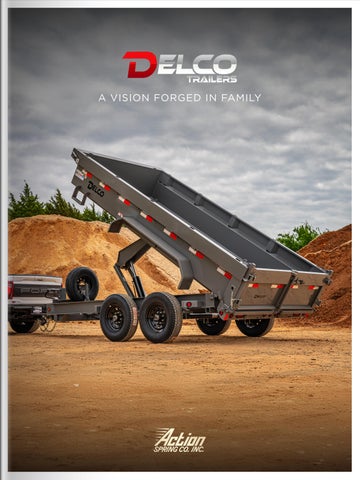

A VISION FORGED IN FAMILY

A vision forged in family, Delco Trailers has grown from a small mom-and-pop business into a nationally recognized brand. We revisit the company, who has spent the last year expanding, innovating, and refining its processes

Writer: Lily Sawyer | Project Manager: Micheal Sommerfield

The light-to-medium trailer market in the US has navigated a period of significant change over the last two years.

Increasing tariffs – including a 25 percent charge on imported steel and aluminum – have increased costs for both manufacturers and consumers by raising the price of raw materials.

This has fueled a fiercely competitive landscape, further intensified by the entry of new market players from Mexico, for example, who offer lower labor and material costs.

Companies operating within this space are therefore focusing on enhancing their value proposition through pricing restructuring and continually prioritizing quality and

customer service, while mergers and acquisitions play a pivotal role in reshaping market dynamics.

As the sector continues to evolve, so does the focus for manufacturers. With consumers increasingly seeking state-of-the-art trailer features, lightweight designs, and advanced safety systems, those embracing innovation are best positioned to thrive.

It is within this context that we revisit Delco Trailers (Delco), headquartered in Paris, Texas, to examine how its activities have developed.

When we spoke last year, the company was in the midst of a transformative expansion, having

opened a new 600,000 square foot (sqft) manufacturing facility.

Today, the Delco team has successfully transitioned its entire production into this cutting-edge facility, demonstrating how the strategic investment has bolstered the company’s position and manufacturing efficiency –despite a backdrop of difficult market conditions.

Since 2024, Delco’s key automation processes have moved from implementation to full operation, resulting in enhanced proficiency, product quality, and capacity.

In addition, the automated powder

coating line – a major focus for the company since last year – is now fully functional, with Delco having contracted Total Finishing Systems to implement the technology earlier this year.

Meanwhile, the seamless flow of trailers from the welding process directly to the overhead rail for coating continues to streamline production and reduce manual handling.

The efforts Delco has put into its finish line have paid off, with a consistent, high-quality finish for every unit, driving forward the brand’s reputation for durability and craftsmanship.

With the automated wash bays

implemented at the end of Q3 2024, this upgrade further automates the manufacturing process, freeing up manpower and ensuring greater consistency when preparing trailers for final finish.

This integration not only boosts productivity but also reinforces Delco’s commitment to quality control at every stage of production.

Beyond these tangible additions, Delco’s inward focus on refining internal processes remains.

The company’s forecasting, for instance, has been fine-tuned to lower material inventory, while streamlined warehouse procedures have enabled Delco to keep better track of trailer components, eliminating

inefficiencies and minimizing missing parts.

An internal ordering system for in-house parts is now fully integrated, providing more efficient monitoring and control of components.

These are just a few examples of small changes the company is making that collectively contribute to a more robust, organized, and scalable operation.

Delco’s strategic investments have fortified its position in a market that continues to deal with high production capacity and increased international competition.

Action Spring Company is a family and woman owned business located in Tulsa, Oklahoma and has manufactured springs, wireforms and metal stampings since 1971. The business was started by Marshall Jackson who started in the spring industry in the mid 1950s. Since 1971, Action Spring has been providing quality products and service

to a wide range of industries including aerospace, agriculture, construction, recreation, electronics, oilfield, trailer and residential – just to name a few, with all of our products being made in America.

After the passing of Mr. Jackson in 2005, Rhonda Miller, Mr. Jackson’s daughter, and her husband, Greg, took over the business and have eliminated some of the manual

machinery with more up-todate equipment to help with the quality and efficiency of manufacturing parts.

