UMEX Cristian Taranu is the Managing Director at UMEX. He is an experienced industry leader with a demonstrated history of working in the maritime industry and has been with the organisation since June 2018. “In the past three years, we have focused our actions to organise a structure oriented to superior quality of services, respecting our every customer’s particular needs,” explains Taranu. “Our 350 workers are permanent employees, specialised, skilled and well trained; we can state that we have crafted a motivated and dynamic collective, respecting the working protocols, the safety procedures, the environment protection.” In 2011, the majority stake of UMEX was acquired by an Agricultural Developer strongly present in the Romanian market, naturally, bulk

cereals and fertilizers have become a key part of its activity range, which is among one of the most important port operators within the segment. For Taranu, he is clear about what sets his organisation apart from competitors and he believes that one of UMEX’s main advantages is its ability to be versatile and handle different cargo types, while performing different services to meet the company’s client’s entire logistics demands within the port. “This way, we have avoided to be restricted and interconnected to limited cargo flows, that may vary significantly and affect drastically our activity.” Another advantage is the quality of service which is linked to the pricing policy. “A major focus of UMEX management is oriented towards the service performance, and such actions are meant to consolidate

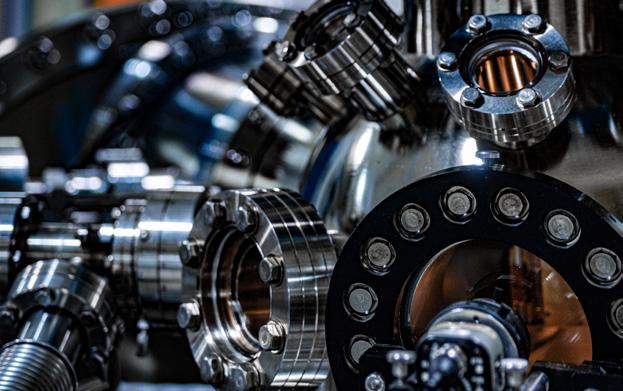

THE FUTURE UMEX FERTILIZER TERMINAL UMEX is constantly investing in modern technology and facilities because it aims to increase the competitiveness of its customers through increasing the standards of port operations. A vital investment of UMEX is the construction of a multifunctional warehouse for handling or storage of bulk fertilizers with a total storage of around 66,000 tonnes, divided into 10 equal compartments, two symmetrical rows of five compartments per row. The warehouse is set to be made of reinforced concrete and will have a completely automated filling system at the upper part, with an unloading capacity from vessels of 1,200 tons/hour (2x600 tons/hour), consisting of two reversible belt conveyors with trippers, as well as an emptying system at the bottom. Each of the 10 compartments of the warehouse will have five-by-five metre access doors. For the delivery of the cargo stored in the warehouse there will be three circuits respectively: - The transfer of bulk cargo to ship loading bin on berth 44 to be loaded on the ship or barge with a crane equipped with grab. - Loading of bulk cargo on the truck or train.

Elica ELICA Sweep Chain Conveyor UNCOMPROMISING GRAIN REMOVAL ELICA is a leading European producer of grain, seed and food handling and processing equipment. Also, it is the first manufacturer of sweep chain conveyors in Europe. What differentiates the sweep chain conveyor from the sweep auger is that there is practically no grain left in the silo after the equipment cycle is finished. The process of emptying a silo does not require any additional manpower to shovel the grain towards the centre as it is with conventional equipment like the sweep augers. ELICA has developed its automation, which shows the actual position of the conveyor in real-time. It helps the operators to supervise the process of emptying the bin directly from the control room. Most importantly, this proprietary software also controls the movement and the speed of both chain’s and tractor’s motors. Staging different scenarios, the automation engineers successfully built up an algorithm to automatically stop, restart or change the direction from forward to backwards if the equipment gets stuck or the pile collapsed over it. All features of this solution now are a result of more than 10 years of research and development in that field. ELICA’s team has more than 30 years of experience in the field of food production, seed preparation and grain processing. The company’s mission is to provide customised solutions for their clients and support them through the process - from setting up the requirements, designing the project, installing, and training to finding the right markets and solutions for managing the business.

- Transfers of bulk cargo to cargo bagging facilities in bigbags. The total cost of the investment is around €18 million and is set to be completed at the end of this year. www.elica-elevator.com

110 | EME Outlook issue 41