Munters (Pty) Ltd 22 Angus Crescent - Longmeadow Business Estate, Johannesburg, Gauteng 1610 South Africa Tel dir: +27 11 997 2000, Mobile: +27836333764

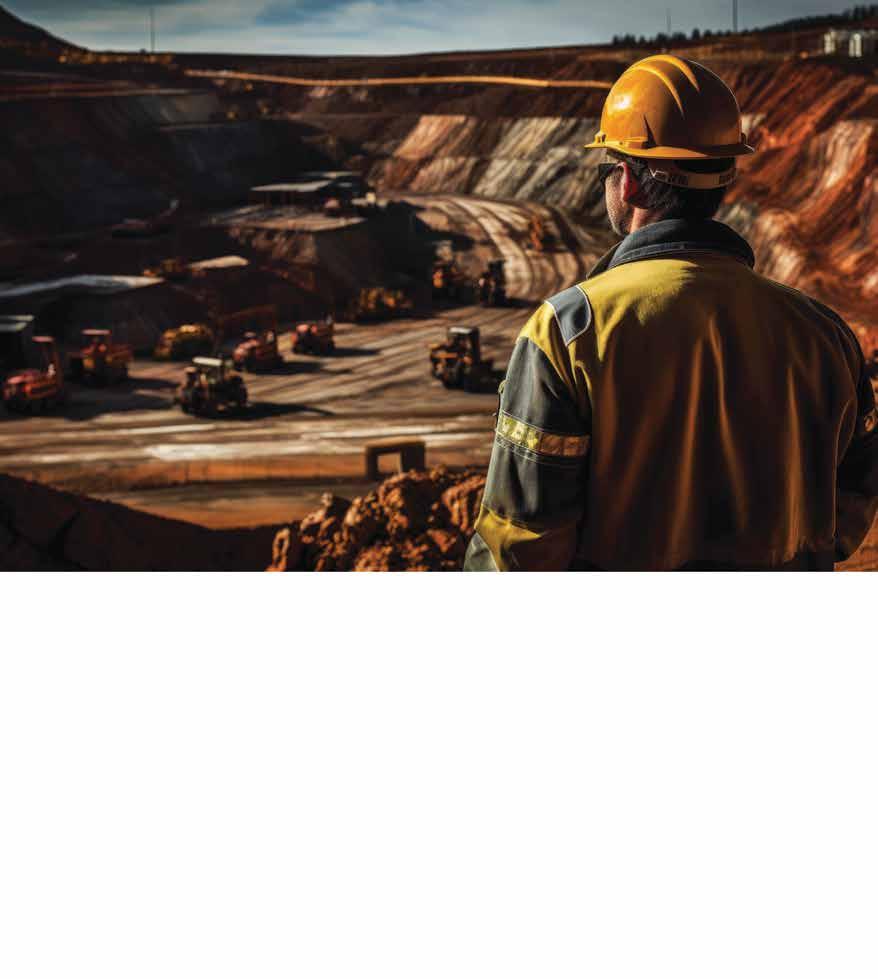

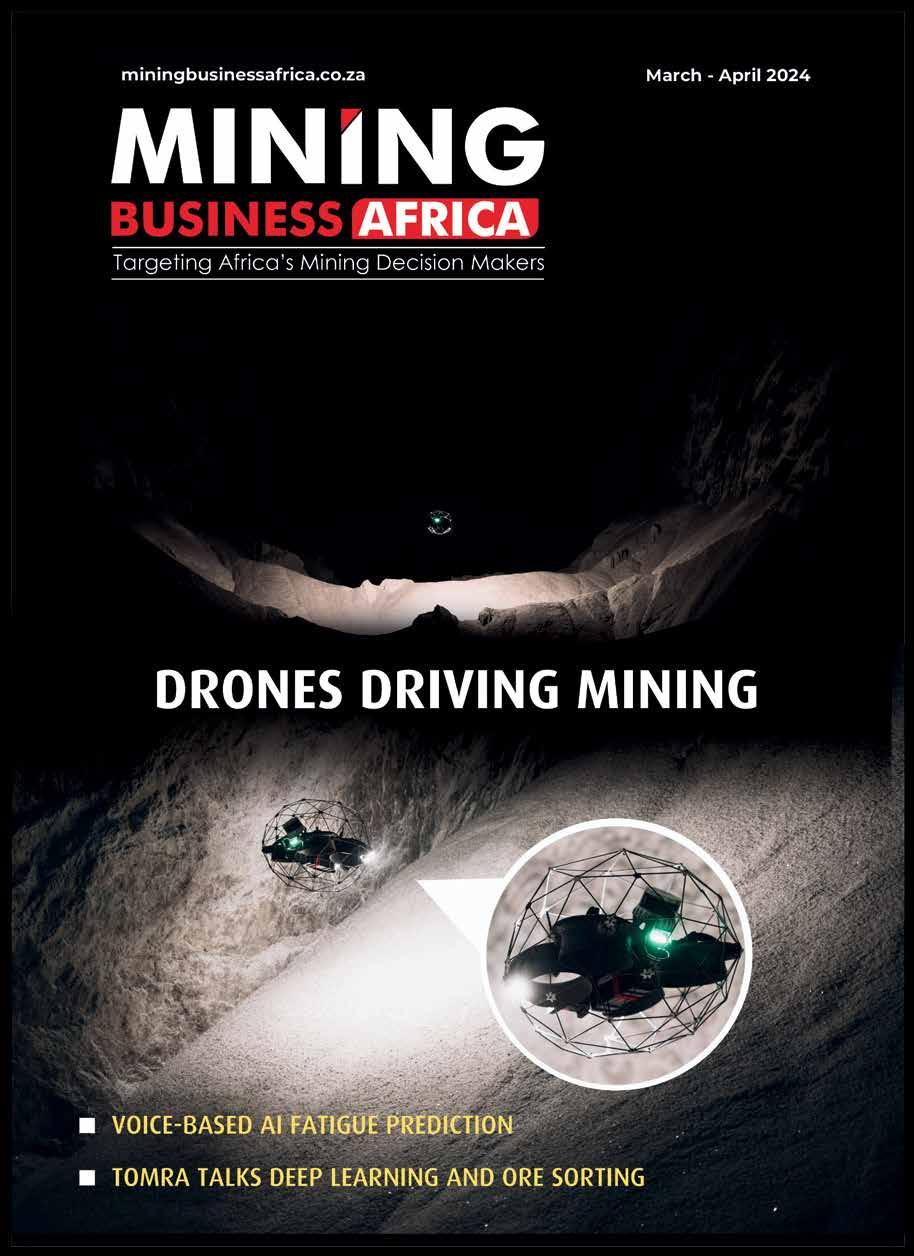

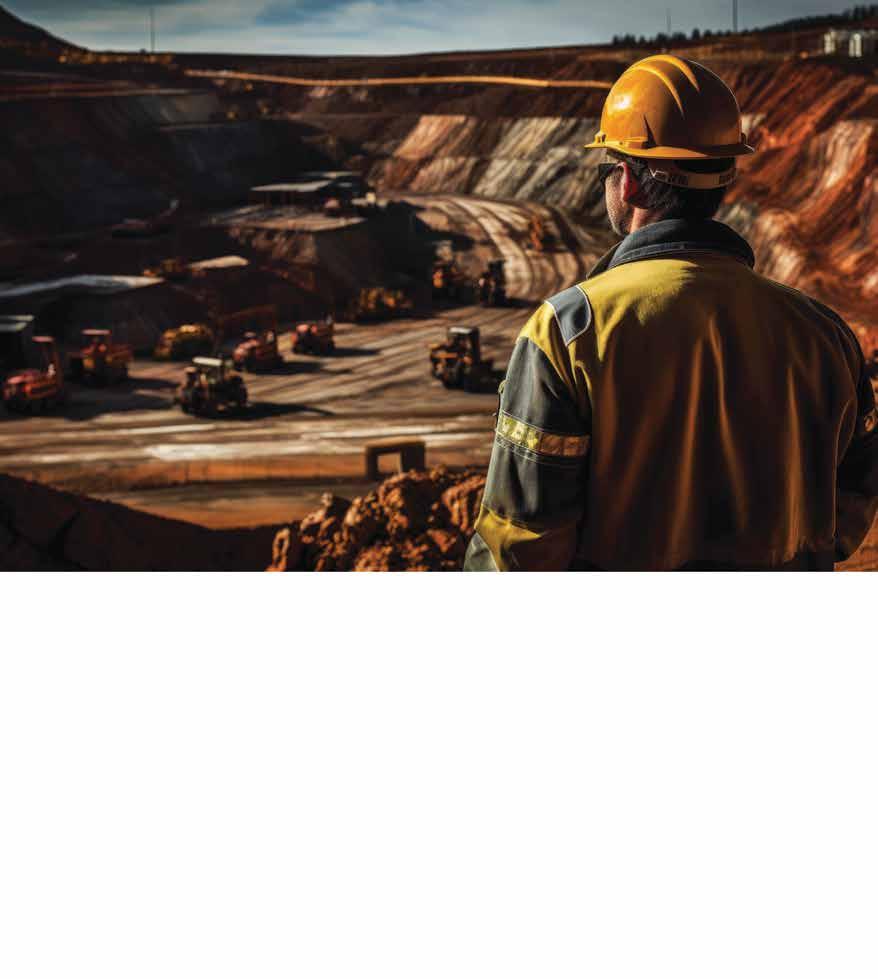

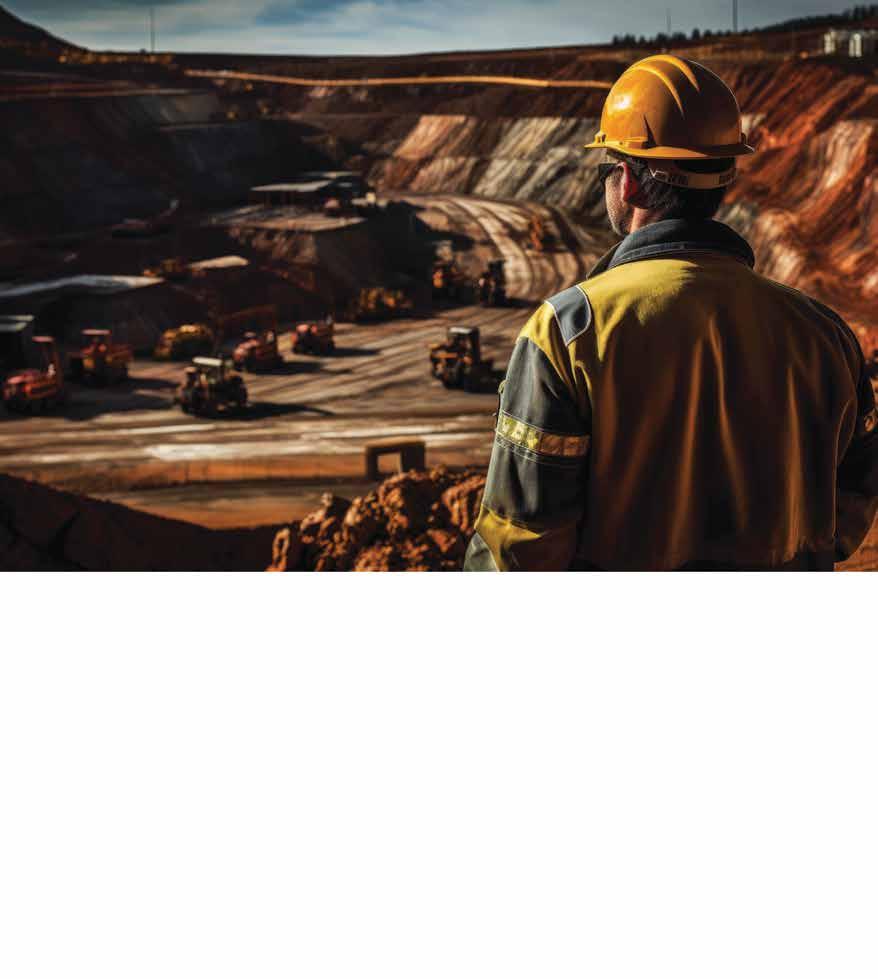

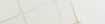

Cover Image:

For all the hype, GPS-enabled drones cannot operate in some nooks and crannies of underground mining. This is where the Elios 3, produced by Swiss drone company Flyability, fills the gap. Equipped with the high-resolution Ouster OS0128 Rev 7 LiDAR sensor, in combination with the world’s leading FARO Connect SLAM algorithm, Elios 3 creates incredibly accurate 3D maps

Susan M.

susanm@miningbusinessafrica.co.za

Sales and Marketing

Winnie Sentabire

winnie@miningbusinessafrica.co.za

+27

Chantelle C.

