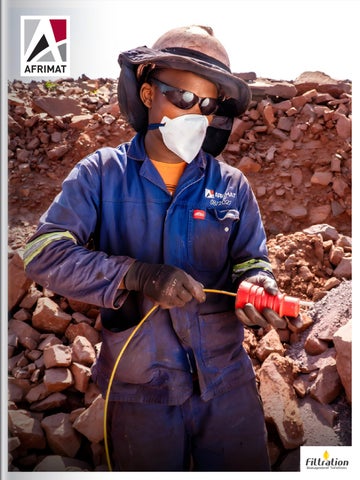

In a rapidly evolving mining landscape, Afrimat Mining Services (Pty) Ltd stands out with its comprehensive pit-to-port solutions, driven by operational efficiency and sustainability. Executive Director, Michael Corbin, discusses its integrated approach, innovative drilling practices, and adaptability across diverse operations

Writer: Rachel Carr | Project Manager: Thomas Arnold

Contributing to the advancement of the mining industry in South Africa (SA), Afrimat Mining Services (Pty) Ltd (AMS), formerly known as Afrimat Contracting International, is a dynamic division of the Afrimat Group (Afrimat) – a leading mid-tier, multi-commodity mining company listed on the Johannesburg Stock Exchange (JSE).

Since its listing in 2006, the group has steadily expanded its footprint across Southern Africa, producing and supplying a range of materials including construction aggregates, iron ore, anthracite, and other

industrial minerals.

AMS was established during the rollout of the Gauteng Freeway Improvement Project, where it initially provided drilling, blasting, and mobile crushing services to major contractors. Since then, the business has evolved significantly as part of Afrimat’s broader strategy to diversify its service offering and expand its value chain.

Today, AMS delivers comprehensive pit-to-port mining solutions across the mining, construction, and quarrying sectors. Its integrated services include mine planning,

drilling and blasting, load and haul operations, crushing and screening, product beneficiation, rehabilitation, and rail load-out management and logistics.

With a strong presence throughout Southern Africa and a growing fleet of modern, fit-for-purpose equipment, AMS continues to play a crucial role in Afrimat’s culture of operational excellence and sustainable growth.

“Our division is powered by a team of highly skilled and dedicated professionals. We are committed to consistently delivering top results and achieving excellence with unwavering

integrity,” introduces Michael Corbin, Executive Director.

“This dedication is deeply rooted in the group’s vision to unlock maximum value across the entire resources sector, ensuring that every endeavour is executed with the highest standards of expertise and ethical conduct,” he adds.

AMS’s strength lies in the seamless integration of its core business segments – mine planning, drilling and blasting, load and haul, crushing and screening, beneficiation, rehabilitation, and rail load-out logistics.

“Each element plays a vital role in the mining and construction value chain, working together to create a streamlined, pit-to-port solution. This integrated model allows for greater control, efficiency, and adaptability across projects, ultimately driving performance and cost-effectiveness,” outlines Corbin.

Of all AMS’s services, drilling and blasting remains one of the most critical. As the first stage of material extraction, its optimisation has a direct impact on the efficiency of downstream processes, which leads

to cost savings for clients.

“By improving blast accuracy and drill performance, we can reduce explosive use, lower material handling costs, and produce enhanced fragmentation, resulting in lower crushing costs and more consistent product quality.”

Current initiatives in this segment include investing in advanced drill technologies, data-driven decisionmaking, and continuous operator training. These efforts are designed to improve precision, safety, and cost control, reinforcing AMS’s position as a leader in efficient mining practices.

Furthermore, owning its fleet of state-of-the-art top hammer and down-the-hole (DTH) drill rigs plays an essential role in enhancing the division’s on-site efficiency and adaptability.

“By having immediate access to equipment, we avoid the delays typically associated with thirdparty rentals, allowing our teams to respond swiftly to changing ground conditions, shifting production targets, or unexpected breakdowns,” Corbin explains.

“It also enables us to tailor rigs to specific geological and operational site requirements. This level of customisation improves drilling accuracy and enhances blasting control – key drivers of overall project performance.”

Beyond operational flexibility,

fleet ownership supports longterm cost control and planning, providing greater predictability in terms of maintenance, upgrades, and replacements – turning the fleet into a strategic asset rather than just a functional tool.

“Ultimately, it gives us greater agility and control – essential qualities in today’s fast-paced mining environment,” notes Corbin.

As it focuses on supporting Afrimat’s internal quarrying and mining operations, AMS is delivering economical, high-performance drilling and blasting services that maintain the group’s competitive edge through precise cost control and operational efficiency.

