We revisit mineral drilling contractor Swick Mining Services, whose executive team reflect on the company’s growth story over the past two years

Writer: Jack Salter | Project Manager: Eddie Clinton

It was a record-breaking FY25 for Swick Mining Services (Swick), a leading provider of drilling services across a wide spectrum of commodities.

The company maintained its full client base and secured all contract extensions and renewals, according to Business Development Manager, Robert Burnett, whom we last spoke to in June 2023.

“Swick achieved a 21.43 percent increase in drill metres, rising from 1.4 million in FY24 to 1.7 million,” he updates us.

The number of rig operations, meanwhile, has expanded from 74 to 84, with the total fleet volume reaching 100 rigs. This includes the seamless integration of seven rigs into Swick’s operations from the merging of Barminco’s diamond drilling business.

Moreover, its operating sites grew from 22 to 27, supported by an increase in personnel from 753 employees to 907.

Swick also expanded internationally, successfully entering Canada with the deployment of two rigs under new client contracts, complementing key tenders it secured with Tier 1 mining companies.

Strategically, the company reinforced its gold-focused operations in FY25, with 44 percent of sites operating in this commodity, supported by favourable market conditions.

As well as gold, the commodities Swick actively supports include copper, nickel, cobalt, lithium, tin, zinc, lead, silver, and uranium.

Each of these presents unique geological conditions that influence drilling methodology, equipment selection, and operational planning.

“Swick’s strategic engagement with clients is underpinned by a deep understanding of their operational priorities and the geological

complexities associated with each resource,” Burnett outlines.

“Our approach is both adaptive and data-driven, ensuring optimal performance and safety across varied terrains and mineral profiles.”

The company’s drilling operations are tailored to meet the specific demands of each commodity, with techniques refined to address hard rock formations, reactive and moisture-sensitive environments, deep and structurally complex ore bodies, and soft sedimentary layers.

Swick’s engineering and field teams continuously innovate to overcome these challenges, leveraging proprietary rig designs, real-time data acquisition, and rigorous safety goals.

Strategic client positioning also ensures the company remains aligned with both short-term project goals and long-term resource development.

“This includes customised drilling programmes based on commodityspecific exploration and production targets, integrated reporting and analytics to support client decisionmaking and regulatory compliance, and collaborative planning to optimise rig deployment, reduce downtime, and enhance cost-efficiency,” Burnett tells us.

Swick further advanced its technology portfolio in FY25 with

investment in DeepEX rigs capable of drilling up to 3,000 metres (m) and large diameter infrastructure holes, providing significant opportunities to clients.

There was a time when the demand for exploration was a lot higher, especially in hole depths of over 1,000m.

However, Swick wasn’t widely known or perceived by the market as being in that space, even though its rigs and personnel were more than capable of doing those types of holes.

The company, therefore, ended up investing in DeepEx to modify its mobile rig to drill even deeper than its standard rig.

“We’ve used the same people within that, and it’s been a very successful part of our business. It’s a small offering we have there but more and more clients are looking at it,” shares Nick Rossides, General Manager.

DeepEX continues to expand the company’s capabilities in underground engineering, delivering innovative, high-precision solutions tailored to the evolving needs of the mining and geotechnical sectors.

With an operational range effective from -90° to +45° angles, it executes precision breakthrough drilling into underground voids to facilitate Cavity Auto-Scanning Laser System (C-ALS) surveys.

