Editor’s Choice

ALEXANDER BATTERY TECHNOLOGIES

The UK’s new manufacturing proposition

KOLLMORGEN

What to look for in your motion control feedback device

SULZER

How Sulzer powers every step of the desalination process

JPB

Ardian acquires stake in JPB Système

SPELSBERG

Enclosure customisation requires the right experience

FANUC

Introducing CODEL’s game-changing Triboelectric dust monitor range

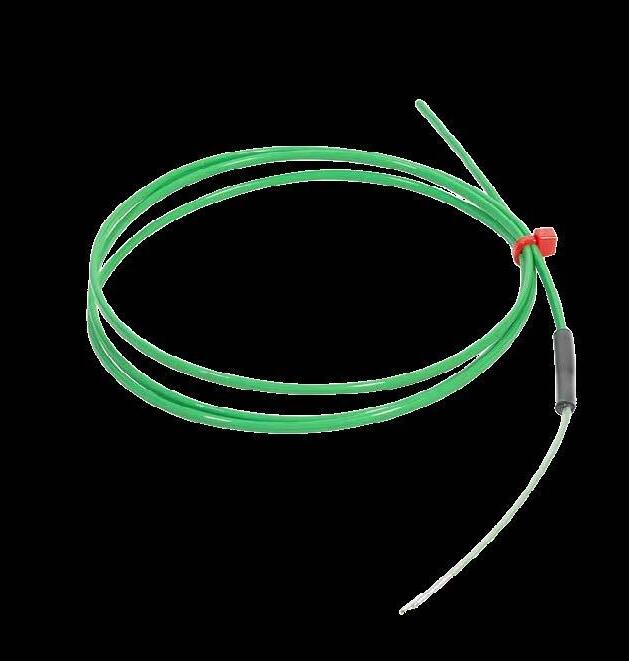

Cover photo: Labfacility

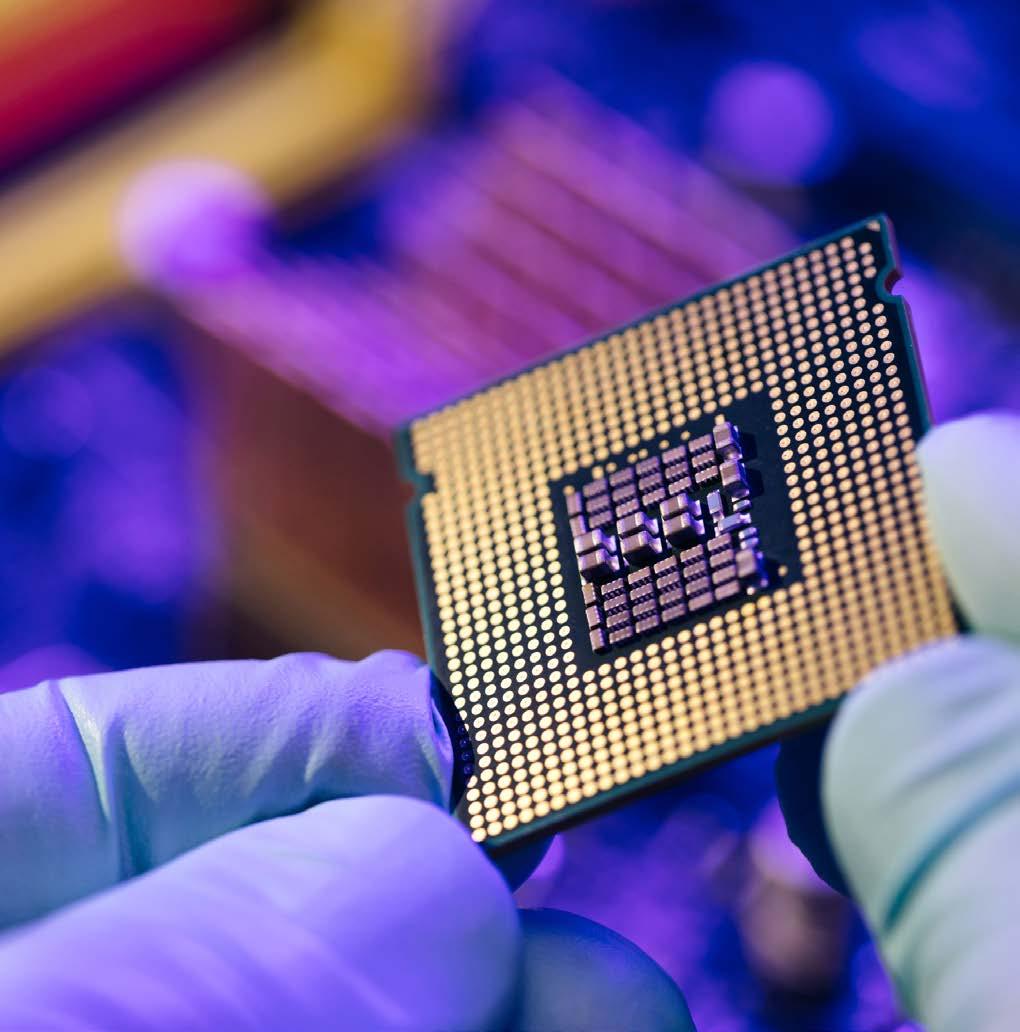

SWINDON SILICON SYSTEMS

How application-specific chips support fast, efficient edge AI

TECHNIDRIVE

Installation tips for maximising shaftmounted gearbox efficiency

BURCKHARDT COMPRESSION

Why expertise matters in compressor overhauls and revamps

FFG

FFG receives major project from India

HIKMICRO

HIKMICRO fighting industrial fire with extended specialist range

VERICUT

Vericut Force brings 20% tool cost savings per part to leading turbine part manufacturer

By using pre-labelled Panduit patch cords and the RapidID Bluetooth-enabled handheld scanner, network engineers can quickly, easily, and more accurately place and trace cables.

The Network Mapping System automates the labour intensive and error-prone cable documentation process to reduce the risk of a network outage. With RapidID, the painstaking labelling process is already done. Additionally, RapidID is a practical alternative to traditional manual approaches and is ideally suited for building a new telecom room, locating installed cabling, or replacing a network switch.

“RapidID is a game-changer for any network engineer,” stated Stuart McKay, Sr Business Development Manager EMEA. “We offer our customers an innovative way to eliminate the pain points around patch cord labelling and documentation for network systems.”

Rapid ID uses patch cords pre -labelled with unique barcodes and a Bluetooth®-enabled handheld scanner to automate labelling, tracing, and troubleshooting in t hree easy steps .

1 2 3

Panduit cables pre-labelled with unique barcode labels.

The mobile app from iOS or A ndroid app stores to a t ablet device

Barcodes using the Bluetoothenabled handheld scanner.

The leading source for innovators in Technology, Manufacturing and Maintenance within the Engineering & Processing industry worldwide.

Published bimonthly, a subscription to PECM magazine is essential for Process Engineers, Chemical Engineers, Instrumentation Engineers, Mechanical Engineers, Plant Engineers, Precision Engineers, Environmental Engineers & General Engineers, Companies and Organizations in the Food, Dairy, Beverage, Brewing, Semiconductor, Pharmaceutical, Biotechnology, Chemical, Oil & Gas, as well as all UK's major manufacturing units.

Every issue of the magazine contains the latest news, in-depth features, together with product innovations and case studies showing how process engineers are implementing new technologies to reduce costs and impact on the environment.

With over 158,000 readers worldwide the publication is widely read, recognized, and well respected within the Process, Engineering & maintenance industries.

A subscription to PECM magazine is the industry's 'must have' publication.

SUBSCRIBE TO 6 BIMONTHLY ISSUES OF PECM FOR JUST £27

• The magazine gets delivered directly to your door once every issue is published

• The quality of the hard copy enhances the reading experience

To Subscribe please call 01304 806039

SUBSCRIBE TO OUR DIGITAL EDITION COMPLETELY FREE OF CHARGE

Designed for the digital age, the magazine has been created for easy viewing on all electronic devices. All our issues stored in one place: get unlimited access to our previous and future issues.

To Subscribe please visit www.pecm.co.uk/subscribe

EDITOR IN CHIEF

Antony Holter editor@mhmagazine.co.uk

BUSINESS MANAGER

Josh Holmes josh@mhmagazine.co.uk

SALES DIRECTOR

Jake Page jake@pecm.co.uk Tel: 01227 937174

SALES MANAGER

Martin Richardson martin@pecm.co.uk Tel: 01304 086039

DIGITAL MANAGER

Jamie Bullock jamie@mhmagazine.co.uk Tel: 01227 936971

EDITOR

Elizabeth Hutton elizabeth@pecm.co.uk

STUDIO DESIGNER

Richard Bland richard@mhmagazine.co.uk

ACCOUNTS DEPT

Alison Holmes accounts@pecm.co.uk Tel: 01227 936976

PUBLISHING DIRECTOR

Martin Holmes martin@mhmagazine.co.uk Tel: 01304 806039

DIGITAL ASSISTANT

Stacey Goodwood Tel: 01227 936971

MH Media Global Ltd. 18/20 Newington Road, Ramsgate, Kent, CT12 6EE Tel 01304 806039 l Fax: 08721 152240 l www.pecm.co.uk

Teknomek has launched a new range of powder-coated laboratory furniture that can be fully customised to your business’ requirements. Starting with an initial site visit, the Teknomek design team will create a layout that compliments current workflows and ensures efficiency for years to come.

