5

5

Through many years of experience working with high shear mixers in many and varied applications, Mixquip has gained a wealth of knowledge and mixing information which has helped our team to test, develop and manufacture best suited products and systems for different applications. Edition 5 of our mixPRO booklets focusses on product and application information to help you in your process when coming to make decisions on how to get best results for your product. This edition will offer mixing tips and answer some of the frequently asked questions about high shear mixing operations.

Enjoy this edition and we look forward to speaking soon!

For more information on our mixer range and mixing solutions visit the Mixquip site at www.mixquip. com, purchase online or speak to an engineer to get access to our extensive knowledge and industry experience applications. Call us today on +61 (02) 4629 3050 for your mixing needs.

Selecting the right mixer for the job is the key to successful process. YOUR PROCESS MATTERS

Mixquip manufactured Powder Liquid Mixers, Inline Emulsifiers and Batch Emulsifiers all apply the required degree of shear to all process material in an efficient and single pass method. Suited to your process, each high shear unit is tailored to suit the requirements of your mixing and blending application.

1. 2. 3. 4. 5. 6. 7. 8.

GUM GUAR GUM

Used for its thickening and stabilizing effect on emulsions and suspensions, Xanthan gum forms a gel structure in water which is shear thinning. Xanthan gum may be used in combination with other modifiers, for example Guar gum, as the two combine to give greatly increased effects to a product.

Xanthan gum can be dispersed into hot or cold liquids, and may grades of gum are available. When added to water, the gum has a string tendency to form lumps and agglomerates in the solution and as a result, a number of dispersion and hydration methods are required to over come this and achieve a homogenous and consistent result.

DIFFICULTIES MIXING XANTHUM GUM

• Formation of agglomerates - standard agitators don’t produce enough shear to break these down.

• Difficult to obtain full yield.

• High levels of gum which compensates poor yield.

• Once viscosity increase has started, agitation of the solution and powder dispersion becomes increasingly difficult.

• Long mixing times to are required to complete dispersion/hydration which can degrade the gel.

• Premixing powders the gums adds to the process time and costs.

Guar Gum is a readily soluble in cold water. It forms a high viscosity solution at low concentrations increasing in viscosity as temperature rises. Widely used for its thickening, stabilizing and gelling effect on emulsions and suspensions, it is often blended with other modifiers such as Xanthan gum, as the two combine to give greatly increased effects.

Mixquip high-shear agitators are able to produce full hydration of the Xanthan gum and agglomerate free dispersions

1. The vessel is charged with liquid and the mixer is started. The Xanthan gum is added to the water as rapidly as possible. The high speed rotation of the workhead creates a powerful vortex, drawing the powder and liquid down into the workhead.

2. The materials are then forced through the slots in the side of the workhead and projected back into the body of the mix. Any agglomerates are broken down as they pass through the slots.

3. The vigorous movement in the vessel ensures that in a short mixing cycle all the material passes many times through the workhead, progressively reducing the particle size and exposing an increasing surface area to the surrounding liquid. This rapidly completes hydration.

• Agglomerate-free solution achieved

• Maximized yield, allowing for products to be formed with reduced gum content, reducing raw material costs.

• Operator error is effectively eliminated.

• Quick mixing times, speeding up operations

• Consistency achieved in product quality on every batch.

• Pre-mixing of the gum is no longer required.

APPLICATIONS

COSMETICS PHARMACEUTICALS

ADVANTAGES

• Agglomerate free mix achieved.

• Operator error eliminated.

• Rapid mixing times.

• Consistent product quality and repeatability between batches.

• Pre-mixing of gums with powders no longer required.

• Maximised yield allowing products to be formulated with reduced gum content, cutting raw material costs.

DIFFICULTIES MIXING GUAR GUM

• Agitators cannot produce enough shear to break down agglomerates that easily form leading to long mix time and low yield.

• Increase in raw material costs.

• Pre-mixing powders adds to process times and costs.

• Gum that has not hydrated during processing can gradually hydrate during storage or transport leading to undesired changes in product viscosity and stability.

Mixquip high-shear mixers can produce an agglomerate-free dispersion and fully hydrate Guar gum much faster compared to traditional methods of agitation.

1. The vessel is charged with liquid and the mixer is started. The gum is added to the liquid as rapidly as possible, where the high-speed rotation of the rotor creates a powerful suction drawing the liquid and powder into the workhead where they are instantly combined.

2. The materials are then forced through the slots in the side of the workhead and projected back into the body of the mix. Any agglomerates are broken down as they pass through the slots.

