As you read this, Flogistix is embarking on an exciting new phase in our company’s history. The merger with FlowCo Production Solutions and Estis Compression will create many opportunities for Flogistix to grow not only our vapor recovery business but also our production optimization and compression offerings. As we have watched the industry evolve and many oil and gas production companies merge, it was important for us to look at our growth potential and strategically align ourselves with partners working towards a similar goal – helping to provide the energy our planet needs but, in an emissions-free environment. Our new structure provides Flogistix more flexibility regarding pricing, increased market share, and diversification of our products and services, and the combined company will offer additional services to our customers including high pressure gas lift, traditional gas lift, and plunger lift. I am confident we are ready to tackle whatever the future holds for our company, and I am proud to be surrounded by such a great team as we take on this new challenge.

Our company’s evolution continues to focus on cutting edge technologies both within the vapor recovery and the methane detection businesses. In this issue of the newsletter, you will learn more about a collaboration between Flogistix and the University of Oklahoma on an innovative sensor technology that would allow for the collection of methane data on a regional scale. In addition, the Commaris team is currently testing a new sensor on the SEEKER that can capture the necessary data for regulatory reporting at the fixed-wing drone’s higher speeds. Likewise, the Pampa manufacturing location recently installed a new plasma table used for cutting components with computer precision and speed resulting in improved productivity and reduced operational costs.

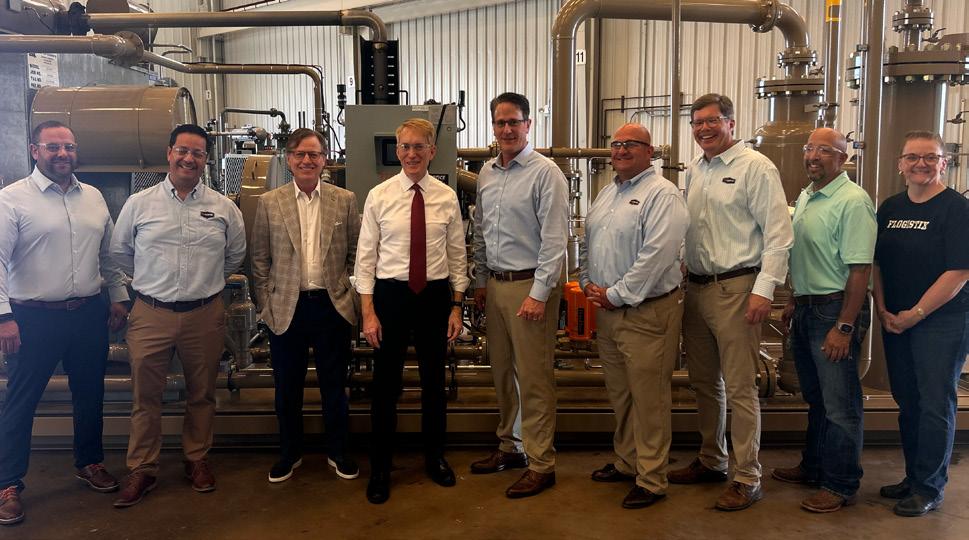

We were fortunate to have United States Senator James Lankford visit our El Reno manufacturing facility in late June. Sen. Lankford who represents Oklahoma, was eager to learn about vapor recovery and how our technology is helping reduce emissions all over the world. Educating our lawmakers is vital to ensuring that as legislation is introduced, the industry’s interests are considered. Developing relationships with officials at our state capitals and in Washington, D.C. gives Flogistix the opportunity to be a resource to these representatives as they make decisions affecting our company, our industry, and our country.

I hope you all have an enjoyable summer and as always, please be safe.

Mims Talton

Mims Talton President and Chief Executive Officer

“ “

...I am proud to be surrounded by such a great team as we take on this new challenge.

Flogistix had the pleasure of hosting U.S. Senator James Lankford, R-OK, at our El Reno manufacturing facility on Tuesday, June 25, for a tour of the site and conversation about crucial legislation and regulations impacting our customers and the industry.

President and CEO Mims Talton and our dedicated team of experts led the tour, showcasing the manufacturing process of our vapor recovery units and sharing insights into our AirMethane emissions detection program. Since its opening in 2022, our El Reno manufacturing facility has cultivated a thriving and innovative community, enabling us to produce cutting-edge technology that captures vapors and reduces wellhead emissions by 99% for our customers. The tour also highlighted our AirMethane detection team and their stateof-the-art drones that are equipped with optical gas imaging cameras to accurately detect gas leaks and ensure regulatory compliance at both federal and state levels for our clients. The tour was a great opportunity to share why our work in El Reno and nationwide is vital.

Our presence in Mexico is increasing as additional units are set in the country. In early June, a Flogistix unit was set for Jaguar, an oil and gas multinational company doing business in Mexico. The unit was rigged up in the Burgos Basin in northern Mexico along the Texas border. The unit is being used as a production enhancement tool to increase production at that facility.

Ian Wilson, Technical Sales Representative, recently travelled to Turkmenistan to attend the Turkmenistan Energy Scientific Conference (TESC). While there, Ian met with William “Ed” O’Brian, Economic and Commercial Officer, U.S. Embassy Ashgabat Turkmenistan and Gozel Hallyeva, Economic Assistant U.S. Economic Commercial Advisor for Turkmenistan.

By Eric Greear, Director of Manufacturing

On May 21, 2024, the Pampa manufacturing team successfully commissioned the Machitech 6’ x 12’ plasma table. This plasma table replaces an end-of-life cutting solution and dramatically impacts the capabilities of the Pampa manufacturing team. The plasma table is essential to our operation as it cuts detailed components that are utilized to build structural weldments. In addition, it will improve productivity by providing faster cut times, reducing secondary operations, and improving the cut quality of each component manufactured on the table.

The table utilizes computer numerical control (CNC) programming to ensure parts are built in strict accordance with the 3D model of the parts being cut. In addition, the machine leverages nesting software to optimize the arrangement of parts on a sheet of metal to minimize waste and cutting time. By leveraging these capabilities, the manufacturing team is poised to improve throughput and eliminate waste. Sub Assembly Lead, Dustin Curtis commented, “This plasma table is going to help us out now and in the future by cutting material more efficiently and with better quality.”

