p. 7 Editor’s Foreword

Leveraging AI in standards p. 18 Open Standards

VITA 95/96 for fiber optics

p. 7 Editor’s Foreword

Leveraging AI in standards p. 18 Open Standards

VITA 95/96 for fiber optics

Pg Advertiser

13 AirBorn – Precision power –because every second counts.

1 Amphenol Corporation –Everything modular, everything scalable, everything Open.Tech. Build it at www.open.tech

1 Annapolis Micro Systems –High density SOSA aligned switches improve performance, reduce SWaP-C

3 Behlman Electronics, Inc. –When it comes to VPX, one company has the most flavors

32 Behlman Electronics, Inc. –Behlman leads the pack again!

17 Elma Electronic – Leaders in modular open standards enabling the modern warfighter

12 LCR Embedded Systems, Inc. –Mission possible

5 Samtec – Interconnect solutions

6 Vector Electronic – 19” vertical board mount VPX/VME/cPCI: Integrated systems, available in full range of RAL colors

Embedded Systems, Inc.

Interconnect

MOSA Industry and Government Summit & Expo August 27-29, 2025 National Harbor, MD https://events.techconnect.org/ MOSA_2025/

DSEI London September 9-12, 2025 London, U.K. https://www.dsei.co.uk/

VITA EDITORIAL DIRECTOR Jerry Gipper jerry.gipper@opensysmedia.com

GROUP EDITORIAL DIRECTOR John McHale john.mchale@opensysmedia.com

ASSISTANT MANAGING EDITOR Lisa Daigle lisa.daigle@opensysmedia.com

TECHNOLOGY EDITOR – WASHINGTON BUREAU Dan Taylor dan.taylor@opensysmedia.com

CREATIVE DIRECTOR Stephanie Sweet stephanie.sweet@opensysmedia.com

WEB DEVELOPER Paul Nelson paul.nelson@opensysmedia.com

EMAIL MARKETING SPECIALIST Drew Kaufman drew.kaufman@opensysmedia.com

WEBCAST MANAGER Marvin Augustyn marvin.augustyn@opensysmedia.com

DIRECTOR OF SALES Tom Varcie tom.varcie@opensysmedia.com (734) 748-9660

STRATEGIC ACCOUNT MANAGER Rebecca Barker rebecca.barker@opensysmedia.com (281) 724-8021

STRATEGIC ACCOUNT MANAGER Bill Barron bill.barron@opensysmedia.com (516) 376-9838

STRATEGIC ACCOUNT MANAGER Bill Baumann bill.baumann@opensysmedia.com (609) 610-5400

SOUTHERN CAL REGIONAL SALES MANAGER Len Pettek len.pettek@opensysmedia.com (805) 231-9582

DIRECTOR OF SALES ENABLEMENT Barbara Quinlan barbara.quinlan@opensysmedia.com AND PRODUCT MARKETING (480) 236-8818

INSIDE SALES Amy Russell amy.russell@opensysmedia.com

STRATEGIC ACCOUNT MANAGER Lesley Harmoning lesley.harmoning@opensysmedia.com

EUROPEAN ACCOUNT MANAGER Jill Thibert jill.thibert@opensysmedia.com

TAIWAN SALES ACCOUNT MANAGER Patty Wu patty.wu@opensysmedia.com

CHINA SALES ACCOUNT MANAGER Judy Wang judywang2000@vip.126.com

www.opensysmedia.com

PRESIDENT Patrick Hopper patrick.hopper@opensysmedia.com

EXECUTIVE VICE PRESIDENT John McHale john.mchale@opensysmedia.com

EXECUTIVE VICE PRESIDENT AND ECD BRAND DIRECTOR Rich Nass rich.nass@opensysmedia.com

DIRECTOR OF OPERATIONS AND CUSTOMER SUCCESS Gina Peter gina.peter@opensysmedia.com

GRAPHIC DESIGNER Kaitlyn Bellerson kaitlyn.bellerson@opensysmedia.com

FINANCIAL ASSISTANT Emily Verhoeks emily.verhoeks@opensysmedia.com

SUBSCRIPTION MANAGER subscriptions@opensysmedia.com

Tel: (480) 967-5581

®

Most manufacturers offer just a few VPX power supplies off the shelf, with high costs for full-custom. The Behlman the most COTS AC to DC and DC to DC units configured for a wide range of high-end industrial and military applications. All feature our state-of-the-art new engineering standard, Xtra-reliable design and Xtra-rugged construction.

Insist on the leader. Not just VPX,

Air-flow-through (AFT) technology: development of a new heatsink generation By Gwenc’hlan

Next-gen fiber optics for aviation: Expanded Beam performance with VITA 95/96

By Thomas Mittermeier,

ODU-USA

Embedded Tech Trends 2025 Wrapup By Jerry Gipper, VITA Editorial Director

(AFT)

Gwenc’hlan Tymen, Interface Concept

standards for aviation

Next-gen fiber optics for aviation: Expanded Beam performance with VITA 95/96

By Thomas Mittermeier, ODU-USA

standards activity updates

The 2025 VITA Technologies Resource Guide features technologies and products based on VITA standards, including OpenVPX and QMC. Also in the Guide: an Embedded Tech Trends 2025 wrapup, VITA standards activity updates, and technology articles focused on the application of VITA standards.

VITA™ 74 VNX™ to 90 VNX+™ Solutions

VITA™ 90 (VNX+™) is a SFF standard that is a direct descendant of VITA™ 74.

VNX™ architectures bring the essential tenants of VITA™ 65 (OpenVPX™) to SFF applications.

VITA™ 42 XMC ™

VITA™ 90 standard-based products serve markets that require rugged performance, as well as data plane interconnect technologies that closely follow the industry’s state-of-the-art.

• Small Form Factor (SFF) switched serial interconnects

• Open-frame backplane design

Features

• 5-inch tube architectures

• 110 GHz RF connectivity via size 16 and size 20 contacts

• Configured with Samtec SEARAY™ Right-Angle Array and FireFly™ Optics

• Rugged fiber optic connectivity via MT ferrules

• COTS solutions for cost optimization and fast time to market

SamArray® High-Density Open Pin Field Arrays

VITA™ 42 XMC™ is a widely deployed mezzanine standard used in high-reliability computers implementing switched-fabric architectures. VITA™ 42 XMC™ specifies solder ball-equipped SamArray® connectors in 10 mm and 12 mm stack heights supporting PCIe® 4.0 performance.

VITA™ 88 XMC+™

SEARAY™ High-Density Open Pin Field Arrays

VITA™ 88 XMC+™ defines an alternative connector backwards compatible with VITA™ 42 electrical footprints. This allows designers to improve existing VITA™ 42 and/or VITA™ 61 designs by swapping connectors. The result is superior Signal Integrity (PCIe® 5.0 and 100 GbE operation) and improved mechanical performance and durability.

VITA™ 42, VITA™ 57.1/57.4

Micro Jack Screw Precision Board Stacking Standoffs

Optional standoffs reduce risk of damage when unmating mezzanine cards. Designated for PCI/104-Express®, VITA™ 42, 57.1 and 57.4 systems for use with SamArray® and SEARAY™ connectors.

VITA™ 57.1 FMC™ & 57.4 FMC+™ Connectors

FMC™ / FMC™+ Standards are essential for FPGA vendors making baseboards and comprehensive development kits to enable Designers to accelerate their VPX™ application development.

VITA™ 66 Optics

Extended Temp FireFly™ Optical Micro Flyover System™ offers multiple connector options including MT38999, MT, MTP® and MXC®

VITA™ 93 QMC™

The VITA™ 93 Standard relies on the high-speed capabilities and the slim, dense design of Samtec’s AcceleRate® HD Ultra-Dense, Slim Body Arrays. The 80-pin (4 x 20) QMC™ Connectors are available in 9 mm, 11 mm, 14 mm, and 16 mm stack heights.

By Jerry Gipper

Artificial intelligence (AI) is increasingly prevalent in today’s news, with new applications leveraging AI emerging daily. The intelligence gained by mining large data sets is becoming more relevant with each release of AI models. Many individuals find it challenging to understand how to use AI to benefit their professional and personal lives.

VITA staff has been discussing the impact of AI on standards development for several years. On one hand, AI-enabled tools are becoming pervasive and anticipated to improve, only getting better with each passing release, necessitating their use to remain competitive. On the other hand, there is long-term concern in the standards community regarding the viability of patentable content created through the use of AI tools. VITA continues to monitor the legal impact of AI, which is being studied extensively by legal communities.

In the current realm of standards development, several VITA working groups have started to utilize commercially available AI tools to enhance document creation and improve the content. Most notably, working groups are using AI to:

› Automate repetitive tasks: AI can automate repetitive tasks such as formatting, proofreading, and checking for consistency in documents. This can save time and reduce errors. Working group editors are employing AI tools such as Microsoft’s Copilot or variations of ChatGPT to rewrite brief text pieces in much more concise terms. These AI tools excel in grammar and generate clear text for rules, recommendations, permissions, suggestions, and observations that are used in VITA standards.