We have state-of-the-art testing equipment to assure high-quality products.

However, it is our experienced and dedicated production and administrative staff that makes Action Spring second-to-none for dependable service and products.

Our sales and engineering team are here to help you design what you might need to create your product. Prototypes can be produced to ensure the right fit, if needed. All parts have a final inspection performed to ensure that customers receive the finest quality parts made to their specifications. We are able to produce compression, extension, torsion and flat springs of nearly any shape or size from .003” to 1.00” wire diameter. Using hightech computerized coilers and lathes, we create the high quality product you want at the custom specifications you need.

Our metal stampings can be made in sizes from .004” to .375” thickness with widths up to 8.00”. Our tooling department can produce a custom die to manufacture your part using the latest in equipment. Our four slides and secondary departments can produce custom manufactured parts to your specifications from .003” to .625” wire diameter.

Action Spring Co. wants to be your source for springs, wireforms and metal stampings. Call us and we will help you with your next order.

By enhancing its efficiency and product quality, the company has carved space for itself as it stands out from other industry players.

Over the last two years, an influx of competitors has pushed trailer

manufacturing companies to evolve, and Delco’s response has been to innovate and improve from within.

The company’s trajectory from a small-scale operation in 2006 to a leading name in the trailer industry is

The 2025 Trailer Tech Expo, powered by the North American Trailer Dealers Association (NATDA™), was held in Reno, Nevada, in February.

The event focused on the technology and tools driving future trailer dealerships, including hands-on training from experts, networking opportunities, and key talks.

Delco attended this year and, alongside connecting with many incredible dealers and industry professionals, was honored to be a finalist for the Customer Service Excellence award.

The company was also proud to pay special mention to its very own Kyran Hollje, Marketing Director, who was named among the finalists for Woman of the Year.

a testament to this relentless focus on improvement.

Delco’s investment in its 600,000 sqft facility has additionally allowed it to scale production while maintaining its core values of quality and consistency.

The company’s ability to produce 150 to 200 trailers per week, with a capacity of 500 units in the same timeframe, positions it to respond effectively to market fluctuations and maintain a strong foothold in the lightto-medium trailer sector.

Delco’s business model remains deeply rooted in the strong relationships it cultivates with customers, suppliers, and employees.

As a family-run operation, the company extends its values of trust and respect throughout this network.

Consisting of nearly 180 independent retailers, Delco’s dealer partnerships are supported by a dedicated team that is committed to creating the best possible product.

The company’s supplier relationships, meanwhile, many of which have lasted for nearly 20 years, are reinforced by the recent appointment of Purchasing Manager, Kevin Dyck, who is focused on building legacies and strengthening communities.

The resulting stability in the supply chain has ensured timely procurement of quality products, which, in turn, has contributed to Delco’s reputation for reliability.

The dedication and talent of the company’s nearly 200-strong staff base remains a core differentiator as it fosters an inclusive environment where every employee’s voice is heard and respected.

By empowering its employees and celebrating their successes, Delco ensures that the passion of its workforce translates directly into the quality of its products.

In March 2025, Delco hosted its annual Trailer Build-Off competition, which honors the next generation of builders by investing in and spotlighting emerging industry talent.

This commitment was further underscored at Delco’s Family Day in May this year, which celebrated the company’s community roots and marked the second anniversary of its facility’s grand opening.

The trailer market continues to evolve in 2025 with broader trends including the integration of smart technologies, a greater emphasis on lightweight materials, and rising demand for

bespoke designs.

Delco’s investments in automation and efficiency mean that it is primed to respond to these changes effectively.

The company’s emphasis on building better, more consistent products, alongside its commitment to both its customers and employees, ensures Delco remains a resilient force in the light-to-medium trailer industry.

Its journey from a small-scale operation to industry leader underscores the importance of a clear, long-term vision for the company.

By continuously refining its processes, leveraging state-of-theart facilities, and staying true to its core values, Delco is not just keeping pace with the market – it is helping to shape its future.