A similar Machitech machine has been operating in the El Reno manufacturing facility for several months and has been utilized very effectively. The El Reno manufacturing team has been very helpful during this project and has shared their collective experience with the Pampa team throughout the installation of the new plasma table. With the El Reno team’s support, the effective project management of Manufacturing Engineer, Rod Wichert, and the hard work of the Pampa manufacturing team, the machine was commissioned in just 70 days from the vendor’s receipt of order- which is a remarkable accomplishment! Plasma Table Operator, Dalton Cross recently had this to say about the Machitech Plasma table, “…it makes precise cuts and is three times faster than the old plasma table. I believe the table will pay for itself quickly… it was a great investment!”

The Pampa team is grateful for this investment and is excited to have the opportunity to leverage this solution to improve productivity, part quality, and reduce operational costs. The addition of a second Machitech plasma table is proof that Flogistix is committed to excellence in manufacturing.

By Eric Greear, Director of Manufacturing

Flogistix has always been passionate about developing a culture committed to safety. In 2024, our manufacturing teams in El Reno and Pampa have embraced this commitment by empowering our employee centered Manufacturing Safety Involvement Team (MSIT) to initiate needed changes to our safety protocol.

The MSIT is comprised of volunteer employees from each department who meet monthly to discuss opportunities and initiatives to improve safety with the Operations Director and EHS Manager at each site. In addition, each MSIT member conducts a monthly audit in KPA (our EHS software) to evaluate and score each area of the manufacturing facilities. These audit results are communicated to the manufacturing leadership to ensure opportunities for improvement are addressed in a timely manner. This provides an effective platform for open and honest communication between our front-line employees and management and a level of accountability for mitigating risks.

In Pampa, the MSIT has accomplished several projects to address safety concerns at their facility. Some projects accomplished by the team have resulted in improved safety by adding lighting to the parking lot

and the test loop. In addition, the team has identified several opportunities that have resulted in capital facility improvement projects which are currently underway at both Pampa facilities. Bobbi Cortez , a lead in the Pampa Finish Department had this to say about the MSIT, “Being a part of the team means that I have a huge impact on making sure my coworkers and myself make it home safely to our loved ones at the end of every workday.” Dustin Curtis, our Fabrication Subassembly Lead, added “The MSIT team has opened my way of thinking and helped me see potential hazards to fellow employees and to understand how to prevent hazards on a much larger scale.”

The MSIT has become a critical component of our safety culture in manufacturing. The MSIT reinforces the belief that every person on the team, regardless of their title, has a role to play in making sure we build a safe work environment. Dreamia Klein, sums this up best, when she says this of the MSIT, “It takes a village, that’s for sure!”

The team is working hard to build an effective platform for communication, collaboration and accountability across our manufacturing enterprise.

Agustin Lioni and Martin Rubin of Vista located in Argentina visited ERM on May 5. The tour included Mims Talton, President & CEO; Jim Merrill, CFO; Drake Andarakes, VP of Sales; Kevin Pollard, VP of Manufacturing; and Sean Ingram, Director of Manufacturing. After the tour, Vista purchased its first Flogistix unit, and we are in discussions to deliver more units to them. They will be one of our focal companies in the Vaca Muerta formation which is in the Neuquen Province of Argentina.

Engineering students from Southwestern Oklahoma State University (SWOSU) toured El Reno Manufacturing (ERM) in April. Hector Godina, Director of Quality and Operational Excellence, and Chesney Swartwood, Manufacturing Engineer, led the tour. Students learned more about vapor recovery, our units, and the scope of operations at ERM. Chesney, an alumnus of SWOSU, was able to share his experience working as an engineer and which courses helped prepare him the most for his job at Flogistix.

By MacKenna Williamson, Communications Intern

Flogistix is participating in a unique collaboration with Assistant Professor Binbin Weng, Ph.D., at the School of Electrical and Computer Engineering at the University of Oklahoma.

The partnership focuses on an $8.5 million project centered on innovative methane sensor technology, which aims to provide accurate, real-time data for oil and gas companies nationwide.

Inspired by OU's "Big Idea Challenge" program, Dr. Weng proposed this interdisciplinary project three years ago, aiming to secure grant money from the Department of Energy. The project, titled "A Regional-Scale Showcase of Hybrid Methane Sensing Networks in the Anadarko Basin," focuses on Oklahoma's biggest asset, the oil and gas industry, and is part of the Department of Energy's Innovative Methane Measurement, Monitoring, and Mitigation, or iM4, technologies program. The project focuses on three types of iM4 technologies: groundbased, satellite, and drone sensors. These sensors are designed to be compact, energy-efficient, and cost-

effective. Instead of targeting individual well sites, Dr. Weng said he aims to collect data at a more extensive, regional scale to give companies the ability to have data backing and accurate emissions to report if government agencies request them. The pilot study focuses on an area of land approximately 10 square miles in the STACK play.

The project has funding over a five-year span, which allows Dr. Weng's team of five postdoctoral researchers and fifteen undergraduate students time to test and research what sensors and automated technologies will provide the best baseline emissions report for operators.

Dr. Weng's team is utilizing advanced infrared technology for their sensors, which detect methane particles indirectly through light, offering a longer lifespan compared to electrochemical detection methods. The sensor is housed in steel boxes mounted on the roof of a Flogistix Tesla, using solar power to ensure low power consumption and continuous operation, which provides an accurate depiction of methane plumes across regions.

Flogistix has been integral to the project, supplying automated technologies like our company Tesla, expertise in methane detection sensors, and direct collaboration with Dr. Weng. Corporate Product Manager Ryan Coe has been involved since the project's inception, while Director of AirMethane Dave Martinez has supported the team during testing days.

The goal of the project, according to Dr. Weng, is to "extend this detailed technology basin-wide, sort of like streetlights." The use of unmanned vehicles like the Tesla ensures zero net emissions and removes the need for manual data collection, simplifying the identification of emission sources and providing companies access to "real-time" data. Dr. Weng says that ideally, OU researchers will distribute and monitor the data, allowing companies to subscribe and receive it when needed.

While the project is just entering its testing phase, Flogistix looks forward to continuing to offer support and collaboration!

Commaris recently flew SEEKER drones in Nevada and Texas, to evaluate sensors that can be used to gather critical data for potential customers.

