Food safety and quality in one place

7

WHAT’S NEW

South Africa’s trendy food and beverage products

8 NEWS

T NA Solutions exhibit at Anuga FoodTec

Eskort expands production capacity

9

INDUSTRY TALK

Bringing innovation and impact together

12

COMPANY FOCUS

Elevating vacuum tech

14

MEAT, FISH & POULTRY

Moving towards the future one chemical at a time

Hygienic and hard wearing chemical resistant floors

The future of sustainable proteins

Understanding fraud in the meat, fish & poultry sector

A safe choice with anti-microbial skins

Offering wholesome quality food

28

SNACKS & CONFECTIONERY

Setting the standard in conveyor tech

Navigating the salt reduction dilemma

Roller Mill Arrikis: Reinvention of an icon

Purpose driven confectionery A healthy snack alternative

38

SUSTAINABLE, RECYCLABLE PACKAGING A sustainable packaging solution

The game-changer in packaging

Compostable PLA bags Recyclable spout pouche

48

CLEAN-IN-PLACE HTST Milk Pasteurisers

Advantages of flushing rings in diaphragm seal systems

Showcasing the efficient DMSU22SA

Unpacking trends and challenges in the food industry

One of this year’s highly anticipated trade shows is the Africa Meat & Poultry Expo scheduled for 12 – 14 June. This inaugural edition offers the perfect platform that brings key actors in the meat, poultry, fish and seafood value chains in Africa with trade, market access, innovations and sustainability as the overriding themes at both the trade show and conference. Turn to page 18 for more details. Still on the meat topic, on page 20 , we bring your attention to fraud in the meat, fish and poultry sector. Find out how this can have far-reaching effects on consumer trust and threaten a brand’s reputation. While cost - effective production of meat remains a priority, concerns over the safety of meat, poultry, and fish products persist and we are being cautioned about the safety of these food products, see page 25. Shifting gears to healthy snack alternatives, the healthy snacking indulgence trend continues to make waves. On page 28 we explore ways to achieve this by navigating the salt reduction dilemma. Read how salt is a component that ignites a debate between consumers and the food industry. Sugar is another contentious component that has had an impact on our health and therefore triggering a confectionery revolution. Find out what the term ‘purpose - driven confectionery’ entails on page 32 and discover how we can address the growing demand for treats that combine indulgence with health benefits while also exploring innovative solutions and functional ingredients at the same time. Check out the game-changer in sustainable packaging solutions on page 40 and find out how the EcoFloat WHITE will enable greater recyclability not only for dairy packaging but for other products that a light sensitive.

Don’t forget to turn to page 6 for the latest and upcoming trade shows!

Till we meet again!

Kelebogile (Lebo) Nondzaba

@SA_FoodReview

THE TEAM

EDITORIAL

Editor: Kelebogile Nondzaba

+27 (0)78

9632

Sub-editor: Gill Abrahams

Layout & Design: Tumi Kunene

ADVERTISING

Key Account Manager: Anita Raath +27 (0) 82 976 6541

anita.raath@newmedia.co.za

Key Account Manager: Càndida Giambò-Kruger +27 (0) 71 438 1918 càndida.giambò-kruger@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland:

Eisenacher Medien Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy:

Ngcombroker

Giacomo Rotunno +39 370 101 4694 g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media

Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk

CIRCULATION

Circulation Manager: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

General Manager: Dev Naidoo

Head of Commercial B2B: Johann Gerber

Production Controller: Mandy Ackerman

Art Director: David Kyslinger

JOHANNESBURG OFFICE

Ground Floor 272 Pretoria Avenue Randburg, 2194

POSTAL ADDRESS

PO Box 784698, Sandton, Johannesburg 2146

Published by New Media, a division of Media24 (Pty) Ltd

MANAGEMENT TEAM

MANAGING DIRECTOR: Aileen Lamb

COMMERCIAL DIRECTOR: Maria Tiganis

STRATEGY DIRECTOR: Andrew Nunneley

CHIEF FINANCIAL OFFICER: Venette Malone

CEO: MEDIA24: Ishmet Davidson

HEAD OFFICE

New Media, a division of Media24 (Pty) Ltd 8th floor, Media24 Centre, 40 Heerengracht Cape Town, 8001

Copyright:

Inline pump filling equipment

Rotary filling equipment

Round bottle labelling

Pharmaceutical labelling & coding

Front and back labelling

Entry level filling equipment

Gravity filling equipment

Inline pump filling equipment

Rotary filling equipment

Round bottle labelling

Pharmaceutical labelling & coding

Front and back labelling

Entry level filling equipment

Gravity filling equipment

Organic & Natural Products

Cape Town, South Africa

26 – 28 April

www.organicandnaturalportal.com

Propak Ghana

Acra,Ghana

23 – 25 April

www.propakwestafrica.com

Analytica

Munich, Germany

9 – 12 April

www.analytica.de

April May

Nampo Harvest Day

Bothaville,South Africa

14 – 17 May

www.grainsa.co.za

Food Pack Africa

Kampala, Uganda

6 – 8 May

www.mxmexhibitions.com

IFAT

Munich, Germany

13 – 17 May

www.ifat.de

Empack

Gorinchem, Netherlands

9 – 11 April

www.empack.nl

Organic & Natural Products

London, UK

14 – 15 April

www.naturalproducts.co.uk

Cibus

Parma, Italy

7 – 10 May

www.cibus.it

SIAL

Shanghai, China

28 - 31

www.sialchina.com

June

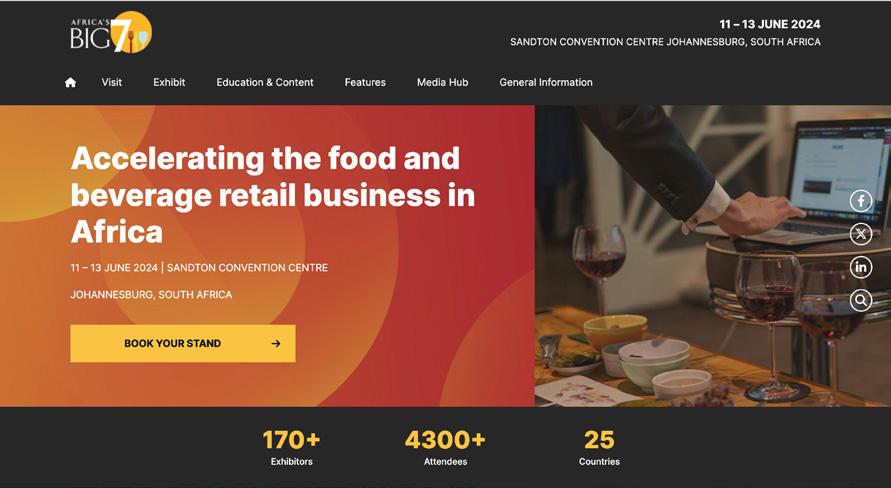

Africa’s Big 7

Johannesburg, South Africa

11 – 13 June

www.africabig7.com

Food & Beverage W/Africa

Lagos, Nigeria

11 – 13 June

www.fab-westafrica.com

IGNITE YOUR SUMMER!

Sundown, heat up! is the feeling that Smirnoff wants to encapsulate this summer with the introduction of its new innovative offering, the latest fiery creation dubbed Smirnoff Spicy Tamarind. Inspired by the bold flavours of Mexico and crafted for the audacious spirit, this new variant is set to redefine your drinking experience and ignite your inner passion. It is now available for sale at leading retailers for just under R230 and may be enjoyed in several ways including the main serve which is as a shot serve cold from the freezer; and in a sharable punch for a group or a lovely local cocktail!

Drawing its intensity from the heart of Mexico and created for those who seek extraordinary experiences, Smirnoff Spicy Tamarind is a tantalizing blend that brings the edge, beckoning all adventure seekers to join its tribe.

Speaking about the launch of the new variant, Refilwe Bosii – Innovation Manager at Diageo – said: “Smirnoff is a pioneer in the world of spirits, and continues to push boundaries, crafting innovative flavours that resonate with today’s diverse and adventurous consumer base. With a legacy steeped in authenticity and a commitment to excellence, the Spicy Tamarind continues this legacy.