› Facilitate collaboration: AI can facilitate collaboration by providing tools for real-time editing, feedback, and communication among team members. This can help streamline the process of developing standards and ensure that all stakeholders are involved. Meetings now use Zoom AI Companion to take meeting notes.

› Analyze large data sets: AI can analyze large data sets to identify trends, patterns, and insights that can inform the development of standards. This process can help ensure that standards are based on the latest and most relevant information. In the future, suites of documents will be analyzed to address conflicts, create design guidelines, and develop training materials.

Some working groups are using AI to assist in generating mechanical drawings. AI tools provide information based on extensive data that may be beyond the reach of working group subject-matter experts. Often these tools present ideas that can be further discussed and analyzed by human subject-matter experts.

VITA working group editors and participants are in the early stages of using AI tools, each with differing degrees of tool knowledge, and may use them more comprehensively in the future to analyze entire documents for issues that must be addressed to create optimal documents. VITA plans to continue exploring AI tools to help create better documents and tools for designers of critical embedded computing systems.

We have yet to witness the day when AI tools assume full control over the development of new standards, as some may fear. The definition of new open standards still involves considerable discussion and collaboration. However, the utilization of AI tools to enhance and expedite this process is likely to be welcomed. The complexity of future architectures being developed and defined necessitates such advancements. AI can predict future trends and developments in the computer industry, helping to create standards that are forward-looking and adaptable to future changes.

By Jerry Gipper, Editorial Director

Note: This update is based on the results of the May 2025 VITA Standards Organization (VSO) meeting, held in Frederick, Maryland, and hosted by Leonardo DRS. Contact VITA if you are interested in participating in any of these working groups. The full reports can be accessed at www.vita.com/StandardsUpdates. Visit the VITA website (http://www.vita.com) for details on upcoming VITA meetings

Accredited as an American National Standards Institute (ANSI) developer, VITA provides its members with the ability to develop and promote open technology standards.

The following standards have recently been ANSI and VITA approved via public VITA consensus ballot:

› ANSI/VITA 46.31-2025, Higher Data Rate

VPX – Solder Tail in Blind via

› ANSI/VITA 47.1-2025, Common Requirements for Environments, Design and Construction, Safety, and Quality Standard

› IEEE Std 2818-2024/VITA 51.4-2024, Reliability Component Stress Analysis and Derating

› ANSI/VITA 68.0-2025, VPX Compliance Channel Standard

› ANSI/VITA 68.1-2025, VPX Compliance Channel – Fixed Signal Integrity Budget Standard

› ANSI/VITA 86-2025, High Voltage Input

Sealed Connector Power Supply

All published standards are available for download by VITA members and are posted at the online VITA Store for purchase by nonmembers.

Standards within VITA may be initiated through the formation of a study group and developed by a working group. A study group requires the sponsorship of one VITA member, while a working group requires sponsorship of at least three VITA members.

Several working groups have current projects underway. Here’s a roundup of these projects:

VITA 47.2 and .3: Class 2 Requirements for Environments, Design and Construction, Safety, and Quality for VITA 47 Plug-In

Modules Dot Standard

Abstract : The VITA 47 group of standards defines environmental, design and construction, safety,

and quality requirements for commercial off-theshelf (COTS) plug-in modules intended for ground and aerospace applications. This revision enables a broader use of these standards across the COTS supplier market with added flexibility in environmental class options. It also corrects typographical errors, adds additional requirements for conformance to improve interoperability and maintainability, and enables rugged design for tactical applications.

Status : Multiple additions and changes are being made to improve the usability of this standard. The revision drafts are in review.

Abstract: This standard establishes the design requirements for an air-flow-through (AFT) cooled plug-in unit. Unlike ANSI/VITA 48.1, which uses cooling air impinged directly upon the components and circuit boards, this plug-in unit uses a compact core heat exchanger located within the central heat sink of the unit and uses a mil-/aero-qualified seal on the inlet and outlet of the heat exchanger, eliminating any direct air contact with the PWB and components. This seal also provides the ability for chassis-level flow balancing, allowing plug-in units with different cooling requirements in the same chassis. This standard defines both a 3U and 6U form factor in various pitches and air inlet sizes, providing a high-performance thermal solution for existing or new CCA [conduction-cooled assembly] designs.

Status: This standard is open for revisions to more clearly define some of the rules and recommendations. Verification method notation being added.

Abstract: This standard defines an air-flow-through module format, 3U and 6U, that uses retractable module rack seals to improve module-chassis seal durability, simplifies the design by eliminating tapered module and chassis features, and allows easy migration of existing CCA designs to an air-cooled module format.

Status: Working group is developing a draft document.

Abstract: The OpenVPX standard uses plug-in module mechanical, connectors, thermal, communications protocols, utility, and power definitions provided by specific VITA standards to define a series of slot, backplane, module, and standard development chassis profiles.

Status: This document is in public ballot for release.

VPX,

Abstract: The VITA 67.3 standard defines an open standard for configuration and interconnect (within the structure of VITA 67.0) enabling an interface compatible with VITA 46 containing multiposition blind-mate analog connectors with coaxial contacts, having fixed contacts on the plug-in module and spring action on the backplane.

Status: Now open for modifications to SMPS interface.

Abstract: This document describes an open standard for creating high-performance fault-tolerant interoperable backplanes and modules to assemble electronic systems for spacecraft and other high-availability applications. Such systems support a wide variety of use cases across the aerospace community. This standard leverages the OpenVPX standards family and the commercial infrastructure that supports these standards.

Status: The standard is open for revisions to the 2022 edition.

VITA 89: MT Circular Connectors – Type 2

Abstract: The VITA 89 MT circular connector standard defines a standard for circular connectors with optical MT. Circular connector shells are compliant to MIL-STD-38999. MT offers options for up to 48 fibers per MT and for physical contact or lensed MT.

Status: VITA working group to develop a new standard for circular connectors with optical MT. Working group is developing draft document.

Abstract: The VITA 90.x (VNX+) family of standards builds on the foundation established by VITA 74 VNX. VNX+ significantly increases performance and system versatility beyond VITA 74, while following its mechanical framework.

Status: VITA 90.0 is in public review for release. Working groups are developing drafts for each level of VNX+.

VITA

Abstract: This standard defines a system definition that provides higher pin density to the backplane for VPX applications.

Status: VITA working group to develop a new standard for higher pin density for VPX.

Abstract: This standard defines a rugged standardized 10 Gbaud interconnect system with a high pin count and high-density, lightweight, rectangular connector (meets MIL-DTL-24308 physical envelope) for I/O. It can support multiple high- bandwidth protocols and power while optimizing SWaP [size, weight, and power] benefits in smaller systems with limited panel space availability.

Status: The working group is reviewing a draft document.

Abstract: This standard defines a Small Form Factor mezzanine (SFFm) that is significantly smaller than XMC with host and I/O interface connectors. The host interface supports modern high-speed serial fabrics. The I/O interface supports either front-panel or backplane I/O. Multiple SFFm modules can be installed on various carrier-card form factors including 3U/6U Eurocards (VPX, cPCI, VME, etc.), VNX+, PCIe expansion cards, and others. It is suitable for deployment in commercial, industrial, space, or military-grade rugged environments with air-cooled or conduction-cooled formats.

Status: VITA 93.0 is open for public review ballot to release.

Abstract: This standard provides requirements for building a power distribution plug-in module with digital controls that can be used in a VPX chassis. The plug-in module will fit within the standards envelope defined for VPX modules in the VITA 48.x standards.

Status: Working group is developing a draft document.

Abstract: This document defines a standard for circular connectors with Expanded Beam Optical (EBO) ferrules. Circular connector shells are compliant to MIL-STD-38999 Series III. EBO ferrules are available in multimode or single mode.

Status: Working group is developing a draft document.

Abstract: This document defines a standard for Backplane Connectors with Expanded Beam Optical (EBO) ferrules. EBO ferrules are available in multimode and singlemode.

Status: Working group is developing a draft document.

Abstract: The VITA 100 suite of standards is an evolution to OpenVPX, VPX, and related mechanical standards while embracing a paradigm shift in technology and capability with at least double the pin density, speed, and power for electrical contacts.

Status: Working group is developing draft documents.

For a complete list of VITA standards available for purchase and their status, go to https://www.vita.com/Standards.

By Jerry Gipper, Editorial Director

Embedded Tech Trends is an extremely effective forum where suppliers of components, boards, and system-level solutions can meet exclusively with members of relevant industry media to discuss technologies, trends, and products. The following is a synopsis of the presentations at this year’s event:

Faster. Stronger. More: Fiber Optics and High-Speed Solutions for Tomorrow’s VITA Ecosystem

By Oscar Banos, Open.Tech by Amphenol

In an era defined by an insatiable demand for speed, capacity, and durability, VITA standards are at the forefront of embedded systems evolution. In this presentation, Oscar delved into the cutting-edge advancements in optical and high-speed connectivity solutions. By exploring the path from chassis wall to PCB, he highlighted the critical role of high-density fiber technologies – such as VITA 66.5 optical interconnects, MT ferrules, and hot-swappable transceivers – in addressing the rising need for reliability, higher throughput, and reduced mean-time-torepair (MTTR).

