ADI’s commercial off-the-shelf (COTS) software-defined radio (SDR) system-on-module (SOM) digitizers enable customers to deploy high-performance distributed sensing techniques at the tactical edge, as quickly as possible.

ATR Systems and Chassis

SAVE Compliant Solutions

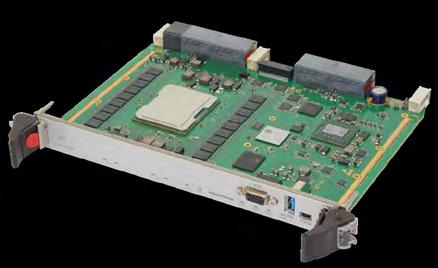

LCR is at the forefront of COTS open standards chassis and custom system designs for VPX, CMOSS, and SOSA architectures in accordance with MOSA directives.

Intelligently engineered designs ensuring operational advantage in the battlefield

SERVING CRITICAL DEFENSE PROGRAMS FOR OVER 35 YEARS

Editor’s Perspective

9 Acquisition … and sustainment reform

By John M. McHale III

Industry Perspective

10 VITA 93 QMC: A modular leap forward for embedded defense systems By Tim Tews, TEWS Technologies

Defense Tech Wire

12 By Dan Taylor

Connecting with Mil Embedded

98 By Lisa Daigle

Guest Blogs

52 Military SBOM adoption: strengthening software supply-chain security By Bob Stevens, GitLab

53 Why MRAM matters more than ever for military embedded systems By David Schrenk, Everspin Technologies

Subscribe to the magazine or E-letter

Live industry news | Submit new products

https://militaryembedded.com/pages/submit

WHITE PAPERS – Read: https://militaryembedded.com/whitepapers

WHITE PAPERS – Submit:

https://militaryembedded.com/pages/submit

TECHNOLOGY UPDATE: Enabling AI in space

14 Onboard space computation strengthens AI-based defense By Ralph Grundler, Aitech

SPECIAL REPORT: Naval radar systems

18 Beyond the horizon: How naval radar is evolving to meet tomorrow’s threats By Dan Taylor, Technology Editor

MIL TECH TRENDS: Test & measurement trends

22 Radar testing in an increasingly contested environment By Haydn Nelson, Emerson Test and Measurement

INDUSTRY SPOTLIGHT:

Managing supply chain, obsolescence, and counterfeit parts

26 Engineering the future of defense systems: A V-model approach to custom embedded solutions By Laure El Mhadder, Milexia

30 Reshaping the contours of warfare: How Western forces are shifting their military strategy By Chris Morton and Bianca Nobilo, IFS

34 Meeting the challenge of airworthiness certification through continuous verification By Jay Thomas, LDRA

40 Onshoring legacy semiconductors: Addressing the supply chain By Lex Keen, SecureFoundry

44 Next-generation fiber optics – the move for modern military and aerospace connectivity By Diana Nottingham, Infinite Electronics

48 Executive Interview: Sustainment reform, obsolescence, aftermarket trends Q and A with Ethan Plotkin, CEO of GDCA By John M. McHale III, Group Editorial Director

To unsubscribe, email

The Arleigh Burke-class guided-missile destroyer USS Delbert D. Black (DDG 119) transits the Mediterranean Sea. Arleigh Burkeclass destroyers have SPY radar on board to locate and track aircraft and missiles.

U.S. Navy photo by Mass Communication Specialist 2nd Class Jimmy Ivy III.

https://www.linkedin.com/groups/1864255/

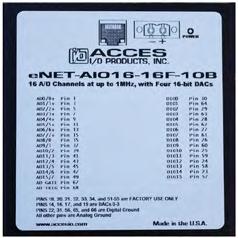

29 ACCES I/O Products, Inc. –M.2 – the new,

world's most advanced 3U OpenVPX rugged modules

Glenair (Heilind/ICC) – ICC connects when failure is not an option –Glenair mil-aero & defense solutions

Interface Concept

Build your HPEC system with our SOSA aligned 3U VPX plug-in cards

7 Kontron – When your system needs more than rugged, you need Kontron 38 Lansdale Semiconductors –Classic designs are timeless 3 LCR Embedded Systems, Inc. –When the going gets tough 41 PICO Electronics Inc –Size does matter! 33 Pixus Technologies –SOSA aligned products in the slot profile configuration you need 28 Sealevel Systems, Inc. –Command the edge

25 Vector Electronics & Technology –19" vertical board mount VPX/VME/cPCI (and more)

17 Wolf Advanced Technology –Rugged, SOSA aligned Nvidia Blackwell 3U & 6U VPX modules

AUSA 2025 October 13-15, 2025

Washington, DC

https://meetings.ausa.org/annual/2025/index.cfm

embedded world North America November 4-6, 2025 Anaheim, CA

https://embedded-world-na.com/

AOC 2025: 62nd Annual Association of Old Crows International Symposium & Convention December 9-11, 2025 National Harbor, MD https://aoc2025.org/

GROUP EDITORIAL DIRECTOR John McHale john.mchale@opensysmedia.com

ASSISTANT MANAGING EDITOR Lisa Daigle lisa.daigle@opensysmedia.com

TECHNOLOGY EDITOR – WASHINGTON BUREAU Dan Taylor dan.taylor@opensysmedia.com

CREATIVE DIRECTOR Stephanie Sweet stephanie.sweet@opensysmedia.com

WEB DEVELOPER Paul Nelson paul.nelson@opensysmedia.com

EMAIL MARKETING SPECIALIST Drew Kaufman drew.kaufman@opensysmedia.com

WEBCAST MANAGER Marvin Augustyn marvin.augustyn@opensysmedia.com

VITA EDITORIAL DIRECTOR Jerry Gipper jerry.gipper@opensysmedia.com

DIRECTOR OF SALES Tom Varcie tom.varcie@opensysmedia.com (734) 748-9660

STRATEGIC ACCOUNT MANAGER Rebecca Barker rebecca.barker@opensysmedia.com (281) 724-8021

STRATEGIC ACCOUNT MANAGER Bill Barron bill.barron@opensysmedia.com (516) 376-9838

EAST COAST SALES MANAGER Bill Baumann bill.baumann@opensysmedia.com (609) 610-5400

SOUTHERN CAL REGIONAL SALES MANAGER Len Pettek len.pettek@opensysmedia.com (805) 231-9582

DIRECTOR OF SALES ENABLEMENT Barbara Quinlan barbara.quinlan@opensysmedia.com AND PRODUCT MARKETING (480) 236-8818

INSIDE SALES Amy Russell amy.russell@opensysmedia.com

STRATEGIC ACCOUNT MANAGER Lesley Harmoning lesley.harmoning@opensysmedia.com

EUROPEAN ACCOUNT MANAGER Jill Thibert jill.thibert@opensysmedia.com

TAIWAN SALES ACCOUNT MANAGER Patty Wu patty.wu@opensysmedia.com

CHINA SALES ACCOUNT MANAGER Judy Wang judywang2000@vip.126.com

CO-PRESIDENT Patrick Hopper patrick.hopper@opensysmedia.com

CO-PRESIDENT John McHale john.mchale@opensysmedia.com

DIRECTOR OF OPERATIONS AND CUSTOMER SUCCESS Gina Peter gina.peter@opensysmedia.com

GRAPHIC DESIGNER Kaitlyn Bellerson kaitlyn.bellerson@opensysmedia.com

FINANCIAL ASSISTANT Emily Verhoeks emily.verhoeks@opensysmedia.com

subscriptions@opensysmedia.com

• MIL-DTL-38999 Series 80 Mighty Mouse

• MIL-DTL-38999 Series Ill SuperNine®

• MIL-DTL-83513 Micro-D

• MIL-DTL-32139 Nano Miniature

• Armorlite'" EMI/RFI Braided Shielding

For 40 years, ICC has supported the strict needs of our customers with value-added assembly, kitting, and packaging of QPL MIL-SPEC and commercial lines. Value added assembly services are available for select Glenair lines.

