WESTSIDE CORPORATION

Australia’s leading oil and gas exporter

PREMCAR PTY LTD

New cars that buyers really want

WESTSIDE CORPORATION

Australia’s leading oil and gas exporter

PREMCAR PTY LTD

New cars that buyers really want

BUMA Australia has a vision to build a modern mining and rehabilitation company, that drives growth, sustainability and prosperity

Chris Ware , General Manager of Mayfield Industries, shares how his company contributes to the growth of Australian electrical infrastructure

For over a decade, our portfolio of in-house magazines has been lovingly produced, printed, and distributed to our esteemed subscribers across the globe from our headquarters in the UK.

But now we are moving with the times, adopting a digital-first approach by producing online-only publications. A major factor in this decision is to minimise our environmental footprint, reducing the carbon emissions involved in the logistics of print magazine distribution and the resources required therein.

“We always planned that when our digital subscribers consistently accounted for 85% of our total magazine subscribers, we would cease printing our publications in-line with our environmental and sustainability goals.”

– Ben Weaver, CEO, Outlook Publishing LtdGoing forward, we will provide print orders of any magazine in-line with the requests of our featured companies, subscribers, and conference & expo partners.

Please get in touch for a print-on-demand quote or visit our website to find out more.

www.outlookpublishing.com/subscribe

Director: Joshua Mann joshua.mann@outlookpublishing.com

HEADS OF PROJECTS

Callam Waller callam.waller@outlookpublishing.com

Deane Anderton deane.anderton@outlookpublishing.com

Eddie Clinton eddie.clinton@outlookpublishing.com

Josh Hyland josh.hyland@outlookpublishing.com

Ryan Gray ryan.gray@outlookpublishing.com

BUSINESS DEVELOPMENT DIRECTOR

Thomas Arnold thomas.arnold@outlookpublishing.com

TRAINING & DEVELOPMENT MANAGER

Marvin Iseghehi marvin.iseghehi@outlookpublishing.com

SALES AND PARTNERSHIPS MANAGER

Donovan Smith donovan.smith@outlookpublishing.com

PROJECT MANAGERS

Cameron Lawrence cameron.lawrence@outlookpublishing.com

Dennis Morales dennis.morales@outlookpublishing.com

Jack Belton

jack.belton@outlookpublishing.com

Jordan Levey jordan.levey@outlookpublishing.com

Kierron Rose kierron.rose@outlookpublishing.com

Kyle Livingstone

kyle.livingstone@outlookpublishing.com

Liam Pye

liam.pye@outlookpublishing.com

Nicholas Kernan

nicholas.kernan@outlookpublishing.com

Poppi Burke poppi.burke@outlookpublishing.com

Taylor Green

taylor.green@outlookpublishing.com

ADMINISTRATION

Finance Director: Suzanne Welsh

suzanne.welsh@outlookpublishing.com

Finance Assistant: Suzie Kittle

suzie.kittle@outlookpublishing.com

Finance Assistant: Victoria McAllister

victoria.mcallister@outlookpublishing.com

Welcome to our 65th edition of APAC Outlook magazine.

As new technologies and energy solutions are increasingly required across the world, their introduction has created strong demand for a multitude of elements and rare minerals.

This has directly resulted in a global mining boom amid a dynamic period of change for the industry, in which the collective focus has pivoted towards managing the environment whilst maximising the extraction of resources.

Australia assumes a frontrunning role in futureproofing the mining sector, for which it is famed across the world thanks to the country’s fascinating mining history.

It is also a particularly exciting time for the industry in Queensland, where several long-term contracts are currently being operated by our cover star, BUMA Australia (BUMA), who has been providing mining services for 75 years.

“The key to our continued contract success comes from our focus on delivering services to meet evolving client needs, using a flexible and adaptable approach,” says Ngaire Tranter, General Manager of BUMA.

“Blackwater is one of BUMA’s most established and successful projects, showcasing efficient operational practices, along with a steadfast commitment to safety, community, and our team.”

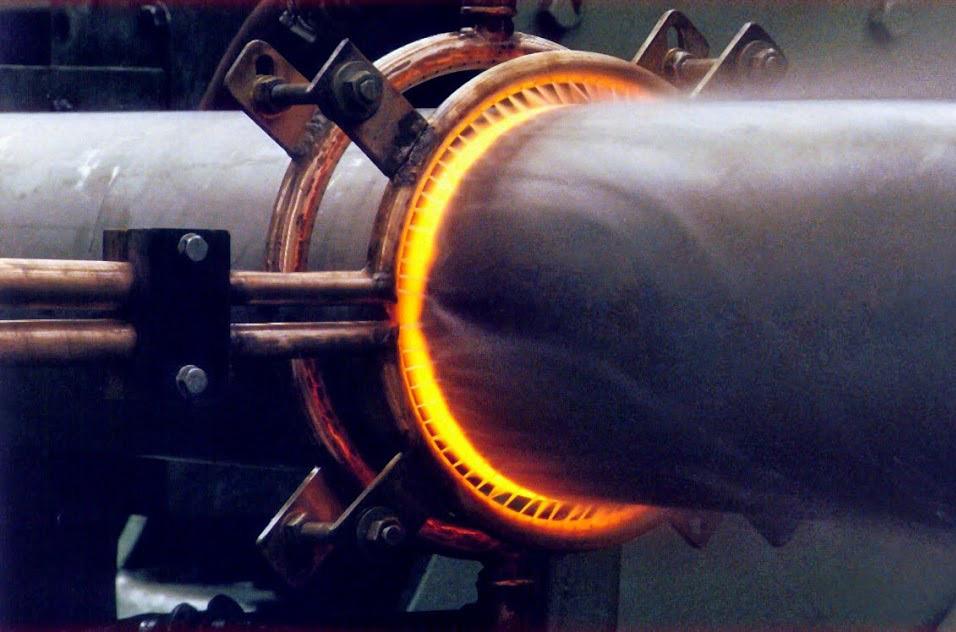

Specialist projects have likewise been executed in Australia and across Asia Pacific by Spiecapag, a leader in pipeline construction contracting and horizontal directional drilling with a regional office based in Brisbane. We delve into four decades of pipeline projects and consider how the company’s expertise is highly transferrable to the hydrogen space, as Australia casts itself as a future renewable energy superpower.

“The hydrogen production technology is still being proven, but increasingly, scale production facilities are being discussed,” notes John Walsh, Managing Director of Spiecapag Australia.

There are equally emerging opportunities in the electrical industry, driven by the transition to a low-carbon economy.

Providing critical electrical infrastructure for various industries, including mining and oil and gas, is Mayfield Industries.

“From conception to production and beyond, we prioritise the well-being of users and ensure that our products not only meet but exceed safety standards,” shares General Manager, Chris Ware.

Elsewhere in our final issue of 2023, learn how Melton City Council is preparing for unprecedented growth, Atos is creating the digital workplace of tomorrow, and Zenith Energy is providing sustainable power.

We hope that you enjoy your read.

Jack Salter Head of Editorial, Outlook Publishing

Around Asia Pacific in seven stories…

PACIFIC COAST PRODUCE, a fruit grower in the far north of Queensland, is hoping to break into the Japanese fruit and veg market with a revitalised importation strategy.

In a nation-first trial, red, waxtipped, ‘ecoganic’ bananas, as well as Queensland-grown Emperor Pearl melons, have been air freighted directly from Cairns, rather than

CHINA’S GOALS TO MEET CARBON NEUTRALITY

IN

A BID to achieve the country’s carbon neutrality goals by 2025, China’s National Development and Reform Commission (NDRC), amongst other government departments, has recently introduced a guideline to solidify a carbon footprint management system. The guideline dictates a national

shipped via Sydney. This has saved both time and money in the export of produce to Japan.

Direct air travel mitigates the negative impacts of shipping that can affect the ripening and overall freshness of fruit. Therefore, the use of a direct export route reduces the risk of food waste and maintains the optimum condition of the produce.

TOYO TIRES MALAYSIA (TTM), a division of Toyo Tire Corporation, won the ‘Team of the Year – Manufacturing’ award at the most recent Malaysia Management Excellence Awards.

TTM has become a key industry player since its inception in 2011 in Taiping, establishing a prominent standing in the tyre and rubber products sector.

The award given to TTM recognises and celebrates the company’s exceptional leadership, as well as the business’ innovative programmes that have generated significant industry gain for the company.

product carbon labelling certification, which refers to the total amount of greenhouse gas (GHG) emissions generated from the production and transportation of a product through its lifecycle.

There are five key development areas indicated by the guideline, including carbon footprint accounting standards, data bases, and certification systems, as well as promoting carbon footprint products and international cooperation.

SINGAPORE’S MINISTRY OF Finance has introduced a new relief package in the form of SGD$1.1 billion, to reduce the burden of the cost of living crisis in the country.

The support package will aid lower to middle-income households and small to medium-sized enterprises (SMEs) in the form of cash payments, vouchers, and subsidiary schemes.

The aid is to be distributed at the end of 2023 and beginning of 2024, to help alleviate the negative impacts of inflation on the population, which have been an ongoing challenge since Singapore emerged from the COVID-19 pandemic.

A NUMBER OF Chinese airlines have cancelled flights to Thailand because of limited tourist demand. Such airlines include Air China, China Eastern, and Shanghai Airlines, who have all cancelled flights between December and January as a result of

booking level requirements not being met.

Earlier in the year, the government introduced an initiative in which Chinese nationals could access a free visa, however, this initiative fell short of the number of tourists it was predicted to generate.

As such, the cancellations are due to the lack of people willing to leave the country, compounded by China’s current economic deceleration.

FOLLOWING A VISIT to Tokyo from Vietnam’s President, Vo Van Thuong, the relationship between Vietnam and Japan has been upgraded to a ‘comprehensive strategic partnership’.

