Safety and Health Management System

REV 7

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 2 of 323

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022

Construction

Construction

O’Donnell/Snider

O’Donnell/Snider

SAFETY AND HEALTH MANAGEMENT SYSTEM

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction Paper copies are uncontrolled. No reproduction in any form without the written permission of the copyright owner. O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 3 of 323 Table of Contents INTRODUCTION .................................................................................................................................. 23 SCOPE ................................................................................................................................................ 23 1.0 LEADERSHIP AND COMMITMENT ............................................................................................. 25 Commitment Statement 25 Management Commitment and Leadership 25 Management Representatives 26 Employee Participation 26 2.0 EQUAL EMPLOYMENT OPPORTUNITY ....................................................................................... 27 Statement of Equal Opportunity 27 Business Ethics/Code of Conduct 27 Conflicts of Interest 27 3.0 IMPLEMENTATION & OPERATION ............................................................................................ 29 Purpose 29 Procedure 29 Open Door Policy 29 Emergency Preparedness 29 Preparedness Requirements 29 Operational Control 30 Compliance with Legal and Other Requirements 30 Disciplinary System ............................................................................................................................... 30 Equipment and Working Conditions 30 Fatigue Management 31 Identified Hazards and Risks................................................................................................................. 31 Management of Change (MOC) 31 Preventative Maintenance Program for Tools and Equipment 32 Reporting of Hazardous Conditions, Security Incidents or Injuries ........................................................ 34 Systems to Control Access or Exiting Customer's Premises 34 Work Permits and Permit to Work Form .............................................................................................. 34 4.0 MANAGEMENT REVIEW ........................................................................................................... 35 Management Meetings 35 Safety Management System Review 35 5.0 WRITTEN SAFETY AND HEALTH GOALS ..................................................................................... 37 Objectives & Safety Programs 37 Safety & Health Goals 37 Legal and Other Requirements 38 Legal Requirements .............................................................................................................................. 38 Means of Tracking Requirements ......................................................................................................... 38

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 4 of 323 Other Requirements ............................................................................................................................. 38 Review of Requirements 38 SPECIFIC SAFETY PROGRAMS .............................................................................................................. 39 6.0 ACCESS TO MEDICAL RECORDS ................................................................................................. 41 Purpose 41 Overview 41 Definitions 41 Procedure 43 Records Retention 44 Transfer of Records Should O’Donnell/Snider Construction Cease to Do Business 44 Employee Information 44 AUTHORIZATION LETTER FOR THE RELEASE OF EMPLOYEE MEDICAL RECORDS 45 ACCESS TO MEDICAL/EXPOSURE RECORDS NOTICE 46 7.0 AERIAL LIFTS ............................................................................................................................ 47 8.0 ASBESTOS AWARENESS ............................................................................................................ 49 Purpose 49 Scope 49 Awareness Level Requirements and Information 49 Asbestos Exposure Control 49 Background of Asbestos 49 Health Effects of Asbestos 50 Possible Locations Where Employees May Be Exposed to Asbestos During Their Job Functions .......... 50 Types of Asbestos 50 Identifying Asbestos ............................................................................................................................. 50 General Safety Precautions 51 Multiple Worksites 51 Personnel Air Monitoring ...................................................................................................................... 51 Medical Surveillance Program 51 Respiratory Protection .......................................................................................................................... 52 Waste Disposal ............................................................................................................................... ...... 52 Training 52 9.0 BLOODBORNE PATHOGENS ...................................................................................................... 53 Purpose 53 Scope 53 Responsibilities 53 Procedure 53 Training ............................................................................................................................... ................. 53 Purpose 47 Scope 47 Procedure 47

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 5 of 323 Availability of Procedure to Employees ................................................................................................ 54 Reviews and Update of the Procedure 54 Exposure Determination ....................................................................................................................... 54 Methods of Compliance 54 Universal Precautions 54 Engineering Controls ............................................................................................................................ 54 Personal Protective Equipment 55 Housekeeping 55 Work Practice Controls 55 Post‐Exposure Procedure 56 Post‐Exposure Evaluation & Follow‐Up 56 Information Provided to the Healthcare Professional. We forward the following 57 Healthcare Professional’s Written Opinion ........................................................................................... 57 Record Keeping 57 Labels and Signs 58 Information 58 VACCINATION DECLINATION FORM 59 POST‐EXPOSURE EVALUATION AND FOLLOW‐UP CHECKLIST 60 10.0 COMPRESSED AIR ................................................................................................................. 61 Purpose 61 Scope 61 Responsibilities 61 Procedure 61 Not Using Compressed Air for Cleaning ................................................................................................ 61 Air Receivers and Indicating Pressure Gauge 61 Safety Valves are Tested ....................................................................................................................... 61 Frequent Draining of the Receiver ........................................................................................................ 61 Handling 62 Storing 62 Use 62 Inspection of Compressed Gas Cylinders 62 Leaking Cylinders 62 Transportation ............................................................................................................................... ....... 63 Empty Cylinder Marking 63 11.0 COMPRESSED GAS CYLINDERS .............................................................................................. 65 Purpose 65 Scope 65 Responsibilities 65 General 65 Cylinder Identification 65 Handling 65 Storing 66 Use 66

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 6 of 323 Inspection of Compressed Gas Cylinders 66 Leaking Cylinders 67 Transportation 67 Empty Cylinder Marking 67 Engineering Controls 67 12.0 CONFINED SPACE/PERMIT CONFINED SPACE ......................................................................... 69 Purpose 69 Scope 69 Definitions 69 Responsibilities 72 Procedure 74 Non‐Permit Confined Space Entry 74 Permit‐Required Confined Space Entry 75 Pre‐Job Planning and Space Preparation .............................................................................................. 75 Pre‐Entry Safety Meeting 76 Equipment 76 Air Monitoring ............................................................................................................................... ....... 77 Ventilation 77 Multiple Employer Procedure ............................................................................................................... 77 Rescue and Emergency Services 78 General 78 Permit‐Required Confined Space Rescue 79 Non‐entry Rescue 79 Issuance/Reviewing of Permit 80 Termination and Closing or Cancelling of Permits 80 Training 80 Retraining ............................................................................................................................... .............. 80 Certification 80 13.0 DISCIPLINARY PROGRAM ....................................................................................................... 85 Purpose 85 Scope 85 Responsibilities 85 Requirements 85 Procedure 85 14.0 DRIVING SAFETY ................................................................................................................... 89 Purpose 89 Responsibilities 89 Driving Safety 89 Reporting of Traffic Violations and Vehicle Accidents 89 Safe Driver Behaviors/Practices 89 Drivers are to be prepared before leaving 90 Vehicle Requirements 90