“When done accurately, ours remains the most costeffective method of rock and ore fragmentation – setting the stage for successful downstream processes,” Corbin assures.

“Whilst internal support remains a cornerstone of our strategy, our growth trajectory increasingly relies on external opportunities. Building strong partnerships and extending our services beyond Afrimat is a key area for our leadership team.”

As AMS navigates this evolving landscape, it is committed to leveraging both its capabilities and partnerships to drive meaningful progress.

“Currently, several key projects in SA reflect our internal strengths and external growth ambitions. Notably, the De Groote Boom chrome mine in

Mpumalanga marks a significant step in our market expansion.

“We recently signed a two-year contract to manage all drilling and blasting operations at this site, which poses unique geological challenges that require technical accuracy and adaptability,” he reveals.

AMS is managing the mine’s complex geology whilst achieving

“OUR DIVISION IS POWERED BY A TEAM OF HIGHLY SKILLED AND DEDICATED PROFESSIONALS. WE ARE COMMITTED TO CONSISTENTLY DELIVERING TOP RESULTS AND ACHIEVING EXCELLENCE WITH UNWAVERING INTEGRITY”

–

MICHAEL CORBIN, EXECUTIVE DIRECTOR, AFRIMAT MINING SERVICES (PTY) LTD

monthly targets of 100,000 to 130,000 cubic metres (cbm) for both waste and chrome ore, demonstrating consistent results.

“Meanwhile, at the Nkomati Anthracite Mine, AMS operates four DTH drill rigs 24 hours a day, six days a week, drilling down to the coal seam and blasting overburden waste to optimise load and haul operations,”

Corbin continues.

This project achieves approximately 600,000 cbm monthly, totalling over 7.2 million cbm annually, showcasing the division’s capacity for continuous, high-efficiency operations in demanding environments.

“In the Northern Cape, AMS is active at four iron ore sites, managing both drilling and blasting for waste and ore.

In an industry where conditions shift rapidly and client demands evolve without warning, adaptability isn’t a luxury – it’s a necessity.

AMS has embraced this reality by cultivating strong, long-term relationships with a network of reliable subcontractors who enhance its ability to respond swiftly and effectively.

“Through strategic partnerships with specialists in crushing, load and haul, and drilling, we’ve built a flexible operational model that ensures continuity and performance, even under tight timelines. These subcontractors are not just service providers, they’re extensions of our team, carefully selected for their technical capabilities, safety track records, and alignment with our values,” Corbin enthuses.

“We often tender for projects in collaboration with our subcontractors, a model that has proven highly effective. By blending our core capabilities with the specialised skills and equipment of our partners, we’re able to offer clients smart, scalable solutions, without the heavy capital expenditure (CapEx) burden.”

This exemplifies AMS’s strategic alignment of practicality and innovation, effectively integrating both concepts to develop organisational effectiveness and cultivate creative solutions.

These sites collectively deliver around 500,000 cbm per month and exceed six million cbm per year, reinforcing our reliability in long-term contracts,” Corbin prides.

These projects not only highlight AMS’s technical capabilities but also underscore its dual focus on delivering value within Afrimat whilst expanding the group’s external market footprint.

Every site plays a role in promoting cost efficiency, operational excellence, and building long-term partnerships in the mining industry.

For Afrimat, its most important ongoing investment is in the development and well-being of employees.

“We’re dedicated to cultivating both technical and managerial talent, recognising that strong leaders at every level are essential for the group’s sustainable growth,” Corbin impassions.

“By consistently upskilling our teams, from specialised mechanical expertise to robust leadership capabilities, we’re building a workforce fully equipped to meet future demands and drive our success.”

In addition, AMS provides operational support to junior miners in the form of mine planning, production, and marketing where required.

Elsewhere, Afrimat’s recent acquisition of Lafarge South Africa Holdings (Pty) Ltd from the Holcim Group has significantly impacted its operations and growth strategy.

The acquisition has been transformative in accelerating Afrimat’s diversification into cement and fly-ash, strengthening the construction materials division, unlocking scale and market reach, and delivering upfront synergies with a clear roadmap to profitability across all assets.

•

• Oil Cleanliness improved f rom ISO 4406 23/22/19 to 15/13/10 in just seven days—well below industry targets. Chromium particles were fully removed.

severe threat to gearbox performance. These abrasive particles accelerate wear on gears, bearings, and seals, leading to unexpected failures, costly repairs, and production delays. With gearboxes valued at over ZAR480,000 and delivery times stretching to 52 weeks, downtime is not an option.