By John M. McHale III, Editorial Director John.McHale@opensysmedia.com

Semiconductor companies that don’t care about the defense market, quickly obsolete chips, new product lines incompatible with previous ones, and expensive end-of-life buys: all chapters in “The Dark Side of COTS,” a scary book for many defense engineers, giving them procurement nightmares.

That book isn’t real – I made it up just now. But the obsolescence headaches that commercial off-the-shelf (COTS) products gave to engineers over the last three decades have been quite real. COTS obsolescence has also been a main topic of our September issue year in and year out, and this year is no different.

COTS – which sprung from a 1994 Department of Defense (DoD) memo from then-Defense Secretary William Perry –was an example of procurement reform. The COTS memo calls for the use of COTS hardware and software in all programs. It was an effort to reduce life cycle costs and, of course, to combat the bad press the DoD got from the oft-cited $400 hammers and $2,000 toilet seats.

More than 30 years later, we find ourselves riding another wave of acquisition/ procurement reform with the DoD’s mandate to use a modular open systems approach (MOSA) in all new programs and technology refreshes. And while MOSA means more COTS in some cases, what it really does is lower longterm life cycle costs of programs by enabling faster upgrades via open architectures, common interfaces, and reusable software.

The Trump administrat ion is looking for further reforms to speed up getting technology – especially autonomous systems – to the warfighter more quickly.

But how do we sustain all this new tech while still having to interface with legacy systems inside platforms that must operate for decades?

Sustainment reform is needed along with acquisition reform, says Ethan Plotkin, CEO of GDCA, a legacy equipment manufacturer (LEM), in an interview on page 48. “Sustainment reform is featuring policies and practice that enable defense programs to more quickly evaluate all available options around sustainment, including engaging legacy equipment manufacturers to establish new sources of supply, basically restarting the production line in partnership with OEMs,” he told me.

LEMs like GDCA are the ones that keep producing parts for mission-critical applications long after the original manufacturer has stopped production. Plotkin cites one VME part that is more than two decades old and still performing reliably for a combat application.

Maintaining a reliable supply chain in the blur of accelerated acquisition and procurement reform is as critical as the new technology being developed.

The Ukraine combat zone is an example of how small drones can be a force multiplier on the battlefield, but it also shows the critical importance of maintaining and sustaining all this new equipment.

IFS’s Chris Morton and Bianca Nobilo write on page 30 that “Ukraine’s artillery consumption outstripped NATO’s production capacity within months, underscoring a fundamental issue: Western defense industries had become structured for peacetime efficiency, not wartime urgency.” They say the slow, bureaucratic procurement cycles led to a model that “is no longer tenable.” Morton and Nobilo call for a flexible, modernized defense industrial base relying on artificial intelligence (AI)-driven logistics and quantum computing-enhanced simulations. “Predictive logistics, already in use in Ukraine, anticipates battlefield demands, ensuring supplies are replenished before critical shortages occur,” they assert.

In the long run, successful MOSA efforts will help with sustainment and the supply chain by enabling faster upgrades with reduced downtime for platforms.

Tanika Watson, executive leader for the GE Aerospace Future Vertical Lift business (in an interview earlier this year) told me that MOSA is already easing modification. The digital backbone in the Future Long Range Assault Aircraft (FLRAA) program “provides the customer with a vendor-agnostic path to make aircraft system modifications with ease when needed,” she said. “They can realize the benefits of MOSA designs from the outset of Future Vertical Lift programs.”

Acquisition reform can speed up technology to the warfighter and sustainment reform can ensure the supply chain stays strong while also combating component obsolescence. But what about the software verification, perhaps the most expensive part of any defense system?

“To be successful, development teams need to adopt a bigger-picture approach that addresses verification throughout the entire software development life cycle,” writes Jay Thomas, director of field development for LDRA, in his article on page 34. He talks about how a DevSecOps [development/security/operations] framework can help reduce costs and risk while improving efficiencies.

So read on. Hopefully it’s less frightening read than the “Dark Side of COTS.”

By Tim Tews

The defense landscape is evolving rapidly – nowhere more visibly than in the skies over Ukraine. There, small, cost-effective drones have become indispensable tools for surveillance, targeting, and tactical disruption. This shift underscores a broader reality: embedded systems must now be smaller, more modular, and rapidly adaptable to new mission requirements. Platforms must be smaller, more modular, and rapidly upgradable. One powerful response to these demands is the emergence of the VITA 93 QMC standard that brings unprecedented modularity, flexibility, scalability, and ruggedness to system designers, making it highly relevant to modern defense and aerospace applications.

In mid-2025, the VITA 93 standard reached a critical milestone as the VITA Standards Organization (VSO) finalized the core mechanical and electrical specifications, and early adopters, including TEWS Technologies, announced their first modules and carriers in alignment with the new standard and first products are expected to be shipped in fall of this year. The announcement of the new standard raised a lot of interest in the market while the ecosystem continues to gain momentum. More product announcements from VITA member companies are expected in the near future.

The VITA 93 working group continues its work by drafting the VITA 93.1 substandard, defining QTM [QMC Transition Modules], small expansion mezzanine modules that will allow interchangeable connector interfaces on QMC carrier cards enabling even more flexibility and modularity.

A strategic leap forward

While mezzanine standards like PMC and XMC continue to play an important role in many embedded systems, evolving application demands – particularly those involving higher I/O density, greater thermal efficiency, and increased modular scalability – have driven the development of new approaches. VITA 93 was created to complement these existing standards by addressing emerging challenges in next-generation designs that require enhanced performance and flexibility across a broader range of platforms.

The VITA 93 standard introduces a modular, stackable mezzanine architecture that supports up to PCIe Gen 6 and allows configurations ranging from a single QMC (26 mm by 78.25 mm) to a quad QMC module (104.375 mm by 78.25 mm). This flexibility makes it a strong fit for systems requiring everything from basic serial I/O to complex, high-throughput sensor processing.

Moreover, VITA 93 is designed with interoperability at its core. A single QMC module can be installed on any compliant carrier regardless of stacking height, cooling method, or vendor. This level of abstraction not only simplifies integration but also promotes ecosystem development and competitive innovation – core goals of the modular open systems approach (MOSA) and related initiatives like the Sensor Open Systems Architecture, or SOSA, Technical Standard.

What sets VITA 93 apart?

Several technical innovations distinguish VITA 93 from prior mezzanine solutions:

1. Scalable architecture: VITA 93 defines four module sizes – single, double, triple, and quad – each supporting a proportional increase in PCIe lanes and I/O pins. A single QMC module offers PCIe x4 and 40 I/Os, while a quad module scales to PCIe x16 and 160 I/Os. This approach enables system designers to

choose the right footprint and bandwidth without needing to change carriers.

2. Universal cooling design: A major pain point in prior standards was the mechanical incompatibility between air-cooled and conductioncooled variants. VITA 93 solves this by using a unified mechanical layout. Designers can convert between cooling types simply by replacing the heatsink, with no PCB redesigns or additional variants needed. The conduction-cooling mechanism also offers superior thermal performance compared to legacy solutions. (Figure 1 & Figure 2.)

3. Flexible stacking heights: To support diverse mechanical envelopes, especially in VPX systems, VITA 93 carriers define four stacking heights – 9, 11, 14, and 16 mm – accommodating tight spaces and maximizing usable PCB [printed circuit board] area. This variable stacking height model enables designers to add components underneath the QMC, optimizing space without sacrificing performance.

4. Simplified system integration: With standardization of interfaces and mechanical dimensions, QMC modules can be swapped across different platforms and carriers. System architects no longer need to coordinate tightly between I/O design and carrier layout, drastically reducing integration effort and time to market.

5. Robust I/O organization: The 40 I/Os of a single QMC are organized into five IOPIPEs, each offering eight single-ended or four differential I/Os. Each IOPIPE comes with its individual ground supporting the integration of isolated interfaces. This setup also aligns well with military applications requiring discrete signal channels and galvanic isolation.

Scaling I/O in a VPX-centric world

VPX is a robust and proven platform, especially with 3U and 6U form factors aligned to the Sensor Open Systems Architecture, or SOSA, Technical Standard and the CMOSS architecture. System integrators face a recurring bottleneck, however: Each VPX slot is expensive, and traditional mezzanine cards like XMC can only offer limited flexibility due to its size; for example, a 3U VPX card can hold only one XMC.

