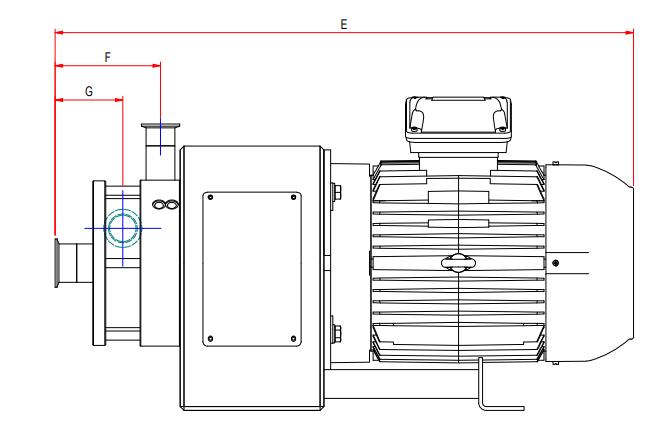

HIGH SHEAR: SERIES 620

LIQUID MIXING

|

|

www.mixquip.com | sales@mixquip.com National Call: 1300 649 784

POWDER

HYDRATE

DISPERSE

HOMOGENIZE

ADVANTAGES

» Suitable for operation at varying temperatures

» Hygienic and sanitary design

» Rapid powder incorporation rates

» Suitable for higher viscosity mixtures of gels, gums and thickeners.

» Reduced energy consumption

» Easy to load, low ergonomic design

» Water flush seals

Solids dispersion remains to be one of the most enduring processing challenges in industry today. The Mixquip Series 620 is ideal for dispersing hard-to-wet powders into liquid without agglomeration, floating or dusting. The Mixquip Series 620 takes a ground breaking approach to mixing powders into liquids.

Traditional powder-into-liquid mixers, often use a vacuum to pull powders into the liquid stream

The Mixquip Series 620 actually drives powder into the liquid stream. This unique action allows the Mixquip Series 620 unit to disperse and hydrate large volumes of hard-to-wet powders and additives, and can be accomplished with high viscosity products and at varying temperatures.

MIXING SYSTEM DESIGN OPERATION SEQUENCE SPECIFICATIONS

STATE-OF-THE-ART MIXING

MIXING OPTIONS

Australian designed and manufactured Mixquip Series 620 powder liquid mixers are available with a wide range of options and configurations to suit your process application.

VIBRATOR

Pneumatic vibrator fitted to solids feed cone is used to overcome bridging and rat-holing that can occur with certain material types.

SAFETY GRILL

Stainless steel safety grill is required for automated solids feed systems to ensure operator safety.

SACK TABLE

A stainless steel sack table is available for Series 620-1 and 620-2.

ACTUATED VALVE

Automated solids feed systems include actuated inlet valve. This valve is a ball-type with no restriction for material bridging.