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 7 of 323 Transportation 90 Traffic Control 91 15.0 ELECTRICAL SAFETY................................................................................................................ 93 Purpose 93 Responsibilities 93 Safe Work Practices 93 Inspections 93 Repairs 93 Extension Cords 94 Outlets 94 Multiple Outlet Boxes ........................................................................................................................... 94 Double Insulated Tools 95 Switches, circuit breakers, and disconnects 95 Ladders & Portable Ladders 95 Energized and Overhead High Voltage Power Lines & Equipment 95 Confined or Enclosed Work Spaces 96 Enclosures, Breaker Panels, and Distribution Rooms ............................................................................ 96 Lock Out/Tag Out ............................................................................................................................... .. 96 Contractors ............................................................................................................................... ............ 96 Fire Extinguishers 97 Electric Shock‐CPR 97 Electric Welders 97 Equipment Grounding .......................................................................................................................... 97 Assured Grounding ............................................................................................................................... 97 Ground Fault Circuit Interrupters 97 M.O.P. Electrical Shutdowns 98 Training 99 Personal Protective Equipment & Safeguards for Personnel Protection 100 16.0 EMERGENCY ACTION PLAN .................................................................................................. 101 Purpose 101 Emergency Response Planning, Issuing and Annual Review Guidelines 101 Reviewing the Emergency Action Plan with Employees ...................................................................... 101 Procedures for Emergency Evacuation Planning 101 List of Potential Emergencies 102 Guidance Procedures for Potential Emergencies 102 Fire 102 Gas Leaks/Chemical Spills 102 Bomb Threats 103 Medical Emergencies 103 Explosions 103 Workplace Violence ............................................................................................................................ 103 Emergency Response Equipment 104 Listing of Types of Emergency Equipment 104

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 8 of 323 Inspection & Maintenance Records .................................................................................................... 104 Media Response Plan 104 Location and Use of Emergency Facilities 105 Fire Protection & Response 105 Protection 105 Response ............................................................................................................................... ............. 105 Alarm & Emergency Communication 105 Alarm System 106 Communications ............................................................................................................................... .. 106 Procedures for Rescue and Medical Services 106 Procedure for Evacuation 106 Preparation for Evacuation 106 Critical Operations Personnel 106 Evacuation Drills 106 Coordination Within a Facility ............................................................................................................ 107 Procedures to Account for All Employees After Evacuation ................................................................ 107 Emergency Evacuation Notification and Routes 107 Sweep Check by O’Donnell/Snider Construction Designated Responders ........................................... 107 Evacuation or Drill Evaluation ............................................................................................................ 108 Emergency Response Program Management 108 Duties 108 Training 109 17.0 FALL PROTECTION ................................................................................................................ 111 Purpose 111 Qualifications of the Person or Position That Prepares Plans 111 Responsibilities 111 Procedure 112 Minimum Standards 112 Stopping a Fall 113 Protection From Falling Objects 114 Portable Ladders 114 Storage 114 Inspections 114 Elevated Personnel Platforms 115 Prompt Rescue of an Employee in the Event of a Fall 115 Fall Protection Plan 115 Controlled Access Zones 115 Safety Monitoring System 116 Incident Investigations 116 Holes and Floor Coverings 116 Training 117 Retraining 118 Documentation 118 18.0 FATIGUE MANAGEMENT ...................................................................................................... 119

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 9 of 323 Purpose 119 Scope 119 Policy 119 Responsibilities 119 Work Hour Limitations and Rest Breaks to Control Fatigue and Increase Mental Fitness 120 Use of Ergonomic Friendly Equipment 120 Analysis of Work Tasks to Control Fatigue 120 Incident Analysis 120 Initial and Annual Training for Workers on Fatigue and Controlling Fatigue 120 19.0 FIRE PROTECTION/PREVENTION ........................................................................................... 121 Purpose 121 Responsibilities 121 Selection and Distribution 121 Labeling of Fire Extinguishers 121 Maintenance 121 Inspection, Maintenance and Testing 122 Use 122 Training 122 Initial Training Outline ........................................................................................................................ 122 Retraining 122 Documentation 123 20.0 FIRST AID ............................................................................................................................. 125 Purpose 125 Responsibilities 125 Requirements 125 Planning 125 Medical Response ............................................................................................................................... 125 Supplies and Equipment 126 Transportation ............................................................................................................................... ..... 126 Training 126 21.0 FIT FOR DUTY....................................................................................................................... 127 Purpose 127 Scope 127 Fitness for Duty Process 127 Pre‐Employment Testing (Physical/Medical Suitability) ...................................................................... 127 Training and Safe Work Requirements (Skills and Knowledge) ........................................................... 127 Personal Medical Reporting Requirements ......................................................................................... 128 Client Drug and Alcohol Testing Requirements 128 Employee Activity and Behavior 128 Fit for Duty Examination 128 Confidentiality 128 Self‐Referrals ............................................................................................................................... ....... 128

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 10 of 323 Management Referral ........................................................................................................................ 128 Procedure 129 Subsequent Fitness for Duty Exams 129 22.0 GENERAL SAFETY & HEALTH ................................................................................................. 131 Purpose 131 Responsibilities 131 Competency and Training 131 Inspections 132 General Facility Requirements 132 Housekeeping 132 Safe Equipment Maintenance ............................................................................................................ 132 Impairment 133 Improper Conduct 133 Industrial Hygiene .............................................................................................................................. 133 23.0 GENERAL WASTE MANAGEMENT ......................................................................................... 135 Purpose 135 Scope 135 Procedure 135 Waste Estimation ............................................................................................................................... 135 Waste Segregation 136 Recycling 136 Storage Requirements ........................................................................................................................ 136 PPE 136 Training 136 24.0 GROUND FAULT PROTECTION/GFCI ..................................................................................... 137 Purpose 137 Definitions 137 Responsibilities 137 Procedures and Guidelines to Eliminate Injuries 137 Assured Equipment Grounding Conductor Program Requirement ...................................................... 137 Ground Fault Circuit Interrupters 138 Assured Equipment Grounding Conductor Program 138 Defective Electrical Equipment is Removed from Service.................................................................... 138 Inspections 138 Types of Testing Performed, When Testing is Done and How Tests are Recorded .............................. 138 25.0 HAND & POWER TOOLS ....................................................................................................... 141 Purpose 141 Responsibilities 141 General 141 Portable Electric Tools 142 Pneumatic Tools 142

