http://www.electrotron.co.za

http://www.electrotron.co.za

Let’s build the future together. Contact us to discuss your next project. G4 Mining and Civils, with operations throughout South Africa, delivers innovative solutions across mining and civil infrastructure.

Cover Image: 02

COVER STORY: PG 02

Intelligent Conveyor Safety

With the consistent increase in mining projects into Africa of late, Electrotron’s one-stopconveyor safety solution is a competitive advantage, and Electrotron is well-equipped andaligned to helping mining operations mitigate potential conveyor belt-related safety risks.

Editor

Nick Barnes

editor@miningbusinessafrica.co.za

+27 10 055 3356

Web/Sub-Editors

Jimmy Swira

Jimmy@miningbusinessafrica.co.za + 27 10 055 3356

Anita Anyango anyangoanita18@gmail.com

Contributing Writers

Chantelle C.

chantellec@miningbusinessafrica.co.za

+ 27 10 055 3356

Susan M. susanm@miningbusinessafrica.co.za

Sales and Marketing

Winnie Sentabire

winnie@miningbusinessafrica.co.za

+27 83 530 6832 | +27 10 055 3356

Angeline Ntobeng

angien@miningbusinessafrica.co.za

+ 27 078 322 5938

+ 27 010 055 3356

Accounts Precious Chirunga

accounts@miningbusinessafrica.co.za

+ 27 10 055 3356

Just when mineral producers were anticipating a windfall from increasing world demand, guess what?

Boom! They didn’t know what was to hit them. Tariffs!

At the Oval Office, the Trump administration has introduced wholesale trade tariffs on all countries. And not to be outdone, some of the USA’s biggest trading partners (formerly NATO allies) are retaliating or threatening retaliation. In a tit-for-tat, China has hit back with a vengeance! Canada has followed suit. The EU says it won’t fold arms. It doesn’t look good for world trade, and fears are that we could be on a precipice of an economic recession. Fears of a replay of 2008 are growing. This uncertainty does not bode well for mining companies, particularly in the critical minerals. It will potentially affect demand from electrical vehicle components, of which critical minerals are a primary raw material, which will halt production. Other commodities will not be spared this fate too.

It’s not good. Hopefully, sanity will return.

Nick Barnes editor@miningbusinessafrica.com

Art Director/Layout

Augustine Ombwa

Arobia Creative Consultancy austin@arobia.co.ke +254 772 187 334

Circulation/Sales info@miningbusinessafrica.co.za + 27 10 055 3356

Published By Media Icon (Pty) Ltd

With the consistent increase in mining projects into Africa of late, Electrotron’s one-stop conveyor safety solution is a competitive advantage, and Electrotron is well-equipped and aligned to helping mining operations mitigate potential conveyor belt-related safety risks.

through its business divisions, which include:

Scanbelt – Intelligent conveyor safety and management

Scancom – Reliable underground radio communication

Scanpanel – Legally compliant flameproof, dustproof, starter and control panels

Scanweigh – Accurate in-motion weighing equipment

Scanchair – Intelligent chairlift safety and management

Scanfire – Fire detection and suppression

AElectrotron's dedication to filling the gap for intelligent conveyor belt safety solutions across Africa. "Our ScanBelt solution can drastically improve efficiency, reduce costs, and prevent injuries and loss of life."

conveyor safety, Electrotron is on a mis-

s Africa’s market leader in intelligent sion to fulfil its strategic vision of expanding its presence across the cont-inent.

“It’s all systems go! We are good to go!” declares Electrotron’s Chief Operating Officer, Shane Thompson, as he illustrates the company’s steadfast commitment.

Thompson provides more details on Electrotron’s 2025 Strategic Vision: “We have a threefold vision for 2025. First, Push into Africa, which entails expanding safety solutions deeper into the continent. Second, Fire Push, which involves enhancing our fire detection and suppression capabilities across Africa. Third, Leveraging Technology, which is utilising advanced technologies to improve safety and efficiency in our mines.” He adds that the company’s drive and optimism are based on strong compet-itive advantages.

Electrotron is well-positioned to meet the needs of mining operations in Africa, largely due to the following competitive advantages:

i.

Electrotron has an impressive 42-year track record, a full-time staff of 63 enabling inhouse design, delivering intelligent conveyor safety equipment and fire detection/suppression solutions.

The company takes pride in offering worldclass solutions that set industry standards

Stressing the relevance of these solutions to mining operations, Electrotron’s CEO, Jack Moshoeu, states, "Our primary mission is to expand these critical solutions deeper into Africa, where they are needed most. These solutions are tailored to meet the specific requirements of our clients and in the end they keep everyone compliant and safe."

Electrotron’s solutions offer superior convenience over comparable intelligent conveyor safety products. This makes them suitable for the African mining environment, mainly in the following areas: Robust design for harsh environments

Comprehensive safety features for legal compliance

Increased end-user availability of conveyors (up to 97%)

User-friendly maintenance

Cost-effective standardisation

Single blueline cable – no need for cable trays

World-class BSDs (rip detectors/misalignment sensors)

Electrotron’s expansion in Africa couldn’t be more timeous. With the increase in projects – especially involving critical minerals in Zambia, the DRC, and other regions – the company sees huge potential on the continent. With increased productivity, conveyor safety risks are expected to rise, making Electrotron’s solutions more relevant than ever.

Recognising this, Thompson highlights

Electrotron is no stranger to the harsh African mining environment. The company has built a strong reputation through the successful completion of numerous projects locally and abroad. With its extensive expertise and proven capabilities in delivering intelligent conveyor safety solutions, Electrotron is set for success. “We are well-equipped to lead the charge,” affirms Thompson.

For more details contact: Shane Thompson

Tel: +27 (0)13 246 2655

Email: sales@electrotron.co.za Web: www.electrotron.co.za

3A Slegtkamp Street, Vaalbank, Middelburg Mpumalanga South Africa

The Electrotron Team is adequately resourced to help mining companies in Africa identify fire safety risks and customise appropriate fire detection and suppression solutions to address them.

Mwhat they consider the bigger picture:

ining operations are more focused on increasing output. Unfortunately, in pursuit of this objective, they may lose sight of potential safety risks, particularly lurking in critical equipment like conveyors. Truth be told, one of the highest risks -if not the most critical one - is the occurrence of a fire outbreak during peak production.

Noting the impact of the risk of fire accidents on operations, Neil Bester, Chief Fire Officer at Electrotron, urges mining companies to adopt sound mitigation measures and implement them diligently. He draws attention to critical areas in conveyor fire detection and suppression:

i. Risk assessment

The first step - the most vital one - is carrying out risk assessments.

“Risk assessments are an absolute must, no matter what type of business you own. Not only do risk assessments help to keep your premises safe, they are also a legal requirement,” Bester emphasises.

“When carrying out your fire risk assessment, identify potential hazards and institute measures to control them. You must also ensure that everyone in the building can escape quickly and safely in the event of a fire outbreak. By logging your assessment and taking note of your findings, you'll have proof that the necessary checks took place,” he expounds.

ii. Must-have fire safety equipment

Every business must have the necessary fire

safety equipment in good working condition. The fire safety equipment ranges from fire extinguishers to fire alarms and suppression systems.

“You must have a fire detection and warning system. In some cases, you may need different types of detectors. This will depend on the type of building you operate in. You must also have fire fighting equipment such as extinguishers, sprinklers, and blankets,” advises Bester.

Besides, the equipment must be effective. Hence, carrying out regular equipment checks will ensure the following conditions are met:

All fire alarm systems, emergency lighting, and extinguishers work and are maintained;

All fire suppression systems work and are serviced; Any faults in systems and equipment are recorded and addressed; and Automatic fire doors close correctly.

iii. The employee’s responsibility Equipment in perfect working condition doesn’t eliminate all the risks. So, employees must take responsibility.

“From not smoking indoors to using kitchen equipment safely, there are plenty of things employees can do to minimise fire risk at work. Make sure all employees understand their responsibilities and do what they can to keep the premises safe,” Bester explains.