Writers

chantellec@miningbusinessafrica.co.za

+ 27 10 055 3356

Mining companies are waiting for the results of General Elections in Africa’s most advanced economy with bated

In the past few weeks, I chatted with a few decision-makers of companies involved in the South African mining supply chain on the sidelines of a high-profile event. The general impression I got was that everybody is waiting for the results of the most critical elections in the 30-year old democracy, scheduled for the 29th of May 2024.

It seems the corporate heads don’t mind how the results will pan out, heads or tails. But specifically, how this will impact their long-term investment plans.

Naturally, executives are worried about the effect of the post-election political risk on their investment. Already, there have been lingering reservations about the uncertainty of mining policy. Coming to the fore is the speed of issuing relevant operating licences and contentious labour laws.

To a large degree, this should be understandable.

A lot has been trumpeted about the massive economic potential that lies unearthed in South Africa’s mining sector. But the potential is not the real thing. Action is needed to turn that into tangible gains for the benefit of every South African citizen.

Hopefully, whichever party or coalition will come to power will have the interests of South Africa’s mining industry at heart. It’s South Africa’s eleventh hour, and decisive action is vital.

30

02 CONTENTS March - April 2024 Media Icon (Pty) Ltd makes every effort to ensure the accuracy of the contents of its publications, but no warranty is made as to such accuracy and no responsibility will be borne by the publisher for the consequences of actions based on information so published. Further, opinions expressed are not necessarily shared by Media Icon (Pty) Ltd. Location: Max Offices Sandton, 145 Second St., Parkmore Gauteng 2196, South Africa www.miningbusinessafrica.co.za

42

Africa’s Eleventh Hour

Editor’s Note Nick Barnes editor@miningbusinessafrica.com South

Editor Nick Barnes editor@miningbusinessafrica.co.za +27 10 055 3356

Jimmy Swira Jimmy@miningbusinessafrica.co.za + 27 10 055 3356 Anita Anyango anyangoanita18@gmail.com Contributing

breath.

Web/Sub-Editors

83 530 6832 | +27 10 055 3356 Angeline Ntobeng angien@miningbusinessafrica.co.za + 27 078 322 5938 + 27 010 055 3356 Accounts Precious Chirunga accounts@miningbusinessafrica.co.za + 27 10 055 3356 Art Director/Layout Augustine Ombwa Arobia Creative Consultancy austin@arobia.co.ke +254 772 187 334 Circulation/Sales info@miningbusinessafrica.co.za + 27 10 055 3356 Published By Media Icon (Pty) Ltd

All-weather Drone for Inaccessible Areas

COVER STORY: PG 30

20

TEAM

Underground

Flyability

Compliance Challenges and Opportunities

MINING BUSINESS AFRICA hears from two practitioners at ENS about the implications of the Subregulations of regulation 8.10 of the Mine Health and Safety Act (MHSA) on diesel-powered Trackless Mobile Machinery (TMMs) in the South African mining environment. Pieter Colyn is a Mine and Occupational Health and Safety Executive and Head of Department, and Warren Hendricks is a Mine and Occupational Health and Safety Executive. This article captures the gist of their views.

diesel-powered

On Wednesday, 21 December 2022, the Minister of Mineral Resources and Energy declared, by notice under GNR.2908 in Government Gazette No. 47790, that sub-regulations 8.10.1.2(b) and 8.10.2.1(b), of regulation 8.10 of the Mine Health and Safety (“MHS”) Regulations, came into force and were effective from the date of said publication. In summary, these sub-regulations require the employer at a mine to provide for the “means”, also known as the so-called Prevent Potential Collision System (“PPCS”), to automatically “retard” (and “stop”) diesel-powered Trackless Mobile Machinery (“TMMs”) to prevent potential collisions between diesel-powered TMMs and pedestrians; and between diesel-powered TMMs and other diesel-powered TMMs, respectively.

Primary duty with the employer

The primary duty to comply with the requirements of the said sub-regulations, rests with the employer, at a mine, for purposes of the Mine Health and Safety Act, 1996 (“the MHSA”). For those employers that have

diesel-powered TMMs at a mine, and where there is a “significant risk” of the occurrence of the categories of collisions as set out in subregulations, the expectation is that the employer must comply with such regulations. This would mean that employers must ensure that their existing fleet of diesel-powered TMMs used at a mine are equipped with such PPCS.

Significant risk determines obligation

Regulations 8.10.2 of the MHS Regulations require employers to take “reasonably practicable measures” to ensure that persons are prevented from being injured as a result of collisions between diesel-powered TMMs, and/ or collisions between diesel-powered TMMs and pedestrians. The aforementioned imparts discretion on the employer to implement such measures at a mine, which takes into account the standard prescribed in the MHSA of “reasonably practicable.”

It should be noted that the regulatory obligation to provide the “means” or so-called

PPCS, as part of the above “reasonably practicable measures”, only arises where there is a “significant risk” of the respective categories of collisions as set out in the sub-regulations. It is further important to note that to fall within the regulatory obligation, the risk must be significant. For instance, if there is a risk of such collisions at a mine, but such risk is not significant, then the regulatory obligation would not apply to such mine and employer.

Comprehensive risk assessment

Whether the risk of the relevant collisions is “significant” at a particular mine, would be informed by the conduct of a comprehensive risk assessment process conducted at such a particular mine, as envisaged in section 11 of the MHSA. Each mine will yield different results depending on the particular circumstances at each mine, and will be informed by way of example and by, amongst others:

• Previous incidents at a mine involving collisions between TMMs, and the statistics related thereto. The nature or extent of the risk of such collisions occurring at the operations should be determined. Also the effect of any such collisions (i.e. fatal, injury or merely minor property damage, etc.). The frequency or reduction of such incidents at the operations would also be considered, for instance, since the implementation of safety measures or controls, etc;

• The interaction (and means of separation) between TMMs at the various areas of a mine;

• The existing measures or controls in place to mitigate the risk of collisions between such TMMs at each mine; and

• The requirements of “reasonably practicable” etc.

• If there is a significant risk of the relevant collisions at a mine, then it would be incumbent on the employer to ensure that it has appropriate implementation plans/schedules/ timetables in place, in relation to compliance with the requirements

2 Mining Business Africa |March - April 2024 Collision Avoidance Regulations: South Africa

Operators of a

Trackless Mobile Machine underground

contained in sub-regulations. It would be prudent for the employer to inform the regional regulator of its implementation strategy. If potential timelines are provided to the regulator in such context, same should be, as far as is possible, realistic, practicable and made subject to any matters which may be outside the control of the employer or matters that may only be considered at a later stage that may influence any potential implementation.

• Should the compliance with certain of the duties and obligations (as set out in regulation 8.10 of the MHS Regulations) be impractical and/or burdensome on the employer, a potential option to consider is an application for exemption (from all or certain sub-regulations or requirements therein) which may be made to the Minister of the Department of Mineral Resources and Energy (“DMRE”) in terms of section 79 of the MHSA. Essentially, an employer may make an application to be exempt from the application from the requirements of the sub-regulations. Each application will be dealt with on its own merits and, likely, on a stringent basis by the office of the Minister of the DMRE considering same. Accordingly, succinct and detailed reasons would have to be set out therein, as to why exemption is appropriate in the circumstances.

Compatibility of PPCS to fleet

In several cases, Original Equipment Manufacturers (“OEMs”) of diesel-powered TMMs do not supply TMMs with PPCS for use at a mine. As such, the employer would be obligated to source compatible PPCS (and related interface and/or communication systems) from specialist OEMs providing such systems. In doing so, employers also have to take into account the compatibility of such systems to their entire fleet of diesel-powered TMMs (all of which are not likely from the same OEM, year, model, specification, etc.), to ensure that same is tested (in the various mining environments and operational circumstances that may exist at a particular mine) and consider the need to modify and/or replace (due to year, age) certain TMMs

to ensure compatibility. The exercise, to say the least, involves the outlay of significant capital expenditure and the requirement to assess, test and implement, in a very limited period of time.

As it stands, and potentially, employers who are not compliant with the requirements of the sub-regulations may be subjected to, amongst others, possible instructions from the regulator to halt/stop mining operations (or TMM operations), administrative fines and/or criminal liability, etc.

Practical complexities

However and whilst the regulations may have good intent, it is unfortunate that the sub-regulations as gazetted do not provide for any grace or transitional period. Apart from the cost implications and possible penalties, the practical complexities of investigating, acquiring and implementing systems may also result in matters which may be beyond the control of the employer. This may include, amongst others:

• That an employer will have to rely on collaborative efforts between multiple and respective OEMs. This may, in itself, take an extended period, i.e. selection, compatibility, negotiation, contract, testing, etc. OEMs will also have to consider the potential for further product and risk liability, and the OEMs will also possibly have to revise and implement additional measures to mitigate same;

• Even assuming that OEMs are willing to collaborate, the testing and practical application of such systems at a mine will, in all likelihood, take an extended and unpredictable period, with “trial and error”. Further, this will depend on the results that same will yield at the relevant time, taking into account the health and safety of all persons (the improper introduction and implementation of such systems may create further risks); and

• The immediate availability and supply of such systems from OEMs, for the population of all relevant TMMs at a mine.

Opportunity for Engagement

There is some respite, though. In several regions, the regulator (in the form of the office

of the regional Principal Inspector of the Mine Health and Safety Inspectorate of the DMRE) has provided employers with the opportunity to engage with the regulator and submit implementation plans/schedules/timetables in relation to compliance with the requirements contained in sub-regulations. This process, however, is not uniform (across the various regions) and is subject to the regulator’s ultimate approval regarding any periods and proposals provided in such implementation plans/ schedules/timetables.

Employers as forerunners

In the bigger scheme of things, notwithstanding the aforementioned challenges, the subregulations open a new chapter in the drive to mitigate the collision of mining vehicles. Employers in South Africa (in conjunction with OEMs) have an opportunity to be the forerunners in the investigation, design, installation, testing, certification and utilisation of such “means” in various mining environments. This brings about opportunities for OEMs to develop new and innovative systems for application at a mine, locally and internationally.

Thus, to ensure compliance with their respective health and safety obligations in terms of the MHSA, OEMs and employers would enter into partnerships to test such systems in “real world” mining environments, which vary and differ from operation to operation. The collaborative arrangements between OEMs and employers will assist in implementing safe and healthy parameters for such systems to operate in such environments.

ENS is the only law firm in Africa with a dedicated Mine and Occupational Health and Safety team/department. Its practitioners specialise in providing advice and assistance to an array of clients in, and outside, the mining industry. They provide practical and innovative solutions in complying with the legislative requirements; opposing prejudicial regulatory oversight and enforcement; appearing on behalf of clients in legal proceedings, as well as assisting clients with the preparation of exemption applications in terms of section 79 of the MHSA.

Mining Business Africa | March - April 2024 3 CONSULTING EXPERTISE VISION RESOLUTION ACTION | | | Expert Witness Services for Legal Proceeding Forensic Delay Analysis BIM & 5D Planning AGILE Project Management Services Alternative Dispute Resolution Claims Advisory Project Planning & Control +27 11 234 8410 admin@evraconsulting.com

AI Gives Workers the Voice to Monitor Fatigue

WOMBATT-VOZ is a voice-based technology originally developed for fatigue prediction among astronauts. So far, the technology has achieved groundbreaking success in multiple industries. Now, inspired by the outcome, the application team at WOMBATT, the technology’s developer, tell MINING BUSINESS AFRICA that they see immense opportunities for the innovation’s deployment in the African mining sector.

By Jimmy Swira

By Jimmy Swira

Necessity is the mother of invention, so goes the saying. And this would apply to the WOMBATT-VOZ, a groundbreaking fatigue risk prediction technology.

Interestingly, what started as a long-duration Space travel project with a scope limited to the client‘s brief, has opened the door for application in multiple industries and activities.

Research & Development

The European Space Agency (ESA) in Noordwijk, The Netherlands, requested WOMBATT to develop a new tool to monitor astronaut fatigue risk for the manned mission to Mars. Thus, precision was key and in addition, the technology adopted should be non-intrusive and predictive.