The battery-powered SEEKER is similar in some respects to the drones that AirMethane uses. It can carry the right sensor for the job, whether sensing methane leaks in pipelines or visually inspecting pipeline rights-of-way. Unlike smaller drones, though, the SEEKER, with its 15-foot wingspan, can fly for up to 2+ hours at speeds of 45-70 mph on a single charge, giving it the ability to cover a lot of ground in a short amount of time. However, that speed advantage can also be a challenge. Many sensors made for traditional drones do not function at the SEEKER’s higher speeds, so continuous development and testing are necessary. Testing new sensors for methane detection on the SEEKER involves large plots of land, dedicated time, and skilled pilots.

In May, Commaris conducted tests by placing a methane tank in a dry lakebed near Commaris’ Las Vegas office, opening the valve, and repeatedly flying overhead. The results were promising, so they followed that with validation testing alongside the AirMethane team in Higgins, Texas. This validation testing included flying over 13 miles of a prospective AirMethane customer’s pipeline, and according to Commaris President Kevin Colburn, while some adjustments are still necessary, the sensor showed promise.

These recent efforts align with the goals of providing support and guidance to the midstream sector in the face of new regulatory requirements for methane leak detection.

Great job, Commaris and AirMethane teams!

By MacKenna Williamson, Communications Intern

By Danny Burrows, Vice President of Software Engineering

Beginning this summer, our IT Ops will start the transition from Google Workspace to Microsoft’s Office Suite. We want to assure you that this transition is all about enhancing our efficiency, collaboration, and productivity as a team. Microsoft offers a wide array of powerful tools and features that will empower us to work smarter and achieve our goals more effectively than ever before. This will also provide familiarity and consistency across the organization.

As part of the transition, we will move existing Google Drive files and folders, emails, calendars, and other key Google applications to the Microsoft ecosystem. You will keep your email, your calendar, and all your files as part of this move. The migration of individual departments will be communicated in advance.

Our IT team is the first department to make the move from Google to Microsoft, so we can address any issues before we have other departments make the transition. We will take a phased-in approach, moving one department at a time to minimize downtime and the number of potential issues that may arise. Non-IT departments will start at the end of June, and all departments will be completed by early

September. We expect a smooth transition, but a move of this nature always has unknowns. Grace and patience are welcome and appreciated. Please inform us of any issues you may encounter as we move forward.

We understand that change can sometimes feel overwhelming, but our IT Ops team is working diligently to ensure a smooth transition process. We will provide all the necessary training and support to help you navigate this change with confidence, as well as helpful links from Microsoft. Be on the lookout for upcoming training, videos, and other learning material in your Paycom account under Training. We hope you find this information helpful and are excited to continue this growth in technology.

If you have any questions or concerns along the way, please don’t hesitate to reach out. We’re all in this together, and IT Support is here to assist and guide you every step of the way.

Here’s to a bright and successful future together!

In today’s whirlwind work environment, the quest for efficiency and productivity is more pressing than ever. As we juggle myriad tasks and deadlines, harnessing the power of artificial intelligence (AI) has become a game-changer. For newcomers to AI, tools like ChatGPT offer a transformative approach to day jobs, streamlining workflows, improving communication, and elevating overall productivity.

Demystifying Ai: A Beginner’s GuiDe

AI may seem intimidating, but tools like ChatGPT are remarkably accessible. With intuitive interfaces and userfriendly experiences, ChatGPT, based on OpenAI’s potent language model, seamlessly understands and responds to human language, making it an invaluable ally for those striving to optimize their workday.

enhancing communication anD collaBoration

ChatGPT isn’t just a tool; it’s a virtual assistant that enhances communication and collaboration. Whether drafting emails, composing reports, or brainstorming ideas, ChatGPT provides suggestions, generates content, and offers valuable insights, fostering effective communication with colleagues and clients.

s treamlining Workflows anD Tasks

Beyond communication, ChatGPT streamlines workflows and automates repetitive tasks. From scheduling meetings to summarizing documents, ChatGPT ensures organizational efficiency, freeing time for strategic initiatives.

By Ali Sylvester, Director of Business Solutions

Practical Tips for optimizing y our Day JoB with chatGPT

1. Research and Information Gathering: Consult ChatGPT for quick answers and insights when facing complex problems or unfamiliar topics. Ask questions like “Can you provide insights or information on [topic]?”

2. Drafting and Refining Documents: Utilize ChatGPT to draft content, refine language, and ensure clarity in communication. Get started by prompting ChatGPT with something like “Can you help me draft an email/ report/presentation on [subject]?”

3. Automating Routine Tasks: Leverage ChatGPT’s automation to handle data entry, scheduling, and followup emails, allowing focus on creative tasks. Leverage task Automation by prompting, “How can I automate [repetitive task] using ChatGPT?”

4. Seeking Feedback and Collaboration: Facilitate collaboration by using ChatGPT to generate discussion prompts and solicit feedback on concepts and proposals. Try asking “Do you have any suggestions for improvement or additional ideas into incorporate to this concept?”

As AI evolves, embracing tools like ChatGPT empowers individuals to work smarter. By optimizing day jobs with AI, professionals unlock new levels of efficiency and productivity, driving success in their careers and organizations.

By Allison Goodman, Vice President of Human Resources

Suicide is a deeply complex and troubling topic when it comes to mental health . Although it is often misunderstood and stigmatized, it’s crucial to address suicide for increased awareness and prevention.

The World Health Organization estimates that close to 800,000 people worldwide die by suicide each year, with countless others attempting it. It can affect individuals of any age, gender, socioeconomic status, or background. While mental illness is a significant risk factor, other factors such as trauma, substance abuse, chronic illness, or social isolation can also contribute to suicidal thoughts and behaviors.

To prevent suicide, it is helpful to know some of the warning signs. These may include but are not limited to talking about wanting to die, experiencing feelings of guilt and shame, or feeling like a burden to others. People struggling with suicidal thoughts may express feeling empty or hopeless or having unbearable emotional pain. They may also exhibit behaviors such as displaying extreme mood swings, withdrawing and isolating from friends and loved ones, giving away important items, changes in eating and sleeping patterns, increased drug or alcohol use, or taking dangerous risks such as driving extremely fast.

It is essential that you reach out for help if you or a loved one is struggling with thoughts of suicide. The Flogistix EAP is one resource you can use that is 100% confidential and free to you and your loved ones. You can access the EAP by calling 888-628-4844. In addition, dialing or texting 988 will put you in touch with the national suicide hotline, where you can obtain help.