This diplomatic move recognises Vietnam’s increasingly prominent role in the global supply chain. In particular, trade tension between Japan and the West has consequently resulted in foreign direct investment (FDI) into Japan as many Western companies relocate to the country.

In a speech broadcast across Japan, Thuong emphasised the importance of the global alliance, marking a new chapter in VietnamJapan relations.

TO PROTECT THE public from the ‘global scam epidemic’, financial institutions across Australia are introducing a new anti-scam system which stops online banking users transferring money if the name given does not match the recipient.

This new initiative is part of a wider ‘Scam-Safe Accord’, pioneered by the Australian Banking Association (ABA) and Customer Owned Banking Association (COBA), which is set to be rolled out across all banks, credit unions, and building societies throughout the country.

Another measure in the accord includes biometric checks to tighten the security of bank accounts, with the system being designed to check users’ faces, fingerprints, and behaviours.

By providing access to real data, digital twins enable Indonesian operators to have eyes on assets and operations that are thousands of kilometres away. Raj Kaushal, Senior Business Development Manager for APAC at James Fisher AIS, explains

Writer: Raj Kaushal, Senior Business Development Manager for APAC, James Fisher AISNestled amidst the equatorial seas, Indonesia emerges as a mesmerising archipelagic state.

Amongst a sprawling tapestry of over 17,000 islands lies an energyrich heart, where geothermal power is drawn from the Earth’s core, and ocean tides beckon as an untapped source of renewable potential.

It also has a rich oil and gas heritage, with production peaking in the 1990s.

However, over the last few decades, the country has faced challenges such as declining reserves, aging oil and gas infrastructure, and regulatory issues, leading to a decrease in oil production and a shift towards natural gas as a lower emissions alternative.

Oil and gas will continue to play a major role in Indonesia’s varied energy portfolio, ensuring domestic energy security, but to continue to do

so, certain challenges will need to be addressed.

The decline in production is owed to the country’s particular set of challenges, such as investment frameworks, field development solutions, and the balance between national and private entity interests. Introducing digital solutions that deliver increased efficiencies can therefore prove to be challenging.

However, digitalisation could provide a solution to a sector filled with data silos. Digitalising operations can bring a whole host of benefits such as reducing asset downtime and improving worker productivity and onsite execution, by bringing together data that helps to paint a vivid picture of an asset’s real-time status.

In Indonesia, assets are typically in remote locations with limited data connectivity. Modern digital systems can support the integration of data to allow engineers and managers to visualise the reality of the situation without wasting time gathering data. These systems can bring together asset data from the most remote corners of the country, helping local oil and gas companies, as well as government entities which provide support and funding, to better understand the safety and operating status of energy hubs and assets.

Digitalised data is vital when dispersed teams are operating on the ground in different locations; it can help to bring the disparate islands of the archipelago together.

Digital solutions providers across the islands can help Indonesian energy producers access enriched views of their assets through centralised, digitalised systems of data management. Pinpointing exact anomalies, faults, and risks, this real-time overview of an aging infrastructure, in remote and unforgiving environments, can plug the gaps in operations.

Newer technologies like digital

twins mean Indonesian operators can access reality data to monitor assets and operations across the archipelago. Through this, the preplanning of maintenance, as well as the delivery and quality assurance of major projects, plays a large role in the broader regional energy context.

For Indonesia’s aging infrastructure, digital twin software models which connect site imagery to existing data could provide significant opportunities to maximise output as the assets degrade.

Whilst digitalisation might plug the gaps and connect the dots, companies can be wary of taking a risk of investing in the search for a return on investment.

However, the opportunity to deliver more value from assets remains. By partnering with software companies – those with local, geographical, and historic knowledge of sites - to support exploration, drilling, and production, national oil companies and smaller, local energy producers in Indonesia can find their operations vastly maximised.

Hesitancy to change can arise in the face of energy security concerns. As such, digital solutions providers looking to make headway in the region need to adapt their approaches, build bridges with flexibility in mind, and consider local nuances.

Historically, long-lasting partnerships across the industry have been fostered through consultativestyle processes. Through this, confidence is built, trust is instilled, and progress is made. By being adaptable, Indonesia’s oil and gas companies can have confidence in adopting innovative digital technologies by making smaller changes in the first instance, and then scaling that success.

This model could mean that Indonesian energy companies are keener to adopt advanced technologies like data analytics and predictive maintenance, ultimately bolstering their operations. With this growth, seeing a return on investment should instill further confidence in these partnerships and technologies, giving Indonesian firms the option to scale operations and adoption.

And the proof has been in the

pudding. With digital twins providing access to real data, Indonesian operators have eyes on assets and operations 3,000 kilometres away, making the invisible, visible. This has already been done at a remote LNG production facility in Indonesia, where James Fisher AIS’ R2S digital twin meant that the team could cut down on over 20 hours of travel time to reach the facility from the nearest hub city, as well as increase collaboration across the dispersed team.

Indonesia has clear ambitions to grow its energy industry across multiple sectors and bolster its power generation.

With agreements in place to export clean energy to Singapore, and recent progress made in prioritising natural gas and geothermal energy, less carbon-intense energy sources also have a part to play in both the energy transition and energy security of the region.

Across oil and gas, geothermal, and natural gas, it’s clear that digital solutions and flexible business models which put energy companies and their pain points first will be key to achieving these.

Raj Kaushal is a chartered engineer with a bachelor’s degree in Mining and Petroleum Engineering, as well as a master’s degree in Reliability and Safety Engineering.

He has 30 years of professional oil and gas experience in technical, consultancy, and leadership roles working within the operations environment in the UK, Angola, Indonesia, and Azerbaijan. Kaushal has been based in Indonesia for seven years and joined James Fisher AIS in 2022.

Kaushal has extensive hands-on experience of successfully deploying digital technologies and engages with operators, asset owners, and key stakeholders across the Asia Pacific region to ensure tangible efficiency improvement to operations.

Since its inception, Translink has pioneered accessible, affordable, and sustainable public transport practices across Queensland, Australia. Peter Milward, Acting Head, shares more about the organisation’s ethos and its future ambitionsWriter: Lily Sawyer

Translink was established in 2003 as an agency responsible for introducing common fares, zones, and ticket types across all public transport modes in the South East Queensland (SEQ) region.

In 2012, it joined Queensland’s Department of Transport and Main Roads (TMR) as one of its six divisions.

“We are an obvious fit within a department that is tasked with moving and connecting people, places, goods, and services safely, efficiently, and effectively across Queensland,” opens Peter Milward, Acting Head of Translink.

TMR’s responsibilities include planning, managing, and delivering a sustainable, integrated transport network across road, rail, air, and sea for the state.

“Translink’s mandate has evolved significantly over the past 20 years, but at our core we remain committed to ensuring Queensland’s transport system contributes to people’s quality of life, a vibrant economy, and a sustainable environment.”

Across its six business areas, Translink has a wide range of responsibilities, including the management of integration, planning, policy, strategy, technology, and service delivery of public transport across Queensland.

Translink’s commitments also extend to the delivery and maintenance of significant rail infrastructure, including planned rail line and station expansion.

Its public transport services include rail, bus, ferry, light rail, event transport, school transport, longdistance rail, coach, and air routes.

“Our state-wide bus network alone has just under 3,000 urban routes that cover more than 160 million kilometres (km) annually, another 2,379 school services, and almost 18,000 stops,” reveals Milward.

Queensland’s large size and relatively low population density makes for some challenges, but Translink has recently expanded into more regional areas.

This brings a consistent and coordinated public transport experience to many diverse communities across a large area.

Last year’s state-wide integration of Translink introduced a consistent fare table and zone structure across 15 regional centres. These Translinkbranded regions stretch 1,700km from Brisbane to Cairns. Public transport customers in these areas now enjoy access to the Translink website, social media channels, MyTranslink app, integrated journey planning, real-time and service disruption information, and Translink’s 24/7 contact centre.

“As part of this integration, we are also rolling out our Smart Ticketing payment platform throughout Queensland,” Milward discloses.

“PEOPLE AND PARTNERS ARE THE CORE OF OUR BUSINESS, AND OUR CUSTOMERS HAVE REGULAR INTERACTIONS WITH THESE PARTNERS”

– PETER MILWARD, ACTING HEAD, TRANSLINK

This platform will introduce new ways to pay for travel on public transport with contactless payment, including those linked to customers’ digital wallets through their smart device.

Translink’s SEQ network extends more than 250km from north to south, and 140km west to Toowoomba.

It spans eight fare zones and is one of the largest integrated public transport networks in the world, covering more than 10,000 square kilometres (sqkm).

However, scale, geography, and the environment make integration and accessibility across all facilities and modes of transport a complex task.

“This challenge makes projects such as Smart Ticketing and delivering improvements for our customers even more rewarding,” Milward excites.

Translink works together with a number of delivery partners as well as state and local government agencies to help plan and deliver its services

and public transport infrastructure.

“People and partners are the core of our business, and our customers have regular interactions with these partners,” Milward enthuses.

Translink’s delivery partners include 18 private operators contracted to provide regional urban bus services, alongside 22 public transport delivery partners operating services across Queensland, and more than 1,200 school bus service contracts.

Bus stops are jointly-funded with many of Queensland’s local councils, to plan and assist with the delivery of services and infrastructure requirements. This can include future planning and funding for public transport services in areas of development and building and upgrading bus stops.

“Customer interactions with our partners aren’t restricted to stepping on board a service. They may plan a journey or check service disruptions with our call centre partner, board at a jointly-funded transport terminal, use

the ticketing system supported by our ticketing partner, visit an accessible station built by our infrastructure delivery partners, or engage with enforcement personnel such as our Queensland Police Service partners,” explains Milward.

“Consequently, we are heavily reliant on our partnerships.”