“DEEPEX ENHANCES STOPE MANAGEMENT, SUPPORTS BACKFILL PLANNING, AND IMPROVES SAFETY THROUGH BETTER VOID VISUALISATION”

– ROBERT BURNETT, BUSINESS DEVELOPMENT MANAGER, SWICK MINING SERVICES

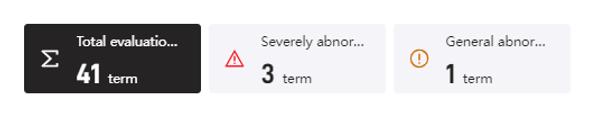

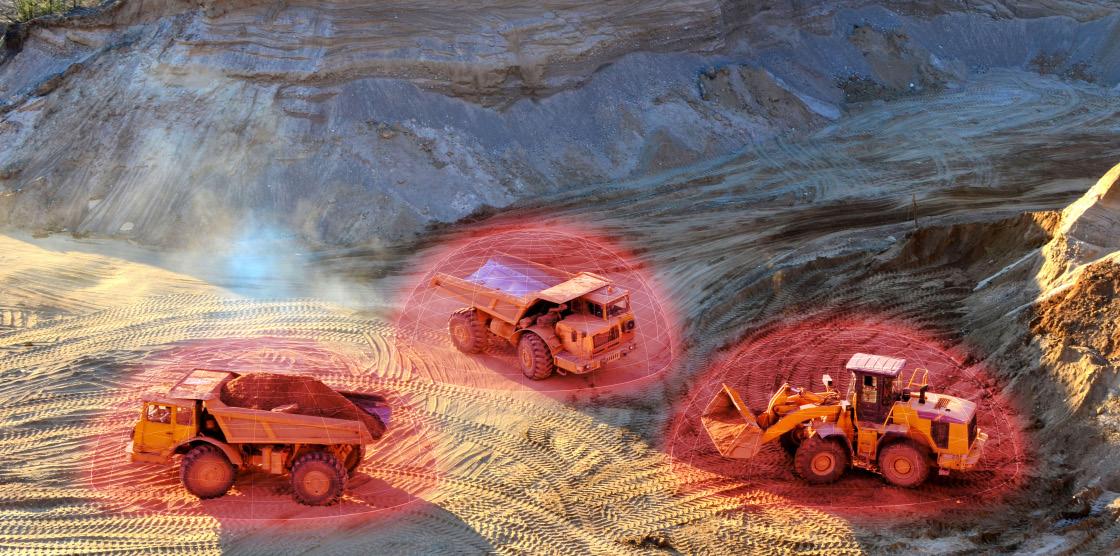

At Fleet Integrations we work with you to find the right Fleet and Driver Safety Solution for your business.

Provide an insight into the history of Fleet Integrations over the last 20 years and how the industry has evolved over this time?

Fleet Integrations was founded more than two decades ago in the United Kingdom and quickly became industry pioneers. What began as a mission to transform driver safety has become a global success story. Today, the company proudly operates from its head office in Australia, servicing clients across multiple continents and leading the way in driver safety technology and consulting.

Briefly introduce us to Fleet Integrations, e.g. a short overview of your main products and services, locations, client base, number of employees, etc.

With over than 25 years of experience and an extensive portfolio of successful projects under our belt, Fleet Integrations is now a recognised name in fleet safety and Driver Safety Systems,

renowned not just for cutting-edge technology, but for its unwavering commitment to protecting lives, reducing risks and driver behaviour. At Fleet Integrations, we deliver tailored solutions to the complex and evolving challenges faced daily by the Mining, Oil and Gas sectors. From our headquarters in Perth, Western Australia, our team is strategically positioned to mobilise rapidly and deliver results anywhere in the world — with precision, efficiency, and expertise

How does Fleet Integrations telematics solutions differentiate it from the competition?

Fleet Integrations goes beyond delivering market-leading products — we embed safety into the DNA of your organisation. Our consulting expertise spans Driver Safety Manuals and Policies, Journey Management Planning, Emergency and Incident Procedures, Coaching and Behavioural Programs, and Risk Collaboration. It’s a truly holistic approach — beginning with hardware integration and culminating in long-term cultural transformation.

Following on from this, in what ways does driver safety underpin the company’s operations and success?

At Fleet Integrations, driver safety isn’t a checkbox — it’s the structural core of our entire operation. It reduces risk, builds trust, and empowers consistent, professional service. Safety is more than compliance; it’s care. When we prioritise driver wellbeing, we strengthen relationships within our team and with our clients.

