◀ Natural State Beer Co.

its annual “Oaktoberfest” featuring a traditionally-made Oktoberfest beer that takes three months to make. The event will include activities for kids, German food specials and an Oom-pah band. “We’ll get very festive,” Hilton says. His nephew, Brady Campbell ’22, plays football at GC and works at Lone Oak with about six other GC students and some alumni, in the kitchen and in other capacities, says Hilton, who coached GC’s junior varsity golf team from 2005-07.

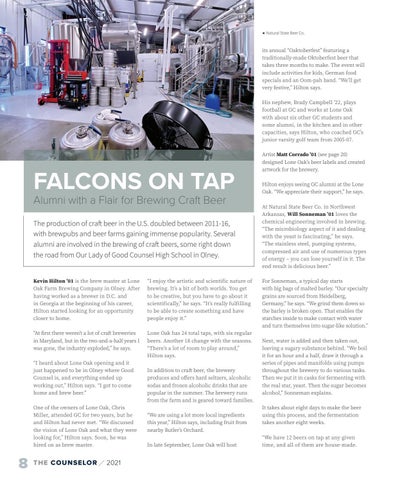

FALCONS ON TAP Alumni with a Flair for Brewing Craft Beer

The production of craft beer in the U.S. doubled between 2011-16, with brewpubs and beer farms gaining immense popularity. Several alumni are involved in the brewing of craft beers, some right down the road from Our Lady of Good Counsel High School in Olney. Kevin Hilton ’01 is the brew master at Lone Oak Farm Brewing Company in Olney. After having worked as a brewer in D.C. and in Georgia at the beginning of his career, Hilton started looking for an opportunity closer to home.

“I enjoy the artistic and scientific nature of brewing. It’s a bit of both worlds. You get to be creative, but you have to go about it scientifically,” he says. “It’s really fulfilling to be able to create something and have people enjoy it.”

“At first there weren’t a lot of craft breweries in Maryland, but in the two-and-a-half years I was gone, the industry exploded,” he says.

Lone Oak has 24 total taps, with six regular beers. Another 18 change with the seasons. “There’s a lot of room to play around,” Hilton says.

“I heard about Lone Oak opening and it just happened to be in Olney where Good Counsel is, and everything ended up working out,” Hilton says. “I got to come home and brew beer.” One of the owners of Lone Oak, Chris Miller, attended GC for two years, but he and Hilton had never met. “We discussed the vision of Lone Oak and what they were looking for,” Hilton says. Soon, he was hired on as brew master.

8

THE COUNSELOR

2021

In addition to craft beer, the brewery produces and offers hard seltzers, alcoholic sodas and frozen alcoholic drinks that are popular in the summer. The brewery runs from the farm and is geared toward families. “We are using a lot more local ingredients this year,” Hilton says, including fruit from nearby Butler’s Orchard. In late September, Lone Oak will host

Artist Matt Corrado ’01 (see page 20) designed Lone Oak’s beer labels and created artwork for the brewery. Hilton enjoys seeing GC alumni at the Lone Oak. “We appreciate their support,” he says. At Natural State Beer Co. in Northwest Arkansas, Will Sonneman ’01 loves the chemical engineering involved in brewing. “The microbiology aspect of it and dealing with the yeast is fascinating,” he says. “The stainless steel, pumping systems, compressed air and use of numerous types of energy – you can lose yourself in it. The end result is delicious beer.” For Sonneman, a typical day starts with big bags of malted barley. “Our specialty grains are sourced from Heidelberg, Germany,” he says. “We grind them down so the barley is broken open. That enables the starches inside to make contact with water and turn themselves into sugar-like solution.” Next, water is added and then taken out, leaving a sugary substance behind. “We boil it for an hour and a half, draw it through a series of pipes and manifolds using pumps throughout the brewery to do various tasks. Then we put it in casks for fermenting with the real star, yeast. Then the sugar becomes alcohol,” Sonneman explains. It takes about eight days to make the beer using this process, and the fermentation takes another eight weeks. “We have 12 beers on tap at any given time, and all of them are house-made.