Fully adaptable to your needs, the work benches and islands are available in mobile or fixed versions with a variety of storage configurations, including sliding cupboards to help facilitate desk sharing. These units can also be fitted with sinks or a power supply via trunking with integrated plug sockets for full versatility.

By opting for a modular lab furniture system, equipment can be added as tasks require, or budget allows, with mobile cupboards and drawer units listed separately to the work benches and islands for full versatility. Bespoke sizes can also be provided to suit the individual requirements of customers.

All of the new workbenches and islands feature Trespa TopLab® Plus countertops, a premium surface material engineered specifically for demanding laboratory and hygienic environments. Trespa TopLab® Plus combines exceptional durability and impact resistance with a non-porous, easy-to-clean surface offering anti-microbial protection. Designed to perform under intensive use, it offers outstanding resistance to chemicals, disinfectants, and cleaning agents, ensuring long-term performance even when exposed to corrosive substances.

By opting for a modular lab furniture system, equipment can be added as tasks require, or budget allows.

The range also includes open-sided lab benches with a tubular rear tie bar for easy cleaning access and improved air circulation as well as height adjustable tables for ergonomic support that prevents muscular strain. Reagent shelving offers another storage option that can be mounted to the work top for double-sided work stations or to the wall - providing easy accessibility to labware and equipment.

Alongside these, Teknomek is also offering a vibration-free balance desk as part of the lab

furniture range. This essential equipment features a marble top to provide a stable, surface for precision instruments. The weight and rigidity of the marble helps to dampen floor vibrations, ensuring precise balance readings even in elevated or less stable lab areas. This maintains accuracy in environments where floor movement could otherwise compromise sensitive weighing tasks.

This new laboratory furniture range is designed to meet or exceed EN 13150 standards for workbenches and follows SEFA guidelines for international best practice, while GMP compliance is addressed for pharmaceutical, biotech and life science laboratories. Teknomek also provides stainless steel furniture for changing rooms and cleanrooms within these facilities.

Book your site visit today on the Teknomek website or give them a call on +44(0)1603 788 833.

• Innovative solutions

• Premium perforation

• Custom processing

• Finishing operations

• Technical advice

With the world’s leading manufacturer of perforated metal as your partner, you gain access to unique expertise and premium perforation solutions. Explore the full potential of perforated

Strengthen your competitiveness and enhance your customer offerings with innovative services and large-scale production capacity from RMIG Solutions. Whatever your plans and requirements, we provide tailor-made solutions that maximise your return on investment.

Due to it’s functionality and durability, perforated metal is the preferred choice across a wide range of sectors, such as manufacturing, processing, safety and architecture. You are invited to explore the potential at rmigsolutions.com

RMIG Ltd · Phone +44 1925 839610 · info.uk@rmig.com · rmigsolutions.co.uk

Specialist T raining for the Storage T ank

L ive online , classroom , blended , e-learning or in-house

• Gain or renew your 5-year Certificates of Competence*

• Courses f for each career stage based on EEMUA 159

• English, Dutch, German and French language options

• Free or discounted for EEMUA Members and Associates

TankAssessor courses*

3-6 November 2025 – in German

– live online

17-20 November 2025 – in English

– live online

9-12 February 2026 – in Dutch

– live online

1-4 June 2026 – in French

– Paris, FR

Tank Integrity Manager course

1-5 December 2025 – in English

–Antwerp, BE

In-house courses

By arrangement for your choice of: time, language, location.

TankInspector courses*

16-18 February 2026 – in English

–live online

23-25 February 2026 – in Dutch

–live online

16-18 March 2026 – in French

–live online

TankBasics courses

9 March - 30 April 2026 – in English – blended, live online

Storage Tanks e-learning

On-demand – in English or Dutch

Also...

Storage Tanks Seminar –Ridderkerk, NL – 27 November 2025

More choices, information and registration at www.eemua.org

US

UK Manufacturer & Supplier of Lifting & Rigging Equipment.

Wire Rope Slings

Round Slings

Flat Slings

Chain Slings

Lifting Accessories

Galv, Black & PVC Coated Wire Rope

Fibre Rope

Safety Bonds

By Mark Rutherford, CEO at Alexander Battery Technologies

For years, the assumption has been that large-scale manufacturing belongs in Asia. China in particular accounts for nearly 30% of global manufacturing output (World Bank, 2023), dominating as the go-to option for cost-conscious supply chains. The UK, by contrast, was long seen as high cost and only suited to niche or specialist production but recent developments suggest that picture is beginning to change.

Some supply chain leaders are beginning to view the UK as a surprisingly cost-effective base, especially when producing for the US and EU. The change is not driven by sudden efficiency gains at home but by the steady erosion of advantages elsewhere.

The calculus that once made offshore production inevitable is looking more fragile. Lengthy lead times, advance payment terms and the friction of shipping goods halfway across the world are becoming harder to justify when tariffs and geopolitical disputes keep adding layers of uncertainty. Products made in China can sit on the water for 12 weeks or more, a vulnerability brought into focus during COVID, when some global shipping costs rose by more than 400%, according to the Drewry World Container Index in 2021. Those increases were once tolerable when the savings from offshore production were dramatic, but with shipping rates still around 60–70% above pre-pandemic levels (FreightWaves, 2025) and wages rising steadily in low-cost regions, the total cost gap is narrowing. What used to be an overwhelming

Some supply chain leaders are beginning to view the UK as a surprisingly cost-effective base, especially when producing for the US and EU.

cost advantage now looks less compelling once risk, delay, and volatility are factored in.

The UK occupies an unusual position in this picture. It is not the top prize in the eyes of the world’s largest economies, but that may work to its advantage. Relations with both the US and EU remain comparatively stable, which makes the UK a practical base for serving both. In a more protectionist era, when governments on both sides of the Atlantic are watching supply

chains more closely, this counts for more than it used to. A senior supply chain manager recently remarked to me that the UK was starting to look like “a low-cost manufacturing centre” for the first time in her career. Her view was not that Britain is cheaper than Asia in absolute terms, but that the combination of trade access, resilience and reduced risk is tipping the balance.

Cost dynamics inside the UK matter too. Regions such as the North East combine long-standing manufacturing expertise with lower property and labour costs than the South. Strong transport links and an established industrial base mean companies setting up there are not starting from scratch. For supply chain leaders, this shifts the calculation from simple cost comparison to risk management. A UK base can reduce exposure to shipping delays, tariffs and currency shocks. These are the factors that are now front of mind when weighing up potential suppliers.

The nature of manufacturing demand is also changing. Many of today’s projects require specialised, mid-volume production rather than mass-produced, commoditised goods. Custom battery packs for OEMs are a good example. Whether for UAV/drones, e-mobility, robotics, medical devices or safety equipment, these solutions often need to be designed around the application rather than bought off the shelf. This kind of work benefits from a location with strong engineering expertise, responsive design support and the ability to move quickly from concept to production - not just the lowestcost manufacturing site.

This helps explain why some of the UK’s traditional disadvantages are starting to fade. Wage differences matter less when speed, resilience and design capabilities are the priority. When those costs are offset by shorter lead times, easier oversight and more flexible delivery to Western markets, the UK starts to look a more reliable and affordable base in practical terms.

It is tempting to dismiss this as a temporary swing brought about by current trade wars and geopolitical

tensions, but the underlying direction of travel suggests otherwise. The risks of long-distance supply chains are not going away. If anything, they are likely to intensify as countries compete to secure domestic manufacturing and protect critical infrastructure. For certain strategic industries, the UK is better positioned today than it has been for decades.

Trying to rival China on sheer scale would be unrealistic. Instead, the UK needs to position itself as a dependable, cost-competitive base for mid-volume production that can supply the US and EU quickly and reliably. For companies choosing their next supply partner, that mix

of reliability, cost control and speed to market makes the UK a serious contender.

The UK may have slipped to 11th in global manufacturing output rankings (MAKE UK, 2025), but that does not diminish its relevance. If anything, it underlines the need to leverage the capabilities that remain. Skilled engineering talent, trusted regulatory frameworks and strong transatlantic trade links exist, especially in long-established manufacturing regions such as the North East of England. When risk, speed and quality are weighted alongside cost, the UK’s offer looks stronger than its headline ranking suggests.

Customised

Proven

Packaged

North Ridge Pumps recently supplied four heavy-duty horizontal multistage pumps for a diesel transfer application operating at 30 bar and a flow rate of approximately 60 m³/h.