At Flogistix, your mental health matters. Please seek help if you or your loved ones are struggling with thoughts of suicide. Let’s end the stigma.

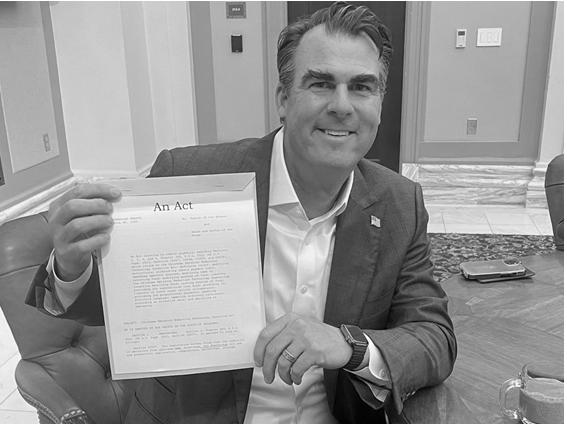

oklahoma emission reduction technology incentive act

On May 28, 2024, Governor Kevin Stitt signed Senate Bill 1505: Oklahoma Emissions Reduction Technology Incentive Act formally approving the legislation, which provides $50 million for emission-reduction projects in Oklahoma’s oil and gas industry.

Senate Bill 1505 expands the provisions of the Oklahoma Emission Reduction Technology Incentive Act, increasing the funding and designating rebate amounts for industry segments. When approved two years ago, the incentive act allowed for $10 million for implementing qualified emission reduction projects, with the Department of Environmental Quality approving all claims for a rebate payment. Although the tax provision for emissions controls was approved by the legislature and signed by Governor Stitt, the program was not funded at that time.

The $10 million has been increased to $50 million, with $30 million earmarked for upstream and midstream and another $20 million to fund downstream projects. Qualifying emissions reduction projects will be eligible for a rebate of up to 25% of documented implementation costs until the funds are depleted.

By Bernadette Granger, Director of Community and Public Affairs

This passion is evident at the beginning of the school year and at Christmas when Flogistix employees rally to meet the needs of children across our multiple locations. This year, Flogistix is continuing to collect school supplies for area schools through our volunteer program, FloGive. Items needed vary from school district to school district. However, below please find a list of universal items needed:

» 24-count box of crayons

» Box of colored map pencils

» Glue/glue sticks

» Loose leaf wide-ruled paper

» Scissors

» 12” ruler

» Bottle of hand sanitizer

» Box of Kleenex

» Highlighters

» Large pink erasers

» Dry erase markers

» Backpacks

» Clorox wipes

» 3-ring binder

» Plastic folders with pockets and brads

For the remainder of 2024, FloGive will focus our volunteer efforts on hosting a school supply drive and a similar effort at Christmas focused on children and youth.

As a reminder, Flogistix will match items or funds donated to buy school supplies.

For more information, please contact your location’s volunteer coordinator or Bernadette Granger at (405) 834-7066 or bgranger@flogistix.com.

By Bernadette Granger, Director of Community and Public

Members of the Flogistix Team gathered in Pampa, on June 11, 2024, to celebrate Whitney Davis, 2023 FloGive Volunteer of the Year. Whitney serves as Payroll/HR Administrator and co-coordinator for our volunteer program, FloGive. She has donated countless volunteer hours to various causes and organizations throughout the Pampa community. A charitable donation to the City of Pampa’s Celebration of Lights has been made in her honor. Whitney exemplifies the generous and giving spirit of the Flogistix family.

Congratulations on a well-deserved honor, Whitney!

Republican National Convention in Milwaukee

Democratic National Convention in Chicago

Election Day

Inauguration Day

On July 4, 1776, 56 delegates from 13 colonies signed the Declaration of Independence, which was written by Thomas Jefferson. John Hancock was the first person to sign, and Charles Thomson originally signed on July 4. The others did not sign until August 2.

By Bernadette Granger, Director of Community and Public Affairs

The upcoming 2024 Presidential Election is an unprecedented re-match between President Joe Biden and former President Donald Trump. Early polls show that the economy, inflation, immigration, and reproductive rights are top of mind issues for most voters. Pundits argue that President Biden’s advanced age and former President Trump’s legal woes will likely be concerns raised throughout the entirety of the campaign. Voters will likely see candidates concentrating their time and resources in key battleground states that include Arizona, Georgia, Michigan, Nevada, Pennsylvania, and Wisconsin.

If you are not registered to vote, you may visit your local county clerk’s office or www.usa.gov or www.vote.gov. Please contact Bernadette Granger at (405) 834-7066 or bgranger@flogistix.com if you have any questions or need any additional information.

The goal of our Get Out the Vote (GOTV) campaign is not to tell our employees how to vote, but to encourage our employees to exercise their right to vote. It is our hope that Flogistix employees feel empowered and confident when entering the voting booth in November as a result of our GOTV campaign.

1777 was the first-year fireworks were used in an official Fourth of July celebration. Congress authorized using fireworks to help mark the first anniversary of the Declaration of Independence.

Sixty-five percent of Americans plan to have a BBQ or picnic on July 4. 150 million hot dogs and 190 million pounds of beef are consumed each Fourth of July.

“The Star-Spangled Banner” was written by Francis Scott Key and was originally a poem. After multiple failed attempts, a bill making “The StarSpangled Banner” our official anthem was finally passed by Congress and signed into law by President Herbert Hoover on March 3, 1931.

The Fourth of July became a federal holiday in 1870.

By Bernadette Granger, Director of Community and Public Affairs

Don’t shortchange yourself by not asking questions.

Growing up in a big family shaped Deanna Rives’ character, prepared her for life, and has helped her in her role as Field Service Supply Chain Manager at Flogistix.

Born and raised in Sheridan, Wyoming, Deanna learned many lessons early in life being a member of a large family. Raised by a single mother, Deanna and her seven siblings learned to be grateful for what they had, to be resourceful, the value of family, and to take care of each other. In addition to her mother’s love, Deanna was surrounded by the love and support of her grandparents, fifty-two first cousins, and a large extended family. Deanna describes her childhood as centered around family whom she calls “the root of everything,” and on whom she depends “to get through the hard times and celebrate the good times.” Learning to take care of family has translated to taking care of her work family, too.

