HIGHER ROI IS WITHIN REACH

The Soy Checkoff is driving demand for high oleic soybeans across the U.S., and our investment has already delivered $320 million in premiums to farmers at a 3-1 ROI1.

OHIO SOYBEAN NEWS

A LETTER FROM THE President

Rusty Goebel

Ohio Soybean Association President

Williams County Farmer

s you went about your day today, how often did you think about soy bioproducts? While you’re tending to your crop, the answer is likely that you didn’t think much about soy-based bioproducts at all.

But bioproducts are becoming an increasingly important market for our soybeans. In fact, biofuels, which make up only a portion of the soybased products pie, account for 13% of the bushel price for beans. And the possible uses of soybean products and co-products in biomanufacturing is truly endless.

Researchers, including those at Airable Research Lab (see page 14) are constantly discovering new ways to use soybean oil, meal, molasses, hulls and more. Airable is supported by our soybean checkoff dollars in an effort to develop new markets for our soybeans. As an Ohio farmer, I’m incredibly proud of the work Airable does on my behalf and I always look forward to seeing their products on shelves.

On the policy side, the Ohio Soybean Association (OSA) is also hard at work to support initiatives to support soy-based bioproducts in the market and bring more biomanufacturing to Ohio. As I write this column, OSA was recently pleased to learn that the U.S. House of Representatives has proposed an extension on the 45Z tax

credit for biofuels producers. OSA and its partners have worked tirelessly to support this initiative and ensure that soybeans – and by extension soybean farmers – are treated fairly. The new proposed rule also ensures that the credit is only available to biofuels that use domestic feedstocks, including U.S. soybean oil.

This is a huge win for farmers and I hope that by the time I sit down to write my next president’s column, this piece of legislation is across the finish line. In the meantime, you can read more about OSA’s involvement in the developing bioeconomy on page 8.

The expansion of new biobased markets for our beans is all possible because of the collective efforts of Ohio soybean farmers as the checkoff and as association members. Without our efforts, who knows if these markets would have existed? And now because of our hard work, who knows how far they’ll go.

President

Rusty Goebel, Williams County

Vice President

Bennett Musselman, Pickaway County

Treasurer

Dustin Converse, Union County

Secretary

Trish Cunningham, Union County

Chairman

Patrick Knouff, Shelby County

Trustees

David Clark, Warren County

Dave Green, Crawford County

Justin Esselburn, Ashland County

Jeff Magyar, Ashtabula County

Scott Metzger, Ross County

Jeremy Price, Putnam County

Ryan Rhoades, Marion County

Andy Stickel, Wood County

Bob Suver, Clark County

Adam Vonderhaar, Preble County

Jennifer Wilson-Oechsle, Van Wert County

American Soybean Association Board Representatives

Rusty Goebel

Scott Metzger

Ryan Rhoades

Staff Credits

Kirk Merritt - Publisher

Julia Brown - Editor

Mackenzie Joseph - Staff Writer

Lauren Gerig - Art Director

Kim Lemmon - Production Manager

Ohio Soybean News is published six times a year by the Ohio Soybean Association, 918 Proprietors Rd., Suite A, Worthington, OH 43085. Phone: 614-476-3100.

Rusty Goebel

Williams County Farmer

Ohio Soybean Association President

Comments and statewide news articles should be sent to the above address. Advertising space reservation must be made by the first of the month preceding publication. In consideration of the acceptance of advertisement, the agency and the advertiser must, in respect of the contents of the advertisement, indemnify and save the publisher harmless against any expense arising from claims or actions against the publisher because of the publication of the content of the advertisement.

For Advertising Sales Contact: Kristin Flowers - (614) 323-9320 kristin@ohioagnet.com

For Address Corrections Contact: Ohio Soybean News at 918 Proprietors Rd., Suite A, Worthington, OH 43085.

Web address: www.soyohio.org

E-mail: cdeboard@soyohio.org

Farmer Leaders Learn More About Legal Threats to

No health regulator anywhere in the world has ever found glyphosate to pose a carcinogenic risk to human health as part of their scientific review of the product. Yet a lack of legislative certainty has fueled costly litigation- in excess of 150,000 cases– that poses a risk to the availability of this important tool.

The litigation industry is targeting crop protection tools such as glyphosate with claims of alternative scientific data. The legal cases claim manufacturers should have put a warning label on their products even though federal regulatory requirements don’t require one.

Some advocates say it’s becoming increasingly difficult keep a product

Crop Protection Tools

like Roundup available to farmers without some sort of federal or state legislative support. In fact, Roundup manufacturer Bayer’s Chief Executive Bill Anderson has said the company could stop making Roundup as early as this year if litigation costs can’t be contained.

Recently, members of the Ohio Soybean Association’s Soy Farmer Action Network (SoyFAN) heard insights on this issue from Elizabeth Burns-Thompson, who serves as the Executive Director of the Modern Ag Alliance. The Modern Ag Alliance is a coalition of more than 100 organizations, including the Ohio Soybean Association (OSA), advocating for U.S. farmers’ access to essential crop protection tools.

Burns highlighted work in legislatures across the country to create protection from this type of litigation. Legislation is pending in several states that would ensure the federally approved product label is the law and a company can’t face litigation if they are following the law.

“Ohio could be a state to see this type of legislative approach soon,” said OSA Deputy Executive Director and Senior Policy Director, Brandon Kern. “We are working closely with our farmer leaders to gain their feedback, so we are prepared if this issue emerges in Ohio.”

You can find more information about the Modern Ag Alliance by visiting www.modernagalliance.org

Supporting Ohio Agriculture and Soybean Producers

Ohio Farm Bureau and Nationwide have a rich history of supporting Ohio's agricultural community. Our partnership remains strong, reflecting our dedication to the farmers who sustain us. We're especially proud to support Ohio's soybean producers, helping to secure a bright future for agriculture in our state.