WOMBATT-VOZ Voice technology

Usually, all current fatigue technologies are based on detection, raising an alert as or just before the microsleep actually occurs. And so, for ESA, it was important to have a robust predictive fatigue solution that was not intrusive for use in Space, as well as GDPR compliant. This culminated in WOMBATT-VOZ Voice technology.

Accordingly, WOMBATT performed a research and development project from 2014 to 2019. After the development of the voice-based generative artificial intelligence algorithm, the tool passed the ESA Factory Acceptance Tests, scoring 90% accuracy in predicting the risk of a fatigue event occurring up to five hours in advance.

Later, in 2019 and 2020, the product was further developed for commercial use in combination with WOMBATT’s patented realtime fatigue monitoring and reporting solution.

On the record-breaking scale of fatigue prediction, Emma Verhardt, WOMBATT’s team leader, comments: “Exceptional accuracy combined with non-intrusive user friendliness sets our new fatigue technology’s performance apart and makes it a game changer.“ Indeed, the technology continues to receive glowing reviews across the industry.

Meticulous planning and thorough execution

The technology’s plaudits are well-merited. It is a fitting product of meticulous planning and thorough execution.

Available options

WOMBATT’s R&D team explored the available options they could exploit. They considered three main ways the body expresses fatigue to the outside world: Electrode-based, Videobased and Acoustic-based.

Then, to arrive at the most effective solution, the team examined four key fatigue monitoring parameters in the industry and on the road:

• Biological parameters e.g. from the voice;

• Vehicular parameters, e.g. lane deviation;

• Physical parameters, e.g. yawning and head nodding; and

• Mathematical parameters, e.g. sleep/wake times, circadian rhythm.

1. Two parameters

Distinctly, the WOMBATT-VOZ Voice technology incorporates two out of the four possible parameters - a biological parameter (voice) and a mathematical parameter (sleep/wake). Justifying the selection, Verhardt explains, “The combination of two parameters consistently increases the accuracy of fatigue risk prediction over time to levels well above 90%, and complies fully with the oil and gas industry standard ANSI/ API 755 recommended practice 2nd ed 2019. Research has proven that human physiological fatigue effects are almost infinitely variable, so a two-step process in managing fatigue is more accurate than relying on the effects of just one parameter.“

Verhardt demonstrates the effectiveness of the voice-based system: “The voice is actually a powerful window into our body. This is because our voice is a muscle, and when we are feeling fatigued our muscles will start to become fatigued as well. We have all felt that at some point in our lives, some more often than others. However, the voice muscle is the only muscle that can express fatigue (amongst other things) via acoustics without physical contact.

So, what we have done is taken the acoustic data coming from the voice, which expresses developing fatigue, and combined it with our generative AI to build an individual voice model for each user, creating a technology that can predict fatigue up to 4 to 5 hours ahead of time with 90% accuracy. Without a doubt, what makes WOMBATT-WOZ cutting-edge is leveraging AI.

4 Mining Business Africa |March - April 2024 Voice-based AI Fatigue Prediction for Mining Projects

Operator fatigue is a high safety risk

Voice-based AI Fatigue Prediction for Mining Projects

The WOMBATT generative AI

The WOMBATT generative AI is data-based, so it is always adapting and learning the unique characteristics of each user’s voice. To complete the product the technology is linked into the WOMBATT management system which allows operations to plan both for and with fatigue before it becomes an ad-hoc risk or event. WOMBATT has integrated a stoplight system (green, orange, red) in which companies can integrate the results into their fatigue risk management protocols.

WOMBATT-VOZ’s Features

As a result of the integration of generative AI, the technology has proved effective. The enduser can rest assured of the following benefits:

i. High accuracy and non-intrusive

WOMBATT-VOZ achieves high levels of accuracy in the field without additional hardware and is non-intrusive for workers. It is a system that can be used broadly within any organisation, for haul truck drivers and service equipment operators, but just as well as for workers in the processing plants.

ii. Integratable

Furthermore, as an SaaS technology, WOMBATT-VOZ can be integrated with dispatch systems or on existing hardware already present at the mine. It can be used as a stand-alone service or as an additional service to existing detection technologies complementing the risk management systems in place.

iii. User-friendly

There is always concern with new technology and how mineworkers adapt to it. WOMBATTWOZ caters for this. It is available as an app which anyone can download free of charge. So it can be on a mobile phone, a tablet or integrated into onboard systems.

“The app itself does not store data and record without the worker’s intervention. For us, this was specifically important during the development to make sure that the worker has agency.

To sketch an outline, the technology requires an intervention of under { five minutes} per day. The worker keys in their code and has to tell the system to start recording by pressing the button. The worker can then see when the recording starts. After 8 seconds, the option to stop the recording is available, and after 15 seconds it stops on its own. The recording can be done anywhere and anytime. In order to comply with the two-step process required by the oil and gas industry fatigue standard ANSI/API 755 Recommended Practice, the worker is required at the first recording of the day or shift to also input their sleep/wake data, i.e. time to bed and wake up time. All subsequent interventions by the worker that day are just voice, and a smart

band or smartwatch can optionally be integrated into the system to automatically record and upload sleep/wake data to the WOMBATT reporting cloud at the start of each shift.

What makes it so effective based on what is available in the field, is that workers gain awareness of their developing fatigue levels. Then, they integrate this knowledge into their personal lives, making them more well-rested before starting work. WOMBATT has found in the field that as the AI becomes more knowledgeable about the individual user’s sleep characteristics over time, and becomes more and more accurate, workers adjust their sleep time. Where a worker has sleep deprivation, the technology feeds this information back to them and they increase their sleep times. WOMBATT has seen in the field a direct relationship between increased sleep times and lower fatigue alerts.

Huge potential in mining environments

WOMBATT-VOZ has a huge potential to enhance fatigue management in mining environments. It is a new generation of fatigue prediction solutions, different from products available on the market. Consequently, by predicting fatigue up to five hours ahead, the technology enables companies to make the most out of risk management and fatigue training.

Deployment

Verhardt shows how WOMBATT-VOZ is deployed, “Lack of sleep is almost always a choice. Of course, there are exceptions where workers have medical issues such as sleep apnea, or perhaps a new family member is keeping them up at night. However, for the majority of us, sleep deprivation and the resultant fatigue is, in fact, a choice. So, with this in mind, raising fatigue awareness already tackles a large part of the problem. We advise users to make a minimum of three recordings per day – the first at shift start to act as a fitness for work, the second during the middle of the shift to assess fatigue risk over the following 4-5 hours and the last as a fitness to drive home measure.“

Typically, most road accidents due to fatigue, for example, occur on the commute home. And so, by giving workers insights into their actual fatigue risk levels, WOMBATT-VOZ creates an awareness of fatigue risk among all employees using the technology which is just as important as a company’s role in fatigue management. This is considering that lack of sleep starts with the employee.

Success

Significantly, WOMBATT-WOZ has registered great success in the reduction of fatiguerelated risks. The technology has been running for four years in the field in multiple industries and both management and workers are impressed with the system’s accuracy in predicting the user’s fatigue risk level. Workers and unions especially appreciate the fact that workers have agency, in that users can decide when and where to make their voice recordings – they are not being continually observed or measured in real-time which is a major problem with all other existing fatigue detection systems.

WOMBATT has developed fatigue risk management protocols for monitoring the technology’s performance within companies. Fascinatingly, thus far, the team at WOMBATT have no records of fatigue incidents on the job. Recently, they received customer data on a reduction in safety incidents of 61% in processing mills since the installation of WOMBATT-VOZ, and customers have observed that fatigue risk within the shift decreases over time.

Significantly, an interesting and general finding has been that at the start of WOMBATTVOZ implementation at a site, sleep time is relatively lower with commensurate higher fatigue risk. In contrast, for sites that now operate the system regularly, there has been an increase in sleep time and a decrease in fatigue risk.

Regarding the data, Verhardt deduces, “In general, the risk reduction demonstrates that fatigue risk management as a predictive measure contributes to the overall safety of the worker. It allows workers to operate more efficiently and alert them to developing fatigue risk during a shift, keeping both them and fellow workers safe.“

WOMBATT recommends WOMBATT-VOZ to African mines. In addition, Emma Verhardt believes that with non-intrusion, worker agency and very high forward-looking accuracy, unions can easily support the system as well. “It is in everyone’s interest to ensure we all stay safe on the job.”

WOMBATT is an Australian-origin fatigue management company, with 25 years of worldwide experience in monitoring, managing and eliminating the fatigue of mining haul truck operators and road transport drivers.

6 Mining Business Africa |March - April 2024

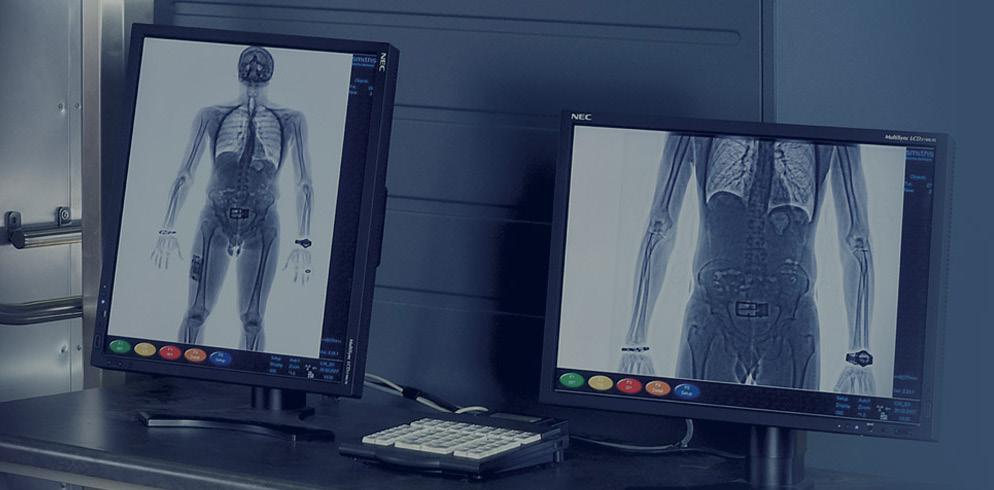

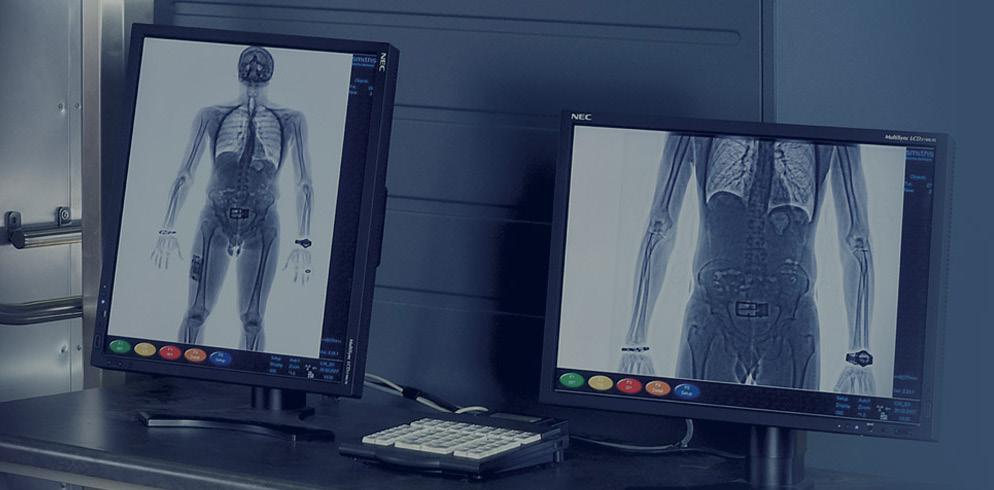

Body Scanner Solutions

Dual view X-ray Body scanner (BS16HR-DV)

For customers who place importance on the prevention of smuggling of precious metals and gems, the Full Body Scanner is an essential security tool. The new machine offers outstanding image quality of the entire body with high image resolution and a flicker free display making it an effective tool for the detection of; Precious stones (including diamonds) and precious metals, Contrabands and threat detection (weapons, explosives, narcotics, etc.), and Objects Concealed internally or externally.

Xscann Technologies boasts an inhouse developed X-ray Management Software (XMS)

Xscann X-ray management software (XMS) Includes: One-off software licensing, Matrix configuration for gender segregation, various access control integration (e.g., Babylon, Impro, Opto, etc.), Algorithm to ensure that personnel will not be subjected to radiation exceeding 1mSv per annum, Logging of personnel radiation data for archiving, Reports generator.