To accommodate the client’s preference for integrating their own drive arrangement, the pumps were supplied in bareshaft configuration for mounting to their selected motor and baseplate.

The units are being installed within a thermal power plant, forming part of the process where heavy fuel oil (HFO) is converted into diesel.

What’s the difference between HFO and diesel?

HFO is a heavy, high-sulphur fuel from crude oil distillation, mainly used in shipping but requiring heated storage. Diesel is lighter, low in sulphur, widely used in transport and machinery, and easier to handle with no special storage needs.

Why might a power plant change from HFO to diesel?

The switch may be made for several reasons, such as:

• Environmental compliance: Switching from HFO to ultra-low sulphur diesel cuts sulphur dioxide emissions by 99% and reduces particulates and CO2 by ~70%.

• Fuel price and supply: HFO is cheaper, but diesel may be preferable if HFO prices rise or supply becomes unreliable.

• Operational flexibility: HFO requires heating and performs poorly at low loads, while diesel flows easily and ensures stable combustion.

• Efficiency and maintenance: Diesel avoids engine problems linked to HFO at low loads, improving performance and reliability.

• Availability: Diesel is often more practical for remote areas lacking consistent HFO supply.

However, diesel offers cleaner, more reliable, and cost-efficient operation.

Multistage pumps use multiple impellers in series to generate high pressure efficiently, saving energy compared to single-stage pumps. Their vertical design also reduces floor space needs. They are ideal for applications requiring high discharge pressure or vertical lift, such as:

• High-pressure fluid transfer in chemical, oil, and gas industries

• Water supply for high-rise buildings and long-distance pumping

• Industrial cleaning and power washing

• Supplying water to high-pressure boilers

• Reverse osmosis in desalination plants

Why specify horizontal multistage pumps for this application?

We specified horizontal multistage pumps because they reliably deliver 30 bar pressure at 60 m³/h, meeting the client’s brief for four heavyduty diesel transfer pumps, while also offering flexibility through variable speed drives and multiple outlet options.

A multistage pump with eight ring stages

To produce the level of performance demanded by our client, we came up with a clever solution for these heavy-duty diesel transfer pumps. Each one incorporated eight ring stages, each one consisting of an impeller, suction and discharge diffuser to deliver the required pressure and flow rate.

In addition, our range comes with the option of rotating the suction and discharge flange to match the existing pipework, removing the need for any changes to pipework.

For high-pressure, high-flow fluid transfer applications, contact North Ridge Pumps for expert advice.

We’re North Ridge Pumps, the UK’s largest pump supplier with over 25 years’ experience. We’re expert at specifying exactly the right pump for every client – not just an off-the-shelf, one-size-fits-all solution.

That’s probably why we’ve completed over 2,000 successful projects for clients all around the world. You can read case studies at www.northridgepumps.com

Industrial environments are facing increasing cybersecurity risks. As Industry 4.0 accelerates with the integration of IIoT devices, smart building systems, and AI-driven automation, the attack surface has expanded.

Cybersecurity is no longer confined to software defences, it requires a robust physical and network infrastructure that can protect assets, enable visibility, and support rapid response and recovery. These attacks include ransomware, insider threats, and exploit targeting physical network vulnerabilities such as exposed ports and unsecured distribution points.

The convergence of IT and OT systems, essential for smart processing and manufacturing, also increases complexity. Legacy systems are now interfacing with modern IP networks, requiring a security-bydesign approach that incorporates both digital and physical safeguards.

Physical infrastructure is the first line of defence in industrial cybersecurity. Unsecured network cabinets, open ports, and exposed cabling can provide attackers with direct entry points. A layered approach to physical security reduces these risks by integrating:

- Port protection devices to block unauthorized access to Ethernet and USB interfaces

- Lockable enclosures to safeguard switches, servers, and critical controllers

- Intelligent power distribution units

for monitoring environmental and access conditions

- Segmented enclosures to isolate network zones and limit the spread of threats.

Zone architecture is a critical concept for industrial environments. By physically segmenting networks at the access layer, organisations can localise the impact of a breach. Industrial distribution frames (IDFs) and zone enclosures allow for switches and cabling to be deployed closer to the production floor, creating smaller, contained network zones.

These enclosures support faster maintenance, localised security policies, and disaster recovery readiness. In the event of an attack, zone segmentation ensures that disruptions are confined, protecting other parts of the operational network.

Visibility is fundamental to industrial and enterprise cybersecurity. Without an accurate inventory

of devices, connections, and configurations, security teams cannot effectively detect or respond to threats. Automated mapping reduces the time to document physical infrastructure, mitigates human error, and ensures faster recovery following incidents.

Products such as Panduit’s RapidID provide a network mapping system which automates the labour intensive and error-prone cable documentation process, resulting in a faster, easier way to place and trace cables and patch cords.

A comprehensive cybersecurity strategy includes robust disaster recovery. For industrial environments, this often takes the form of a secondary, isolated network architecture. In the event of an attack, critical production functions can be transferred to a standby system that is shielded from the compromised primary network.

Regulatory requirements for cybersecurity are tightening worldwide. Frameworks such as ISO/IEC 27001:2022, NIST Cybersecurity Framework, and the EU NIS2 Directive mandate security measures that extend into the physical infrastructure of industrial networks.

As industrial environments continue to evolve toward highly connected, intelligent operations, cybersecurity must adapt in parallel. Strong industrial network infrastructure, integrating physical security, zone segmentation, asset visibility, and disaster recovery provides the foundation for a resilient defence against modern data security threats.

When it comes to the world of motion control, it’s easy to take your feedback device for granted. After all, it’s a small part of the system and is typically tucked inside the motor housing, out of sight and out of mind. However, the impact this seemingly minor component has on a system’s accuracy, performance, reliability, and ease of integration is hard to overstate.

Today’s servo systems depend on accurate, consistent feedback to maintain position, control speed, and execute complex motion profiles. But not all feedback devices you can specify are created equal. Traditional encoders or resolvers still do the job in many applications, but application requirements increasingly need devices that go beyond the basics. Design engineers also want faster integration and less testing time. Modernizing your feedback device can mean reducing wiring, simplifying setup, or eliminating long-standing compromises on resolution, accuracy, and smoothness of motion.

Whether you’re specifying a new servo system or looking to simplify an existing design, it’s worth asking: what do you actually need your feedback device to do, and what’s now possible?

Most engineers don’t start out looking for a feedback device. They’re looking for performance, reliability, and a system that behaves the way it’s supposed to, every time. That means starting with the right questions – not “which sensing technology is best?” but “what performance does my application need to achieve?”

At the most basic level, your feedback device needs to deliver the resolution and accuracy required to drive the motion loop effectively. Too little, and you’ll see ripples in motion, jitter in position holds, vibration in the machine, or just plain inaccurate positioning. Too much, and you might be paying for more capability than needed. Mechanics connecting to a motor shaft can only so accurately connect to the part of the machine doing the work which is where the motion really matters.

Other considerations quickly come into play, such as how smooth the motion is, how noisy the signal is, and how much bandwidth does it offer compared to your requirements. Fortunately, these are mostly straightforward questions, and most engineers know how to weigh them up.

But modern feedback devices also bring in another category of features that extend beyond the basic specs and simplify the machine as a whole.

This is where many of today’s biggest gains are being made.

They include:

Simple cabling: Servo systems used to rely on dedicated feedback cables, sometimes requiring 13 or more wires just for feedback. That meant bigger cabinets, more connectors, tighter bends through cable trays, and more hands-on work during installation.

Modern single-cable feedback systems simplify all of that. By taking the motor power cable and just adding two wires for feedback data to fit everything into a single cable, they reduce effort and cut install time. Single-cable can make a major difference on compact machines where space is tight and reduce machine build time

Built-in motor ID: Many modern feedback devices now include onboard memory that stores the motor’s ID, specs, and even tuning parameters. When connected to a

compatible drive, the system can automatically recognize what it’s working with.

That means setup becomes faster, more consistent, and less prone to human error. In systems where motors are easy to mix up – say, a high-speed and low-speed variant sharing identical housing – this auto-recognition helps prevent costly mismatches. It also supports smoother global deployment, especially when machines are shipped across regions with different voltage standards.

Thermal monitoring: Temperature sensors are vital for protecting motors, but traditionally they’ve required their own wiring back to the drive. With smarter feedback systems, temperature data can now be sent over the same digital link used for position data.

This combination streamlines wiring even further and makes it easier to monitor winding temperatures in real time. The result is better protection against overheating, more consistent performance, and fewer points of failure.

Functional safety support: In applications where people work close to moving machinery, safety is vital. Some modern feedback devices now support functional safety features directly through the encoder.

These certified encoders allow safety systems to reliably monitor motor position and intervene if motion goes outside expected bounds. Integrating safety at the feedback level reduces the need for extra sensors or relays, simplifies system design, and helps meet compliance requirements without overcomplicating the machine.