A fleet recognised for professionalism and safe conduct becomes more than dependable — it becomes a brand known for forward-thinking leadership.

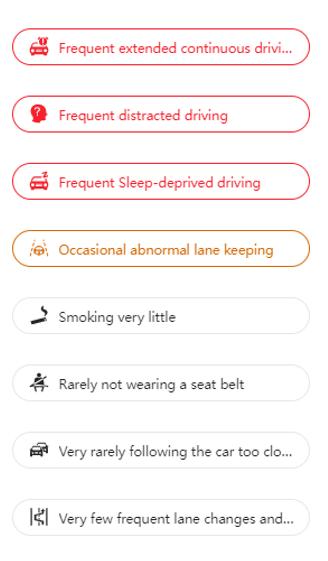

How does Fleet Integrations optimise vehicle fleets for mining and oil and gas operations specifically?

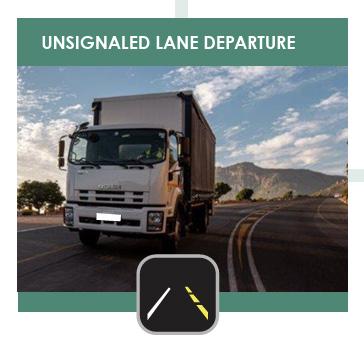

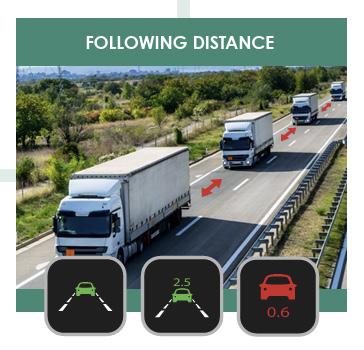

Fleet Integrations empowers fleets with advanced In-Vehicle Monitoring Systems (IVMS), delivering real-time insights into driver behaviour — from the initial login to the vehicle to provide accountability through to all aspects of driving risk and journey monitoring. These systems provide instant in cab alerts irrespective of cellular service and trendbased reporting, enabling immediate intervention and long-term risk reduction.

Pushing past traditional telematics, our AI-driven fatigue and distraction monitoring leverages eye

movement analysis and micro-sleep detection to identify risk before it escalates. In-cabin warnings keep drivers informed, while backend alerts support operations teams in making fast, informed decisions.

Both technologies integrate seamlessly into broader safety strategies, transforming data into decisive action and converting risk into measurable control.

Could you elaborate on your partnership with Swick Mining? In what ways do the two companies mutually benefit each other?

Fleet Integrations was engaged by Swick Mining through the previous works provided within the Perenti Group, as part of a broader initiative to elevate safety and operational efficiency across their light vehicle fleet. Our team implemented advanced In-Vehicle Monitoring Systems (IVMS) and AI-powered driver monitoring technologies to promote safer driving behaviour, manage fatigue risk, and ensure compliance with stringent site protocols.

These integrated solutions have significantly reduced on-road incidents, enhanced driver accountability, and streamlined reporting throughout Swick’s operations.

The partnership has not only strengthened Fleet Integrations’ presence in the mining sector but also deepened our understanding of the unique safety requirements in underground, surface, and remote environments. This insight continues to inform and refine our solutions, allowing us to better serve the evolving needs of resourcesector clients.

What completed, ongoing, or recent projects would you like to showcase in the article? For each, please provide some key details and explain why the project is important or special to the company.

One of Fleet Integrations’ most impactful ongoing initiatives is the national deployment of IVMS and AI-based driver fatigue monitoring systems across Swick Mining and Perenti Group assets throughout Australia. This project reflects a significant commitment by both companies to elevate safety standards — particularly in high-risk, remote environments where driver vigilance is essential.

Fleet Integrations was entrusted to design and install a fleet-wide solution encompassing real-time vehicle tracking, fatigue detection technologies, and comprehensive behavioural reporting.