Growing Opportunities: Positioning Ohio for Success in the Bioeconomy

As demand for sustainable solutions grow, the bioeconomy—defined as the production of renewable biological resources and their conversion into value-added products like biofuels, bioplastics, and biomaterials—is proving a powerful driver of economic development.

The U.S. bioeconomy supports more than 4 million jobs nationally, and this number is projected to rise as biobased markets expand. These jobs often intersect with workforce development priorities, including STEM education, technical training, and advanced manufacturing. Biomanufacturing, the backbone of the bioeconomy, combines advanced science with traditional industries to create new markets and opportunities for farmers.

For soybean farmers in particular, the bioeconomy presents opportunities. Soy-based products — such as lubricants, plastics, foams, and fuels

— represent a growing share of the industrial bioproducts market. As demand for renewable products rises, Ohio’s soybean growers are positioned to benefit from diversified markets and new revenue streams. Promoting domestic bio-based manufacturing also enhances supply chain security, and helps buffer commodity markets from global shocks.

At the national level, initiatives like the USDA’s BioPreferred Program have spurred growth by encouraging federal agencies and consumers to choose biobased products, helping build markets for American-grown commodities. With strategic investment and policy alignment, states across the country are seizing the opportunity that this emerging sector presents. Ohio is well-positioned to lead in this area of economic development.

States like Minnesota and Nebraska have launched innovative policies to

support bioeconomy growth as well, offering tax incentives, grants, and public-private partnerships to draw investment and encourage innovation. Minnesota’s Bioincentive Program, for example, provides production-based payments to companies that manufacture renewable chemicals and advanced biofuels using agricultural inputs. These incentives not only attract companies to locate in-state, but also help support farm economies by building new, value-added markets locally.

Nebraska is also a leader in the bioeconomy, driven by Governor Jim Pillen’s vision to position the state as a hub for agricultural innovation. At the Nebraska Ag and Economic Development Summit in 2024, Pillen highlighted a $5 billion investment in a new bioindustrial manufacturing facility that would utilize local ag products — such as corn and soybeans — to create sustainable fuels and biobased materials.

Ohio Innovation in Action

In Ohio, the one-of-a-kind Airable Research Lab is pioneering the development of soy-based products with practical commercial applications. Airable is at the forefront of soy biobased research and development, working with commercial and industrial clients to develop materials and final products. Ohio’s central location, transportation infrastructure, research institutions, strong manufacturing base and agri-business ecosystem strengthen the state’s potential competitive edge in this sector.

To fully realize this opportunity, Ohio must address remaining barriers, including regulatory uncertainty. The

Ohio Soybean Association is collaborating with partners to identify and develop strategies to meet these challenges in Ohio.

During the organization’s annual legislative day earlier this year, OSA farmer leaders asked policymakers to help bring together stakeholders, identify gaps and develop policies to allow Ohio to become a leader in this area. The organization also hosted advanced manufacturing staff from JobsOhio, the state’s economic development arm, at Airable labs recently. The visit made clear that important resources exist for biomanufacturing companies considering in Ohio for their operations.

Continued legislative support at the state level — particularly through targeted funding, workforce development initiatives, and market incentives — will be essential to accelerating growth and positioning Ohio as a national leader in this area. OSA will be pursuing these ideas as a leading priority issue.

As other states move quickly to capitalize on this economic wave, Ohio has the building blocks to lead the way in biomanufacturing. Strategic investment today can ensure lasting success for farmers, researchers, and manufacturers across Ohio.

America’s soybean farmers are at the heart of our nation’s future. By supporting clean fuels, you’re not just fueling vehicles. In 2025, clean fuels will utilize 13.6 billion pounds of soybean oil.

Visit cleanfuels.org and learn how clean fuels can secure a stronger future for U.S. agriculture.

Airable Research Lab

Board Leadership

Bill Bayliss

At Airable Research Lab, farmer leadership shapes innovation. Our Board of Directors brings together experienced growers and industry experts, creating a vital link between the farm and the marketplace. With insights from both agriculture and industry, they guide Airable’s mission to transform soy-based research into real-world commercial success.

Bill Bayliss farms 2,000 acres in Logan County, Ohio, and serves as Chairman of the Ohio Soybean Council Board of Trustees.

Robin Bowen

Robin Bowen is Senior Vice President of External Affairs for the Corn Refiners Association and the Plant Based Products Council. Raised on a farm, she brings agriculture-based policy expertise and advocacy experience, helping to connect bioproduct innovation with state and federal policymaking.

Jerry Bambauer

Jerry Bambauer farms 900 acres in Auglaize County, Ohio, and serves on the Ohio Soybean Council Board of Trustees.

Todd Hesterman

Todd Hesterman farms nearly 1,000 acres of soybeans, corn, and wheat in Henry County, Ohio, and serves on the Ohio Soybean Council Board of Trustees.

Jeff Magyar

Jeff Magyar farms 3,000 acres of soybeans and corn in Ashtabula County, Ohio, and serves on the Ohio Soybean Council Board of Trustees.

Scott Porter

Scott Porter is CEO and co-founder of Dynamic Green Products (DGP), a key commercial partner of Airable. His expertise in commercialization and product development supports Airable’s mission to bring innovative soy-based solutions to market.

Dr. Ajay Shah

Dr. Ajay Shah is a professor in the Department of Food, Agricultural, and Biological Engineering at The Ohio State University. His research in sustainable engineering and agricultural systems strengthens Airable’s scientific foundation.