Its smaller footprint enables multiple QMC modules on a single 3U VPX carrier, supporting multifunction processing without the need for multiple full-sized cards. As the military moves toward software-defined multifunction systems, this ability to pack heterogeneous I/O and compute onto one card becomes vital.

Moreover, the modular nature of VITA 93 aligns with the principles of MOSA, offering interoperability, vendor independence, and rapid upgradability – key demands for programs adhering to SOSA aligned procurement mandates.

Integration into the broader VITA ecosystem

VITA 93 does not exist in isolation – it’s a complementary addition to standards like VPX (VITA 46/48), VNX+ (VITA 90), and even external standards bodies such as PCI-SIG and PICMG. This interoperable nature ensures broad applicability in systems built on PCIe, CompactPCI Serial, and other small-form-factor platforms.

In a world where new threats emerge faster than procurement cycles, VITA 93 offers a new blueprint for agility. It meets the growing needs for flexibility, performance, and interoperability in a way that legacy standards simply cannot. Whether enabling scalable mission computing at the tactical edge or facilitating rapid system upgrades in airborne ISR [intelligence, surveillance, and reconnaissance] platforms, QMC is a timely and powerful addition to the modular embedded ecosystem.

QMC modules enable designers to add or swap new I/O capabilities at the module level without redesigning carriers or consuming precious slots. For defense contractors adapting rapidly to changing mission profiles, QMC delivers the time-to-market, cost, and SWaP advantages they need to remain competitive and mission-relevant. With ratification underway and productization accelerating, VITA 93 is not just a new standard – it is the future of mezzanine I/O.

Tim Tews is one of the two general managers at TEWS Technologies. TEWS Technologies – which provides rugged COTS [commercial off-the-shelf] and custom solutions for defense and aerospace applications – has been an active VITA member for well over 30 years. Together with Jan Zimmermann, Tim successfully managed the company’s succession and is responsible for all aspects of the business, especially its strategy and business development. Tim holds an MBA and master’s in project management from Bond University, Australia.

TEWS Technologies https://www.tews.com/

For more info on the TEWS Technologies white paper, please visit https://tinyurl.com/9d5nunr8

• Various SOSA® slot profiles supported

• High-speed dual-plane 100 Gigabit Ethernet Switches

• Arm®/Intel®-based Single Board Computers

• VITA 66.5 FPGA boards

By Dan Taylor, Technology Editor

Autonomous surface vessel Defiant christened under DARPA NOMARS program

DARPA held a christening ceremony for the USX-1 Defiant, an autonomous unmanned surface vessel (USV) built under the No Manning Required Ship (NOMARS) program. The 180-foot-long, 240-metric-ton vessel is designed from the keel up to operate without human crew, with a simplified hull intended to enable faster production and maintenance in smaller commercial shipyards, according to a statement from DARPA. Defiant is undergoing final systems tests ahead of an extended at-sea demonstration to evaluate reliability and endurance.

According to DARPA, the vessel is built to operate in openocean conditions, including sea state 5/rough conditions without performance degradation, and to resume operations after more severe weather. The NOMARS program seeks to advance the development of fully unmanned ships, reducing reliance on optionally manned platforms and demonstrating scalability for U.S. and allied naval use. Following the agency trials, Defiant will be transferred to the U.S. Navy.

Stalker drone selected for prototype phase of Army’s long range reconnaissance program

Redwire subsidiary Edge Autonomy won a prototype contract from the U.S. Army to provide its Stalker uncrewed aerial system (UAS) for evaluation under the Army Long Range Reconnaissance (LRR) program. The prototype systems will include modular payloads, secure communications, autonomous mobility, and advanced sensors tailored to meet various mission profiles, according to the Redwire announcement. The Army is expected to conduct operational testing in the coming months.

Edge Autonomy’s Stalker UAS was developed with a modular open systems approach (MOSA), which the company says supports flexibility and mission-specific configurations. Redwire says that the platform is designed to deliver long-endurance surveillance and reconnaissance capabilities in contested or remote environments, while providing real-time data to support battlefield decision-making.

Radar platform used by missile agency focus of $311 million deal

Vessel-construction company Tote Services won a firmfixed-price contract with the U.S. Navy, worth as much as $311.4 million, to support the operations and maintenance of the Navy’s Sea-Based X-Band Radar (SBX-1), a semi-submersible, self-propelled platform that provides ballistic missile tracking information for the U.S. Missile Defense Agency (MDA).

The vessel is operated for the MDA to provide limited testsupport services and is a contingency component of the Ground Based Mid-Course Defense element of the Ballistic Missile Defense System for the U.S. Strategic Command. The Navy’s Military Sealift Command describes the SBX-1 as a 389-foot by 238-foot platform that operates with 34 civilians and 49 military personnel onboard. The contract concludes in March of 2031.

High-power laser weapon system ordered by NATO country for counter-drone missions

Electro Optic Systems (EOS) will deliver a 100-kilowatt class high-power laser weapon system to a European NATO member for counter-drone operations, the company announced. The 71.4 million euro ($83.3 million) order includes production, spare parts, training, and documentation, and is scheduled to be fulfilled between 2025 and 2028.

According to the company statement, the laser system addresses emerging threats posed by drone swarms and includes integrated subsystems such as radar, threat detection, target acquisition, and beam control. EOS says this is the first export order globally for a laser weapon of this power class. The system builds on the company’s previous work in kinetic counter-drone systems and was developed following three years of testing.

AI technology from Oxford Dynamics to be integrated into BAE Systems platforms

BAE Systems made an equity investment in Oxford Dynamics, a U.K.-based startup focused on artificial intelligence (AI) and robotics, as part of a strategy to accelerate the integration of emerging technologies into defense systems.

The first phase of the collaboration, say BAE Systems officials, will integrate Oxford Dynamics’ AI technology into BAE Systems’ Prophesea platform, a digital tool designed to monitor and sustain mission readiness across military assets such as warships, armored vehicles, and aircraft. Founded in 2020, Oxford Dynamics develops AI-powered autonomous systems that interpret data, coordinate actions, and support realtime decision-making. According to the company, the technology aims to improve planning and response in complex operational environments. Oxford Dynamics will continue to operate as an independent company.

Commercial SATCOM services for U.S. Army to be provided by SES Space & Defense

SES Space & Defense won a five-year, $89.6 million Sustainment Tactical Network (STN) contract to provide commercial satellite communications (COMSATCOM) services to the U.S. Army. The contract includes global Ku-band geostationary satellite bandwidth and commercial teleport services, supported by the Commercial Satellite Communications Office (CSCO) under the aegis of the U.S. Space Force, to deliver strategic long-haul network transport and base-support communications.

According to the company, the STN service integrates commercial satellite links with terrestrial networks to connect teleports and global network centers, ensuring worldwide coverage for Army operations. SES Space & Defense reports that it has previously provided similar services under another military program.

Uncrewed systems for military to reach $47 billion by 2032, survey predicts

The size of the military uncrewed aerial system (UAS) market is projected to reach $47 billion by 2032, driven largely by increasing military spending and the growing procurement of military drones by nations’ defense forces, according to a market survey by MarketNewsUpdates.

The study authors cite the global military UAS market size as $14.14 billion in 2023, projecting that it will grow from $16.07 billion in 2024 to $47.16 billion by 2032, exhibiting a combined annual growth rate (CAGR) of 13.15% during the forecast period. In terms of region, the survey found that North America dominated the military UAS market in 2023, with a market share of 36.1%. The U.S. in particular is projected to experience major growth in the UAS market, reaching an estimated value of $10.71 billion by 2030.

By Ralph Grundler

As artificial intelligence (AI) capabilities for space advance, onboard edge processing is also improving, providing nearreal-time access to data insights that were previously unobtainable. It’s a shift from information access to actionable intelligence, as AI helps manage the increasingly crowded data landscape and enhance electronics operating in the space environment. Preprocessing at the edge provides less – but more valuable – data, optimizing transmission bandwidth and reducing data latency to rapidly deliver critical information directly to the point of need. Onboard AI is also being used to monitor space systems and manage in-orbit communication, troubleshoot onboard operations, and enable dynamic mission shifts.