However, he acknowledges that in an emergency, employees may understandably panic and be disoriented. “Escaping

from the building they spend 40 hours a week in may initially seem easy. However, when panic sets in and the pressure is on to get outside, some people freeze up and realise they don't know what to do.”

iv. Regular fire drills

Therefore, employers are obligated to raise workers' awareness of the correct evacuation procedures. Carrying out fire drills and ensuring everyone takes them seriously is essential.

Logging the results of drills can help identify any issues that arise. Information can answer these questions: Did anyone stop to get their coat? Did anyone pop into the toilet before making their exit? In the event of a real fire, these actions could prove fatal.

Asked about proper evacuation procedures in a building, Bester responds: “In the event of a fire, avoid using escalators and elevators. It's vital that staircases are available and people in the building can find them. Although your employees will know where the staircases are, visitors might not. So, ensure clear signage is on the premises pointing to escape routes.

Check all escape routes and exits for obstructions and hazards that could slow people down in an emergency. It's important to keep your premises as clean and tidy as possible at all times.”

Neil Bester and the dedicated team at Electrotron are on hand to address all fire detection and suppression challenges at mining operations across Africa.

For more details contact: Niel Bester

Tel: +27 (0)13 246 2655

Email: sales@electrotron.co.za

Web: www.electrotron.co.za

3A Slegtkamp Street, Vaalbank, Middelburg, Mpumalanga, South Africa

Röchling Industrial is a Germany-headquartered, globally focused plastics processor that develops and supplies individual high performance plastics for all industrial areas, including mining operations and other industries. The company has been rolling out Matrox® liners, intelligent conveyor lining solutions (sensors embedded in plastic sheets) globally - most recently in African mining. Michal Sládek, the company’s Industry Manager for Mining, fields questions from MINING BUSINESS AFRICA on the relevance of intelligent conveyor lining in conveyor safety and efficiency.

By Jimmy Swira

MBA: Some African mining operations may believe they are well-equipped with fire detection and suppression systems (and don’t need more). What would you tell them about incorporating intelligent conveyor lining (sensors embedded in plastic sheets)?

MS: There are more levels of fire protection. In general, it is, of course, always better to avoid a fire than to deal with it. For example, our Matrox® liners or materials in general with electrically conductive properties eliminate electrostatic charging, which can be very dangerous in dusty and closed environments. Temperature sensors can detect increasing temperatures, which point to possible ignition of a fire. Flame-retardant or self-extinguishing liner grades like Matrox® SE help to suppress the spreading of fire. As you can see, there are many ways to deal with fire hazards – and usually, the best way is to combine them.

MBA: What opportunities does this create for conveyor monitoring?

MS: It is another piece of the puzzle. You want to have the complete picture of your conveying system to run it in the most effective way possible. And for this, you must be able to collect data from particular parts of the system – including liners. For us, so-called smart solutions are an important field where we develop customised solutions with our customers. This gives mines new opportunities regarding monitoring systems from start to end, especially in critical, non-accessible, or remote areas through data regarding wear status, temperature, or even the noise level of your lining. It is not just safety issues like fire prevention - each new set of data increases efficiency as well.

MBA: How does intelligent lining enhance a mining operation’s existing conveyor monitoring system?

MS: As mentioned before, lining is just one part of the whole system, but the concept of

Smart Matrox liners with integrated wear and temperature sensors is boosting reliability, reducing risks, as well as direct and indirect costs. Data collected from various critical parts of a mining operation can be integrated into the existing process control system or accessed through the independent Röchling Industrial IoT platform. This platform also sends early warnings, status reports, and can even automatically reorder spare parts ahead of time, before they wear out.

MBA: Every mine has unique challenges. What factors should be considered before installing an intelligent lining?

MS: Without going too much into details – it is like any other monitoring or data-collecting system. The first thoughts should be about the direction – what kind of data would help me to run my equipment in an efficient way, and where is the best measuring point? For lining, it could mean, for example, choosing the right areas for placement of wear and temperature sensors.

MBA: Do you have any updates on the latest intelligent lining technologies that you can share with us?

MS: The final goal is to have a “digital twin” of your mine where all critical data from your operation is centrally connected. To run a mine efficiently and minimise shutdowns, the best possible condition report of all critical lining applications is crucial. And more generally speaking, we are interested in supporting the process of creating a digital mine. Whatever data someone is interested in collecting, we are interested as well.

Röchling Industrial SE & Co. KG is one of the three divisions of Röchling Group, which has been in existence for more than 200 years. The others are the automotive and medical divisions.

www.roechling.com/industrial

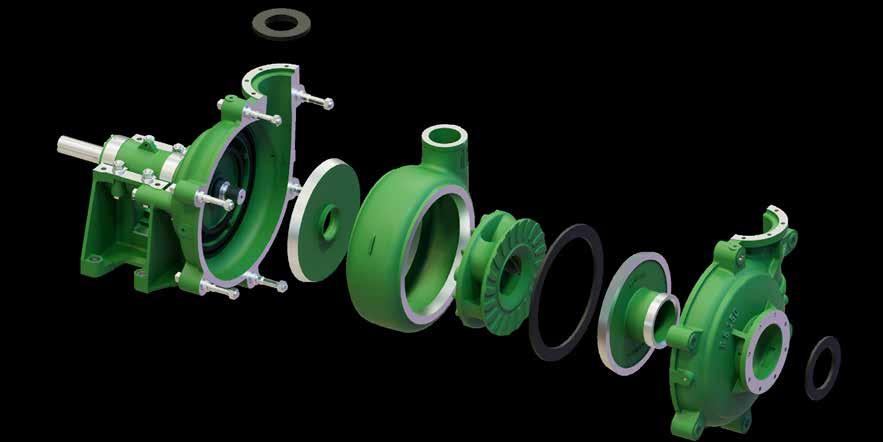

Interact with our AR 3D pump models and seal assemblies

YEARS OF POWERING PROGRESS, PUMPING EXCELLENCE

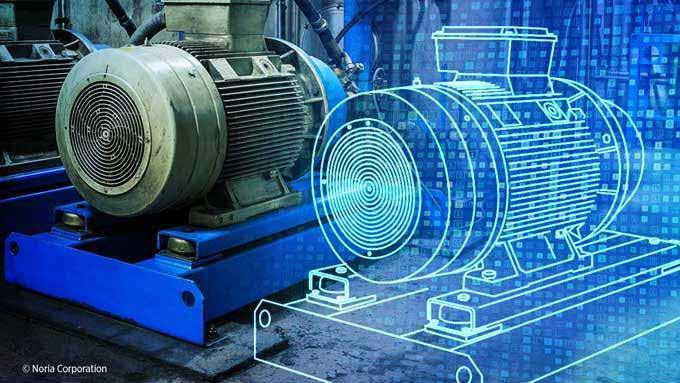

Intelligent conveyor belt monitoring - combining ultrasonic, vibration, and acoustic sensors with machine learning - offers real-time, accurate, and early detection of longitudinal conveyor rips before they escalate and cause costly failure. It is a vital tool for mining companies focused on operational efficiency and reliability.

A belt rip detection used to detect longitudinal rips on steel cable and fibre conveyor belts in realtime

By Nick Barnes

For operations undermining the significance of sound conveyor belt rip detection, picture this: A seemingly small rip on a conveyor belt can have a domino effect, halting critical processes all the way to the mill. The ensuing production loss can translate into revenue loss. In a worst-case scenario, damage to components may necessitate unplanned repairs and replacements, coupled with potential fatalities. Not a desirable experience when production is at its peak.

Let’s face it: Performing longitudinal conveyor belt rip detection using conventional systems often falls short of enhancing equipment efficiency, safety, and reliability.

While they serve a purpose, conventional detection systems — such as inductive loops and fibre optics — have inherent shortcomings.

Miniotec, a conveyor belt automation consulting firm, analyses the two techniques in a review: “Inductive loop systems require embedding sensor loops into the belt, which can compromise belt integrity and are susceptible to damage, leading to false alarms.”

On fibre optic sensors, the company points out, “While sensitive, they demand significant infrastructure investment and are prone to environmental or operational damage, making them less ideal for harsh mining environments.”

What’s worse, these systems often struggle under varying operational conditions that adversely affect detection capabilities. For instance, there have been instances where these systems have failed to detect anomalies promptly, resulting in extensive belt damage and costly downtime.