3. Fresh materials are constantly drawn into the workhead. The vigorous movement in the vessel ensures that in a short mixing cycle all the material passes many times through the workhead, progressively reducing the particle size and exposing an increasing surface area to the surrounding liquid. This rapidly completes hydration.

SAUCES & DRESSINGS MILK PRODUCTS SWEETS VARNISH

SAUCES & DRESSINGS MILK PRODUCTS SWEETS VARNISH

As a natural polymer, Alginates are obtained from brown seaweed and when mixed under the correct conditions, are soluble in water. They are used as stabilizing, gelling and thickening agents in the food, pharmaceutical and chemical industries.

Examples of use in products are spreads, sauces and bakery products to provide the correct mouth feel in low-fat formulations. Alginates have film-forming properties when mixed at high concentrations and dried, making them suitable for use in plant-based products such as vegetarian sausage casings and skins.

• Formation of agglomerates when agitation does not provide enough shear.

• Increase in processing times as pre-mixing with other ingredients is required

• Difficult to obtain full yield

• When combining the alginates with other gums this increases the viscosity leading to difficulties with standard agitating equipment being able to handle the viscosity increase and continue to move the product consistently around the vessel.

• Problems associated with aeration at higher concentrations where the viscosity is a lot greater.

Mixquip High Shear mixing options are the perfect solution for effectively dispersing alginates.

1. The vessel is charged with liquid and Powder Liquid Mixer is started. The alginate powder is added into the powder feel funnel and the valve is opening, drawing the alginate directly into the high velocity liquid stream.

2. The powder and liquid mix passes through into the workhead, where it is exposed to intense mechanical and hydraulic shear, ensuring complete dispersion and achieving and agglomerate free mix.

3. The product is pumped back into the process vessel. Once powder addition is complete, a short period of recirculation completes the process.

• Thickening effect of the alginate is maximised.

• Increase in the yield of raw materials

• Lower raw material costs as product reformulations can reduce amounts of alginates used.

• Processing times are reduced which also reduces the risk of unintentional temperature rises

• Consistency and uniformity across batches with agglomerate free mix achieved

• No need to pre-mix the alginate

• Powder can be incorporated into the mix even with increase in viscosity.

• Agglomerate-free mix achieved.

• No pre-mixing of dry ingredients required.

• Fast mixing times.

• Consistent product quality and repeatability.

• Stable viscosity of the end product.

• Rapid powder absorption rate.

• Yield of pectin is maximised, obtaining full gelling effect.

• Filtration stage can be eliminated.

Obtained from a variety of different fruits, Pectin is classed as a polysaccharide. It is used for a gelling and thickening agent in a wide range of foods, including jams, jellies and other preserves.

• Formation of agglomerates, pectin particles remain undissolved inside the agglomerates. Standard agitators don’t not provide enough shear to break these down.

• Difficult to obtain potential full yield.

• Slow powder addition in order to reduce the formation of agglomerates.

• Pre-mixing of dry ingredients, which in turn increases labour costs and process times.

• Long mixing times to complete required dispersion and hydration.

• Partially hydrated pectin removed during filtration is wasted, increasing costs and reducing product quality.

• As viscosity increase starts, the agitation of the solution and powder dispersion becomes increasing difficult.

• Any undissolved pectin can gradually hydrate during storage and processing, leading to undesired changes in product viscosity.

Using a Mixquip High Shear Mixers enables processing times to be reduced, improves product quality and eliminates operator error.

1.Pectin is added to the water and dispersed. The high-speed rotation of the rotor blade creates powerful force drawing the water and pectin from the vessel into the workhead.

2.The water and pectin are exposed to intense shear in the walls of the workhead where they are instantly combined, breaking down all agglomerates.

3.The product is forced back out into the vessel as fresh material is drawn into the workhead.

Starch is used as a thickening, stabilizing and binding agent in many foods, including soups, sauces, gravies and baked products. Unmodified starches are relatively easy to disperse and generally do not increase in viscosity until heated or cooked. Starch can be modified by a number of methods to obtain functional properties such as texture, appearance, viscosity and stability under heating or freezing.

• Formation of agglomerates when starch powder is added to water.

• Once viscosity increase has started, agitation of the solution can become increasingly hard.

• Long mixing times to achieve desired hydration of the powder.

• Potential full yield difficult to obtain through raw material losses.

• Premixing of powdered ingredients

• Undissolved starch can gradually hydrate after processing which can lead to undesired changes in product viscosity.

Mixquip High Shear agitators provide benefits and overcome the problems associated with mixing of starch.

1. The mixing vessel is charged with liquid and the agitator is started. Starch is added to the water as fast as possible as the high speed rotation of the rotor pulls the liquid and powder into the workhead where they are instantly combined.