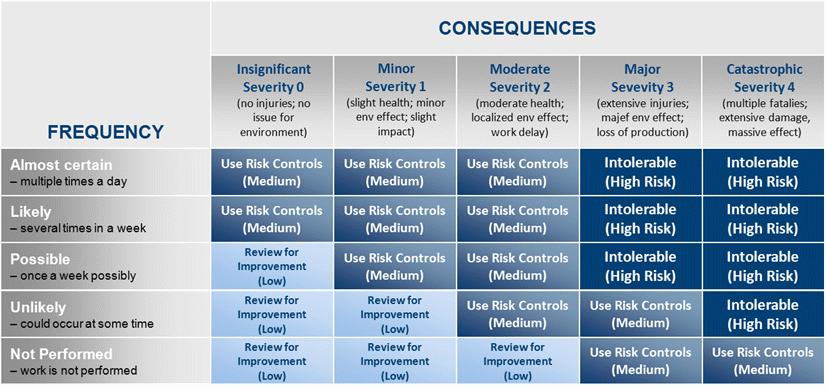

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 11 of 323 Powder Actuated Tools (Tools actuated by an explosive charge) 144 Hydraulic Power Tools 144 Hydraulic Jacks 145 Loading and Marking 145 Operation and Maintenance 145 Abrasive Blast Cleaning Nozzles 145 Fuel Powered Tools 145 Guarding Portable Tools 145 Portable Circular Saws ........................................................................................................................ 146 Switches and Controls ........................................................................................................................ 146 Portable Abrasive Wheels 146 Safety Guards Exceptions 146 Mounting and Inspection of Abrasive Wheels 147 Portable Grinders 147 Other Portable Grinders ..................................................................................................................... 147 26.0 HAZARD COMMUNICATION ................................................................................................. 149 Purpose 149 Introduction 149 Responsibilities 149 List of Hazardous Chemicals 150 Safety Data Sheets (SDS) 150 Methods to be Used to Inform Employees of the Hazards of Non‐Routine Tasks 151 The Use and Care of Labels and Other Forms of Warning 151 Multi‐Employer Job Sites and/or Multi Work Site 153 Multi‐Work Sites 154 Multi‐Employer Job Sites .................................................................................................................... 154 Training 154 27.0 HAZARD IDENTIFICATION AND RISK ASSESSMENT ................................................................ 155 Hazard Identification 155 Defining Hazards 155 Identifying Hazards 155 Continued Hazard Identification ......................................................................................................... 156 Risk Assessment 156 Risk Assessment Matrix ...................................................................................................................... 156 Risk Assessment Procedure................................................................................................................. 156 Risk Control 157 Emergency Control of Hazards 157 Job Safety Analysis (JSA) 157 Hierarchy of Controls 157 Risk Controls 158 Training 158 28.0 HEAT ILLNESS....................................................................................................................... 159

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 12 of 323 Purpose 159 Definitions 159 Requirements 159 Provision of Water .............................................................................................................................. 159 Access to Shade 159 Control Measures 159 First Aid 160 Training 161 29.0 INCIDENT INVESTIGATION .................................................................................................... 163 Incidents & Non‐conformances 163 Equipment 164 Incident Reporting Matrix 164 Time Elements 164 Incident Review Team and Incident Investigation Report ................................................................... 165 Initial Identification/Assessment of Evidence ..................................................................................... 165 Collection/Preservation and Security of Evidence 165 Witness Interviews and Statements 165 Preparation of the Written Incident Report 165 Incident Notice Form 166 Corrective Actions Resulting from Incident Investigations .................................................................. 166 Injury Classification ............................................................................................................................. 166 Training 167 30.0 INJURY/ILLNESS RECORDKEEPING ........................................................................................ 169 Purpose 169 Scope 169 Responsibilities 169 Procedure 169 Posting 170 31.0 JOB COMPETENCY ............................................................................................................... 171 Purpose 171 Scope 171 Responsibilities 171 General 171 Organizational Chart 171 Identification of Minimum Qualifications 171 Documentation 171 Training and Competency Needs 172 Verification Before Being Allowed to Work 172 Supervisor Safety Management Training 172 Purpose 163 Responsibilities 163 Procedure 163

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 13 of 323 32.0 JOBSITE SECURITY ................................................................................................................ 173 Purpose 173 Scope 173 Responsibilities 173 General Information 173 Risk Assessment............................................................................................................................... ... 173 Measures That Can Be Used To Reduce Jobsite Security Incidents 173 Reporting ............................................................................................................................... ............. 173 Incident Investigation ......................................................................................................................... 174 Training 174 Employees Being Informed 174 Retraining 174 Documentation 174 33.0 LADDER SAFETY ................................................................................................................... 177 Purpose 177 Definitions 177 Responsibilities 177 Inspection, Care and Safe Work Practices of Ladders 178 Inspection 178 Care 178 Ladder Safe Work Practices 178 Portable Ladders 179 Fixed Metal Ladders ........................................................................................................................... 180 34.0 LOCKOUT TAGOUT ............................................................................................................... 181 Purpose 181 Responsibilities 181 General 181 Devices 181 Specific Energy Control Procedures 181 Specific Sequence for Application of Energy Control 182 Procedures for Handling Multiple Groups of Workers 183 Release from Lockout/Tagout 184 Removal of Locks 184 Contractors 185 Periodic Inspections of the Energy Control Procedure 185 Training 185 Retraining 186 Training Documentation 186 35.0 MANUAL LIFTING ................................................................................................................. 187 Purpose 187 Responsibilities 187 Procedure 188

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 14 of 323 Worksite Assessment .......................................................................................................................... 188 Work Controls 189 Handling Heavy or Awkward Loads .................................................................................................... 189 Incidents and Injuries 190 Review & Updating Lifting and Handling Loads Program 190 Training 190 36.0 MOBILE EQUIPMENT ........................................................................................................... 191 Purpose 191 Responsibilities 191 Mobile Equipment 191 37.0 NOISE AWARENESS .............................................................................................................. 195 Purpose 195 Responsibilities 195 Procedure 195 Hearing Conservation Program 195 Surveys 195 Sound Level Surveys ............................................................................................................................ 196 Exposure Surveys 196 Signage 196 Audiometric Testing 196 Records 197 Hearing Protection Devices 197 Training 198 38.0 PANDEMIC PREPAREDNESS .................................................................................................. 199 Purpose 199 Assignment of Ownership of the Pandemic Disease Plan 199 Assumptions 199 Effective Internal/Employee Communication Procedure 199 Effective External/Customer Communication Procedure 200 Business Continuity Planning 200 COMMAND STAFF: 200 OPERATIONS SECTION: 200 LOGISTICS SECTION: 201 PLANNING SECTION: 201 FINANCE SECTION: 201 Pandemic Response by Pandemic Phase 201 Work At Home or Stay At Home Policy 201 Infection Control Measures 201 Implementation, Testing, and Revision of the Plan 202 Process for Implementing Lessons Learned Following a Pandemic Event 202 Training 202 39.0 PERSONAL PROTECTIVE EQUIPMENT ................................................................................... 203

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 15 of 323 Purpose 203 Responsibilities 203 General 204 Eye Protection 204 Safety Glasses 204 Goggles ............................................................................................................................... ............... 205 Face Shields 205 Head Protection 205 Hearing Protection 206 Types ............................................................................................................................... ................... 206 Care and Maintenance 206 Fit 206 Hand Protection 206 Gloves 206 Cut Resistant Sleeves .......................................................................................................................... 207 Foot Protection 207 Fall Protection 208 Electrical Protection 208 Worksite Hazard Assessment 208 Proper Fitting or Sizing of PPE 208 Defective Equipment is Not Used 208 Monitoring 208 Training 209 Retraining 209 Documentation 209 40.0 POWERED INDUSTRIAL TRUCKS ........................................................................................... 211 Purpose 211 Definitions 211 Responsibilities 211 General 211 Safety Guards 212 Operations 212 General ............................................................................................................................... ................ 212 Traveling 213 Loading 213 Operation of the Truck........................................................................................................................ 213 Maintenance and Inspection of Forklifts 214 Training 215 Refresher Training .............................................................................................................................. 216 Certification 216 41.0 RESPIRATORY PROTECTION ................................................................................................. 217 Purpose 217 Scope 217