Chad Warner

Chad Warner farms 1,900 acres of soybeans, corn, and wheat in Darke County, Ohio, and serves on the Ohio Soybean Council Board of Trustees.

The Ohio Soybean Council has done a lot with farmer funding over the years, from improving crop quality to implementing sustainable farming practices to educating stakeholders about agriculture and the checkoff. But perhaps the boldest, most innovative venture was establishing Airable Research Lab, the only R&D lab 100% focused on finding new uses for soybeans.

How is Airable doing?

Since its founding in 2019, the team has grown to eight full-time and three part-time employees. Lab leadership has already established several strategic commercial partnerships and is in promising talks with several more. Seven soybean state organizations are funding the lab, including OSC, doubling the original budget. The lab space at Ohio Wesleyan University is expanding, and Airable is opening a

second lab with additional capabilities. Most important, the lab has developed 10 soy-based products that have entered the market, with more in the works.

With these successes in mind, we here at Ohio Soybean News thought it might be worth a peek behind the Airable curtain. This issue is dedicated to Airable—projects, products, players and more.

“Here’s the bottom line: Airable finds more uses for soybeans, and demand goes up, sales go up, prices go up— and the farmers reap all those benefits.”

– Bill Bayliss, OSC Chairman

“We always have our soybean hats on, looking for more uses for the farmers’ agricultural products.”

– Barry McGraw, Founder and Chief Laboratory Officer

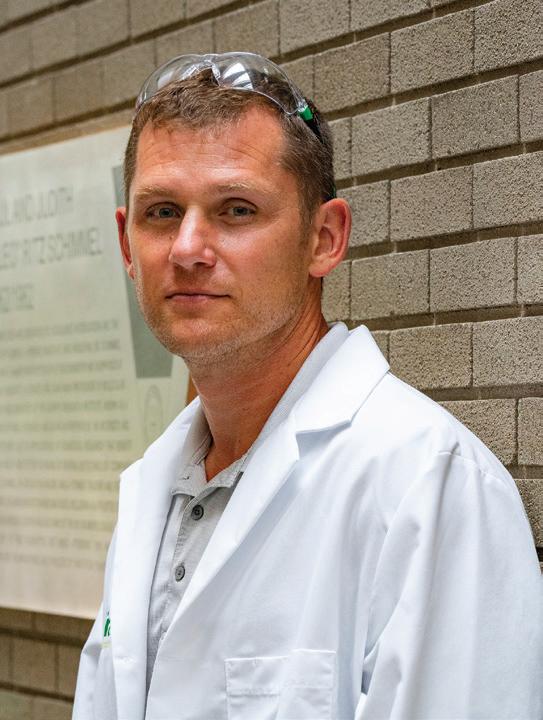

What would Airable Research Lab be without its research team?

“Pretty quiet,” says Barry McGraw, Founder and Chief Laboratory Officer of Airable and the driving force behind the lab. He is a graduate of Shawnee State University, which is also home to Airable Research Lab #2 (see pages 16-17).

With a bachelor’s in plastics engineering, Barry became a researcher and manager at Battelle, the world’s largest non-government research facility. In 2013, he joined the Ohio Soybean Council as Director of Product Development & Commercialization. Within a few years, he saw the benefit of creating an OSC-based research lab focused on soy-based products.

“About five years ago, we asked ourselves why we were paying other people to do research that we could do ourselves,” Barry explains. “Having our own lab allows us to do things so much more cheaply and efficiently.”

“We’re focusing on an Americagrown product that enables us to replace current market products that are negatively affecting our world and those in it—this is a fulfilling endeavor. The goal has always been to make the world a better place for us and for future generations.”

– Olivia Susi

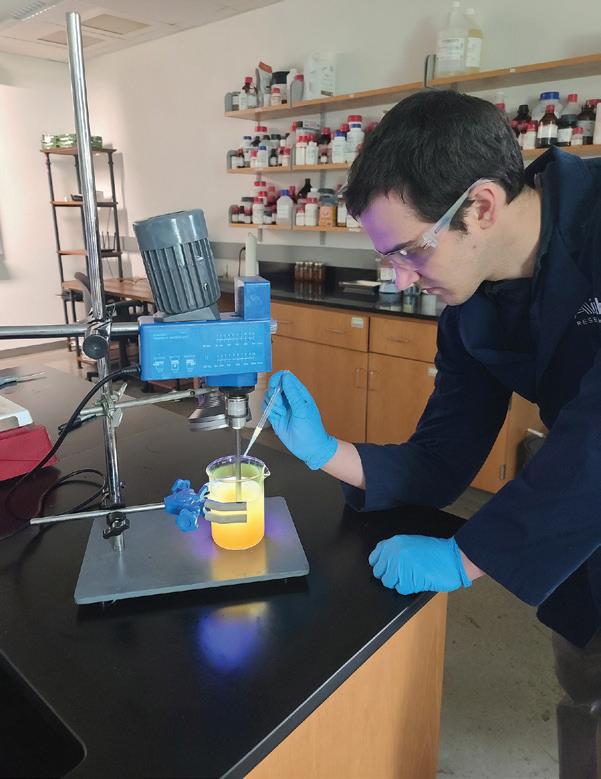

The lab is far from quiet, with nine full-time researchers and two interns who are hard at work developing soybased products.

Barry’s team is led by Dylan Karis, whose quiet intelligence and dedication are immediately apparent. He joined in 2020, bringing a PhD in chemistry and experience in polymer synthesis. “I’m an advocate of a sustainable economy,” says Dylan, “and to make that future a reality, R&D has to go beyond the chemistry lab and lead to something with commercial value.”

Next is Rob Cain, a senior scientist with over 20 years’ experience and a former Battelle researcher. He worked on everything from toothpaste to fuel cell membranes. “Companies are turning to soy now, more than ever before, because of the sustainability push,” says Rob.