XMS reporting includes: X-ray totals by radiation, X-ray totals by name, Over quota individuals, Excessive entries, Excessive dummy scans, Excessive holds, Scan logs, search logs, etc.

Address: 6 Guernsey Drive, Longmeadow East, Edenvale, 1610

Tel: +27 11 608 1504 | Fax: +27 11 608 1570

Email: axel@xscann.com, charl@rdscreening.com, rudzani@xscann.com

Web: www.xscann.com | Partners: www.ceia.net; www.smithsdetection.com

Mining Business Africa

GLASSES WATCH

BELT

COINS CELLPHONE

Competent Operators, Reliable Results

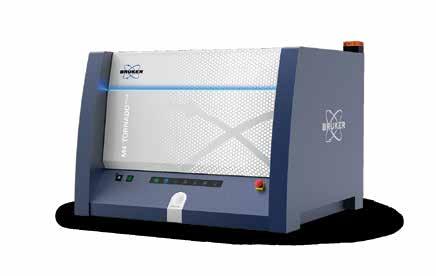

While the penetration of X-ray fluorescence (XRF) spectrometers has revolutionised ore sample analysis, it has not eliminated the need for best practice. Requisite operator competence has never been more critical to producing reliable results. This is what XRF specialist Maggi Loubser points out.

Advances in electronics and detectors, as well as software development, have made X-ray Fluorescence spectrometry seemingly effortless for the end user. As a result, XRF spectrometers, like other analytical instrumentation, have shrunk to such an extent that a geologist or operator can now easily have his own handheld XRF spectrometer with him in the field. As result, hand-held spectrometers have changed the game in mineral sample analysis.

Disruptive development

Hand-held XRF spectrometers have without any shadow of a doubt been one of the most disruptive developments in mining and exploration in the past decade. Suddenly the laboratory could be taken to the ore body without the

need to wait for long laboratory turnaround times. An exploration team can get an in-situ indication of the ore grade, and the mine operators on where a seam runs.

Not a magic wand

However, while handheld XRF analysers offer incredible convenience, the catch is that the physics behind the technique has not shrunk. The physics of XRF spectroscopy has not changed nor the statistics of representative sampling.

For all its wonders, a handheld XRF spectrometer is not a magic wand. It can only analyse that which you put in front of that sample aperture, and the X-ray photons making it to the detector are even fewer due to geometry, the density of the sample, matrix effects etc.

This suggests that if the operator (the person behind the instrument) does not have insight into how data is generated and what the limitations are, gigabytes of meaningless data can easily be produced. The operator needs the requisite competence.

The biggest challenge that arises is where previously a carefully calculated volume of sample, representative of the ore body/seam was sent to the laboratory, where its size was decreased through a carefully designed comminution process to produce a representative analytical aliquot still representative of the original bulk, now, the operator just analyses unprepared random direct measurements and expects the data to correspond to the laboratory results.

8 Mining Business Africa |March - April 2024 Hand-held X-ray Fluorescence (XRF) Spectrometers in Ore Grading

With Handheld XFR spectrometers offer the convenience of analysis at the right at the coal face of mining activity

Unsurprisingly, this is the reason why exploration geochemists have been and are still grappling with representative sampling since the 1950s when Pierre Gy (Gy P.M. 1976) published the first of his many works on the subject. (Esbensen 2014-2020).

Vital steps

Thus, there are vital steps that an operator has to follow to get reliable results from handheld XRF spectrometers. Worth mentioning are the following:

1. Comparison between in-situ to laboratory analyses

For this reason, it is essential to experimentally compare the uncertainty from in-situ analyses to laboratory analyses, then, combine it with a cost/ time benefit analysis, to decide whether the uncertainties are acceptable. Without practical evaluation of the results obtained in-situ, and an understanding of the uncertainties, the instrument is no more than a random number generator!

2. Increasing analytical accuracy

Fortunately, many steps can be taken

in the field to increase the accuracy of results a hundredfold in sample preparation. These include:

i. Grinding and homogenising samples

Grinding samples fine and homogenising samples cause an exponential increase in analytical accuracy. In the laboratory, the sample is ground to a fineness small enough for the longest wavelength photons (light elements) in a sample, to escape the sample with equal probability than a shorter wavelength (heavier element). Fortunately, today there is a lot of portable equipment used for the task. These vary from small manual crushers and mills operating with a small percussion drill and batteryoperated grinders, or an angle grinder with a capture vessel enabling one to cut through a rock and collect representative sample dust.

ii. Drying samples

Drying samples is another vital process. Samples are dried to eliminate the effect of moisture on absorbing long wavelength light elements. In the laboratory they are ignited to get rid

of volatile components like CO2 in a measurable fashion. This enables accurate recalculations of elements the XRF cannot determine due to their low atomic number, and followed by fusion to destroy the mineralogy and minimise matrix effects. In the field, a UV lamp can suffice in drying samples enough to make light element analyses more accurate.

iii. Optimal instrument calibration

To ensure the instrument is optimally calibrated for your specific matrix is crucial. Typically, the factory calibrations are executed with a wide set of matrices to cover as many matrices and large analytical ranges as possible, but at the cost of accuracy for a specific matrix.

Thus, it is crucial to evaluate the factory calibration on your material and use a slope and intercept adjustment with certified reference materials in your matrix, also called derivative calibrations. If your spectrometer has the ability, do a matrix-specific calibration on your material, or provide the factory with a set of reference materials in your matrix and ask them to do so at the time of purchase.

Mining Business Africa | March - April 2024 9

Hand-held X-ray Fluorescence (XRF) Spectrometers in Ore Grading

In addition, just as in a geochemistry laboratory, daily check samples are crucial to gauge the stability of an instrument. Typically, the sample window is often polypropylene, and it could be broken without anybody noticing, except that measurements will suddenly be much higher as the extra absorbing layer between the sample and detector is gone.

An instrument usually comes with a factory check sample, and this is important, because this data can always be compared to the factory commissioning data, but it is important to have a stable control sample including your elements of interest. This is even more important when a project uses multiple handheld instruments. In this case, you need a set of monitor sample data if you want to combine data from different spectrometers.

As a rule, handheld XRF spectrometers are incredibly robust and stable. Different from high-power systems, they do not decrease in sensitivity over time. Thus, when a tube or detector breaks, it breaks. The biggest agent of deterioration is operators who drop instruments or puncture detectors by pushing the instrument directly against protruding rocks.

iv. Application of matrix correction software

Ultimately, all these steps ensure that the sophisticated matrix correction software is applied effectively to give the most accurate results.

v. Determining a representative sample

A representative sample that is as accurate as possible must be determined. First of all, it is important to calculate how many in-situ analyses are necessary over a given area/volume to give representative results. Follow the same process as you would have done to determine your original carefully designed sampling plan for collecting material to send to the laboratory. Again, this involves taking the largest particle sizes, the density of the country rock, and the concentration of elements of interest into consideration. Compare these samples with laboratory analyses to calculate your uncertainty.

Selecting the right instrument

Plainly, it is critical to make informed

decisions when it comes to selecting instruments used for an application. Usually, the lower-power instruments are used for metal sorting or heavy element analyses where the fluorescence yield of the elements of interest is high. For accurate light element analyses (Mg –S), a silicon drift detector is an absolute prerequisite and some instruments now come out with graphene or equivalent detector windows that absorb less of the radiation coming from the sample leading to much higher sensitivity for light elements. For instance, Cl is a nightmare on a Rh tube instrument operated in an air atmosphere due to Argon peak overlap.

Higher-end instruments are calibrated with different power and filter settings for different parts of the periodic table and so all elements from Mg to U can be covered in three phases. Always ensure you have access to the manufacturer’s calibration tables to ensure your analytical range falls within the calibrated range, else a type of standard adjustment will be necessary to extrapolate the calibration maximum. Unfortunately, if you have a very unique matrix, a slope and intercept adjustment may not be enough to compensate for the difference in your material and the general factory calibration.

In a nutshell, there are several factors to be considered when determining the type of XRF instrument to be used for a sample, specifically:

• Always consider your application and the fact that the needs may change over time.

• Get the most robust instrument you

can afford with the most relevant factory calibrations you can afford.

• Ensure you can get good support and service from the supplier –often people buy less expensive instruments on the internet only to find out the manual is unreadable, and no local support is available.

• However, it is important to make the most of the convenience handheld XRF spectrometers offer. The most important issue is to commission your instrument properly before commencing any project. Do repeatability and reproducibility studies, test your sampling frequency, and test the accuracy against reliable laboratory analyses. Set up quality control protocols for each instrument and collect and store the data diligently should adjustments to data be necessary at a later stage. Remember, the spectrometer has no psychic abilities, it can only analyse that which the operator places in front of the analyser window!

Dramatic transformation of exploration geochemistry

From the foregoing, the main takeaway is that there is no question that handheld XRF spectrometers are probably the most exciting development in X-ray Fluorescence spectroscopy in the last decade. Since the silicon drift detectors were developed making light element analyses possible, this tool has transformed the capabilities of exploration geochemistry dramatically. However, the role of competent operators in producing reliable results has never been more critical.

Gy, P.M. 1976. The sampling of particulate materials – A general theory. International Journal of Mineral Processing, 3(4):289-312

Esbensen, K.H., et al. 2014-2020 Sampling Columns. Spectroscopy Europe Asia. https://www. spectroscopyeurope.com/sampling

Maggi Loubser is a Bruker-appointed Application specialist in South Africa and has 35 years of XRF experience and about 15 years of handheld experience. She consults intensively in the mining industry, especially handheld spectrometers. Currently she is based at the University of Pretoria.

10 Mining Business Africa |March - April 2024

How to OBTAIN™ Improved Throughput and Sorting Precision

Hard on the heels of the groundbreaking launch of OBTAIN™ at the Investing in African Mining Indaba, Stefan Jürgensen, Software Team Leader at TOMRA Mining, fields questions from Mining Business Africa. In the interview, he elaborates more on the value OBTAIN™ will add to X-RayTransmission (XRT) singleparticle sorting tasks in mining, and underlinesTOMRA’s commitment to supporting mining companies interested in the software.

MBA: On their own, TOMRA’s flagship X-Ray transmission (XRT), Near-Infrared (NIR) and Laser sensor-based sorting technologies ostensibly have been working perfectly, breaking milestones in recovery. Why has TOMRA decided to tap into deep learning through OBTAIN™?

SJ: TOMRA is continuously evaluating new technologies that can further advance sensorbased sorting. We strive to offer the most sensitive and robust sensors, the most energyefficient and precise ejection systems, and the most advanced and reliable data processing technology. Although the current hype about large language models directs the most attention to human interaction with AI, there are unique features of the Deep Learning approach that perfectly augment our current XRT sorting technology to enhance throughput without compromising sorting quality. OBTAIN™ adds an extra layer of intelligence.

MBA: Does the introduction of OBTAIN™ suggest there are inherent limitations with the capabilities of AI-powered XRT, NIR and Laser sorters? Please elaborate.

SJ: Innovation is a continuous journey: over the past three decades, TOMRA has been

at the forefront of developing cutting-edge sorting solutions for mineral processing. Every new generation of sorters has built upon the foundation of its predecessors, incorporating advancements in technology, efficiency, and accuracy. With the introduction of OBTAIN™,

we are once again pushing the boundaries of what is possible in sensor-based sorting. We are maximising resource utilisation and promoting sustainability.

MBA: Demonstrate how the software, through data from deep learning, can bring single-particle precision to high-throughput particle sorting.

SJ: Single-particle sorters generally need not consider the interaction between neighbouring particles in material streams. This approach allows for precise analysis of each particle’s properties and can increase the accuracy of the sorting decision, but at the cost of a throughput suitable only for laboratory-scale applications. With OBTAIN™, TOMRA bridges the gap between precision and throughput. We use Deep Learning to apply knowledge about particle characteristics that enable the same type of analysis used for single-particle sorting at throughput rates of tens of thousands of particles per second, even when particles are clustered.

MBA: We notice that, despite the hype about AI, which is almost akin to religious fervour, TOMRA has been leveraging this groundbreaking technology since 1993. How does this experience help

12 Mining Business Africa |March - April 2024 Ore Sorting Software

Albert du Preez, Head of TOMRA Mining

Tomra’s COM XRT 2.0 Sorter installed

TOMRA’s R&D team when devising solutions?

SJ: Artificial Intelligence (AI) is a vast scientific domain, with numerous conferences each year, even for small subtopics within the field. Like most technologies, AI lacks a universal “Silver Bullet”; instead, there are many different approaches for its implementation and utilisation. Furthermore, today’s sensor-based sorters feature sophisticated multi-staged data processing pipelines.