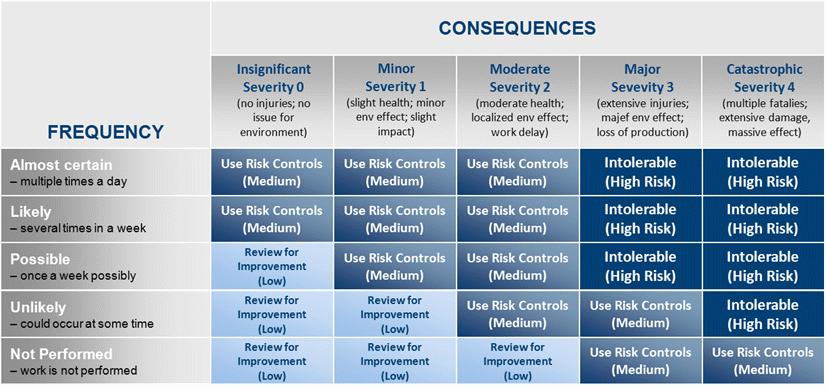

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 16 of 323 Respiratory Program Administrator 217 Medical Evaluation Requirements 218 General ............................................................................................................................... ................ 218 Medical Evaluation Procedures 218 Supplemental Information for the PLHCP 219 Medical Determination ....................................................................................................................... 219 Additional Medical Evaluations 219 Work Site Procedures 220 Respirator Selection Criteria 220 Hazard Identification 220 Selection of Respirator 220 Brand and Models 222 Estimate of Exposures and Contaminant Information 222 Respirator Fit Testing 222 Use, Maintenance and Care of Respirators 223 Use ............................................................................................................................... ...................... 223 Cleaning and Storage Requirements 224 Cleaning Procedures ........................................................................................................................... 224 Storage and Inspection ....................................................................................................................... 224 Breathing Air Quality and Use 225 Repairs 226 Voluntary Use 226 Workplace Monitoring 227 Recordkeeping 227 Program Evaluation 227 Training 227 Retraining 227 42.0 RIGGING MATERIAL HANDLING ........................................................................................... 229 Purpose 229 Scope 229 Responsibilities 229 General 229 Material Handling 229 Training 230 43.0 SAFE RETURN TO WORK....................................................................................................... 231 Purpose 231 Scope 231 Responsibilities 231 Definitions 231 General Requirements 232 Employee Reporting Responsibilities 232 Non‐Retaliation 232 Prohibited Actions 233

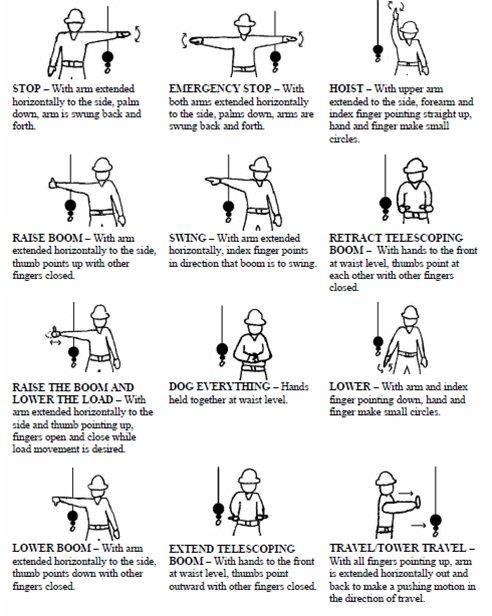

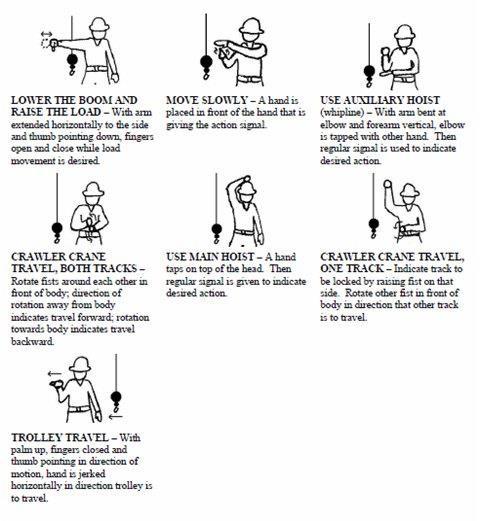

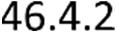

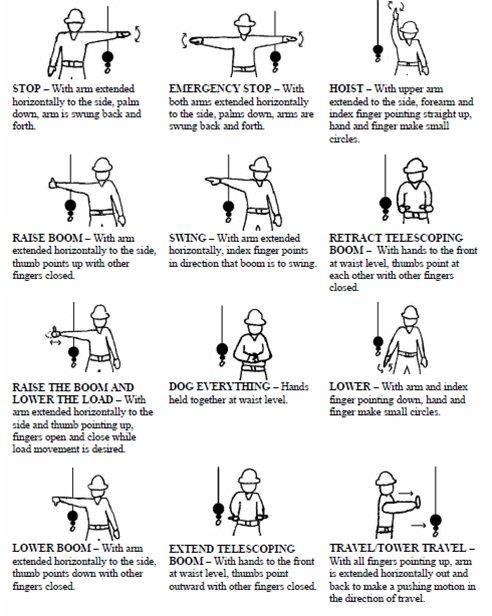

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 17 of 323 Return to Work Coordination 233 Medical Records for Injured Employees Must be Kept Confidential 233 All Documentation Related to an Incident is Maintained by O’Donnell/Snider Construction 233 Local Health Care Providers 233 Temporary Assignment / Modified Work Procedures 234 Training 234 44.0 SCAFFOLD SAFETY................................................................................................................ 237 Purpose 237 Responsibilities 237 General Requirements 237 Inspections 238 Mandatory Signs & Tags for Defects Found 239 Modifications 239 Hazards Associated with the Use of Scaffolds 239 Duties of a Competent Person Assembling/Disassembling Scaffolding 240 General 240 For Training ............................................................................................................................... ......... 240 For Inspections............................................................................................................................... ..... 240 For Suspension Scaffolds .................................................................................................................... 240 For Erectors and Dismantlers 240 For Scaffold Components 240 Tube & Coupler Scaffolds ‐ Light Duty 241 Tube & Coupler Scaffolds ‐ Medium Duty 241 Training 241 Retraining 242 45.0 SHORT SERVICE EMPLOYEE .................................................................................................. 243 Purpose 243 Definitions 243 Responsibilities 243 General 243 Mentoring Oversight & Monitoring 244 Short Service Employee Identification 244 Notification & Communication Processes 244 46.0 SIGNALING FOR CRANES ...................................................................................................... 245 Purpose 245 Scope 245 Responsibilities 245 General Requirements 245 When a Signal Person Must Be Provided 245 Stop Work Immediately ...................................................................................................................... 246 The Types of Signals to be Used 246 Qualification Requirements of the Signal Person 246