The team also includes innovation engineer Alex Shand and research chemist Olivia Susi. Alex has a background in polymer processing, and Olivia specializes in repurposing biological systems for functional use.

Rounding out the team are four newcomers: Jillian Jacobsen (engineer), Nick Fein (chemist), Sam Karlock (engineer), and Kurtis Williams (researcher). Two summer interns will also join the lab, continuing its part nership with the university. The team balances science and engineering, theory and practice. Their diverse backgrounds support a shared mission: advancing sustainability and helping farmers.

This group isn’t isolated in a lab. They meet regularly with farmers, clients, and stakeholders.

“All the team members try really hard to listen to our clients, to understand what they want,” says Barry. “They enjoy seeing others be successful.

“A lot of folks talk about innovation,” he adds. “But we do it.”

“It’s exciting to be at the forefront of the push for biobased products and to see an idea go from that—an idea—to a sustainable market-ready product.”

– Alex Shand

FOUNDED AIRABLE IN 2019.

Barry McGraw

TITRATES A SOLUTION.

Dylan Karis PREPARES PRODUCTS FOR DEMONSTRATION

Olivia Susi TESTS

Alex Shand

Rob Cain

Airable Research Lab expanding to Shawnee State in hopes of more soybean innovation

By Joel Penhorwood, Ohio Ag Net

major investment in agricultural research is taking shape in southern Ohio. With $1 million dedicated to renovating and expanding Shawnee State University’s Advanced Manufacturing Center, Airable Research Lab is setting up a new hub aiming to unlock new market opportunities for soybean-based products.

In February, Barry McGraw, founder of Airable Research Lab, joined Ohio farmers, industry leaders, and dignitaries to celebrate the expansion. Airable Research Lab, a business line of the Ohio Soybean Council (OSC), signed a memorandum of understanding with Shawnee State University to expand operations to a second location, on the Shawnee State campus. The collaboration will benefit students,

researchers, and Ohio’s agricultural economy with new capabilities in plastics, robotics and advanced manufacturing, all focused on the creation of new markets for soybean-based products.

“Airable Research Lab started in late 2019–2020 with the whole idea of accelerating commercialization of soy biobased products, working directly with industrial and consumer companies to develop what they need versus just doing research. We’re using farmers’ checkoff money to do research based on customer need and client need; thus, we’re just increasing the probability of having commercial success and creating demand for the soybean farmer,” McGraw said.

“So why are we at Shawnee State? We’re headquartered in Delaware, and our business model is utilizing underutilized college or university space. We founded the company at Ohio Wesleyan University, where we lease their chemistry space. So we have a lot of chemistry space, and we’re getting good at what we

of clients asking for polymers and composites, but we really just don’t have the capabilities. We’ve been talking to Shawnee State and signed an agreement that says they’re going to build a facility within their Advanced Technology Center that’s really going to be more of a chemical engineering polymer coating space. Not only are we going to be able to do a lot of chemistry using soy to create demand, but now we’re getting into polymers, which are very big commodity-type market right now — and we’re again using university space, partnering with the entrepreneur side of it to use space and support our current business.”

The new facility will add capabilities for creating new soy products. The $1 million expansion is fully funded by state soybean checkoff boards, including Airable’s seven funding partners: the Kentucky Soybean Board, Illinois Soybean Association, Iowa Soybean

Association, Michigan Soybean Committee, Missouri Soybeans, North Dakota Soybean Council, and, of course the Ohio Soybean Council. The funding marks an important investment in the future of soybean research and development. These funds will primarily support the construction of a state-of-the-art 1,500-square-foot bioprocessing facility tailored to meet the specific needs of Airable’s research team. This expansion is part of a larger $5 million renovation of Shawnee State’s facility, with the lab set to be completed by the fall of 2026.

“We’ll be able to develop more applications using soy. I’m excited because we can do projects we can’t do now, and we work with clients to develop soy-based products without adding a lot of overhead costs to the soybean farmer checkoff,” McGraw said. “We’re still in that same business model, staying efficient using underutilized space with the key of accelerating soy-based products, the licensing and commercialization. With equipment like injection molders, extruders and all the analytical equipment the university has, that allows us to develop products so much faster.”

The focus of Airable Research Lab is the commercialization of new products using soy.

Adam Miller, interim dean for the College of Business and Engineering Technology at Shawnee State, said the new partnership means exciting things for the school and its students.

“We really try to engage with industry to be able to provide those opportunities where students are able to understand what it’s like working with people and just having that innovation culture or that innovation ecosystem in place where they can learn about what it takes to be a researcher or what types of opportunities are out there,” Miller said. “I think there’s a benefit for our students beyond the classroom aspect and that we will have some interaction and engagement with the Ohio Soybean Council, Airable Lab and the researchers that they have on campus.”

Bill Bayliss is a Logan County farmer and chairman of the Ohio Soy Council Checkoff Board and also chair of the Airable Research Board.

“It creates more demand for our product — that is No. 1. Soybeans are made out of 80% meal and 20% oil. In the past, our customers were the livestock and poultry farmers. But now, as the world evolves, we see the oil is becoming a driving force behind demand, and so we’re coming up with all kinds of different ways to utilize the oil part of it,” Bayliss said. “We’re trying to take the checkoff funds that every farmer contributes — one-half of 1% of the dollar they got from their soybeans — to put into research and build the market for the future.”

Education, business and government leaders from the area and around the state were on hand to celebrate the move, which Ohio Department of Agriculture Director Brian Baldridge hailed as a big win for Ohio’s farmers.