So, it beggars belief why many mining operations still stick to using conventional methods despite increasing data on costly failures.

Certainly, it is worthwhile to explore the opportunities conveyor automation through intelligent belt monitoring offers. By combining universal sensors and smart (intelligent) analytics, mining companies can detect conveyor belt rips in real-time.

The integration of ultrasonic, vibration, and acoustic sensors creates a multi-sensor cluster monitoring approach. This combination brings real-time data, which enhances detection accuracy across diverse operational conditions.

Through correlating data from multiple

sensors, automated systems can deliver broad but precise insights. Machine learning algorithms analyse patterns across various operational scenarios and sensor inputs to identify and predict potential failures before they occur. This ensures consistent and continuous monitoring for predictive maintenance.

Generally, it provides the ability to anticipate issues and address them proactively before they snowball into costly crises.

In particular, mining operations benefit from continuous real-time monitoring of belt rips through automated systems in the following ways, according to Tru-Trac:

i. Increased Efficiency

By streamlining processes, automation results in faster and more efficient material handling.

ii. Reduced Downtime

Early detection of potential problems informs proactive maintenance strategies, which minimise downtime.

iii. Enhanced Safety

There is a high risk of carrying out manual interventions in hazardous areas. Automation can reduce the need for this, improving worker safety.

iv. Lower Maintenance Costs

By preventing damage and optimising performance, automation can lead to lower maintenance costs.

There is no question that, as mining companies focus on enhancing equipment efficiency, safety, and reliability of their conveyor systems, intelligent belt rip detection is a vital tool.

Credits for some of the information:

• “Conveyor Belt Rip Detection: Using Universal Sensors and Smart Analytics to Improve Mining Operations in Real-Time” – Miniotec

• “How Multi-Sensor Intelligence is Reshaping Conveyor Belt Reliability” – Tru-Trac

Smart Mine strategically bolsters the Group’s services to the mining industry by offering cutting-edge, AIoT-based solutions, driving growth across the African continent.

Smart Mine’s Solutions, Smart Lockout, Smart Conveyor, Stop-Start Retrofit, and Smart Inspection, aim to optimise mining operations and promote sustainable business practices.

Maximise conveyor system efficiency with Smart Conveyor by Bosch Rexroth Smart Mine. Prevent downtime and reduce maintenance costs.

Smart Lockout from Bosch Rexroth Smart Mine ensures personnel safety during machine and equipment repairs and maintenance.

Smart Inspection from Bosch Rexroth Smart Mine is a customisable web-based application that streamlines inspection processes.

Boost your mining efficiency with Bosch Rexroth Smart Mine's Stop-Start Retrofit. Cut fuel use and emissions while enhancing productivity.

Despite a very tight schedule during the 2025 Investing in African Mining Indaba, the CEO and Chairman of Guangxi LiuGong Machinery was excited to outline the company’s plans to provide African mining companies with relevant intelligent technologies and electric equipment solutions.

By Jimmy Swira

Embracing relevant technologies to ensure that their operations are safe, sustainable, and efficient is one of the surefire ways African mining companies can realise more value from their assets. That’s why they should partner with reliable suppliers of mining and construction equipment.

Zeng Guang’an, the CEO and Chairman of Guangxi LiuGong Machinery, shared this sage advice with African mining companies recently at the Investing in African Mining Indaba 2025, where the company showcased its vast product range to wowed delegates.

On the sidelines of his engagements, he took a moment to speak to Mining Business Africa. Enthusiastically, Guang’an reassured prospective African customers that the multinational company is well-positioned to deliver tailored solutions to meet their specific needs, including comprehensive after-sales parts and services.

He highlighted LiuGong’s evolution from humble beginnings in 1958 to a global leader in supplying a wide range of cutting-edge electric equipment and intelligent technology solutions for mining, construction, and agricultural production.

Regarding the contemporary demands of African mining, Guang’an referred to the company’s electric product range as a ‘perfect fit’. Key takeaways demonstrated the company’s commitment to sustainability, efficiency, safety, and reducing operating costs:

LiuGong designs and manufactures energyefficient electric and hybrid mining equipment. With low fuel consumption, these machines produce lower emissions than traditional dieselpowered equipment, contributing to cleaner air and a reduced carbon footprint. They guarantee high performance while minimising environmental impact.

What’s more, LiuGong provides training and education to its clients and operators on sustainable mining practices. This includes best practices for equipment operation, maintenance, and environmental stewardship.

ii.

The company incorporates advanced technologies such as telematics and IoT (Internet of Things) to optimise equipment performance. These technologies help monitor equipment health, predict maintenance needs, and ensure efficient operation. Additionally, unmanned driving and remote control technology enhance safety.

Predictive maintenance reduces downtime and unplanned expenditure on spare parts. This, combined with energy-saving technologies, increases profitability.

One of the biggest concerns about overseas equipment suppliers to African mining operations is the certainty (or uncertainty) of after-sales parts and services. Addressing this, Guang’an assured that LiuGong considers reliable aftersales parts and services key ingredients for customer satisfaction.

To meet this need, the company has several initiatives firmly in place for Africa:

• Strengthening local collaboration: In South Africa and the region, LiuGong collaborates with ELB to share local warehouses and improve spare parts coverage.

• Technical support system: Combining remote diagnosis with on-site service, the LiuGong Smart Service App enables LiuGong service engineers, headquarters engineers, and local dealer experts to conduct remote consultations to solve problems.

• Building localised service capabilities: LiuGong has established a dealer joint training centre in South Africa to certify local technicians, covering modules such as hydraulics, electrical, and intelligent systems.

On the significance of this approach, Guang’an stressed: “LiuGong understands the importance of after-sales service. Our partnership with dealers ensures that every user of our service receives responsive support and high-quality spare parts supply.”

While some overseas suppliers take a shortterm approach when serving African customers, LiuGong focuses on long-term, trust-based cooperation. Specifically, Guang’an explained that several attributes give LiuGong a competitive edge in this area:

• Technology accumulation: Practical experience in addressing challenges in mining areas, extreme working conditions, and equipment solutions.

• Localisation services: Ensuring rapid response and cost optimisation.

• Green transformation: Commitment to sustainability, compliance, and long-term value.

What is more, African mining companies partnering with LiuGong benefit from its extensive global presence, including:

• 30 subsidiaries and offices worldwide

• 12 R&D bases

• 20 global manufacturing facilities

• 500 global dealers

From the foregoing, Guang’an declared that the company is perfectly positioned to meet the needs of African mining projects of any scale: “Our products are engineered to deliver. Besides, our team is always customer-oriented and committed to providing you with the highest quality solutions and services. We believe that cooperation with LiuGong will bring higher efficiency and greater value to your mining operations.”

Looking ahead, Guang’an pronounced ambitious goals for Africa: “We are confident in the African market. Our goal is to become a leader in the African mining industry through technological innovation and sustainable development.

Since its establishment in 1958, LiuGong has achieved milestone upon milestones - from launching China’s first electric loader in 2015 to developing the world’s first unmanned roller and implementing a 5G remotecontrolled excavator. To date, LiuGong has surpassed 1.5 million global sales, with products covering over 180 countries.

Looking ahead, the company plans to introduce larger-tonnage mining products, deepen applications of pure electric mining trucks, and expand hybrid technologies to reduce carbon emissions in mining areas.

For African mines pushing greater depths, compliant hoisting isn’t an option, but a business mandate.

By Nick Barnes

Underground mining activities are going deeper – in some cases even ultra-deep. Depths can reach up to two kilometres (one said the other day that they are going further in search for the coveted ore).

This environment presents complex challenges in the area of safety and efficiency. Inevitably, one of them is in the movement of supporting personnel and equipment from the surface. That’s why hoisting equipment (Koepe, Blair multi-rope, drum) has to be in perfect condition at all times. Unfortunately, the more they are exerted, hoists face high risk of failure. This can lead to accidents – resulting in fatalities and damage to equipment. These have a huge impact on operations.

Legislation

Cognisant of this, in various countries, legislation obligates use of equipment that complies with relevant health and safety regulations. There is legislation applicable in various jurisdictions.