One feature that’s quickly becoming an expectation rather than a simple nice-tohave is multi-turn absolute feedback. This allows a system to know not just the shaft angle within a single revolution, but how many full turns have occurred, even when the system is powered off.

Without multi-turn tracking, the system has no idea where it is on that axis after a power cycle. The common workaround is a homing routine: the machine slowly moves to a reference point and resets itself. While this works, it’s inefficient and vulnerable to mechanical faults.

Multi-turn absolute feedback lets machines skip the homing process entirely. Power up, and they’re ready to go. That means shorter startup times, fewer moving parts (no home switches), and fewer chances for something to go wrong.

There are several ways to achieve this. Some devices use small internal gearboxes to track turns, but this adds cost, complexity, and physical length to the encoder. These gears also limit usable multiturn range, usually to 12 bits. Other feedback devices use battery backups, which are compact and straightforward, but can potentially create maintenance issues down the line and reliability issues with unscheduled battery failures.

Energy-harvesting feedback devices offer a modern alternative to both. These generate just enough power from shaft rotation to store turn counts in non-volatile memory. The result is a compact, battery-free, maintenance-free solution that fits into the same footprint as a basic encoder.

So, how do you decide what to specify?

For most applications, a modern digital feedback device with multiturn absolute capability via energy

harvesting, single-cable support, provides motor thermal data, and has motor catalog data is a safe and future-ready choice. Devices like Kollmorgen’s SFD-M are designed to meet the demands of generalpurpose motion systems, delivering high performance, low cost, and reduced system complexity.

And if you’re building systems at scale, it’s worth thinking in terms of pre-matched components, such as those supplied by Kollmorgen. Drives, motors, and feedback devices that are designed to work together out of the box reduce integration complexity and speed up development.

Whether you approach feedback at the component level or the system level, the key is to pick devices that reduce the number of compromises your machine has to make.

It’s time to expect more

Feedback devices used to be simple. You picked a motor and got the feedback device it came with. You wired it up and tested whether the included feedback had the resolution and performance you needed. But today’s systems demand more – and deliver more in return. Features like single-cable installation, energy-harvesting multi-turn feedback, plug-and-play configuration, and built-in safety and diagnostics are fast becoming standard in well-designed motion platforms.

You’re not just choosing a sensor, you’re choosing a system that needs to work, reliably and efficiently, every day. That’s why it makes sense to look beyond the component spec sheet and consider how the feedback device supports the system as a whole.

Modern servo solutions – like those built around Kollmorgen’s SFD-M – show how far this technology has come. These are complete systems designed to simplify integration, support long-term reliability, and give machine builders fewer things to worry about.

www.kollmorgen.com

In the world of manufacturing, precision is everything. You will know how a consistent appearance, performance, taste and texture is vital in meeting your quality standards, reducing waste and protecting your brand with the consumer. Relying on the manual control of transfer is not only putting the burden on your production team (and we all know that time is money!), but also increasing the chance of recipe inaccuracies due to human error.

And that is why the accurate transfer of chemicals, process fluids or ingredients combined with the AMP-CONTROL peristaltic pump really is a “batch made in heaven”.

Castle Pumps have recently solved two clients’ batching requirements with their AMP-CONTROL peristaltic pump. The first was a manufacturer of low calorie sweeteners looking to batch 10 litres of Glycerin at a time during the production process of their products. The second was involved in the treatment of industrial wastewater and wanted to dose 5-10 litres of ferrous sulphate and caustic soda at a time from an IBC into the water being treated.

Both wanted control over the speed at which they could transfer and the ability to accurately determine how much to transfer in each batch. And that’s when Castle Pumps knew the AMP-CONTROL was the ideal solution.

Peristaltic pumps are often used for batching applications thanks to their smooth operation and ability to accurate dose even the smallest volume of fluids at low flow

rates. Another huge benefit of the peristaltic design is that with the inner hose being the only wetted part, there is only one component to wear and maintain without risk of seals leaking and valves blocking.

The AMP-CONTROL model in particular however had the intelligence to satisfy the companies’ requirements of automation and accuracy without the need for the clients purchasing and installing additional control equipment.

As well as its variable speed drive, the beauty of this pump is that it allows batching to be specified either by volume or by intervals, as well as a calendar for operation automation at set date/times. This peristaltic dosing pump also comes with configurable inputs and outputs that can be used for signal relays to determine when the pump

should operate for example when fluid in the receiving container has dropped to a set low level. These benefits allow for highly precise dosing of the additives whilst also freeing up operator time to carry out more value adding tasks.

As a fail-safe the AMP-CONTROL also comes with a hose leakage sensor to shut down the pump and alert the operator, as well as a hose replacement alert for preventive maintenance after a set interval to prevent downtime in production.

Getting the wrong pump for your process can result in inconsistency in the finished product, crushed solids, clogging, excessive wear, loss of productivity, waste of costly product or at worst, contamination. Always trust technical experts to specify the right pump for your application.

Pump smarter, not harder. Use our 15 years’ experience to save excessive wear, process failures, product waste & operator time.

✓ FDA & 3A hygienic solutions for food and drink

✓ Highly accurate dosing of ingredients & additives

✓ Delicate fluids sensitive to consistency changes

✓ Solid-laden products without crushing or clogging

✓ 99.98% barrel emptying to prevent product waste

✓ Models for the safe handling of cleaning chemicals

Contact our technical sales engineers now!

With climate change intensifying droughts and reducing freshwater availability, population growth placing increasing pressure on existing resources, and industrial demands pushing water consumption to new heights, global water scarcity has emerged as one of the most pressing challenges of our time.

According to a 2024 United Nations report (1), roughly half of the global population currently experiences severe water scarcity for at least part of the year, with around a quarter facing “extremely high” levels of water stress. For many regions, traditional freshwater sources such as rivers, lakes, and aquifers are no longer sufficient to meet the needs of growing communities and economies.

Desalination—the process of converting seawater into freshwater—has become an essential solution for tackling this problem. As such, the global desalination market is now expanding at a rate of more than 9% annually (2), with demand projected to grow significantly, driven by the urgent needs of water-scarce regions such as the Middle East, North Africa, and parts of Asia.

There are several different desalination technologies available, but over recent years reverse osmosis (RO) has become the most widely adopted method worldwide. By forcing seawater through semi-permeable membranes to separate, RO desalination provides an effective and scalable solution capable of delivering millions of gallons of fresh water every day. Its

According to a 2024 United Nations report (1), roughly half of the global population currently experiences severe water scarcity for at least part of the year

flexibility makes it suitable for both large-scale municipal plants and smaller industrial applications.

However, despite decades of incremental improvements making RO more efficient than ever, there’s no denying the fact that it is still an energy intensive activity. For the operators of these plants, and for their customers, efficient, reliable high-pressure pumps and process equipment play a crucial role in minimizing their energy consumption and the final cost of the supplied water.

The route from seawater to freshwater in a reverse osmosis (RO) desalination plant is a sophisticated, multi-stage process that relies on advanced engineering to ensure efficiency, reliability, and environmental sustainability. At every step, Sulzer plays a pivotal role, offering tailored products and services that optimize the entire process from intake to distribution.

The first step in the desalination process involves drawing seawater from the ocean through carefully designed intake structures. These

structures are engineered to minimize environmental impact, preventing large debris, sand, and marine life from entering the system and damaging downstream equipment. The efficiency and reliability of this initial stage are critical, as any disruptions can cause costly operational issues.

Sulzer plays a decisive role in this stage by supplying a range of high-efficiency pumps specifically designed for seawater intake in reverse osmosis applications. The key products include vertical turbine pumps (VTPs) and axially split case pumps, each tailored to meet different intake requirements.

These pumps are engineered to withstand the harsh marine environment and continuous operation under demanding conditions. They are constructed from corrosion-resistant materials, such as duplex or superduplex stainless steel, which provide excellent resistance to chlorideinduced corrosion and biofouling, ensuring that the need for replacements and maintenance is kept to a minimum.

Once the seawater enters the plant, it undergoes pre-treatment to remove suspended solids, sand, biological materials, and other impurities that could damage or clog the RO membranes. This stage is crucial for ensuring the longevity and efficiency of the membranes, which are sensitive to fouling and scaling. Effective pre-treatment not only protects the membranes but also enhances the overall efficiency of the desalination process.

Nordic Water, a Sulzer brand, supplies advanced sand filters that efficiently remove particulates from the seawater, ensuring that only clean water reaches the membranes. To further enhance water quality, Sulzer’s Chemtech division can supply static mixers where chemicals such as flocculants, coagulants, and biocides are evenly distributed throughout the water, optimizing the removal of contaminants. These mixers are able to deliver minimum pressure drop and effective mixing in a small footprint.