I’m excited because we can do projects we can’t do now, and we work with clients to develop soy-based products without adding a lot of overhead costs to the soybean farmer checkoff,” McGraw said.

“As farmers, we all we know we’re price takers. With efforts like this, we are making sure that we have markets for the future through collaboration to create opportunities for the future of research that we need to do to make sure our markets are stronger than ever,” Baldridge said. “What is that next piece of the puzzle that creates markets and opportunities for Ohio soybean farmers?”

Soybeans are Ohio’s most-produced crop by acreage and the top export crop, bringing in $6 billion in annual revenue in Ohio.

on SoyFoam™ The Scoop

Sometimes innovation comes from a little luck and a lot of hard work. That is the story behind SoyFoam™ TF1122, a revolutionary firefighting foam made from soy flour, developed by Cross Plains Solutions with support from the United Soybean Board and the soybean checkoff.

Three years ago, Cross Plains Solutions CEO Alan Snipes and retired Cargill chemist Dave Garlie teamed up after being approached about using surplus soy flour in a new product. Garlie had been working on a soy-based adhesive that unexpectedly foamed, a flaw for construction adhesives but a breakthrough for firefighting. They soon discovered that SoyFoam™ not only extinguishes fires but also penetrates materials to prevent re-ignition.

made prod uct safety a top priority. “Whatever we make, we are going to make it safe,” said Garlie, inspired by a close friend and firefighter who fell ill after chemical exposure.

SoyFoam™ earned GreenScreen GoldTM Certification after extensive testing, becoming the only firefighting foam to achieve zero detectable fluorine even at parts-per-billion levels. It is also highly biodegradable, breaking down 69 percent in just 18 days.

This spring, the Ohio Soybean Council partnered with the Harrison Township Fire Department to host a demonstration showcasing SoyFoam™’s capabilities. Firefighters and farmers attended the event, witnessing firsthand the foam’s ability to suppress both Class A and Class B fires.

“Utilizing products that are PFAS-free and 100 percent biodegradable is a significant win for all of us,” said Harrison Township Assistant Fire Chief Colt Cline. “We are always looking for ways to keep our firefighters safe and healthy.”

For farmers, SoyFoam™ represents another opportunity to build demand for U.S. soybeans. “This is a winwin-win for Ohio agriculture,” said Steve Reinhard, a soybean farmer and former firefighter. “It is good for first responders, good for farmers, and good for the environment.”

Cross Plains Solutions estimates that current applications of SoyFoam™ could utilize protein from 12 million bushels of soybeans annually. Work is also underway to help departments afford the switch to safer foams through financial assistance programs.

For more information, visit crossplainssolutions.com.

State Soybean Boards Join Forces to Expand Soy-Based Markets Partnering for Progress

In today’s marketplace, demand is surging for renewable and sustainable product ingredients. America’s soybean farmers are rising to meet that challenge. At the heart of this effort is Airable Research Lab, a business line of the Ohio Soybean Council (OSC), that’s turning soybeans into real-world solutions for industrial and consumer applications. But this isn’t just an Ohio story. Six other Qualified State Soybean Boards (QSSBs) have joined forces with Airable to bring checkoff-funded innovation to life, working together to accelerate research, commercialization, and market expansion for soy-based products.

Each of these state partners shares a common goal: to drive soybean demand through innovation. By pooling their investments in Airable, they’re not only increasing the lab’s capabilities but ensuring farmer dollars

are used efficiently and strategically to create tangible returns.

Founded in 2019, Airable began as a bold idea by the Ohio Soybean Council to bring product development in-house. According to Barry McGraw, Airable’s Founder and Chief Laboratory Officer, the council realized it could get far more value by funding its own lab than by outsourcing innovation.

“The lab and soybean states have a common goal to drive demand for soybeans, and we’re all working together using a variety of strategies to achieve that goal,” said McGraw.

“We’re not funding just one project; we’re creating an ecosystem that can deliver results across many markets.”

Now, seven soybean boards are behind the lab, with new partnerships continuing to grow. With expanded staff and facilities, Airable is juggling over 30 active projects and has already helped

commercialize 10 soy-based products, with many more on the horizon.

As the momentum behind biobased and sustainable products continues to build, Airable Research Lab is proving that collaboration is the key to unlocking market potential. By joining forces and leveraging collective strengths, state soybean boards are creating a powerful ecosystem for soy innovation one that delivers meaningful, measurable value back to the farm.

With continued support from Ohio, Kentucky, Iowa, Illinois, Michigan, North Dakota, and Missouri, the future of soy is being shaped by forward-thinking partnerships that put farmer dollars to work in smart, scalable ways.

Together, these seven states are not only advancing soy-based solutions; they’re rewriting the playbook on how agricultural innovation gets done.

“The Illinois Soybean Association is proud to work closely with Airable Research Lab through our Soy Innovation Center. With their support and expertise, we’re accelerating the availability of sustainable, soy-based products, which ultimately supports farmers, the economy and the overall health of consumers.”

Todd Main, Market Development Director, Illinois Soybean Association

“Through the checkoff, we are partnering with industries to create environmentally responsible, sustainable and biobased products. We are able to partner with these industries, leveraging our deep knowledge of soy and their investment to codevelop novel products that help meet their needs while enabling a new market for farmers.”

Matt Herman, Chief Officer of Demand and Advocacy, Iowa Soybean Association

“I had the privilege of visiting Airable Labs in 2022 and was pleased to see their commitment to the creation of new products. In a season of low commodity prices, it is more important than ever to focus on the research and development of new uses for soybeans. Airable is a definite win for the soy industry.”

