“Miniscule design details matter most.”

Project Photos

01 Turkey Road, Sonoma, CA

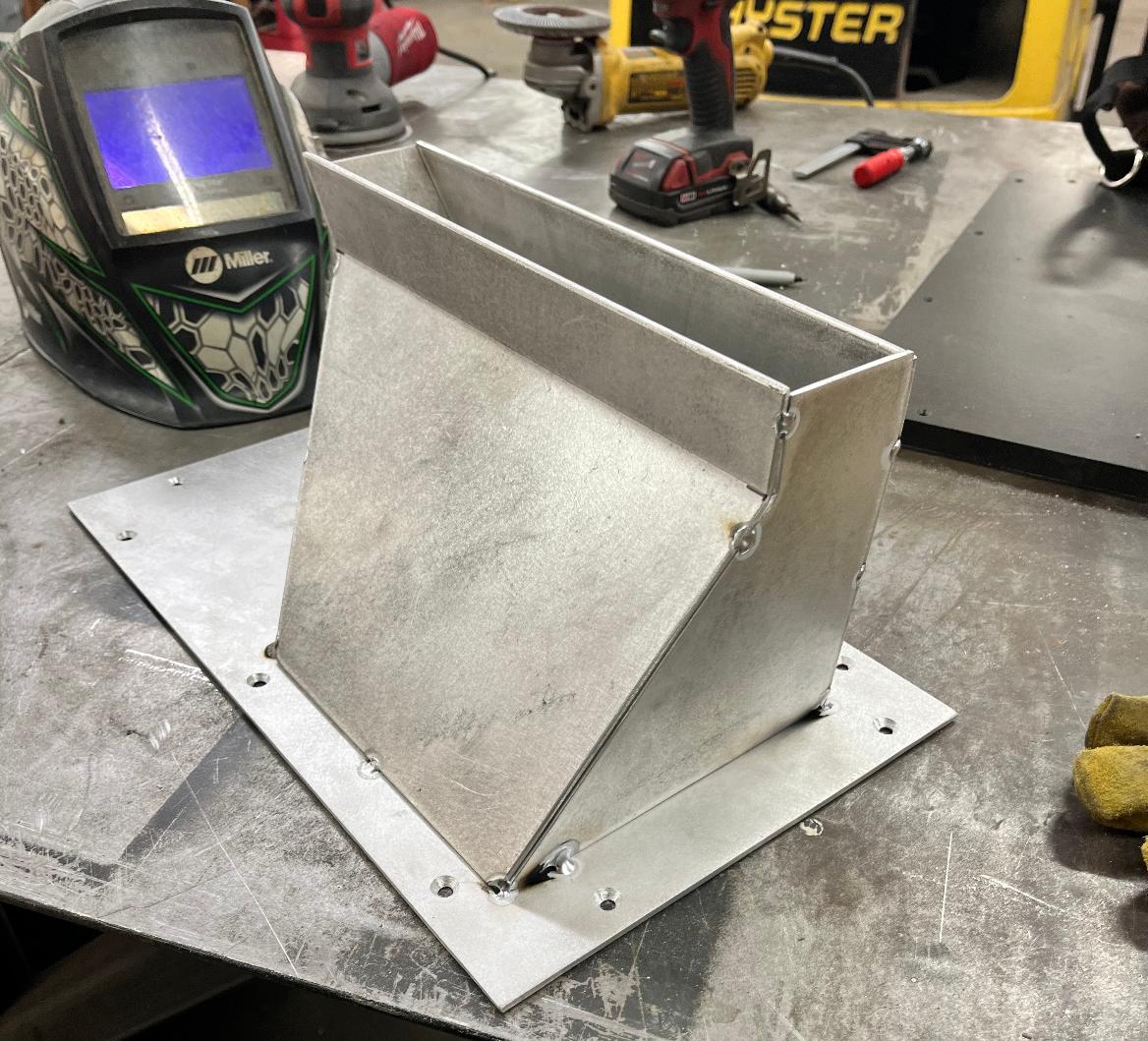

5,000 sq-ft ground-up construction of a modern, single-family, 3-bedroom home with pool on 4 acres of vineyards with full development of utlilities, wells, drainage and a ADU/Barn. MurphyMckenna transformed raw materials into finished products, helping the client and designer’s vision come to life. We fabricated exterior louvers, doors, a bronze backsplash, entry gate, hood range and multiple other structural elements.