KWV CRUXLAND KALAHARI TRUFFLE GIN WINS AWARD

Cruxland Kalahari Truffle Gin, an exquisite creation from South Africa’s esteemed KWV distillery, has been honoured with the South Africa - Country Winner Gold award in the London Dry Gin category at the 2024 World Gin Awards, held at the Hurlingham Club in West London. This achievement marks the fifth time that Cruxland Gin has been honoured with such a prestigious accolade, reaffirming its status as a world-class contender.

Recognised for celebrating the pinnacle of gin craftsmanship and innovation, the World Gin Awards have spotlighted Cruxland Gin for its exceptional quality and unique flavour profile, derived from the rare Kalahari truffle. This accolade underscores KWV’s dedication to embracing the rich biodiversity of South

CREATE CRUNCHY TEXTURES WITH VISUAL APPEAL

Africa and its commitment to excellence in distilling.

“We are thrilled to receive this prestigious award, and it further motivates us to continue pushing the boundaries of gin craftsmanship,” said Pieter Do Bod, General Manager of Spirits at KWV. “We extend our gratitude to the World Gin Awards for recognising the dedication and expertise that went into creating Cruxland Kalahari Truffle Gin.” KWV Cruxland

Kalahari Truffle Gin is distinguished by its infusion of hand-harvested Kalahari truffles, which bring a distinctive and luxurious character to the classic gin experience. These truffles, unearthed in the vast expanses of the Kalahari after the annual rains, add a depth of flavour that is as rare as it is captivating.

Ingredients specialist Loryma has a wide range of ingredients for all types of coated products. The Lory® Crumb portfolio includes several extrudates in various shapes and colours for breadings. With a unique appearance and crunch, they are perfect for plant-based meat alternatives, vegetable sticks, meat and fish products, and desserts. A selection of native and modified starches

ensures optimum adhesion and crispness in batters, tempura coatings and dustings.

Eye-catching breadings

breading texture and are characterised by high temperature and colour stability. As a result, visual appeal is guaranteed even under demanding conditions, thus allowing for the crating of superior, added-value breaded products. Images: Supplied by clients

TNA SOLUTIONS EXHIBIT AT ANUGA FOODTEC IN COLOGNE

Visitors can engage with TNA’s experts at Stand E068 in Hall 10.1 to explore how TNA can serve as a complete line solutions partner, providing end-to-end expertise for snack producers.

At Anuga FoodTec, TNA solutions will exhibit a range of solutions for French fries and savoury snacks.

These markets are growing fast. According to the latest GlobalData research, the global savoury snacks sector is expected to yield a CAGR of 8.1% during 2022-27 and reach $260.3 billion in 2027. At the same time, the global French fries market is set to grow at a CAGR of 6.7% to 2027, reaching over $18.5bn in terms of value. To help food producers meet the growing market demand, TNA offers complete processing and packaging solutions designed with high output in mind.

“What we are demonstrating at Anuga FoodTec is our in-depth understanding of the balance required to satisfy consumers and retailers, while keeping brands profitable,” commented Twan van den Berg, global sales manager, Processing, at TNA solutions. “We use our capabilities, expertise and portfolio to deliver complete line solutions in partnership with our customers, drawing on our deep process knowledge to ensure any new technologies

can be integrated with minimal operational disruption and maximum impact.”

The snack industry faces multifaceted challenges, including regulatory, environmental, and consumer pressures. Agility, innovation, and strategic planning are essential for these companies to stay competitive and succeed. Working with a complete line solutions partner offers several benefits.

TNA is at the forefront of providing innovative equipment solutions to help food makers address the challenges above, realise goals and exceed their expectations. TNA creates and sustains complete processing and packaging solutions from receiving, destoning, washing, peeling, inspecting, slicing, blanching, dewatering, continuous vacuum and batch frying, deoiling, sorting, distribution, seasoning, and packaging. This holistic approach ensures that every stage of production is optimised for peak performance, minimising downtime and reducing the total cost of ownership.

To read more, visit: www.foodreview.co.za

ESKORT EXPANDS PRODUCTION CAPACITY BY 50% IN GAUTENG

Eskort, South Africa’s leading pork manufacturer, has expanded its Gauteng production capacity by 50% with a factory extension officially launched in mid-February.

The 10, 000m² development in Heidelberg – the small town where the company has produced world-class pork products for 70 years – will allow Eskort to increase production to meet retail needs.

The enlarged factory is equipped with the largest continuous box freezer in Africa, capable of freezing 120,000kg of products to minus 18°C every 24 hours. Boxes move on a conveyor belt through the freezing chamber where the air is kept at minus 41°C – a temperature that occurs naturally only in polar regions.

Chilled and frozen warehouses in Heidelberg now have multi-level picking mezzanine floor systems, the first of their kind in the food industry in South Africa. These systems maximise vertical space by including mezzanine floors that create additional levels for storage and picking, and they allow Eskort to handle a high volume of orders quickly and efficiently.

Arnold Prinsloo, Eskort chief executive officer for the past 17 years, says the core objective of the factory extension is to create efficiencies. “A big part of this expansion includes the addition of carcass chillers as well as the installation of a huge box freezer to accommodate the infl ux of raw material,” he says.

To read more, visit: www.foodreview.co.za Images:

ZIPPY EDIBLES PARTNERS WITH COPERION

To significantly advance its production, Zippy Edible Products Pvt Ltd, Rudrapur/ India, decided on a Coperion ZSK 54 Mv PLUS twin-screw extruder with a cooling die and a high-accurate Coperion K-Tron K2-ML-D5-T35 feeder to manufacture High Moisture Meat Analogues (HMMA). With this state-of-theart extrusion system, the company is not only able to produce various types of meat analogues that are tailored to the dynamic needs of the Indian market but also enters a new era of food processing using extrusion technology.

Zippy Edibles produces various plantbased dishes such as Soya Chaap, a popular North Indian delicacy known for its meatlike texture, on the Coperion system. This versatile food extruder is ideally suited for this task as it offers high operational reliability as well as a flexible and economical production set-up. The ZSK 54 Mv PLUS twin-screw extruder features a specific torque of 11.3 Nm/cm3 and screw speed up to 1500 min-1 ensuring a constantly highquality level. With the high throughput of the machine the Indian food specialist can produce up to 500 kg per hour of HMMA and can thus meet the high demand for vegetarian products. Thanks to the deeply cut screw flights with a diameter ratio Do/ Di of 1.8 the system ensures a very large free

screw volume that improves the feed intake of plant-based ingredients that are often poorly flowing. Furthermore, the modular process section of the extruder can flexibly be adapted to changing requirements, giving Zippy the possibility to expand their range of protein products over time. The versatility of the Coperion extruder allows for extensive control over various parameters to create different types of extrudates which can be formed, coated and marinated to target the individual market needs.

PARTNERSHIP AS KEY

Zippy’s decision to partner with Coperion was made not only based on the advanced technology but also on process technology support and the availability of local contacts. Comprehensive trials at the Coperion Test Lab in Stuttgart, Germany, as well as support

“Zippy Edibles produces various plant-based dishes such as Soya Chaap, a popular North Indian delicacy known for its meat-like texture, on the Coperion system.”

DID YOU KNOW

The versatility of the Coperion extruder allows for extensive control over various parameters to create different types of extrudates which can be formed, coated and marinated to target the individual market needs.

prior to the purchase of the machine and after-sales support helped Zippy to use the machine to its full capabilities. Moreover, the local on-site support by Coperion India facilitates fast reaction which led to building up a reliable partnership.

Sarthak Singhal, director of business development at Zippy Edibles, added: “We are very proud to announce the successful commissioning of the state-of-the-art Coperion extrusion system, marking a significant advancement in the production of high moisture meat analogues. This collaboration supports us in our vision to innovate and provide cost-effective, highquality meat alternatives. We invite you to experience the future of food processing. Together, we are setting new standards in the Indian industry, delivering innovative solutions that cater to the evolving tastes and preferences of consumers.”

Coperion – www.coperion.com

Unlocking senses at the 22nd SAAFFI Seminar

Unlocking our sensational world: Sensory storytelling through Flavours and Fragrances’, was this year’s theme at SAAFFI’s 22nd annual seminar.