Translink’s role in planning, delivering, and adapting its services in ways that benefit customers is driven by its 10-year plan, Creating Better Connections for Queenslanders

The core components of this plan include developing safe and reliable services, responding to evolving community needs, implementing seamless end-to-end journeys and accessible passenger transport, and overseeing environmentally sustainable operations.

“While big ticket items often get the glory, we understand it is sometimes

the smaller things that make the most appreciable difference for our customers,” Milward acknowledges.

Two recent changes have seen impressive customer engagement, including Translink’s near-field communications (NFC) technology that allows customers to tap their smartphone at a bus stop to quickly access up-to-date information regarding their journey, without the

need for an app. It also assists people with visual impairments and those who do not speak English as their first language, as the technology can translate the web page.

“In less than a year, NFC has seen more than 500,000 scans from more than 250,000 unique users,” details Milward.

“When we trialled approval to take bikes and e-scooters on peak-period

SEQ trains several years ago, the uptake was also impressive,” he continues.

Therefore, Translink changed its policy to accommodate bikes and e-scooters on board. In the first year, there were more than 237,000 bikes and e-scooters taken on board peakperiod trains, resulting in an increase of more than 27 percent of people taking the train as part of their journey.

“AT OUR CORE WE REMAIN COMMITTED TO ENSURING QUEENSLAND’S TRANSPORT SYSTEM CONTRIBUTES TO PEOPLE’S QUALITY OF LIFE, A VIBRANT ECONOMY, AND A SUSTAINABLE ENVIRONMENT”

– PETER MILWARD, ACTING HEAD, TRANSLINK

As the host city for the 2032 Olympic and Paralympic Games, Brisbane will see significant infrastructure development in preparation for the event.

“To support SEQ’s growing population and rail patronage demand between Brisbane, Logan, and the Gold Coast, we need to double the number of Beenleigh and Gold Coast train services over the next 20 years,” Milward divulges.

Translink has begun to implement a variety of transport improvements to achieve this goal.

Firstly, the Logan and Gold Coast Faster Rail project will remove a key bottleneck on the SEQ rail network, to allow Gold Coast express trains to easily bypass Beenleigh trains during peak periods.

Unlocking this network capacity requires duplicating tracks in both directions between Kuraby and Beenleigh, through the implementation of a wider corridor and track straightening in some areas.

As well as duplicating the number of tracks between Kuraby and Beenleigh from two to four, the project will also deliver modernised rail systems, station upgrades, and five level crossing removals to improve accessibility and safety.

Park ‘n’ ride upgrades and an active transport corridor along the length of the 20km rail corridor will also be delivered through the project.

“Planning, community engagement, and procurement activities are now underway. Additionally, a dedicated accessibility reference group was established earlier this year to contribute to accessible outcomes for all transport users,” he tells us.

The Beerburrum to Nambour Rail Upgrade project will equally provide additional track capacity and reliability, and increased passenger and freight services to the growing Sunshine Coast region, north of Brisbane.

“Early works have recently been completed, and pre-construction and design activities have started on the first main stage.

“This stage will duplicate about 13km of track, address three level crossings on the alignment, expand three park ‘n’ ride facilities, and undertake associated road works. In keeping with our integrated network vision, a new bus interchange has also

been built at one of the stations along the rail line,” Milward explains.

The business case for a Direct Sunshine Coast Rail Line project is underway with consultation already beginning for the Sunshine Coast Public Transport project.

“Both projects aim to enable greater travel choices for short, local, and long trips. They are designed to ease traffic congestion and improve efficiency of the broader transport network through reduced car dependence,” outlines Milward.

As the country anticipates the Brisbane 2032 Olympic and Paralympic Games, Translink will capitalise upon its reputation for reliability and excellence.

“We look forward to building on that success as we welcome visitors to our beautiful part of the world in 2032,” Milward concludes.

Solutions maintain

People are a real source of pride for FIELD Mining & Resources, the division of FIELD Solutions Group working to design, build, and maintain successful IT infrastructure for mining organisations. We find out more with Jody Barlow, Head of Mining and Resources

As technological advancements and digital transformation have drastically changed the face of the mining industry, reliable and seamless communication networks are of critical importance to operations.

Indeed, from remote mining sites to global supply chains, the driving force behind innovation, operational efficiency, safety, and sustainability within the industry is connectivity.

Due to a range of issues, however, implementing the correct technology for the mining sector can be challenging.

Addressing complexities such as the distance between operations, large-scale data management, cybersecurity risks, and regulatory compliance requirements demands specialised expertise and a proactive approach to technology implementation and management.

FIELD Mining & Resources, a division of Australia’s challenger telecommunications carrier, FIELD Solutions Group (FSG), understands these critical IT challenges faced by the industry.

A technology leader that provides bespoke solutions for all IT needs, FIELD Mining & Resources’ customers in the mining and resources sector include Kestrel Coal Resources (Kestrel), Bowen Coking Coal (Bowen), Ravenswood Gold (Ravenswood), and more.

“Every mining company has different requirements. In the case of our largest client, Kestrel, we are their trusted end-to-end ICT partner; we look after everything for them,” says Jody Barlow, Head of FIELD Mining & Resources.

With dedicated on-site team members providing support and extra feet on the ground to Kestrel, the partnership exemplifies FIELD Mining & Resources as a one-stop shop for the IT needs of all clients.

Writer: Jack Salter

“FROM OUR PERSPECTIVE, WE NEED TO GUARANTEE A HIGH LEVEL OF UPTIME ON THE MINE BECAUSE IF IT GOES DOWN, IT COSTS MONEY”

– JODY BARLOW, HEAD OF MINING & RESOURCES, FIELD MINING & RESOURCES

“If they need software, hardware, or anything else, they come to us, and we procure and manage it for them. It’s really bespoke, and we provide everything from data connections to desktop support,” Barlow notes.

FIELD Mining & Resources, whose purpose-built network solutions are designed to optimise network performance, scalability, and connectivity, also looks after the security of the network, which is where the division’s expertise and professionalism come to the fore.

“We focus on not only providing connectivity as a solution but a secure network. That’s an important piece; security can cripple a mine, so we spend a lot of time, effort, and money to make sure it is on point for our clients,” he adds.

By providing a holistic approach to managed services and a single point of contact, FIELD Mining & Resources maximises operational uptime.

“From our perspective, we need to

guarantee a high level of uptime on the mine because if it goes down, it costs money. Ultimately, it comes back to being the partner of choice to look after their assets,” emphasises Barlow.

In July 2023, FIELD Mining & Resources announced that it had been awarded an enterprise managed services contract by Ravenswood.

The division will supply connectivity as well as managed services, security, and cloud services for Ravenswood, together with on-site resourcing supporting the mine. Additional IT and procurement services will also be sourced on an as-needed basis during the three-year contract.

The deal with Ravenswood reinforces FIELD Mining & Resources’ focus on delivering integrated IT managed services and is a departure from the coal mines that the division has most experience in.

“Coal is what we specialise in, and Ravenswood is the first time that we have forayed into gold mining,” Barlow reveals.

Nevertheless, by partnering with FIELD Mining & Resources, Ravenswood will benefit from a very broad range of skillsets to service

their requirements.

“We’re an aggregator of professional services, so where our own internal staff don’t have the skillsets required, we are highly engaged with our partners who can then fill the gaps that we have,” outlines Barlow.

“Ravenswood has three to four full-time IT staff working on the mine site, so our job is to support those guys. We also support everyone else from a remote hands point of view, as well as look after the security of their network.”

COST SAVINGS – Managed services can save businesses money, as FIELD Mining & Resources provides services at a lower cost than hiring an in-house team. Additionally, the division uses advanced tools and technologies that allow the team to perform tasks more efficiently, reducing costs further.

SCALABLE SOLUTIONS – FIELD Mining & Resources’ managed services can be scaled up or down to suit business needs. If the customer experiences growth or expansion, additional services or resources can be provided as required.

EXPERT SUPPORT – The FIELD Mining & Resources team are experts in cybersecurity, cloud computing, data management, and network infrastructure. By outsourcing business IT, clients can access the knowledge and skills of these experts without having to hire and manage an in-house IT team.

INCREASED PRODUCTIVITY – FIELD Mining & Resources proactively maintains services, which can help identify and resolve issues before they cause downtime or other problems. This can reduce the risk of IT-related issues impacting business operations, saving time and money.

Meanwhile, FIELD Mining & Resources is close to making some exciting announcements in the Tier 1 mining space, placing it even more firmly on the map.

“That’s hopefully going to put us on another level and show some of the larger mining organisations that we are not just a smaller player, even though the Kestrels and Ravenswoods of the world are very large clients,” Barlow affirms.

As FIELD Mining & Resources’ recruits locally and invests in its people, the division’s head office in Queensland and remote office in Emerald are growing as a result.

People are a real point of difference for FIELD Mining & Resources, as they substantiate how it provides mining clients with superior service both on-site and in the office.

“The benefit of working with an outsourced IT firm is that we have the scale, but also the professionals,” Barlow states.

The FIELD Mining & Resources team of qualified, professional Programme Managers, Project Managers, Network Architects, and

Engineers has extensive experience in building and maintaining networks in remote locations and managing complex projects.

In Townsville, for example, where Ravenswood is based, the team was tasked with understanding the lay of the land and the idiosyncrasies of a gold mine compared to the coal mines that FIELD Mining & Resources has traditionally worked with.

“They’re a different mine, and they obviously mine different things, but at the end of the day it’s about going in and understanding what works and how it works,” shares Barlow.

“We have dedicated staff to make sure we understand what makes Ravenswood tick, and that’s how we support their mine.”

As a former professional rugby league player, team camaraderie was always a big thing for Barlow, a people person who has always enjoyed being around bigger teams.