TOMRA’s substantial experience in the field of AI and its application to sensorbased sorting, and the collaboration of our teams of experts allow us to select the most suitable AI technology for each part of our processing pipelines. OBTAIN™ represents the convergence of cutting-edge technology and decades of expertise.

MBA: How does a mine incorporate OBTAIN™ into its existing TOMRA ore sorting process? How is the team responsible at OBTAIN™ involved?

SJ: TOMRA assesses the benefits of using OBTAIN™ for the mine’s sorting needs and offers OBTAIN™ upgrade packages if they are advantageous for the mine. These packages enable seamless integration of OBTAIN™ into the mine’s existing COM XRT sorters. The process of installing OBTAIN™ is straightforward and can be carried out by any trained TOMRA Service technician. All new COM XRT sorters are ready for OBTAIN™ as an optional feature.

OBTAIN™ can improve the performance of TOMRA’s COM XRT sorters in throughput and sorting quality. The achievable improvements depend on many factors like the feed stream’s PSD and other site-specific requirements. Therefore, we recommend getting in touch with our Sales representatives. In our Test Center, we can determine in which way OBTAIN™ can be put to best use for each COM XRT sorter.

MBA: In a nutshell, how do mining companies benefit from adopting OBTAIN™ in sensor-based ore sorting processes.

SJ: By implementing OBTAIN™, mining companies achieve consistent performance from sensor-based ore sorters across a wide range of throughput. This flexibility allows them to either process more material or improve sorting quality. Additionally, the statistical data collected from the sorted material streams becomes more accurate.

MBA: Last but not least, TOMRA always sees a lot of opportunities in the African mining sector. What are your plans to serve this lucrative market with revolutionary sensorbased ore sorting technologies in 2024?

SJ: At TOMRA, our commitment is to deliver top-tier sorting technology to the African mining industry. We continually strive to innovate in sensor-based sorting, and we are already preparing to unveil exciting new features.

Mining Business Africa | March - April 2024 13

Stefan Jürgensen

Tomra’s COM XRT 2.0 sorter

Identifying New Opportunities

The Industrial Valve Summit (IVS), one of the biggest showcases for the global valves sector, is scheduled to take place in Bergamo, Italy from 15 to 16 May 2024. Mining Business Africa (MBA) finds out from Luca Pandolfi, Industrial Valve Summit (IVS) Project Manager, about what is in store at the event amidst groundbreaking advances in valve technology.

MBA: Various players in the industry are looking forward to the Industrial Valve Summit (IVS). Looking back, what do you particularly consider as milestones of the IVS postCovid-19 pandemic, in terms of attendance numbers and diversity of participants (exhibitors)?

LP: Despite the international travel restrictions and the delicate global scenarios that were taking place in 2022, the fourth edition of IVS drew a record 12,000 visitors from over 60 countries, as well as almost 300 exhibiting companies. This was an increase of 17% compared to IVS 2019.

Two years ago, we saw a drop in registrations from the Far East countries. However, we expect that the Summit edition, which is just around the corner, will have many more operators from this geographical area participating. The growth trend was

noticeable from the very first moments of the exhibition.

The third edition of the Summit attracted over 250 companies and 10,800 visitors to Bergamo. This was 36% more than the 8,000 attendances recorded in 2017. Further back, the number trebled in comparison with the 3,500 accesses recorded in 2015.

Generally, this data indicates how IVS has consolidated itself as an essential event for the entire global supply chain connected to industrial valves and flow control.

MBA: What is the relevance of the event to valve and flow control companies targeting the Middle East and Africa (MEA) region?

LP: The MEA markets represent a very dynamic scenario for the valve and flow control industry, and international

companies are attentive to the opportunities in this area. On the one hand, the Summit will attract important players from the UAE, Saudi Arabia, and the Persian Gulf in general. On the other hand, IVS will represent the stage on which to intercept the major projects in the Oil&Gas field under development in the African continent, including, for example, Nigeria and Mozambique.

MBA: What should we look forward to the IVS May 2024 on the programme’s schedule?

LP: The Summit organisers, in collaboration with VALVEcampus (the event’s scientific partner), have unveiled the IVS 2024 conference calendar: a total of 46 conferences, round tables, workshops, case studies and laboratories, for a more than onethird larger plan compared to the 34 in-depth technical sessions offered at IVS 2022. The programme is structured

14 Mining Business Africa |March - April 2024 International Exhibition & Conference on Valves & Flow Control Technologies

2024

around eight macro-themes: additive manufacturing; digital technologies applied to valves, actuation, and control; sealing and fugitive emissions; valve design and materials for severe services; standardization and standards development; supply chain management; AI applied to mechanical design, procurement and manufacturing; energy transition, carbon capture utilisation and storage. These are complemented by round tables discussing hydrogen, analysing market trends, the Corporate Sustainability Reporting Directive (CSRD), greenhouse gas management and other topics.

MBA: Tell us about new participants with new specialities bringing new dimensions to the event.

LP: The market specialities of the new exhibitors reflect the topical themes on which the industry is identifying new opportunities. These are hydrogen, Carbon Capture Utilisation and Storage and the large-scale distribution of water resources, such as dams and aqueducts.

MBA: Specifically, is there anything related to machine learning AI and machine learning in valves and flow control?

LP: IVS 2024 will have a special area dedicated to artificial intelligence. Exhibitors involved in IA applications in the field of valve production and utilisation will have the chance to exhibit their products and services in a special dedicated area. They will present speeches, company presentations and workshops during IVS.

The ongoing development of AI opens the valve supply chain to new possibilities and renewed

operating models. Noteworthy, the rapid integration of technology into the industrial organisation already represents a competitive advantage for companies in the industry.

MBA: Last but not least, what is the relevance is the IVS 2024 to the global supply valve and flow control supply chain?

LP: IVS has taken on a central role within the sector, generating increasing interest from the industry. The Summit has become a point of reference for EPCs, end-users and technology manufacturers, all of which consider the event much more than just an exhibition. In addition to being a key event in business development, IVS is an international meeting place to read and interpret change, identifying and analysing the challenges of the entire supply chain. IVS offers the opportunity to meet the major players in the global supply chain and to forge new business relationships. Last but not least, it provides an opportunity to delve into technological innovations and examine market evolutions and socio-economic macro-trends.

The KSB GIW® MDX pump line delivers proven results in the harshest hard rock mining applications.

Mining Business Africa | March - April 2024 15 GIW® MDX = BEST IN CLASS MILL CIRCUIT PUMP W: www.ksb.com/en-za T: +27-11-876-5600

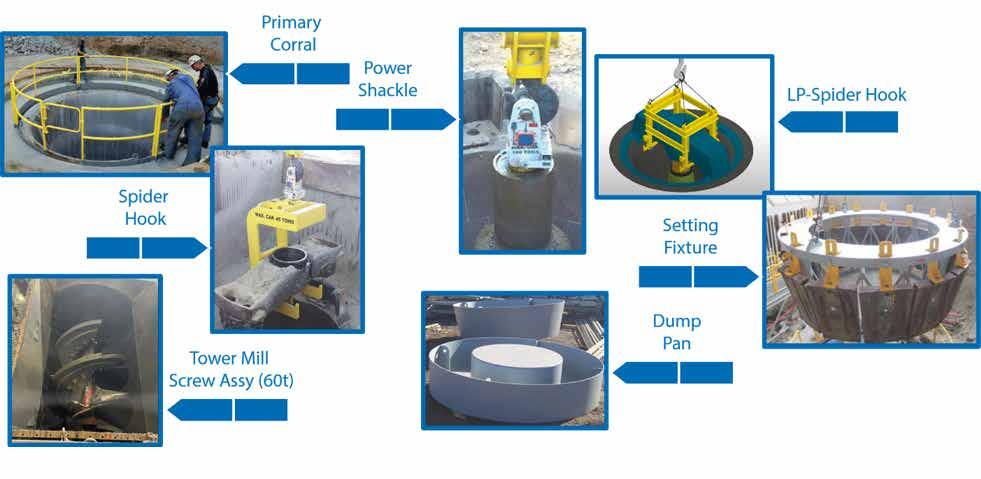

ME Elecmetal’s integral solutions to improve your production strategies and productivity goals

Take on the unique challenges at your mining operation and positively impact priority KPIs.

ME FIT System is our integrated solutions program for large mining operations. It focuses on creating value for mining processes by quantifying the impact of their solutions while improving key productivity indicators in mineral extraction and processing. Our ME FIT program solutions are made possible through mutual collaboration between our clients and the ME Elecmetal multidisciplinary team. By having an in-depth understanding and knowledge of each site’s operational issues we are able to positively impact their priority key performance indicators: productivity, reliability, availability, safety, efficiency and / or energy consumption. We align with the priorities of our customers, positioning ME Elecmetal as a true strategic partner in mining.