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 18 of 323 STANDARD HAND SIGNALS 247 47.0 SILICA .................................................................................................................................. 249 Purpose 249 Scope 249 Specific Exposure Control Methods 249 Alternative Exposure Control Methods 255 Permissible Exposure Limit (PEL) 255 Exposure Assessment..................................................................................................................... 255 Reassessment of Exposures 256 Methods of Sample Analysis 256 Employee Notification of Assessment Results 256 Observation of Monitoring 256 Methods of Compliance 257 Engineering and Work Practice Controls ............................................................................................ 257 Respiratory Protection 257 Specified Exposure Control Methods 257 Housekeeping ............................................................................................................................... ...... 257 Written Control Plan 258 Medical Surveillance 258 Initial Examination 258 Periodic Examinations 258 Information Provided to the PLHCP 259 PLHCP’s Written Medical Report for the Employee ............................................................................ 259 PLHCP’s Written Medical Opinion for SUBCONTRACTOR .................................................................... 259 Additional Examinations 259 Communication of Respirable Crystalline Silica Hazards to Employees 260 Hazard Communication ...................................................................................................................... 260 Employee Information and Training 260 Recordkeeping 260 Air Monitoring Data 260 Objective Data 261 Medical Surveillance ........................................................................................................................... 261 48.0 SPILL PREVENTION AND RESPONSE ...................................................................................... 263 49.0 STOP WORK AUTHORITY ...................................................................................................... 273 Purpose 273 Scope 273 Roles and Responsibilities of Employees and Management 273 Stop Work Authority Steps 273 Follow‐Up 273 Purpose 263 Scope 263 Requirements 263

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 19 of 323 Training 274 50.0 SUBCONTRACTOR MANAGEMENT PLAN .............................................................................. 277 Purpose 277 Scope 277 General Requirements 277 Pre‐Qualification of Subcontractors 277 Criteria for Selecting Subcontractors 277 Subcontractor Involvement 278 51.0 TRENCHING SHORING EXCAVATION ..................................................................................... 279 Purpose 279 Responsibilities 279 Utilities and Pre‐work Site Inspection 279 Protection of the Public 280 Protection Against Falls 280 Protection of Workers in Excavations 280 Access and Means of Egress 280 Structural Ramps 280 Ladders ............................................................................................................................... ................ 281 Exposure to Vehicular Traffic .............................................................................................................. 281 Employee Exposure to Falling Loads ................................................................................................... 281 Warning System for Mobile Equipment 281 Hazardous Atmospheres ..................................................................................................................... 281 Personal Protective Equipment 282 Protection from Hazards Associated with Water Accumulation 283 Stability of Adjacent Structures 283 Protection of Employees from Falling Objects & Loose Rocks or Soil 283 Soil Types 284 Daily Inspection 284 Training 285 Retraining 285 Documentation 285 52.0 WELDING CUTTING HOT WORK............................................................................................ 287 Purpose 287 Scope 287 Definitions 287 Responsibilities 287 General 288 Fire Prevention Measures 289 Confined Space 289 Fumes, Gases & Dust 291 Personal Protection 291 Cleaning Compounds 292

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 20 of 323 Cylinders 292 Arc Welding & Cutting 293 Resistance Welding 294 Transmission Pipeline 295 Pressure testing 295 Oxygen Fuel Gas Welding & Cutting 295 Fire Watch Requirements 295 First Aid Equipment 296 Training 296 53.0 BUSINESS CONTINUTY ......................................................................................................... 297 Purpose 297 Objectives and/or Goals of the Business Continuity Plan 297 Roles and Responsibilities 297 Business Continuity Risk Assessment 297 Organizational Resilience Enhancements 298 Preparation 298 Disaster Occurs ............................................................................................................................... .... 298 Pandemic Crisis 298 Business Continuity Core Planning 298 Financial, Operational, and Business Continuity Requirements 299 Sample Evacuation Planning If Required 299 Remobilization 300 Internal Communication System 300 Continual Improvement 300 Training 300 54.0 COVID‐19 ............................................................................................................................. 303 COVID‐19 (Coronavirus) Action Plan 303 Purpose 303 Recommendations for Fully Vaccinated People 303 Scope 304 Interventions to Protect Unvaccinated and Otherwise At‐Risk Workers 304 Facilitate employees getting vaccinated ............................................................................................ 304 Physical Distancing for Unvaccinated and Otherwise At‐Risk Workers 304 Personal Protective Equipment........................................................................................................... 305 Visitors............................................................................................................................... ................. 305 Ventilation 306 Cleaning and Disinfection 306 Record and Report COVID‐19 Infections and Deaths 307 Isolation & Quarantine 307 Isolation 307 Quarantine 307 Measures Appropriate for Workplaces with Mixed‐Vaccination Status Workers 308 Training 309

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022 O’Donnell/Snider Construction O’Donnell/Snider Construction Doc No: SHMS Initial Issue Date 10/03/2017 Revision Date: 10/25/2022 SAFETY AND HEALTH MANAGEMENT SYSTEM Revision No. 7 Next Review Date: 10/25/2023 Page: 21 of 323 55.0 CRANES .............................................................................................................................. 311 Purpose 311 Scope 311 Responsibilities 311 Procedure 311 Operator Qualification 312 Load Chart 312 Modifying Equipment 312 Prior to Lifting 312 Marking Boundaries 313 Overhead Power Lines 313 Assembling/Disassembling Equipment 314 Handling the Load 314 Size of Load 314 Attaching the Load ............................................................................................................................. 314 Load Lifting Manual 315 Safe Lifting 315 Logbook Procedure 315 Inspections 316 New Equipment 316 Daily ............................................................................................................................... .................... 317 Monthly 317 Yearly ............................................................................................................................... .................. 317 Rigging 317 Rigging Breaking Strength and Load Rating ....................................................................................... 318 Rigging Inspection and Rejection Criteria 318 Slings 318 Hooks ............................................................................................................................... .................. 319 Operational Procedures 319 Rigging a Load ............................................................................................................................... ..... 320 Signaling 320 Training 321 56.0 REVISIONS CONTROL PAGE .................................................................................................. 323

SAFETY AND HEALTH MANAGEMENT SYSTEM

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 22 of 323

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022

Construction

Construction

O’Donnell/Snider

O’Donnell/Snider

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

Introduction

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 23 of 323

The O’Donnell/Snider Construction Safety and Health Management System has been developed to provide a systematic approach to safety and health in order to have an incident free culture of safety.

Scope

• The O’Donnell/Snider Construction Safety and Health Management System applies to all operations conducted by O’Donnell/Snider Construction.

• Any new acquisition, project, joint venture or contract controlled by O’Donnell/Snider Construction shall follow its requirements.

O’Donnell/Snider

Uncontrolled copy if printed. Valid on day of printing only.

on: 25 October 2022

Printed

Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 24 of 323

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022

Construction

Construction

O’Donnell/Snider

O’Donnell/Snider

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

1.0 LEADERSHIP AND COMMITMENT Commitment Statement

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 25 of 323

The O’Donnell/Snider Construction Safety and Health Management System (SHMS) are driven by leadership and commitment from senior management and its readiness to provide resources for HSE matters. O’Donnell/Snider Construction is committed to providing a productive, safe and healthy work environment for our employees, contractors, clients, customers and visitors.