Replicating that feeling on the rugby field in the commercial world quickly led to mentoring, managing, and leading.

“I MANAGE A GOOD TEAM, AND I’VE ALWAYS BEEN ABLE TO PUT THE RIGHT PEOPLE IN THE RIGHT PLACE, ALLOWING THEM TO DO WHAT THEY DO TO THE BEST OF THEIR ABILITY”

– JODY BARLOW, HEAD OF MINING & RESOURCES, FIELD MINING & RESOURCES

“I like to classify myself as a leader more than a manager. “Together everyone achieves more” is the one catchphrase that I use; I lead from the front and don’t tell people to do something that I wouldn’t be prepared to do myself,” Barlow says.

“I manage a good team, and I’ve always been able to put the right people in the right place, allowing them to do what they do to the best of their ability.”

Together with his staff, Barlow is always on the lookout for the next

large mining operation that FIELD Mining & Resources can partner with, especially now it has demonstrated its capabilities and the expertise of its workforce.

“The utopia is always to find the next mining client that will need to utilise our services. We’ve got a really good story to tell, so we want to expand our client base and find more mining organisations,” Barlow sets out.

Being a trusted advisor is the key to FIELD Mining & Resources expanding and putting its best foot forward in the marketplace.

This is based on providing mining organisations with the services they require with true transparency and partnerships.

“A true partnership for me is both parties going in with their eyes open and understanding what is required from each other – that’s what we’re looking for,” concludes Barlow.

Chinmay Mishra,

Product Marketing

outlines the opportunities and trends for mobile virtual network operators in Asia Pacific

Senior Manager at Optiva, Guest contributor: Chinmay Mishra, Senior Product Marketing Manager, Optiva

The global mobile virtual network operator (MVNO) market has increased from USD$36 billion in 2012 to more than USD$88 billion in 2022.

This rapid growth can be attributed to the number of strategic opportunities opening up in the market. The rising need for communication-based services, the pivot to remote working, the popularity of digital media, and the move to mobile wallets are just some of the trends driving these opportunities.

As the rollout of 5G continues and the economy becomes increasingly customer-centric, MVNOs have emerged as a way to better cater to subscriber needs, offering the kind of flexibility, scalability, and convenience that traditional mobile network operators (MNOs) lack.

However, such opportunities have a limited time window. In the scramble for subscribers, MVNOs must remain agile and adaptable in order to delight customers with competitive, targeted propositions that speak directly to their needs.

Analysing global MVNO trends offers a unique perspective of the realities facing the telecommunications (telecoms) industry, revealing which opportunities are worth pursuing and the efforts and resources involved in pursuing them.

The MVNO market is not only massive, but also very regional, with different parts of the world experiencing varying growth patterns and opportunities.

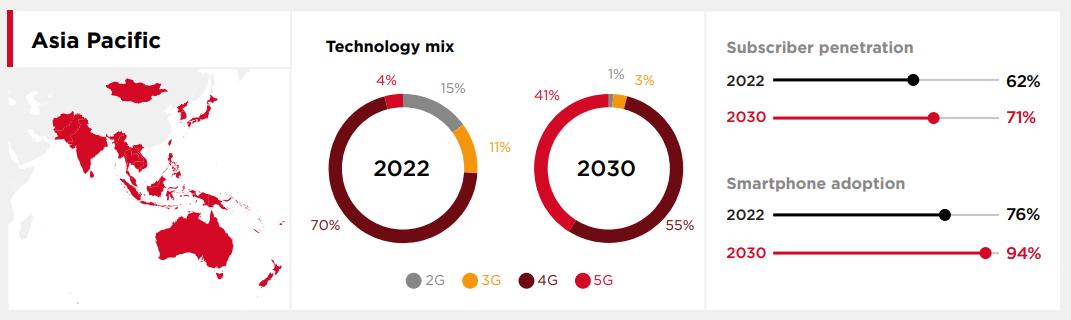

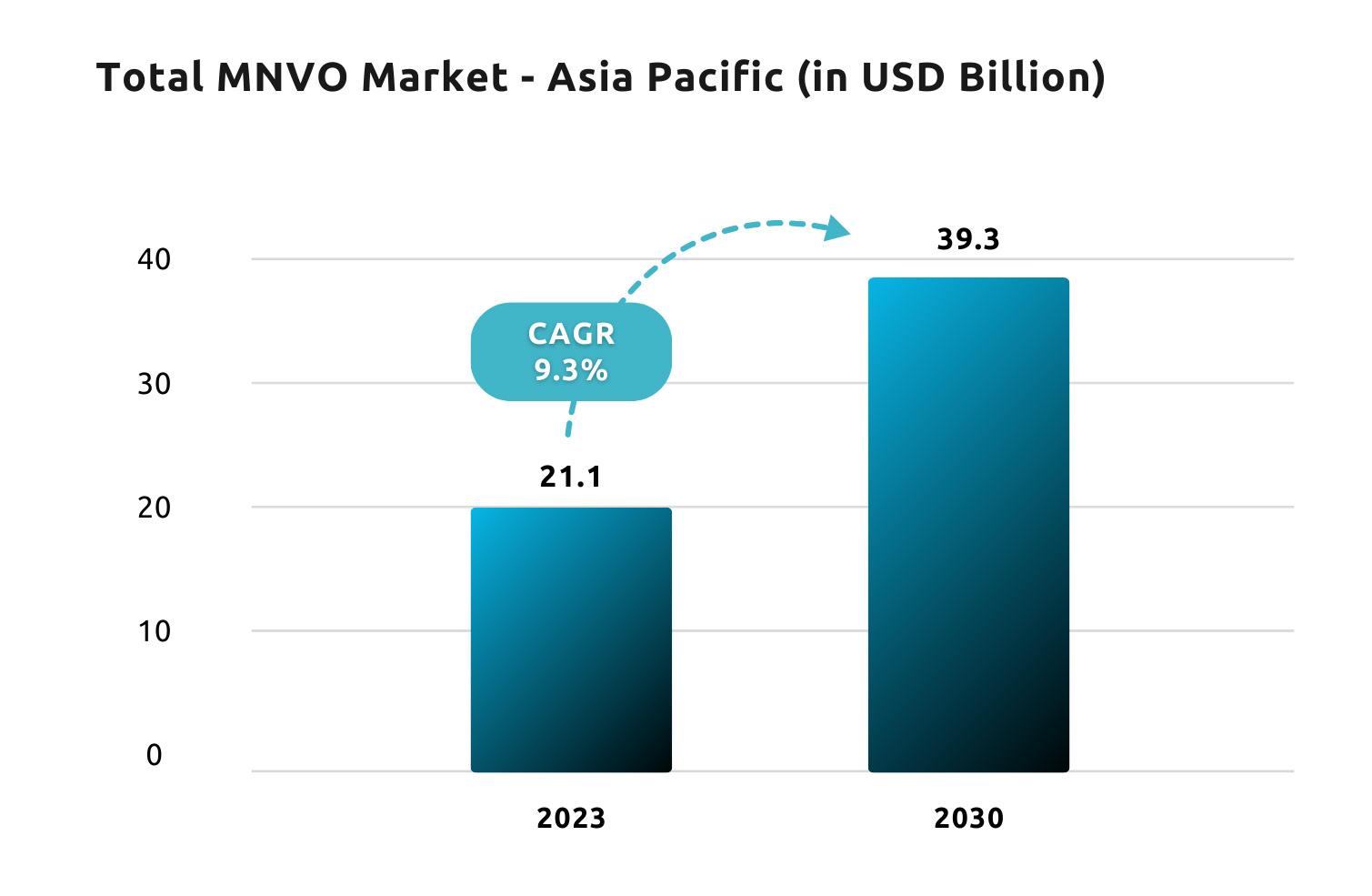

In 2023, the total MVNO market in Asia Pacific stood at USD$21 billion and is projected to grow to USD$39.3 billion at a compound annual growth rate (CAGR) of 9.3 percent.

Smartphone adoption is expected to grow from 76 percent in 2022 to 94 percent in 2030, with 5G dominating 55 percent of the technology mix by 2030. Mobile data traffic per

smartphone is also expected to more than triple to 60 gigabytes (GB) per month by 2028.

Asia Pacific therefore shows some promising emerging trends for MVNOs, particularly in a greenfield environment.

5G adoption is growing, but monetisation has been difficult because existing customers are not likely to pay extra for 5G vanilla connectivity on their smartphones, particularly in a cost-sensitive market like Asia Pacific.

In other words, 5G alone is not enough to entice new subscribers. This, however, provides a perfect opportunity for greenfield MVNOs.

5G might offer greater speeds, lower latency, and much higher capacity, but that alone doesn’t give subscribers much to get excited about.

Use cases that leverage the potential of this technology, such as extended reality, are needed to make the switch to a 5G-based MVNO more appealing. Asia Pacific already leads in 5G standalone deployments, with full rollouts already present in seven countries as of 2023. The networks are there; now the services are needed.

is a method of providing wireless connectivity to a fixed location, such as a home or business, through radio

signals rather than traditional wired connections like copper or fiber optic cables.

FWA is used in areas where building traditional infrastructure is impractical or cost-prohibitive. As of March 2023, 17 operators in eight Asia Pacific countries offer 5G FWA services. Markets where the fixed broadband technology mix is skewed towards xDSL, such as Australia, also see potential for 5G FWA.

Successful examples:

• In 2023, Globe Philippines’ FWA accounted for 25 percent of home broadband revenue. It targets rural areas as well as urban areas where fiber broadband is not yet available.

• The REALLY DeWi network is powered by the people, bringing the sharing economy to the telecoms industry. The network is fuelled by strategically positioned cell site radios hosted on rooftops and balconies, making increased speeds and seamless roaming available to all customers on the network.