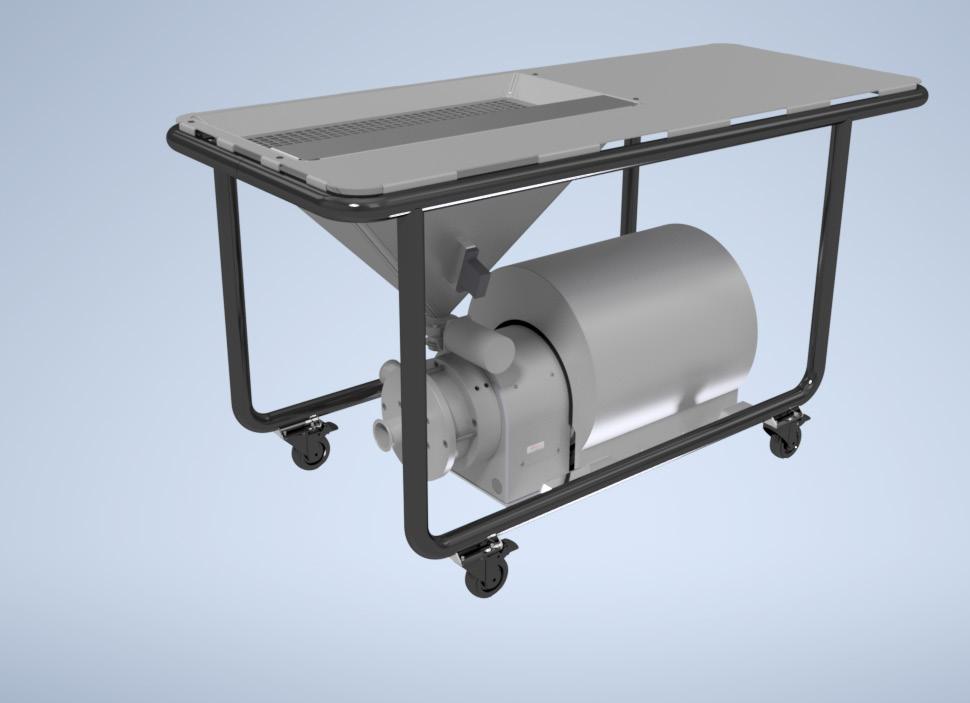

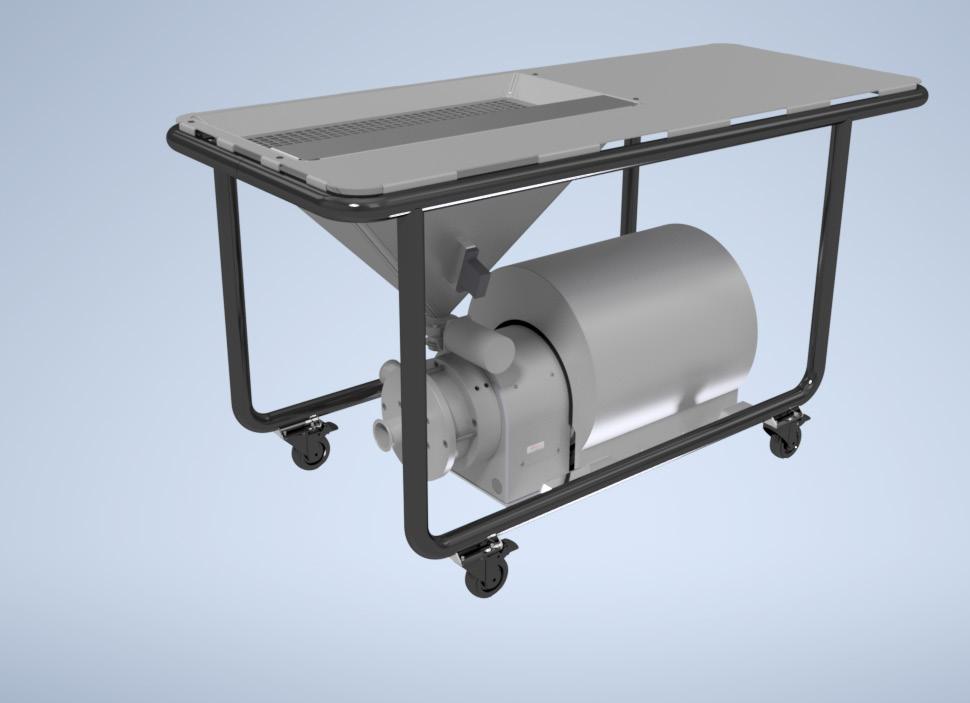

MOBILE TROLLEY

Sack table includes option for mobile trolley.

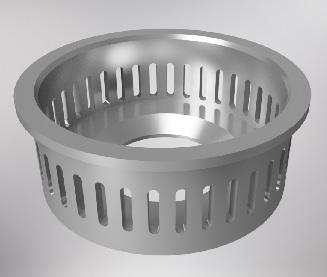

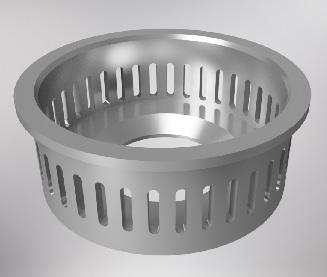

ROTOR/STATOR

MOTOR SHROUD

Stainless steel motor shrouds are available for food and pharmaceutical applications requiring 3A standards.

MIXING SYSTEM DESIGN OPERATION SEQUENCE SPECIFICATIONS

FAST . EFFICIENT . RELIABLE

Providing the ultimate solution to Powder Liquid Mixing, the Mixquip Series 620 enables simple, effective and sanitary means of incorporating powders into liquid at high viscosities and over a range of temperatures, producing an agglomerate-free, consistent product, every time. The Series 620 is engineered to suit the following factors; repeatability, speed, minimum aeration and improved vessel hygiene through the CIP system.