Products and Services that Make a Difference

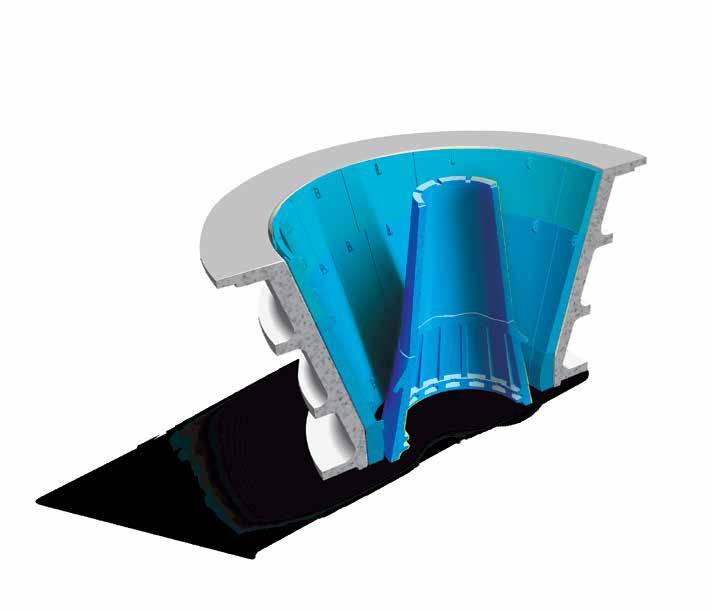

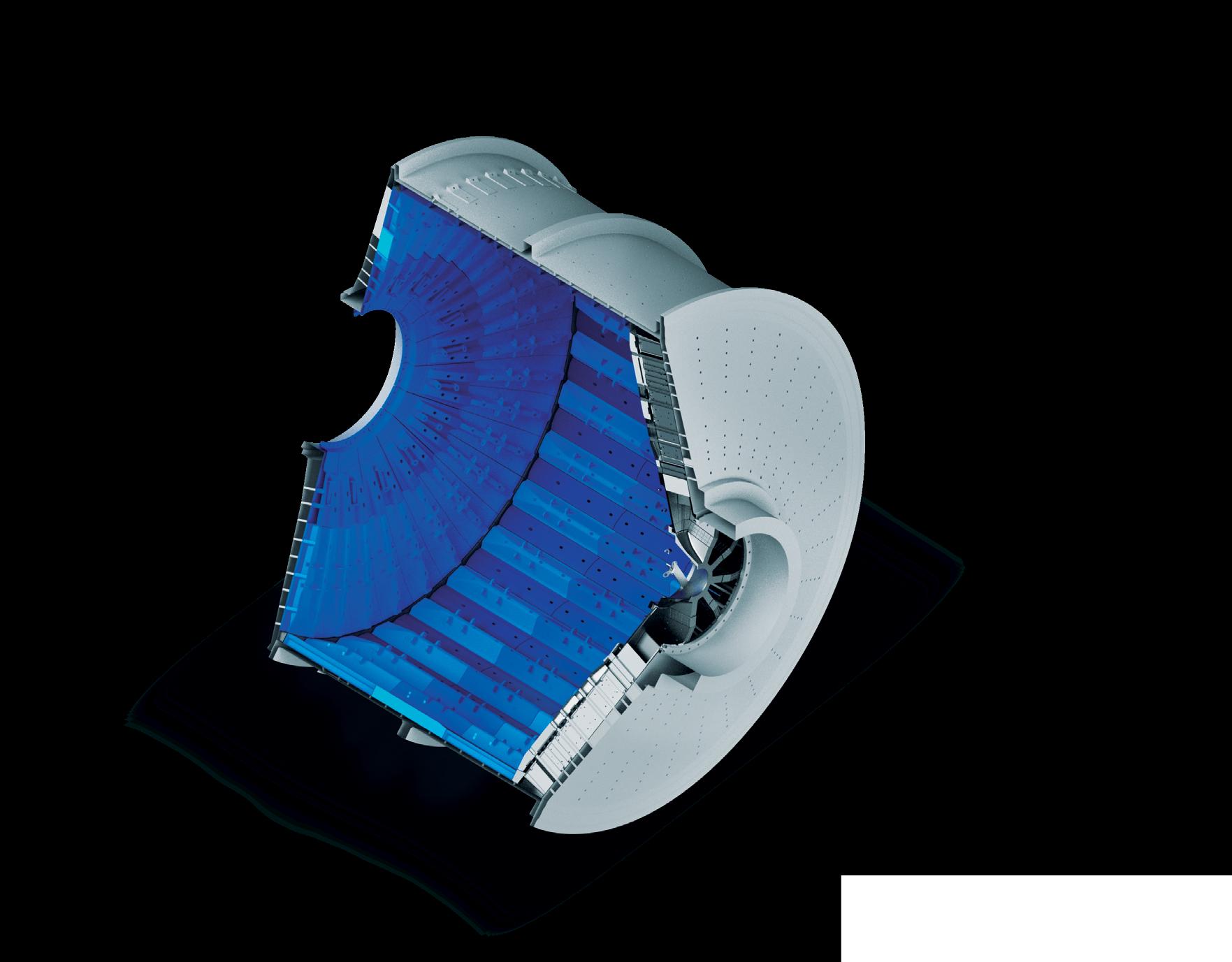

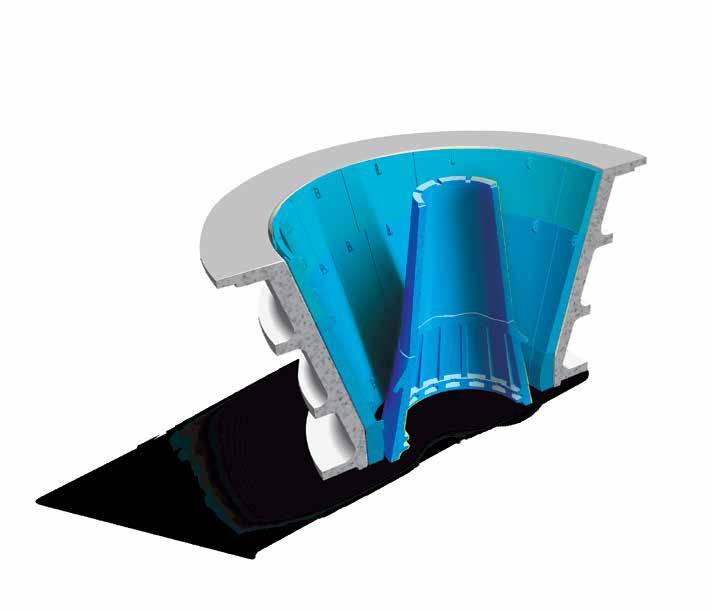

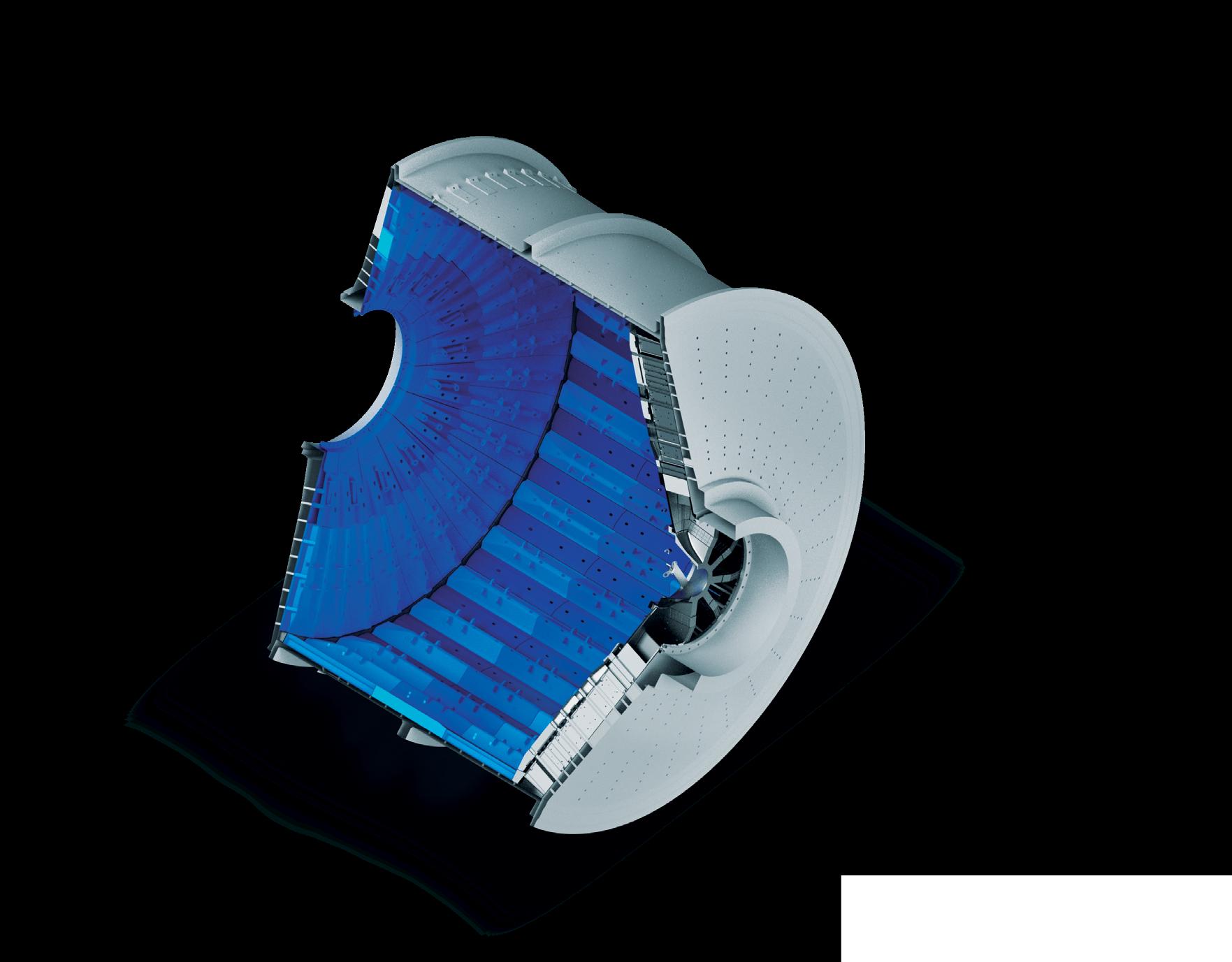

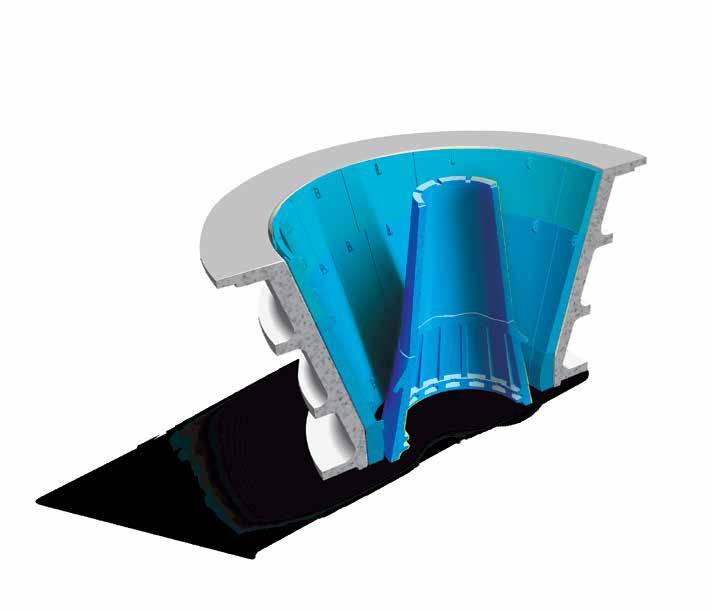

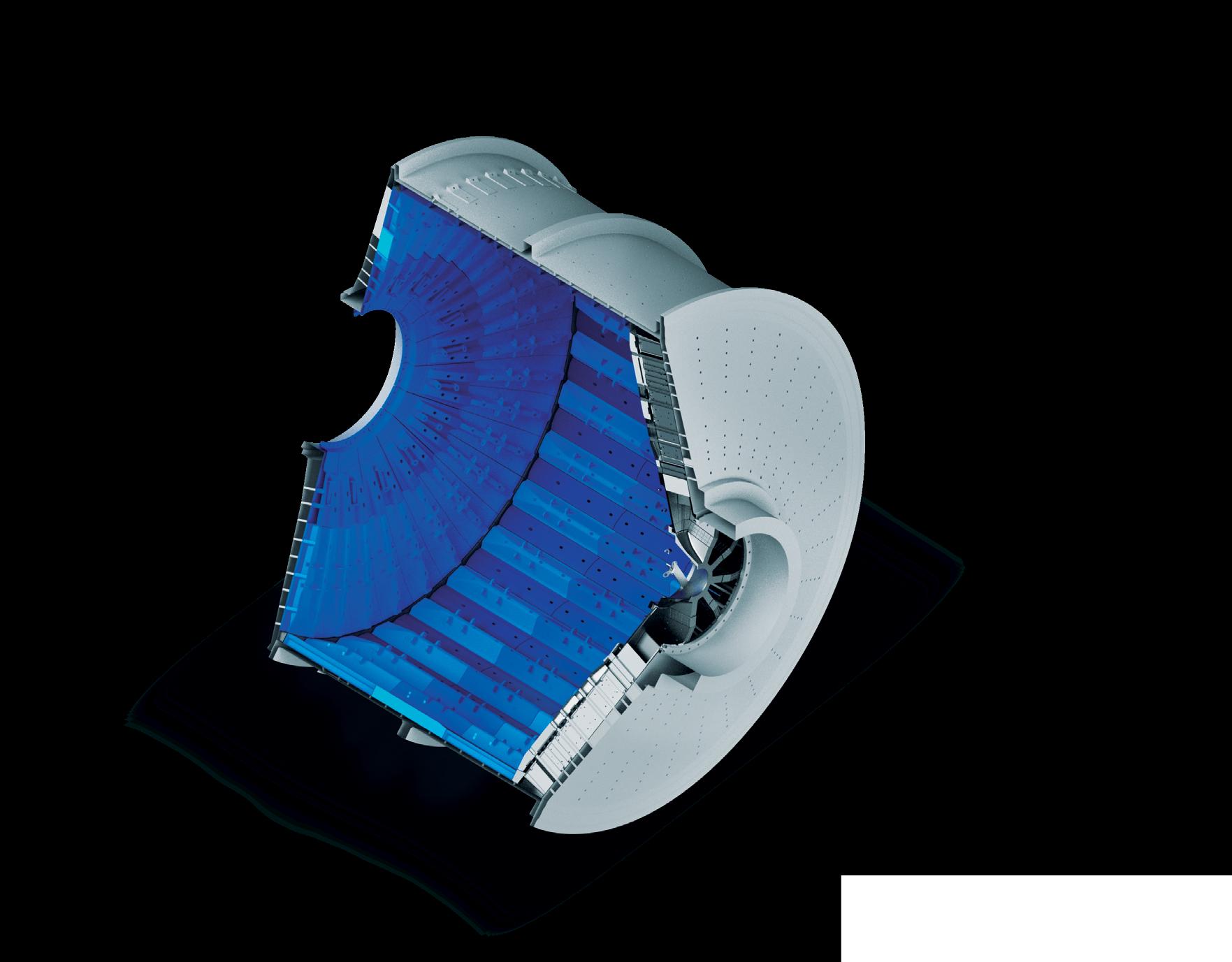

Mill Liners

Grinding mill liners are subjected to severe impact and high abrasion. They must be manufactured using the best technologies and designs for superior strength and durability. That is why we make sure we offer customers the best possible solutions for every challenge and mill type.