With so much investment going into 5G and business-to-consumer (B2C) proving hard to monetise, businessto-business (B2B) is now taking centre stage as the growth driver for the industry. However, the B2B

segment is not traditionally one of the main strengths of telcos, particularly in Asia Pacific.

A recent survey carried out by TMForum in Asia Pacific found that 41 percent of telecoms companies in the region get less than 10 percent of their total revenue from the B2B segment in contrast to the global average of 15 percent.

Telcos need to carefully cherry-pick the B2B use cases that will work for them. Developing this new segment will take time for telcos in Asia Pacific, and MVNOs are expected to ride on this opportunity.

5G standalone and private 5G propositions are resonating well within B2B. This represents lowhanging fruit for the industry, as this segment needs a very specific and streamlined business and sales model from the existing B2C segment.

The Internet of Things (IoT) also shows good prospects and is expected to grow. In fact, a recent TMForum survey found that 57 percent of telcos in Asia Pacific believe IoT to be the best-chance opportunity for growth.

Successful examples:

• A GSMA report on private networks indicates that 16 percent of operators in Asia Pacific anticipate that private networks will contribute to over 20 percent of enterprise revenues by 2025.

• In Japan, local 5G licenses in the 4.7 and 28 gigahertz (GHz) frequency bands can be allocated by local governments to non-mobile operators seeking to deploy private 5G networks. Fuijitsu used the 4.7 GHz spectrum to deploy automated guided vehicles (AGVs) to transport goods around parts of its factory.

The average mobile traffic data per smartphone in Asia Pacific is higher than the global average and also is expected to grow threefold by 2028. Asia Pacific demographics are also skewed towards the younger generation, who are digital and tech savvy. They expect digital touch points, and many of them are power users of the digital lifestyle.

This high-spending, loyal, and brand-conscious segment will always be an attraction for MVNOs. Markets where existing MNOs have little incentive to innovate or single brands cater to broad categories provide a perfect opportunity for digital-born MVNOs.

These MVNOs generally dictate high margins and get to profit quickly with a digital-only approach.

Successful example:

• A service called “by.U” by Telkomsel in Indonesia, which targets youth and digital-savvy customers with data-heavy bundles, is a good example of a digital-born brand. SIMs are delivered to a user’s home, recharges and top-ups are easy, and the onboarding process is 100 percent digital.

“MVNOS MUST REMAIN AGILE AND ADAPTABLE IN ORDER TO DELIGHT CUSTOMERS WITH COMPETITIVE, TARGETED PROPOSITIONS THAT SPEAK DIRECTLY TO THEIR NEEDS”

– CHINMAY MISHRA, SENIOR PRODUCT MARKETING MANAGER, OPTIVA

–

“THE DYNAMIC LANDSCAPE OF THE MVNO MARKET IN ASIA PACIFIC, MARKED BY THE BURGEONING ADOPTION OF 5G, INNOVATIVE APPROACHES IN FWA, AND THE STRATEGIC SHIFT TOWARDS B2B AND DIGITALSAVVY SEGMENTS, UNDERSCORES A

TRANSFORMATIVE SHIFT”

CHINMAY MISHRA, SENIOR PRODUCT MARKETING MANAGER, OPTIVA

The rise of new technologies is opening the door to new opportunities that may generate revenue or help build a business model that can be a competitive advantage for MVNOs.

Technologies like eSIMs, network function virtualisation (NFV), software defined networking (SDN), artificial intelligence (AI), generative AI (GenAI), blockchain, edge computing, and the Metaverse show strong potential.

Greenfield MVNOs can use these technologies to disrupt the capitalintensive telecoms industry. For example, blockchain can help build a distributed network system with smart contracts for easy onboarding.

GenAI can help personalise plans for every subscriber, whilst edge computing can be invaluable to governments and enterprises.

New technologies like the Metaverse are already doing well

in advanced Asia Pacific telecoms markets like South Korea, Japan, and China.

FinTech is another area in which the region is excelling. However, MVNOs will have to become “techcos” rather than telcos to win this highly competitive market.

Successful example:

• SK Telecom launched a Metaverse app called “ifland” in July 2021. It was downloaded over 12 million times with a monthly average interactive time of 61 minutes, and received more than 2,000 partnership enquiries in just 18 months.

The dynamic landscape of the MVNO market in Asia Pacific, marked by the burgeoning adoption of 5G, innovative approaches in FWA, and the strategic shift towards B2B and digital-savvy segments, underscores a transformative shift.

Adding to its growing family of regional titles; EME Outlook, Africa Outlook, APAC Outlook, North America Outlook, and sector titles; Mining Outlook and Manufacturing Outlook –Outlook Publishing is proud to announce the birth of a digital magazine and web platform for the healthcare sector.

As organisations worldwide must navigate a new healthcare landscape defined by technological innovation in the wake of the COVID-19 pandemic, now is the time to showcase the strides being taken in this critical sector.

A multi-channel brand, Healthcare Outlook will bring you the positive developments driven by organisations across the healthcare industry through its various platforms. Discover exclusive content distributed through its website, online magazine, social media channels, and dispatches delivered safely to your inbox with a bi-weekly newsletter.

Through this compelling new venture, we intend to foreground the movers and shakers of the industry. To participate as a featured company and join us in this exciting endeavour, contact one of our Project Managers today.

APAC OUTLOOK is a digital product aimed at boardroom and hands-on decision-makers across a wide range of industries on the continent.

With content compiled by our experienced editorial team, complemented by an in-house design and production team ensuring delivery to the highest standards, we look to promote the latest in engaging news, industry trends and success stories from the length and breadth of the Asia Pacific region.

We reach an audience of 220,000 people across the continent, bridging the full range of industrial sectors: agriculture, construction, energy & utilities, finance, food & drink, healthcare, manufacturing, mining & resources, oil & gas, retail, shipping & logistics, technology and travel & tourism.

In joining the leading industry heavyweights already enjoying the exposure we can provide, you can benefit from FREE coverage across our digital platforms, a FREE marketing brochure, extensive social media saturation, enhanced B2B networking opportunities, and a readymade forum to attract new investment and to grow your business.

To get involved, please contact Outlook Publishing’s Managing Director, James Mitchell, who can provide further details on how to feature your company, for FREE, in one of our upcoming editions.

Since the beginning of civilisation, earth’s resources have been mined and subsequently used to make energy, manufacture, and create wealth and trade. Contract Mining has been a part of this in some form or another.

Fast forward to the 21st century, and the global mining industry is booming, as a multitude of elements and rare minerals are in high demand as a direct result of the introduction of new technologies, energy solutions, and goods that are required across

the world. Today, contract mining services play a major role in mine site development, the extraction of ore, and mine site rehabilitation – through to mine closure works.

Mining in Australia is a vast industry that remains famous worldwide due

BUMA Australia has a vision to build a modern mining and rehabilitation company, that drives growth, sustainability, and prosperity. We dig deeper into the company’s story with Chief Operating Officer, Russell Taylor and General Manager- Rehabilitation, Ngaire Tranter

Writer: Ed Budds | Project Manager: Eddie Clintonto its fascinating history, power in the export market, and its role as a trendsetter in ‘futureproofing’ the wider mining sector.

Furthermore, the high quantity of mining sites in the country means that the industry provides a sizable

prospective job market for Australian citizens, as well as for the number of foreign workers who want to work in the field due to its esteemed global standing.

The Australian mining industry has become more efficient at extracting

maximum product but in a more sustainable way. No longer is mine site rehabilitation an afterthought to mine development, it is planned for at the pre-feasibility stage of the mine life cycle. New technologies are being embraced in rehabilitating mined

Ngaire Tranter, General Manager: “People are our greatest strength at BUMA and remain central to our ongoing success. We provide meaningful career development opportunities for our employees so that they feel both challenged and fulfilled at work.

“We are a beliefs-driven organisation, and we believe that our commitment to our core values of safety, integrity, progress, collaboration, and people further facilitate the process of creating a positive work experience for all of our staff.”

areas and also in the monitoring and maintenance of the rehabilitated land.

The mining industry currently finds itself in a dynamic period of change, as the collective focus has turned to developing efficient mechanisms to manage environmental and social considerations, whilst maximising resource extraction.

Additionally, the industry as a whole is striving for an enhanced quality of rehabilitation as opposed to a focus simply on obtaining quantity.

BUMA Australia (BUMA) is well placed to provide this high-quality rehabilitation delivery and practices, which is demonstrated by the work it has conducted for clients in the past, and present and will continue to do so in the future.

“With the increase in prescriptive compliance in environmental licensing, we’re currently working closely with our clients in the implementation space to essentially operationalise planning documentation that is designed for

seeking environmental approvals and associated licensing,” introduces Ngaire Tranter, General ManagerRehabilitation of BUMA.

At present, approximately 1.2 million people are employed in the Australian mining industry, with the sector’s net worth of exported resources totalling an estimated AUD$160 billion.

Existing as a nation with an abundant supply of metals and materials, the country has naturally enjoyed a long and successful mining history, dating back to its first human habitation around 60,000 years ago.

The First Nations people initiated Australia’s first-ever mining operations, which included fossicking for stones suitable for weapons and tools and digging for ochre. This was then used for making pigments for the paint used in rock art and body painting, forming an integral part of their culture and distinctly unique heritage.

As seen throughout its past, Australia is home to a wealth of materials that the nation has mined and exported to help drive its economy. Historically, the top four mining resources have been:

IRON ORE – Australia has been exporting iron ore, its most significant source of export revenue, since the 1960s, first helping to support Japan’s post-war redevelopment.

COAL – Australia is the biggest coal exporter in the world. As well as being vitally important to the export market, coal helps fuel the country and is primarily used to produce around 80 percent of the nation’s electricity needs.

Australia’s biggest coal mine is Peak Downs, located in the Bowen Basin in Queensland.

