays as key risks. Mitigation strategies include dual sourcing, crosscalibration protocols, and vendor diversification.”

To ensure that HAESL is well-placed to take advantage of the current uptick in MRO demand, the company is embarking upon various projects to improve its efficiency and increase its expertise.

At the heart of this transformation is HAESL’s digital ambition, which seeks to unlock efficiencies and redefine how aero engine MRO operations are managed through the adoption of new digital technologies.

“A dedicated digital team was only established a year ago. Despite this, they have already launched a fully integrated customer portal, which

streamlines everything from purchase order approvals to audit compliance. The portal supports real-time visibility into reservations, stock levels, and planner-customer workflows,” explains Edmunds

More fundamentally, HAESL has commenced an enterprise resource planning (ERP) system replacement, which will be delivered over the next two years. This will include the implementation of SAP Business Suite 4 SAP HANA (SAP S/4HANA), and iMRO as a manufacturing execution system.

Alongside efforts to ensure all data is available through a full migration to cloud storage, HAESL is building a

“HONG KONG’S POSITION AS A KEY AVIATION HUB IS BUILT ON A COMBINATION OF GEOGRAPHIC, ECONOMIC, INFRASTRUCTURAL, AND STRATEGIC ADVANTAGES THAT MAKE IT UNIQUELY COMPETITIVE BOTH LOCALLY AND GLOBALLY”

– GEORGE EDMUNDS, CEO, HONG KONG AERO ENGINE SERVICES LIMITED

future-ready digital backbone that will support artificial intelligence (AI) forecasting, Microsoft’s Power BI dashboards, and software development and IT operationsdriven app development.