Architect: Zimmerman & Associates

Interior Design: Studio Becky Carter

Lighting Design: Techlinea

Structural: ZFA Structural Engineers

Olive Hill Lane, Woodside, CA

An 8-year, multi-phase development project on 3.5 acress in Woodside, CA inspired by the Château de La Colle Noir, formely owned by Christian Dior. Our team fabricated a significant quantity of structural elements to support the construction of this elegant Accessory Dwelling Unit (ADU).

Completed scope: Interior remodel of a 7,000 sq-ft single-family estate.

Remaining scope/In Progress: ADU accessory building and landscape.

Architect: BAR Architects & Interiors

Interior Design: BAR Architects & Interiors

Landscape Architect: STRATA Landscape Architecture

Structural: Strandberg Engineering

MurphyMckenna designed and fabricated metal perforated screens, a mechanical enclosure, and a garage door. The process included shop drawings, mock-ups, hardware specifications, shop and on-site fabrication. The perforated panels act as an artful fusion of durability, and aesthetic appeal wrapping alongside the home. The garage creates a secure barrier while also adding a nice customized architectural feature to the exterior.

Architect: Axelrod Architects

Interior Design: Axelrod Architects

Structural: Strandberg Engineering

General Contractor: Zega Builders Trenton Way, Menlo Park, CA

Miscellaneous Projects

Metalworking is a diverse craft that encompasses a wide range of techniques and applications. From forging and welding to machining and casting, metalworkers manipulate various types of metals to create functional and decorative objects. We often employ a combination of traditional craftsmanship and modern technologies, such as computer-aided design (CAD) software and CNC machining, to achieve precise and complex results. Miscellaneous metalwork represents a dynamic and multifaceted discipline within the broader field of metalworking.

Process 02

Design and Planning:

The design process begins with understanding the customers’ requirements and creating a design for the desired product or component. This involves determining the materials being used, dimensions, tolerances and any specific features or functions required.

Material Procurement and Preparation:

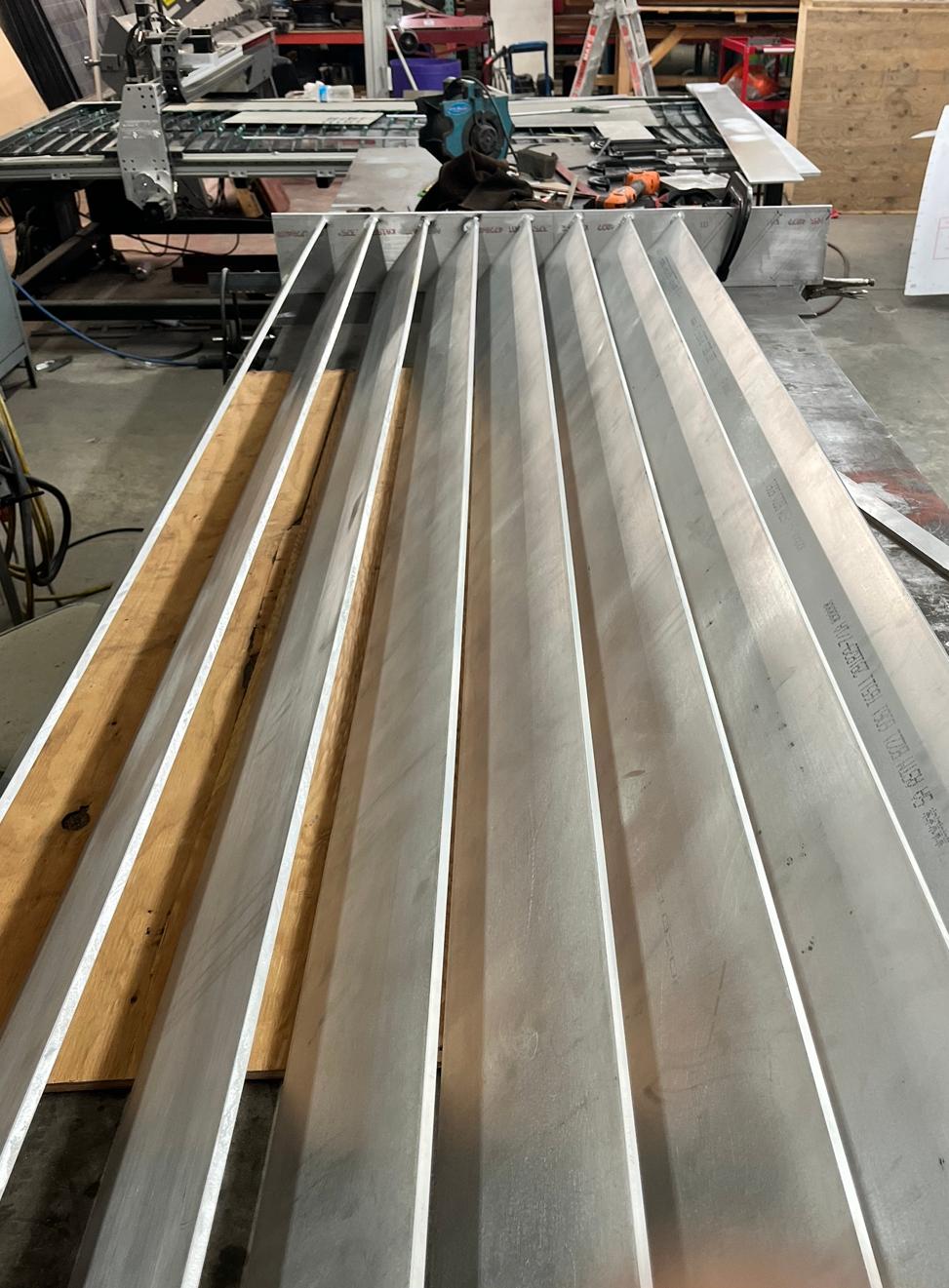

Once the design is finalized, the necessary materials are procured. The first step in any metalworking process is selecting the appropriate metal for the job. This could be steel, aluminum, bronze or any other type of metal depending on the specific requirements of the project. Once the material is selected it may be cut or shaped into the desired size and form using specific tools.

Metal Fabrication:

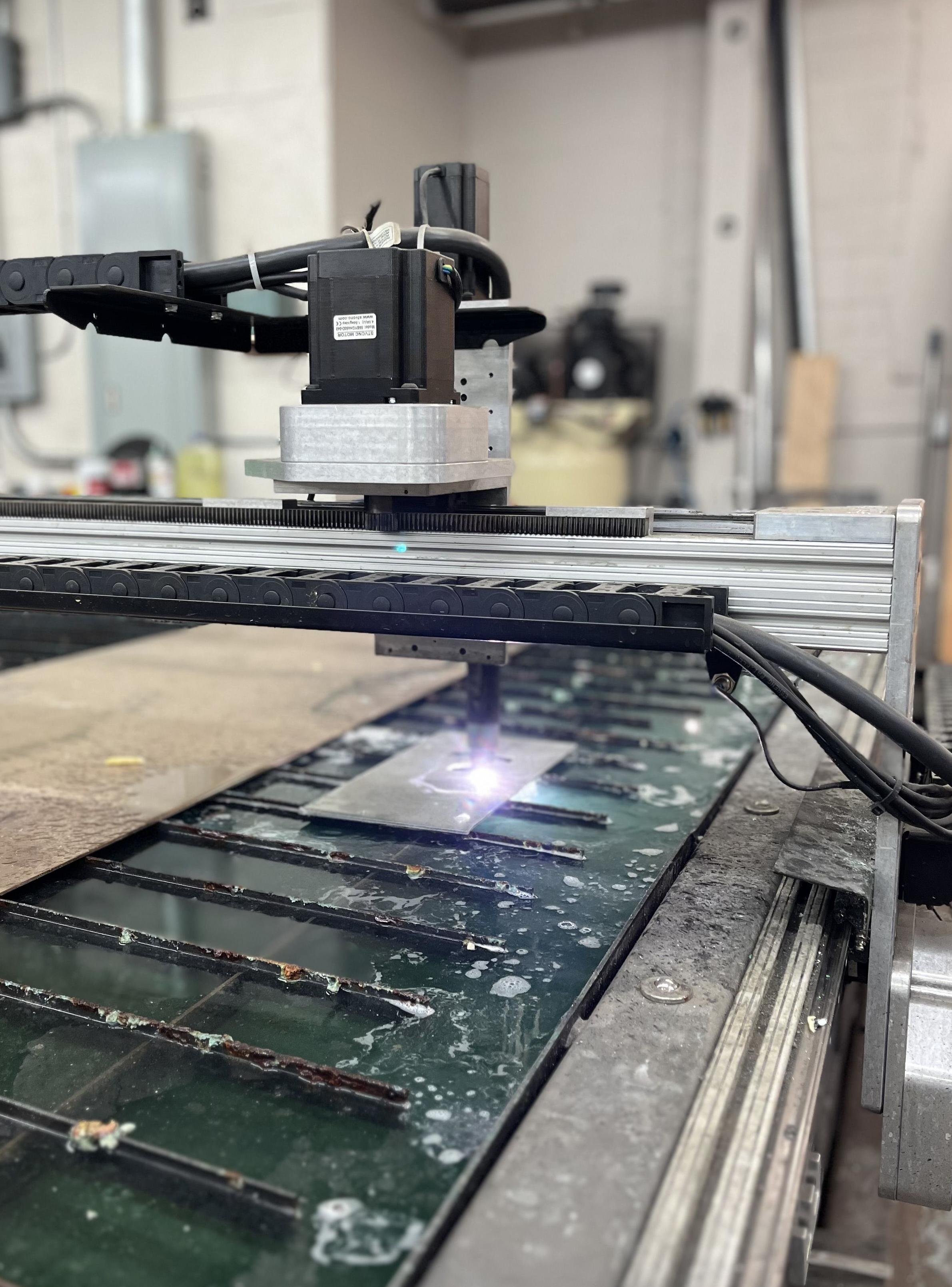

Fabrication involves shaping the metal into the desired form using various techniques such as bending, welding, and machining. This could include processes like welding two pieces together, bending metal parts to precise dimensions using lathes, mills or CNC machines.

Forming and Shaping:

Fabrication often involves forming and shaping the materials into the desired shape and size. This can be done through processes such as bending, rolling or stamping. For example, metal sheets may be bent into angles or curves using a press brake, while tubing may be formed into specific shapes using a tube bender.

Welding and Joining:

Forming and shaping is a crucial part in metalworking. This can be done using various welding techniques such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), or arc welding. Welding is used extensively in metal fabrication to create strong and durable connections between two metal parts.

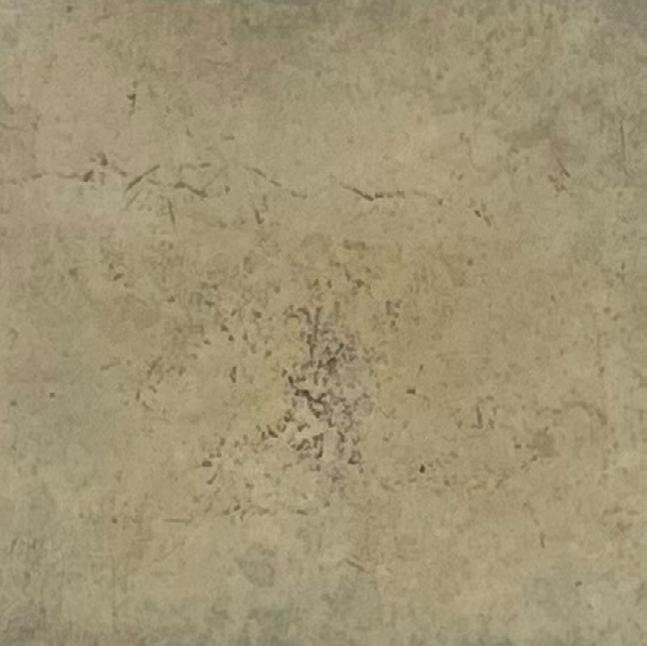

Finishing and Surface Treatment:

After fabrication the product may undergo finishing processes to improve its appearance and functionality. This could involve grinding, sanding, polishing, or painting to smooth out rough edges, remove surface imperfections and apply protective coatings to enhance durability and corrosion resistance.

Overall, the processes involved in a metal shop are diverse and can vary depending on the specific requirements of the project. From material selections, to preparation, to fabrication, welding, and finishing, each step plays a crucial role in producing high- quality metal parts and projects.