GOLD – With a history of gold rushes and an abundance of gold resources, it is no surprise that Australia continues to be a prominent focus in the world’s growing demand for gold. In 2021 alone, the country’s gold exports totalled 257 tonnes. Its biggest gold mines are in Western Australia (WA), including the Boddington Gold Mine, and the Kalgoorlie Super Pit. As the country holds the title of the largest gold mine reserve in the world, there is no sign of Australia’s gold mine industry slowing down any time soon.

URANIUM – Australia is the world’s fourth largest producer of uranium, behind Canada, Namibia, and Kazakhstan, and holds 28 percent of the world’s known recoverable uranium resources. Due to the potential uses of the material, Australia exports it worldwide to countries that have agreed to use uranium for peaceful purposes only.

Later, upon the arrival of European settlers to Australia, the process of large-scale mining truly began. The first reported discovery of coal occurred in 1791 and was found by a family of escaped convicts, William and Mary Bryant, and their children.

This defining discovery was unearthed just three years after the arrival of the first fleet of settlers. The exact location of the find is unknown, but it is believed to have been located in Glenrock Lagoon in the Newcastle and Hunter regions of New South Wales (NSW).

Eight years later in 1799, coal was being exported with shipments that were sent regularly to India, thus initiating a long and prosperous history of exporting mined materials.

Lead mining began in 1841, which was shortly followed by copper in 1842. Both resources were regarded as monumental developments for the Australian economy, with the subsequent gold rush era in the 1850s catapulting the nation firmly onto the global map.

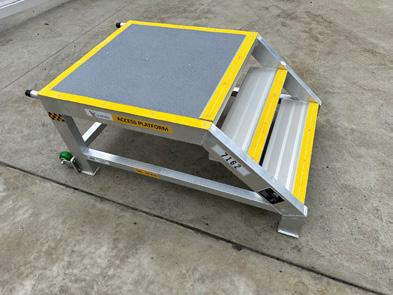

Over the past six years, Ostwald Steele Electrical Pty Ltd (OSE) has operated heavily across the East Coast of Australia as one of BUMA Australia’s key partners through delivering high-quality professional trade labour, developing safety improvement products, efficiency solutions, and being utilised as the leading electrical contractor on various infrastructure projects within its operations.

Having developed and continually growing a solid team of value-driven professionals, OSE covers much more than just mining equipment maintenance. The company is known for its ability to resolve complex issues through ‘Expanding Solutions’ paired with the belief that anything is possible.

OSE’s mission to provide elite maintenance trade services and industry solutions for mining, commercial, industrial, and residential operations and contractors is achieved alongside BUMA Australia and has played a huge part in the growth and diversification of OSE’s services offered to BUMA and the wider industry.

Having diversified teams specialising in their own unique fields - mining maintenance, electrical contracting, and product R&D, OSE’s team comprises multiple trades and industryrelated talent, i.e., electricians, HD fitters and mechanics, auto electricians, refrigeration mechanics, servicemen, and apprentices. Externally, OSE partners with quality and valuealigning companies as a strength in its product development and infrastructure fields.

Having a permanent workforce allows OSE to invest in its people and their careers, resulting in a team of professionally developed tradespeople who remain consistent in innovation, quality, and efficiency while greatly assisting with closing the trade shortage gap by cross-training and upskilling its workforce in overlapping trade and industry fields.

OSE prides itself on machine availability and increasing companies’ overall productivity.

What sets the company apart is knowing and understanding the value and importance attached to having a wellmaintained and readily available fleet of equipment operating at maximum capacity on a consistent basis. Having internal targets clearly communicated to both the team and clients, OSE delivers results from the ground up, maintaining a smooth mining and production operation for every client.

Specifically, the company has a professional focus on electrical technology and equipment advancements across various industries and a solution focus on upskilling its workforce to align with the evolving needs of its clients. OSE invests heavily in cross-training electrical and mechanical fields, offering dual trade apprenticeships to ensure its people are as technically skilled and knowledgeable as possible on heavy equipment electrical adaptation. OSE is known for providing extra value to its client’s maintenance operations and always maintaining a positive company culture.

With a deep understanding of defect management, machine

With a deep understanding of defect management, machine schedules, and thorough preventative maintenance, OSE reliably ensures the highest level of maintenance for every mining fleet. With continuous advancement and innovation, the OSE team operates with the utmost attention to detail to achieve fast diagnosis and repair of any and all breakdowns, ensuring minimal downtime and protecting operational yield. With values that include the promotion of integrity and transparency, solutions and success, risk management and a safe environment, and the professional development of the people who encompass OSE, the company is set to be the leading global resource for professional trade skills and industry solutions within the energy sector.

With silicosis currently playing a dominant role in mine workers’ health deterioration, professional bodies, including the QLD mines inspectorate and regulatory bodies, identified an area of high exposure to hazardous respirable substancesthe practice of cleaning fine dust from electrical components. After this discovery, OSE went searching for a solution to ensure the protection of its team and industry professionals.

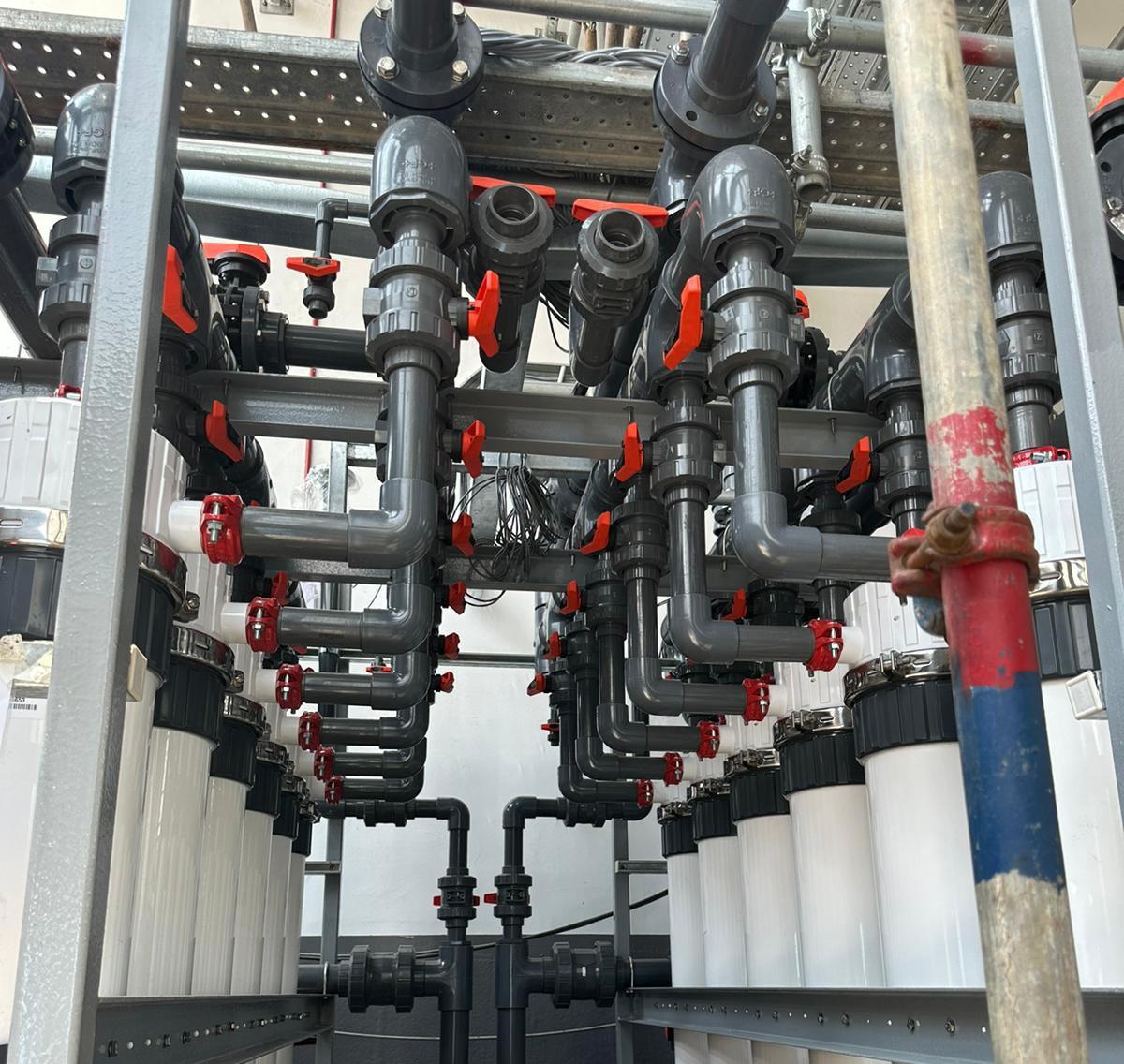

Co-developed with Australia’s leading air quality engineers Synergetics, the pLEV™ system (portable Local Exhaust Ventilation) is an air-operated cleaning system used to effectively clean electrical cabinets and components on electro-mechanical mobile plant and mining equipment. pLEV™ can be adapted to most mining air cleaning tasks where dust exposure is a concern, including:

• Electrical cabinets

• Switchboards

• Electric motors

• Alternators

• MG sets

• Drive motors

• Grids

The pLEV™ system works by creating negative pressurecontrolled environments in electrical cabinets. Dust is disturbed using the pLEV™ SmartLance and extracted safely and effectively using the pLEV™ Extractor.

pLEV™ Extractor is responsible for creating the negative pressure environment and the safe extraction of airborne dust. It has a dual-stage extraction fan that directs airflow through a HEPA-13-rated filtration system before then being released into the atmosphere as clean air. The portable extraction unit weighs under 14kg, is easy to work with and light to wear.

pLEV™ SmartLance HP (high pressure) enables the use of compressed air in the extraction environment. It features illumination, multivariable sensors for failsafe operation and optional cloud-based reporting. The SmartLance monitors particle exposure through air quality sensors with failsafe shutdown technology at the ready if an unlikely exposure event occurs. Negative pressure sensors are fitted to the SmartLances to prevent use outside the operational environment and to avoid accidental exposures.

pLEV™ SmartLance EX (exhaust) houses all the same safety and failsafe technology as the SmartLance HP but uses exhaust air directly from the Extractor to dislodge dust. Intended for use as a field unit, this air supply option allows for easier transportation due to the elimination of the need for compressed air.

pLEV™ Covers are lightweight, durable, and tailored to most common electrical cabinets and components. The covers are used to seal the cabinet to create a negative pressure extraction environment and minimising the risk of potential dust exposure. pLEV™ Covers are designed to give the operator a clear view of inside the cabinet so that they can see what they are cleaning.