By Thomas Mittermeier and Christian Hobmaier, ODU GmbH & Co. KG

The limitations of current fiber connectivity solutions in the rugged embedded system world continue to be an issue for end users in defense/aerospace applications. In particular, these limitations are low mating cycles and the requirement for excessive cleaning in the field. The new Expanded Beam Optical (EBO) Fiber Ferrule from 3M is the answer to these limitations. Very high mating cycles and a low susceptibility against dust, as well as excellent transmission values, are a game changer for end users. The EBO Ferrule is available in Single Mode and Multimode). Small in size, the ferrule can be implemented in Circular as well as Backplane connectors.

QMC VITA 93 Introduction

By Mark Littlefield, Elma Electronic

The developing VITA 93 standard specifies a new high-performance mezzanine module and carrier card interface. Designed for small form factors, the QMC mezzanine aims to bring performance of XMC modules to a tiny package, enabling users to mix and match I/O functions on VPX, VNX+, and other platforms. This presentation served as an introduction to VITA 93 QMC standard.

By Jan Zimmermann, TEWS Technologies

This presentation served as a technical overview of the VITA 93 QMC standard.

By Robert Greenfield, Acromag

This presentation discussed possible implementations of the VITA 93 QMC standard.

By Steve Devore, Leonardo DRS

VITA 100 is a new standard in development for high performance critical embedded computing applications. Steve is the chair of the VITA 100 working group. This presentation outlined the goals of the VITA 100 working group and the numerous sub-working groups, concluding with a timeline set by the working groups.

VITA 100 –A Giant Leap for Interconnect: Next-Gen VITA 100

By Mike Walmsley, TE Connectivity

With advances in silicon packages, there is a need to accommodate increased power consumption, higher pin counts, and higher data rates while maintaining a smaller footprint. These requirements will be a challenge when implementing OpenVPX in next generation systems. In this presentation, Mike reviewed advances in interconnect for tomorrow’s embedded systems and preview the next generation connector – with increased pin count, data rates, and capacity –selected for VITA 100 architecture.

By Greg Rocco, MIT Lincoln Laboratory

This presentation contrasted the profile strategy between OpenVPX and VITA 100. The VITA 100 working group has a goal of developing fewer, more focused profiles.

VITA100.20:

Securing the Manageability of Next-Generation Mission Critical Processing Systems

By Dan Toohey, Mercury Systems, Inc.

The revolutionary VITA 100.0 standard will enable the integration of more complex subsystems than VITA 46/VITA 65. These complex systems will require capable system-management solutions to properly and securely maintain them and deliver features equivalent to those found in commercial processing systems. VITA 100.2 strives to fulfill the user need to manage their VITA 100.0 solutions. This presentation discussed the objectives, planned capabilities, and key features of VITA 100.2, including security management and why it’s important for mission-critical processing.

By Mark Klein, RTX – Raytheon

RTX – Raytheon is an ardent supporter of open systems architectures. RTX is a supporter and active participant in many VITA working groups, even taking the lead in VITA 47 Common Requirements for Environments, Design and Construction, Safety, and Quality Standards. This presentation highlighted Raytheon’s commitment to open standards.

By Ivan Straznicky, Curtiss-Wright Defense Solutions

Digital engineering or model-based engineering is the preferred method for complex system design. This presentation explained some of the benefits of digital engineering; Ivan concluded with a call to action to leverage digital engineering now.

By Ethan Plotkin, GDCA

This presentation explored how OEMs can unlock hidden potential within their organizations by gaining visibility into the true costs and liabilities of legacy support. It addressed key challenges such as short-term focus, underestimating obsolescence costs, and inefficient processes, while offering actionable strategies for improvement. By identifying gaps in current resource usage and implementing formal obsolescence management plans, OEMs can reclaim operational efficiency and redirect focus toward growth and innovation.

By Jake Braegelmann and Ryan Jansen, New Wave Design

Advancements in multi-function aperture (MFA) sensors are transforming defense systems by enabling adaptive, reconfigurable sensor processing algorithms and seamless multi-modal data integration within a highly SWaP-optimized framework. Despite the potential, these technologies pose new challenges from traditional sensor processor architectures, requiring hardware resource allocation and reconfiguration, efficient movement of large amounts of sensor data, and a strategy to qualify new algorithms as they become available. This presentation reviewed these obstacles and what is needed from an architecture and open standards perspective to unlock the full potential of multi-function apertures for next-generation sensor processing applications.

By Matthew Burns, Samtec, Inc.

As small-form-factor (SFF) System-on-Modules (SoMs) increase in performance, pin count. and density, SoM designers are challenged to define component placement, PCB layout, pinout, and interconnect options for digital, analog, RF, power, and control signals. Additionally, routing I/O expansion protocols on SoMs and SoM carrier cards enable rapid prototyping and system emulation. Several new and ongoing SFF SoM open-standards efforts are simplifying system design while addressing the need for next-gen performance. In this presentation, Samtec technical experts reviewed the latest SFF SoM open-standards efforts including UxV/35, VITA 93, SGeT HFM, and PICMG COM-HPC.

By Jerry Hovdestad, AirBorn, a Molex Company

This presentation addressed the flexibility possible with VITA 62 power-supply designs. It highlighted recent demonstrations where, of necessity, a high-power VPX supply was run backwards to serve as a regenerative load and provide power back to the input and presented possible additional nonstandard uses of the design to allow systems to offer other functions without the long, drawn-out “design from scratch” process.

By David Tetley, Elma Electronic

The SOSA Technical Standard is evolving to define rules for software architectures, specifically through the SOSA Reference Architecture, Edition 2.0, Version 2. This

edition outlines rules and profiles for the software Run-Time Environment (RTE) that SOSA modules must operate within, ensuring high portability. Key software elements defined in the standard include the System Manager and Task Manager, which standardize the management of platform health, operation, configuration, and security, facilitating mission operations. These elements contribute to over 250 software interactions.

The integration of these software elements aims to create an “app store” of SOSA modules, allowing for easy replacement of modules without code changes. However, this scope presents challenges for developers who prefer to focus on core applications rather than management frameworks. To address these challenges, the development of toolkits and reference implementations is suggested to reduce development overhead and save significant time.

LCR products enable the fullest capabilities of the best aspects of VPX and SOSA aligned LCR is at the forefront of COTS open standards chassis and custom system designs for VPX, CMOSS, and SOSA architectures in accordance with MOSA directives. Intelligently engineered designs that bring operational advantage to the battlefield.

IN AN ERA DEFINED BY AN INSATIABLE DEMAND FOR SPEED, CAPACITY, AND DURABILITY, VITA STANDARDS ARE AT THE FOREFRONT OF EMBEDDED SYSTEMS EVOLUTION.

By Ralph Grundler, Aitech Systems

This presentation examined the growing reliance on open standards to enable space applications, specifically examining command and data handling systems, earth observation satellites, and interconstellation networking. It also explored next steps for this open standard in future deep-space and lunar missions for commercial and military applications.

By Nigel Forrester, Concurrent

Intel processors are used in many highperformance embedded computing applications. This presentation discussed the major caveats to be aware of when using Intel processors in critical embedded-computing applications.

By Brian Arbuckle, Embedded Market Research

Brian closed the event by reviewing highlights from market research he recently conducted for VITA. VITA publishes quarterly reports reviewing activity from financial performance to new products, contracts, and mergers in the VITA technology market. An annual report goes deeper into revenue estimates of VITA technology suppliers forecasting market sizes and shares across the various VITA technologies. The 2023 annual report is available online (www.vita.com/ MarketData).

All of these presentations, with video, are posted at https://embeddedtechtrends.com/. It is highly recommended that you view the videos to get the maximum information.

AirBorn’s innovative VPX Power Supply is a VITA 62, 6U system designed for demanding defense applications. This SOSA-aligned, conductioncooled, switch-mode unit supports 270 VDC input IAW MIL-STD-704 — ensuring mission-critical performance in the toughest environments.

Auxiliary DC Output: +3.3V/60A

Efficiency of >94% Typical Above 50% Load

Input-Output Isolation 2100VDC

Main DC Output: +12V/180A

Programmable Regulated Current Limit

VITA 46.11 System Management

By Gwenc’hlan Tymen

A recent study was performed to improve the cooling capabilities of electronic boards; based on the VITA 48.8 Mechanical Standard for VPX REDI Air Flow Through Cooling,standard recommendations, a new generation of heatsinks was developed. Numerical tools are used to design and prevalidate the heatsink through thermal and fluidic simulations. In the framework of the system here, the product ComEth4682e, the heat is generated by the multiple electronic components placed on the board, whereas the cooling is ensured by an airflow circulating inside the fins and having an inlet temperature of 85 °C. The study found that the thermal benefits of air-flow-through technology outweigh those found in air-cooled equipment.