The Indian American author, newage philosopher and healer, Deepak Chopra said: “Self-awareness is your awareness of the world, which you experience through the five senses (sound, touch, sight, taste, and smell). Pay attention to your sensory impressions and be aware of those five ways that the world comes to you.”

ABOUT SAAFFIFor the last 23 years, the annual SAAFFI seminar has attracted around 200 key personnel drawn from a wide range of companies both in the flavour & fragrance sector, and from FMCG companies (who are users of flavours and fragrances), as well as academics, consultants, regulators, raw material suppliers and anyone interested in the fascinating world of fragrance and flavours. The day offered valuable learning and networking opportunities to people in management, sales, marketing, technical, procurement, R&D, applications, operations, and tertiary level students.

The SAAFFI 22nd annual seminar is an industry event for every serious flavour, fragrance, food, beverage, cosmetic and FMCG professional –simultaneously offering a day of fun, insight and inspiration!

SAAFFI, the South African Association of the Flavour & Fragrance Industry, represents all aspects of the flavour, fragrance and allied industries. It unites the industry across noncompetitive issues, freeing up individual organisations to grow their business.

Our entire interaction with the world around us – whether it be personal, professional, physical, spiritual, intellectual or emotional – is through our five senses. Our reactions to these stimuli define who we are, what we stand for and what we can achieve.

Reframed, the five senses are NOT only of importance to the Flavour, Fragrance, Sensory and Consumer Science professions, but are the means with which we all respond to every aspect of our environment.

The full-day programme featured an impressive line-up of speakers, a handson workshop, an inspiring motivational presentation, and a networking cocktail event. This year’s programme aimed to highlight the fundamental role of sensory integration, sensory evaluation and sensory awareness in the flavour, fragrance and related sectors.

TOPICS COVERED BY INTERNATIONAL AND LOCAL SPEAKERS:

A. Sensory Intelligence –

• Understanding the senses and how we all process millions of sensory messages uniquely

• Understanding how sensory spaces around us influence our living, learning and working

• Aligning people and space for best productivity, using our sensory profile.

B. What’s more important - the journey or the destination? The Vital Role of Sensory in the Product Development Journey

C. I told you so! True South African Food Choice Stories

D. The flavour that left a bad taste in my mouth! The importance of Bitter Blockers

E. Flavour Trends in Africa – What Flavours are “HOT” for the African consumer?

F. Fragrance Trends - What are international factors influencing Fragrance TRENDS taking?

G. The Sensory Allure of FlowersInspirational flowers bring Botany to the Boardroom for self-discovery, solution-oriented mindset and strategy development. How do journeys using flowers and plants promote wellness and change?

H. The Enigmatic Connection Between Scent and Sensory Perception: A Holistic Perspective

An expert panel drawn from inside and outside of the Flavour & Fragrance industry, explored the topic: “The Science behind the Consumer Brain and its relevance for the Flavour & Fragrance Industry” asking questions including:

1. Why people choose differently - the diversity of the consumer

2. Why products have different appeal.

3. Matching a consumer with a brand.

4. What does it mean for the F&F industry? The live full-day seminar was held on Thursday 14 March 20243 at the Conference Centre of the GIBS Business School in Illovo, Johannesburg. The hands-on Workshop invited participants to: “Identify and Recognise your Sensory Self”, with the session leaving all involved informed, energised, motivated and challenged.

New Africa head office elevates vacuum technology

Kelebogile Nondzaba engages in a Q&A with Minal Debipersad, head of marketing at Busch Vacuum and Pfeiffer Vacuum Africa, to talk about the company’s rich history, current offerings, expansion plans, and the significance of their new state-of-the-art premises in Johannesburg.

Busch Vacuum Solutions has a rich history dating back to 1963 when Dr. Karl Busch and his wife, Ayhan Busch, founded the company in Maulburg, Germany. Initially, the company focused on developing vacuum pumps and systems for industrial applications. Over the years, The company has expanded its product line to include a wide range of vacuum, ultra-high vacuum and overpressure technology solutions catering to various industries such as packaging, plastics, food processing, medical, oil and gas, vacuum cooling, and more.

“Driven by a commitment to innovation and quality, Busch Vacuum Solutions has grown into one of the leading manufacturers of vacuum pumps, systems, and service worldwide. With a global presence spanning over 40 countries, our company continues to deliver cutting-edge solutions and service to meet the evolving needs of its customers,” says Debipersad.

The company plays a significant role in Busch Vacuum Solutions’ global operations, serving as the main hub for the company’s presence in the African continent from the head office in Johannesburg. Busch Africa boasts a robust presence with sales and service branches strategically located in Cape Town, Durban, and into Africa in Ghana, Kenya and Egypt.

With a dedicated team of professionals and a strong focus on customer satisfaction and service, Busch South Africa has built a reputation for excellence in providing innovative vacuum solutions tailored to the unique requirements of African markets.

Q. WHAT ARE THE COMPANY’S CURRENT OFFERINGS?

Vacuum pumps and overpressure: We provide a wide range of vacuum pump technologies, including oil rotary vane, dry rotary vane, screw, dry claw, liquid ring pumps, turbo pumps, leak detectors and blowers, catering to various applications and performance requirements.

Vacuum systems: Our vacuum systems are tailored to specific industrial processes, offering central vacuum solutions and turnkey solutions for applications such as packaging, medical and more. These systems integrate pumps, condition monitoring, controls, and accessories to optimise performance and efficiency.

Vacuum and ultra-high vacuum accessories: We offer a variety of accessories such as digital monitoring to monitor equipment health and performance, filters, gauges, valves, and fittings to enhance the functionality and performance of vacuum systems, ensuring reliable operation and maximum productivity.

Service and support: Our national service centres and certified technicians provide comprehensive support, including maintenance, repair, and optimisation services, to ensure the continued performance and reliability of our equipment.

Q. WHAT ARE YOUR FUTURE PLANS?

Expanding market presence across Africa: We aim to further expand our presence in emerging markets and industries, leveraging our expertise and experience to address evolving customer needs and market trends across the African continent. And more so with the Pfeiffer vacuum range of pumps in the high vacuum and ultrahigh vacuum applications.

Developing energy-efficient solutions: The team of engineers develop both proven and tailormade water and energyefficient vacuum solutions that minimise environmental impact and reduce operating costs for our customers, aligning with global sustainability goals.

Advancing digitalisation: Busch and Pfeiffer have invested in digital technologies to enhance the connectivity, monitoring, and control capabilities of our pumps and systems, enabling predictive maintenance, remote diagnostics, and real-time optimisation.

Acquisition of Pfeiffer Vacuum: Busch

Vacuum Solutions and Pfeiffer Vacuum have joined forces to revolutionise vacuum solutions across the globe and specifically in Africa. This expansion broadens Busch Vacuum’s market share across all four vacuum level classes, enabling them to extend their client base from medium and rough vacuum to encompass high and ultrahigh vacuum. This union marked the dawn of a new era in vacuum technology on the African continent.

Overall, our goal is to remain at the forefront of vacuum technology innovation, providing cutting-edge solutions and exceptional service to empower our customers and drive their success in an everchanging world.

WHY THE NEED FOR BIGGER AND BETTER PREMISES?

Busch Vacuum’s decision to build a stateof-the-art vacuum solutions centre in Johannesburg reflects our commitment to enhancing our operations and services across South Africa and the African continent. The new building serves as a strategic hub for various technical initiatives aimed at advancing our products and solutions to better serve our customers.

HERE’S WHY WE PURSUED THIS EXPANSION:

Increased capacity: With growing demand for our products and services in Africa, we needed a larger facility to accommodate our expanding operations, including service and pump overhauls, warehousing of stock,

system building, Pfeiffer expansion and technical testing capabilities.

Advanced facilities: The new building houses state-of-the-art facilities such as a fully equipped service centre, Pfeiffer Class 10 000 clean room, volumetric flow testing equipment, liquid ring test bay, online condition monitoring systems, and a dedicated training room. These facilities enable us to maintain the highest standards of quality, precision, and efficiency in our operations.

Enhanced customer experience: This purpose-built facility, was built to streamline processes, improve lead times, and offer more comprehensive support to our customers. The new premises also provide a platform for showcasing our capabilities and demonstrating the value of our products and services to clients and prospective clients.