The pLEV™ system improves the health and safety of all those who work daily in mining maintenance by preventing hazardous dust exposures that occur through traditional cleaning practices on electrical cabinets and components.

At its core, OSE is driven by the purpose of expanding solutions, dedicating itself daily to the growth of skills, safety, and technical expertise among its team. With a forwardlooking approach, OSE has evolved its services to align with the global shift towards cleaner living, emerging as a leader in comprehending, maintaining, and repairing electro-drive equipment and technology across various industry sectors.

The company’s commitment to sustainability is complemented by its investment in a permanent workforce.

This strategic choice not only fosters a team of consistently innovative and skilled tradespeople but also positions OSE at the cutting edge of technology. Through continuous research and development, OSE tackles challenges with a solution focused mindset, producing new technology and equipment that expands solutions and delivers optimal outcomes for clients.

The heart of OSE’s success lies in its unparalleled expertise in maintaining operational fleets and enhancing machine availability through defect management, machine schedules, and preventative maintenance, thus boosting overall

MINING AND INDUSTRIAL

• OSE offers a comprehensive range of services to industrial and mining companies, including electrical infrastructure projects and electrical contracting to specialised mining equipment maintenance contracts.

• With nearly a decade of experience in mining and remote electrical work, the company confidently offers everything from basic electrical installations to complex electrical repairs and system upgrades including renewable energy options and standalone power gen systems.

COMMERCIAL

• OSE is a trusted provider of commercial electrical services, offering quality electrical installations, repairs, and maintenance for businesses of all shapes and sizes.

• With experienced and certified electricians on staff, OSE provides comprehensive and reliable electrical solutions to meet any commercial need.

RESIDENTIAL

• With expertise in lighting, power, maintenance, and smart home systems, OSE offers comprehensive solutions tailored for homes, sheds, and outdoor areas.

• Whether it’s a new build, renovation, landscaping, or electrical upgrade, the team has the knowledge to bring any idea to life.

productivity for its clients. Internal targets, transparently communicated, serve as guiding lights, ensuring seamless mining and production operations. OSE’s unique focus on electrical technology advancements, workforce upskilling, and cross-training amplifies the company’s commitment to staying ahead in the ever-evolving landscape of technology and safety standards.

In response to the industry-wide challenge of silicosis and OSE’s commitment to protecting people, OSE collaborated with partners, including Synergetics, to pioneer the groundbreaking pLEV™ system. This portable Local Exhaust Ventilation system redefines safety standards, offering a meticulous solution for cleaning electrical cabinets and components, vastly minimising the risk of hazardous mining dust exposure from these tasks. Components like the pLEV™ Extractor, SmartLance HP, SmartLance EX, and Covers truly showcase OSE’s dedication to health and safety advancement.

OSE’s journey is marked by the cultivation of a team of value-driven professionals, a testament to its commitment to ‘Expanding Solutions’ and fostering a positive company culture. This ethos propels the company beyond the confines

of mere mining equipment maintenance, positioning it as a leader in resolving intricate challenges with an unwavering belief in the attainability of anything. OSE’s scope now spans mining, commercial, industrial, and residential sectors, made possible by a permanent workforce committed to unwavering innovation, quality, and efficiency.

BUMA’s vision is to build a modern mining and rehabilitation company, that drives growth, sustainability, and prosperity. The basis of this vision is the core values of safety, integrity, collaboration, people, and progress.

PEOPLE – BUMA’s greatest strength is its people, and the company recognises their history and values how they shape its future.

SAFETY – BUMA is dedicated to working safely and believes this is a mindset, a way of thinking, and a commitment to the well-being of its people, communities, and the environment.

INTEGRITY – The company is founded on good people doing good things. “We do what we say we are going to do” isn’t just a tagline for BUMA, as the company always deliver on its promises.

COLLABORATION – BUMA actively seeks collaboration with all stakeholders to find common solutions and positive outcomes.

PROGRESS – The company pursues growth and sees change as an essential part of its journey.

Gold was first discovered in NSW in 1823, and in the decades following, more and more influential finds were dug up across Australia.

The exciting news of the discovery of gold spread worldwide, and as people began emigrating to the country in huge numbers, population growth increased exponentially alongside fresh agricultural and industrial development. The transformations of the 1850s saw Australia producing approximately a staggering 40 percent of the world’s gold supply.

However, during the first half of the 20th century, the nation witnessed

a steady decline in mining activity, with new mineral finds becoming more and more scarce. Subsequently, during the second half of the century, Australia once again witnessed a resource boom, with discoveries including nickel, oil, natural gas, and uranium. These prominent discoveries prompted a resurrection of global interest in the country’s mineral resources.

With abundant resources, it is no surprise that mining is so prevalent throughout Australia.

Specifically, Western Australia (WA) is widely considered the epicentre of Australian mining and a major force in the industry worldwide. It is home to a vast number of natural resources and some of the country’s largest mines

WA currently plays host to 98 percent of Australia’s iron ore and 60 percent of the country’s gold reserves. These plentiful resources mean that at present, more than 20,000 people in WA work in the mining industry.

These are particularly exciting times for the Queensland mining sector, as growing demand has meant that explorations for new mines have begun in the north and east of the state, with the potential to create even more jobs in the future.

In the 2021/22 financial year, the Queensland mining industry contributed a record AUD$94.6 billion to the Australian economy.

Staggeringly, despite its large number of mines and impressive economic contribution, the industry only takes up 0.1 percent of the state’s surface area.

Victoria, meanwhile, continues to play a significant part in the country’s mining history. In 1851, gold was discovered in Ballarat, which triggered the gold rush that gripped the country and the wider world. It is still a key location for the production of gold, brown coal, mineral sands and antimony today, and is filled with great potential for future mineral exploration.

Mineral projects play an important role in regional development within Victoria, whilst mining creates lucrative employment for regional Australians and supports a broad supply chain of businesses.

The state is additionally home to the Fosterville Gold Mine, the largest gold mine in Victoria. Exploration also proceeds elsewhere, such as in Glen Wills, an isolated mountain area near Mitta Mitta in north-east Victoria.

Recently, a spotlight has been placed on the growing demand for

green energy alternatives and battery technologies. Therefore, mineral exploration is widely underway with a particular focus on vanadium and lithium.

BUMA was established in 2021, to acquire the Open Cut Mining Business of Downer. This acquisition included the transition of all people, mining services contracts, assets, systems, and IP from a business that successfully provided mining services in diverse locations across many commodities since 1922.

In only two years of operating as BUMA, 750 new employees have joined the business, the number of operations has increased by 57 percent, and the size of the business has doubled. BUMA has exploded onto the Australian market and further strategic growth is planned.

BUMA’s rapid growth has been based on the quality of services that it provides its clients and its strict adherence to the company’s core values. BUMA pursues a relationship-based long-term approach and willingness to work with clients to ensure the mutual success of all projects.

“Ensuring we provide value to our clients through all stages of mining, including rehabilitation, is a mainstay of our business,” Taylor informs us.

With a strong focus on delivering optimal outcomes for our clients and a strong commitment to safety, innovation, and technology BUMA Australia has quickly become one of Australia’s leading mining contractors.

BUMA is an established mining services provider currently operating several long-term contracts within Queensland. The company has been providing mining services for 75 years and has established, numerous longterm relationships within the industry.

“THE KEY TO OUR CONTINUED CONTRACT SUCCESS COMES FROM OUR FOCUS ON DELIVERING SERVICES TO MEET EVOLVING CLIENT NEEDS USING A FLEXIBLE AND ADAPTABLE APPROACH”

– RUSSELL TAYLOR, COO, BUMA AUSTRALIA

BUMA’s current contracts are diverse, tailored to suit client requirements, encompassing a range of services from full mine operation, pre-strip, coal mining, processing plant maintenance and operation, and statutory management, as well as incorporating activities from greenfield development to closure and rehabilitation services.

With a strong commitment to safety, systems and technology, BUMA pursues a relationship-based, long-term approach to ensure the mutual success of all its projects.

“The key to our continued contract success comes from our focus on delivering services to meet evolving client needs, using a flexible and adaptable approach,” Taylor remarks.

“Our strength lies in our people,

with an experienced and diverse workforce of over 1,500 individuals, who conduct new-to-industry training programmes.”

Further to this, BUMA’s operational capabilities and technical services include mine planning, dozer push, dragline operation, load and haul operations, wash plants, and drill and blast across seven different sites.

BUMA also provides full mining services, including statutory roles, at both the Broadmeadow East and Burton mines. In addition to the Bowen Basin, the company has also provided full mining services, which include statutory roles and coal delivery to power stations at the Meandu mine for the last 10 years, as well as the Commodore mine for over two decades.

Underpinning every facet of the business, BUMA has established a set of core values that are applied daily throughout the business, and with a well-established history of successfully completing rehabilitation and environmental projects, BUMA now offers a full suite of services from mine development through to closure, including progressive rehabilitation as the mine advances.