Mark Senk, President and Michigan soybean farmer, Michigan Soybean Committee

“New uses is one of my favorite places to invest Kentucky’s checkoff funds… Partnering with an entity like Airable is just good business. They know what products the industry is looking for, they know how to develop those products, they’re familiar with the patenting process, and they already have a pipeline of industrial clients built up. We are farmers—not experts in any of that. Why would we try to reinvent the wheel when we can partner with Airable on a wheel that’s already working well?”

Barry Alexander, Chairman and Kentucky soybean farmer, Kentucky Soybean Board

“What Airable provides is a link between us as a checkoff and end users of soybeans. It’s a quick response for troubleshooting the potential for a product to be made with soy, without the time delays often associated with university research.”

Bryan Stobaugh, Director of Licensing and Commercialization, Missouri Soybean Merchandising Council

“The North Dakota Soybean Council is proud to partner with Airable to advance the research, development, and commercialization of soy-based products across industrial and consumer markets. With Airable’s proven expertise in developing innovative soy-based solutions for diverse industries, this collaboration allows us to leverage our combined resources to bring more soy-based products to market. Ultimately, this initiative will help drive greater demand for soybeans.”

Miki Miheguli, Director of Agronomy and Research, North Dakota Soybean Council

The Buzz About Seed Oils

By Sarah Alsager and Mark Messina, PhD, MS Soy Nutrition Institute Global with support from the United Soybean Board

Anyone who reads the newspaper, scrolls social media, or watches television has undoubtedly heard something about “seed oils.” Recent survey data shows that 75% of American adults reported they are at least somewhat familiar with seed oils. That statistic is especially striking considering that this term is relatively new and has only been used in nutrition conversations over the past couple of years. While most Americans have heard of seed oils,

FACT #1:

SEED OILS MAY LOWER CHRONIC DISEASE RISK.

One argument of those against seed oils is that they are a modern addition to the diet and because of that must be the cause of diabetes and obesity. Seed oils are a relatively modern addition, gaining popularity in the 1960s with the emergence of soybean oil. Before that, most of the fat used for cooking was animal fat, such as butter, tallow, and lard. It is also true that chronic diseases like obesity and type 2 diabetes have increased over the past 60 years, although heart disease mortality has decreased. However, many societal changes over time have contributed to the obesity epidemic (e.g., increased screen time). Just because both of these things have occurred does not mean that one caused the other. Furthermore, studies monitoring thousands of individuals for decades show seed oil intake is not associated with diabetes. In fact, higher seed oil consumption is linked to lower diabetes risk. Population studies show diets higher in linoleic acid are associated with lower risk of heart disease, diabetes, and overall mortality.

most also have trouble identifying what they are. Seed oils are, as the name implies, oils extracted from seeds including corn, soybean, rice bran, grapeseed, canola, cottonseed, sunflower, and safflower. Sesame seed is also a seed oil but for unknown reasons was not included in the list of seed oils established by the anti-seed oil folks. Popular oils like olive and palm are not seed oils because they are extracted from fruits. Survey results also revealed

FACT #2:

SEED OILS PROVIDE ESSENTIAL FAT AND DO NOT INCREASE INFLAMMATION. Another argument from the anti-seed oil faction is that they are high in fat and increase inflammation. Seed oils are high in linoleic acid, a type of polyunsaturated fat. Americans consume about 8% of their calories in the form of linoleic acid, which aligns with recommendations from the American Heart Association to consume 5 to 10% of total calories from it. When polyunsaturated fat replaces saturated fat, blood cholesterol levels are lowered, which is why seed oils have health claims. Research shows linoleic acid doesn’t increase inflammation or oxidative stress. The notion that they do is outdated thinking.

that 28% of Americans avoid consuming seed oils. This sentiment directly conflicts with recommendations by the American Heart Association to consume polyunsaturated fats such as corn oil, soybean oil, and canola oil. These oils have FDA-approved health claims stating that they may reduce the risk of coronary heart disease. Here are three facts about seed oils that address some of the concerns you may have heard.

FACT #3:

SEED OILS PROVIDE HEALTH BENEFITS, REGARDLESS OF PROCESSING.

The processing of seed oils is another concern from critics. The steps involved are tightly regulated and follow safety standards. While processing is how the oil is made, what matters most is how the oil affects our health. High-quality research shows seed oil consumption benefits health. In addition to lowering the risk of cardiovascular disease and diabetes, evidence shows seed oils may benefit liver function and reduce dementia risk. In many countries, the bigger problem is consuming too little polyunsaturated fat, which seed oils provide. The bottom line: scientific evidence supports including seed oils in our diet. For more information and the full article, visit sniglobal.org/seedoils.

SEPTEMBER 16-18, 2025

COME VISIT US!

We are located at the corner of Friday Ave. & Tractor St.

BOOTH 441

Molly Caren Agricultural Center | London, OH

Record Breaking Virtual Field Trip to Anthony Thomas Chocolate Factory Highlights Food Science and Soy

More than 200 classrooms across Ohio tuned in to watch GrowNextGen’s virtual field trip to the Anthony Thomas Candy Company in May, setting a new attendance record. Students got an inside look at how science and soy come together in the candy making process during a 45-minute behind-the-scenes tour of the factory.

Led by chocolate experts, the trip highlighted real-world applications of chemistry, physics, and food science. Students saw each step of production, from mixing raw ingredients to packaging the finished Buckeyes, while learning how soy ingredients, like soy lecithin, are essential for texture, shelf life, and product consistency.

Perfect for classrooms studying food science, chemistry, and agriculture, this virtual field trip showed how soybeans grown in Ohio help power everyday products in surprising ways.

Want more sweet science? Visit grownextgen.org for free classroom curriculum, career videos, and future field trip opportunities.

Missed the live event? Scan the QR code to watch the recorded field trip on YouTube and bring the chocolate factory experience to your classroom anytime.