The strategic importance of this rollout lies not just in its technical execution, but in its industry influence: partnering with two of Australia’s most respected mining and drilling providers reinforces Fleet Integrations’ role as a trusted safety partner in the resources sector.

At its core, this initiative prioritises driver wellbeing. This project exemplifies our broader mission: helping operators embed genuine safety cultures through intelligent systems, meaningful insights, and responsive field support.

T +618 9264 6800

E info@fleetintegrations.com www.fleetintegrations.com

After 27 years of visionary leadership, Kent Swick, Founder and Managing Director, officially announced his retirement in January this year.

From a modest start-up focused on long hole production, he built Swick into the largest underground diamond drilling company globally, pioneering mobile drill rig technology and expanding into international markets.

Kent’s legacy is not only defined by innovation and growth but by the culture he cultivated – one of integrity, resilience, and excellence.

“His retirement marks the end of an era, but his influence will continue to shape Swick’s trajectory,” Burnett reflects.

This real-time mapping technology enables accurate measurement of void dimensions, muck pile propagation, and stope or cave geometry.

“DeepEX enhances stope management, supports backfill planning, and improves safety through better void visualisation,” elaborates Burnett.

Its engineering scope also includes seismic smart marker installations in high-activity ground zones, which can be spaced as close as 50 centimetres apart.

These sensors transmit live geotechnical data to engineering teams, enabling predictive modelling of seismic events and cave behaviour, proactive risk mitigation, and realtime geotechnical monitoring.

“DeepEX also drills and installs stress cells to monitor in-situ stress conditions, supporting structural

integrity assessments and mine design optimisation,” Burnett notes.

The rigs additionally provide high-precision drilling for critical underground infrastructure, including drainage systems, electrical and communication cabling, and paste fill lines, which reduces installation time and ensures alignment with mine service layouts.

“Underground infrastructure drilling allows the mine to continue growing and service other areas,” Rossides affirms.

Equally, rigs are equipped to safely drill into and continue through large underground voids, supporting exploration, ventilation, and infrastructure expansion.

“DeepEx rigs are engineered for versatility and performance, with drilling strategies such as top-down collar, bottom-up, and custom fit-forpurpose equipment,” Burnett informs.

“This flexibility ensures compatibility with a wide range of underground applications, from instrumentation to service line installation.”

Alongside its investment in DeepEx rigs, Swick is committed to operational excellence through its comprehensive Driller Training Programme, which is designed to upskill, retain, and develop the next generation of drilling professionals.

The programme’s initiatives begin at a world-class training facility at the Swick headquarters in Perth, Western

“ONCE IN THE FIELD, TRAINING CONTINUES THROUGH A HANDS-ON, ENGAGING EXPERIENCE LED BY OUR DEDICATED TECHNICAL TRAINERS, ALONGSIDE EXPERIENCED OFFSIDERS AND DRILLERS”

– CHRIS LOO, OPERATIONS MANAGER, SWICK MINING SERVICES

Australia (WA), where every new driller’s offsider begins a structured onboarding journey.

This facility provides a controlled environment where new recruits are introduced to the fundamentals of drilling operations, safety protocols, and equipment handling, ensuring they are well prepared before stepping on site.

“Once in the field, training continues through a hands-on, engaging experience led by our dedicated technical trainers, alongside experienced offsiders and drillers,” reveals Chris Loo, Operations Manager.

“This on-site mentorship model

ensures that learning is continuous, allowing new team members to build their skills and capability in the role.”

The collaborative environment fosters knowledge sharing and reinforces a strong safety culture, which is critical to Swick’s operational success.

To formalise and recognise the skills acquired, all offsiders are enrolled in the Certificate II in Drilling Operations, whilst drillers progress through the Certificate III and IV qualifications.

“These nationally accredited certifications not only validate technical proficiency but also provide clear career pathways within the business,” Loo highlights.