Our commitments are communicated to all employees, contractors and suppliers and include:

• To instill a corporate culture where harm to our staff through work is totally unacceptable;

• To be proactive in assessing health, safety and environmental hazards for new business, new and existing work systems, practices and equipment;

• To encourage team problem solving at all levels of the organization to implement work practices that continually improve safety, environmental standards and productivity;

• To report and investigate incidents and implement systems and practices that prevent reoccurrence;

• To ensure compliance with legal requirements and industry standards;

• To train managers and employees to competently perform work described in safe work procedures;

• To provide information to all employees, contractors and customers that inform them of health safety and environmental issues relevant to O’Donnell/Snider Construction operations;

• To ensure products are safe and without adverse environmental impact.

• All O’Donnell/Snider Construction staff have a responsibility for implementing this safety and health management system by striving to achieve a zero tolerance towards hazards, incidents and injuries.

• We continuously improve safety and health management by setting objectives, plans and performance measures and regularly reviewing progress against the targets set.

• We involve our staff in safety and health management through training and by contributing in identifying, assessing and controlling hazards.

Management Commitment and Leadership

Senior management of O’Donnell/Snider Construction shall provide leadership for safety and health activities and assume overall responsibility for the SHMS. This responsibility includes:

• Establishing, actively promoting, and maintaining the SHMS;

• Providing appropriate financial, human, and organizational resources to plan, implement, check, review, and correct the SHMS;

• Defining roles, assigning responsibilities, establishing accountability, and delegating authority to implement an effective SHMS;

• Establishing and implementing a safety and health policy and measurable objectives;

• Reviewing the organization's SHMS at planned intervals;

• Ensuring that employees and employee representatives are consulted; and

O’Donnell/Snider

Uncontrolled copy if printed. Valid on day of printing only.

on: 25 October 2022

Printed

Construction

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 26 of 323

• Encouraging active participation on the part of employees and contractors in the establishment and maintenance of the SHMS.

Management Representatives

The O’Donnell/Snider Construction senior management shall, if warranted due to O’Donnell/Snider Construction workforce size, designate one or more representatives of management who, irrespective of other responsibilities, shall have defined roles, responsibilities, and authority for ensuring that this SHMS is established, maintained and reviewed to support:

• Effective processes to identify and eliminate or control work‐related hazards and risks;

• Reporting on the performance of the SHMS to senior management, employees, and employee representatives (if present) as appropriate for review and as the basis for improvement.

Employee Participation

Employee participation is an essential aspect of the SHMS. O’Donnell/Snider Construction shall provide employees and employee representatives, if warranted due to O’Donnell/Snider Construction workforce size, with time and resources to participate effectively in the development of the safety and health policy and in the process of SHMS planning, implementation, training, evaluation, and corrective action; and encourage employee participation by providing mechanisms that:

• Support employee participation, such as identifying and removing barriers to participation;

• Establish workplace health and safety committees or employee representatives where required by legislation and, where applicable, collective agreements or other requirements; and

• Ensure that employees and employee representatives are trained in, and consulted on, all aspects of SHMS associated with their work.

O’Donnell/Snider

Uncontrolled copy if printed. Valid on day of printing only.

on: 25 October 2022

Printed

Construction

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

2.0 EQUAL EMPLOYMENT OPPORTUNITY Statement of Equal Opportunity

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 27 of 323

O’Donnell/Snider Construction is an equal opportunity employer and will not discriminate in recruiting, hiring, training, promotion, transfer, discharge, compensation or any other term or condition or employment on the basis of race, religion, color, age (over age 39), sex, sexual orientation, gender identity, national origin, or on the basis of disability if the employee can perform the essential functions of the job, with a reasonable accommodation if necessary. Any employee who is aware of discriminatory conduct or who has any concern about a possible violation of this policy should immediately report the conduct or concern to his or her supervisor, designated human resource personnel or any corporate officer.

Business Ethics/Code of Conduct

O’Donnell/Snider Construction is a professional, responsible, and law‐abiding business entity, and we have a well‐ deserved reputation for integrity. Your conduct and the conduct of every other employee contributes to that reputation. You may not take any action or engage in any conduct that would cause O’Donnell/Snider Construction, or any of its employees , embarrassment or humiliation that creates the appearance of impropriety, or otherwise causes or contributes to our Company or its employees being held in disrepute by the general public, or the Company’s clients, customers or other employees.

You are expected to devote your best efforts and full‐time attention to the performance of your job at O’Donnell/Snider Construction. Any material activity of a personal or non‐Company related nature is not allowed during working hours, and may be grounds for discipline, up to and including termination of employment.

Conflicts of Interest

Following are some ways in which conflicts of interest could arise:

1. Being employed (employee or close family member ) by, or acting as a consultant to, a competitor or potential competitor, supplier or contractor, regardless of the nature of the employment, while you are employed with O’Donnell/Snider Construction.

2. Hiring or supervising family members or closely related persons.

3. Developing a personal relationship with a subordinate team member of the Company that might interfere with the exercise of impartial judgement in decisions affecting the Company or any team members of the Company.

4. Entering a personal relationship with an employee of a competitor, supplier or customer.

5. Serving as a board member for an outside commercial company or organization.

6. Owning or having a substantial interest in a competitor, supplier or contractor.

7. Having a personal interest, financial interest or potential gain in any O’Donnell/Snider Construction transaction.

8. Using proprietary or confidential Organization information for personal gain or to O’Donnell/Snider Construction’s detriment.

9. Using Company assets or labor for personal use.

10. Committing the Company to give its financial or other support to any outside activity or organization without express prior written approval from the Board; or,

O’Donnell/Snider Construction

Uncontrolled copy if printed. Valid on day of printing only.

on: 25 October 2022

Printed

SAFETY AND HEALTH MANAGEMENT SYSTEM

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 28 of 323

11. Placing company business with a firm owned or controlled by an O’Donnell/Snider Construction employee or his or her family.

12. Accepting gifts, discounts, favors or services form a customer/potential customer, competitor or supplier, unless equally available to all O’Donnell/Snider Construction employees.

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022

Construction

O’Donnell/Snider

O’Donnell/Snider Construction

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

3.0 IMPLEMENTATION & OPERATION

Purpose

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 29 of 323

To encourage participation in good safety and health practices and support for our policy and objectives by consulting and communicating with all employees.

Procedure

Methods used to involve employees in hazard identification, risk assessment and risk control and to encourage employee involvement in the safety and health process include:

Open Door Policy

It is preferred that the immediate supervisor and/or project management be consulted for resolution of the concern; however, O’Donnell/Snider Construction maintains a strong open‐door policy to report problems or concerns to any level of management without fear of reprisal of any employee.

Through effective implementation and operational controls O’Donnell/Snider Construction benefits by:

• Providing a framework for a systematic and integrated approach for safety and health management which allows the SHMS to become part of the fabric of our business

• Making the SHMS "system" dependent and not "person" dependent

• Promoting sound safety and health management which becomes a means of doing business and not an end in and of itself

• Positioning O’Donnell/Snider Construction as a safety and health leader.

Emergency Preparedness

Preparedness Requirements

Each O’Donnell/Snider Construction worksite shall have contingency plans that identify the potential for incidents and emergency situations. Refer to the O’Donnell/Snider Construction Emergency Action Plan.

These shall include, as a minimum:

• Plans for responding to an emergency that may require a need for rescue or evacuation is found.

• Plans to address workplace violence

• Plans to address medical emergencies

• Plans to address any other known or potential emergency

Each facility shall conduct an annual routine emergency evacuation drill.