High-Performing Products Offer

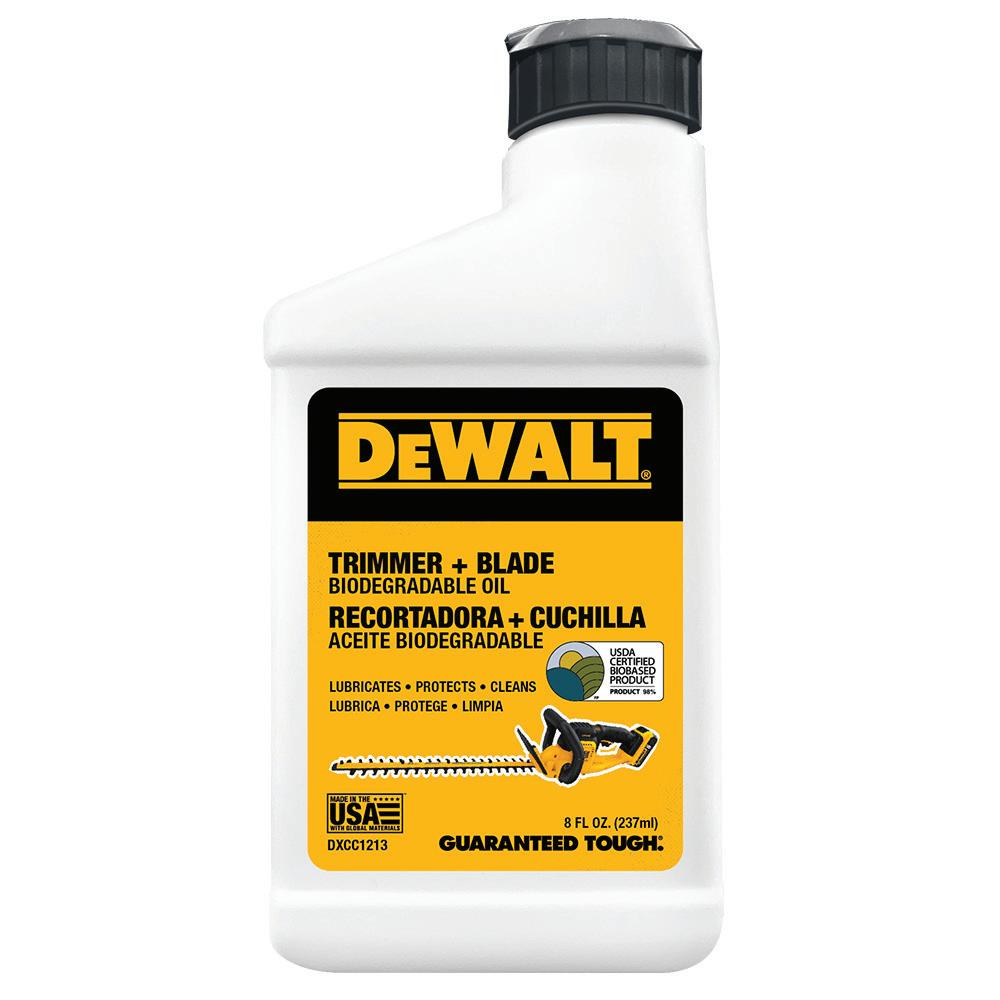

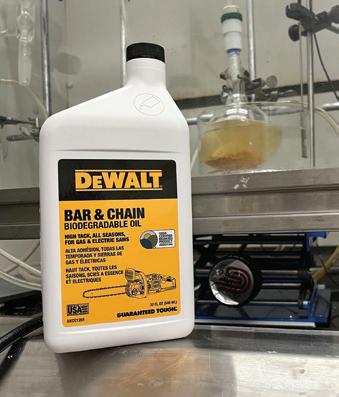

Performance and sustainability combine in three new soy-biobased products that are now available to consumers nationwide thanks to a partnership between Dynamic Green Products (DGP) and U.S. soybean farmers. The United Soybean Board (USB) and the Ohio Soybean Council, through the soybean checkoff, supported the development of DGP’s new soy-biobased trimmer and blade oil, high-load grease and multi-use 3-in-1 oil.

“Using U.S. Soy puts a check mark in every box we have,” said Scott Porter, CEO of Houston-based DGP. “It’s a circular product for our economy. Farmers grow it, processors process it, we take it and turn it into great products, operators use it, it goes into the environment and breaks down, and then the cycle starts all over again.”

and extending equipment lifespan. The high-load grease is formulated to stand up to heavy loads and extreme pressure in industrial applications, construction and more. The multi-use 3-in-1 oil provides quick penetration, rust prevention and lasting lubrication. All three are USDA Certified Biobased Products, manufactured by DGP and sold under Stanley Black & Decker’s DEWALT® label on Amazon. They will be available at additional retail outlets as the product launch continues.

also been able to develop additional products,” Porter added.

“These sustainable products made with U.S. Soy here in America are safer for people and the planet.”

“We welcome DGP’s launch of additional soy-biobased products that are high-performing and cost-effective,” said Jeff Magyar Ashtubula county soybean farmer and United Soybean Board Director. "These sustainable products made with U.S. Soy here in America are safer for people and the planet.”

“Using U.S. Soy puts a check mark in every box we have,” said Scott Porter, CEO of Houston-based DGP

According to Porter, the trimmer and blade oil is a professional grade oil for pruners, hedgers, lawnmower blades and shears, offering superior lubri-

“We’re grateful for the ongoing support of U.S. soybean farmers which has allowed us to bring products to market exponentially quicker than we could have without it, and we’ve

DGP launched a soy-biobased bar & chain biodegradable oil in 2024, with soybean checkoff support. It is available at Amazon, Home Depot, Ace Hardware, Bomgaars, Mac Tools, Grainger, Acme Tools, Atwoods, Family Farm & Home, Do It Best and others. The company plans to launch additional soy-biobased products later this year.