Artificial intelligence (AI), broadly speaking, comes with many different algorithms that are applied to various applications. The key to using AI for space is to understand what algorithms are most relevant to facilitate edge processing and computation within a space system. One example is the International Space Station, which currently has very

controlled use cases of large language models (LLMs) in progress, but most space applications will involve machine learning (ML).

ML, a function very familiar to military and defense, is currently providing most of the edge-processing applications on Earth, and this concept can easily

translate into the space environment. As the preferred AI method to take complex situations and boil them down to a simple mathematical probability, ML can provide guidance for many edge applications, such as providing input on what action to take within a space system’s main command and data handling (C&DH) functions.

Space ecosystems with robust data-processing capabilities continue to evolve, integrating enhanced surveillance, image processing, communications, and video analytics. These systems are being designed to not only process information, but also compute the data on board and provide only relevant information to the warfighter, giving them an extra split-second decision-making advantage during defense operations. Winning the battle goes beyond weapons and platforms; it’s about processing information faster and computing that data more accurately to provide the users with that crucial edge. (Figure 1.)

Expanding autonomous space applications

AI-based intelligence is enhancing operations within and among in-orbit autonomous space systems, leading to more intuitive computing capabilities. Powerful and compact space-rated systems are fueling new areas of autonomous space capabilities, such as advanced image, signal, and edge processing in areas as diverse as object detection, threat assessment, and earth observation.

Satellite constellations are another excellent example of autonomous operations. Simple AI/ML algorithms can engage controls to reorient the satellite to change the drag profile and change the position of the satellites or space vehicles. Not only can AI maintain the relative positions of each satellite in real time, but the AI engines in the swarm can also autonomously reconfigure a specific satellite’s mission profile to adapt to the mission requirements.

System-based operations

The most common hardware approach to AI/ML is using GPGPUs [general-purpose computing on graphics processing units], where hundreds or thousands of processors run in parallel, which is instrumental in managing the increased computational demands of today’s space-based systems. Nowhere is data input, processing, and clarity more applicable than in mission-critical military operations. GPGPU-based processing can manage the exponential number of data inputs and image resolution now used in space systems. The method is flexible to be reprogrammed for the changing missions.

GPGPU processing has helped to elevate AI to places where it can help optimize complex, highly sophisticated computing by reliably managing higher data throughput and balancing system processing for more efficient computing operations.

AI-enabled constellations

AI-based constellations are revolutionizing what is possible in space applications. IQSat, the first AI-enabled PicoSat of its kind, uses onboard AI and ML to actively interpret and analyze data directly in space, unlike traditional satellite systems that passively collect data. This AI/ML onboard capability drastically reduces the time between data collection and actionable insight, so what once took hours or days can now happen in near-real-time. Critical information, like tactically actionable updates, is delivered directly to the user.

Using Intuidex's Higher Order-Low Resource Learning (HO-LRL) date-modeling technology, the small, rugged platform detects patterns, anomalies, and changes in behavior as they happen, not just after the fact. IQSat is small enough to be held in the palm of your hand and can be deployed in a constellation of five to thousands. (Figure 2.)

Operating in a constellation adds more complexity to the flight software of the satellite. These additions may include constant adjustments to maintain the correct operational formation plus coordinating the multiple functions across different satellites, depending on the task at hand. These are all functions that are expertly handled using AI. In the event of a satellite malfunction, AI algorithms can detect failure and enable one of the other satellites in the constellation to provide the needed functionality and turn off the other payloads.

This new AI-enabled space-based technology reduces latency, improves response times, and ensures continuity in extreme environments where communication is limited. Using AI in this way not only enables dynamic onboard response for autonomous system management, but also gives the user unprecedented intelligence insight into critical areas such as surveillance, threat detection, object tracking, strategic monitoring, and border security.

Building space electronics also centers on risk-mitigation strategies. Successfully applying AI-based technologies within in-orbit networks requires ruggedization to withstand the extreme environmental factors of space, with careful consideration of parts testing and characterization prior to launch, shielding, redundancy, power management, and EMC mitigation.

Edge AI hardware in space-rated systems requires a very different degree of survivability than what is required in automobiles or factories. Specific techniques are used to ensure that edge-processing hardware can endure the harsh environment of space and that the onboard AI/ML capabilities can help moderate and manage the system in response to environmental effects through checking for anomalies.

Radiation: The biggest and most concerning issue of space flight is radiation. For lower-orbit and shorter missions, radiation can impact the life of satellites or impact function when there are stronger solar events while being deployed. For longer-term missions in deeper orbits, resilience to prolonged radiation exposure is critical for mission success. There are several well-known techniques – such as shielding and redundancy – that can help mitigate radiation, but depending on the application, these techniques can have a varied degree of success and the extra weight is not always possible.

Another mechanism that can be used in a space-rated system is the ability to restart: Special hardware can be used that considers the impact of radiation so that it knows when to power off and back on after annealing has occurred or solar radiation has passed.

Electromagnetic compatibility (EMC): EMC can affect the vehicle itself or the multiple payloads within, causing interference and disruption. By testing and understanding the EMC profile of the different payloads as well as of the vehicle, special hardware can reduce the power of the vehicle to make sure there is no interference and that the payload or vehicle will work properly. Testing to prove survivability is adequate in most use cases.

Edge AI hardware in space-rated systems requires a very different degree of survivability than what is required in automobiles or factories.

Heavy ion damage: It is crucial to understand the effects of heavy ion damage –a special form of radiation from deep space – to the space vehicle and the payload. Testing and characterization can help prepare hardware and software to mitigate these events, a critical use of successful AI applications in space.

Up-to-date operational intelligence is paramount to the success and safety of modern defense initiatives, and AI has a unique opportunity to provide significant benefits across a range of activities. Today’s AI-enabled space-based infrastructure is helping to fuel definitive strategic shifts in modern warfare, not only by helping to manage the data available from today’s embedded systems, but also by facilitating the processing and computation of that data in near-real-time. The resulting reduced latency and optimized bandwidth usage provides critical actionable data to the end use or for the system to act autonomously. MES

Ralph Grundler is Director of Space Business Development and Space R&D at Aitech. Ralph has 30 years of computer and semiconductor industry experience, particularly in the development and marketing of semiconductors, IP, SoCs, FPGAs, computers, and embedded systems. Before joining Aitech, he worked at Flex Logix, a supplier of radhard eFPGA technology; and Synopsys, where he did marketing for interface IP subsystems working with space ASIC developers and IP prototyping hardware as well as business development for the Japanese market.

Aitech • https://aitechsystems.com/

Naval radar systems

By Dan Taylor

Naval radar operators peer at screens filled with hundreds of contacts that could be anything from harmless seabirds to coordinated drone attacks. Artificial intelligence (AI) algorithms sort through ocean clutter in real time, distinguishing genuine threats from false alarms in seconds rather than minutes. Software updates push new threat recognition capabilities to radar systems overnight. These systems are the new reality of modern naval radar technology: mechanisms that must evolve continuously to counter threats that are smaller, cheaper, and more numerous.

Recent conflicts have demonstrated how small, inexpensive drones and other lowsignature threats are changing naval warfare fundamentals. Where naval forces once prepared for high-value targets like fighter jets and cruise missiles, they now face swarms of expendable platforms that can overwhelm traditional defense systems through sheer numbers and unpredictable behavior.

From improved detection algorithms to entirely new testing methodologies, the naval radar industry is rebuilding itself around the reality that tomorrow’s threats will be smaller, smarter, and more numerous than anything previous generations of military personnel have faced. The solutions emerging from defense contractors reveal how quickly naval forces must adapt to maintain their edge in an increasingly contested maritime environment.

Searching through the swarms Naval radar operators face a problem that would have seemed impossible just a decade ago: too many targets to track. Small swarms of uncrewed aerial systems (UASs) can deploy dozens or hundreds of platforms simultaneously. This new situation creates “a high-density tracking environment that stresses radar beam management and processing resources,” says Miki Daniel Nielsen, manager of naval sales at Terma (Arlington, Virginia)

Nielsen. “Small drone swarms represent a fundamentally different challenge to naval radar systems compared to traditional threats such as aircraft or surface vessels,” Nielsen says. “While conventional threats are few and high-value, swarms may involve dozens or even hundreds of low-RCS [radar cross-section] drones moving unpredictably and often at low altitudes.”