The bottom line is that although its wording may be different, legislation in various countries serves the same purpose – enhancing safety.

Generally, legislation stipulates that equipment has to be compliant with various regulations in terms of design, installation, and maintenance.

In the South African context, the Mine Health and Safety Act (MHSA) is the reference point. Under the legislation, Chapter 8 of Machinery and Equipment (8.5 Lifting Equipment Regulations) covers standards and specifications on hoisting equipment. In a nutshell, its scope is in the following core areas:

• Safety standards for hoist operation, braking systems, and emergency controls.

• Load limits and inspection requirements to prevent overloading and mechanical failures.

• Regular certification and compliance checks.

Therefore, mining companies have to make informed choices on the hoisting equipment to utilise. Usually, this depends on depth, needed capacity, and loads.

So, what happens when mines use non-compliant equipment? Events documented worldwide

indicate that the consequences of using faulty equipment can be very ghastly to contemplate.

In South Africa, there have been numerous cases of accidents involving non-compliant hoisting equipment, unfortunately, with fatalities. Two among high-profile accidents that have occurred include:

i. No. 6 Shaft, Hartebeesfontein Gold Mine – 24th December 1990

At No. 6 Shaft, Hartebeesfontein Gold Mine – an automatic man winder failed to stop, causing the conveyance to collide into the headgear crash steel at a rope speed of 13m/sec. 11 people lost their lives, and 22 were permanently disabled (paraplegics).

ii. Impala Rustenburg’s Shaft 11 –November 2023

At Impala Rustenburg’s Shaft 11 – 13 employees were killed and 73 injured when a lift they were on failed. During an ascent, the conveyance unexpectedly reversed direction and descended back to the shaft. The emergency protocol to halt the descent failed.

These examples clearly mirror consequences of faulty systems. It goes without saying that all critical steps must be followed thoroughly – from designing, commissioning, up to operation.

According to the Lifting Association of South Africa, the following factors determine the design of a hoist:

• Depth and capacity requirements – Deeper mines require more robust systems to minimise the costly risk of failure.

• Type of material transported – Ore, personnel, or equipment may require different hoist configurations.

• Hoist type – At a mine’s disposal are drum hoists, friction (Koepe) hoists, or Blair multirope hoists.

Proper installation ensures the system operates safely and efficiently. Critical aspects include:

• Can the structure of hoist towers, headgear, and shaft infrastructure built to handle high loads be carried?

• Misalignment can cause excessive wear and

We offer our clients a comprehensive service including design, manufacturing, supply, installation, commissioning and site servicing of winders, winches, hoists, sheaves, rope-handling and related equipment.

Our single point of contact service provides seamless interfacing between all disciplines and covers all major equipment brands.

As an independent systems integrator for shaft hoisting systems, we have extensive systems engineering and project management experience. Our service includes planning, mechanical design and construction of winders and various systems. We satisfy clients' hoisting and general industrial requirements with custom-designed solutions.

We design, manufacture, install, commission, maintain and refurbish a variety of hydraulic systems for industrial and mining applications. A comprehensive range of specialist hydraulic products and related services is available. We offer our clients individually tailored solutions in compliance with applicable standards and regulations.

We provide full engineering, manufacture and supply of all electrical aspects for legacy as well as modern winders including drive, control and safety systems for all winder types and all rope handling equipment. Our products cover fully automated as well as manual control systems, brake control systems and cage and level-control systems and can be provided as retro-fit or new equipment. Our extensive systems integration experience enables us to incorporate electrical, mechanical and hydraulic equipment of all makes.

Our experienced, in-house Services Department personnel manage and execute the site work required to install and commission both new and refurbished winders as well as carry out site upgrades, emergency breakdown repairs and maintenance work. We also offer Level 1 dynamic braking and cage accelerometer inspections as well as annual inspections of hoisting systems.

scan the QR Code to learn more

breakdowns. Is the alignment and balancing suitable?

• Are the safety mechanisms, load-bearing capacities, and braking systems functioning optimally?

Therefore, testing and commissioning is key.

Last but not least, it is important to ensure all safety mechanisms, load-bearing capacities, and braking systems function properly.

Once the hoisting equipment is up to task, mining companies should ask themselves the following critical questions: Is the hoist equipment in the right condition? When was the last time it was tested (thoroughly that is, not as a typical tick-box routine measure)? Profoundly, there is a statement which stuck from a presentation from a Minerals Council of South Africa’s Report on Safety in Mining: You can’t cheat your way to compliance. It will catch up with you.

Fact: hoisting equipment must be maintained to high standards to reduce the risk of malfunctioning, thereby improving safety. Compliant Hoisting Is Non-Negotiable in Deep-Level Mining. For this reason, thorough condition monitoring tests are critical.

Specifically, the following tests are central –Winder Safety Circuit Interlocks, Speed-distance protection at the upper and lower limits of the wind and in mid-shaft, Brake deceleration tests, Degree of Protection tests, and Slack & Tight Rope tests (Winder Dynamic Testing 1 October 2015: Adriaan van der Westhuizen). These testing procedures can be carried out during actual operating conditions without risking the safety of personnel

or exposing machinery and equipment to damage. Fortunately, mining operations have a number of testing methods to carry out predictive maintenance. WearCheck recently shared an article which highlighted the following array of techniques:

• Vibration analysis – detection of imbalances, misalignments, or bearing issues.

• Thermal imaging – identification of overheating components, electrical faults,

or friction issues.

• Acoustic emissions monitoring –picking up stress cracks or wear early.

• Oil analysis – detecting contamination and wear in hydraulic and gear systems.

Manual monitoring is time-consuming and may lead to intermittent issues remaining hidden or being identified too late. Remote monitoring and IoT integration – collecting real-time data which enables early detection of failure to schedule preventive maintenance.

Automatic collection, monitoring, and analysis of data in real-time helps mining companies increase production performance, identify potential functional safety hazards, and optimise maintenance scheduling. Automated hoists can operate continuously with minimal human intervention. Mining operations can incorporate advanced automation and control systems into their design. African mines can improve safety and efficiency by integrating automation and digital monitoring solutions, reducing unplanned downtime and enhancing productivity.

Sure-fire safe and efficient operations

All in all, effective mining hoisting systems must adhere to legislation through careful design, precise installation, and advanced condition monitoring for predictive maintenance. That is the only sure-fire way of ensuring safe and efficient operations, ultimately, achieving compliance.

Spill Doctor recently tackled one of its most complex projects— designing and installing a compliant flammable store for a client with very limited space. The challenge was to safely store 48 IBCs (1000L each) or 192 drums (210L each) containing various flammable liquids while adhering to strict safety regulations. Working closely with engineers, the local Fire Department, and Environmental Authorities, it was agreed to double stack the largest unit we manufacture, the SD96 Model. To ensure the unit was compliant and to enhance safety, a 2-hour fire-rated spacer was installed between the units and a nearby building. Another

challenge we faced during the installation was craning both units over 30 metres in the air and across 50 metres from an adjacent property, as the site had limited direct access. To further improve accessibility, we incorporated 6 metre remote-operated roller shutter doors, making storage and handling more efficient. Within just four months the unit was successfully approved, installed, signed off by all relevant authorities, and is now fully operational. This project showcases Spill Doctor’s expertise, adaptability, and commitment to providing custom flammable storage solutions that meet the highest safety standards.

There is an ongoing revolution in fleet management in mining — Software as a Service (SaaS) is making powerful, real-time, compliance-driven tools accessible, affordable, and efficient for operations of all sizes.

For a long time, software has been officebound, expensive — considered the preserve of big companies with huge capital outlay, money to burn. Most small businesses found acquisition of software forbiddingly expensive, though they appreciated its relevance.

=Software as a Service (SaaS)

This is no longer the case. Software as a Service (SaaS) has made critical software inclusive. This is evident in fleet management for transportation services. In Africa, small outfits can now access essential software for their respective operations.

As a cloud-based solution in fleet management, with Software as a Service (SaaS) platforms, mines are able to manage vehicles and drivers better through insights from real-time data.