Setting itself apart with high-quality products, a dedicated approach to customer service, and a vast inventory of vehicle parts supported by an Australia-wide courier network, Oriental 4WD and Commercials emerges as a first-choice spare parts supplier.

Specialising in late model low-kilometre vehicles, Oriental 4WD & Commercials (Oriental) is Australia’s largest 4WD, Commercial, and SUV dismantler.

Established in 1966 and as one of South Australia’s (SA) very first wreckers, we’ve been here long enough to have built a reputation as Australia’s leading dismantler – a title we strive to live up to every day.

Located in the southern suburbs of Adelaide, our large, well-organised,

five-acre site is fully equipped to provide the best possible products, services, and spares to our clients.

Our unmatched industry expertise, meanwhile, has allowed us to impart unique market knowledge to our customers, going above and beyond to assist them in any way we can.

At Oriental, we understand the importance of having access to high-quality 4WD spare parts to ensure the smooth running of your vehicle.

Therefore, we are committed to providing our customers with the highest quality parts at the best prices.

Supported by an Australia-wide courier network, our extensive, nationally integrated inventory system ensures parts can be found quickly, accurately, and at a competitive price.

Our dedication to quality is recognised by our customers, who often commend us on the quality, variety, and price point of Oriental’s products. We strive to deliver a fast and reliable service. If we don’t have the parts you need, we will go above and beyond to source them for you!

What’s more, Oriental stands behind the quality of our products with a minimum three-month parts and labour warranty, which can be extended up to six and twelve months depending on the vehicle.

Dedicated to meeting the needs of our customers both online and in person from our main site in Lonsdale, SA, a wellinformed member of our team is always on hand to help – no matter how rare the spare part.

• High quality parts

• Excellent customer experience

• Large network of leading dismantlers

• Save money off new part prices

• Three months minimum parts guarantee.

• Toyota

• Ford

• Nissan

• Mazda

• Mitsubishi

• Holden

• Hyundai

• Isuzu

• Subaru

• Great Wall Motor (GWM)

• Suzuki

• Renault

• Jeep

• Dodge Ram Trucks

• Volkswagen

• Chevrolet Silverado

• LDV vans and utes

• Mercedes vans and utes

A valuable partner to Swick Mining (Swick), Oriental’s vast plethora of highquality, low-kilometre components, parts, and services sets it apart from other suppliers.

Having earned its reputation as a key partner to Swick over the years, the company is keen to partner with more mining companies who are seeking specialised replacement and spare parts for their mining fleet vehicles.

Choose Oriental today for the largest range of spare parts and the industry’s most competitive prices.

With the dismantled vehicles located onsite, we go above and beyond to source your spare part from within our inventory – even if it’s not on the shelf.

Having garnered a reputation for customer service excellence over the years, Oriental has secured a solid base of repeat customers who return time and again for not only the company’s extensive portfolio, but its competitive prices.

In addition, our deep-seated passion for the iconic Toyota LandCruiser range particularly the 79 series utes, which we have an extensive inventory of high quality, late model, low kilometre parts available.

Alongside half a century of hands-on experience, means we have built an

unparalleled suite of industry expertise, and are always eager to share this knowledge with our clients.

In addition to providing top-quality products, Oriental has a fully equipped workshop complete with highly qualified mechanics onsite to service, repair, and fit your part to your vehicle. Committed to recycling – not wrecking –Oriental’s advanced, cutting-edge facilities are equipped to handle the safe removal, separation, containment, and recycling of potentially harmful fluids such as coolants, batteries, and brake fluids. Properly separated by our dedicated team

of professionals, these components can be fully recycled, helping reduce the risk of adverse environmental impacts and waste. In this way, Oriental’s sustainable approach goes hand-in-hand with the environmental, social, and governance (ESG) requirements of many of its clients. Moreover, the company’s longstanding experience in dealing with all types of spare parts, fixtures, and fittings means it can repair or repatriate almost any 4WD vehicle. So, if you need a part fix, fit, or simply want to find out more about Oriental’s dismantling service, give us a call today! We believe that no job is too big or small, and we’re here to help.