Deanna’s raising has benefited her in her role as Field Service Supply Chain Manager which she describes as having “many moving parts.” Deanna’s resourcefulness serves her well as she does her best to ensure customers and coworkers alike have what they need. According to Field Service Area Manager, Aaron Grossi, “when Deanna is here, she gives it her everything. She is a very passionate [employee]. There is no comparison. She is just that good and cares that much. She’s compassionate toward everybody,” said Grossi. Celebrating her 20th anniversary with Flogistix in June, Deanna describes the hardest part of her job as trying to keep people happy. A people-pleaser by nature, Deanna hates disappointing people, and strives to get answers to every question and complete every task in a timely manner.

When she is not working, Deanna and her husband of 38 years, Wade, can be found camping in the Big Horn Mountains. Most weekends they enjoy the natural beauty of Wyoming with their son, daughter and son-in-law, grandchildren, and two dogs. Together, they enjoy visiting as many National Parks as possible in their camper. In May, they were fortunate to see five National Parks in Utah. When the Wyoming winter leaves them craving sunshine, they head to sunnier climate and hope to see the San Antonio Riverwalk soon. Deanna maintains she is happy anytime she is with her family no matter the locale. Her life outside of work revolves around family, and she is “satisfied being with family while pursuing their passions.” Deanna proudly boasts that she is her family’s biggest cheerleader and does not mind spending endless hours in bleachers cheering on her grandchildren.

When asked to give advice to new hires, Deanna said “be receptive to information and don’t ever be afraid to ask for help. Don’t short-change yourself by not asking questions. No one knows it all in this industry, but if you ask, someone probably has the answer.”

Sound advice, Deanna! Congratulations on your 20th anniversary with Flogistix. We are blessed to have you as a part of the Flogistix family.

By MacKenna Williamson, Communications Intern

I want to provide resources and remove roadblocks for my employees

Denys LeBlanc exemplifies leadership and dedication. Since joining Flogistix as Vice President of Field Services in May, his main focus has been understanding how to best support his team.

Denys grew up in New Brunswick, Canada, where he attended a local community college and earned a diploma in electronics engineering technology. While studying, he was introduced to the oil and gas industry and began his career with Schlumberger in 2001, working in field service immediately after graduation. He relocated 3,000 miles away to Alberta, Canada, to join the industry and met his wife in the process.

Moving around for work isn’t new for Denys; in fact, he moved to Midland, Texas in 2013 after several years in Alberta and has lived in the U.S. ever since. He, his wife, and three kids are currently in the process of moving to Oklahoma City, where he says they are excited to attend live sporting events, explore the outdoors, and be part of the tight-knit OKC community.

Denys has spent 23 years in the industry, working in operations for the entirety of his career. In his job as Vice President of Field Service, Denys is excited to meet and learn alongside the field service team while being a leader who truly cares for employee wants and needs. “I want to provide resources and remove roadblocks for my employees so business can execute,” he said. One thing that drives Denys’ work ethic is creating healthy competition with himself. He says as a data-driven person, he is continually setting goals and motivating himself to aim for better.

Outside of work, Denys can be found in his home gym, on a road trip to camp with his family, or traveling to see his identical twin brother, Marty, and other family members who still reside on the east coast of Canada.

Welcome to the Flogistix team, Denys! We are glad you’re here!

Joins Commaris

By MacKenna Williamson, Communications Intern

In April, Commaris had the pleasure of welcoming Sean Rieb to the team as Director of Engineering.

Sean grew up in Albuquerque, New Mexico, with a family of engineers and tinkerers. His early passion for problem-solving led him to follow in their footsteps and pursue a degree in Electrical Engineering from the University of New Mexico.

Now a veteran engineer with more than 35 years of experience, primarily in the aerospace and aviation industries, Sean brings a wealth of knowledge to Commaris.

Sean’s passion for engineering is fueled by his love of problem-solving. “I love building. I am curious about what makes things work, how to get to every stage of a project, and how to do so effectively,” he shared. His enthusiasm for tackling puzzles and finding innovative solutions drives his work, where he enjoys tinkering, building, and problem-solving daily while strategically leading a team of engineers and pilots. Whether it’s coding, soldering, or reviewing technical documents, Sean is fully engaged to ensure the team functions seamlessly.

In his free time, you can find Sean working on his 1980 Honda motorcycle, building engines and carburetors, or fixing things in the garage while still making time to travel and support his family at various sporting events. To Sean, family is the most important thing in life. “Whatever their endeavor, I make sure I am there to support,” he said.

Sean is particularly excited about returning to aviation-related projects after a two-year hiatus from the sector. He says he is ready to dive back in, leading by example and maintaining high standards of practice.

Welcome to the Commaris team, Sean!

By MacKenna Williamson, Communications Intern

We are excited to welcome four new interns to the Flogistix team this summer, joining our Software Engineering, Product Development, and Creative departments.

In Software Engineering, Abe Artus and Ben Patrick are collaborating with Vice President of Software Engineering Danny Burrows to reconstruct the FloWorks app for customers.

Joseph Sylvester, our Product Owner intern, is designing a new workflow for the FloWorks app. He is also gaining hands-on experience with the production process at the El Reno manufacturing facility, guided by Director of Business Solutions Ali Sylvester.

Creative intern Rachel Golla is working under Manager of Creative Solutions Adam Ragsdale. She is enhancing Flogistix’s branding by creating new animations for the Flogistix logo, developing collateral material, and contributing to upcoming campaigns.

We look forward to seeing the valuable contributions they will make this summer!

By Mike Southard, Vice President of EHS

In North America, 20% of the snake population is venomous. A snake bite by a venomous species may lead to severe injury and sometimes even death. Knowing what first aid measures to do and not do after a snake bite is important. Here are some frequently asked questions and first aid measures.

What should I do after a snakebite?

If you are bitten by a venomous snake, call 911 or contact your local emergency number immediately. Look for signs such as pain or swelling or a change in color at the site of the bite. You must visit an emergency room and may have to take anti-venom shots immediately. If possible, take a picture of the snake. There are up to nine different species of rattlesnakes in the areas where we work, and the anti-venom shot is specific to the snake type.

What is the first aid treatment for a snake bite?

If a non-venomous snake bites you, you will still need medical attention from a physician. If bitten by a snake, it is important to stay calm and lie in a semi-reclined position while keeping the bite wound below the heart. This will prevent the venom from spreading to other parts of the body. Call 911 for emergency medical help.