According to information providers of SaaS to mining operations who were keen to share with Mining Business Africa, fleet management brings to the fleet management task the following:

1. Cloud-Based Access

Remember the era when a software vendor used to send personnel to company premises and disrupt the day’s operations, ask for permission to access every staff member’s computer to configure something inside there?

That seems like light years ago. In contrast, these days, small companies can access SaaS fleet management solutions through a web browser or mobile app. Effectively, this eliminates the need for on-premise software installation and maintenance.

With the traditional model of fleet management software, you have to pay a full amount before

accessing the software. Unfortunately, this excluded start-ups that regarded software as essential, but as a luxury they could not afford due to financial constraints.

However, conveniently, with SaaS, end-users (in this context, even junior mining companies) pay recurring fees to access software and its features. It could be through a flexible monthly arrangement for the end-user’s convenience. No more upfront payment.

3.

Through tracking vehicles in real-time, mining operations have knowledge about driver performance data and other vital information. This data informs correct decision-making.

While traditional fleet management software is known for its rigidity, SaaS can be adapted to changing needs, for instance, changing fleet requirements or expanding to new locations.

Operational Benefits

From an operational perspective, SaaS platforms provide end-users these benefits:

i. Vehicle Tracking

Where is the vehicle? Sometimes fleet managers find themselves in a position where traditional software lets them down, when needed the most. However, with real-time GPS tracking, they are able to monitor vehicle locations and optimise routes.

ii. Driver Management

With SaaS platforms, fleet managers are able to track how their drivers are performing, monitor driving behaviour and eliminate violations, and manage driver tasks.

iii. Maintenance Management

Imagine how onerous manual scheduling or scheduling with antiquated software is? Handily, with automated scheduling, SaaS generates maintenance tasks, alerts, and reminders. This helps prevent breakdowns and reduce downtime.

iv. Fuel Management

How much fuel have we used? Is there too much wastage? Ease of tracking fuel consumption and identifying areas for potential improvement can lead to significant cost savings.

v. Compliance

Compliance is often aspired for but rarely attained — with great difficulty and at a high financial cost. However, without a doubt, the most important aspect of SaaS solutions is their capability to ensure compliance with regulations.

vi. Improved Efficiency

By rationalising operations and providing realtime data to inform correct decisions when and as needed, SaaS solutions can significantly improve fleet efficiency.

vii. Cost Reduction

In contemporary mining, costs are not falling — a very unfortunate situation. But SaaS platforms offer cost-saving avenues in the form of fewer breakdowns, reduced fuel consumption, and optimised routes. Cumulatively, these can lead to substantial benefits.

viii. Enhanced Safety

Sometimes drivers can act as they wish, going off the work perimeter, flouting safety protocols. However, through SaaS platforms, real-time tracking of vehicles and monitoring of driver performance can improve driver safety and reduce accidents.

ix. Better Communication

Bad communication is a recipe for inefficiency. Unfortunately, with traditional fleet management systems, this is not guaranteed. However, conveniently, SaaS platforms facilitate smooth communication between dispatchers, drivers, and other stakeholders.

Affordable, effective, and convenient, SaaS platforms have revolutionised fleet management in mining, enabling complicated tasks to be accomplished. Most importantly, it has relieved the burden of compliance. SaaS is clearly in the driver’s seat, steering change in mining.

“By unifying Fleet Management data across all mobile assets and providing real-time, decision-grade insights, Powerfleet empowers mining operations to enhance safety, improve efficiency, reduce costs.”

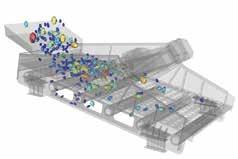

Mining operations must manage highvalue assets efficiently and safely to remain competitive and compliant. From material-handling equipment in facilities to vehicle fleets navigating the site terrain, these companies need comprehensive visibility and control to optimise operations and uphold strict safety standards.

Powerfleet’s Unity is a SaaS-based, hardwareagnostic AIoT platform that delivers complete operational visibility for mining operations. This innovative ecosystem ingests data from virtually any IoT device, OEM system, or external data source, applying artificial intelligence and machine learning to harmonise and simplify diverse datasets. By transforming fragmented operations into a unified system, Unity provides a single pane of glass for real-time intelligence and smarter decision-making.

Powerfleet stands apart as the only provider delivering a truly end-to-end AIoT ecosystem, integrating fleet, in-facility operations, and AIdriven safety solutions into a single integrated environment. Mining companies can manage everything from fleet vehicles to materialhandling equipment through one unified platform, eliminating operational blind spots while ensuring businesses stay compliant, sustainable, and competitive. Unity connects all critical assets, people, and processes across the entire supply chain, spanning facilities, logistics hubs, and vehicle fleets.

Within mining facilities, forklift operations present significant safety considerations. Powerfleet’s comprehensive in-facility solutions

address these challenges head-on:

• Pedestrian Proximity Detection: AI-powered vision systems proactively prevent accidents by identifying people and industrial vehicles, alerting operators to potential hazards before incidents occur.

• Forklift Gateway: This central hub provides wireless, automated tracking and management of powered industrial vehicles. It controls access based on driver credentials and enforces safety protocols, such as mandatory pre-use inspections.

• Digital Video Recorder: This system continuously records during vehicle operation and automatically saves video clips capturing events like impacts. It provides comprehensive records for incident analysis and driver coaching.

• Speed Manager: Automatically reduces vehicle speed in response to qualifying events, preventing potential collisions before they occur.

Enhancing on-road fleet performance

Beyond in-facility operations, Powerfleet’s solutions extend to vehicle fleets travelling between sites:

• Real-Time Monitoring: Track vehicle location, status, and performance metrics to optimise routing and respond quickly to changing conditions.

• Driver Behaviour Analysis: Vision AI monitors driver fatigue and distraction, providing immediate alerts to prevent accidents before they happen.

• Maintenance Optimisation: Predictive analytics identify potential issues before breakdowns occur, reducing costly downtime and extending asset lifespans.

Driving operational excellence

Mining companies implementing comprehensive asset management solutions experience significant operational improvements across multiple business areas. Operations see reduced safety incidents through improved visibility, decreased fuel costs through optimised operations, and lower maintenance expenses through predictive analytics. For example, one construction equipment customer reported a 33% decrease in vehicle-related damage costs after implementing Powerfleet’s comprehensive safety solutions.

Powerfleet’s solutions are purpose-built for the mining industry’s specific requirements, with modular components that can be selected based on operational needs and scaled as operations grow.

Mining operations partnering with Powerfleet gain significant competitive advantages through:

• Industry-Leading Expertise: With over 30 years of experience in fleet management and IoT solutions, Powerfleet brings unmatched industry knowledge to mining operations.

• End-to-End Coverage: A complete solution for managing both in-facility material-handling equipment and on-road vehicles from a single platform.

• Enhanced Safety: AI-powered solutions that proactively identify and mitigate risks before accidents occur, protecting both personnel and assets.

• Operational Efficiency: Data-driven insights that optimise resource utilisation, reduce fuel consumption, and streamline maintenance.

• Regulatory Compliance: Automated reporting and inspection tools that ensure adherence to industry regulations and standards.

By unifying data across all mobile assets and providing real-time, decision-grade insights, Powerfleet empowers mining operations to enhance safety, improve efficiency, reduce costs, and maintain compliance – delivering measurable improvements to the bottom line.

For more information on how Powerfleet can transform your mining operations, visit www.powerfleet.com

The combination of data and sensing technology is delivering steadily improved functionality to proximity detection systems. This is providing an avenue for mining companies to reduce vehicleto-vehicle or vehicle-to-pedestrian mobile equipment-related accidents.

As mining operations increase activities in pursuit of more revenue, they are grappling with new risks from mine to mill, as the expression goes: more risk, more reward. One of these is safety-related risks in fleet management. The more their fleet of mobile equipment is involved in operations, the more increased cases of collisions - whether vehicleto-vehicle or vehicle-to-pedestrian - occur.

Proximity Detection Systems (PDS)

To minimise the impact of these risks, mining companies need Proximity Detection Systems (PDS) that speak to their specific needs. Compounding matters is that every mining operation faces unique risks.

Ultimately, for every mining operation, the impact of a collision event is far-reachingdowntime to operations, potential loss of revenue, and fatalities attracting heavy penalties.