“By investing in structured learning and professional development, we not only enhance workforce capability but also strengthen employee engagement and retention, ensuring our teams are equipped, motivated, and ready to meet the challenges of modern drilling operations.”

Another aspect of Swick’s operational excellence is the expertise and experience of its employees, with

around 15 percent of the workforce having been at the company for 10+ years.

Since 2023, the organisation has experienced significant growth in staffing, with the current headcount exceeding 730 direct hires across Australia.

This expansion reflects a strategic focus on building internal capability whilst leveraging the support of several labour hire businesses.

“The collaboration between direct

employment and labour hire partners has proven highly effective, enabling flexible workforce balance and ensuring operational continuity across all sites,” Loo observes.

A strong focus has been placed on upskilling Swick’s supervision and management personnel through a range of targeted training programmes, including the implementation of the Leadership Development Programme.

The programme is designed to enhance leadership capability and

support professional growth across the organisation.

Complementing this are nationally recognised qualifications such as the Certificate IV in Training and Assessment, Mental Health First Aid Certification, and the Statutory Supervisors Certification, ensuring the company’s leaders are equipped with essential compliance and instructional skills.

“Additionally, in-house programmes like the Introduction to Supervision training and the redeveloped Drilling

REAL-TIME DATA INTEGRATION –

Enables smarter, faster decisions underground.

CUSTOM ENGINEERING

SOLUTIONS – Equipment and methods are adapted to each project’s unique geological and operational context.

SAFETY-FIRST APPROACH – All drilling and installation methods are designed with safety and ground stability as top priorities.

PROVEN PERFORMANCE –

Successfully deployed across multiple high-seismic and complex void environments.

Fundamentals course are tailored to support the development of drillers, reinforcing technical proficiency and operational excellence,” states Loo.

COLLABORATIVE EFFORT

Swick’s maintenance and engineering teams play a critical role in ensuring mechanical availability remains paramount across all operations. Their support is instrumental in driving the performance and growth of both new builds and rebuilds.

In the demanding world of mining and drilling, reliability isn’t just expectedit’s essential. With machinery operating in high-dust, high-load environments and pushed to extremes across remote locations, lubricant choice can mean the difference between costly downtime and continuous production. That’s where TotalEnergies steps in, with its Rubia Works range of lubricants engineered specifically for the realities of mining operations.

As one of the world’s largest integrated energy companies, TotalEnergies brings unmatched expertise in lubrication technology, combining global innovation with practical, onthe-ground understanding of mining sector challenges. The result is a range of heavy-duty engine oils that not only protect engines but actively enhance performance and reduce costs.

Mining and drilling equipment faces some of the most punishing operating conditions across any

industry. Extended run times, abrasive contaminants, heavy load cycles, and high-temperature environments place continuous strain on engines and hydraulic systems.

TotalEnergies’ Rubia Works 4000 and 5000 ranges have been formulated specifically to handle these extremes. Using high-quality base oils and advanced additive systems, these lubricants deliver outstanding thermal stability, wear protection, and shear resistance.

Rubia Works 4000 15W-40 is engineered for extreme off- and on-highway conditions, offering exceptional oxidation resistance, extended drain intervals, cleaner engines, and proven performance under high temperatures. It meets top OEM approvals and is a premium, low-SAPS lubricant meeting the latest API CK-4 Standard.

Rubia Works 5000 10W-40 is formulated with synthetic technology base oil and the latest generation additives, providing enhanced

piston cleanliness and lubrication performance. Rubia Works 5000 10W40 is the ultimate solution for engines operating in demanding environments such as quarrying, construction and mining. This high-performance engine oil is engineered to endure long working periods under severe conditions, including high loads, dust and heat.

Whether running under full load in the heat of an open cut or grinding through abrasive material in underground tunnels, Rubia Works is proven to hold up under pressure.