The challenge goes beyond sheer numbers. Small UASs naturally mimic harmless objects that naval radar systems encounter daily

“Their signatures may resemble those of birds or wave tops, increasing the risk of missed detections if the radar is not optimized for high-resolution discrimination in such environments,” Nielsen notes.

Perhaps most troubling for operators is what Nielsen describes as “the question of intent.” A drone swarm might include platforms that look identical on radar but serve completely different purposes –some gathering intelligence, others jamming communications, and still others carrying weapons. This ambiguity forces split-second decisions about which contacts pose the greatest threat.

Terma’s response centers on artificial intelligence (AI) that can learn to distinguish patterns in real time. Traditional radar processing relies on fixed rules to filter out false returns from waves and weather, but these methods struggle with low-signature threats like drones. (Figure 1.)

“AI changes the game by enabling pattern recognition that adapts in real time,” Nielsen says. “Machine learning models can be trained on radar return profiles, EO/IR [electro-optical/infrared] signatures, and behavioral patterns to identify and classify targets with a higher degree of confidence – even when signal-to-noise ratios are low.”

The company’s AI-based classifier can recognize and categorize small drones at significant distances, helping operators focus on genuine threats while filtering out harmless contacts. The system also

combines inputs from multiple sensors – radar, EO/IR, electronic support measures, and automatic identification systems – to create what Nielsen calls “a unified target picture that’s far more accurate than any single-sensor feed.”

Looking ahead, Nielsen says his company sees radar systems evolving from simple detection tools into decision-support systems that help smaller crews manage increasingly complex threats.

“Radars must evolve from pure sensors into decision-support systems, offering clarity in complexity,” Nielsenhe asserts, pointing to the trend toward leaner crew structures across naval forces.

Recent conflicts have made one factor particularly urgent: detecting threats that fly just above the ocean surface where traditional radar systems struggle to see them.

Northrop Grumman produces the AN/SPQ-9B radar, which uses X-band technology specifically designed to counter sea-skimming antiship missiles that other radar frequencies might miss entirely.

“X-band radars excel at detecting sea-skimming missiles, as they offer higher resolution for distinguishing small targets and increased accuracy tracking fast-moving targets

compared to other radars,” says Greg Teitelbaum, vice president of maritime/ land systems and sensors at Northrop Grumman (Falls Church, Virginia).

The challenge of detecting low-flying threats becomes exponentially more difficult when waves, weather, and electronic interference create what radar operators call “clutter” – false returns that can mask genuine threats. Northrop Grumman has developed enhanced signal processing techniques that they say help X-band radars cut through this interference more effectively than other systems. (Figure 2.)

Teitelbaum points to operations in the Red Sea as an example of how “increasingly sophisticated threats necessitate faster decision-making, which requires software-defined systems that allow for the rapid introduction of advanced capabilities.”

This lesson has shaped Northrop Grumman’s approach to developing nextgeneration maritime radars, Teitelbaum notes. The execut ive says t hat the company is moving toward digital software-defined architectures that can be updated rapidly as new threats emerge, rather than requiring lengthy hardware modifications.

“Our digital software-defined radars [enable] more precise detection measurements of range and velocity,” he explains, adding that the modular design also means these systems can be installed quickly across different types of ships without extensive modifications to existing platforms.

Northrop Grumman is developing technologies aimed at countering hypersonic and other advanced antiship weapons using a new maritime X-band radar. This system will use distributed filtering and advanced beamforming techniques designed to perform in what Teitelbaum calls “today’s most challenging electromagnetic environments.”

With this technology, ships can “see through noise and operate effectively in increasingly complex electromagnetic environments,” he adds.

Radar systems as building blocks

Raytheon (Arlington, Virginia) is taking a different approach with its SPY-6 radar family by building systems that the company claims can handle multiple missions simultaneously while adapting quickly to new threats through software updates.

Older systems like the SPY-1 were built as single, large units, but SPY-6 uses modular building blocks that can be scaled to fit different ships and mission requirements.

“SPY-6 is the Navy’s first truly scalable radar,” says a Raytheon SPY-6 spokesperson. “Each radar is built with individual ‘building blocks’ called radar modular assemblies (RMAs). Each RMA is a self-contained radar antenna in a 2-foot-by-2-foot-by2-foot box. The RMAs stack together to fit the mission requirements of any ship.” (Figure 3.)

This modular approach enables what Raytheon calls Distributed Maritime Operations, in which sensors across different platforms can work together to create a comprehensive picture of the battlespace.

“Distributed sensors across land, sea, and air domains can be connected to provide a detailed picture across a large area, allowing for improved tracking of ballistic missile targets,” the spokesperson explains.

Recent naval operations have highlighted another key advantage of the SPY-6 design: ammunition conservation. In environments like the Red Sea during the past several years, where ships face sustained threats over extended periods, the ability to engage targets more efficiently becomes critical.

“SPY-6 provides better detection and tracking capabilities, not only allowing sailors to identify threats earlier, but they also reduce the number of missiles needed to be deployed per threat, which allows for more Vertical Launch System (VLS) cell offensive opportunities,” according to the Raytheon spokesperson.

“This is critical as conserving munitions is a big factor in the Red Sea conflict.”

Raytheon has designed SPY-6 around software-defined capabilities that can be updated rapidly as new challenges emerge. The company uses what the spokesperson describes as “a baseline of software code that’s continually upgraded, shared, and re-used across multiple radar programs – similar to the apps you use on your smartphone.”

This approach enables Raytheon to gather data from military exercises and conflicts to enhance radar performance across its entire product line, then push

those improvements to deployed systems through software updates rather than hardware modifications, the spokesperson notes.

Rayt heon’s Andover, Massachusetts facility houses both radar development and a military-grade gallium nitride (GaN) foundry, enabling the company to control the entire development process from advanced materials research to final system integration.

“As technology needs advance and change, the foundry evolves to create trusted differentiating capability,” says the Raytheon spokesperson. MES

Keysight Technologies (Santa Rosa, California) faces the challenge of testing increasingly complex radar systems before they ever reach a ship. The company's work reveals how difficult it has become to validate radar performance when the threats themselves are constantly evolving.

“Modern naval radar systems face increasingly complex testing challenges due to the evolving nature of electromagnetic warfare,” says Chris Johnston, director of radar and electronic warfare test solutions at Keysight Technologies. “Traditional test and evaluation methods are insufficient to meet the demands of today’s operational environments.”

The shift toward software-defined radar systems has fundamentally changed how testing works. Whereas older radar systems had fixed capabilities that could be tested once and certified, today’s platforms can be reprogrammed with new software that changes their entire behavior. (Sidebar Figure 1.)

“Stakeholders now expect sub-24-hour turnaround times for system updates and validation,” Johnston explains.

The question becomes even more complex when considering how modern naval radars integrate with other systems.

“Multifunctional platforms integrating radar with other subsystems require comprehensive testing across all domains,” Johnston notes. Testing a radar system now means validating how it works with electronic warfare (EW) systems, communications networks, and weapons-control systems simultaneously.

Keysight sees even bigger changes coming as new technologies mature. Quantum sensing and computing promise unprecedented sensitivity and resolution, but they also “introduce challenges in signal validation and environmental control,” Johnston says.

Similarly, AI-driven radar systems that use machine learning (ML) for adaptive signal processing will require completely new approaches to testing.

“AI-driven radar systems using machine learning for adaptive signal processing will require innovative built-in test strategies and fault isolation techniques,” he explains. Traditional testing assumes predictable system behavior, but AI systems learn and adapt in ways that can be difficult to anticipate.

Keysight engineers are also preparing for passive radar systems that detect targets by analyzing reflections from commercial radio and television signals rather than transmitting their own radar beams.

“As undetectable passive radars gain prominence, testing must evolve to assess their unique operational characteristics,” Johnston notes.