“We have key operational sites that are actively working under Progressive Rehabilitation and Closure Plan (PRCP), which provides us with first-hand knowledge of rehabilitation delivery requirements under this new regime.”

One of the operations that BUMA is most proud of is the Blackwater Mine, which is situated in the Central Highlands of Queensland, known for its mining heritage and substantial coal deposits.

Blackwater is one of BUMA’s most established and successful projects, showcasing efficient operational practices, along with a steadfast commitment to safety, community, and our team.

As such, BUMA has been conducting truck and excavator pre-strip operations at Blackwater since 2012. Each year, the company’s fleets mine over 44 million banked cubic meters of material. To facilitate the efficient movement of this material, BUMA operates and maintains a substantial equipment fleet, which includes a Hitachi EX8000 excavator, three Caterpillar 6060 excavators, and a Hitachi EX3600 excavator. These are further supported by 28 Komatsu 930E and CAT 789 haul trucks.

Led by Project Manager, Freya Perrins, Blackwater’s success is a testament to the collective strength and expertise of its diverse and

seasoned workforce. The Blackwater project’s established training department oversees the site’s newto-industry programmes such as the First Nations work readiness initiative that has been operating since 2016.

The purpose of the work readiness initiative is to provide an introduction to mining life and offer helpful advice on potential career pathways in the industry. The programme covers topics that employees will face on a day-to-day basis to help assist those who are new to the mining sector or even the BUMA workforce.

Overall, this has had great success in preparing new-to-industry operators to be successful in securing full-time positions in the company.

“Diversity is a valued part of BUMA’s

employment approach, and we are committed to fostering a diverse and inclusive workplace that facilitates opportunity and respect,” Perrins tells us.

“Our focus on cultural inclusiveness is active and ongoing, and we are continually working to build our organisational culture with a focus on enhancing workforce diversity,” he establishes.

BUMA’s relationship with the community is a significant component of its business and the company’s reputation as a valued corporate citizen and community-conscious organisation has been achieved by consistently working closely with its neighbours. Subsequently, BUMA is committed to continuously

implementing this across all its projects.

The future of the company will depend on its ability to maintain its social license to develop, operate, and close mines consistently alongside its stakeholders’ expectations.

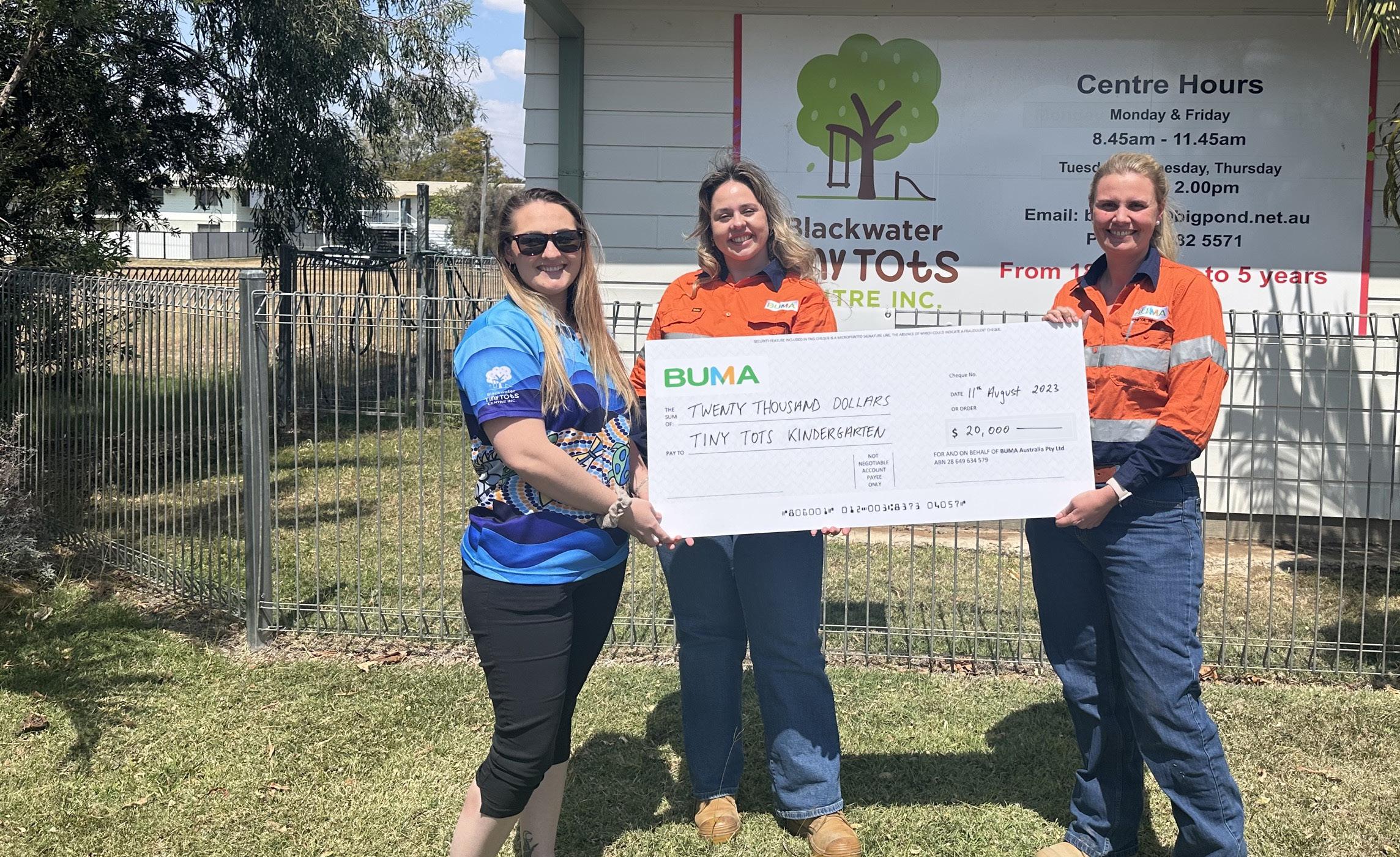

“At Blackwater, we highly value our community and continuously seek opportunities to assist both individuals and local businesses. This support extends to local goods and services procurement, as well as offering ongoing financial assistance to various local initiatives, including the Tiny Tots Kindergarten Centre, local youth football teams, and the Blackwater Police Citizens Youth Club (PCYC) Braking the Cycle (BTC) programme,” she adds.

A trusted, family-owned company for over 45 years, built on honesty, integrity, and safety. Led by Gayle Coldwell and her son Brendan, our experienced team operates in Australia and the Asia Pacific region, delivering top-quality drilling services tailored to your needs. Safety, expertise, and commitment are our priorities.

Conclusively, the Blackwater Mine has consistently maintained a high level of operational efficiency and a strong commitment to safety standards. This achievement has been made possible through BUMA’s people, technology, and thorough safety measures.

It has become a significant focus for BUMA to carry on delivering exceptional service in collaboration with its clients, BUMA recognises that there has been a significant investment into technical resources to develop rehabilitation and closure

To achieve the company’s vision, BUMA’s senior leadership and management:

• Take accountability for the effectiveness of quality management.

• Guarantee that all quality objectives have been set and are maintained adjacent to internal auditing and monitoring in order to enhance customer satisfaction.

• Promote the use of a process approach and risk-based thinking.

• Engage, direct, and support people to contribute to the effectiveness of the quality management system, encourage improvement and professionalism, and motivate employees

This list of policies is communicated to all employees, subcontractors, and organisations working for BUMA.

plans across the Australian mining industry. As such, the delivery of works in accordance with these requirements is paramount.

“We aim for long-term stable and sustainable landforms, with our focus firmly set upon efficiency in earth movements right from bulk earthworks through to the ongoing management and maintenance of completed areas,” Taylor comments.

“This, supported by our quality control and evidence-based monitoring processes, ensures that we support our clients in equally meeting their scheduled physical delivery and statutory reporting outcomes,” he furthers.

Today, rehabilitation activities at Stanwell’s Meandu Mine commence as soon as areas become available,

with over 930 hectares (ha) of native vegetation rehabilitation already completed across the site.

This year, the Meandu site is aiming to achieve an additional 41.5 ha of native vegetation rehabilitation. Significant work has already occurred, with the land profiled, topsoiled, and seeded earlier this year. Previously, during 2022, BUMA successfully completed 28.7 ha of native vegetation rehabilitation across the Meandu Mine.

“Our native vegetation rehabilitation areas, designed to meet the final post-mining landform, exemplify our commitment to safety, stability, sustainability, and adherence to environmental regulations,” Tranter shares.

“To ensure the project’s success, we thoroughly follow government

“OUR STRENGTH LIES IN OUR PEOPLE, WITH AN EXPERIENCED AND DIVERSE WORKFORCE OF OVER 1,500 INDIVIDUALS”

– RUSSELL TAYLOR, COO, BUMA AUSTRALIA

regulations, incorporating specific design elements such as gradients, cover materials, and drainage systems.”

Similarly, BUMA also designed and constructed a network of rock-lined drains, utilising basalt rock sourced from the mine, to manage the overland flow and mitigate the risk of erosion.

“We place topsoil across the entire rehabilitation surface, drawing from on-site topsoil stockpiles that are assessed for quality, ensuring optimal performance for native vegetation

rehabilitation. To reduce the compaction of the cover material, we employ a single-pass method, which included the processes of fertilisation, ripping, and seeding,” he continues.

BUMA is committed to restoring the environment to its natural state, a promise that extends to its choice of seeds. Over 600 kilograms (kg) of seeds, comprising a diverse mix of species of trees, shrubs and grasses mirroring the local regional ecosystem, are spread across the rehabilitation site.