Throughout the pre-treatment process, the pumps maintain optimal flow rates at required pressure and efficiency, ensuring the continuous and stable operation of the plant. They will also provide the minimum required pressure towards high pressure pump and Energy Recovery Devices. By keeping the flow consistent, these pumps help minimize the risk of operational disruptions and maximize the efficiency of downstream processes.

Once the seawater has been pretreated, it enters the actual RO stage—the heart of the desalination process. In this phase, seawater is pressurized and forced through

semi-permeable membranes that effectively separate salts from the water.

The membranes allow only water molecules to pass through, while the remaining concentrated brine—rich in removed salts—is discharged for safe disposal. This stage is highly energy-intensive, accounting for a significant portion of a desalination

plant’s operational costs, making energy efficiency and precise pressure control critical to the process.

Sulzer plays a pivotal role in optimizing this phase by supplying high-pressure feed pumps. These are engineered to deliver the consistent, high-pressure flow required to push seawater through the RO membranes and typically account for more than half of a desalination plant’s power consumption. This makes Suzer’s ability to provide reliable, efficiency pumps a key element of running an effective operation.

In some desalination plants, a second pass of RO membranes is introduced to further refine the quality of the final product water. This additional stage ensures that the desalinated water meets even the most stringent purity standards, particularly for

industrial or specialized municipal use. To support this, Sulzer supplies dedicated second pass pumps, designed to maintain the necessary pressure and flow for this additional membrane filtration phase.

In addition, Sulzer can supply booster pumps to help integrate energy recovery devices (ERDs) into the RO process to significantly improve energy efficiency. ERDs capture the hydraulic energy from the high-pressure brine reject stream and transfer it back to the incoming seawater.

After the RO membranes have filtered out the salts and impurities, the water is not quite ready to drink or use in industry just yet. Without essential minerals, it can taste flat or even slightly acidic, and over time, that acidity can cause corrosion in pipes and storage systems. That’s why post-treatment is so important— it helps balance the water’s composition, making it safer, more stable, and better-tasting.

In order to eliminate any acidity, carbon dioxide (CO2) must be introduced following reverse osmosis and prior to remineralization. Sulzer’s specialized static mixers play

a crucial role in this process by efficiently dissolving CO2 gases directly into the water stream and ensuring thorough mixing within the main line. This innovative approach eliminates the need for dedicated CO2 dosing or injection systems, simplifying the overall process and reducing the operational complexity.

At this stage, minerals like calcium and magnesium are added to improve the taste and ensure chemical stability. By fine-tuning the post-treatment process, Sulzer helps desalination plants deliver fresh, high-quality water that’s ready for municipal, agricultural, or industrial use—while also protecting the systems that distribute it.

Sulzer’s comprehensive solutions

Many companies supply individual pieces of equipment for desalination, but Sulzer stands apart as a full-line supplier— offering everything from intake to distribution. With a seamlessly integrated portfolio of pumps, filters, mixers, and maintenance services, Sulzer ensures that every stage of the desalination process works efficiently and reliably together. Few companies can match its ability to deliver a complete, end-to-end solution for desalination plants.

In addition to its equipment portfolio, Sulzer provides a range of support services that help plants maintain peak performance over the long term. Long-term service agreements (LTSAs) are available for critical equipment like high-pressure and booster pumps, covering scheduled annual maintenance and offering rapid field service response—typically within 24 to 72 hours, depending on site location and technical needs.

Sulzer also plays a key role in retrofit projects, particularly as more operators replace maintenance-heavy Pelton

Desalination is constantly evolving, with each new project pushing the boundaries of efficiency, reliability, and scale.

turbines with modern, energyefficient ERDs. In other cases, changes in plant operating conditions have prompted the need for updated hydraulic components to match new duty points—challenges Sulzer’s engineering teams are well equipped to address.

To support more reactive maintenance needs, Sulzer offers spare parts and corrective services when issues arise, helping restore pumps to their original performance with minimal disruption.

Sulzer also delivers when it comes to the less tangible aspects of supporting desalination; namely experience and expertise. Sulzer has been a trusted partner in

the sector for decades, and its technology helps produce over 20 million cubic meters of freshwater every single day. Each project brings new insights, allowing Sulzer’s teams to continuously refine and improve their solutions.

Sustainability and efficiency are also at the heart of everything Sulzer does. Its technologies are designed to minimize energy consumption and reduce maintenance needs, making desalination more cost-effective and environmentally friendly. Optimized hydraulic designs lower operational costs, while corrosionresistant materials and advanced sealing systems extend equipment lifespan—reducing downtime and enhancing long-term sustainability.

Desalination is constantly evolving, with each new project pushing the boundaries of efficiency, reliability, and scale. Every year, the industry finds new ways to make the process smarter, more sustainable, and more cost-effective. As a longtime partner to the sector, Sulzer is proud to play a role in that progress—helping plants run more efficiently, last longer, and deliver more fresh water to the people who need it.

Introducing Teknomek’s new laboratory furniture that is built for science, backed by compliance.

Adapt your laboratory as your needs grow with mobile, fixed and sliding cupboards. Ensuring maximum efficiency for changing work processes.

With Trespa® TopLab Plus worktops and stainless steel options for specialist areas, our solutions are designed to meet relevant EN and GMP standards.

We will map out a customised design to suit your workflow that balances practicality with long-term flexibility.

Ardian acquires stake in JPB Système, a leading provider of innovative solutions for the aerospace sector and Industry 4.0.

With this primary transaction, Ardian’s Growth team is partnering with Damien Marc and the key managers of JPB Système to accelerate the group’s international growth and support its innovation strategy.

JPB Système, a leading French industrial player specializing in the design of self-locking fastening solutions for aircraft engines, welcomes Ardian, a world-leading private investment firm, as a minority shareholder.

Founded in 1995 and led by Damien Marc, who succeeded his father in 2005, JPB Système has established itself as a strategic partner to major global engine manufacturers

(including Pratt & Whitney, Safran, GE and Rolls-Royce), thanks to its portfolio of patented products, recognized industrial excellence, and strong capacity for innovation. The group, headquartered in Seine et Marne, generates over 90% of its revenue internationally and employs nearly 200 people.

This transaction marks a major new milestone in the group’s growth, aiming to accelerate its international expansion, strengthen its innovation capabilities, and support its role as a key player in the industry of the future.

The partnership is designed to consolidate JPB Système’s leadership in its core markets and support

the company’s entry into new segments through a sustained innovation policy and close customer relationships based on a deep understanding of their needs.

Ardian will leverage the strength of its international network and its expertise in supporting high-growth companies to help drive the group’s technological and organizational development.

Ardian also intends to support the commercial and technological development of JPB Système’s innovations, notably Keyprod, a hardware and software solution for real-time machine performance monitoring, and Boltrakk, a fastening monitoring system aimed at new

aerospace and industrial markets. These solutions fully embody the group’s innovative DNA and will open up new avenues for growth.

Ardian Growth: Alexis Saada, Romain Chiudini, Florian Dupont, Solène Hamouda

Legal: McDermott Will & Schulte (Diana Hund, Herschel Guez, Auriane Tournay, Benoît Maïto, Côme de Saint-Vincent, Louisiana Lungu, Naré Arshakyan, Charles de Raignac, Emie Paganon, Mai Matsubara, Sabine Nauges, Yves-Emmanuel Le Roux)

Financial: Eight Advisory (Christophe Delas, William Jarraud, Paul Mathonnat)

Strategic: Strategy& (Xavier Monin, Thierry Calatayut, Léo Lengelé)

Management : Damien Marc, Emmanuel Bordry

Conseil M&A et financement : Alantra (Olivier Guignon, Florian Touchard, Noémie Curmi, Julien BordierLorenzi, Simon Berta, Jules Dormoy)

Conseil juridique : Hogan Lovells (Matthieu Grollemund, Pierre-Marie Boya, Eliott Fourcade, Paul de Boishebert, Cassandre Porges, Lucas Glicenstein, Alexis Caminel, Elise Criez)

Conseil financier : Eight Advisory (Stéphane Vanbergue, Mehdi Laghmiri, Arnaud Lassiaz, Pierre Rochard)

JPB Système designs, develops, and manufactures patented self-locking fastening solutions and connected monitoring technologies dedicated to the aerospace sector and Industry 4.0. Its innovations secure critical assemblies, reduce maintenance costs and downtime, and contribute to the sustainable performance of aircraft engines.

Based in Villaroche, near Paris, and employing nearly 200 people, the company generates over 90% of its revenue from exports, and works with the world’s leading engine manufacturers, including Safran, Pratt & Whitney, GE, Rolls-Royce, and ITP Aero. Recognized as an

“Ardian’s minority investment in our capital marks a major milestone in the history of JPB Système. This partnership will accelerate our international development and strengthen our innovation capabilities in the fields of aerospace and Industry 4.0. We are honored to join forces with Ardian, a world-class investment firm, as we pursue our ambition to reinforce French industrial excellence and push the boundaries of innovation on a global scale.”