Q. TELL US ABOUT THE LAUNCH?

The launch of this building on the 13th of March 2024 is a significant milestone for Busch Vacuum Solutions in Africa. It represents our ongoing commitment to innovation, excellence, and customer satisfaction.

The presence of our Co-CEO, Ayla Busch, and the head of the economic department from the German Embassy, Mr. Enrico Brandt, underlines the importance of this event and highlights the strong partnership between Busch Vacuum Solutions, key stakeholders and clients.

During the launch event we will showcase the capabilities of our new facility, demonstrate our latest technologies, and engage with clients to understand their evolving needs and challenges. It’s an opportunity for us to strengthen relationships, foster collaboration, and demonstrate the teams dedication to driving success for our customers in Africa and beyond.

EXPANDING AND INVESTING INTO AFRICA

Busch Vacuum Solutions boasts a robust presence with sales and service branches strategically located in Cape Town, Durban, Ghana, Kenya and Egypt. The expansion into Africa presents an exciting opportunity for Busch and Pfeiffer Vacuum to bring our cutting-edge vacuum technology to the markets and industries across the continent. “While we have established a strong presence in South Africa, we recognise that the vast potential of the African continent extends far beyond its borders, and there is a growing demand for innovative vacuum solutions across various

sectors.” highlights Debipersad.

Africa’s diverse economies and industries, ranging from manufacturing and mining to agriculture, oil and gas and healthcare, present numerous opportunities for us to make an impact. By expanding our reach into new regions and countries, we aim to leverage our expertise and experience to address the unique challenges and requirements of African businesses and industries.

With our comprehensive range of products, services, and technical expertise, we are well-positioned to support the development and growth of key sectors across Africa. Whether it’s providing vacuum solutions for packaging and processing applications in the food and beverage industry, supporting mining operations with reliable vacuum pumps, or assisting healthcare facilities with specialised vacuum systems, we are committed to meeting the diverse needs of our customers across the continent.

ACQUISITION OF PFEIFFER VACUUM

Busch has embarked on several transformative projects to introduce and advance Pfeiffer Vacuum’s cutting-edge solutions across Africa. Sean Pieterse, managing director of Busch Africa, elaborates on the acquisition of Pfeiffer Vacuum stating, “Busch Vacuum Solutions Africa has been given a strong boost with the acquisition of Pfeiffer Vacuum. As a full subsidiary of Pfeiffer we now add their world leading range of high and ultrahigh vacuum pumps, vacuum systems and components as well as leak detection services and products. Our focus is on service and being close to our customers, and we strive to be recognised as the smartest solution provider across the continent. I give our Pfeiffer customers my personal commitment that they will receive the same care and attention that Busch offers the market now.”

Busch Vacuum Solutionswww.buschvacuum.com

Pfeiffer Vacuumwww.pfeiffer-vacuum.com

Moving Toward the Future, One Chemical at a Time

In today’s rapidly changing world, Ecowize is steadfastly contributing to a brighter, cleaner future. We are continuing to expand our already comprehensive range of chemicals.

While innovation drives us to develop more sustainable and efficient products, it is our core values that navigate us toward developing best-in-class chemical solutions beyond the food and beverage industry.

Throughout the process, teamwork and transparency underpin every step, giving us the confidence to stand proudly behind our range of products.

At Ecowize, our journey of innovation begins by simply listening to our customers. We see your feedback as more than just comments; we consider it invaluable guidance that helps us imagine new and improved versions of our products.

Together, our dedicated team of chemists, engineers, and consultants explore the intricate world of active ingredients formulating until they find the perfect balance for effective, stable and sustainable products.

A COMMITMENT TO EXCELLENCE

We subject all our products to rigorous testing in line with global benchmarks. This includes the European Standard (EN) testing protocols for disinfectants, as well as the South African adaptation (SANS). Every hard surface disinfectant we offer is registered with the NRCS under VC8054, meeting stringent criteria for use on food contact surfaces.

Our suite of chemicals undergoes thorough toxicology evaluations by autonomous entities such as Intertek or NSF International. These organisations manage the registration of non-food compounds that are used for food contact and non-food contact food surfaces, ensuring compliance with food safety norms and regulatory mandates.

At Ecowize, adherence to rules and regulations is not just a requirement—it is a fundamental aspect of our corporate conduct. As the food safety industry

" At Ecowize, adherence to rules and regulations is not just a requirement—it is a fundamental aspect of our corporate conduct."

grapples with ever-evolving regulations, we stay ahead of the curve, continually adapting to uphold the integrity of our products and guarantee compliance with industry standards. When regulations shift, we respond swiftly, updating our formulations to align with new requirements without compromising product quality.

MORE THAN JUST CHEMICALS: WE OFFER A SERVICE

Our sales and operation teams undergo extensive training, equipping them with the knowledge to educate our customers on effective product usage. They provide expert recommendations for products and equipment to streamline applications, thereby minimising costs and risks for our clients. We don’t just supply chemicals, we serve as a valuable resource for our customers. Our team provides insights on correct sanitisation procedures and establishes robust protocols to be followed during microbial outbreaks, ensuring that our customers are always prepared and protected. At Ecowize, the safety of our employees and customers is more than a priority—it’s a fundamental value that defines who we are. As we gear up for an exciting new chapter with the launch of our upcoming products, we stand proudly behind our commitment to quality, safety, and service. By focusing on customer feedback, collaboration, stringent testing standards, and proactive regulatory compliance, we are setting the stage for a cleaner, safer future — one chemical at a time.

Images: Supplied by client

Ishida solution helps to modernise poultry packing

The installation of an Ishida multi-head weigher at Roldrob SA, one of Poland’s leading poultry processors, has enabled the company to greatly increase production throughput and efficiency, reduce giveaway and improve the quality of the finished product.

THE ISHIDA CCW-RV-214W-1S-30-WP MULTIHEAD WEIGHER

The Ishida CCW-RV-214W-1S-30-WP multihead weigher, a 14-head models with 3 litre hoppers, at Roldrob’s plant in Tomaszów Mazowiecki is handling a range of fresh, chilled and frozen products, including breaded items such as chicken nuggets. The weigher has replaced a manual weighing process and, as the company’s production manager Sławomir Kołodziejek confirmed, the result has been emphatic.

“Although we had a very committed and competent team, manual weighing is extremely difficult and time-consuming, and

" The weigher is currently handling a variety of pack sizes from 120 grams to 10 kilograms, delivering consistent accuracy across all sizes. The most common pack size are 400g tray which are filled at up to 35 trays per minute. "

the probability of weighing errors is very high,” he explained. “Such inconsistencies mean increased costs and lower productivity.

“By comparison, the capabilities of the Ishida weigher, with its enormous capacity and impressive weight consistency, are unrivalled.”

The weigher is currently handling a variety of pack sizes from 120 grams to 10 kilograms, delivering consistent accuracy across all sizes. The most common pack size are 400g tray which are filled at up to 35 trays per minute. Ishida - www.ishidaeurope.com

Hygienic, hard wearing and chemical resistant floors

Verni speciality construction products has a wealth of experience in battling with different resin screed systems applied by contractors.

SINGLE-LINE GUARANTEE

The company, manufactures and applies its flooring systems by offering a singleline guarantee with no split responsibilities or double mark-ups. Verni was recently contacted by Excellent Meat, packagers of high-quality meat for local and international markets. They were called to assist in specifying the correct flooring solution for the deli production expansion to its Elsies River facility. Verni got involved in the design stage and with many years of experience in the industry were able to recommend appropriate systems to suit the client’s production requirements and budget. Extra attention was paid on surface preparation as is standard on all Verni projects. This ensures the successful applicaton of the flooring systems.

Supaflor-PU systems, which are hardwearing, hygienic and chemical resistant polyurethane floor screed systems were chosen and applied to all three phases of the project. These systems are food-grade and do not allow for bacteria growth. SupaflorPU is a non-slip system and suitable for wet environments.

SUPAFLOR-PU HD 9MM

Supaflor-PU HD 9mm was specified to be applied in high traffic areas, which are exposed to severe mechanical damage from meat hooks dropping and pallet trolleys. The system is extremely durable and can withstand the harshness of such an environment.