With operations in more than 130 countries and a presence across key mining regions worldwide, TotalEnergies combines global resources with regional responsiveness. The company operates 47 lubricant manufacturing plants, 9 grease facilities,

and two world-class R&D centres, and combines industrial strength with rapid delivery and technical support where it’s needed most.

Its technical teams collaborate closely with mining operators and OEMs to ensure compatibility with evolving engine technologies.

Rubia Works lubricants are approved by leading manufacturers including Caterpillar, Komatsu, Hitachi, and Volvo, making them a trusted choice for mixed fleets and standardised maintenance programs.

LONGEVITY AND LOWER COSTS

Equipment performance and profitability in mining are deeply interconnected. Unplanned

maintenance, accelerated wear, and suboptimal oil performance all lead to increased operating costs. Rubia Works addresses these risks with a formulation that:

• Protects against high-temperature oxidation and breakdown

• Maintains stable viscosity under mechanical stress

• Promotes piston cleanliness and sludge control

• Enables extended drain intervals, reducing service frequency

This translates to lower total cost of ownership and greater equipment availability - key benefits for operators focused on maximising production.

Rubia Works is more than just an engine oil. It’s the result of extensive field testing, ongoing collaboration with OEMs, and decades of experience supporting industrial and off-highway sectors. Every formulation is developed with the unique requirements of

mining in mind - high temperatures, harsh environments, and the need for continuous, high-load operation.

And with TotalEnergies’ commitment to quality control, logistics support, and technical expertise, mining operations have a lubricant partner that understands the pace and pressure of their industry.

In an industry where uptime is critical and failure is costly, TotalEnergies Rubia Works offers performance you can count on. Built for endurance and proven in extreme conditions, it keeps mining equipment moving - safely, efficiently, and without compromise. When it comes to protecting assets and powering productivity in mining, Rubia Works does more than meet the challenge. It’s built for it.

totalenergies.com.au enquiries-au@totalenergies.com

With the capacity to build 21 rigs through their workshops in FY26, the teams are focused on delivering highquality, reliable equipment ready to meet demands in the field.

“This collaborative effort not only underpins operational readiness but also reinforces our commitment to excellence and continuous improvement,” emphasises Loo.

The key for Swick in terms of performance is that it manufactures and operates the drill rigs and gets feedback straight away from people out in the field.

This feedback is taken back to the company’s engineering teams who can quickly make any changes, unlike off-the-shelf products.

“We can design our rigs for what we’re doing, which really speaks to

“PERENTI SAW IT AS A GOOD OPPORTUNITY TO TRANSFER BARMINCO’S DIAMOND DRILLING BUSINESS TO SWICK. IT WASN’T WHERE THEY ARE POSITIONING THEMSELVES AND IT WAS PROBABLY A DISTRACTION, WHEREAS THAT’S OUR FOCUS”

– NICK ROSSIDES, GENERAL MANAGER, SWICK MINING SERVICES

our performance,” Rossides sets out.

Swick also has teams that focus purely on specialised programmes for specific customer requirements and can be deployed to certain sites.

“It might be a one-off programme that the client asks for, so we have specific teams we can send. The same can be said for our operations, management, and even health, safety, and environment (HSE) teams,” enlightens Rossides.

“All these people have come from an operational background within Swick, so they’ve actually experienced that type of work and have the solutions. It’s not just something they’ve read –they’ve actually lived it themselves, which goes a long way in terms of what our clients expect, so that’s been a very big part of our success story.”

DDH1, a highly respected Tier 1 global operator, was acquired by diversified mining services group Perenti in 2023.

As one of four highly respected DDH1 brands, Perenti welcomed Swick to the group and is now one of the largest drilling services contractors globally, offering a complete range of underground and surface drilling services including specialisation in deep directional drilling.

“From Perenti’s point of view, part of the acquisition was to get a drilling arm within their organisation and a little bit more oversight in terms of surface and underground drilling, which is where we come in,” explains Rossides.