2. Forces draw the powder and liquid into the workhead where they are subjected to intense high shear. The product is forced out and back into the main solution.

3. Fresh materials are constantly drawn into the workhead. The vigorous movement in the vessel ensures that in a short mixing cycle all the material passes many times through the workhead, progressively reducing the particle size and exposing an increasing surface area to the surrounding liquid. This rapidly completes hydration.

GRAVY BAKED PRODUCTS

• Agglomerate free mix achieved

• Operator error eliminated

• Rapid mixing times

• Consistency and uniformity between batches

• Powder incorporated easily despite increase in viscosity

• Maximised yield and starch is fully hydrated.

BEVERAGES ICE-CREAMS

CHEESE

• Ability to add carboxymethyl cellulose straight into the vessel, eliminating operator error.

• No pre-mixing required.

• Achieve agglomerate free mix.

• Maximum yield.

• Consistent product quality on every batch.

• Fast mix times, more product processed.

• Stable viscosity achieved in the end product.

• Greater uniformity.

Carboxymethyl cellulose is a water-soluble hydrocolloid from cotton or wood pulp. Used in the food industry, either alone, or in combination with other hydrocolloids as a thickening and stabilizing agent and to bind free water. Example applications include beverages, cheese, ice cream, sauces, baked goods and frozen desserts. It can also be used to improve mouthfeel in powdered beverages.

DIFFICULTIES MIXING CARBOXYMETHYL

• Dispersion and hydration can prove slow and difficult, especially at higher concentrations forming lumps when added to water.

• Premixing powders with the carboxymethyl cellulose adds to process time and operation costs.

• Hard to break down agglomerates leading to long mixing times and low yield.

• Once viscosity increase has started, agitation of the solution becomes difficult.

• Long mixing times.

• If not properly mixed, the carboxymethyl cellulose can lead to undesired changes in product viscosity.

The process involved in mixing of Carboxymethyl Cellulose can be sped up using a Mixquip High Shear agitator.

1. Carboxymethyl Cellulose is added straight into the vessel and liquid mix.

2. High Speed rotation of the rotor create powerful suction drawing the Carboxymethyl Cellulose into the liquid and into the workhead where they are instantly combined.

3. The mixture is then forced out through the workhead into the main body of the solution.

SOUPS SAUCES & DRESSINGS

SOUPS SAUCES & DRESSINGS

A protein derived from collagen, Gelatin is a colorless, tasteless and odorless powder used as a gelling agent in many applications. It is widely used in the food industry in confectionery products such as jellied lollies, as well as other food goods such as meat products and dairy and desserts. It can be used in low-fat products to replace texture and mouthfeel that is lost with removal of the fat. It is also used in beverages as a clarifying agent for beers and wines.

• Formation of agglomerates, conventional agitators do not provide enough shear to break these down leading to long mixing times.

• High raw material costs as lots of formulations include unnecessarily high levels of gelatine.

• Long mixing times to reach required hydration.

• Difficult to disperse powders after viscosity increase has started.

• Rehydration of gelatine proves a slow and difficult process as it easily forms lumps when added to water.

• If the gelatine hasn’t been properly dispersed, this can gradually hydrate during storage leading to undesired changes in product viscosity.

THE MIXQUIP HIGH SHEAR SOLUTION

Use of a Mixquip High Shear agitator provides benefits in speeding up processing times and operations for mixing gelatine into solution.

1. Gelatine is added into the mixing vessel.

2. The high speed rotation of the rotor blade pulls the gelatine and liquid into the workhead where they are intensively mixed between the rotor and stator.

3. The mixture is them pushed through the holes in the stator and back into the main body of the mix. This process repeats ensuring the powder is fully dispersed and hydrated.

ADVANTAGES

• Gelatine can be added directly into the mixing vessel.

• Agglomerate free mix achieved.

• Maximized yield.

• Product can be formulated with reduced gelatine, reducing raw material costings.

• Consistency in product quality and stability across all batches.

• Fast mixing and processing times.

SAUCES & DRESSINGS BEVERAGES

ADVANTAGES

• Maximised yield of raw materials as thickening agents are fully hydrated and other ingredients completely dispersed.

• Consistent product quality and stable emulsions across batches.

• Agglomerate free mix achieved.

• Fast mixing times.

• Ability to achieve a globule size of 5-7µm.

Flavour Emulsions are used widely in a range of food, drinks and dairy products to enhance product taste.

DIFFICULTIES MIXING FLAVOUR EMULSIONS

• Solution has to be agitated for a long period of time to ensure the gum is fully hydrated.

• Formation of agglomerates.

• A pre-emulsion is required in order to obtain the desired globule size.