In embedded systems, one of the major causes of electronic board malfunctions comes from the lack of control regarding the thermal removal1. Indeed, through the electrical energy needed to guarantee their functioning (Ri²), each electronic component produces some heat; if the heat removal is not well achieved, the component can overheat, reach its critical operational temperature and stop working. In the worst cases, it can even generate a thermal runaway regime (flames and/or gas production) which would then be catastrophic for the equipment. Failures of electronic boards due to thermal issues are estimated to 55%2. It is then essential to precisely design the adapted managing cooling system.

In modern equipment, the electronics components tend to be progressively miniaturized3,4. The goal behind this action is to get some additional free space on the boards to finally place other components and match with performances requirements which are more and more evolved5. However, several works from literature have highlighted the fact that the traditional cooling solutions (conduction or forced convection through a heatsink for example) will soon reach their limits and will not be able anymore to sufficiently cool electronic boards having high electrical power6,7. A technological boundary seems then to emerge here.

In this context, VITA 48.8 guidelines suggested the air-flow-through (AFT) solution which is aimed to overcome the technical weaknesses of conventional cooling systems8. A proto-heatsink was designed by carefully following the VITA 48.8 standard recommendations. The AFT heatsink design is then compared to a more conventional heatsink through 3D steady-state numerical simulations to pre-validate the concept, before being finally developed to be tested at the Interface Concept lab. In this study, the ComEth4682e product 9 (with power around 83 W) is used as a testing board.

A. The thermal interface materials

To avoid any overheating and to optimize the cooling of the electronic boards, finned heatsinks are generally placed on components to increase the thermal exchange area with the environment. The convective heat transfers are defined by Newton’s laws of cooling:

q = ℎS(ΔT)

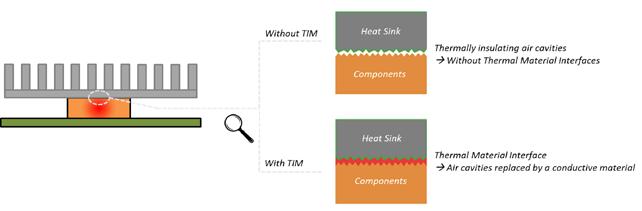

However, a direct contact between the heatsink and the electronic components would lead to inefficient heat transfers. Indeed, at the microscopic level, some insulating air cavities (λ ≈ 0,025 W.m-1.K-1) are present at the interface, due to natural imperfect surfaces. That is why an intermediate buffer is added between the heatsink and the component: thermal interface materials (TIM). They are often made of soft silicone (λ ≈ 5 W.m-1.K-1) and their goal is to fill the microcavities of air to enhance the heat transfers from the components to the heatsink. (Figure 1.)

In electronics, the classical air-forced convection heat transfer mode, here called air cool (AC) and in which a finned heatsink is placed on components, is commonly used. For this cooling strategy, a lateral airflow (having a controlled inlet temperature and flow rate) is applied and the system is then globally cooled. The technological limit: The air can be uselessly in contact with some parts which do not require cooling (for example, PCB sides, nonheating elements) and the efficiency is then not optimized.

Recently, AFT technology has been discussed in the VITA 48.8 standard8. The base cooling principle is the same as the AC one (lateral air forced convection), but the technical evolution is here that the airflow is concentrated inside the fins of the heatsink. The cooling efficiency is then optimized because the fluid is not unnecessarily in contact with irrelevant environments. The possible fluidic recirculation or deviation created by the contact between air and components are then avoided. Figure 2 gives a simplified example explaining the differences between the conventional AC technology and the new AFT one.

As seen in Figure 2, the components C1 and C2 are placed on a PCB. Only C1

dissipates enough energy requiring a heatsink but C2 does not need to have any heat removal. In the AC situation, the airflow is uselessly disturbed by C2, as well as on the top of the heatsink or the bottom of the PCB. In the AFT situation, the air is channeled on the fins and then only cools C1, optimizing the cooling efficiency.

To adjudicate the potential benefits of the AFT technology, two heatsink designs were created through the CAO module of SolidWorks2023: the first one is dedicated to the AFT and the other one to the AC. (Figure 3.) The number of fins as well as their heights are the same for the two designs so as to be directly comparable.

As observed in Figure 3, the AC design is made of a single part corresponding then to a conventional heatsink, whereas the AFT one is made of three parts including a top and a bottom cover in order to respect the VITA 48.8 recommendations. These two designs are next investigated through numerical simulations.

The flow simulation module of SolidWorks2023 was used to solve a formulation of the Navier-Stokes equations10. They are presented below and respectively correspond to a formulation of the mass, momentum and energy law conservation:

How is the modeling of the different materials done to have a realistic study? The electronic components are taken into account through a “Two-Resistances” or “2R” modeling. It is a simplified resolution where the component is made of 3 nodes (Junction/Case/Bottom) (Figure 4.).

θJB and θJC are thermal resistances and generally given by the supplier of the components.

When their presence is needed, TIM are modeled as solid bodies. Some tests performed at the Interface Concept lab led to a regression law λ=f(h) giving the influence of TIM height h on thermal conductivity λ and has been implemented in our model.

AFT and AC heatsinks are made of high thermal conductivity aluminum. PCB is considered as an orthotropic material. Its planar conductivity is set to 25 W/m/K whereas its transversal one is set to 1.5 W/m/K. Air is used as a cooling fluid having a uniform and constant flowrate Q of 40m3.h-1 at the inlet of the heatsink. Its conductivity was set as a temperature-dependent parameter, which was taken directly from the Flow Simulation module of SolidWorks2023.

In this numerical 3D study, the two heatsinks were placed inside a parallelepipedic box. Consistent comparisons between the two configurations were set by using strict boundary conditions. To investigate the heatsinks in the most severe conditions, the cooling temperature was set to 85 °C, representing the highest range of the VITA standard.

The two computational models/heatsinks have approximately 17 million cells. An Intel Xeon Gold 2.90Ghz processor with 16 cores was used, with around four hours of calculation time needed for each case to get the final results (presented in §2e).

Before any detailed analysis, a first classical step is to check the correct physical behavior of the model. One parameter which can be easily validated is Tout as it can be analytically evaluated from a thermal balance with the equation

P = m˙ × G p × (T out − Tin)

and then compared to simulations that measure outlet temperature vs. flow rate. It was observed that the numerical result is really close to the analytical estimation, as the apparent deviation is lower than 1%, validating the thermophysical aspect of the model. Post-treatment also allowed study of several physical parameters, as the flow patterns. Two main differences appear between AC and AFT configurations: In the AC configuration, air flows everywhere it can – below the PCB, against the edges of the components, and outside the fins of the heatsink, which generates a kind of chaotic behavior. In the AFT configuration, air is well canalized inside the heatsink fins and no fluid deviation appears; the flow is much smoother.

Consequently, as the flow patterns are greatly different between AC and AFT, it thereby implies some variations concerning the heat transfers, as observed in Figure 5 showing the thermal fields of the heatsinks.

In Figure 5, it is qualitatively observable that the AC heatsink is globally hotter than the AFT one, as the hot spots are more numerous. Additionally, more quantitative information extracted in post-treatment concerning the electronic components showed that the greatest thermal gain goes for the Switch Ethernet (P=65.8W) where Tj is around 5 °C lower with the AFT configuration and Tj is around 3.5 °C lower for the CPU (P=4.3W).

This thermal study showed the benefits of the AFT technology. Indeed, for a equivalent studied configuration between AC and AFT (same Tin, Q, materials or

numbers of fins), a significant thermal gain on a major component can be obtained.

In view of the promising obtained numerical results, an AFT module has been recently physically developed. In addition, a dedicated test bench has also been designed and mounted at the Interface Concept lab.

The result: The AFT module gave satisfying experimental results, close to the the simulation ones for pressure drop or thermal measurements, thereby validating the final step of this study.

Gwenc’hlan (Gwen) Tymen has been the Thermal & Mechanical Team Leader at Interface Concept for nearly three years. He obtained his PhD in Heat Transfers and Fluid Mechanics in 2017. Gwen then continued to further acquire strong tecℎnical and scientific backgrounds in high reputation academic laboratories and international industrial firms. He aims to keep developing new and innovative tecℎnologies, from numerical simulations to physical test benches. Readers may reach him at gtymen@interfaceconcept.com.

Interface Concept https://www.interfaceconcept.com/

References

1. Qian et al., “Thermal Management on IGBT Power Electronic Devices and Modules,” IEEE Access, vol. 6, p. 12868-12884, 2018, doi: 10.1109/ACCESS.2018.2793300.

2. Halouani, “Modélisation et simulation multi-physiques pour la fiabilisation des composants électroniques,” thesis, Université de Technologie de Troyes; Université de Sfax (Tunisie), 2020. September 2023. [En ligne]. Disponible sur: https://theses.hal.science/tel-03808647

3. Arshad, M. Jabbal, P. T. Sardari, M. A. Bashir, H. Faraji, et Y. Yan, “Transient simulation of finned heatsinks embedded with PCM for electronics cooling.”