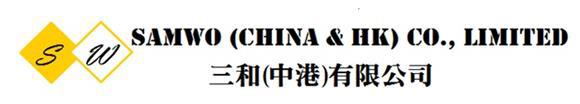

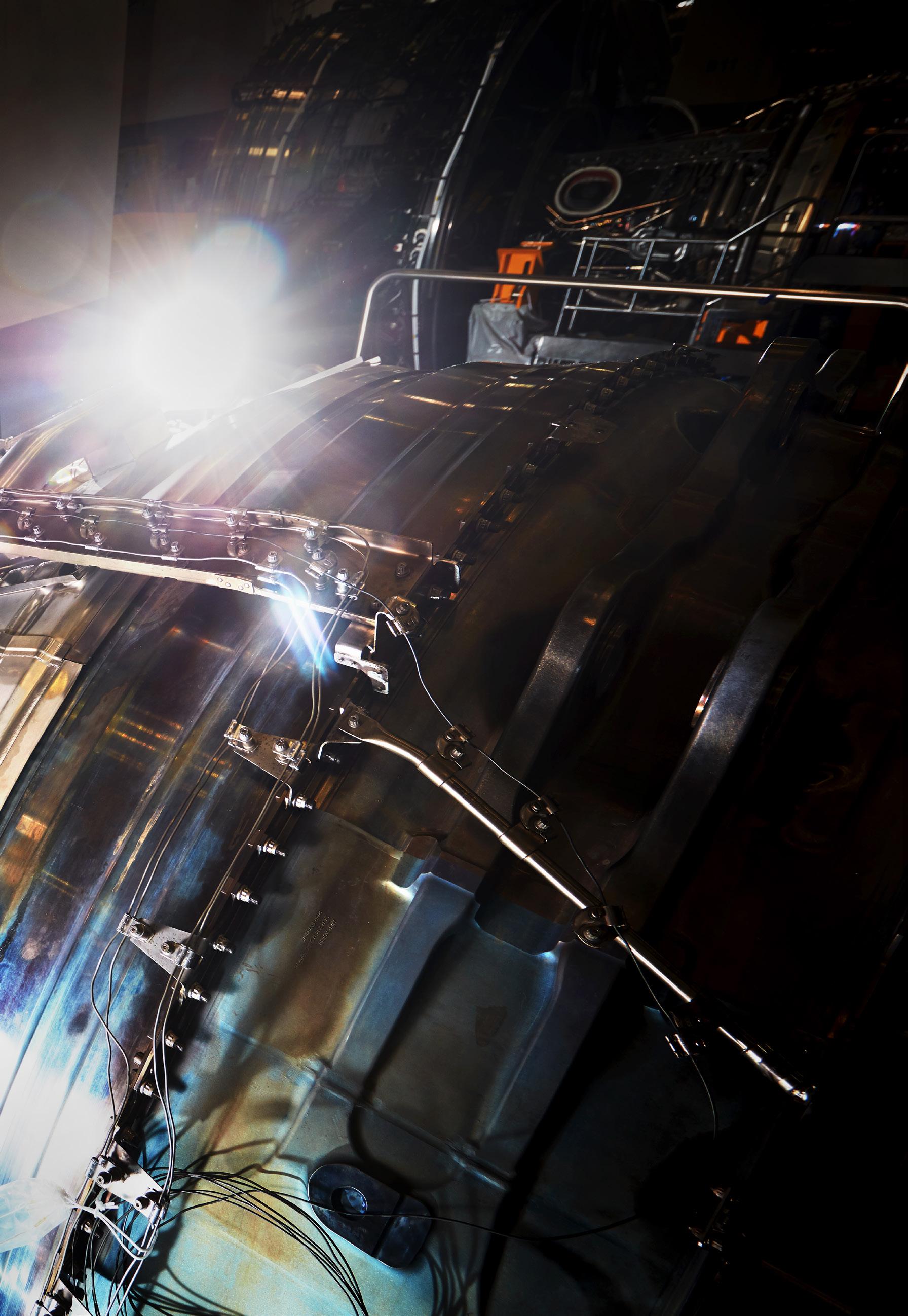

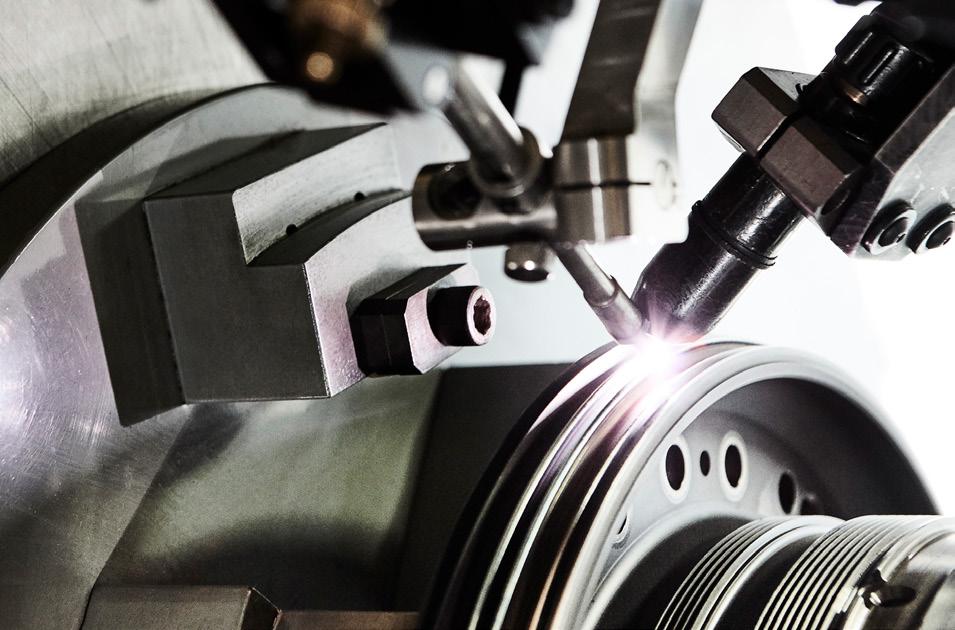

In addition, HAESL is investing in cutting-edge technologies to enhance precision and reduce turnaround times through its smart manufacturing initiatives.

The Connector Inspection System, for example, is a portable, automated solution that minimises human error and inspection time, whilst a robotic welding project introduces AI-driven optimisation for complex shapes, improving safety and reducing fatigue-related turnover.

“These innovations are part of our broader strategy to become a centre of excellence in component repair and

advanced manufacturing,” explains Edmunds.

Finally, to meet growing demand, HAESL is expanding its physical footprint and operational capacity. Recent upgrades include the purchase of additional computer numerical control (CNC) milling machines and coordinate measuring machines, as well as facility expansion, both on-site through innovative storage solutions and off-site through the rental of additional space.