ME Elecmetal analyzes customer operations to determine the ideal combination of design and materials to achieve the optimal performance of their equipment. Whether it is an AG, SAG, ball, tower or rod mill, our innovative liner and alloy designs deliver proven performance, while minimizing costly reline and downtime. We collaborate closely with operators and

plant maintenance crews to monitor wear performance and production rates, customizing each liner for the best possible performance. All variables are considered in this analysis — from the characteristics of the ore and the customer’s operative strategies to their production goals. We identify opportunities for improvement and adapt to challenges as they arise to offer solutions that exceed customer expectations.

Our liners are manufactured according to the highest quality standards and state-of-the-art technology and engineering, resulting in the most reliable, lowest total-cost-of-ownershipsolutions for our customers.

Grinding Media

ME Elecmetal designs, manufactures, and supplies the highest quality forged steel grinding media for SAG and ball mills in the world. Our

16 Mining Business Africa |March - April 2024 Mill Lining Solutions

extensive field experience, engineering and consulting expertise enables us to accurately analyze operational data, so we can support our customers to achieve continuous improvement in their grinding processes. The process begins when we deliver the grinding media to your site and ends when your final product exits the mill.

Our experience and large-scale grinding media production capacity have positioned ME Elecmetal as a strategic partner in the global mining market. Our experienced and knowledgeable sales and application engineers can help you monitor and improve your processes by collecting and analyzing operating data, improving media charging practices and offering solutions to optimize your grinding media consumption and improve throughput.

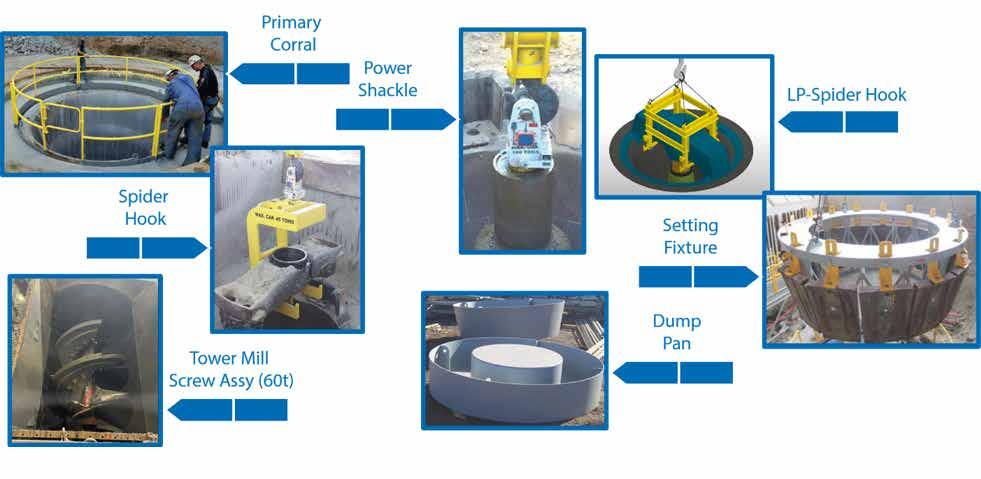

Crusher Wear Parts and Safety Tooling

ME Elecmetal is the leader in offering wear solutions to crusher operators. We provide wear parts for primary, secondary, and tertiary crushing applications for the mining, aggregate and recycle industries with optimal designs and alloys specifically developed for each

application. We will help tackle any customer challenge, while striving to maximize the benefits we provide. We can adapt to any type of equipment customers may have on site.

With a focus on safety, durability, and easeof-use, ME Elecmetal also offers a full line of Crusher Safety Tooling products designed to help you get the job done safer, faster, and smarter! Our products include:

• Primary corrals

• Dump pans

• Setting fixtures

• Crusher nuts

• Power shackles

• Spider hooks

• Customized solutions

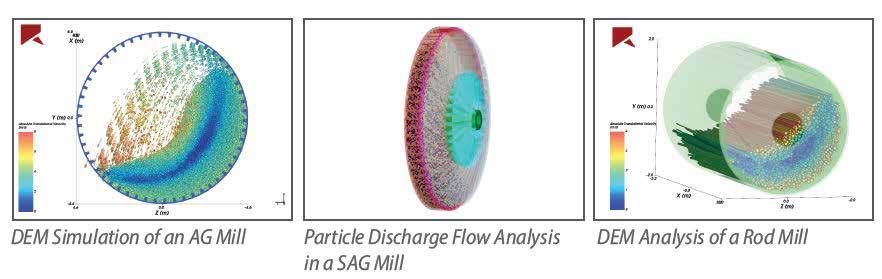

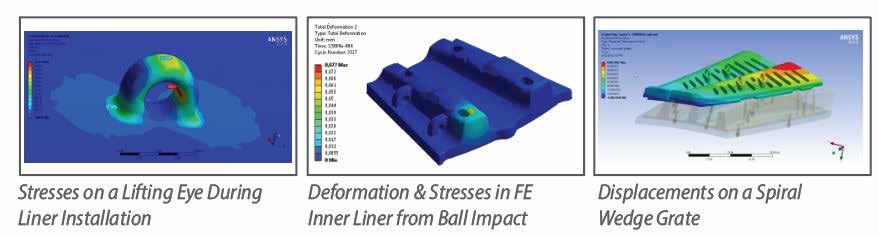

Optimization Tools and Services

There is an increasing demand in the mining industry for technology capable of optimizing processes, equipment, and performance. ME Elecmetal believes there is always room for improvement. We focus on delivering tailormade technology solutions for grinding and crushing applications, with a complete offering

of optimization tools, including wear monitoring, to further improve efficiency and provide our customers with timely information.

ME Elecmetal’s technical support and training goes beyond standard services offered by other suppliers. These services include DEM and FEM simulation services, 3D laser scanning for wear analysis, reline optimization, continuous improvement programs, grinding circuit optimization, and more.

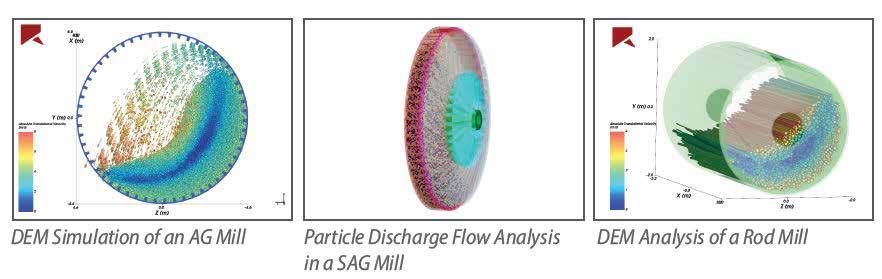

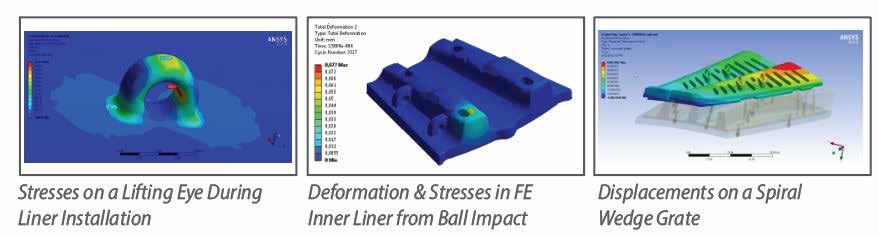

3D DEM Simulations FEA Simulations

Load levels, water percentage, speed, liner design, ball mill size and bolt torque are some of the variables that come into play, and digitization allows these variables to be addressed individually, or in combination to gain a better understanding of the operation.

Contact Us Today!

For more information on ME FIT Solutions and to learn more about how ME Elecmetal can help you optimize your mining processes, visit www.meelecmetal.com or call 480-730-7500

Mining Business Africa | March - April 2024 17

Enhancing the Mining Production Cycle with Loadscan®

Loadscan® is an advanced LiDAR volume scanning and measurement system supplied by SITECH SA (Pty) Ltd

Ensuring profitability, efficiency, and safety in mining operations relies heavily on accurate payload monitoring. However, conventional load monitoring methods are susceptible to errors - leading to financial losses, equipment damage, and safety compromises.

The Loadscan® Mine Payload Scanner (MPS)

SITECH SA addresses these challenges with the Loadscan® Mine Payload Scanner (MPS). This advanced payload monitoring solution utilises the

latest LiDAR technology to optimise truck loading, reduces the cost per ton of hauled material, increases profits, and improves productivity.

The scanner employs state-of-the-art LiDAR lasers, coupled with proprietary software, to precisely measure the volume of material loaded into a truck with an operating accuracy of ± 1%.

The process involves scanning the empty truck to create a reference scan in the database and then re-scanning the loaded truck to measure the exact volume of the hauled product.

The Loadscan mining software provides real-

time reports on volumetric measurements and creates 3D load profiles, allowing identification of underloading, overloading, off-centre loading, or carryback of material. This information enables prompt corrective actions to be taken to optimise loading cycles and improve operator efficiency.

Benefits of LiDAR-based payload monitoring

When it comes to LiDAR-based payload monitoring, there are some immediate benefits that the Mine Payload Technologies (MPS)

20 Mining Business Africa |March - April 2024

Monitoring for Mining Operations

Payload

Payload Monitoring for Mining Operations

brings. The LiDAR-based scanner uses eye-safe technology, it doesn’t require human contact to operate, there are no ongoing calibration costs needed, and it provides load data to an accuracy of ± 1%. Along with this, there is a wide range of long-term benefits that a mine payload scanner brings with it. These include:

• Real-time monitoring and reportingUsing Loadscan’s secure cloud-based MyScanner data management system, a 3D scan is created for every truck coming in or out of the site. These scans can be used to educate loader operators to prevent overloading or off-centre loading, ultimately enhancing trucking cycles.

• Truck bunching occurs when heavily loaded trucks become slower up ramps, holding up other trucks and creating bottlenecks in production. By ensuring trucks aren’t overloaded, you are also ensuring your mine is running efficiently.

• Avoiding carryback to improve operations

- Mine operations are often hindered by carryback as it has a serious impact on productivity, shift tallies, and the number of manual data entries required. By scanning all of your loads with the Mine Payload Scanner, carryback out of the mine is accounted for and can be deducted from shift tallies, improving the accuracy of actual loads shifted.

• Improving health and safety by reducing off-centre loading -This is a difficult issue to identify and quantify on a mine site as both overloading and carryback, along with uneven loading, feed into this problem. However, this doesn’t negate the fact that uneven load distribution adds stress to trucks’ components, reducing their working life and adding substantial costs to your operation. Using

Loadscan’s 3D scanning technology, offcentre loading is calculated and reported within the four quadrants of the truck bin. Truck drivers are then notified by an LED message board and can take corrective action. By reducing both overloading and underloading, the MPS minimises wear and tear, improves production efficiencies, and identifies carryback issues, enhancing the accuracy of actual loads shifted.

• Enhanced Portability and Customisation

- Loadscan’s Mine Payload Scanner (MPS) stands out for its exceptional portability and adaptability, seamlessly integrating into diverse sections of both surface and underground mining operations. This dynamic capability allows the MPS to be strategically relocated and customised to key areas such as transfer tips, shaft bottoms, hoisting shafts, waste- and ore stockpiles, backfill- and rehabilitation sites, and loading bays. Whether tracking truck loads from the critical phases of material transfer (mine-to-plant) or optimising efficiency in stockpile management, the MPS ensures real-time monitoring and reporting. The flexibility and mobility of the MPS empower mining companies to tailor its deployment, maximising its impact on various phases of the mining process.

Case studies of Mine Payload Scanner

In a real-world application, Aeris Resources’ Tritton copper mine in NSW experienced a 9.7% increase in trucking factor after installing a Loadscan® system in 2022. The decision was driven by consistent inaccuracies in previous payload measurement systems and limited forward compatibility with truck fleet upgrades.

A recently released report on the economic benefits of load volume scanning in underground mining further underscores the value of Loadscan’s technology. The study —

UNDERGROUND MINING; Economic benefits of load volume scanning of underground mining trucks — was conducted over seven months at a Central Queensland underground gold mine and revealed issues such as carryback, excessive fuel consumption, and under-utilisation of equipment contributing to unnecessary operating costs and lost revenue.

The study showed that the average load on all trucks could be considerably improved by addressing underloading. This would not only improve loading cycles but also reduce fuel costs, both of which considerably impact profitability. In this case, an increase of just 10% in the average load would be valued at ± $1 million per annum.

Loadscan and SITECH SA

Over 20 years ago, Loadscan invented and patented the original load volume scanner, and since then they have been the market leader in providing certified, accurate and reliable load information. In 2021 the company created Mine Payload Technologies, a specialist mining division within the company, to deliver deeper insights and added value to the sector.