4. R. Gharaibeh, Y. M. Manaserh, M. I. Tradat, F. W. AlShatnawi, S. N. Schiffres, et B. G. Sammakia, “Using a MultiInlet/Outlet Manifold to Improve Heat Transfer and Flow Distribution of a Pin Fin Heatsink,” Journal of Electronic Packaging, vol. 144, no 031017, May 2022, doi: 10.1115/1.4054461.

5. L. Moore et L. Shi, “Emerging challenges and materials for thermal management of electronics,” Materials Today, vol. 17, no 4, p. 163-174, May 2014, doi: 10.1016/j. mattod.2014.04.003.

6. Ealy, J. V. Anda, D. Gallagher, et D. Vos, “On Characterizing Air-Flow-Through Chassis: An Investigation of Manifold Flow in Rugged Electronics Enclosures,” in 2021 20th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm), June 2021, p. 428-440. doi: 10.1109/ITherm51669.2021.9503179.

7. B. Samet, M. Bilgili, et I. Gı̇Rı̇Ş, “Takılabilir Modüllerde Kullanılan Elektronik Kartların Doğrudan Hava Akışı ile Soğutulmasının İncelenmesi.”

8. ANSI/VITA 48.8-2022, “Mechanical Standard for VPX REDI Air Flow Through Cooling, 1.0” to 1.5” Pitches.”

9. Interface Concept – Embedded boards and systems for defense and industry markets,” https://www.interfaceconcept.com/produits/ethernet-switches/3U-VPX/376-ComEth4682eCommutateur-1102540100-Gigabit-Ethernet-et-routeur-IP-au-format-3U-VPX (September 2023).

10. Sobachkin et G. Dumnov, “Numerical Basis of CAD-Embedded CFD White,” 2014. [En ligne]. Disponible sur: https://www.semanticscholar.org/paper/Numerical-Basis-of-CADEmbedded- CFD-White-Sobachkin-Dumnov/56f54b31c528c588cfb465d953c2b0f24ea9e297

Go from development to deployment with the same backplane and integrated plug-in card payload set aligned to SOSATM and CMOSS. Includes chassis management, power and rugged enclosure for EO/IR, EW, SIGINT and C5ISR applications.

By Thomas Mittermeier

Due to a variety of factors, military aviation is an extremely challenging environment for the integration of electronic systems. Basic principles such as size, weight, and power (SWaP) optimization are beyond question and have always been one of the most central requirements for all components. Due to high environmental requirements, the components must be extremely robust and resistant, which is reflected in high development costs and prices. Spurred on by the drive for technological superiority, the market and the existing subsystems are developing at a rapid pace.

If integrators can choose from a large number of subsystem providers available on the market, this choice presents them with important decisions. Procurement contracts usually define strict requirements as to where and how the components must be available. No matter how promising a technology sounds and how much it would put the company ahead of the competition, a lack of availability can break the neck of the overall system.

This makes it all the more understandable that central military aviation programs prefer to rely on proven standards that are characterized by proven performance and multi-layered availability. It is therefore up to manufacturers to make their technological innovations available to the market as quickly as possible via open standards. This happened recently with the initiation of two new VITA standards that introduce a new contact technology to the world of embedded computing.

Fiber optic has been an integral part of data transmission technology for decades. Optimum SWaP features (extremely light, space-saving and incomparably fast) characterize the solution and make it the key technology for the complex board systems of military aircraft. However, precise transmission requires extremely time-consuming cleaning, which consequently results in high effort and increased costs. As no sensible alternative exists to date, MT ferrules are used en masse in the frame of standardized backplane and I/O circular connectors in modern platforms.

Expanded Beam Performance technology offers a remedy and embodies long-awaited features: little to no cleaning, a long service life and optimum optical transmission properties. Sounds good, but how is that possible?

Expanded Beam Performance is an advanced version of Expanded Beam contact technology. In contrast to the physical contact (PC) solutions commonly available on the market, it is characterized by contactless transmission of the light signals. As a result, signal transmission is less susceptible to contamination or interference due to mechanical shocks and vibrations. A long-service life is also possible, as there is no wear on the contact ends.

Expanded Beam technology has been known and used on the market for some time. However, previous connection systems could not keep up with the excellent transmission properties and high packing densities of PC solutions. These weaknesses have been eliminated by the innovative design of the Expanded

Beam Performance ferrule. What remains is a highly potent contact technology that is characterized by the following features:

› 12 fibers per ferrule

› No cleaning required under normal conditions

› Extremely low insertion loss values even under harsh environmental conditions

› 50,000 mating cycles

› Insertion loss: SM: < 0.35 dB (typical) / < 0.7 dB (max.)/ MM: < 0.15 dB (typical) / < 0.3 dB (max.)

› Return loss: SM: > 60 dB (typical) / ≥ 55 dB (min.)/MM: > 45 dB (typical) / ≥ 35 dB (min.)

The longevity of the technology makes it the perfect transmission variant for demanding applications such as military aviation. The greatly reduced maintenance requirements in combination with the long service life play a key role in the total cost of ownership. The systems also support the emergency services in critical situations, as platforms are ready for use again more quickly thanks to shorter maintenance times.

Important strategic steps were taken at the beginning of 2025 to ensure that the new system is quickly and widely available. VITA 95 and VITA 96 Working Groups were proposed and formed in January. VITA 95 is focused on circular I/O connectors based on 38999, Series III housing. VITA 96 defines different dimensions of backplane connectors for the transmission of up to 96 fibers.

Thanks to the advanced technology, modules can be swapped within the system in a matter of seconds without the need for maintenance. Normally, this process requires extensive cleaning of the physical contact areas - every time they are swapped. Three variants: Type A, B and C offer three different dimensions of the connection solution, which is based on the apertures of the existing VITA 66 Optical Interconnect on VPX connection standard. This will make it easier for companies to integrate the new technology, as existing modules do not need to be modified. The individual fibers are connected as usual via optical transceivers, which can be attached directly to the circuit boards. The first versions of the new connection generation have already been presented by the German connection specialist ODU under the name ODU BACKPLANE.

In addition, the developing VITA 95 standard defines several variants of I/O interfaces that connect glass fibers via the Expanded Beam Performance ferrule. Here too, future solutions will be based on the dimensions of the well-known VITA 87 High Density (HD) MT Circular Connector standard. MIL-DTL 38999, Series III enclosures offer familiar handling to the users, simplifying the transition. ODU TACTICS currently offers four solutions in shell sizes #11, #13, #15 and #17.

Thomas Mittermeier is Strategic Business Development Manager for Aerospace/Military Fiber Optic Applications at ODU-USA. He specializes in advanced connectivity solutions.

ODU-USA • odu-usa.com

VPX7600 3U VPX SBC with Intel Tiger Lake-H Xeon W CPU

Acromag’s new VPX7600 is a SOSA aligned I/O Intensive single board computer. This SBC features Intel’s 11th Generation Tiger Lake-H Xeon W-11000E Series processor. The high-performance 8-core processor supports up to 32GB of dual-channel, soldered-down DDR4 ECC memory. It also contains an integrated Intel Gen12 UHD Gfx-32 graphics engine. A wide variety of I/O peripherals are supported. The XMC expansion site enables advanced computation capabilities with plug-in mezzanine modules. A DisplayPort 1.4 interface on the backplane with HBR3 data rates supports 4K resolution. NVME SSD on-board storage holds up to 1TB of data. Other peripheral interfaces include a 2.5GBASE-T port, USB 3.2, USB 2.0, SATA III, 4x GPIO, and an RS422 or dual RS232 ports. Air-cooled and conduction cooled versions are available. Board support packages facilitate use with Microsoft Windows®, Linux®, and VxWorks™ operating systems.

Acromag www.acromag.com

Ą Intel 11th Gen Xeon-W Tiger Lake-H 8-Core CPU

Ą 32GB of dual channel DDR4 SDRAM with ECC

Ą Up to 1TB NVMe SSD on-board storage

Ą 100Gb Ethernet Data Plane

Ą 10Gb Ethernet Control Plane

Ą x4 PCIe Gen3 Expansion Plane

Ą IPMC VITA 46.11 Tier-3 System Management

https://acromag.org/VPX7600

solutions@acromag.com

877-295-7088

www.linkedin.com/company/acromag @acromag

AirBorn’s Mighty VPX Power Supply

The VPX Power Supply is a 2300W+, 6U solution offering industry-leading power density and efficiency. Built to meet VPX and VITA 62 open architecture standards, it delivers rugged, high-performance power in a modular design. With 95% efficiency, it provides nearly twice the output of typical 6U supplies, helping meet modern defense demands without increasing size. Conducted EMI emissions are well below VPX limits, offering cost and space savings over competing solutions. Engineered for mission-critical defense systems, AirBorn’s VPX Power Supply includes embedded intelligence for flexible power distribution. It actively manages voltage, current, and temperature across units. A dual data bus allows system controllers or chassis managers to monitor input voltage, output loads, temperature, and other key metrics, improving reliability by enabling predictive maintenance and helping prevent failures.