O’Donnell/Snider

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022

Construction

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

Operational Control

Compliance with Legal and Other Requirements

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 30 of 323

The Manager, with assistance from the O’Donnell/Snider Construction Safety Manager, leads the development, documentation, and maintenance of applicable operational controls. Operational controls are developed for safety and health requirements identified in the Safety and Health Compliance Matrix.

Disciplinary System

Management is committed to the safety excellence of its employees by providing an injury and incident free workplace. All employees are to abide by the regulations, safety rules and the use of safe work practices and procedures. Refer to the O’Donnell/Snider Construction Disciplinary Procedure.

Safety violations will be handled in an objective but firm manner. The enforcement progression follows the steps outlined below with documentation at each stage:

• Verbal Warning

• Written Warning

• Dismissal

Violation of any of the below rules will not be tolerated on the job and are additional grounds for immediate discipline up to and including dismissal:

• Consuming or being in possession of alcohol or illegal drugs on O’Donnell/Snider Construction premises, or on any O’Donnell/Snider Construction job‐site, is prohibited.

• No weapons or firearms of any type are allowed on the worksite.

• Fighting, horseplay, practical jokes or otherwise interfering with other workers is prohibited.

• Theft, vandalism or any other abuse or misuse of O’Donnell/Snider Construction property is prohibited.

• All unsafe acts and conditions, including “near miss” incidents, are to be reported to appropriate supervision promptly.

• Hard hats, safety boots and safety glasses are to be worn at all times on all job‐sites.

• All work shall be carried out in accordance with appropriate safe work practices and your supervisor’s direction.

• Only those tools that are in good repair, with all guards and safety devices in place, shall be used.

• Attempted or actual physical force to cause injury, threatening statements or other actions to cause an employee to feel they are at risk of injury.

Equipment and Working Conditions

• Damaged and faulty equipment reporting procedures must be in place.

• No equipment shall be operated unless the employee has received proper training by the supervisor.

• Tools and equipment damaged during use must be replaced or repaired only by a qualified person.

O’Donnell/Snider

Uncontrolled copy if printed. Valid on day of printing only.

on: 25 October 2022

Printed

Construction

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 31 of 323

• Floors, platforms, ramps, stairs and all walking surfaces for employees must be maintained in a state of safe repair and kept free of slipping and tripping hazards. If such areas are taken out of service, reasonable means shall be taken to prevent entry or use.

• O’Donnell/Snider Construction shall ensure that worksite traffic is controlled to protect employees and subcontractors. This will be accomplished through engineering controls or administrative controls either by O’Donnell/Snider Construction or via our subcontractors if they maintain control of the traffic on the worksite. Each worksite must have a designated safe way of entering and exiting.

• O’Donnell/Snider Construction will ensure that housekeeping issues such as keeping the work site clean and free from materials or equipment that could cause employees to slip or trip are addressed.

• O’Donnell/Snider Construction will ensure all equipment is maintained, safe to perform adequate strength for its purpose and free from obvious defects.

• Any equipment being found to be defective or in need of repair shall be tagged out, isolated from service by being turned into an employee’s direct supervisor and not used until repaired by a qualified repair person.

Fatigue Management

Refer to the O’Donnell/Snider Construction Fatigue Management Procedure. The guiding principles of fatigue management shall be incorporated into the normal management functions of the business and include the following:

• Employees must be in a fit state to undertake work

• Employees must be fit to complete work

• Employees must take minimum periods of rest to safely perform their work

The following work hour limitations and will control job rotation schedules to control fatigue, allow for sufficient sleep and to increase mental fitness. If local legislated requirements are higher they shall be followed.

1. Every Employee shall have necessary work breaks in order to avoid fatigue. These scheduled breaks will apply to both driving and on‐site hours.

2. Unfamiliar or irregular work should be avoided.

Identified Hazards and Risks

Operations and activities associated with hazards and identified risks are addressed within the SHMS through the worksite hazard assessment.

Management of Change (MOC)

The Manager identifies facility and operational changes for review. The O’Donnell/Snider Construction Safety Manager determines whether the changes have a potential impact the operational controls and, if so, updates the operational controls in conjunction with the Manager. Modifications and revisions to operational controls are communicated to relevant personnel via the site specific HSE plan.

O’Donnell/Snider

Uncontrolled copy if printed. Valid on day of printing only.

on: 25 October 2022

Printed

Construction

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 32 of 323

Preventative Maintenance Program for Tools and Equipment

All tools, equipment and vehicles must be properly maintained so that workers are not endangered. Preventive maintenance is the systematic care and protection of tools, equipment, machines and vehicles in order to keep them in a safe, usable condition limit downtime and extend productivity. Maintenance tasks themselves are potentially hazardous and can result in injury. This maintenance program must be prepared at a site level and:

• Be well organized and scheduled

• Controls hazards

• Defines operational procedures, and

• Trains key personnel

General requirements for equipment maintenance include:

• Obtaining a copy of the maintenance schedule recommended by the manufacturer.

• Ensuring that maintenance is performed as required.

• Ensuring that the person(s) performing the maintenance are competent (e.g. licensed mechanic).

• Retaining records of maintenance/service conducted.

• Specifying who is responsible for overseeing equipment maintenance and where the records are kept.

• Set up a system for removal and tagging of damaged or defective tools and equipment.

Tools and Equipment Maintenance Program

• Only properly trained workers are to use tools, equipment and vehicles.

• Inspect all tools, equipment and vehicles before using.

• For vehicles, inspection will consist of doing a circle check.

• If applicable, maintenance schedules for all tools, equipment and vehicles are to be respected.

• Each jobsite supervisor is to conduct a bi‐weekly inspection of all tools, equipment and vehicles on the site. This inspection is recorded bi‐weekly using an inspection checklist based on the type of equipment and vehicles at that site.

• If at any time a worker judges that a tool, equipment or vehicle is unsafe for use, they are to properly tag the item and inform the supervisor immediately.

• Tools, equipment or vehicles that are tagged unsafe shall be either repaired or replaced ‐ O’Donnell/Snider Construction management shall be informed.

REMINDERS: Always use Hand and Power Tools Safely

• Select the right tool for the job.

• Keep tools in good condition.

• Use tools the correct way.

• Keep tools in a safe place.

Maintenance Personnel Qualifications ‐ All individuals who perform maintenance work on O’Donnell/Snider Construction tools shall have the appropriate skills, accreditation and/or certification. This certification applies both to O’Donnell/Snider Construction employees and to contracted maintenance services.

O’Donnell/Snider

Uncontrolled copy if printed. Valid on day of printing only.

on: 25 October 2022

Printed

Construction

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 33 of 323

Mobile Equipment Maintenance Program ‐ Maintenance Personnel Qualifications ‐ All individuals who perform maintenance work on O’Donnell/Snider Construction mobile equipment will have the appropriate skills, accreditation and/or certification. This certification applies both to O’Donnell/Snider Construction employees and to contracted maintenance services.