• Partially hydrated material can build up on the shaft of the mixer and the vessel wall.

Using a Mixquip High Shear agitator allows for intermediate stages of production to be removed, improved product quality as well as reducing processing times.

1. The continuous phase is pumped into the mixing vessel. The mixer is started and the powdered ingredients can be added without premixing. The high speed rotation of the rotor creates a powerful suction which draws liquid and solid ingredients into the workhead, where they are subjected to intense shear.

2. The powdered ingredients are de-agglomerated in the clearance between the ends of the rotor blades and the stator wall, becoming fully dispersed. The product is forced out through the stator at high velocity and returned to the mix, as fresh ingredients are simultaneously drawn into the workhead.

3. The combined intake and expulsion of ingredients sets up a circulatory mixing pattern within the vessel. In a short time all the ingredients pass through the workhead and dispersion is completed. The dispersed phase is added to the vessel and an emulsion is rapidly formed. Particle size is progressively reduced, producing a stable and homogeneous mixture.

Mixquip high shear agitators are designed and manufactured for each specific mixing application and process. Each feature numerous advantages for a wide range of applications in successfully dispersing and hydrating powders in solution to achieve a homogenous, stable mix as well as speeding up operations and overall increase in productivity and profitability as a result.

The Mixquip Series 600 Emulsifier, is able to perform a wide range of duties, suited to almost all mixing processes –from mixing, emulsifying, homogenizing, disintegrating and dissolving. All duties are carried out with efficiency and flexibility to suit exact requirements. The sanitary construction provides benefits for industries where advanced CIP and SIP facilities are required.

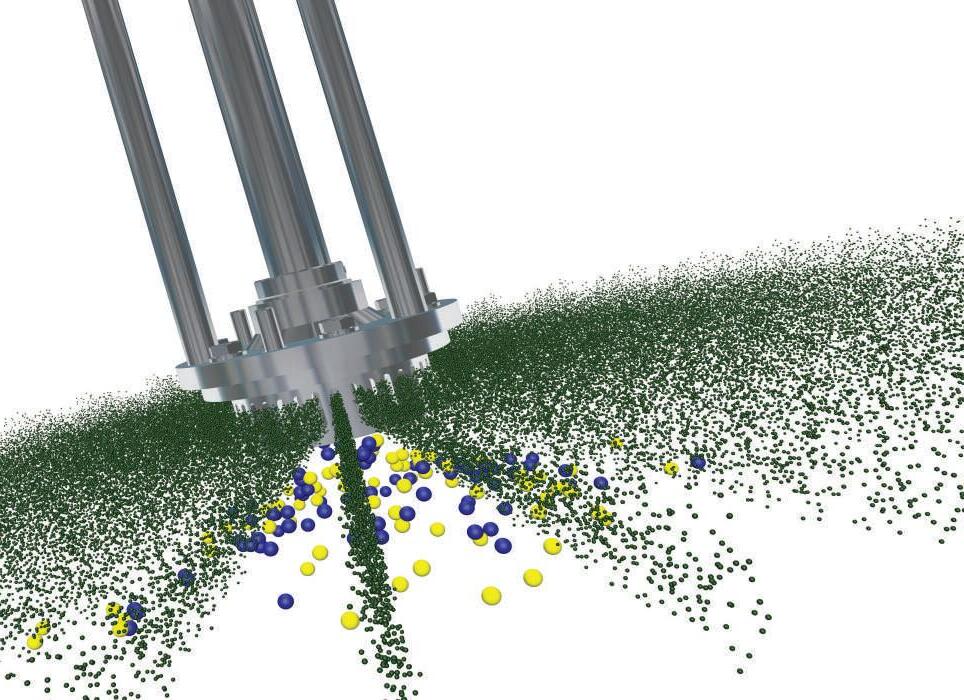

Solids dispersion remains to be one of the most enduring processing challenges in Industry today. The Mixquip Series 620 is ideal for dispersing hard-to-wet powders into liquid without agglomeration, floating or dusting. The Series 620 takes a ground-breaking approach to mixing powders into liquids.

The range of high shear batch mixers are made robust and simple ensuring cleaning and maintenance is kept to a minimum. Each mixer is designed and manufactured for interchangeable work-heads allowing for a variety of different products with just the one mixer. The option greatly increases the flexibility of these mixers, allowing them to be moved from vessel to vessel and to be raised and lowered during operation, if required, in order to give the optimum mixing position at varying stages of the process.