Supaflor-PU SL Screed was specified in the balance of the areas, which are exposed to water and foot traffic. Even though the flooring is medium-duty, it is still hardwearing, slip resistant and easy to clean. In order to maintain compliance and for ease of cleaning, Supaflor-PU W, Verni’s polyurethane walling grade was installed to walls and columns to form a coved skirting. The Supaflor-PU Systems installed were used in conjunction with the company’s range of fast curing primers in order to ensure the

project deadline was met.

All expansion/construction joints within the concrete were mirrored through the Supaflor-PU screeds and sealed with VerniPU (Hi-chem) joint sealant.

The project programme was tight. Verni put all efforts in to ensure the client achieved their deadline within budget and ensuring they received a world-class production facility.

"Supaflor-PU is a non-slip system and suitable for wet environments."

DID YOU KNOW?

Verni has 18 years of proven performance in the food and beverage processing industry. The company can undertake complete restorations, breaking out existing flooring systems and concrete, compacting and installing new stainless steel drains and installing Verni-Supaflor resin flooring systems.

Email: info@verni.co.za

Unveiling the Future of Sustainable Protein

Trade & market access, innovations & sustainability take center stage at the Inaugural Africa Meat & Poultry Expo 2024.

The meat, poultry, fish and seafood value chain offers some of the brightest prospects in Africa’s quest to provide nutritious and abundant food to its growing population and to meet the drive for sustainable business and economies in the continent, now and into the future. These value chains are also set to undergo the most aggressive transformation, as the sector is projected to register more investments in aquaculture farms; storage, processing and packaging facilities; and retailing infrastructure to meet rising demand for sustainable and affordable protein sources in Africa. The inaugural edition of the Africa Meat & Poultry Expo offers the perfect platform to bring together the key actors

“Discover the latest products and technologies - from feed, to equipment and packaged products - at the Expo Hall.”

in the meat, poultry, fish and seafood value chains in Africa and globally to define the future of the sector in Africa, with trade & market access, innovations & sustainability the overriding themes at the trade show and conference.

EXPO HALL

Discover the latest products and technologies - from feed, to equipment and packaged

products - at the Expo Hall.

The Africa Meat & Poultry Expo 2024 edition will feature an Expo Hall showcasing the A-Z of the meat, poultry, fish and seafood industry, including Fresh and packaged meat, poultry, fish and seafood products

Nutrition and Health products - animal feed, supplements, vitamins and minerals etc

Aquaculture Farming Equipment & Technologies

Processing and packaging technologies,

ABOUT AFRICA MEAT & POULTRY EXPO

The Africa Meat & Poultry Expo (AMPEX) – the premier trade show and conference for the thriving meat, poultry, fish and seafood industry in Eastern Africa and beyond. Join more than 5,000 attendees at the Sarit Expo Centre in Nairobi, Kenya from June 12-14, 2024, for Eastern Africa’s Biggest Meat, Poultry, Fish & Seafood Industry Trade Show. This highly anticipated event brings together a diverse range of stakeholders, all under one roof, including: Abattoirs and cottage processors of meat, poultry, fish and seafood and their value added products; Commercial and industrial processors of meat, poultry, fish and seafood and their value added products; Formal retailers including supermarkets and convenience stores Operators of hotels, restaurants and cafeterias, including fast-food outlets and delis Commercial butcheries and other outlets in meat, poultry, fish and seafood products; Farmers, traders, distributors and dealers in meat, poultry, fish and seafood products; Global, pan-African,

engineering and automation tech; storage, digital and other supply chain solutions. Ingredients & Chemicals - spices, herbs, preservatives etc

Lab and food safety technologies; consultancy, training and testing services

Renewable energy, Utilities and more Financial & Insurance services

The Africa Meat & Poultry Expowww.africameatpoultryexpo.com

regional, national Government ministries and agencies; county government departments and agencies; Suppliers of cold-chain, post-harvest handling, storage, processing and packaging technologies, renewable energy and other services; NGOs/ development organisations and academic/research institutes involved in the meat, poultry, fish and seafood value chain. Discover the latest technologies, market trends, and value-added products in Africa’s fast-growing meat, poultry, fish and seafood value chain! With three days of immersive learning, daily conferences, and a dynamic Exhibition Hall showcasing fresh and processed products from Africa and around the world, AMPEX offers unparalleled sourcing, networking, and business opportunities. Don’t miss out on this unique platform to forge valuable connections and drive the growth of the meat, poultry, fish and seafood value chain in Africa! Get ready to experience the future of the industry – join us at AMPEX 2024 – Eastern Africa’s Biggest Meat, Poultry, Fish & Seafood Industry Trade Show.

Understanding fraud in the meat, fish & poultry sector

Acts of fraud can have far-reaching effects on consumer trust, and can threaten a brand’s reputation. As food manufacturers, brand owners and industry professionals, it’s imperative to comprehend the complexities of this issue and implement strategies to combat fraud effectively.

The rise of food fraud presents the food industry with an ongoing challenge. For meat, fish and poultry, the risk of fraud is significant. This is due to a combination of factors, including the high value of these products worldwide, the similar sensory properties of different species, and the ease with which comminuted and processed products may be adulterated.

Acts of fraud can have far-reaching effects on consumer trust, and can threaten a brand’s reputation. As food manufacturers, brand owners and industry professionals, it’s imperative to comprehend the complexities of this issue and implement strategies to combat fraud effectively.

TYPES OF FRAUD

Food fraud can take on different forms in meat, fish and poultry products. Typically, these acts of fraud involve adding something and not declaring it, or mislabelling product information, or substituting one species with another – all performed with the intention of making extra profit.

Some examples of different types of fraud include:

• Adding undeclared plant- or dairy-derived filler materials to processed products to bulk them up

• Adding undeclared colourants to products to improve their perceived quality

• Adding undeclared preservatives to products to prolong shelf life

• Selling frozen and then thawed products as fresh products

• Mislabelling the species, country of origin or production method of a product

• Diluting, or substituting one species (usually of higher value) for another (usually of lower value)

• Not declaring the use of substances such as antibiotics and growth hormones

PREVALENCE OF FRAUD

Of all the historic incidents of meat fraud, the ‘horsegate’ scandal of 2013 is probably the most notorious. Hundreds of tonnes of European beef products were found to contain undeclared horse meat. The incident revealed a major breakdown in the traceability of the food supply chain, and heightened food industry and consumer awareness around species authenticity.

In South Africa, studies revealed that 31% of fish samples and 68% of processed meat products collected from local retail outlets were found to be fraudulent, containing different species to the ones indicated at the point of sale.

Although these study findings cannot be extrapolated industry-wide, they indicate that the issue of food fraud is indeed prevalent in the local context.

FRAUD AND CONSUMERS

Consumers rely on the accurate and complete declaration of food constituents to enable them to make product choices that are consistent with their lifestyles.

Products that are mislabelled can pose major ethical concerns for consumers with aversions to consuming particular species. For example, people of the Muslim and Jewish faiths are prohibited from consuming pork products, and beef products are prohibited in Hinduism. Fraud involving such products can have a major emotional impact on these consumer groups.

Furthermore, products that contain undeclared dairy or plant filler materials (such as soya or gluten) as bulking agents may pose an allergenic risk to select

individuals which can be life-threatening.

Some other undeclared compounds can pose health concerns, for example antibiotics, veterinary drugs and toxic substances such as melamine, formaldehyde and azodyes.

WHAT ABOUT UNINTENTIONAL FRAUD?

The mislabelling of products sometimes occurs when supply chains are complex and traceability becomes difficult. Whether deliberate or unintentional, mislabelling leads to compromised product authenticity, and puts a brand’s image at risk.

Additionally, products may be contaminated with undeclared species during processing. The need for high production efficiencies, the use of difficultto-clean equipment and insufficient species-control guidelines are some of the factors that contribute to the prevalence of cross-contamination. Although crosscontamination is usually unintentional, it can lead to the same deterioration of consumer trust in products and in the manufacturers producing them.

COMBATING FRAUD

It can be challenging to stay one step ahead and protect your products and business against food fraud, but there are strategies that can be implemented.

Firstly, it is important to retain transparency and traceability throughout your supply chain. You must try to track products from source to shelf and be able to identify fraud ‘blind spots’ to minimise the vulnerability of your products.