Next, clean the wound . If the bite site is bleeding, gently clean the area with soap and water. If possible, dress the wound. Do NOT clean the area under running water.

Venomous snake bites can be fatal. Therefore, get medical help as early as possible. The most severe symptoms may only appear after several hours. Since snake bites can potentially be fatal, they should always be treated as a medical emergency.

Symptoms

Snakebite wounds and symptoms may differ based on the amount of venom inside your body. Most snake bites occur on the extremities.

Typical symptoms include:

• Pain, itch, and scratch at the site

• Severe burning pain at the site within 15 to 30 minutes

• Swelling and bruising

• Change in color at the site

• Nausea, labored breathing, and weakness

• Odd taste in the mouth

• Skin tingling

• Difficulty speaking and lightheadedness

• Venomous snakes can sometimes bite without injecting venom. These “dry bites” only irritate the site, and still require medical attention.

What are the “dos” and “don’ts” of snake bites?

Do

• Take the first aid steps listed above while waiting for medical help.

• Remain still and calm . This helps slow down the spread of venom.

• Remove jewelry, shoes, or any tight clothing before the snakebite wound starts to swell.

• Keep the snakebite area at or below the level of your heart .

• Wash the wound with soap and water and keep the wound clean. While not necessary, you may cover the area with a sterile, dry dressing.

• Draw a circle around the bite area and write the time beside it. This will assist with medical treatment.

Don’t

• Don’t use a tourniquet or apply ice to the snakebite area.

• NEVER puncture or cut the wound area in an attempt to release the venom.

• Avoid drinking any caffeine or alcohol. This speeds up the venom absorption inside the body and may worsen the situation.

• Don’t harm or try to capture the snake. When possible, you may use your smartphone to take a picture of the snake from a safe distance to help medical staff identify the correct anti-venom to administer.

Familiarize yourself with the types of snakes present in the areas where you will be working or recreating. If you see a snake, leave it alone and maintain at least six feet distance from the snake. Do not attempt to move or scare the snake to flee, as this could lead to being bitten. Remember, only professionals should handle snakes.

By Mike Southard, Vice President of EHS

“Four wheels move the body; two wheels move the soul.”

“Four wheels move the body; two wheels move the soul.”

Riding a motorcycle is an adventurous and exhilarating experience. By nature, motorcycles attract a contingent of risktakers who may be much more aggressive in their driving/riding habits. These riders often find themselves the makers of their misery as single-vehicle accidents result from excessive speed or poor riding skills paired with high-risk behavior. But what about most riders? Most are more careful and take much less risk than these other aggressive riders.

However, the harsh reality is that motorcycle riding can be very dangerous if proper precautions are not taken. Motorcycles account for roughly 14% of all road fatalities which is five times more fatal than other forms of transportation. With statistics like these, it makes sense to take safety seriously while riding motorcycles. We’ve compiled a list of tips, so you can safely enjoy your ride.

Motorcycle safety refers to the practices and precautions taken to protect riders from risks while using motorcycles on the road. It encompasses multiple safety aspects, from rider behavior and protective gear to motorcycle maintenance and compliance with traffic laws. Following these practices can significantly reduce the likelihood of accidents and keep individuals safe on the road.

One of the best ways to keep safe during motorcycle rides involves knowing what risks you can encounter on the road. Here are ten of the most common motorcycle safety hazards to watch out for:

Lack of visibility Motorcycles are smaller and more difficult to see than other vehicles, increasing their risk of collisions. Thus, other drivers are more likely to overlook them on the road, especially in blind spots or when changing lanes.

Road conditions Defects on the road surface pose safety hazards to motorcyclists. For example, potholes, loose gravel, uneven pavements, or oil spills can decrease traction on the road, resulting in accidents.

Distracted driving Drivers engaged in activities like texting, talking on the phone, or using in-car technology are less likely to notice motorcycles and more likely to be involved in collisions. Failing to look at the road properly is the leading cause of motorcycle-related crashes in the United States.

Driver negligence Negligent actions from other drivers present a serious threat to the safety of motorcyclists. Crashes are more likely to occur when drivers suddenly change lanes, run the red lights, or fail to yield right-of-way.

Impairments Drivers under the influence of alcohol, drugs, or medications are more likely to get involved in accidents, as these conditions can give them reduced reaction time, diminished coordination, and impaired judgment. In the United States, 29% of motorcycle-related injuries have resulted from drunk driving.

Intersection collisions Intersections are common locations for motorcycle accidents. Motorists may misjudge the distance of motorcycles or their speed when turning left or crossing intersections.

High-speed collisions

Excessive speeding seriously increases the risk of accidents for motorcycle riders. The faster the vehicle goes, the less time riders have to react to impending hazards, and the gravity of the crash heightens.

Lack of protective gear Failure to use protective equipment, such as helmets, pants, gloves, and boots, makes riders susceptible to head injuries, fractures, and abrasions.

Weather conditions Adverse weather conditions, such as rain, strong winds, fog, or snow, expose motorcyclists to additional hazards. Slippery surfaces, reduced visibility, and poor traction can compromise riders’ safety, especially if they aren’t careful.

Lack of experience Inexperienced motorcycle riders are more vulnerable to safety hazards due to poor judgment, improper control, and a lack of knowledge about safe riding practices.

Now that you know the most common hazards in motorcycle safety, what are some tips for vehicles to safely share the road with motorcycles?

• Take extra care when making a left turn. It is safest to let the motorcycle pass to avoid turning in front of the rider.

• Pay special attention at intersections. Nearly one in three motorcycle fatalities happen at a roadway intersection.

• Give driving your full attention. Even a momentary distraction, such as answering a phone call or changing the radio station, can have deadly consequences.

• Look twice when changing lanes. Check mirrors and blind spots, and always use turn signals.

• Give motorcycles room when passing. Move to the passing lane and don’t crowd the motorcyclist’s full lane.

• Stay back. If you’re behind a motorcycle, always maintain a safe following distance. When a motorcyclist downshifts instead of applying the brake to slow down, it can catch drivers off guard since there are no brake lights to signal reduced speed.

• Slow down. Obey posted speed limits and drive to conditions.

• Remember… “Share the Road: Look Twice for Motorcycles”

Whether you are riding a motorcycle or operating a vehicle, everyone on the road should practice the Smith 5-Key Crash Avoidance System to ensure you get to your destination safely.