In response, PDS providers are introducing solutions to help mining companies mitigate the risk of accidents. Interestingly, the opportunities opened by technological advances have led to an expanding scope of capabilities. This was evident at two recent exhibitions - the 2025 Electra Mining Africa and the 2025 Investing in African Mining Indaba - where leading industry players active in Africa showcased their products.

What’s trending?

There is so much happening that it’s difficult to keep track of everything. However, recently, Johannesburg-based PDS company Boyco Electronics shared information with Mining Business Africa that provides a clear picture. Anton Lourens, the company’s CEO, outlined the following developments defining contemporary PDS offerings:

i. Single fully integrated solution

The combination of multiple sensing technologies into a single, fully integrated sensing solution is one example of the improved PDS offerings being developed. Software for these specific, comprehensive PDS requirements drives functional performance, optimising this solution.

As PDS technology evolves and matures, the demand for processing power and the ability to process multiple sensors has increased dramatically since the first basic PDS units were developed. Conveniently, the development of technologies -particularly artificial intelligence (AI) solutions and big data mining - has provided the PDS industry with the required processing platforms. A similar trend is unfolding in sensor technology, where rapid expansion has introduced more suppliers offering specific technology solutions that provide improved and more diverse functions.

ii. Central to mine automation

PDS will be central to the drive towards mine automation. Some stakeholders view it as the foundation for autonomous vehicles, particularly with the enhancements around Level 9 engineering control solutions for trackless mobile machines (TMMs).

iv. Different PDS requirements for different operations

Interestingly, various mining stakeholders and organisations are engaged in work streams to clearly define specific PDS requirements that are applicable to different operations.

This is significant as, typically, labour-intensive operations have different requirements compared to automated operations. Similarly, locally, there is more engagement from OEMs who play a key role in the proximity detection ecosystem. OEMs are also driving their own standards and regulatory compliance.

What

Integration enhances safety in the use of mobile equipment, mainly in the following areas:

In addition to the standard PDS functionality, the user gains significant benefits from using the data as a tool for change management.

i. High-risk areas

Beyond the ability to analyse traffic flow, mines can identify actual high-risk areas and implement mitigation interventions.

ii. Driver behaviour

With the deployment of additional integrated technology, the data can also be used to measure and improve operator behaviour. This could lead to productivity increases.

On the whole, integration of data and sensor technology has enabled mining companies to effectively mitigate vehicle-to-vehicle and vehicle-to-person accidents in mining operations and improve Level 9 compliance. What’s more, productivity translates into increased revenue.

Through KalPRO TireSight autonomous tyre inspection solution, Kal Tire is providing real-time monitoring that is helping prevent costly downtime and extend tyre life across global mine sites.

Kal Tire’s TireSight Station at a Mining Site

This scene could be anywhere at a mine site in Africa: Damaged tyres on a haul truck waiting for its turn on the tyre pad, but the onsite team is busy finishing up another previous scheduled tire change. The downtime clock is ticking.

Unfortunately, this eventuality is not always factored in when mine management is planning production. But it is a reality with huge implications on operations, not least manifesting through lost production or potentially irreparable damage to an asset necessitating replacement. To add insult to injury, sometimes heavy penalties and reputational damage follow.

With traditional tyre management practices, there can be a high risk of tyre-related accidents. After all, a 63 inch tire when inflated to 110 PSI has enormous stored energy. The team at Kal Tire has observed this many times from its consultations on mines internationally. There is no second-guessing the possibility of incidents as mines ramp up production.

KalPRO TireSight autonomous tyre inspection

Kal Tire says it is time for African mining operations to be open to innovations in tyre management to meet their safety and production objectives. The company calls on them to utilise autonomous tyre inspection as an alternative to traditional approaches to tyre monitoring.

Kal Tire has been deploying its KalPRO TireSight stations, an autonomous tyre inspection solution powered by Pitcrew AI, to mines in Canada, Chile and Colombia. Encouraging feedback from clients indicates that the solution results in tangible gains, bringing a broad range of benefits. They are keen to participate in more projects to help mines increase haul truck uptime.

Managing different sites internationally for clients is no easy feat. Asked how the company pulls it through without glitches, says Christian Erdelyi, Kal Tire’s Mining Tire Group Manager, Mining Technology Solutions: “It takes more than just technology for Kal Tire to create an effective tyre management solution,”

On what the tyre solutions multinational brings to the table, Erdelyi explains to Mining

Business Africa: “Fifty years of expertise, over ten years of mining fleet performance data collected in TOMS (Kal Tire’s Tire & Operations Management System), and its people.”

Thanks to Kal Tire’s rich know-how and Pitcrew AI innovation, thermographic inspections of mining trucks has become the gold standard of tyre maintenance.

Strategically placed on a mine site, TireSight stations can detect some tyre conditions hidden from the human eye. As trucks pass the inspection stations, Pitcrew AI cameras carry out thermal inspections to record the front and rear tyres. “TireSight identifies friction heat coming from cuts, mechanical separations, or other damages on the tyre,” Erdelyi explains.

Responsible for the communication to the site and using data from the Tyre Pressure Monitoring System (TPMS) and other aspects, Kal Tire’s remote condition monitoring team conduct an expert review of all available information. This helps to distinguish whether the detected damage is a condition hidden under the tread, like a separation, or a condition like

a cut where the belts or cords are exposed and the rubber is missing. They also focus on other conditions, like hydraulic leaks, coolant leaks, issues with struts on the truck, and more.

The workflow with accurate information allows the inspector to know in advance where the damage is located and what type of damage to look for. This then informs how Kal Tire’s technicians at the mine site respond to the event.

Considerably, Kal Tire and Pitcrew AI are transforming tyre management. Many inspection scans reviewed by the remote condition monitoring team have been identified and reported. “While some sensors on trucks monitor several of those issues, there were occasions where the TireSight team was able to identify problems first and prevent greater damage,” says Erdelyi. In one instance, the team was able to identify an engine leak on a truck during dumping. The notification enabled the truck to be shut down, preventing further top-end damage to a brand-new engine of a 400-tonne-class truck,” Erdelyi cites.

To date, over the last 12 months in particular, TireSight has scanned trucks nearly a million

times. It has enabled the Kal Tire condition monitoring team to identify 4,000 cases of tyre and truck damage. Of those, 1,200 resulted in interventions where the mine site teams knew ahead of time and were informed about the upcoming maintenance needs.

At one customer site, the use of TireSight has improved the Mean Time Between Tire Service (MTBS) from 17 to 27 days. Furthermore, tyre life has increased by more than 25%, and the number of tyre shop events has decreased by more than 30%. All of this has resulted in a downtime reduction of around 3,000 hours per annum, without losing productivity. Erdelyi attributes this success to the collaboration between the customer, OEM, Pitcrew and Kal Tire as the tyre service provider.

Noteworthy, TireSight’s success is down to Kal Tire’s unique approach for each mine, which is two-fold:

• If the main goal is to prevent tyre fires from friction heat, trucks need to be monitored with higher frequency. Strategic locations across the haul road help scan those trucks multiple times per hour.

• If the main goal is to identify tyres early enough in their life for repair, positioning the station by fuel depots may be sufficient,

allowing trucks to be scanned up to twice a day. Multiple systems per mine site can help achieve maximum fleet coverage.

So after KalPRO TireSight’s success, what’s next?

Always forward looking, Kal Tire sees great opportunity in autonomous open-pit mining operations, Erdelyi reveals. Typically, autonomous machines need daily inspections, but they operate best without interruptions from humans. When humans enter autonomous areas, they need to undergo additional training, and exclusion zones and other safety precautions need to be established.

“This presents a good opportunity for TireSight,” Erdelyi says.

“We can inspect these machines without requiring a human to enter the autonomous zone or causing dispatch interference. Besides, an AHS truck does not need to leave its dedicated working area for an inspection. For staffed trucks, operators can more easily detect issues in the driving behavior of the vehicle, but for AHS trucks, this is more difficult.” This statement underlines Kal Tire’s commitment to diligently detecting tyre defects to increase haul truck uptime.