Marc, CEO, JBP Systeme

“JPB Système embodies French industrial excellence and innovation in service of the global aerospace industry. We have been impressed by Damien Marc’s vision and the quality of the JPB Système team. We are proud to support JPB Système in achieving its ambitions by leveraging all of Ardian’s human, sector-specific, and international resources.”

Alexis Saada, head of growth & senior managing director, Ardian

“We are convinced that innovation and growth are essential drivers of sustainable value creation. This investment in JPB Système perfectly illustrates our commitment to supporting companies that place technology, excellence, and agility at the heart of their development.”

Romain Chiudini, Managing director growth, Ardian

“Industry of the Future Showcase,” JPB Système is a member of GIFAS, French Fab, and Bpifrance Excellence.

A pioneer in integrating digital technologies at the heart of industrial production, JPB Système also develops Keyprod, a hardware and software solution for real-time machine performance monitoring, and Boltrakk, an innovative system for monitoring the tightening of fasteners. These innovations reflect the group’s commitment to paving the way for a smarter, more connected, and more efficient industry.

Ardian is one of the world’s leading private investment houses, with $192 billion in assets managed or advised on behalf of more than 1,860 clients worldwide. Leveraging our expertise in Private Equity, Real Assets, and Credit, we offer our clients a broad range of investment opportunities and have the agility

to meet their needs, which is one of our defining characteristics. Ardian Customized Solutions builds tailor-made investment portfolios, develops specific investment strategies adapted to each client’s needs, and provides access to funds managed by leading partners. Private Wealth Solutions offers dedicated services and access solutions for private banks, wealth managers, and institutional private investors around the world.

With Ardian employees representing a majority of the shareholding, Ardian places particular importance on talent development and values a collaborative culture based on collective intelligence. Spread across 20 offices in Europe, the Americas, Asia, and the Middle East, our 1,050+ employees are fully committed to generating superior returns through responsible investment strategies and in compliance with the highest ethical and social responsibility standards. At Ardian, we are fully dedicated to building sustainable businesses.

Menzel Elektromotoren has been certified for the production of large squirrel-cage motors in ignition protection type Ex p pressurization for operation in zone 1 hazardous areas where an explosive gas/air mixture is likely to occur in normal operation. The test specimen, a compressor motor for the petroleum industry, underwent a gas displacement test (test of the air purge system), leak test and pressure test. The German technical inspection service TÜV Nord comprehensively tested and certified the construction method. To win the approval, the manufacturer had to prove its ability to control the purging air flow for all its relevant motor series in such a way that no gas pockets remain inside the motor casing. Menzel can apply this manufacturing procedure to stock motors in a wide output range and is thus able to flexibly and quickly provide competitively priced Ex p motors featuring the product categories 2G and 3G. Pressurized motor construction is typically suitable for squirrel-cage motors from 400 mm shaft height. It is available for all voltage ranges and with air-to-air or air-to-water heat exchangers (cooling types IC 611, IC 616 or IC 81W).

An air-purge system allows potentially flammable gases to be removed from the motor frame before the motor is started and to maintain a constant positive pressure during operation to prevent the ingress of explosive gases. The terminal boxes feature the ignition protection type Ex eb increased safety.

Plant operators often face the challenge that they cannot find suitable replacements for obsolete motors. The choice of explosion-proof drive systems in particular is limited. Up until now, the only alternative was to buy a standard motor with the required explosion-protection rating and adapt the installation site and/ or driven machine, sometimes at considerable time and expense. Menzel’s certification for the construction and manufacture of protected motors now gives customers more freedom of choice and flexibility. The German manufacturer specializing in large electric motors always configures motors for the individual application and installation conditions. Likewise, the air purge system for pressurized motors

is individually calculated and implemented, ensuring that the finished systems meet the highest safety standards.

For a petrochemical company, Menzel has recently manufactured an Ex p compressor motor based on its MEBKSL series, which matches the original motor in all mechanical and electrical interfaces. The compressor motor for an oil refinery is labeled II 3G Ex pzc ec ic IIC T3 Gc for zone 2. It has a rated voltage of 6000 V and a rated output of 1635 kW. Before shipping, the motor was rigorously tested in the company’s inhouse test facility, including load and type testing.

Menzel’s Ex p motors were named the Product of the Year in the 2023 AEMT Awards

For further information, please visit www.menzel-motors.com/pressurized-exp-motors-zone1-operation/

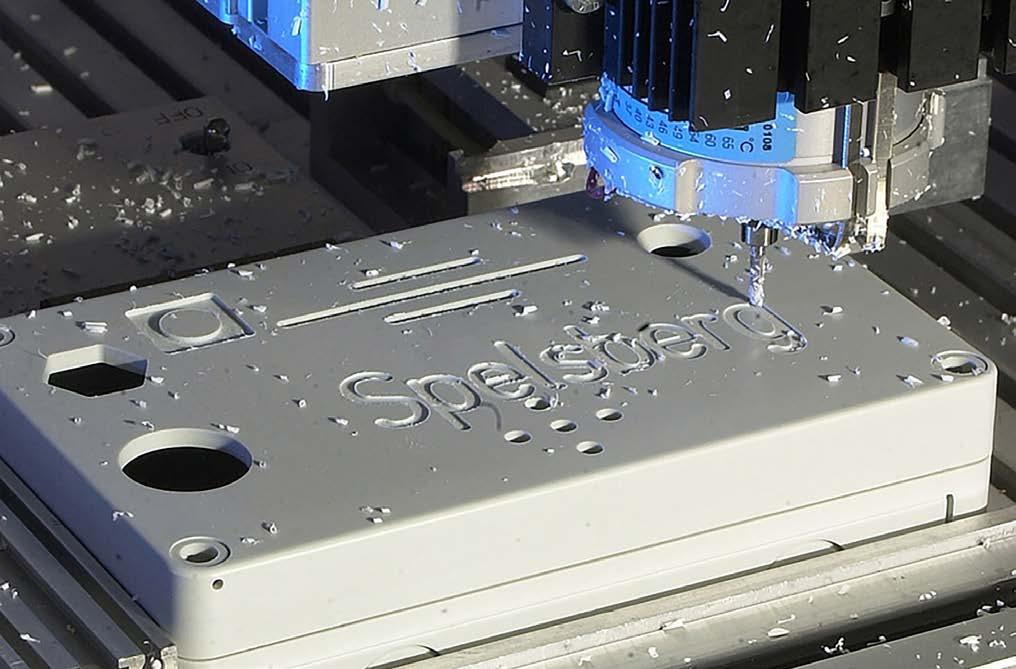

If a standard enclosure can’t accommodate a component such as a touch screen, or if a cable requires a specific entry point, customisation might be required. Based on CNC milling and drilling, the structural integrity and ingress protection of the enclosure demands that customisation requires precision techniques and the right experience. The most effective way to achieve this is to involve an enclosure supplier that provides customisation services in-house.

Chris Lloyd, Spelsberg UK’s Managing Director, discusses how to approach enclosure customisation.

When a design engineer requires an enclosure to protect electronic components or electrical terminals, customisation of the housing might be required. This process typically means adapting the enclosure using precision tooling to integrate equipment that requires access

to, or input from, the outside environment, such as keypads and HMI touch screens, sensors or cameras, or buttons and dials. Creating non-standard entry or exit points is also frequently required to accommodate cabling.

Before powering up our CNC machine, the first stage is to investigate whether a standard production enclosure can fulfil the criteria. A broad range of housings offering flexibility over dimensions, cable entry and exit points with knock-out holes, and internal fixing options, can all potentially achieve the aim without a cut being made. Meanwhile, for effective mounting and to achieve efficient cable routing, selecting the right location for the enclosure can also impact the scale of customisation required, if any. Research to specify the right enclosure might be possible by reviewing designs online, but a faster and surer way is to present

design requirements to an enclosure specialist who can advise on the options available.

If customisation is required to achieve specific needs, it’s vital to select an enclosure that can withstand the process while still maintaining its protective integrity. When this involves milling cut outs or drilling holes, it also usually means sourcing the right flange to meet the required IP rating. While the enclosure manufacturer should be able to advise on how far the housing can be customised, the extent of this knowledge often depends on their own experience with CNC machining. A key advantage of working with an enclosure manufacturer that provides customisation, as opposed to working with a third-party or adapting the units in-house, is that accountability over production quality remains with a single point of contact.

The first aspect of customisation is design. A CNC machinist will be able to work with CAD drawings or use software that can transpose the customer’s plans to make an exact match that can be read by the CNC machine. While an enclosure manufacturer that offers customisation will be able to provide a design if a customer doesn’t already have drawings, this service can also save time for OEMs. An experienced enclosure specialist will not only be able to confirm the specification of milling and drilling, but will also advise on broader considerations such as cable routing into and out of the enclosure.