Operator Qualifications and Training ‐ All individuals who operate mobile equipment, cranes, vehicles etc. will have the appropriate skills, accreditation and/or certification. This applies to both O’Donnell/Snider Construction employees and contracted equipment services. The approval process includes the following:

• Possession of a valid driver's license appropriate to the type of equipment

• Successful completion of a practical operating exam administered by competent and authorized personnel

• Vision test to meet the appropriate standard ‐ Vision tests must be conducted by competent and authorized personnel

• Hearing test with or without a hearing aid must be adequate for the specific operation. Hearing tests will be conducted by competent and authorized medical personnel.

• No history of epilepsy or of a disabling heart condition or any other physical disability or impairment.

• The operator shall be trained in the following:

o Their responsibilities to operate the equipment in a safe manner

o Familiarity and comprehension of safety requirements for the piece of mobile equipment which they intend to operate

o Manufacturer’s operating and maintenance procedures;

o Hand signals and/or other requirements set by O’Donnell/Snider Construction.

Records ‐ The maintenance program must contain a recording system. Part of this system should be made up of inventories and schedules. In addition, the recording system should document what maintenance work was done, when, and by whom.

Monitoring ‐ The monitoring functions in a maintenance program fall into two areas. First, the staff responsible for operating and/or maintaining equipment must monitor that equipment to ensure that appropriate checks and maintenance are done. Secondly, management must monitor the entire program to ensure that it is functioning in accordance with O’Donnell/Snider Construction policy.

Scheduled Inspections and Maintenance ‐ All mobile equipment is to be inspected and maintained according to the following Equipment Inspection Schedule as a minimum. Records of all inspections and maintenance are completed and maintained for review and approval.

Maintenance of equipment, release of lubrication fluids, etc., is performed only in approved areas. Spills and leaks from equipment are cleaned up promptly.

Pre‐Operation Checks

• Walk around checks on all pieces of mobile equipment are necessary to ensure the unit is safe to operate both from the personnel standpoint and for the equipment; that is, all fluids must be at the correct level and all components must be intact.

O’Donnell/Snider

Uncontrolled copy if printed. Valid on day of printing only.

on: 25 October 2022

Printed

Construction

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 34 of 323

• Check for personnel in the cab area and around the equipment. Before the operator commences the pre‐ start checks, the operator should check the cab area for other operators and others who may be working around the equipment.

• Visual check ‐ The operator should walk completely around the equipment looking underneath the equipment, in the engine compartment, and in the cab.

• Brake Lines ‐ Visually check the brake lines for leaks. Check for moisture on the brake line. Report any leaks to maintenance for repair as soon as possible. DO NOT operate equipment with brake leaks.

• Steering Assembly ‐ Check the tie rod ends, pins and keepers, drag links, ball joints, steering rams and hoses; Check that all the joints are tight; Report any faulty conditions to your supervisor. Note: Never operate a truck with faulty steering.

Reporting of Hazardous Conditions, Security Incidents or Injuries

• All employees have a responsibility for reporting hazardous work conditions or acts that are encountered on the job site.

• Employees shall not perform any work they feel is unsafe. Each employee is required to immediately report any unsafe condition or act to their immediate supervisor. Any employee may report hazardous work conditions without fear of reprisal.

• Employees shall immediately report any injury, near miss and incidence of fire, property damage, theft or other security related matter and environmental non‐conformance, before reporting for work, and any non‐work injuries or prescriptions that could affect their ability to safely perform their normal job.

• Failure to report incidents, hazardous work conditions or near misses shall result in disciplinary action.

• Additional methods for reporting hazardous conditions include: Weekly safety meetings; O’Donnell/Snider

Construction BBS Safety Observation Form to the O’Donnell/Snider Construction Safety Manager/ Supervisor

• Direct communications with any member of O’Donnell/Snider Construction supervision or management;

• Client hazard reporting methods.

Systems to Control Access or Exiting Customer's Premises

• All vehicles will be properly insured and equipped with all client vehicle required safety equipment.

• All staff will have proper client required training and identification prior to entering a client location.

• All staff will log in and log out per client requirements.

• No material will be brought onto or leave client property without permission from the client in accordance with their requirements.

Work Permits and Permit to Work Form

O’Donnell/Snider Construction will utilize client work permits in accordance with their guidelines. Work will not begin until the client work permits are completed. O’Donnell/Snider Construction will develop a permit to work form where required by client or legal requirement.

O’Donnell/Snider

Uncontrolled copy if printed. Valid on day of printing only.

on: 25 October 2022

Printed

Construction

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

4.0 MANAGEMENT REVIEW Management Meetings

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 35 of 323

On a schedule, determined by the O’Donnell/Snider Construction President, senior O’Donnell/Snider Construction management must meet at least annually and address the following subjects:

• Review of Performance (Objectives and Safety Programs)

• Corrective Actions and Inspection Review

• Safety and Health Management Resources Adequacy

• Operational Controls

• Roles and Responsibilities

• Review of Safety and Health Policy

Meeting results are documented through meeting agendas and minutes that include an executive summary and a summary of post review action items.

Safety Management System Review

The O’Donnell/Snider Construction Safety and Health Management System are reviewed at least annually by the O’Donnell/Snider Construction Safety Manager to evaluate its success in meeting the goal and objectives for safety within O’Donnell/Snider Construction.

The O’Donnell/Snider Construction Safety Manager maintains a record of the review. Results of the annual review are incorporated into changes to the O’Donnell/Snider Construction Safety and Health Management System manual, site specific HSE plans or appropriate safety procedures.

O’Donnell/Snider

Uncontrolled copy if printed. Valid on day of printing only.

on: 25 October 2022

Printed

Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 36 of 323

Uncontrolled copy if printed. Valid on day of printing only. Printed on: 25 October 2022

Construction

Construction

O’Donnell/Snider

O’Donnell/Snider

O’Donnell/Snider Construction

SAFETY AND HEALTH MANAGEMENT SYSTEM

5.0 WRITTEN SAFETY AND HEALTH GOALS Objectives & Safety Programs

Doc No: SHMS

Initial Issue Date 10/03/2017

Revision Date: 10/25/2022

Revision No. 7

Next Review Date: 10/25/2023

Page: 37 of 323

To establish and maintain management programs to achieve identified safety and health goals.

The O’Donnell/Snider Construction Safety Manager establishes safety and health management programs based on objectives and responsible parties are notified of their requirements.

Where significant modifications in working practices, processes or equipment are expected the management program will provide for new hazard identification and risk assessments.

Progress for safety and health management programs is reviewed as part of the Key Performance Indicator procedure and Management Review procedure and shall be evaluated quarterly.

Safety & Health Goals

The O’Donnell/Snider Construction Safety Manager identifies goals by:

• Aligning objectives with O’Donnell/Snider Construction policy, legal and other requirements, hazard abatement procedures

• Making objectives specific, measurable and achievable

• Gathering input from employees and interested parties

• Incorporating Management Review procedure results

Examples of goals include:

• Reduction of risk levels

• Elimination or reduction in frequency of undesired incidents

• Implementing additional features of the O’Donnell/Snider Construction Safety and Health Management System

After goals are identified the O’Donnell/Snider Construction Safety Manager prioritizes them and establishes a scope, objective, time scale, target, responsibilities and resource requirements for each identified objective and provides a safety management program.

Performance against developed goals is measured by and communicated to employees in memos, safety meetings and other as‐needed methods.