Sustainability Benefits

More information about soy-based products can be found at www.soybiobased.org.

Because of the potential for biobased products to create new markets for soybeans, U.S. soybean farmers have invested millions of dollars to research, test and promote biobased products. Much of this work was done through the United Soybean Board, which is composed of 77 U.S. soybean farmers appointed by the U.S. Secretary of Agriculture to invest soybean checkoff funds. This article was provided by the soybean checkoff.

Dr. Bhima Vijayendran REMEMBERING

arlier this year, the Ohio Soybean Council (OSC) received the sad news that a long-time friend, partner, and soy product innovator, Dr. Bhima Vijayendran, had passed away. OSC had a relationship with Dr. Vijayendran at Battelle Memorial Institute spanning over fifteen years. During that time, primarily under Dr. Vijayendran’s leadership, Battelle and OSC partnered on a number of technical projects focused on developing new uses for soy-based products. Not only did he provide technical leadership on these projects, but he also supported the commercialization efforts when a product was ready for market.

A number of soy-based bioproduct technologies were developed and licensed for commercial use under Bhima’s direction. Some of these included a soy-based plasticizer, a soy-based toner, soy-based polyols, and a soy-based powder coating. All of these technologies won the prestigious R&D 100 Award, and the soy toner also received a Presidential Green

Chemistry Award from the Environmental Protection Agency.

The advantages of developing these new technologies were numerous. Developing products from renewable resources reduces U.S. dependence on foreign oil and improves U.S. energy security with much less impact on the environment. More importantly to soybean farmers, these advancements create new markets for soybeans and soybean products, thus meeting the goal of the Ohio Soybean Council and the soybean checkoff to increase the profitability of Ohio farmers.

Dr. Vijayendran had a passion for the development of agriculturally based bioproducts and was an industry leader in that regard. The opportunities for agriculture and industry to work together in Ohio, across the United States, and around the world to build a bright future for new soy-based products were greatly enhanced by Bhima’s work. After retiring from Battelle, he continued his contributions as a valuable consult-

ant to OSC’s Airable Research Lab, which was established to develop new commercial soy products.

Reflecting on Bhima’s impact, Airable Research Lab founder and chief laboratory officer, Barry McGraw shared, “Bhima’s support to OSC’s research arm—and later to Airable— has been long-standing and invaluable. Along with working on joint projects, he was one of Airable’s first consultants, stepping in until a full-time staff was on board. Just as important, Bhima gave me advice over the years that I follow to this day, especially in the areas of client negotiation and product commercialization. He was a great colleague and mentor and, even more importantly, just a good person.”

Bhima will be deeply missed by all those in the soybean industry who had the pleasure of knowing him. OSC board members, OSC staff, industry partners, and co-workers all greatly appreciated his intellect, vision, collaborative nature, and grace.

Through the Years with OSC

1997

Collaboration with Battelle Begins

The Ohio Soybean Council (OSC) initiates a major partnership with Battelle, one of the world’s leading independent R&D organizations, to explore and develop innovative, sustainable soy-based products.

2008

Presidential Green Chemistry Award for SoyBased Toner

OSC and its partners earn the U.S. Presidential Green Chemistry Challenge Award for the development of a soy-based toner, an environmentally friendly alternative for the printing industry that reduces petroleum use.

2002

OSC Wins First R&D 100 Award

OSC’s collaborative efforts gain global recognition when they won their first prestigious Research and Development 100 (R&D 100) Award for developing environmentally friendly soybean-oil-derived plasticizers for polyvinyl chloride resin.

2013

Barry McGraw Joins OSC

OSC welcomes Barry McGraw as Director of Product Development & Commercialization, bringing 15 years of experience from Battelle, where he helped develop award-winning soybased technologies.

2017

Launch of Roof Maxx

Roof Maxx launches as a soy-based shingle rejuvenator developed by the Ohio Soybean Council, Ohio State University, and Battelle, offering an affordable way to extend roof life by up to 15 years.

Airable Research Lab Opens

OSC launches Airable Research Lab, a new business line aimed at expanding soy use in household and commercial products, building on over 20 years of successful product development and partnerships.

2019

2024

Partnership with DGP for Bar and Chain Oil

OSC forms a partnership with DGP (Dynamic Green Products) to develop and commercialize a soy-based bar and chain oil for chainsaws and heavy machinery, offering a biodegradable, high-performance alternative to petroleum products.

EnzoMeal Wins R&D 100 Award

OSC and Battelle develops EnzoMeal®, a soy-based fish feed ingredient that removes non-digestible carbohydrates and boosts protein content. This development wins the 2017 R&D 100 Gold Special Recognition Award in the Corporate Social Responsibility category, highlighting its potential to revolutionize sustainable fish farming.

2020

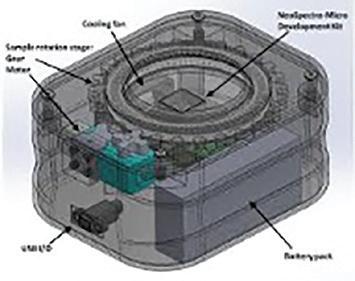

Crop Quality Sensor Receives 12th R&D 100 Award

OSC partners with The Ohio State University to develop a handheld sensor for screening crop quality, earning a 12th R&D 100 Award.

2025

Expansion to Shawnee State University

Airable Research Lab announces a $1 million expansion to Shawnee State University’s Advanced Manufacturing Center, creating a new hub for developing soy-based products and renewable polymers.