CADmine

Founded in 2009 as a result of customer demand for reverse engineered

the company specialises in designing, developing and manufacturing quality products for a broad range of applications including new machine and workshop safety equipment, replacement parts for OEM machines reverse engineering to reduce costs for the consumer. Our key strength along with our quality of products and service is our ability to find and develop solutions for those who are looking for gains in safety and efficiency in the workplace.

✔

✔

✔

Phone:

“Swick remains committed to environmental, social, and governance (ESG) principles, innovation, and delivering value to clients and shareholders.

“The company continues to support decarbonisation and safety through automation with the scheduled launch of the Gen3 E-Rig in FY26, positioning Swick for sustained growth and leadership in underground diamond drilling.”

– Robert Burnett, Business Development Manager

“We represent and are the only ones doing underground drilling. Perenti’s biggest division is contract mining; they have operations globally, and drilling goes hand in hand with mining, especially underground.

“You won’t find anyone else in Australia that is operating 15 or 16 rigs underground at any one site. If clients are looking for big multi-rig contractors for a single site, that’s what we do and where we specialise,” he assures.

Barminco, an underground mining services company acquired by Perenti in 2018, had its own drilling division in Australia at one stage.

Over the years, however, Barminco has concentrated more on the mining side, with Swick taking over two of their sites in Australia since it was acquired.

“Perenti saw it as a good opportunity to transfer Barminco’s diamond drilling business to Swick. It wasn’t where they are positioning

themselves and it was probably a distraction, whereas that’s our focus,” Rossides elaborates.

“We took on all their Australian work and the people associated with those jobs, so basically all the workforce stayed on and transferred over to Swick.

“Coming under Perenti gives us a huge piece of the pie, especially in the growth period we are going through, and access to a lot more capital. I see that as a big benefit for our clients and it provides them a level of comfort,” he adds.

Back-of-office functions such as HR, IT, and even safety are centralised systems, whilst the support Swick gets from an organisation the size of Perenti is also very helpful and has been lent on a fair bit in terms of the company’s international growth.

“We’ve been able to utilise them for entering into new jurisdictions rather than just relying on ourselves to do that. They’ve got a bigger scope

for that and a lot more people within those areas that can help us out,” acknowledges Rossides.

“Whether Perenti has actually helped us win more work is something that I couldn’t quantify, but there’s definitely a lot more support to help us grow, especially with the contract mining piece, so it has been positive,” he smiles.

One thing Perenti has stayed true to is allowing Swick to keep its renowned brand and culture.

Even though it has been a publicly listed company for many years, Swick has always held onto and maintained its family values.

“I’ve been with the company for nearly 20 years, and when I started, we had three drill rigs. We’ve now got 84 operating globally, but we still instil that family feel,” Rossides prides.

“We’re very big on rewarding and promoting the good work that our

people do. It’s not just a case of here’s your pay and away you go – we’re quite flexible in our work rosters and very family-orientated.

“We include families in a lot of things we do. That’s probably our number one thing because we know they support our people back home, so we’re very mindful of celebrating families and try to do that as much as possible,” he continues.

Keeping the family feel of the business goes a long way and isn’t limited to what Swick does out in the field, as everyone in its corporate offices also has the same attitude.

“We all roll our sleeves up and get stuck into the work. Everyone’s very invested in what we do to see the business succeed.”

Along with family, safety and being solutions-focused are important values for Swick, with the latter something the company has always driven to uphold.

Innovation is the biggest thing

the company is known for, having designed the first true underground mobile rig.

“That was a big innovation in itself, but we also look at the way we work, the applications we put in place, the way we treat our people, and our systems as innovation as well,” acclaims Rossides.

“We’re very big on taking innovation from the field, so those who are working on the rigs will come up with some of these solutions. We design what we can in-house to better the rigs themselves and make them safer and more productive,” he concludes.