To tackle this challenge, Filtration Management Solutions (FMS), in partnership with DesCase, deployed an advanced Offline Filtration System (OLUHS1A). Equipped with a heater, Oil Quality Sensor (OQS), Contamination Monitoring Sensor (CMS), and glass fiber filter elements, the system was installed on two critical gearboxes at a South Af rican sinter plant. Additional components included desiccant breathers, a 3D Bullseye®, and breather adapter kits-all designed to eliminate moisture, detect contamination, and support visual oil analysis.

• Iron wear reduced by 2.5x, extending gearbox life and reliability.

Massive Return on Investment:

•Annual cost savings: ZAR160,000 per gearbox

•Total system cost: ZAR460,000 (for two gearboxes)

• Payback period: Only 17 months

•Internal Rate of Return (IRR): Over 200%

•5-year Net Present Value (NPV): R620,000

The OLUHS system continuously filters and monitors oil, maintaining optimal cleanliness whilst excluding contaminants. This significantly reduces f riction, minimises maintenance downtime, and extends the service life of gearbox components.

Protect your critical assets, improve safety, and boost production quality.

Partner with FMS and Des-Case for a proven filtration solution that delivers measurable ROI.

This strategic move is particularly significant as AMS’s primary focus is currently on Sub-Saharan Africa, where it recognises considerable potential within the continent’s vast, underutilised mineral resources and developing mining sectors.

“Many African nations lack in-house expertise or capital, creating a demand for experienced contract miners like us,” enlightens Corbin.

Indeed, strategic growth and diversification necessitate strategic partnerships with local entities, which can provide invaluable local knowledge and shared risks. Afrimat’s proven ability to acquire and revitalise distressed assets could be applied to international mining operations.

“Despite significant opportunities, there are also challenges, including international expansion which involves geopolitical risk, logistical complexities, intense competition, stringent environmental, social, and governance (ESG) compliance, and substantial capital requirements,” he points out.

“WHILST INTERNAL SUPPORT REMAINS A CORNERSTONE OF OUR STRATEGY, OUR GROWTH TRAJECTORY INCREASINGLY RELIES ON EXTERNAL OPPORTUNITIES. BUILDING STRONG PARTNERSHIPS AND EXTENDING OUR SERVICES BEYOND AFRIMAT IS A KEY AREA FOR OUR LEADERSHIP TEAM”

– MICHAEL CORBIN, EXECUTIVE DIRECTOR, AFRIMAT MINING SERVICES (PTY) LTD

However, AMS’s two key priorities for the coming year are the seamless integration of the group’s latest acquisitions and the continued upskilling of its workforce.

These efforts are critical in positioning Afrimat for sustainable expansion, with a particular focus on scaling the contracting division in 2026.

“By strengthening internal capabilities and building a skilled, agile team, AMS is laying the foundation for long-term growth and competitiveness in the mining services sector,” concludes Corbin confidently.

Tel: +27 21 917 8840

info@afrimat.co.za https://www.afrimat.co.za/

Our Core Services Include: 49 Years of Trusted Rail Solutions

For nearly five decades, Rail & Siding has proudly delivered top-quality maintenance services across rail sidings, mainlines, and the construction of new railway lines and related civil works. Our commitment is simple: deliver the highest standard of work efficiently and right the first time.

Built on a foundation of integrity, trust, honesty, and humility, our business continues to grow under the unwavering guidance of our Heavenly Father.

Rail & Siding – 49 Years of Trusted Rail Solutions

• Rail Siding Maintenance

• Construction and Planning

• Track Installation in Concrete

• Rail Welding and Refurbishment

• Rail Track Reinstatement

• Rail Siding Inspections and Condition Assessments

• Ultrasonic Rail Testing

For nearly five decades, Rail & Siding has proudly delivered top-quality maintenance services across rail sidings, mainlines, and the construction of new railway lines and related civil works. Our commitment is simple: deliver the highest standard of work, efficiently and right the first time.

• Track Geometry Measurement

• Mechanical Screening and Tamping Projects

Built on a foundation of integrity, trust, honesty, and humility, our business continues to grow under the unwavering guidance of our Heavenly Father.

Our Core Services Include:

At Rail & Siding, we don’t just offer a service — we forge reliable, long-term partnerships based on trust and performance. We are proud to be part of the Afrimat Group, continuing our legacy of excellence in the rail industry.

• Rail Siding Maintenance, Construction & Planning

Tel: +27 21 917 8840

info@afrimat.co.za https://www.afrimat.co.za/