The PressurePro Pulse Tyre Pressure and Temperature Monitoring System helps prevent costly haul truck tyre failures in mining operations. Produced by the American company Advantage PressurePro, it is distributed by Wheel Hub Trading in collaboration with South African-based dealer Nerospec OSCON to the African market.

Tyres are important elements of a vehicle, representing a significant investment in both purchase and maintenance costs. Like all items subject to wear, tyres have operating limits and a service life. However, many are disposed of before reaching their full service life.

The Need for Monitoring Tyres

To appreciate the significance of healthy tyres, one can use an analogy of the human body.

When a person visits a doctor with health concerns, the first thing checked is their temperature and blood pressure. Similarly, these parameters should be monitored in tyres, as they directly impact service life, operational costs, and cost per kilometre of vehicle mileage, among others. The fact is: tyres require constant monitoring, not just when problems arise.

The Ineffectiveness of Manual Monitoring

One may ask: what is the best way to monitor tyres? Of course, it can be done manually. Usually, companies have regulations requiring tyre pressure checks, which drivers typically perform using a mechanical pressure gauge. As a rule, these checks occur twice daily - when shifts change and when the vehicle is stationary.

“In our experience, not every company strictly follows these regulations. Even when crews are responsible, they do not always have the time or physical ability to check tyre pressure. Valves may be in poor condition, especially during seasonal changes. Often, access to the inner tyre is limited, and its valve may not be extended to the outer wheel,” notes Nikita Lomagin, CEO of Wheel Hub Trading.

“Such checks are not only inconvenient but also ineffective because tyre pressure must be

monitored 24/7. Constant monitoring is crucial while the vehicle is in operation rather than when it is parked, as generally, most tyre issues occur while driving. As you know, a tyre pressure gauge cannot measure pressure while the vehicle is in motion,” Lomagin explains.

This is where automatic tyre condition monitoring systems provide a critical solution. These systems are increasingly common in specialised vehicles, particularly in the mining industry.

The principle is simple. According to tyre manufacturer guidelines, even a 1% underinflation can contribute to increased rolling resistance, leading to reduced fuel efficiency and accelerated tyre wear, resulting in up to a 1.5% under-mileage.

Based on Wheel Hub Trading’s experience, around 50% of tyres are regularly underinflated, with approximately 25% in the critical zone. This means that an average mining operation could be losing between 10% and 50% of its tyre budget.

When underinflated (which is more common than overinflation), a tyre does not function properly. Its geometry changes, excessive shoulder wear occurs, rolling resistance increases, and more heat is generated - which

may potentially result in carcass separation. When a tyre’s geometry is suboptimal during operation, rubber layers twist and rub against each other, generating heat and accelerating wear.

What is more, it is important to note that tyre pressure fluctuates constantly due to air temperature, load, and road conditions. Obviously, stopping to check tyre pressure manually is impractical.

The PressurePro Pulse System consists of sealed, one-piece vibration- and shock-resistant sensors with internal batteries. These sensors continuously measure tyre pressure and temperature. They are screwed onto the tyre valve and convert mechanical air pressure into a radio signal, transmitting data to the monitor in the driver’s cab every seven seconds. If pressure or temperature deviates from preset parameters, the driver is alerted by a signal on the monitor.

One of the key benefits of the PressurePro Pulse System is that it monitors all tyres simultaneously. If a sensor fails, it can be replaced easily without affecting the others. In addition, the system allows data to be displayed remotely to dispatchers.

This is particularly important for companies with large fleets where remote monitoring of vehicles is essential.

Most importantly, the PressurePro Pulse System optimises costs, particularly in terms of tyre lifespan. Among other factors, tyre pressure plays a significant role in determining tyre lifespan. For instance, a mining dump truck operates on six wheels, with each tyre costing between $15,000 and $60,000. A full set of tyres can range from $90,000 to $400,000, depending on the brand and size.

Results gathered from mining sites worldwide show that the PressurePro Pulse System has revolutionised tyre monitoring. Encouraged by this success, Nerospec OSCON and Wheel Hub Trading have partnered to introduce the PressurePro Pulse System to the African market, combining cutting-edge machine health monitoring with world-class tyre pressure and temperature management.

This collaboration delivers more than just technology - it brings a smarter, data-driven approach to tyre safety and operational efficiency in mining and heavy vehicle industries.

With a well-established distribution network

and industry-leading after-sales support, this partnership ensures that Africa’s mining and industrial sectors have access to a globally trusted, agnostic tyre management system.

Nerospec is excited about the immense benefits this strategic partnership will bring to tyre monitoring for clients across the African continent.

Unlike traditional solutions, PressurePro seamlessly integrates into existing fleet operations, offering mines real-time tyre condition monitoring through Nerospec’s SIMAC software. This provides instant alerts, predictive maintenance insights, and fleet-wide visibility, empowering operators to make better, faster decisions.

For heavy vehicle fleets, this means fewer unexpected failures, reduced downtime, and significantly lower tyre and fuel costs. Designed to work across all fleet types, regardless of make, model, or age, the PressurePro Pulse System offers a universal solution for mining, trucking, and heavy industrial operations.

“We are proud to partner with Wheel Hub Trading to bring the PressurePro Pulse System to Africa. With its instant cost-saving benefits and industry-leading tyre management capabilities, we are confident that PressurePro will become the go-to choice for businesses across multiple industrial sectors,” says Lee Bothma, Group Head of Sales at Nerospec OSCON.

In FIBCs, benefits like lightweight robustness, environmental friendliness, and compliance with safety standards are undeniable. Unsurprisingly, they have become the preferred choice for mining projects across Africa. However, selecting the right supplier presents a selection dilemma. Making an informed choice requires prudence and due diligence.

If durability, robustness, safety, and environmental friendliness are the qualities mines need in ore packaging, then FIBCs are the perfect fit (Image: LC Packaging)

By Jimmy Swira

Afortnight ago, this writer was at a copper mine in Zambia at the peak of production.

Arms crossed, mining managers gleefully watched as haul trucks took turns moving ore. “We have never been this busy in five years,” said the helmeted, burly shift manager, a smile of content written on his face.

No prize for guessing that a similar scenario is playing out at other copper mines elsewhere on the continent – thanks to high demand in critical minerals. Obviously, increasing activities means more need for suitable packaging to facilitate easy storage, handling, and transportation of processed materials.

Flexible Intermediate Bulk Containers (FIBCs)

Among a host of others, Flexible Intermediate Bulk Containers (FIBCs), which are made of polypropylene (PP), are an option that comes in handy. The heavy-duty bulk bags meet the need for affordable, high-quality, versatile packaging solutions. This explains why they are also used extensively in industries such as the food and beverage, personal care, and pharmaceutical industries.

Other flexible packaging options include woven PP bags, net bags, and paper bags. However, in contrast, these have limited usage and are not suitable for heavy-duty applications.

Why Are FIBCs the ‘Real Deal’?

When it comes to preserving ore, there are challenges involved in storage, handling, and transporting ore. The main ones are the properties of the materials, such as chemical content and abrasive nature. So, the packaging has to withstand these and secure invaluable assets.

Manufacturers this publication approached shared information generously about their customer preferences. Unanimously, they mentioned the following as what makes FIBCs the obvious choice (‘the real deal,’ as one supplier put it) by a country mile:

1. Durability

Polypropylene is a chemical-resistant, mouldresistant, and rust-resistant polymer. These properties render it ideal for harsh conditions at mining sites. Due to this material of construction, FIBCs can withstand the abrasive nature of rocks and metals and potential exposure to harsh weather conditions.

2. Lightweight but Robust

Flexible packaging requires less material than rigid containers. However, their lightweight nature belies their robustness. They are designed to hold significantly more weight. For example, a 3 kg bag can handle two metric tonnes of material.

Due to their adaptability, FIBCs are easily stored in warehouses or open areas as they can be lined, ultraviolet-protected, and water-resistant. Besides, they can be easily handled (loaded and unloaded) by equipment such as forklifts, diggers, trucks, loaders, and forklifts. This ensures the quality of the valuable ore is well preserved.