Next, you must establish stringent quality control protocols, to verify the authenticity, composition and integrity of meat, fish and poultry products. These can take the form of regular supplier audits and inspections and laboratory testing to detect fraudulent activities, where products are spot-checked for the presence of undeclared species and adulterants.

It is crucial to prioritise species-specific testing and screening for adulterants, particularly for those that pose a food safety risk to consumers, such as common allergens, or may have ethical implications. Regular testing becomes essential whenever there is suspicion of adulteration or contamination, and is a valuable tool for the ongoing monitoring of meat, fish and poultry product authenticity.

Lastly (although numerous other strategies exist), there must be a focus on consumer education. By empowering consumers with knowledge about food fraud, and an awareness of how to make informed purchasing decisions – such as reading product labels, supporting transparent and reputable brands, etc. – the risk of food fraud can be reduced.

We invite you to discuss your testing objectives and food fraud concerns with our team of experts. Together, we can work towards ensuring the integrity of your products and combating food fraud.

Make the safe choice with these anti-microbial skins

“We are known for our high quality of products and our attention to customer service. We are proud of our product, and deliver the best after sales service to our customers to ensure they have a happy buying experience. The after sales relationship is very important to Icecold Bodies,” he points out.

“Times have changed dramatically since March 2020, and market conditions continue to become tougher. With price increases in all input material, we needed to be more innovative to ensure we stay competitive. “We also recognise the need to spend more time on research and development to satisfy our customers’ requirements. In tough times, it is not easy to spend money on research and development, but to survive you need to do things differently. We joined hands with some of our key suppliers to develop new products for the industry.

coating of anti-microbial properties to assist and maintain the highest standards of hygiene. The anti-microbial coating prevents contamination during the loading, off-loading and transportation stages of food products. The technology also kills the pathogens on contact and this stops bacterial spread inside the body. “We will always have to clean, but with the new antimicrobial skin, we can have peace of mind knowing that we have assistance from the skin itself to protect our product against harmful pathogens,” Gildenhuys enthuses.

• Standard, brilliant white skins for inner and outer skins

• Anti- Microbial Ice Grey (Rhinotex) for internal use

• Rhinotex for external and internal use.

“With guidance from our competent sales team, the customer can choose the best options/combination of skins for his product. Our goal is still to deliver the best product possible to satisfy the customer’s needs and we do understand that the customer requires a very durable body that can satisfy his needs at a competitive price,” he concludes.

Icecold Bodies – www.icecoldbodies.co.za

FAST FACT

If their business grows, our business also grows – so it is a win-win situation.” The company successfully launched its anti-microbial skin for the food industry recently. The technology features a surface

Icecold Bodies is a household name in the refrigerated and dry freight transportation industry in South Africa. Food Review spoke to Burt Gildenhuys on what makes their product offering stand out. Images:

“We introduced a new product Rhinotex skin. This skin is very durable and strong. It performed excellent during the tensile, flexure and punch tests. The skin is designed to be more robust and will damage less, eliminating small damages. The Rhinotex skin is an excellent choice for trucks and trailers that are exposed to harsher working conditions. It can stand up against the small bumps and rough handling during loading and off-loading. The skin is more resistant to side impact and is not damaged easily,” he points out. Icecold Bodies now provides a broader range of skins to customers to choose from:

4th generation polyurethane insulation increases the thermal properties of between 15 to 20%. The aim of this, in combination with the Rhinotex skin, is to deliver a durable and robust insulated body with better temperature control and cooling fuel efficiency.

Meeting your needs for wholesome quality food

While the cost-effective production of meat, poultry & fish products is an ever-present topic for food development teams, the safety of these food products as well as the eating quality remains of great interest within the industry.

With South Africans having dealt with increased bouts of load shedding recently, the spoilage of meat products has been thrusted back into the spotlight. Assisting producers with the supply of wholesome and safe to consume products is a key fundamental for us at Brenntag. We also assist our customers in developing great tasting food products through our technical expertise and supplier support.

INHIBITING SPOILAGE OF MEAT PRODUCTS

To address the issue of food safety in meat products, we have partnered with Corbion, a supplier of a range of food ingredients and solutions for use in foodstuffs to reduce the susceptibility to microbiological spoilage of such products. When it comes to food safety, few products can perform as well as our Opti.Form Powder. Opti.Form delivers top-shelf Listeria control and extends shelf life, all while improving yield, purge and texture in meat and poultry products. The product is a very effective antimicrobial powder blend suitable for use in dry blend and liquid applications. It’s low dosage rate makes it a very cost-effective solution for use in a wide range of applications and is often incorporated in batch pack solutions or can be used directly in emulsions and/or brine solutions. We have seen the impact of Listeria in the ready-to-eat meat segment and recommend this offering for the control of Listeria specifically. As noted, this blend

“With South Africans having dealt with increased bouts of load shedding recently, the spoilage of meat products has been thrusted back into the spotlight.”

of antimicrobials with sodium lactate, sodium acetate and sodium diacetate combined with the specific production method, makes this a highly effective food safety offering.

DEALING WITH SODIUM REDUCTION CHALLENGES

The use of salt as an antimicrobial agent in lowering the water activity and enhancing flavour is well documented, but this humble ingredient also plays a role in food texture. Salt, however, has several functionalities in meat products from allowing proteins to bind more fat and water to controlling colour development in fresh meat products. Reduction of salt driven by regulation has led to a plethora of solutions with the initial being Potassium and yeast based offerings to ensure that the umami flavour profile is well maintained. These do have their own challenges, as the balance of providing safe to consume and great tasting processed meat and poultry products need to be maintained. A very good solution in our

arsenal of products include a fermentation based flavouring solution in our PuraQ Arome NA4, with Purasal HiPure P Plus being another solution. Apart from these Brenntag can also provide animal proteins to further enhance flavour in meat dishes and/ or stocks. Brenntag’s Food Solutions division has developed their own range of blends and solutions to aid food producers in providing products with reduced salt and more specifically sodium contents. This combined with ingredients from our ingredients partners allows us to offer a wide range of solutions to our customers who seek to deliver great tasting products while adhering to strict regulatory requirements.

SUCCULENCE IN MEAT

Phosphates have been used for the “unfolding” of proteins to allow for improved moisture binding for almost a century. With increased consumer demand for the reduction or complete removal of these salts for a cleaner label offering, producers have yet another challenge to contend with. While there are various hydrocolloid offerings that can be used to help bind water, the specific functionality of phosphates to use muscle fibres to bind inherent water makes it somewhat unique as a food ingredient. Continued pressure for replacement or removal thereof has led to some advances where phosphate-free brines are being offered. The use of fibres in such solutions can allow for cost savings, improved moisture binding, easier injection processes and even

improved sensory aspects such as juiciness and texture. Whether you are producing fresh, frozen or IQF products, we can assist in providing you with a suitable solution such as our Chicken 150 offering recently showcased at FIE Frankfurt.

BATTERED AND BREADED

Whether your preference is for breaded or battered meat, poultry, or fish offerings, the additional sensorial appeal these coating systems provide cannot be denied. They are intended to create a tasty crust, with a degree of crunch and flavour profile dependent on the type of coating used. Producers may choose either method though a good understanding of the end application and desired functional profiles are important. Breadings are all about providing an additional sensory dimension to meat and poultry products through their contribution of colour, flavour and texture. These adds a protective layer keeping the protein tender and juicy on the inside and crispy on the outside. A double breading process, yields better coverage, appearance and hold times. Such a system is a dry application that will

typically provide sufficient oil uptake and moisture loss to ensure the correct sensory elements as noted before. Batters on the other hand are wet application products that will set during the frying process to provide the desired coating. While also providing a substrate for flavour and colour delivery, batters are much softer coatings than breading systems. We understand the need for a two stage or three stage coating system

and can help you develop the most suitable offering through our ingredient offering. So, whatever your desired end product, Brenntag is suitably able through their diverse portfolio to help you develop the right product you need or improve based on the latest market trends.

Brenntag – www.brenntag.com

You partner for food safety

Chiorino manufactures conveyor and process belts that full comply with the latest European and International Food Regulations, and are particularly recommended for HACCP systems with Certified Food Compliance.