SITECH SA is the sole supplier of Loadscan solutions in the African region – providing the latest technologies to the mining- and construction industries, resulting in dramatic improvements to productivity and efficiency through all stages of the production cycle.

For more information, visit www.sitech.co.za/loadscan/

22 Mining Business Africa |March - April 2024

Telematics in Mining: a Game-changing Collaboration

Available from MiX Telematics, MiX Fleet Manager Premium comprises a sophisticated onboard computer that collects and transmits valuable vehicle and driver data.

In the ever-evolving landscape of the mining industry, the integration of digital technologies has become imperative. However, the industry’s unique challenges make achieving seamless connectivity a formidable hurdle. As mining ventures delve deeper into this digital realm, the complexity of managing diverse data streams continues to escalate.

From extraction to distribution, telematics can manage every aspect of a company’s assets including lighting towers or generators, right through to heavy vehicles like trucks, buses, and state-of-the-art machinery in mines. Mining managers are focused on keeping assets and personnel safe, ensuring constant access to their full fleet by regularly scheduling maintenance, achieving their green goals by lowering their carbon footprint, lowering their operational costs, and improving their bottom line.

With a focus on key performance indicators (KPIs), MiX Telematics provides technology aimed at elevating mining capabilities, allowing mining companies to connect their business with a single, integrated platform that monitors equipment, assets, and fleet vehicles through vehicle and video telematics.

Our flagship solution, MiX Fleet Manager

Premium, comprises a sophisticated onboard computer that collects and transmits valuable vehicle and driver data. Driver behaviour, performance, fleet locations, engine diagnostics for preventative maintenance, and optimised route planning are tracked and monitored to aid a business in improving productivity & efficiency. The solution also tracks a range of connected metrics in real-time, improving asset utilisation while reducing operating expenses. This pre-emptive information gives site managers full visibility to all areas of their operations; equipping them with the data to continuously improve efficiency and performance.

Advancements in AI-powered technology have enabled the utilisation of video telematics in mining. The MiX Vision Al dashcam solution uses advanced machine learning to monitor risky driving behaviours and fatigue that could lead to fatal accidents. The camera solution, coupled with the tracking solution offer data and controls so that when incidents do occur, there is a trail of evidence to facilitate investigation, resolutions, and further corrective actions.

Moreover, MiX Telematics has embraced newer technologies to introduce modern solutions for data access and visualization. These include embedded dashboards, PowerBI

for self-service analytics, and MiX Integrate for raw data retrieval. MiX KPI Manager leverages powerful fleet data, offering customisable self-service analytics to track performance on key issues affecting (mining) fleet risk, safety, efficiency and sustainability.

The mining sector is also particularly sensitive to the impact that operations can have on the environment, and it’s our objective to demonstrate the efficacy of telematics to improve not only the health of employees on-site but to help companies reduce carbon emissions and achieve sustainability targets. “Additional benefits of telematics solutions in mining include optimised onsite communication, task and journey management, driver behaviour and performance monitoring, improved driver and employee safety, improved site, vehicle, and asset safety,” says Henry Smith, Fleets Sales Director at MiX Telematics Africa.

“From a MiX Telematics perspective, the solutions offered are refined and developed continuously to meet customer demand. As technology develops and becomes more accessible and affordable; the (mining) industry is realising the added value of telematics solutions” concludes Smith.

Mining Business Africa | March - April 2024 23 Fleet Management for Mining Operations

ESG Reporting for Mining Operations

Effective Reporting, Enhanced Performance

The surefire way through which African miners can be ESG compliant is by using reliable reporting tools

Acid mine drainage is one of the sticky issues that ESG reporting highlights

Currently, there are ongoing exploration and mine development projects to meet the demand for critical minerals to drive the green energy transition in Africa. One of the vital aspects central to their implementation is the integration of Environmental Social Governance (ESG) reporting compliance into core pillars and strategies of the respective players. Based on the mission statements of major listed mining companies active on the continent, it seems the companies involved are pulling all the stops to meet set targets.

However, one may ask: In light of these efforts, how effective are their well-intentioned efforts?

One of the biggest worries is the effectiveness of reporting techniques mining companies use. This is considering that the process entails collecting loads of data from different departments on various ESG aspects to meet the expectations of executives, the board of directors, investors, and the rating agencies.

Unfortunately, manually handling the maze of data required is complex and highly susceptible to error. This can result in mining companies falling short of expectations in ESG reporting. Thus, there is a solid business case for the adoption of new techniques to streamline data processing.

Solid business case

At the Investing in African Mining Indaba 2024 in Cape Town ESG was discussed at length, just

as the previous year’s event. At the end of the deliberations, one crucial aspect emerged: The solid business case for the use of effective ESG reporting tools to enhance performance.

Sabine Anderson, Principal Mining Engineer at SRK Consulting in Cardiff, United Kingdom, was a key member of the global SRK Consulting team at the Mining Indaba in Cape Town. Prominently, she highlighted a palpable shift from risk mitigation to value creation in ESG.

Cognisant of ESG’s value, corporates are integrating ESG considerations into decisionmaking and operations. Conspicuously, there is a recognition of the link between ESG performance and financial value.

Mining entrepreneur and SSC Group founder, Fred Arendse, touched on ESG as a key factor in accessing capital during a panel discussion at the Investing in African Mining Indaba 2023 (ESG Risks in the Mining Sector). “ESG has an impact on financing, whether through equity or debt. Globally, ESG has risen to the top of the regulatory agenda with the result that for financiers, ESG is unequivocally measured with defined environmental, social, sustainability, and governance systems of measurement resulting in the coined phrase, “sustainable finance.”

More scrutiny than ever

Small wonder, stakeholders are scrutinising mining companies more than ever. There is immense

pressure on companies to substantiate their performance in alignment with their commitments, Anderson pointed out.

Markedly, stakeholders no longer take ESG reports presented at face value. Appreciating more of its value, they are asking ‘tough’ questions.

Nomsa Mbere and fellow partners at Webber Wentzel, a law firm servicing clients in African mining, noted this in an article (Mining companies need to watch ESG-related risks in 2023). They said stakeholders demand transparency from mines and their holding companies, particularly those operating in conflict-sensitive or conflictaffected jurisdictions). Coming to mind is cobalt, a critical mineral for Lithium-Ion battery manufacture, mined in the DRC under atrocious conditions, resulting in large-scale environmental devastation.

Reliable report

Plainly, given the above scenarios, collecting and processing data has never been more important, as Arendse explained during the panel discussion in 2023: “The qualification and quantification of environmental, social and governance (ESG) risks and uncertainties across the mining lifecycle continue to gain more prominence and relevance in the business world.” For African mining operations, the importance of using reliable reporting tools cannot be overstressed.

26 Mining Business Africa |March - April 2024

• The Industry’s largest stock inventory to suit leading crusher brands

• Mining grade premium manganese and alloy crusher liners

• Expert Technical Support and Unrivalled Customer Satisfaction

• Global Reach - Supplying Worldwide

At CMS Cepcor ®, we are dedicated to providing you with high-quality crusher parts and service. With decades of experience, we have earned our reputation as the leading aftermarket supplier. Whether you operate a quarry or a mining operation, trust CMS Cepcor ® to keep your crushers running smoothly.

AUTHORISED CMS STOCKIST - AFRICAN CRUSHERS AND LINERS Contact - admin@africancrushers.co.za / +27 76 991 7438

THE CRUSHER PARTS SPECIALIST

Unlocking Capital and Mitigating Risks

The Team from Onyen demonstrated the capabilities of the firm’s AI-driven reporting system at the Investing in African Mining Indaba 2024. Encouraged by the rave reviews, they are confident the solution will shake up ESG reporting in African mining as players position themselves to participate in the green energy transition. Onyen is a Canadian-based and globally-focused provider of ESG reporting software to organisations in mining and other sectors.

Alot is said about the risk that Environmental, Social and Corporate governance (ESG) factors pose for miners. But perhaps most downplayed is that it represents an opportunity to create long-term value for stakeholders.

The reality is that sound Environment, Social, and Governance (ESG) reporting will be pivotal to the success of the exploration and development of critical minerals in Africa. Hence, it is paramount that organisations involved utilise tried and tested reporting tools.

Canadian-based and globally focused, Onyen informs players in African mining that its AIdriven reporting solution eliminates the burden of compiling relevant data related to vital factors in ESG inherent in traditional reporting methods.

Showcased at the Investing in African Mining Indaba for the second time (the first was in 2023), the solution could not have come at a more perfect time. ESG landscape is shifting to keep abreast of changes in the mining business.

Markedly, it has dawned on miners that a good ESG score is not just about ticking the compliance boxes. More importantly, it is about earning stakeholder trust and facilitating access to capital. Ernst & Young Africa’s strategy and transactions leader, Quintin Hobbs, pointed this out at the Investing in Mining Indaba 2024 during

a presentation (Mining Risks and Opportunities Study).

Hobbs underlined the growing role of ESG credentials in attracting significant capital investment in new mining projects. “Major mining houses are reassessing business models to better address capital risks and opportunities. Companies’ continued capital discipline is “reaping rewards” for shareholders and broader stakeholders.“

Furthermore, Hobbs noted that organisations specialising in critical mineral projects have the edge.“The issue of capital raising is attracting more attention, with capital markets recognising the key role critical minerals will play in the energy transition.“

And so, to attract capital to their projects, exploration and mining companies must improve their ESG performance. The rule of thumb is: ‘the higher the ESG performance, the better the prospects of accessing capital’. It is not surprising that investors are finicky about forthright and impactful reporting.

Clearly, mining companies must utilise inventive solutions that not only fulfil compliance mandates but also facilitate capital acquisition and risk mitigation.

28 Mining Business Africa |March - April 2024

Filling the gap: Onyen’s AI-driven reporting system

Onyen’s AI-driven reporting system fills the gap in the need for forthright and impact reporting. Emerging as a ‘game-changing solution’, it provides a distinct advantage for mining companies to navigate the evolving ESG landscape.

Beyond compliance

The team involved in the software is confident that the reporting system will enable miners to achieve more than compliance, particularly in the following ways:

1. Cutting-Edge Artificial Intelligence: Revolutionising the Power of Data

Typically, ESG reporting entails compiling data from different departments located at various locations. Onyen’s ESG reporting is very convenient for performing this task.

Through utilising cutting-edge artificial intelligence, the core of Onyen’s ESG reporting has revolutionalised the task of processing and analysing vast amounts of data. In particular, by capitalising on the capabilities of AI, Onyen ensures comprehensive and accurate data collection.

In this way, organisations can generate meaningful insights into their ESG performance. Ultimately, this not only facilitates compliance with the latest standards but also proactively addresses emerging sustainability trends, perfectly positioning them for long-term success.

2. Access to Capital: A Strategic Imperative

As highlighted at the Investing in African Mining Indaba 2024, access to capital is intricately linked to a company’s ESG performance. Onyen’s AIdriven reporting system provides an advantage in this regard. Not only does it simplify the reporting process, but also amplifies the credibility of disclosed information. The ensuing heightened transparency resonates positively with investors. This increases the likelihood of attracting capital, as socially responsible investors, private equity firms, and other funding sources actively seek alignment with companies with best practices.

3. Risk Mitigation: A Proactive Approach to Sustainability

Mining companies are focused on mitigating risks associated with climate change, biodiversity loss, workforce safety, and corporate governance. In Onyen’s AI-driven reporting system, they have

a suitable tool.

By employing advanced analytics and predictive modelling, Onyen identifies potential risks before they escalate and become too costly to manage. This enables companies to implement targeted mitigation strategies.

On the whole, the proactive approach safeguards against financial losses. In addition, through demonstrating a commitment to building a responsible and resilient business, the system enhances the organisation’s reputation.

4. Enhanced Compliance: Navigating Regulations Confidently

Staying compliant is crucial in the rapidly transforming ESG domain. Accordingly, Onyen’s ESG reporting system adapts seamlessly to evolving regulations. Thus, ensuring organisations remain compliant without overburdening resources.

Thanks to its flexibility and scalability, particularly, Onyen particularly facilitates internal gap analysis. As a result, it empowers businesses to navigate the complex regulatory landscape confidently by avoiding penalties and reputational damage associated with non-compliance.

5. Stakeholder Engagement: Building Trust Through Transparent Communication

In mining operations, effective ESG reporting transcends meeting regulatory mandates. It has