FEATURES

Ą Auxiliary DC Output: +3.3V/60A

Ą Peak Efficiency of 95%

Ą Input-Output Isolation 2100VDC

Ą Main DC Output: +12V/180A

Ą Overvoltage, Overload, & Overtemperature Protection

Ą Programmable Regulated Current Limit

Ą VITA 46.11 System Management

https://www.airborn.com/6u-vpx-power-systems/vpx-power-supply/product/vpx-power-supply

AirBorn – A Molex Company www.airborn.com hovdestadj@airborn.com

512-863-5585

www.linkedin.com/company/airborn-inc/mycompany

Amphenol’s next-generation 3U VPX Ethernet switch, the RaptorLink 64X50, is SOSA aligned and features VITA-91 connectivity, offering double density with support for speeds of up to 50G per lane on the backplane. The switch operates with 64 individual channels, supporting speeds of 1G, 10G, and 25G in NRZ mode, and 50G in PAM-4 mode. Additionally, it supports multiple ganged protocols, including 40Gx4, 50Gx2, and 100Gx4 in NRZ mode, and up to 400Gx8 in PAM-4 mode. This makes the Ethernet switch highly adaptable for future backplane architectures. All boards are built with Amphenol MIL-HD2 SOSA/VITA 91 and/or R-VPX Evolution series connectors. Management is handled by two on-board quad-core ARM processors, each with ample memory for complex networking applications. The switch includes a full suite of SOSA-aligned IPMI status functions for various chassis manager requirements. In summary, the RaptorLink 64X50 integrates two managed 32-channel, 50G Ethernet switches into a single, 3U SOSA-aligned, VITA-91 VPX board. Several versions of the RaptorLink switch are available with 50G PAM-4 and NRZ connectivity configurations. Each model includes a comprehensive management software suite with features such as MACsec, Time-Sensitive Networking (TSN), and a 60-second boot time. The switches are offered in the following configurations:

• Dual 64x50G switch – SOSA aligned VITA-91 double density and speed connectors

• Single 32x50G switch – SOSA aligned VITA-91 double density and speed connectors

• Single 40x50G switch – SOSA aligned VITA-91 double density and speed connectors

• Additionally, a single 32x50G switch is available with legacy RVPX SOSA aligned connectors.

To meet the demands of applications requiring low power consumption and fast boot times (under 10 seconds), several configurations of the switch are available with up to 25G NRZ speeds and lightweight management software. These options include:

• Dual 64x25G switch – SOSA aligned VITA-91 double density and speed connectors

• Single 32x25G switch – SOSA aligned VITA-91 double density and speed connectors

• Single 32x25G switch (with legacy RVPX SOSA aligned connectors) Along with the switch and processing infrastructure available in many different configurations, the RaptorLink 64X50 has a VITA46.11 Tier 1 compliant IPMI solution for sensor, link state, health, BIT, and other reporting to chassis managers. It also supports redundant IPMB interfaces and IPMB fast modes.

https://open.tech/raptorlink-64x50-sosa-ethernet-switch

www.open.tech

Ą Dual 32-channel Ethernet switch chips, capable of speeds up to 50G PAM-4 and NRZ speeds up to 25G.

Ą Support for multiple speeds: 1G, 10G, 25G, 40G, 50G, 100G, and 400G (PAM-4 and NRZ formats).

Ą Layer 2 and Layer 3 network management capabilities, including support for time-sensitive networking (TSN), MACsec, and advanced routing applications.

Ą Dedicated management interfaces via dual RS-232 and 1GBase-T.

Ą SOSA-aligned 12V power input with a full IPMI controller for chassis management.

Ą Powered by dual quad-core ARM CPUs with DDR4-SDRAM, flash memory, and EEPROM.

Ą Linux OS with comprehensive network management software.

Ą Fully ruggedized to withstand extreme environmental and EMI/EMP conditions.

Ą Interfaces for power diagnostics and more.

Ą Meets the following environmental specifications:

Ą Operating Temperature: -40ºC to 85ºC while operating.

Ą Storage Temperature: -55ºC to 125ºC.

Ą Humidity: 0-100% non-condensing humidity during operation.

Ą Vibration: 10g peak, 5-2,000 Hz sine vibration, and 40 G peak shock cycles.

Ą Altitude: -1,500 to 60,000 ft with rapid depressurization.

Ą EMC: Designed to comply with MIL-STD-461E.

sales@open.tech

www.linkedin.com/company/101690501/

Annapolis WILDSTAR™ Versal Premium Boards are the highest performing OpenVPX COTS FPGA Processing Baseboards on the market, with capability for 100Gb Ethernet over copper on the VPX backplane. Blind mate optical and/or RF (VITA 66/67) is also available. All 100GbE boards are VITA 65-compliant and align with the SOSA Technical Standard.

These SOSA aligned Plug-In Cards (PIC) integrate the latest Versal Premium FPGAs up to VP2802 with 472 AI Engines. AMD’s new Versal ACAP FPGAs are engineered for processing-intensive applications like Radar, EW, and SIGINT.

High-performance digitization is via Mezzanine Card(s) connected to FMC+ based I/O site(s). Choose between a JESD-based (bandwidth optimized) or LVDS-based (latency optimized) approach.

Annapolis rugged FPGA boards are designed from the ground up to perform at the highest levels in the harshest environments. They are designed and tested for reliability, utilizing high performance air, conduction, or air-flow-through cooling for thermal control.

Designed & Manufactured in USA

All Annapolis products are engineered and manufactured under one roof in the United States. This co-location of engineering and manufacturing allows for more aggressive design, and better quality control and production flexibility.

between Bandwidth or Latency-optimized Versal Boards

Ą General Features

• Up to two AMD Xilinx Versal Premium FPGAs

• Multiple levels of hardware and software security

• A Full Board Support Package for fast and easy Application Development

� BSP options include traditional RTL and new DFX RTL and Vitis paths

Ą Mezzanine I/O

• Optimized for VITA 66/67 interfaces

• Based on FMC+

• Available options:

� Jariet Electra-MA: 2TX (64GSps)/2RX (61GSps)

� Xilinx RFSoC: 2TX (5GSps)/8RX (5GSps)

� Xilinx RFSoC: 4TX (5GSps)/4RX (5GSps)

� TI 2TX (3.2 GSps)/2RX (3.2 GSps)

� Others covered under NDA

Ą Mechanical and Environmental

• Air, conduction, or AFT cooled: -55°C to +85°C Operating

• Available in extended temperature grades

• Hot swappable for air-cooled variants

• Only requires +12V and +3.3VAUX from backplane

www.annapmicro.com/versal-products/ WILDSTAR Boards are cooled via Air, Conduction, or Air-Flow-Through

VITA 91 Connectors double the available backplane density

3U VPX Switches/Chassis Feature VITA 91 High Density Connectors

Annapolis is the first embedded computing manufacturer to integrate new high-density VITA 91 connectors into its COTS products. 3U OpenVPX Chassis and Switches with HD VITA 91 connectors have much higher performance and lower latency. The HD connectors double the available backplane density, allowing for the use of just one 3U Switch per eight payload slots, versus four previously.

VITA 91 HD connectors allow for a completely switched backplane, so the expansion plane is no longer defined by a fixed backplane PCB, but is now flexible and fully reconfigurable. Chassis and backplanes with two HD switch slots allows for one switch to handle all Data and Control Plane Ethernet, with the second switch dedicated to the expansion plane. The expansion plane supports Dual 100Gb Ethernet, 8x Gen4 PCIe, or 128 LVDS.

With VITA 91 HD connectors, SOSA aligned VPX Switches and Chassis keep pace with the high speed and bandwidth of the latest high-performance transceivers and FPGAs, including Agilex 9 Direct RF-Series and Versal Premium. These boards and systems are ideal for challenging applications including low latency jamming, EW, or radar.

WP3P20 HD Switch includes up to 64 Gen4 PCIe and up to 128 LVDS

The following SOSA aligned Switches integrate high density VITA 91 connectors and one or two AMD Xilinx Zynq UltraScale+ MPSoC Motherboard Controllers.

The following SOSA aligned Chassis integrate high density VITA 91 connectors and a VITA 46.11 conformant Chassis Manager.

Application Development

• Standard Chassis Manager support delivered with all systems

• Optional Full Board Support Package for Chassis Manager

� Enables customization if needed of Zynq PS and PL

� Provides fast and robust HDL-based application development environment

https://www.annapmicro.com/vita91/

Direct RF sampling is transformative for Signal Acquisition and Signal Processing. Direct RF data converters operate directly at the antenna frequency, reducing latency and eliminating the need for intermediate frequency stages. Also, Direct RF conversion can instantaneously tune across a very wide frequency span – from 0.1 to 36 GHz. Now you can directly digitize and process wideband signals, simplifying system architecture and enabling new EW, SIGINT, and spectrum processing capabilities.