Services: - CNC MACHINE

- TIG WELDING

- MIG WELDING

- SHEET METAL FORMING

- MACHINING

Services Materials Finishes 03 PENNYLOAFER

- POWDER COATING

- PATINA - SHOP DRAWINGS

- POLISHING & FINISHING

Materials:

- ALUMINUM

- STAINLESS STEEL

- BRONZE

- MILD STEEL

Patina Finishes:

Architect References

“Anthony and the team at MurphyMcKenna have been a pleasure to work with and are able to provide early phase estimating services in addition to general contracting.”

BAR Architects

Earl Wilson, BAR Architects - ewilson@bararch.com

“Sometimes there is an innate and successful fluidity that develops and guides a project towards success. An ability to think outside the box and ‘on the fly’ problem solving are strong MurphyMcKenna traits. Not only are they experts at finding ways to execute a design, but they are extremely proficient at staying on schedule. It is also through a clear and concise management of the project that made our experience memorable.”

Terry&Terry Architecture

“We thoroughly enjoyed the collegial teamwork with MurphyMcKenna on the job. Our client received clear reporting on project costs and schedule, while we as architects got superior care on both infrastructure and installation details. Their projects are characterized by craftsmanship and built to last.”

2M Architecture

“I’ve known and worked with Anthony Murphy for over twenty years. We’ve done exceptional projects together. What makes them special is the relationship between art, technology, and craft, between architect and builder. MurphyMcKenna are “Master Builders” they bring expertise and professionalism to the work that we share, elevating the process and product”.

LEVY art + architecture

Ross Levy, LEVY art + architecture - ross@levyaa.com

“MurphyMcKenna are excellent collaborators bringing their expertise and attention to detail from construction estimates to finish craftsmanship. True teamwork!”

BAR Architects

Tim Hepworth, BAR Architects - THepworth@bararch.com

Jee-Hee Haar, BAR Architects - jhaar@bararch.com

“We appreciate how thorough, and detail oriented the MurphyMcKenna team is. Our collaboration was exceptional and made the client experience seamless and our job as designers that much easier!”

McCaffrey Design Group

Alice Cummings, McCaffrey Design Group - alice@mccaffreydesigngroup.com

“MurphyMcKenna has been very helpful on a current project where significant solid rock excavation under an existing home is occurring. They have been responsive, found the perfect subcontractor for the work, and we are looking forward to embarking on this project. The project also includes surgically cutting a new 49’ elevator shaft through the existing three-story home to the garage below. With such a complicated project, we feel we are in good hands with MMC”.

MacCracken Architects

Steve MacCracken, MacCracken Robinson Architecture - stevem@macarchs.com

“I’ve worked with MurphyMcKenna on a project that required great attention to detail, as the products used were high end and needed to be installed in a very precise manner in order to show off their beauty. The project was also running on an extremely compressed schedule, and it finished on time without a sweat. Anthony’s team is courteous, patient and professional; they do a great job of monitoring and supervising their subcontractors, and they’re very communicative.”

Studio Ku

“I would give MurphyMcKenna a 5-star recommendation to anyone looking for a General Contractor with a direct honest approach to remodeling or building their home in the Bay Area. Both Sean and Anthony are straight to the point and what you see is what you get.

As a Modular Designer, I have worked with Anthony on numerous projects in the Bay Area. I would have no hesitation in referring MurphyMcKenna for your construction needs.”

NYŪ Designs

Paul Nyulassie, NYU Designs - paul@modernprefabhouse.com

“We have successfully completed several very high end and complex projects with MurphyMcKenna Construction. As consultants with 30 years’ experience in the custom residential market, we always look forward to collaborating with MurphyMcKenna; they are highly organized, professional and produce premium results. Anthony Murphy and the entire team are exceptional builders. I recommend MurphyMcKenna Construction every chance I get”. Techlinea Inc.

Alexa d’Argencé, Ken Fulk, Inc. - alexa@kenfulk.com

Michael Rex, Michael Rex Architects - rex@michaelrexarchitects.com

Scott Couture, Couture Architecture - design@couturearchitecture.com

Jerome Buttrick, Buttrick Projects - jerome@buttrickprojects.com

Linda Herman Consulting - linda@lindahermanconsulting.com

Heidi Richardson, Richardson Pribuss Architects - heidi@rp-architects.com

McKenna

Murphy

McKenna

Murphy