Key features: Excellent resistance to cut and abrasion

Superior resistance to most aggressive fats and oils

No edge tray

Very high flexibility

Extraordinary Resistance to Cleaning Systems

Thanks to the high resistance to hydrolysis, HP belts and HP ‘Compact Drive’ belts do not undergo deterioration due to the “Clean-In Place” washing and sanitization processes with warm water, steam, foam and aggressive detergents. The user can benefit from the belt’s long service life and significant costs reduction.

Chiorino HP belts are at the forefront of hygiene and food safety with total compliance of the HACCP system.

Johannesburg | T: +27 (0)11 397 1268 | andrew@chiorino.co.za

Cape Town | T: +27 (0)21 510 1361 | wh@chiorino.co.za

Durban | T: +27 (0)31 792 5500 | sr@chiorino.co.za

www.chiorino.com

FastBack sets the standard in conveyor technology

With over 20,000 units sold, FastBack stands as the go-to conveyor for handling a diverse range of challenging products, from fresh chicken to snacks, fresh produce, cookies, candies, and beyond.

Its patented slow-forward and fastback horizontal motion technology has revolutionised the industry, setting the standard for excellence.

Originally introduced with the FastBack Horizontal Motion Conveyor, the FastBack lineup now encompasses a comprehensive suite of feeding, proportioning, and lining solutions for product handling. Each solution in the range inherits FastBack’s signature benefits, ensuring gentle product transport through its unique slow-forward and fast-back horizontal motion cycle.

As the unrivaled leader in its field, FastBack continually innovates, incorporating design features tailored to meet customer needs and preferences. These conveying solutions prioritise product integrity, avoiding damage or segregation, and preserving coatings. FastBack reliably handles even the most challenging products, all while remaining energy-efficient, quiet, and adaptable.

PROPORTIONAL GATE 3.0 WITH CROSS FEEDER SECTION

This groundbreaking proportional distribution system by FastBack uses unique cylindrical outlets that rotate to divert a proportional

“With over 20,000 units sold, FastBack stands as the go-to conveyor for handling a diverse range of challenging products, from fresh chicken to snacks, fresh produce, cookies, candies, and beyond.”

portion of product, so the main product supply continues to flow as it allocates amounts to individual weigher/bagmaker stations. Downstream stations are no longer “starved” and do not need to wait for product.

The patented design introduces various advantages that make it the premier gate in the industry. Proportional, granular feeding keeps product uniform and improves packaging, and on-machine seasoning performance adds 1 to 5% improvement in overall line efficiency. The gentle, innovative design diverts product without creating a single pinch point which reduces typical product breakage by 4 or more percent.

Ideal Applications for FastBack Revolution®

DID YOU KNOW

The gentle, innovative design diverts product without creating a single pinch point which reduces typical product breakage by 4 or more percent.

Proportional Gate include snack foods, frozen fruits and vegetables, confectionery, cereal, pet food, meat and poultry, French Fries and any product which readily conveys on a FastBack.

Heat and Control –www.heatandcontrol.co.za

Industry

changing equipment + technology designed for results

Our value-added systems prepare and cook consistently superior beef, pork, chicken, turkey, fish and other meat products including alternative meat to create a distinctive quality that stands out in the marketplace.

• Preparation + Processing

• Battering + Breading

• Frying + Oil Management

• Branding + Searing

• Cooking, Roasting + Drying

• Coating + Seasoning

• Product Handling

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

Navigating the salt reduction dilemma

Salt is a component that ignites a debate between consumers and the food industry. These years, the keyword is ‘reduction’, as seen in the increase of products on sale with a salt related claim (low/no/reduced sodium).

Snacks is one category with the highest percentage of product launches with a reduced salt claim. Awareness of salt reduction is growing. Encouraged by consumers’ expectations and regulations, food manufacturers are reformulating their recipes to reduce the salt content. It is an opportunity to go towards or reinforce a “natural” image with consumers. The reformulation of food recipes is also an opening for innovation and promoting products to new consumers such as the elderly or younger generations. All food categories are concerned but mainly the snacks where the consumption has increased in the recent years.

WHY IS REDUCING SALT SO DIFFICULT?

Reducing salt is not as easy as it would seem because it plays multiple notes in food. When you reduce it in food, the flavours are less intense. Consumers consider flavour and taste to be important when choosing a product. The salt used in the formulas has an impact on the price of the final product. It is an inexpensive way to give food flavour. Reducing salt means finding tasty and cost-effective alternatives to maintain gustative attractiveness of products. Let’s see how yeast extracts can help formulators to reduce salt while preserving the taste of their products.

“These years, the keyword is ‘reduction’, as seen in the increase of products on sale with a salt related claim (low/no/ reduced sodium). ”

YEAST INGREDIENTS, THE IDEAL ALLY FOR SALT REDUCTION

Biospringer successfully supports manufacturers in addressing the worldwide movement for salt reduction by offering a wide range of yeast extracts that subtly reveal the flavour of their products.

In short, yeast is a natural flavouring ingredient that works just like spices. When added to a recipe, it can bring out taste and boost flavours. There are different types of yeast ingredients and each one has a specific influence on taste as is demonstrated in our 360° wheel of taste. It allows you to get subtle and savoury taste profiles by bringing base-notes like bouillon, but also specific notes like meaty, cheesy, and vegetable flavour notes according to the product.

Our solutions allow food formulators to reduce salt by up to 30 percent without compromising on taste. For example, in a smoked yeast seasoning “yeast extract creates a more rounded and balanced flavour profile while reducing salt content in your recipe” – says our food experts.

FIND A INSPIRING RECIPE

REDUCED SALT BBQ CHIP SEASONING

ABOUT BIOSPRINGER

At Biospringer, we’re proud to be a specialist in creating food ingredients from yeast. Our mission is simple: we partner with our clients to create innovative and natural origin ingredients from yeast fermentation, helping to make food tastier and healthier while being reliable and respectful of the planet and people. With our extensive product range, dedicated technical and scientific teams, and extensive R&D, we help our customers to develop flavourful recipes, solve specific development challenges, and create healthy and nutritionally balanced products. As a business unit of Lesaffre, Biospringer offers innovative solutions that are as relevant now as they were at our founding, back in 1872.

Roller Mill Arrakis: Reinvention of an icon

The all new Arrakis MRRK roller mill from Bühler has a host of new features and improvements. In line with the trend for increased digitisation and automation, the roller mill has state-ofthe-art hardware and software for smoother production and enhanced operational efficiency.

“Digitisation has the potential to revolutionise almost every aspect of the food, feed and mobility industries,” comments Glen Koster, Area Sales Manager, Bühler Johannesburg. “Harnessing the power of digital technology means we can address vital issues such as food safety, transparency along the value chain, energy conservation and waste reduction more efficiently than ever before.”

The internet of things (IoT), cloud computing and other innovative digital technologies are transforming the way the world works. Bühler aims to be at the forefront of this transformation. More than 85 % of Bühler’s solutions can be accessed via a single, secure platform, taking productivity to the next level.

“For our customers, this is like having your best operators working around the clock. The ability to instantly transform data into realtime action means that unplanned machine downtime, and the wasted energy that goes with it, may soon be a thing of the past,” predicts Koster.

With Bühler automation systems, food manufacturers can fully automate their tracing process. This helps reduce administrative work up to 80% compared to manual tracing and ensures the delivery of seamless trace information for any audit within minutes.

AUTOMATED TRACING FOR STREAMLINED PROCESSES

Looking at the latest innovations incorporated in the all-new Arrakis, the feeding unit provides a continuous product flow and ensures an even spread. This is important because feeding is a crucial step in the grinding process. The design has been kept deliberately simple, with no need for an additional motor and frequency converter due to the fixed-speed feeding roll being connected directly to the main roll’s drive.

“This straightforward system ensures that less time is spent on installation and maintenance,” says Koster. “The heart of Arrakis is its grinding unit, a true pillar you can rely on thanks to its stable grinding performance.”

In addition, Arrakis uses a proven loadcell sensor to keep a constant product level in the inlet and adapts the feeding gap to ensure a stable product flow over the entire gap of the grinding rolls. This increases operational reliability and minimises the need for operator intervention.