Looking ahead, Johnston says he sees testing methodologies evolving to match the increasing software focus of naval radar systems. While hardware capabilities like resolution and signal power remain governed by physics, software now handles most of the critical functions including signal classification, threat identification, and adaptive beamforming.

This shift means “testing methodologies must evolve to validate both hardware performance and software adaptability, ensuring seamless integration and mission effectiveness,” he says.

By Haydn Nelson

Radar systems are critical for situational awareness, threat detection, and tracking, and their mission only becomes more challenging with time. In today’s congested and contested electromagnetic spectrum, systems must contend with dense signal environments, deliberate interference, and deceptive transmissions, all while evolving toward greater adaptivity, agility, and resilience. Keeping pace with these advancements requires equally sophisticated validation and test strategies.

Radar development for military use is increasingly focused on integration, adaptability, and software-defined operation. Many systems now combine radar, communications, and electronic warfare (EW) into a single radio-frequency (RF) front end, expanding capability while also introducing new layers of complexity. Cognitive radar architectures are also gaining ground, using machine learning (ML) to adjust waveforms, optimize beamforming, and avoid interference in real time. Advances in digital programmable arrays, such as act ive electronically scanned arrays (AESAs), are enabling finer spatial control and

greater agility. These designs introduce new requirements for precise synchronization across wide bandwidths and densely populated signal channels.

These innovations pose definite hurdles for validation and test. Modern radar systems must perform reliably across a broad set of conditions, including rapidly changing signals, fluctuating spectrum access, and environments where signals may be ambiguous or deliberately deceptive.

Simultaneously, development cycles are accelerating. Test teams are now expected to verify more functionality across a wider range of mission scenarios, all within shorter timeframes. This shift is driving the need for flexible, programmable test environments that can accurately simulate dense RF activity and adapt to evolving system requirements.

Effective radar testing today depends not only on high signal fidelity, but also on the ability to respond in real time. Systems must support precise control over timing, Doppler

effects, and signal amplitude in order to evaluate behaviors such as target discrimination, agile beam steering, and interference rejection under realistic conditions.

The moder n RF battlespace

Electromagnetic spectrum operations (EMSO) have expanded the threat landscape from physical platforms to signallevel act ivit ies. In this domain, radar systems must detect, track, and classify targets while navigating jamming, spoofing, and spectrum denial.

Testing in this context brings new challenges that reflect the contested and rapidly evolving environment of the RF spectrum. Radar systems are expected to maintain performance amid dense signal congestion, where military and commercial emitters operate in close spectral proximity. They must also withstand intentional interference, including adaptive jamming techniques that can evolve and change during operation. As spectrum use becomes more dynamic, systems need to switch frequencies, modulate waveforms, and reconfigure beams on extremely short timelines, often within a few milliseconds. Validating these behaviors requires test setups that can generate and manage multiple RF signals at once, while keeping precise control over timing and signal characteristics.

These conditions are difficult to replicate in traditional test environments. Over-the-air (OTA) testing and open-air ranges offer realism but lack repeatability and control. Chamber-based or hardware-in-the-loop (HIL) setups offer isolation and precision but require flexible instrumentation capable of real-time emulation.

Meeting these demands calls for a shift in how radar testing is approached. Modern test environments must be built on modular systems that use reconfigurable signal transceivers, wideband RF inputs and outputs, and open software interfaces. This combination enables test engineers to model evolving spectrum threats, inject interference with precision, and observe system responses under repeatable, high-fidelity conditions that support both validation and iterative development.

As radar systems continue to evolve in both architecture and function, test environments must keep pace and offer faster, more repeatable validation across a growing range of mission conditions.

Among the growing set of challenges is the need to verify the performance of AESAs. Testing these systems often requires over-the-air configurations that can evaluate beam agility, sidelobe behavior, and scan patterns under realistic conditions. These scenarios typically rely on chamber-based or near-field setups, which offer both RF realism and the measurement consistency needed for repeatable results.

At the same time, radar designs are expanding to include wider bandwidths and higher channel counts. This growth leads to a sharp increase in data volume, which places greater strain on acquisition systems, storage, and post-processing pipelines.

AirBorn’s VPX Power Module is a VITA 62, Open VPX compliant, 6U system with models for a 270 VDC input IAW MIL-STD-704.

Auxiliary DC Output: +3.3V/60A

Peak Efficiency of 95%

Input-Output Isolation 2100VDC

Main DC Output: +12V/180A

Overvoltage, Overload, & Overtemperature Protection

Programmable Regulated Current Limit VITA 46.11 System Management

High-throughput architectures and real-time analysis tools are becoming essential to keep pace and avoid bottlenecks in technology advancements.

Test environments must also support fast iteration. Schedule pressures extend beyond development to production and sustainment phases, where automation, integrated calibration, and low manual overhead are key to maintaining both speed and accuracy

The increased use of commercial off-the-shelf components and FPGA [field-programmable gate array]-based signal chains adds another layer of complexity. These elements can introduce variability in latency, noise performance, and spectral behavior. As a result, it becomes critical to characterize subassemblies not just in isolation, but as part of the full radar system. This step is especially important late in the development cycle, when integration and design changes are still underway.

Flexibility first

Legacy test systems were often built for specific radar models, waveform types, or frequency bands. While these approaches worked well for earlier generations, they struggle to keep up with the demands of today’s rapidly evolving radar designs and expanded mission scopes.

A more effective strategy embraces a platform-based, software-defined, and modular architecture. This approach allows test systems to adapt alongside radar development without requiring full hardware replacements. Key features include the ability to generate real-time scenarios that inject targets with dynamic delays, Doppler shifts, and attenuation profiles, accurately replicating real-world conditions. Modular signal transceivers provide coverage across wide bandwidths and frequency ranges, while scalable channel counts support increasingly complex systems. (Figure 1.)

Open software interfaces enable integration with digital twins, scenario generators, and mission-modeling frameworks. At the same time, calibrated and synchronized signal paths ensure the precision needed for time-sensitive measurements such as range delay and phase coherence.

This flexible architecture supports early prototyping, closed-loop testing, and continuous validation throughout design, production, and life cycle sustainment. When

implemented effectively, it enables radar developers and test engineers to work in parallel, speeding time to deployment and improving confidence in system performance under the challenging conditions typical of EMSOs.

Preparing for what will come

Radar systems will continue to evolve in step with the changing RF battlespace. In 2025 and beyond, radar test goes beyond simple validation to encompass simulation, emulation, and adaptive response. The increasing complexity of multifunction RF systems calls for test environments that are scalable and capable of keeping pace with the speed and complexity of the systems themselves.

Meeting these challenges depends on test platforms that support missionspecific workflows, real-time scenario generation, and precise signal control. Moving away from fixed, hardwarecentric setups toward modular and programmable architectures enables development teams to accelerate innovation while maintaining signal realism and measurement accuracy.

As the spectrum contest intensifies, the ability to test radar systems under realistic, large-scale conditions with confidence will be critical to maintaining readiness and resilience. MES

Haydn Nelson is a U.S. Navy veteran with more than 20 years of experience in wireless and DSP technology applications. He has worked in several industries –from military and aerospace research to RF semiconductor test – and has broad experience in radar/ EW and communications systems. Haydn currently serves as a business development manager at Emerson Test and Measurement for its wireless prototyping and deployment applications in military and aerospace markets.

Emerson Test and Measurement www.ni.com/radarew

Managing supply chain, obsolescence, and counterfeit parts

By Laure El Mhadder

In modern military operations, embedded computing platforms must deliver uncompromised performance, withstand extreme environmental stress, and seamlessly interface with complex electronic subsystems – all while adhering to strict regulatory and life cycle constraints. Integrating custom or modified hardware into these operational environments is a multidimensional challenge that spans thermal resilience, electromagnetic compatibility, system interoperability, and long-term component availability.

In defense electronics, success is measured in performance reliability and system availability over decades, not just performance at launch. Technical excellence must be balanced with practical constraints, ensuring that every embedded solution has passed stringent qualification, optimized against obsolescence, able to handle extreme deployment environments, and modular and scalable.