By Mike Southard, Vice President of EHS

To continue promoting a culture that places the safety of our workers, communities, and environment above all else, monthly evaluations of submissions into our behavior-based Brake for Safety Program will be conducted and one Brake for Safety Event will be selected that highlights this value. Flogistix would like to announce our monthly Brake for Safety Champion for May 2024, Scott Adams, Field Technician-Watford City

Scott was dispatched to a location to evaluate a trouble call initiated by an operator who reported the little Joe regulator was leaking from the bypass and scrubber blow case. Upon arrival, Scott noticed a strong chemical smell that irritated his eyes. He isolated the unit and recognized an H2S scavenger chemical line plumbed into the offside discharge piping just off the skid. He noted that the ball valve to the supply bypass and scrubber blow case pressure was open. He believed this to be the source of the chemical leak. He contacted the operator, requested permission, and was authorized to turn the chemical pump off. He then exited the location, initiated a Brake for Safety, and contacted his supervisor and EHS area representative.

Due to the circumstances surrounding the Brake for Safety, an investigation was initiated. It was discovered that the tanks the VRU was pulling from had H2S levels of 180+ ppm which was unknown to Flogistix staff at the time. A plan was initiated to repair the unit under air with rescue staff available, and the unit was brought back online without further incidents.

I would like to express my gratitude to Scott Adams for being a Brake for Safety Champion and supporting the EHS program. His actions have subsequently reactivated the Incident Review Committee comprised of staff from accounting, sales, and EHS to determine gaps within our current processes of identifying H2S locations and disseminating the information to field staff.

I would also like to recognize Alberto Andrade and Brian Shaffer who also submitted Brake for Safety events during the month of May 2024, for their commitment to the EHS program.

Flogistix employees who are selected as a monthly “Brake for Safety Champion” are presented with a $100 gift card.

His actions have subsequently re-activated the Incident Review Committee...

March April May

Mid-Continent

Mid-Continent

Mid-Continent

Marie Clark, Human Resource Coordinator, and David Carrillo, Field Service Technician-TX, attend Midland College’s Job Fair in March. Over 100 students and alumni attended the job fair. Marie and David discussed what Flogistix does and what benefits we offer to prospective employees, received resumes, and handed out Flogistix swag.

In March, Scott Arnold and his wife Pam joined the Colorado Oil and Gas Association’s Oil and Gas (COGA) Day at the Colorado State Capitol . The event was hosted by COGA and the American Petroleum Institute (API) and was designed to show support for the oil and gas industry. Over 200 people voiced opposition to Colorado Senate Bill 24-159 which called for an end to fossil fuel use by 2030. The voice of the people was heard when the bill was later struck down.

Hosted at the Canadian County (Oklahoma) EXPO & Event Center, the Community Night Gala benefits a different local nonprofit each year. The 2024 event was held on March 19, and El Reno Manufacturing team members Jeremy Alexander, Tara Alexander, Donald Dick, Ben Sawyer, and Sean Ingram attended with family and friends. This year’s event raised over $83,000 for CASA and its mission to provide services for foster children in Canadian County, Oklahoma.

Kristin Hincke, VP of Sustainability and Public Policy, Kenna Williamson, Communications Intern, and Bo Smith, Oklahoma Region Account Manager, represented Flogistix at the 18th Annual Energy Gala hosted by the National Stripper Well Association on April 26. During the event, the Flogistix team had the opportunity to engage with U.S. Senator Steve Daines (R-Montana), who was honored as the 2024 Legislator of the Year. They discussed Flogistix’s initiatives, technology, and the impact of recent regulations on our customers.

Members of the Flogistix team attended the Alliance’s Sine Die celebration again this year. The term Sine Die is a Latin word routinely used to acknowledge the adjournment of a legislative session. David Martinez, Alicia Stark, Jim Merrill, and Kristin Hincke joined legislators and other industry friends to celebrate the end of Oklahoma’s 2023 session at the Harn Homestead, a 10-acre historical site, claimed during the Great Land Run of 1889.

The North Texas Chapter of GPA Midstream Association held its annual scholarship golf tournament on May 6 in Dallas. As a sponsor, Flogistix provided golfers the opportunity to have a ball dropped via drone to improve their game. All proceeds benefit the NTGPA Midstream Foundation Scholarship Program which provides financial awards to students studying for oil and gas industry jobs.

In May, Flogistix was represented at the Williston Basin Petroleum Conference, the largest event and trade show focused on the Bakken. Kristin Hincke, Vice President of Sustainability and Public Policy; Troy Fagan, Bakken Area Manager; and Bernadette Granger, Director of Community and Public Affairs, spent time networking with other industry representatives and learning about important issues unique to the area.

More than 2,400 attendees visited 75 vendor booths to learn about innovation in the oilpatch and heard from industry and public policy experts including North Dakota Governor Doug Burgum and Congressman Kelly Armstrong. In addition, a celebration was held to recognize the 5 billion barrels that have been produced from the Bakken.

Flogistix was well represented at a recent industry luncheon held by the Petroleum Alliance of Oklahoma at the Petroleum Club in OKC. Chuck Duginski, CEO of Canvas Energy, shared his experience as he led the company, then known as Chaparral Energy, through Chapter 11 bankruptcy restructuring, the global pandemic, and a rebranding to what is now Canvas Energy.

Flogistix team members Lou Esquivel and Alex Garcia attended the 10th Mexico Gas Summit held May 16-17 in San Antonio. The Summit is the premier oil and gas event bringing together international business executives focused on energy development in Mexico. Since energy reform was passed in Mexico eight years ago, opportunities have been created for companies interested in onshore infrastructure development in the country. Lou and Alex have spearheaded Flogistix’s expansion into Mexico.

Flogistix celebrated receiving The Oklahoman’s Top Workplaces Award in 2023 with an employee appreciation event, giving employees time to eat and enjoy each other’s company at Chicken N’ Pickle on Friday, May 3. President and CEO Mims Talton spoke at the event, congratulating employees on their hard work and company-wide commitment to kindness. Employees were also entered in a free raffle for prizes, including Flogistix merchandise and Amazon gift cards while enjoying games of pickleball, pool, ping pong, and cornhole.