When the machine is not in operation, the feeding gap is closed automatically, preventing any accumulation of product between the rolls. This saves you time and energy when restarting Arrakis. A quick release function allows fast opening of the feed module.

"With Bühler automation systems, food manufacturers can fully automate their tracing process. "

Thanks to its wide opening angle, the cleaning flap ensures the rapid discharge of any product remaining in the feed module. These design features save time by greatly simplifying cleaning operations, streamlining all the required steps.

The new solid synthetic scraper hovers tightly over the rolls to replace the bristle brushes. The scraper experiences up to three times less wear and eliminates the risk of product accumulation. This results in improved food safety and decreased maintenance.

The flexible knife holder allows the knives to align themselves to the surface of the rolls automatically by constantly applying optimal pressure, eliminating the need for manual adjustments. The blade also undergoes uniform and therefore reduced wear.

The integrated grinding gap adjustment is stripped down to its essential parts for a simplified design that facilitates cleaning

Images:

and maintenance. The patented grinding gap adjustment ensures rigidity and stability over time to maximise grinding performance.

In terms of state-of-the-art control, Arrakis has an intuitive interface that provides a quick, simple overview of key operating parameters. Accessible in English and Chinese, it makes controlling and monitoring Arrakis straightforward. The integrated touchscreen is available as an optional extra is it is not essential to control the roller mill.

“Safety is our top priority, and Arrakis integrates several protective features to ensure safety without hindering performance,” says Koster. Perforated side panels allow for quick and safe inspection of Arrakis while the machine is running. An added bonus is improved cooling by means of optimised airflow. Safety grids protect roller mill operators from moving parts while affording them optimal access for product sampling.

the robust casting frame with the loadcarrying structure translates into a high vibration absorption. This durability ensures reliability for long operating periods. Arrakis is built to the same footprint as MDDK, ensuring that one-to-one replacements are possible. Installation is fast and simple with no need to adapt the flowsheet or extend the existing building.

THE FUTURE OF MILLING: ARRAKIS PERFORMANCE UNLEASHED

The Arrakis MRRK forms part of Bühler’s extensive roller mill and integrated grinding system portfolio. It includes the Dolomit MDDP/Q, the Diorit MDDY/Z, the Antares MDDR/T and the Arrius MRRA. “The Arrakis MRRK roller mill represents the successor to a milling icon,” says Koster.

efficiency, and the optional integrated touch screen for ease of operation. “New features have also been included to guarantee hygienic and safe operation,” adds Koster. The Arrakis offers overall best performance for a straight production line.

“The Arrakis is the latest addition to our state-of-the-art roller mill portfolio. Optimally equipped to efficiently grind high throughput of the same commodity, Arrakis is stable and reliable, easy to operate and allows for fast and simple installation,” highlights Koster. It is available in a four- and eight-roller configuration.

As the challenges facing our planet grow, so does the need for game-changing solutions. Harnessing the power of digital technology means we can address vital issues such as food safety, transparency along the value chain, energy conservation and waste reduction more efficiently than ever before.

Looking at the sturdy design of the Arrakis,

A special focus of the design is the increased robustness and reliability of the grinding unit, quick and easy installation, a simplified feeding unit for enhanced

Buhler – www.buhler.co.za

Reinventing an icon

A reassuring, familiar face – but with a host of new features and improvements.

Same footprint, trustworthiness, state-of-the art hardware and software for smoother production and enhanced operational efficiency. This is the all new Arrakis.

Purpose driven Confectionery

Sugar’s impact on health has triggered a confectionery revolution. Carien Schoeman from Savannah explores the realm of purpose-driven confectionery, addressing the growing demand for treats that combine indulgence with health benefits. Discover innovative solutions and functional ingredients reshaping the sweet landscape.

In the last decade or so sugar has been villainised due to its role in increased frequency of chronic illnesses like diabetes and obesity globally. One of the top current consumer trends is healthy indulgence. Consumers are looking more and more for the best of both worlds, indulgence with health benefits. The confectionery world is not excluded from this trend, on the contrary it’s a big driving force in this sector of new product launches globally. Consumers are looking for more than just full sugar or sugar free options when it comes to confectionary. The need for products that offer a health advantage beyond basic nutrition, is increasing. Customers are actively searching out functional products with active ingredients and claims that offer holistic health benefits.

THE HEALTHY INDULGENCE TREND

Reducing sugar or using a sugar alternative is one of the ways to increase the health benefits of a confectionery product. Sugar is the main ingredient in most confectionery products, sugar replacements need to be both sweet and functional properties in the final product. In confectionary sugar is widely used for its pleasant sweetness, ability to carry flavour, caramelise, act as a texturising agent, and many more technical properties. Replacing sugar has been proven to result in some challenges. With BENEO products like

“Reducing sugar or using a sugar alternative is one of the ways to increase the health benefits of a confectionery product.”

Palatinose and the Orafti range of inulin and oligofructose from Savannah Fine Chemical a guilt-free indulgence is possible.

Palatinose (isomaltulose) is a functional carbohydrate with a GI of only 32 giving a smart sustainable energy solution to sucrose replacement. It is derived from sugar beet and having similar technological properties than normal sugar, it has a mild sucrose-like taste it allows flavours to shine in products and enhancing the overall indulgent experience. Palatinose lowers the blood glucose response with slow-release action thus ensuring no sugar spikes or crashes.

ORAFTI – NATURAL SWEETNESS REINVENTED

Palatinose is fully digested and thus does not result in a laxative effect compared to other sugar alternatives. Replacing 30% of the sucrose with Palatinose will already have a positive effect on the blood glucose response compared to the full sucrose version.

Palatinose has a teeth friendly version available, making it a perfect ingredient to use in treats for children. Palatinose is perfect to utilise in gummy applications, chocolate, marshmallows, cereal, and nut bars to name but a few.

The Orafti range of inulin and oligofructose have long been used for sugar and fat reduction. Orafti Inulin and oligofructose are natural vegetable ingredients. Orafti Inulin and oligofructose are soluble fibres derived from the chicory root. Orafti Inulin and oligofructose are the most studies soluble fibre prebiotics available on the market with numerous substantiated health benefits based on scientific studies. These health benefits include prebiotic for gut & digestive health, lower effect on blood glucose, increase in calcium absorption.

The unique combination of technical properties and link to health benefits has already made Orafti Inulin and Oligofructose a worldwide success in the food and beverage industry as a replacement for sugar. Orafti Inulin and oligofructose have no effect on taste or texture of the final product. Orafti Inulin like Orafti HSI is perfect for use in reducing sugar in chocolate, with the added benefit of a creamier chocolate. Orafti L85LL is a long shelf life oligofructose syrup that can be used as a glucose syrup and sugar replacement in products like gummies, marshmallows, liquorice, jellybeans, caramels, toffees, nougat, granola bars and protein bars. Find all these product solutions and more at Savannah Fine Chemicals. Savannah

of additives to help create the taste, texture, performance and appearance you need for your food & nutritional products. We represent leading global manufacturers & our specialists can provide you with unrivalled sales support bringing the highest quality products to market:

Bakery ingredients: flavour, texture and fortification - Beverage ingredients for innovation - Confectionary: healthier & tastier alternatives to enhance your brandCulinary solutions for sauces, dressings and prepared meals that will innovateDairy & Desserts: texture and functionality - Flavour & fragrance creation - Health & sports nutrition.

+27 31 313 3338

+27 21 830 5306

A healthy snack alternative

Snack trends are constantly evolving making this market one of the fastest growing categories in the food industry and while consumers are looking for comforting convenient snacks – they are also consciously seeking products with healthier options such as less sugar and more functional ingredients, explains Andrew Green, snacks business unit manager, Ishida Europe.

INTUITIVE PRODUCT

LABELLING DEMANDS

We explore the move towards the use of natural ingredients and the increasing demand for intuitive product labelling. Not forgetting the important role that colour plays. After all, people eat with their eyes first, therefore, confections must look appealing and delicious at first sight. According to Euromonitor International, value sales of snacks are expected to show higher growth rates during 2022 to 2026 than in 2020 and 2021, and healthy snacks are projected to see the highest CAGR.

MEETING CONSUMER DEMANDS