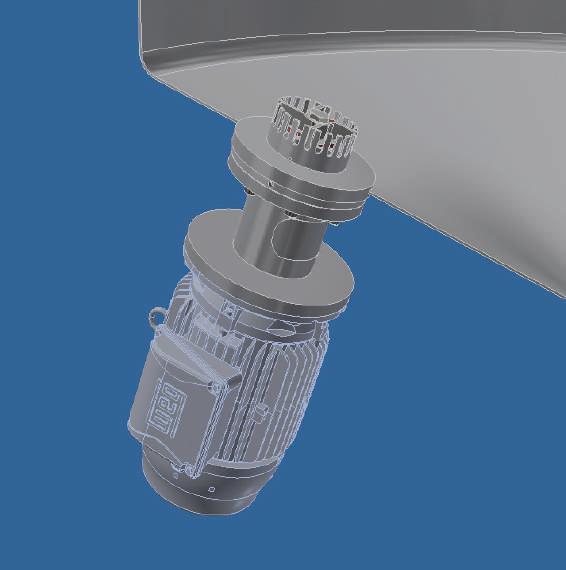

Mixquip’s Series 560 range of high shear bottom entry emulsifiers are designed to fit into the bottom of a mixing vessel. The Series 560 is often used in conjunction with a gate anchor impeller for successful mixing of high-viscosity products. The base-entry emulsifier provides high shear homogenisation whilst the gate anchor impeller distributes the product evenly throughout the mixing vessel.

FOOD & DAIRY MANUFACTURER

MELBOURNE VIC

THE PROBLEM

Needed to increase the production of chocolate and strawberry flavoured milks.

THE CHALLENGE

Powder additions were too slow and the old mixer was difficult to maintain and clean.

THE SOLUTION

Install of a Mixquip Series 620-2 with a CIP Lid. Faster addition of powders, hygienic and no clumping.

CHEMICAL MANUFACTURER

MELBOURNE VIC

THE PROBLEM

No means of mixing in hydrophobic powders

THE CHALLENGE

Add 10 12 tonnes of powder to mixture each shift. No altering of existing equipment.

THE SOLUTION

Mixquip Series 620-3, 37kW with variable speed, mixes in a Bulka Bag of powder every 40 minutes.

BEVERAGE MANUFACTURER

SYDNEY NSW

THE PROBLEM

Sugar, pectin and other ingredients had to be pre-mixed in a small tank which was slow and labour intensive, as well as extra items to clean.

THE CHALLENGE

Needed to speed up powder and sugar additions.

THE SOLUTION

Mixquip Series 620-1 with bag table, much safer and easier to use. Customer purchased one for Sydney branch and within 3-4 weeks another for their Brisbane branch.

FERTILIZER MANUFACTURER

MOUNT GAMBIER SA

THE PROBLEM

Changing from unloading 20kg bags of urea pellets off a pallet on top of a tank and slashing open bags.

THE CHALLENGE

Generated a lot of dust, long mixing times, labour intensive and downtime for a forklift.

THE SOLUTION

Mount Mixquip Series 620-3 37kW at ground level and use bulka bags. Faster mixing times, Urea granules cheaper in bulka bags which saved costs as well as significantly faster batch times.

PHARMACEUTICAL MANUFACTURER

NOWRA NSW

THE PROBLEM

Needed to mix CMC and polymers to create high viscosity gels.

THE CHALLENGE

Hydrate the CMC without fish eyes or agglomerates.

THE SOLUTION

Install of Mixquip Series 620; able to use less CMC due to the hydration of minute particles created by the milling action of the powder liquid mixer.

FERTILIZER MANUFACTURER

MELBOURNE VIC

THE PROBLEM

Keeping the organic material suspended in the fertiliser mix. Required addition of binding agent emulsifier (Xanthan)

THE CHALLENGE

To hydrate the Xanthan and bind it to the organic particulates and stop them falling out of suspension. Minimum floor space available for additional mixing equipment.

THE SOLUTION

Mixquip Series 620-2; client comment - ‘The best piece of equipment I have ever bought, couldn’t do without it’.

FOOD MANUFACTURER

SYDNEY NSW

THE PROBLEM

Getting special ingredients eg. breadcrumbs, chocolate chips, fine powders into an ice-cream mix.

THE CHALLENGE

Getting them to flow and induct into the fluid stream.

THE SOLUTION

Mixquip Series 620 feed hopper is mechanically fed into the Liquid Stream at a constant rate regardless of material and viscosity.

FOOD MANUFACTURER

SMITHTOWN TAS

THE PROBLEM

Getting an even dose of coating and seasoning on the potato wedges

THE CHALLENGE

Be able to vary dose of seasoning according to potato throughput.

THE SOLUTION

Mixquip 620 with automated dosing of spices into hopper with a recirculation water loop.