Lyndy Affeld, Corporate Account Manager-Tulsa and former API board member volunteered at the American Petroleum Institute’s (API) Bakersfield Golf Tournament in May. One of two yearly fundraisers, this tournament is extremely well attended and raises money for API’s scholarship fund. The 94 participating teams raised over $60K, bringing API’s scholarship fund to $100K. Recently, 26 students from Kern County California received $100K in scholarships.

Flogistix was well represented at Governor Gregg Abbott’s 2024 Small Business Summit in Pampa on June 14. Pampa was one of 15 communities selected to host the Governor’s Summit. According to a press release from Governor Abbott’s office, the Summit offered a “variety of sessions bringing together local, state, and federal resource partners to provide key insights on critical business topics. The Summit also provides participants the opportunity to network with other business owners…” While in attendance, the Flogistix team learned of grant opportunities and heard from keynote speaker Texas Workforce Commissioner Joe Esparza. Our Pampa Flogistix team remains active in the community and represents us well. Thank you, Eric, for your leadership and outreach efforts!

Pictured: Lisa Anderson, Jo Holman, Eric Greear, Rod Wichert

In June, David Martinez and Danny Cassady with AirMethane and Kevin Colburn and Jason Daub with Commaris attended the Energy Drone & Robotics Summit in Houston. Hosted by the Energy Drone & Robotics Coalition, the conference is the largest event in the world for UAVs., robotics, and Data/AI/ML, exclusively focused on business and technology of unmanned systems, automation, and data/AI in energy and industrial operations.

A highlight of the summer is the Petroleum Alliance of Oklahoma’s Annual Meeting. Held annually in Dallas, Texas, this meeting brings together company leaders from across Oklahoma to discuss current issues facing the oil and gas industry.

At this year’s gathering, Bernadette Granger, MacKenna Williamson, Kristin Hincke, and Lyndy Affeld heard from Oklahoma legislators and former Secretary of State Mike Pompeo.

TWO THOUSAND TWENTY-FOUR 20 24

In April, Bernadette Granger, Director of Community and Public Affairs , completed 200 hours of yoga teacher training to become a certified yoga teacher. On weekends, Bernadette teaches gentle yoga at Midland Yoga Works as well as private lessons. Namaste!

On December 19, Maximus Piercefield, Field Mechanic-Permian Midland , and fiancée Reagan welcomed baby boy, Maverick Jamison Piercefield . Maverick weighed 8 pounds 2 ounces and was 21 1/4 inches long and is their first born. Congratulations, Maximus and Reagan!

Angelina Alcozer, daughter of Nick Alcozer, Purchasing ManagerPampa , recently attended her senior prom. During her senior year at Pampa High School, Angelina was in the top 10% of her class, was three credit hours shy of an associate’s degree, and participated in dance, track, and piano. She will attend West Texas A&M in the fall and will later transfer to the University of North Texas. Well done, Angelina!

Elijah Grigg was born on April 12, to proud parents Logan and Lauren Grigg . Elijah weighed 7 pounds 8 ounces, was 21.5 inches long, and joins big brother, Isaiah. Proud papa, Logan Grigg, works at El Reno Manufacturing as a Maintenance Tech. Congratulations, Logan, Lauren, and Isaiah!

Members of the Pampa team gathered in May to celebrate Guadalupe Albus. Guadalupe graduated from Clarendon College with an Associate of Science degree. Guadalupe juggled working full-time as a Production Planning Assistant and completing her degree. Well-done and congratulations, Guadalupe!

Congratulations to Chris and Charlene (Zamora) Hernandez on the birth of their baby girl, Evalina Hernandez ! Evalina was born on May 14, 2024, weighed 4 pounds 14 ounces, and was 18.5” long. Evalina’s proud papa, Chris, a Production Manager at our El Reno Manufacturing facility.

Brooklyn Spruit , daughter of Rick Spruit, Salesman-St. Clairsville Office, recently made the All-Western Pennsylvania State Team (WPIAL) in lacrosse. Brooklyn finished her junior year at South Fayette High School as the team captain of her lacrosse team, scored her 100th varsity goal, and was also selected for the Section 2A First Team for the second year in a row. Good job, Brooklyn!

Juan and Vivana Davila welcomed their third child, Monserrat Davila on June 3. She weighed exactly 7 pounds and was 19 1/4” long. Her proud papa is a welder at our El Reno manufacturing facility. Congratulations, Juan and Vivana!

NAME POSITION LOCATION

Ashley Ventris

Brent McCormack

Javier Marrufo

Brian Wright

Abraham Artus

Joseph Sylvester

Benjamin Patrick

Connor Chappell

Nicholas Lucarelli

Neil Gonzalez

Sean Rieb

Marcus Dailey

Jose Aguirre

Jesus Marquez

Carlos Montanez Chapa

Chase Geddis

Renato Amico

Denys LeBlanc

Debry Bryans

Rachel Golla

Anjalina Thomas

Senior Financial Accountant II Corporate

Business Development

Yard and Warehouse Associate

Sales Houston

Field Shop Permian Midland

NetSuite Program Manager Corporate

Software Engineering Intern Corporate

Junior Product Owner Intern Corporate

Software Engineering Intern Corporate

Senior Software Engineer-Edge Computing Corporate

Field Service-Rebuild

Field Service-Rebuild

Field Shop DJ Basin

Field Shop DJ Basin

Director of Engineering Massachusetts

Field Service Tech

Field Service Tech

Field Service Tech

Field Service Tech

Field Service Tech

Field Service Tech

Manufacturing-Wyoming

Field Shop Permian Delaware

Field Shop Permian Delaware

Field Shop Permian Delaware

Field Shop DJ Basin

Field Shop Permian Midland

Vice President of Field Services Corporate

Field Service Tech

Field Shop Permian Midland

Junior Content Creator Intern Corporate

Manufacturing Intern

El Reno Manufacturing

Allen Mikeska

In May, Allen Mikeska accepted the position of Area Manager of the Eagle Ford Shale. With this promotion, Allen and his family will relocate to Victoria, Texas, from Amarillo.

Allen brings a wealth of knowledge to his new role. During his nine years with Flogistix, Allen has held a variety of roles across many departments including manufacturing, test loop, finish and panel shop, and field service. Allen also learned additional duties including operating our portable gas chromatographic unit and our RDI camera.

Congratulations and best wishes, Allen!

Special thanks to Kendall Mussman for taking on additional duties to help cover the Eagle Ford Shale area in the interim.