Annapolis is now offering the lowest latency and highest bandwidth 64 GSps Direct RF solutions on the market:

• WILD FMC+ DME1 (top) – an OpenVPX Mezz Card

• WILDSTAR 3AE1 (right) – a 3U OpenVPX Baseboard

• WILDSTAR SAF1 (below) – a Small Form Factor Module

Ą WILDSTAR SAF1 Small Form Factor Module (photo below)

• Ideal for edge applications close to the sensor and in other tight envelope man-packable environments

• Intel Altera Agilex 9 MCP1 Direct RF-Series AGRW014 FPGA

• ADC: 4 Channel, 64 GS/s, 10 bit Resolution

• DAC: 4 Channel, 64 GS/s, 10 bit Resolution

• Option for Jetson AGX Orin™ GPU/CPU processing

Ą WILD FMC+ DME1 ADC & DAC Mezz (photo above)

• Pair one with a 3U Baseboard or two with a 6U Baseboard

• One Jariet Technologies Electra-MA Transceiver

• ADC: 2 Channel, 40-64 GS/s, 10 bit Resolution

• DAC: 2 Channel, 40-61 GS/s, 10 bit Resolution

• Analog Input Bandwidth: 20GHz (-6dB) typical

• Maximum Instantaneous Bandwidth: 6.4GHz

• Run Time Selectable ADC Decimation: 8-1024x

• JESD204B/C interface with 16 lanes up to 30Gbps

• Developed in alignment with SOSA™

Backplane optical and RF support with VITA 66/67

Ą WILDSTAR 3AE1 3U OpenVPX FPGA Processor (photo above)

• SOSA aligned 3U VPX Plug-In Card

• Intel Altera Agilex 9 MCP2 Direct RF-Series AGRW027 FPGA

• ADC: 8 Channel, 64 GS/s, 10 bit Resolution

• DAC: 8 Channel, 64 GS/s, 10 bit Resolution

• Supports Analog Interface Cards for front-end personalization

• Air, Conduction, or Air-Flow-Through cooled

• Developed in alignment with SOSA™

Contact us today to request block diagrams and additional specifications.

www.annapmicro.com/direct-rf-products/

Chassis Managers / SoMs / Hardware Management Cards are Optimized for VITA 65/SOSA™ Profiles

We now offer four VITA 46.11-aligned WILD™ Cards that can be used for Chassis Management, Systems on Module, or Hardware Management. They enable critical chassis control, maintenance, and security functions, are optimized for VITA 65/ SOSA profiles, and offer commercial-off-the-shelf (COTS) availability. They are highly-integrated modules. They provide access to plug in card (PIC) JTAG and Maintenance ports, CLK1 usage via on-board Zynq FPGA, network functions, and some optional advanced security functions. For security, they implement security signal interfaces and a Xilinx UltraScale+ Zynq MPSoC and latest Microsemi PolarFire FPGA, which can be end-user fied with the optional BSP.

Shown mounted to a 3U VPX Backplane

Ą Capability: Provides control and access to Plug-In Card JTAG and Maintenance ports, CLK1 usage, network functions & optional advanced security functions

Ą FPGAs: Xilinx UltraScale+™ Zynq (ZU5EG or ZU11EG or ZU15EG) & MicroSemi PolarFire

Ą Mounting: Directly on backplane, or via 3U or 6U VPX plug-in carrier card

Ą Power: Only requires 3.3V

Ą Optional BSP: For customizing Zynq PS & PL for security

Ą Standards: VITA 46.11 & MIL-STD-1553

Ą Availability: Commercial off-the-shelf

www.annapmicro.com/product-category/chassis-and-backplane-accessories/

Annapolis Micro Systems, Inc. www.annapmicro.com marketing@annapmicro.com 410-841-2514

Dawn RuSH™ Ru-gged S-ystem H-ealth monitoring systems monitor and control enclosure system voltages and temperatures remotely. Add-ons monitor currents, humidity, air pressures or virtually any other parameter. Accurate, self-calibrating. Military-tested.

Control fans, power supplies, LEDs, backplane signals or almost anything else imaginable. Can run off virtually any power source. Ethernet enabled.

Only 2.0” W x 5.9” L x 1.2” H. Its outputs can control fans, power supplies, LEDs, backplane signals or almost anything else imaginable. Its inputs can monitor temperatures, fan speed, voltages, I2C, or the state of any user-defined signal. The user interface is LED, LCD, VF, RS-232 or Ethernet. A wide variety of add-on “Sidekick” modules provide even more functionality.

Dawn VME Products www.dawnvme.com

Ą Runs on DC or AC (50-440Hz) at 4.5-270V, depending on model.

Ą Controls fan speed on the basis of temperature (power to drive the fans must be provided by an external source).

Ą Monitors 9 fan tachometers. Variable-threshold fan speed error detection for early prediction of fan failures.

Ą Accepts 4 analog or 8 digital temperature sensors. Programmable automatic shutdown on a variety of fault conditions.

Ą Totally configurable through an easy, menu-driven interface. Handles all outputs (LED, LCD, Ethernet and RS-232) simultaneously.

Ą “Sidekick” add-on modules monitor current, AC line (voltage and phase), vibration/acceleration, temperature, humidity, air pressure (down to 0.05” H20).

Ą Rugged – withstands over 15 G’s in all axes. -40C to 85C operation.

https://www.dawnvme.com/shop/rush-system-health-monitors/rush-426-wizard/

sales@dawnvme.com

510-657-4444

ComEth4690e - 3U VPX SOSA® aligned 100GbE Switch

The ComEth4690e is a 3U VPX 100 Gigabit Ethernet Level 2/3 switch aligned with the SOSA® technical standard, compliant with the SLT3-SWH-6F1U7U-14.4.14 profile. It features two separate on-board Ethernet switch matrices, each of them is managed by its own ARM processor, thus completely isolating the Control plane from the Data plane of the 3U VPX system to provide the highest security level ever. The ComEth4690e offers 31 SerDes (DP 24 + CP 7) routed to the rear VPX connectors and 9 Serdes (DP 8 + CP 1) to the front panel. It takes advantage of the modularity of the Ethernet matrices to configure each Serdes (or group of Serdes) individually in 1G-KX, 10G-KR, 25G-KR, 40G-KR4 or 100GKR4 Ethernet mode on the rear and 1/10/25GBASE-SR or 40/100GBASE-SR4 fiber optic ports (MPO connector) on the front. This high-performance switch can be configured remotely via the Switchware web interface, SNMP or CLI. The ComEth4690e is available in a conduction-cooled version.

Ą 3U VPX

Ą Switching for 2 independent domains

Ą VITA 65.0 SLT3-SWH-6F1U7U-14.4.14

Ą Up to 40 ports

Ą 1/10/25GBASE-SR, 40/100GBASE-SR4 (front)

Ą 1GBASE-KX, 10/25GBASE-KR, 40/100GBASE-KR4 (rear)

Ą Aligned with the SOSA® Technical Standard

https://www.interfaceconcept.com/products/ethernet-switches-and-routers/cometh4690e/

Interface Concept www.interfaceconcept.com

SOSA™ Aligned Enclosures, Backplanes, & Chassis Managers

info@interfaceconcept.com 510-656-3400 www.linkedin.com/company/interface-concept

Pixus offers various MIL rugged and COTS enclosure solutions for 3U or 6U OpenVPX boards. There are several SOSA™ aligned slot profiles to choose from, with backplane designs to PCIe Gen4, 100GbE, and High Density 56Gbaud/s speeds. The company also has quick-turn SOSA aligned backplanes in chassis in dozens of SOSA aligned slot profile configurations.

The MIL rugged ATRs utilize a modular design tailored to a customer’s specific application based on proven standard base platforms. Our ATRs come in conduction-cooled, airflow over fins in sidewalls, and liquid through sidewall configurations. Contact Pixus for Air Flow Through (AFT) and Air Flow By (AFB) designs. All Pixus chassis come with the option of our SOSA aligned Tier 3+ chassis hardware manager in a SlotSaver mezzanine format that fits behind the backplane.

Pixus Technologies www.pixustechnologies.com

Ą Pixus offers various MIL rugged COTS enclosure solutions for 3U and 6U OpenVPX / SOSA aligned boards

Ą Backplane design expertise up to and above 100GbE speeds, vast array of SOSA aligned slot profile options

Ą SlotSaver mezzanine-based SOSA aligned chassis hardware manager, Tier 3+, 100% USA software/firmware

Ą Conduction-cooled, airflow through sidewalls, and liquid cooled through sidewall configurations

Ą Quick-turn prototyping and accelerated project development options

Ą Pixus USA is a proud member of the SOSA Consortium

https://pixustechnologies.com/products/category/openvpx

sales@pixustechnologies.com

916-297-0020

Introducing the Kontron VX307H Computing Node, the ultimate SOSA™ Architecture Booster

Offering best-in-class performance and XMC support on VITA 48.8 Air Flow Through (AFT) models, this rugged 3U embedded server card redefines the SWaP-C limits and enhances the capabilities of your HPEC architectures. Designed as a reusable building block with numerous innovations and extensions to fulfill the most demanding mission profiles.