4. Environmentally Friendly

Bulk packaging is not best known for its green credentials. However, FIBCs are lined and water-resistant, minimising the risk of external environmental impact. In addition, as they require less material than rigid containers, FIBCs leave a small environmental footprint.

5. Safety

In mining operations, compliance with health and safety regulations – in the South African context, the Mine Health and Safety Act (MHSA) and the Occupational Health and Safety Act (OHSA) – is not optional but obligatory. In terms of adherence to safety practices, FIBCs are up to the task.

Generally, FIBCs are a suitable alternative to traditional fragile packaging, which can be a safety hazard to personnel while filling, transporting, and stacking.

In that respect, prudence in procurement processes is the operative word as, in contemporary FIBCs, durability and affordability are not just enough; compliance with Environmental, Social, and Governance (ESG) standards is also crucial.

There are a wide range of FIBC brands out there from suppliers targeting Africa’s mining operations. Isn’t that a pleasant selection dilemma?

In theory, it is, but not when, ostensibly, there are near-identical FIBCs on the market. However, while there may appear to be nothing much separating them, products from manufacturers are unique – at least that’s what manufacturers claim. This complicates informed decision-making.

Hence, the mining manager in Zambia and his colleagues have their work cut out in applying prudence and due diligence as they shop around for suitable FIBCs to meet their respective needs.

• Easy to install - cut to shape/size

• Hygienic and easy to clean

• Four-way drainage

• Warm & comfortable for barefoot traffic

• ‘Sanitized’ Anti-bacterial & anti-fungal properties

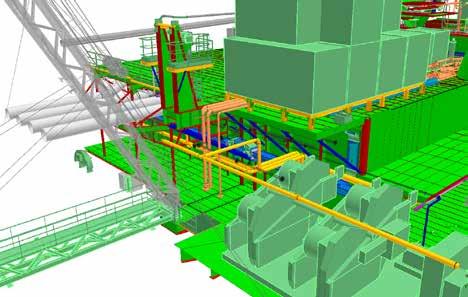

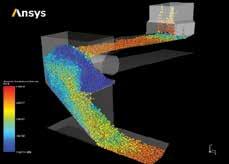

Utilising AI algorithms and historical data, simulation tools have brought more predictability in decision making, eliminating error-prone estimation methods. This has led to marked improvements in efficiency, safety, cost reduction, and most importantly enhanced ESG compliance reporting.

By Nick Barnes

These are good times for African mining operations specialising in critical minerals and gold. “It’s Christmas time!” an analyst on Bloomberg TV summed up market sentiment in early March, reacting to a rally in the stock prices of listed critical minerals and gold companies. In boardrooms, executives are relishing the prospects of record revenue on the balance sheet. However, they are well aware that accomplishing their production objectives hinges on offsetting increasing risks to their businesses - from pit to port (and even beyond, up to mine rehabilitation and closure).

The main operational risks they face are numerous and complex - some unique to specific commodities, operations, and locations. However, the general consensus among delegates at the 2025 Investing in African Mining Indaba was on the following:

1. ESG

Environmental, Social, and Governance (ESG) reporting compliance is no longer optional; it has become obligatory. Stakeholders expect operations “to be up to date.” Little wonder it has become key to accessing project capital. Among lending institutions and investors, there is a bias towards funding projects that are ESG-compliant.

The deeper operations go (this applies to gold and PGMs), the higher the accident risks posed to workers. This increases the burden of complying with Health and Safety regulations - such as the Mine Health and Safety Act in the South African context and the Department of Labour Occupational Health and Safety Act (OHS) or similar regulations in respective jurisdictions.

Another challenge is managing rising operating costs. Typically, mining operations devote significant financial resources to energy for processes such as communication, concentration, and mineral extraction. Conservative estimates suggest this accounts for no less than 30 percent of operating costs. Increased activity means higher energy costs.

This, coupled with other operational expenses, can reduce revenue. Hence, mines must seek innovative ways to contain costs.

A wave of resource nationalism is sweeping across the continent due to regime changes in West Africa. A case in point is Canadian miner Barrick’s experience in Mali, which is under military rule. The company was asked to pay billions in tax arrears to the state.

Generally, there is increased demand from resource-rich countries to change ownership

models of mining operations by renegotiating previous agreements.

This wave of resource nationalism has even extended to host communities. Now more ‘enlightened’ people expect tangible benefits from the mineral resources in their areas. This is prompting mining companies to increase Corporate Social Investments (CSI), which requires more revenue.

Clearly, the above-mentioned risks are a major concern. However, mining companies can turn these challenges into opportunities by exploring innovations in engineering design at the mine planning stage. This will ensure their operations are safe, profitable, sustainable, and compliant.

Addressing these risks using traditional engineering design methods may fall short, undermining efforts to meet production targets. Typically, traditional mine planning methods involve estimations - if not outright guesswork. That’s why they are inherently error-prone and time-consuming.

While these methods may have worked in the past, it no longer makes sense to rely on them. In the past, the cost of mineral ore extraction at shallow levels was comparatively cheaper, environmental regulations were lax, and communities were less informed about their rights.

Unfortunately, design-related oversights at the mine planning phase can have significant implications on the life of a mine. Errors could result in major financial losses, extended timelines (if not outright delays), breaches of health and safety, and environmental regulations, and conflicts with host communities.

Therefore, there is a strong business case for adopting alternative methods in engineering design. Unsurprisingly, engineers are increasingly turning to advanced engineering simulation tools. By utilising artificial intelligence (AI) algorithms and historical data, simulation tools can help solve contemporary challenges in exploration and mining (ore processing, waste management, and resource optimisation).

At the exploration stage, they combine detailed geological data - such as seismic surveys, magnetic readings, and soil samples - into a single 3D model of underground mineral deposits. Similarly, in mineral extraction, simulations help analyse the behaviour and interactions of materials and equipment throughout the process.

Conveniently, teams across the globe can access securely stored data on cloud platforms. This enables seamless collaboration, allowing them to analyse real-time data for informed decision-making.

By simulating real-world conditions as precisely as possible, engineers can optimise designs. When validated against real-world measurements, the benefits of simulation technology are tangible:

In exploration projects, this technology enables teams to focus on high-potential areas while reducing unnecessary drilling - an energyintensive activity. While enhancing overall efficiency, this approach also conserves energy.

The same applies to comminution and mineral

extraction. In comminution, specifically, by modelling the interaction between particles and machinery, simulation tools allow precise analysis of crushing and grinding processes. The detailed information gathered helps improve energy usage and ensures consistent particle sizes for downstream processes.

In flotation tanks and hydrocyclones, simulation models enhance process efficiency and reduce operating costs. By analysing fluid and particle behaviour, simulations contribute to improved recovery rates.

• In flotation tanks, models help visualise how air bubbles interact with mineral particles, improving recovery rates.

• In hydrocyclones, modelling particle collisions and separation allows for more effective mineral extraction.

Overall, accurate insights from simulation models help mines focus only on high-potential areas. This results in significant reductions in project timelines—by up to 50%.

Another efficiency-related benefit is improved equipment uptime. The data derived from simulations informs maintenance decisions, enhancing equipment availability and reducing downtime, which boosts productivity.

Simulation models can help organisations minimise emissions from mine-to-mill activities.

Another key area is tailings dams. In tailings management, simulation tools model the settling behaviour of particles, which is crucial for preventing overflow and ensuring stability. This can help prevent tailings dam failures, like the recent one in Zambia.

More broadly, the mining industry stands to gain significantly from digitisation. The World Economic Forum’s whitepaper on Digital Transformation Initiative: Mining and Metals Industry estimates that digital transformation could help reduce CO₂ emissions by 610 million tonnes.

By instantly analysing accurate data, mining operations can identify potential risks in their activities. This enables them to adopt relevant strategies to minimise accidents and fatalities, ensuring compliance with Mine Health and Safety regulations.

iv.

Increased revenue from optimised projects using simulation models can be reinvested in various CSI activities within host communities. This fosters stronger relationships between mining companies and local populations.

v.

The benefits of safe, efficient, sustainable, and cost-effective operations, along with improved stakeholder relationships, can translate into higher ESG rankings. All told, using predictive modelling, mining companies can separate highvalue projects from less viable ones, directing resources where it matters.