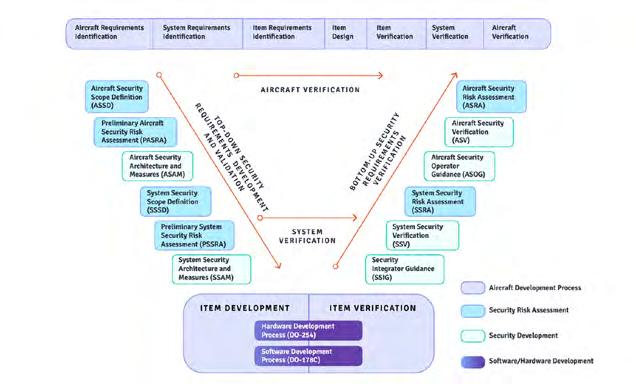

To meet these demands, a rigorous systems-engineering methodology based on the V-model development framework, tailored specifically for the defense electronics sector, can be applied to engineering problems. This approach enables the delivery of modified off-the-shelf (MOTS) and fully custom embedded solutions that are not only compliant and ruggedized but also engineered for longevity, maintainability, and field-readiness.

The embedded challenge in military use

Whether in aerial drones, naval platforms, or tactical ground vehicles, embedded systems such as mission computers, control units, and sensor fusion nodes must

deliver consistent functionality under harsh environmental conditions:

› Temperature ranges: from -40 °C to +70 °C (operational)

› Shock resistance: up to 40 g as per MIL-STD-810G

› Vibration exposure: continuous across 10 Hz to 2,000 Hz

› EMI/EMC exposure: compliant with MIL-STD-461

› Ingress protection: sealed enclosures up to IP68

Moreover, mission duration and reliability are critical. These systems often operate for 30,000-plus mission hours, wit h the expectation of little to no downtime.

Compounding this situation, the rapid evolution of semiconductor technology –with average component life cycles of

Figure 1 | A diagram shows a V-model approach to engineering, which is designed to ensure traceability, compliance, and risk management while taking into consideration supply-chain volatility and component obsolescence. Milexia diagram.

two to five years – clashes with military procurement timelines that can span decades. Without proactive design foresight and obsolescence management, field reliability is at risk.

A custom V-model process enables full traceability, requirement verification, and risk mitigation from initial specification through in-field operation. It supports:

› Structured, stage-gated development

› Design-to-validation traceability

› Life cycle-aware component selection

› Pre-qualified rugged designs

› Client co-engineering and feedback loops

The implementation of the V-model is not only compliant with defense industry best practices, is custom-optimized for the development of MOTS and fully bespoke embedded systems. The V-model ensures traceability, compliance, and robust risk management, particularly in addressing supply-chain volatility and component obsolescence. (Figure 1.)

From RFQ to after-sales support, the V-model is shaped as follows:

1.RFQ and risk analysis

Projects begin with a detailed technical intake and feasibility review. A cross-functional team performs a risk matrix analysis, covering:

› Mechanical and thermal integration

› Interface compatibility (USB, CAN, RS232/422, SDI)

› Environmental constraints (MIL-STD-810, DO-160, IP ratings)

› Component supply risks (EOL forecasts, single-sourcing, lead times)

This early scrutiny ensures engineering resources are only applied when the solution is viable and scalable over the system’s intended operational life.

This phase includes early visibility on end-of-life (EOL) components and single-source supply threats, enabling engineers to proactively recommend alternatives or redesign paths. A go/no-go decision ensures engineering resources are only committed when the solution is denoted as viable long-term.

2.Compliance and risks matrix

Once approved, all customer specifications are mapped into a version-controlled compliance matrix, linking each to its:

› Functional implementation

› Validation plan

› Risk level (technical or supply-related)

This structured mapping ensures design choices remain transparent, auditable, and traceable across all life cycle stages.

3.Architecture and detailed design

This phase includes:

› Full mechanical 3D CAD models (STEP/IGES)

› Signal-integrity simulations (SI) and thermal analysis (<85 °C thresholds)

› Selection of industrial-grade components with 10-plus year availability

› Review of PCB layout, electromagnetic interference (EMI) shielding, thermal path, and connector placement

A detailed design review (DDR) finalizes component selection and layout, aligning engineering, sour

4.Prototype and prequalification

A production-intent prototype is developed for:

› Mechanical validation

› Thermal cycling and thermal ramp testing

› Salt spray and humidity exposure (accelerated aging)

› Firmware/software validation (boot sequence, I/O interface integrity)

Component changes due to sourcing issues are flagged and revalidated here, maintaining system robustness.

5.Testing and qualification

Formal testing is performed in accordance with military and aerospace standards, including:

› MIL-STD-810G (vibration/temperature)

› MIL-STD-461 (EMI/EMC)

6.Production and full life cycle support

Following successful qualification, the system enters production using fully validated components and configurations. Products are delivered fully tested and ready for deployment: fully validated bill of materials (BOM), with all critical technical documentation packs (wiring, diagrams, compliance of declarations), and serial-number tracking and traceability.

Beyond delivery, added value is found in continuous support for the customer throughout the product’s operational life. Maintenance, repairs services, firmware updates, and replacements are handled efficiently, with quick turnaround and access to spare parts. Ongoing monitoring of component life cycle status ensures t hat potential obsolescence issues are addressed proactively, preserving system reliability and availability well into the future.

Case study: Custom embedded solutions for maritime special forces

Milexia recently completed a project that involved the design and delivery of two embedded computing platforms for a leading defense contractor operating in the optronics and avionics space. The systems were destined for integration aboard both maritime vessels and Special Operations Zodiac rigid inflatable boats (RIBs), where resilience and interoperability were paramount.

Results using V-model process

In both cases, Milexia leveraged the full V-model process, involving technical and operational specifications, prototyping, testing, qualification, and serial production. More than 80 hours of stress and compliance testing was performed per unit. These systems are now in serial production, with life cycle contracts ensuring part tracking and upgrade paths over a projected 10-plus-year deployment period.

Engineering with life cycle in mind

In defense electronics, success is measured in performance reliability and system availability over decades, not just performance at launch. The V-model framework aligns technical excellence

with practical constraints, ensuring that every embedded solution is mission-validated through stringent qualification, life cycle-optimized against obsolescence, environmentally hardened for extreme deployment scenarios, and both modular and scalable for future adaptations. MES

Laure El Mhadder is Sales Director, Electronics at Milexia. With over a decade of experience in embedded computing for defense, aerospace, and industrial markets, she specializes in guiding mission-driven organizations through technically complex, life cycle-sensitive design and deployment strategies.

Milexia • https://milexia.com/

Managing supply chain, obsolescence, and counterfeit parts

By Chris Morton and Bianca Nobilo

Looking ahead, defense planning and force structure will begin to look different as nations look to adapt to the new contours of conflict, not only to aid nations in active conflict, but also to protect their own countries in the future. Technology is transforming the battlefield – whether the return of attrition warfare, supply-chain shifts, the use of artificial intelligence (AI), drone swarms, or quantum defense – and nations are beginning to alter their defense tactics to compete.

The three-year Russia-Ukraine war has grown into a high-intensity conflict that is reshaping global assumptions on the future of warfare. Throughout the three years, Western military readiness has been put to the test and failed on several counts, whether it’s depleted ammunition stockpiles or a lack of supply-chain resilience.

Attrition warfare, once thought to be outdated, has returned as Russia and Ukraine try to wear each other down. A spotlight has been cast on the battlefield’s ability to combine traditional kinetic operations with low-cost asymmetric technologies.

Supply-chain woes and responses Ukraine’s artillery consumption outstripped NATO’s production capacity within months, underscoring a fundamental issue: Western defense industries had become structured for peacetime efficiency, not wartime urgency. For decades, spending priorities reflected

counterinsurgency operations, not large-scale conventional warfare. Defense manufacturers followed slow, bureaucratic procurement cycles, building to long-term program specifications rather than operational needs. This model is no longer tenable.

A key lesson from the Ukraine conflict is the critical link between battlefield endurance and industrial adaptability. Russia’s defense industrial base was not built for a prolonged war and has struggled to pivot under pressure. In contrast, Ukraine’s ability to draw on external support networks has created a more resilient long-term position – underscoring the strategic value of a flexible, modernized defense industrial base (DIB).