The potential of what designs can be practically achieved also depends on CNC capabilities. This can include techniques such as milling to create slots, holes, contours, 3D shapes, or complex geometries, as well as drilling, countersinking, and tapping to create threaded holes. Micronlevel precision is required to ensure that components and cabling fit precisely. This is essential to achieve

durability by removing unwanted freedom of movement, as well as ensuring tight sealing to prevent ingress over time, and enable fast and simple installation.

The precision and repeatability of the CNC machine is vital, but the quality of the process is also reliant on the experience of the machinist, who must take multiple factors into account. In addition to tool selection and set up, including ensuring sufficient sharpness and the right cutting speed, criteria including the melting temperature of thermoplastics is critical, where exacting adjustment of the cutting tools is required alongside appropriate cooling techniques.

To ensure the enclosure isn’t strained during CNC machining, housings must be appropriately secured with vacuum technology, balanced with sufficient stability to prevent twisting or deformity. If the process isn’t carefully managed, the enclosure’s plastic walls can also deform through internal strains

released during machining. While tempering is a technique that can avoid this happening, awareness of the required tolerances is the recommended approach.

Speed of production is a further advantage of retaining customisation with the enclosure manufacturer, and Spelsberg’s in-house CNC service can return a prototype customised enclosure within 24 hours. Even if a customer has their own CNC capability, an enclosure supplier that quickly provides the service will reduce demand on internal engineering resources.

As well as CNC machining, additional services that save time for the customer include assembly with the insertion of components such as PCBs and keypads. Customisation can also include on-enclosure printing and embossing to add branding or user instructions. Whatever the level of customisation required, the most effective approach is to rely on the services provided by an experienced enclosure manufacturer.

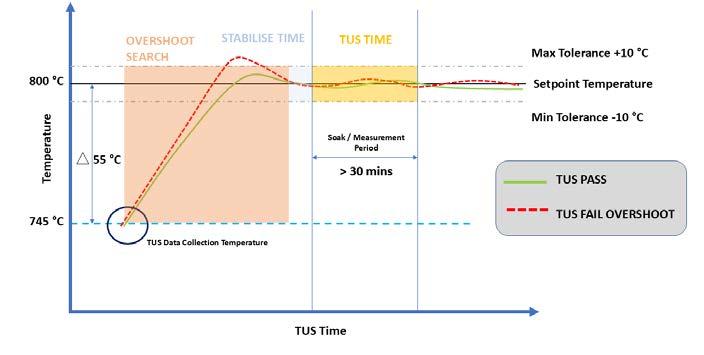

The PhoenixTM solution to your AMS2750 & CQI-9 heat treatment temperature uniformity survey (TUS) pyrometry challenges

In today’s heat treatment industry, we are all faced, daily, with the challenges of complying to regulatory standards. In automotive manufacturing heat treated materials and parts are governed by CQI-9 and in aerospace AMS2750H (Issued 07/24 NADCAP AC7102/8).

A key requirement of the pyrometry standards is to perform a Temperature Uniformity Survey (TUS) of the heat treat furnace. The aim of the temperature uniformity survey is to provide evidence that the furnace technology is providing accurate and uniform temperature conditions over its working volume. As shown in the schematic the furnace is tested at critical temperature setpoints against target temperature tolerances to reflect the furnace classification and material/product heat treat processing certification requirements.

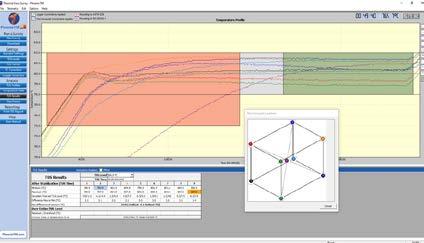

Traditionally Temperature Uniformity Surveys (TUS) are performed using a field test instrument accurate to ±0.6 °C or ±0.1% of temperature reading. The data logger is located externally to the furnace with thermocouples trailing into the furnace heating chamber. The PhoenixTM PTM4220 external data logger (accuracy ±0.3 °C) is connected directly to a TUS frame used to measure the temperature uniformity with up to 20 thermocouples.

For continuous (belt & pusher) furnaces the PhoenixTM ‘Thruprocess’ TUS principle overcomes the problems of trailing

thermocouples. A multi-channel data logger (PTM1220/1210) travels into and through the heat treat process protected by a thermal barrier. The thermal barrier design and specification is customised to suit the process being monitored (Time/Temperature/Pressure etc). Accurate cold junction compensation technology provides a data logger accuracy of ±0.3 °C over the whole data logger operating range of 0 to 80 °C / 110°C. This is essential as the operating temperature of the data logger in use will change from its original calibration temperature. Available with a RF Telemetery option the TUS temperature data can be transmitted direct from the furnace

to an external monitoring PC during the survey.

The PhoenixTM Survey software is a custom designed software package developed specifically to address CQI-9 and AMS2750 requirements. The software allows full live data review (numerical & graphical), during the data collection step against the pre-set tolerance limits. To maximise accuracy data logger and thermocouple correction factors can be applied automatically in the software. Following TUS data collection the survey software allows full TUS data analysis, furnace class assessment and creation of a fully compliant report against the specific deliverables of the pyrometry standards.

• No trailing thermocouples so quick, safe and effective

• Measure from up to 20 thermocouples with a single data logger

• Ideal for surveying semi-continuous, continuous or modular furnaces

• Live RF telemetry TUS data collection options

• Oil, salt and water quench thermal barrier options

• Efficient real time TUS of static furnaces

• Robust compact external data logger design

• Easy to transport and set-up

• Thermocouple type and plug connection options for quick installation

• Cold junction compensation to give accurate data in changing environmental temperatures

• Fully compliant with AMS2750 & CQI-9

• Full 0.1 °C / 0.1 °F resolution/readability

• Apply accurate data logger and thermocouple correction factors with ease

• Full control over real time data collection and TUS analysis

• Generate your complete TUS reports with efficiency and confidence

Huck® fasteners have long been a trusted solution in industries requiring high-strength, vibrationresistant fastening. These fasteners play a crucial role in ensuring structural integrity and safety in a wide range of applications and industries. Given their significance, many engineers and professionals frequently turn to search engines with technical queries about Huck® fasteners. In this article, we address some of the most commonly asked questions about these specialised fasteners.

What are Huck® fasteners?

Huck® fasteners are advanced fastening solutions designed to provide secure, high-strength joints that resist vibration and loosening over time.

What are the different types of Huck® fasteners?

Huck® fasteners come in various types, each designed for specific applications.

HuckBolts®: also known as LockBolts® are a two-piece, highstrength fastening system consisting of a pin and a collar, designed for permanent, vibration-resistant joints. They are installed using a swaging process, which eliminates the need for re-tightening, making it ideal for structural, transportation, and heavy-duty applications requiring superior strength and longterm reliability.

Huck® Blind Fasteners: are highstrength, one-sided (blind-side) fastening solutions used when access to the blindside of a joint is restricted. They provide vibration resistance, high shear strength, and consistent clamping force, making them ideal for aerospace,

automotive, rail, and structural applications where reliability and quick installation are essential.

Which industries use Huck® fasteners?

Huck® fasteners are widely used across multiple industries, including:

Automotive & Heavy-Duty

Trucks: Common in truck chassis, suspensions, and trailers for secure, maintenance-free fastening. They can be used in anything, including defence vehicles and F1 racing cars!

Railroad & Transportation: Applied in railcar construction and track infrastructure to withstand constant vibrations.

Construction & Infrastructure: Utilised in bridges, portable buildings and large metal framed structures for strong, permanent joints.

Solar Energy: Huck® fasteners are used in solar panel mounting systems to secure structures against wind loads and environmental stress.

Wind Turbines: Huck® fasteners are used in tower assembly, nacelles, and rotor components for secure, vibration-resistant connections.

Shipbuilding & Marine: Resistant to corrosion and extreme conditions, making them ideal for naval and commercial ships.

Manufacturing & Industrial Equipment: Used in a multitude of production lines for durable and efficient fastening solutions.

Aerospace: Used in aircraft assembly for their lightweight strength and vibration resistance.

If there’s a fastening requirement, Huck® fasteners have a solution.

How do Huck® fasteners differ from traditional bolts?

Huck® fasteners differ from conventional bolts in several ways:

Vibration Resistance: Unlike bolts and nuts that can loosen over time due to vibrations, Huck® fasteners maintain their hold, making them ideal for high-vibration environments.

Installation Speed: Huck® fasteners are installed using hydraulic, pneumatic and battery tools, making the process faster and more efficient than tightening a bolt and nut.

Structural Integrity: The swaging process of Huck® fasteners creates a permanent joint, eliminating the need for re-torquing or maintenance.

What installation tools are required to install Huck® fasteners?

Installing Huck® fasteners requires specialised tools. These tools include:

Pneumatic: Powered by compressed air, these tools are commonly used in high-volume assembly lines.

Hydraulic: Used for heavy-duty applications, providing more force for larger fasteners.

Battery-Powered: Offering mobility and flexibility for production and field applications.