HAESL’s capacity expansion strategy could lead to the company overhauling up to 425 engines annually, as well as up to 50 module sets.

Sustainability is a central pillar of HAESL’s business strategy, with

clear goals and measurable progress across environmental, social, and governance areas.

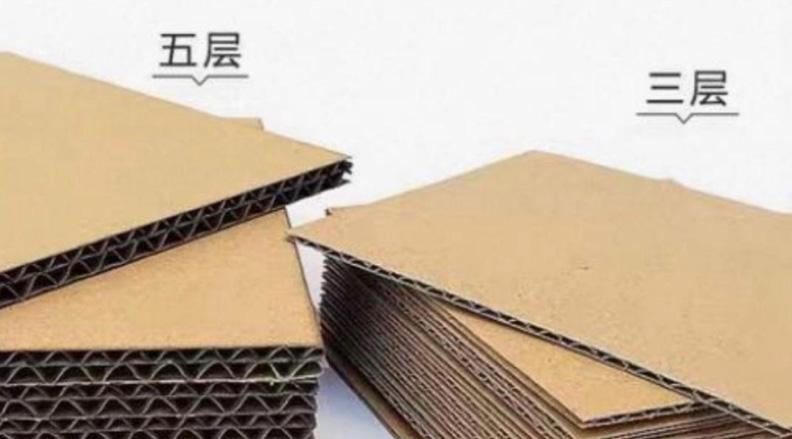

The company has made significant strides in reducing its environmental footprint, achieving a 17.1 percent reduction in carbon intensity and lowering water usage to 46 litres per attended hour. Waste management initiatives, such as centralised recycling stations, support HAESL’s goal of 60 percent waste diversion by 2030.

“We also emphasise sustainable procurement, aiming for full compliance with our Supplier Code of Conduct by 2030,” explains Edmunds.

“We encourage suppliers to reduce packaging and adopt recyclable materials and collaborate with Rolls-Royce on standards. EcoVadis assessments have helped identify areas for improvement in procurement ethics and environmental documentation, with corrective actions already underway.”

On the social front, HAESL promotes inclusion and community engagement. Internal programmes such as the HAESL Women’s Network (HWN) and Male Allies were established in 2023 to support gender equality.

With an initial target in 2023 of 13 percent female representation in a male-dominated industry, the percentage of females employed has now grown to 16 percent of a larger workforce, indicating progress in this area. Community outreach also includes youth development and partnerships with non-governmental organisations (NGOs), reinforcing the company’s role as a responsible corporate citizen.

Looking ahead to 2026, HAESL is setting ambitious targets that reflect its commitment to operational excellence, innovation, and sustainability.

“We plan to maintain engine output at above 360 units, and with increasing richness in the workscopes

of the engines we overhaul, this will deliver a record three million workload hours in 2026, requiring a further seven percent increase in headcount, on top of double-digit increases already seen in the last two years. Achieving this growth will be challenging and require enhanced planning and capacity management, but none of this is new to HAESL,” furthers Edmunds.

He also notes that the forward projection for engine demand in the coming years continues to look promising. As a result, HAESL is confident it can provide a stable working environment where staff can develop traditional MRO skills whilst learning new ones as the company unlocks the potential of new technologies.

Edmunds believes technology advancements will transform the

working environment, making the industry more attractive to a new generation coming into the workforce. To create this environment, the company will be investing over USD$300 million in the coming 10 years, with investments focused on automation, digital infrastructure, and facility upgrades.

“Innovation remains a key focus, with continued investment in new technologies such as automated welding and additive manufacturing technologies,” expands Edmunds. These advances aim to streamline processes, improve safety, and eliminate workshop bottlenecks.

However, unlocking the opportunities these technologies represent will only be possible if it can support this through relevant talent development.

As a result, HAESL remains committed to upskilling its current

workforce, with promotions and role expansions planned across key departments, supported by the right training, reinforcing the company’s commitment to internal career growth.

“None of these plans will deliver further growth and efficiencies without strategic alignment with Rolls-Royce and collaboration through joint governance reviews on areas such as cost model refinement and coordinated planning for future engine capability,” concludes Edmunds.

cb@haesl.com

www.haesl.com