Artificial intelligence (AI)-driven logistics and quantum-enhanced simulations will determine which militaries can sustain modern war. Predictive logistics, already in use in Ukraine, anticipates battlefield demands, ensuring supplies are replenished before critical shortages occur. Indeed, in the context of contested logistics at the strategic level, variables that include a dynamic and quickly changing threat environment require analysis at the speed of AI. At the operational and tactical levels, commanders on the battlefield who have access to sophisticated pattern analysis that studies political, military, social, and the physical environments – among others –can sustain combat operations in theater and force the enemy to consider multiple, complex dilemmas.

AI-driven supply optimization will analyze real-time battlefield conditions to adjust production and distribution dynamically. Nations that fail to integrate AI into logistics, manufacturing, and deployment will be less responsive and fall behind.

AI is reviving the defense industry

Mass production of high-tech weaponry has failed under wartime conditions. The U.S. Replicator Initiative is attempting to reverse this inefficiency by integrating AI-driven automation into defense production. This shift mirrors the years around World War II, when industries like Ford, Hershey, and Singer pivoted to war manufacturing. The difference now is that software-defined warfare demands companies that can handle real-time iteration, rapid scaling, and autonomous system integration.

Ukraine is already deploying AI-driven drone manufacturing, battlefield analytics, and smart munitions at speeds that outstrip traditional defense manufacturers. At the February 2025 Munich Security Conference, Danish Prime Minister Mette Frederiksen warned: “We have a problem, friends, if a country at war can produce

faster than the rest of us.” The future of defense production will favor firms that leverage AI to shorten the OODA loop [Observe, Orient, Decide, Act], accelerating design, testing, and manufacturing cycles.

A new low-cost asymmetric angle of warfare

Traditional military platforms are being undermined by low-cost, high-impact technologies: A $500 drone can disable a $10 million tank, and it’s thought t hat one-t hird of the Russian navy’s Black Sea fleet has been neutralized by Ukrainian drones. AI-powered swarm warfare – networked, autonomous loitering munitions – has forced militaries to reconsider large, centralized command nodes, which now serve as easy targets. Ukraine’s success in AI-assisted reconnaissance, drone coordination, and battlefield analytics has compelled Russia to adopt similar tactics, both signaling and spurring the rapid evolution of AI in modern conflict.

Speed and scale now outweigh cost and complexity. Monolithic, exorbitant, and slow-moving weapons programs –designed for decades-long procurement cycles – are being reconsidered in an asymmetric context where AI is already embedded in ISR [intelligence, surveillance, and reconnaissance], autonomous drone targeting, and automated force coordination. In previous conflicts, nations without the resources to repel a larger, wealthier adversary were at a significant disadvantage.

Ukraine has demonstrated that through the precise application of low-cost asymmetric capabilities, its forces can effectively even the stakes against a much larger foe. Many smaller nations will likely take note and look to apply this same acquisition strategy as a hedge against aggression. Larger, wealthier nations cannot ignore this trend – they will not only need to counter this asymmetric threat, but they will also need to develop these capabilities to work alongside major weapon systems. Although power project ions and global deterrence still require the employment of “majestic” type weapon systems on a

Managing supply chain, obsolescence, and counterfeit parts

global scale; low-cost AI driven asymmetric capabilities enables a military to present multiple dilemmas to a potential adversary. A great example is CCAs – collaborative combat aircraft – autonomous uncrewed aircraft now under development by the U.S. Air Force and others that are leveraged as a part of traditional fighter development. (Figure 1.)

AI and the soldier – who will take charge in battle?

Lethal autonomous weapons (LAWs) are no longer theoretical. AI-assisted targeting is already operational, with Ukraine leveraging AI-enhanced intelligence, surveillance, and reconnaissance (ISR) to predict enemy movements. The debate is no longer about whether AI will be used in battlefield decision-making, but rather how to ensure its use remains ethically constrained, legally accountable, and aligned with international human rights norms.

The key ethical and legal distinction now lies between human-in-the-loop (oversight required), human-on-theloop (oversight optional), and humanout-of-the-loop (fully autonomous lethal decision-making). A shift toward removing human oversight in lethal engagements risks violating the fundamental principles of proportionality, accountability, and distinction in warfare. If AI decision loops become too fast for meaningful human intervention, militaries risk ceding moral and legal responsibility to algorithms, diminishing the very accountability that underpins the laws of war.

Highly useful as stand alone or in combination with other backplanes, with or without RTM connectors. Multiple units can be topology wired using MERITEC VPX Plus cables. The Dawn family of one-slot OpenVPX test station and development backplanes gives engineers the ability to perform compatibility tests and easily reconfigure payload module profiles and slot interoperability to meet custom requirements.

A nation that first entrusts real-time combat decisions to AI would not just redefine military power but could also fundamentally alter the rules of engagement, setting a dangerous precedent for warfare devoid of human ethical judgment. This shift would mark the most profound military transformation since nuclear weapons, but unlike nuclear deterrence, where human deliberation remains central, fully autonomous weapons could remove the last safeguard between war and unchecked machine-driven violence. Any integration of AI in lethal force must be bound by strict legal frameworks and international oversight to prevent an irreversible slide toward algorithmic warfare without moral restraint.

Moreover, AI-driven cyber warfare is already escalating – deepfake disinformation campaigns as a part of a broader psychological operation, automated hacking, and AI-enhanced cyberattacks are becoming standard tools of statecraft.

Reaching the milestone of quantum computing

Rugged, Reliable and Ready. You need it right. You want Dawn.

Technology is not just reshaping the theatre of war, but also its preparation and context: Quantum-enhanced simulations could transform military planning, enabling strategists to model complex, multi-variable conflicts with more granular precision.

Quantum computing’s military potential remains largely theoretical, but its longterm implications are existential. The

most immediate concern is encryption: current cryptographic systems will be obsolete the moment quantum decryption achieves practical deployment. NATO, China, and Russia are already racing to develop quantum-resistant security protocols. The winner of this race will have a significant advantage in the future of digital warfare.

On the battlefield and in the bases, AI is reshaping military power

Across several fronts, the race for AI leadership in defense is on. Whether it’s defense organizations struggling to keep up with the unfamiliar contours of AI-driven conflict; both large and small AI organizations entering the defense sector; China and Russia integrating AI across a strategic level; or the U.S., the UK, and other defense forces integrating AI into their military operations, t he race is underway. To truly dominate military power in the 21st century, the winner must also be able to scale and operationalize AI across not only defense but logistics, manufacturing, and industrial resilience quicker than its counterparts.

The Russia-Ukraine battlefield has become a live testing ground for the new contours of war, where asymmetric strategies, real-time decision-making systems, and digital warfare are redefining how military force is sustained. But conflict is not won entirely on the battlefield, but by who combines autonomy, agility, and intelligence across their entire defense ecosystem.

It is not only in defense, though, where AI can be decisive. On an economic scale, AI can be utilized to enhance industrial productivity, financial systems, and modern technologies that will all help maintain defense efforts. As AI’s growth continues, it is crucial for defense capabilities and economies to work in tandem, leveraging technology as it becomes the key to strategic longevity and not just a battlefield advantage. MES

Chris Morton is Global Industry Director for Aerospace & Defense at IFS. A retired attack helicopter pilot with 21 years of military and aviation experience, his career has ranged from leading combat units in operational theatres to shaping strategic planning at the Pentagon. He now advises A&D clients on transformation while driving industry strategy within IFS.

Bianca Nobilo leads AI ethics, government relations, and thought leadership on the Executive Board at IFS. She spent a decade at CNN as an anchor and correspondent, covering major global events and conflicts and previously worked across aerospace and defense briefs in the U.K. Parliament.

IFS https://www.ifs.com/

With a huge selection of SOSA aligned backplane & configuration options, Pixus has a solution for you. We offer a vast array of slot sizes in speeds to 100GbE, PCIe Gen4, & beyond. Contact Pixus today!

Managing supply chain, obsolescence, and counterfeit

By Jay Thomas