Powered by the Intel® Xeon® D-2700 Platform, the VX307H is offered with a 12, 16, or 20-core processor with features like 100Gb Ethernet, PCIe gen4, and an on-chip DMA engine. AVX-512 VNNI support is engineered for AI, signal processing, and cryptography, offering double the performance over previous generations for critical applications like computer vision and media processing.

The VX307H is available in VITA48.8 AFT and conductioncooled versions, operating in extended temperature ranges and aligned with industry standards. Leveraging the VX307H architecture is a sure way to deploy a vast choice of applications and serve demanding programs with a single computer blade for years to come, optimizing development efforts and long-term logistics.

Unleash the potential of your engineering projects with the SOSA™ Architecture Booster – Kontron VX307H Computing Node.

Contact us to explore how this rugged solution can transform your defense applications.

Ą Intel® Xeon® D-2700 HCC processor with 100Gb Integrated Ethernet

Ą From 12 to 20 processing cores to be adapted to SWaP-C applications

Ą Enhanced instructions for Artificial Intelligence and Signal processing (Intel AVX-512, VNNI)

Ą Up to 64GB DDR4 memory with ECC

Ą New VITA48.8 AFT (Air Flow Through) and VITA47 CC3 (Conduction-Cooled) support

Ą XMC support on VITA48.8 AFT versions

Ą Security enforced by Hardware Root of Trust

Ą Designed in accordance with SOSA™ requirements

Ą Meets VITA 47 class EAC4 V2 (extended temperature environments up to of 0 °C/+55 °C)

Ą Long term availability with 10-years of typical lifecycle

Ą Ensures trustable data with M.2 NVMe SSD Boot storage

LCR’s VE02 chassis broadens the utility of the SAVE standard by enabling dual 4-slot plus power supply VPX SOSA aligned systems to fit within the SAVE envelope for Army ground vehicles. The design facilitates complementary operational or redundancy requirements within the SAVE envelope. Individual cooling systems provide added thermal protection for high power dissipating systems in high speed applications.

SAVE (Standardized A-Kit / Vehicle Envelope) compliant systems ensure component compatibility, upgradability and efficiency in integrating mission systems into army ground vehicles by defining uniform interfaces, physical dimensions, and power requirements. SAVE promotes modularity, reduces costs, and streamlines upgrades across diverse platforms in defense applications.

The custom backplanes support 3U VPX SOSA aligned payload architectures common to systems conforming to the standard and the V02 supports the complete connector complement under the standard. Dual 4 payload and 1 power supply backplanes enable use of commonly applied SOSA aligned modules and their associated profiles. It is specifically designed to accommodate integrated payload combinations in SAVE deployment chassis including Ethernet switch, I/O intensive SBC, radial clock and compute intensive full aperture FPGA/RF cards. The rugged design is intended for deployment in a wide range of C5ISR applications as noted in the SAVE standard. The VE02 reflects LCR’s commitment to COTS open standards chassis and system designs for OpenVPX, CMOSS, and SOSA architectures in accordance with MOSA directives. Custom I/O panels may include the full complement of application driven connectors supporting a wide range of signal speeds and types.

At LCR, our experienced and engaging engineering team will work with you to ensure mission success and LCR program managers are industry professionals who provide highly effective management from program start to finish.

LCR Embedded Systems

Serving critical defense programs for over 35 years

Ą Facilitates complementary operational or redundancy requirements within the SAVE envelope

Ą Dual VE02 chassis meet SAVE dimensional requirements: 9.3" (H), 15.9" (W) x 16.1"

Ą Custom backplane topologies supporting OpenVPX and SOSA aligned payload module profiles

Ą Mil-Std-1275 power supply for ground combat vehicles

Ą Up to 750W VITA 62 pluggable power supply in each chassis mounted within the SAVE envelope

Ą VITA 66 and 67 Optical and RF support

Ą Individual cooling systems provide added thermal protection for high power dissipating systems

Ą Conduction cooled with forced air assist w/dual 92mm mil-rated fans

Ą Application driven custom I/O panels with MIL-STD connectors

https://www.lcrembeddedsystems.com/dual-system-save-chassis/

LCR Embedded Systems ww.lcrembedded.com

sales@lcrembedded.com

www.linkedin.com/company/lcr-embedded-systems-inc-

CONEX® LC Series

The LightCONEX® series of optical plug-in and backplane module connectors for OpenVPX systems is Smiths Interconnect's answer to the stringent SWaP requirements of today’s defense applications in which fiber optics are replacing high bandwidth copper interconnects.

This series of active, blind-mate optical interconnects offers flexibility, light weight, very high bandwidth, and forward compatibility.

The LightCONEX active blind-mate optical interconnect is a revolutionary solution for OpenVPX systems that includes a fixed, plug-in module connector and a floating backplane connector compatible with VITA 66.5 and aligned to the SOSA® Technical Standard.

• Increases volumetric density of 3U and 6U high-speed switch and processor boards by integrating an optical transceiver into a plug-in module connector

• Intermateability with OpenVPX 66.5-defined backplane connectors enables multiple sources and drives faster design cycles

• Reduces SWaP with rugged MIL-STD qualified, edge-mounted, optical interconnects

• Enables ultra-high port bandwidth density of up to 700 Gbps full duplex (28 lanes at 25 Gbps) in a single half-width slot

• Simplifies OpenVPX board assembly and rework by eliminating fiber pigtail on edge-mount transceiver

• 10G and 28G per channel datarates in TRX, TX-only, and RX-only configurations

• OpenVPX single board computing, C5ISR embedded systems

• Available in Styles A, C, C Hybrid, and D

VME and VME64x, CompactPCI, PXI, or OpenVPX chassis are available in many configurations from 1U to 12U and 2 to 21 slots, with power options up to 1,200 watts. Dual hot-swap is available in AC or DC versions, and Vector’s redundant power supply design supports N+1 configurations for high-reliability applications. All chassis support a wide range of backplane types and are built in-house in the USA, ensuring tight process control, high quality, and fast turnaround.

Our platforms are designed with flexibility to accommodate highspeed signaling requirements, rear I/O capability, and thermal strategies suitable for both air- and conduction-cooled environments. Solutions can be tailored to meet demanding electrical, mechanical, and thermal constraints depending on system requirements. Chassis designs support hot-swappable fans, plug-in power modules, filtered airflow, and meet UL, FCC, and IEEE 1101.10/11 compliance standards. All systems are fully assembled, wired, and tested in-house before shipment.

Series 2370 chassis offer the lowest profile per slot. Cards are inserted horizontally from the front, with options for 80mm rear I/O. Chassis are available from 1U, 2-slot up to 7U, 12-slot configurations for VME, CompactPCI, PXI, or OpenVPX systems.

Series 400 enclosures feature side-filtered air intake and rear exhaust, supporting up to 21 vertical cards. Power options include hot-swappable AC or DC supplies with embedded system monitoring for voltage and temperature.

Series 2151 is a rugged 5U chassis supporting up to 8 slots of 3U x 160mm Eurocards with 80mm rear I/O. It accommodates various backplane architectures and can be configured for either forced-air or conduction cooling.

Integration services are available, including system-level assembly, custom wiring, and validation.

We are also the premier supplier of chassis accessories, including custom front panels, card guides, handles, filler panels, air blockers, card extenders, and more – all engineered to meet your integration needs and most items ship from stock.

• Most rack accessories ship from stock

• Modified ‘standards’ and customization are our specialty

• Card sizes from 3U x 160mm to 9U x 400mm

• System monitoring option (CMM)

• AC or DC power input

• Power options up to 1,200 watts

The new VITA 93 – QMC standard addresses the inherent challenges in current mezzanine card standards through its innovative QMC architecture, enabling unprecedented modularity, flexibility, and scalability while maintaining backward compatibility and rugged reliability. VITA 93 – QMC builds on lessons learned from previous standards, blending their best features with new capabilities for the future.

Our QMC Starter Kit provides you the opportunity to gain first experiences with the VITA 93 – QMC standard, showcasing, evaluating, and prototyping the true potential.

TEWS Technologies: Driving Innovation in Embedded Solutions

Leveraging our extensive experience in PCIe-based solutions, TEWS Technologies is committed to leading the adoption of the VITA 93 –QMC standard. Our product portfolio encompasses a range of QMC modules, from simple I/O interfaces to high-performance FPGA-based solutions, along with compatible carrier cards. This initiative underscores our dedication to providing cutting-edge, customizable solutions for diverse applications. Our first products are available with many more to come.

TQMC400 4 Channel Full-Modem RS232/RS422/RS485 Programmable Serial Interface

TQMC401 4 Channel High Speed Sync / Async Serial Interface

TQMC600 Reconfigurable FPGA with Digital I/O

TQMC700 Reconfigurable FPGA with AD/DA & Digital I/O