Are Huck® fasteners reusable?

No, Huck® fasteners are designed to be permanent. Once installed, they cannot be removed without damaging the fastener. If disassembly is required, the fastener must be mechanically removed and replaced.

Reusing nuts and bolts can also compromises structural integrity due to thread deformation, fatigue, and reduced clamping force.

Torque relaxation and material wear increase failure risks, especially in high-load or vibrationprone applications.

For safety and reliability, engineering best practices recommend new fasteners to maintain precise tension and prevent mechanical failure.

How do Huck® fasteners compare to welding?

Many industries choose Huck® fasteners over welding due to the following advantages:

Speed of Installation: Huck® fasteners can be installed in seconds, whereas welding is time-consuming.

Consistent Strength: Welds can be inconsistent due to material variations and operator skill, whereas Huck® fasteners provide uniform strength.

Safety: Welding requires specialised training and safety precautions, whereas Huck® fasteners can be installed quickly with minimal training and risk.

No Heat-Affected Zones: Welding can weaken surrounding materials, whereas Huck® fasteners maintain the integrity of the structure.

How do you select the right Huck® fastener for your application?

Choosing the right Huck® fastener depends on several factors:

Load Requirements: Determine the strength needed for the application.

Material Compatibility: Ensure the fastener material matches or is compatible with the materials being joined.

Environmental Conditions: Consider factors like corrosion resistance, temperature, and exposure to chemicals.

Accessibility: Choose between blind (one-piece) or LockBolts® (twopiece) fasteners based on assembly constraints.

What are the maintenance requirements for Huck® fasteners?

Since Huck® fasteners create a permanent joint, they require little to no maintenance. Unlike traditional fasteners, which need periodic re-tightening, Huck® fasteners maintain their strength and integrity throughout their service life. However, regular inspections of the structure in which they are used are still recommended to ensure overall safety.

Huck® fasteners have revolutionised fastening technology with their strength, durability, and vibrationresistant properties. As industries continue to seek reliable and maintenance-free fastening solutions, the demand for Huck® fasteners remains strong. Whether you’re an engineer, technician, or procurement specialist, understanding the fundamentals of Huck® fasteners can help you make informed decisions about their applications and benefits.

How can Star Fasteners help with Huck® fasteners?

Star Fasteners UK Ltd is a leading distributor and expert in Huck® fasteners, offering comprehensive support to help you make informed decisions about their applications, benefits, and installation. Here’s how we can assist:

Expert Technical Advice: Our team provides specialist guidance

on selecting the right Huck® fasteners based on load requirements, material compatibility, and environmental conditions.

Product Range & Availability: We offer a wide selection of Huck fasteners, including LockBolts®, blind fasteners, and installation tools, ensuring you get the right solution for your needs.

Installation Support:

We supply pneumatic, hydraulic, and batterypowered installation tools and can provide training on proper usage for efficient and secure fastening.

Cost & Performance Optimization:

We can help to identify costeffective fastening solutions while ensuring long-term reliability in high-vibration and structural applications.

After-Sales Service: We provide ongoing support, maintenance advice, and troubleshooting to ensure your fastening solutions perform optimally.

Do Star Fasteners offer a tool repair and hire service?

Tool Repair Service: We provide comprehensive maintenance and repair services for installation tools, ensuring your equipment remains in optimal condition.

Tool Hire Service: Star Fasteners offers short- and long-term tool hire options, ideal for busy periods or specific projects requiring specialised equipment. We also provide service hire tools while your equipment is under repair in our workshop.

By addressing these frequently asked questions, Star Fasteners hopes to provide valuable insights for those considering Huck® fasteners for their projects. Their superior performance and reliability make them a leading choice for industries where strength and durability are paramount.

At MTM Products, we’ve been manufacturing industrial graphics for over 40 years. Based in Chesterfield, Derbyshire, we’re proud to be one of the UK’s leading suppliers of custom printed labels, nameplates, graphic overlays, vinyl cut decals and safety signage. Since our founding in the mid-1970s, we’ve built strong partnerships with OEMs across a wide range of industries — including automotive, rail, medical, industrial electronics, and construction.

What sets us apart is our ability to deliver bespoke, high-quality solutions tailored to demanding environments. Whether our products are used outdoors, in medical equipment, or in harsh industrial settings, we ensure they meet strict performance and regulatory requirements. We use a combination of modern digital printing, traditional silkscreening, laser cutting and CNC technology to produce items that are both functional and durable.

Quality and compliance are central to everything we do. We’re certified to ISO 9001:2015 and ISO 14001:2015 standards, and we’re proud to be an authorised UL label supplier — giving our customers added assurance when it comes to safety and regulatory compliance.

We’re not just a manufacturer — we see ourselves as a service company that makes things. That means we work closely with you from the initial design consultation through to full-scale production. We’ll help you choose the right materials, adhesives, finishes and print

processes based on your application, usage and environment. We also aim to be transparent about lead times, pricing and order values — including our minimum order value of £100.

Recently, we’ve invested in new equipment — including a flat-bed cutter, CO2 and fibre laser machines.

Quality and compliance are central to everything we do.

In March 2026, we will implement a new ERP system to improve our efficiency and service levels too. This is part of our ongoing commitment to innovation and continuous improvement.

As a proud member of Made in the Midlands and MAKE UK, we’re committed to supporting British manufacturing and providing stable, long-term supply partnerships for our clients.

If you’re looking for a reliable, experienced partner to deliver high-quality industrial graphics, nameplates or overlays — designed for your environment and built to last — we’d love to hear from you.

The new ZQ901 pull-wire emergency stop switch by Schmersal is characterised by its robust stainless steel enclosure. It offers optimal mechanical and chemical protection in harsh environments and provides the ideal solution for a wide range of applications.

Thanks to the new housing material, the ZQ901 can be used on transport and material handling systems as well as on large system used in the food processing and chemicals industries. The tried-and-tested technology, used in industrial settings, meets the highest availability standards. The ZQ901 offers an emergency-stop function and manual rest, wire break detection and lengths of wire up to 75 metres.

For more information, scan the QR code to download your free brochure.

SCHMERSAL | Enigma Business Park

www.schmersal.co.uk

uksupport@schmersal.com

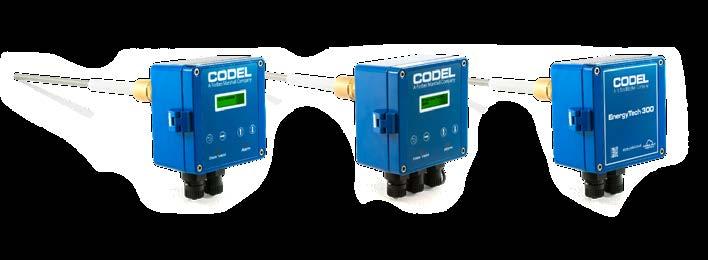

In an era where environmental regulations are tightening and industrial efficiency is nonnegotiable, CODEL has launched a trio of triboelectric dust monitors tailored to meet diverse compliance and operational needs with precision and reliability.

Available now, CODEL’s Triboelectric Dust Monitor Range comprises three model families:

• DCEM 6000

A premier, QAL1-certified analyser designed for continuous emissions monitoring. It meets the stringent EN 14181 and EN 15267-3 standards, delivering exceptional accuracy and sensitivity for processes where regulatory compliance is critical.

• EnergyTech 600

(including ET 600 and ET 610)

A versatile mid-range option certified to EN 15859, offering real-time particulate measurement for balanced compliance and operational insight. ET 600 excels as a dust monitor, while ET 610 is optimized for early-stage filter leak detection, ideal for process control across power generation, cement, chemical, and manufacturing sectors.

• EnergyTech

A cost-effective solution built for burst bag detection in dust extraction systems, offering fast, reliable alerts in applications such as woodworking, mineral processing, and bulk material handling.

What sets this range apart is the proven triboelectric sensing method, known for its robustness, minimal maintenance, and accurate, realtime readings. Unlike optical devices susceptible to alignment issues, humidity, or soot, triboelectric monitors deliver dependable performance even in harsh industrial environments.

Each monitor in the Triboelectric Range integrates seamlessly with CODEL Cloud, a centralized digital hub for real-time data, reporting, and analytics. This connectivity enables proactive maintenance, enhanced compliance tracking, and improved filtration efficiency, all accessible remotely and securely.

CODEL officially unveiled the Triboelectric Range earlier this year and received an overwhelmingly positive response from both customers and distributors. Industry feedback praised the range’s versatility, accuracy, and costeffectiveness, especially in reducing operational downtime.

Whether the project demands high-level regulatory monitoring or practical filter control, there’s a model tailored to deliver precision under the relevant standards.

•

Access to real-time data through CODEL Cloud, issues can be addressed before escalation, reducing maintenance costs and retaining uptime.

Built with scalability and adaptability in mind, the Triboelectric Range supports evolving environmental standards and industry expectations.