& Linctus » Carbopol Dispersions

MIXING SYSTEM DESIGN OPERATION SEQUENCE SPECIFICATIONS

NEED A MIXING SYSTEM OR HAVE SPECIAL PROCESS REQUIREMENTS? TELL US WHAT YOU NEED: 1300 649 784 | SALES@MIXQUIP.COM PHARMACEUTICAL & VETERINARY CHEMICAL INDUSTRIAL FOOD & BEVERAGE PAINT & COATINGS APPLICATIONS

» Gum Dispersions » Oral Suspensions » Cosmetics & Toiletries » Fumed Silicas » Specialty Chemicals » Oil Blending » Suspending Agents » Syrups

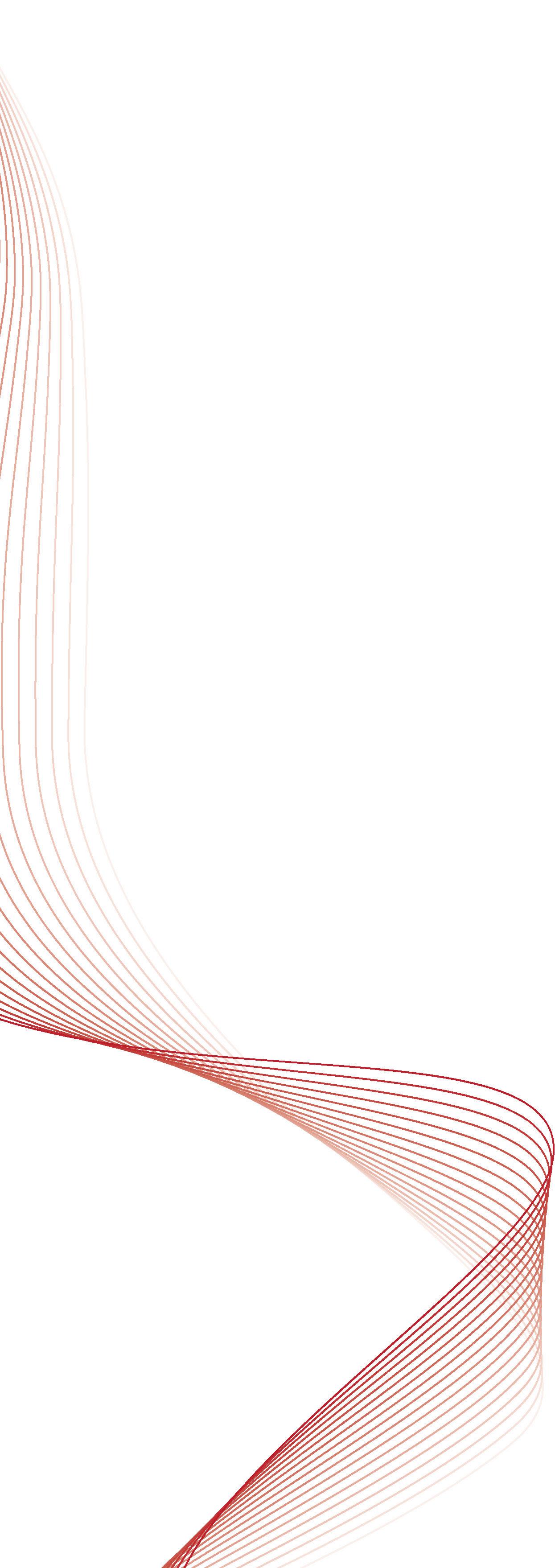

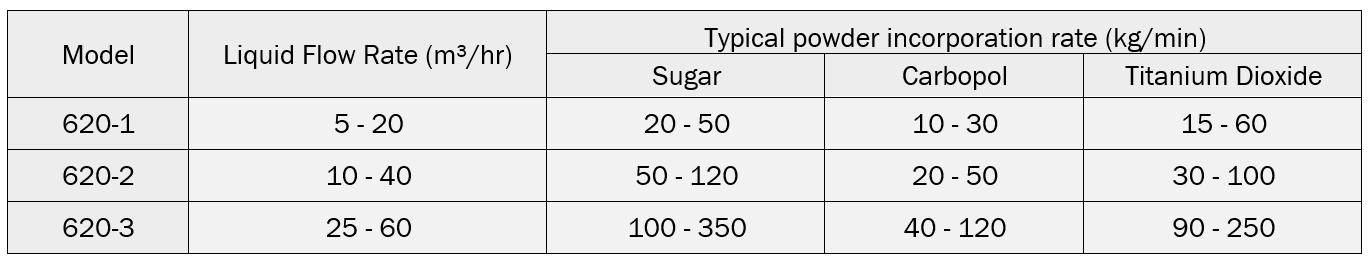

TYPICAL PERFORMANCE

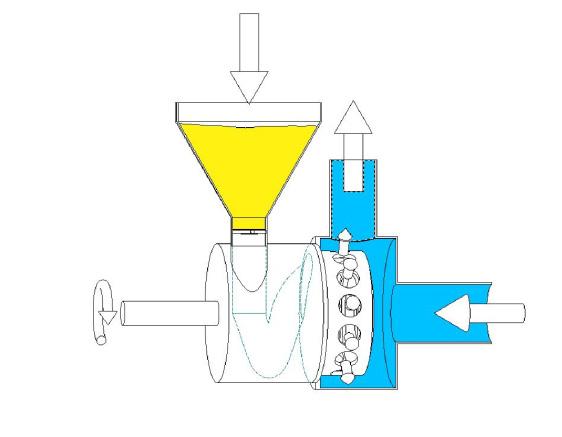

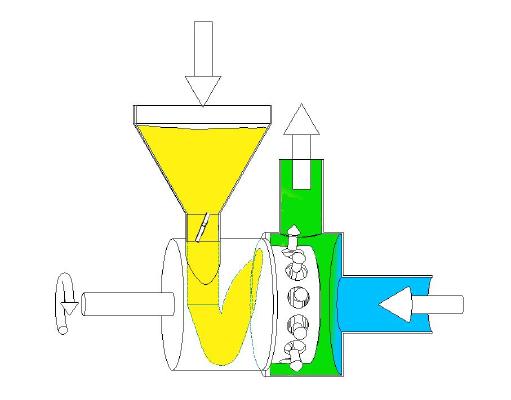

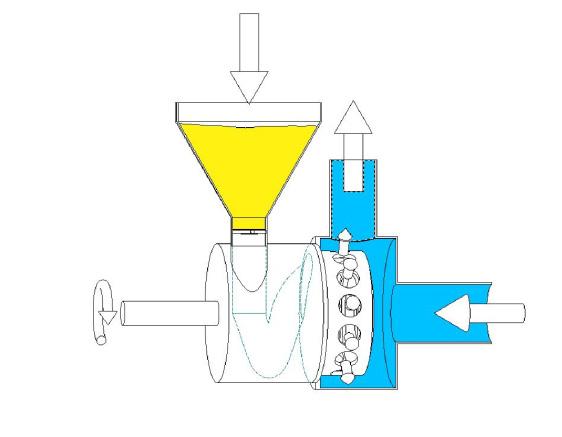

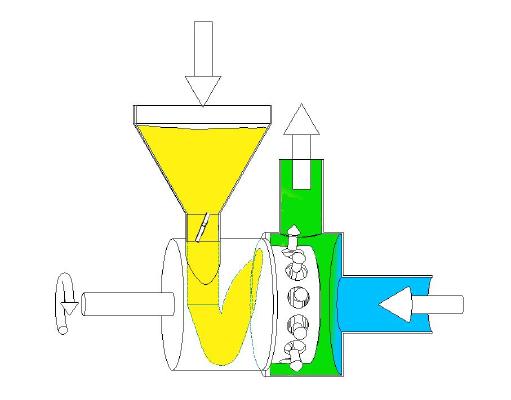

STAGE 1

The self-pumping mixer recirculates liquid from the process vessel through the workhead at a high velocity.

STAGE 2

After the powder is added in the funnel, the valve under the funnel is opened and the materials are drawn into the mixing chamber and subjected to intense mixing in the chamber by the highspeed rotor.

STAGE 3

The powder and liquid components are forced through the high shear workhead and are instantly combined as they are subjected to intense mechanical and hydraulic shear. The resultant mix is pumped into a vessel.

*Figures are based on repeated practical testing and represent typical values for guidance only.

MIXING SYSTEM DESIGN OPERATION SEQUENCE SPECIFICATIONS

OPERATING SEQUENCE

TM