9 minute read

Full steam ahead

AFTERTREATMENT OPTIONS GROW, AS 1ST LGIM-W DELIVERY NEARS

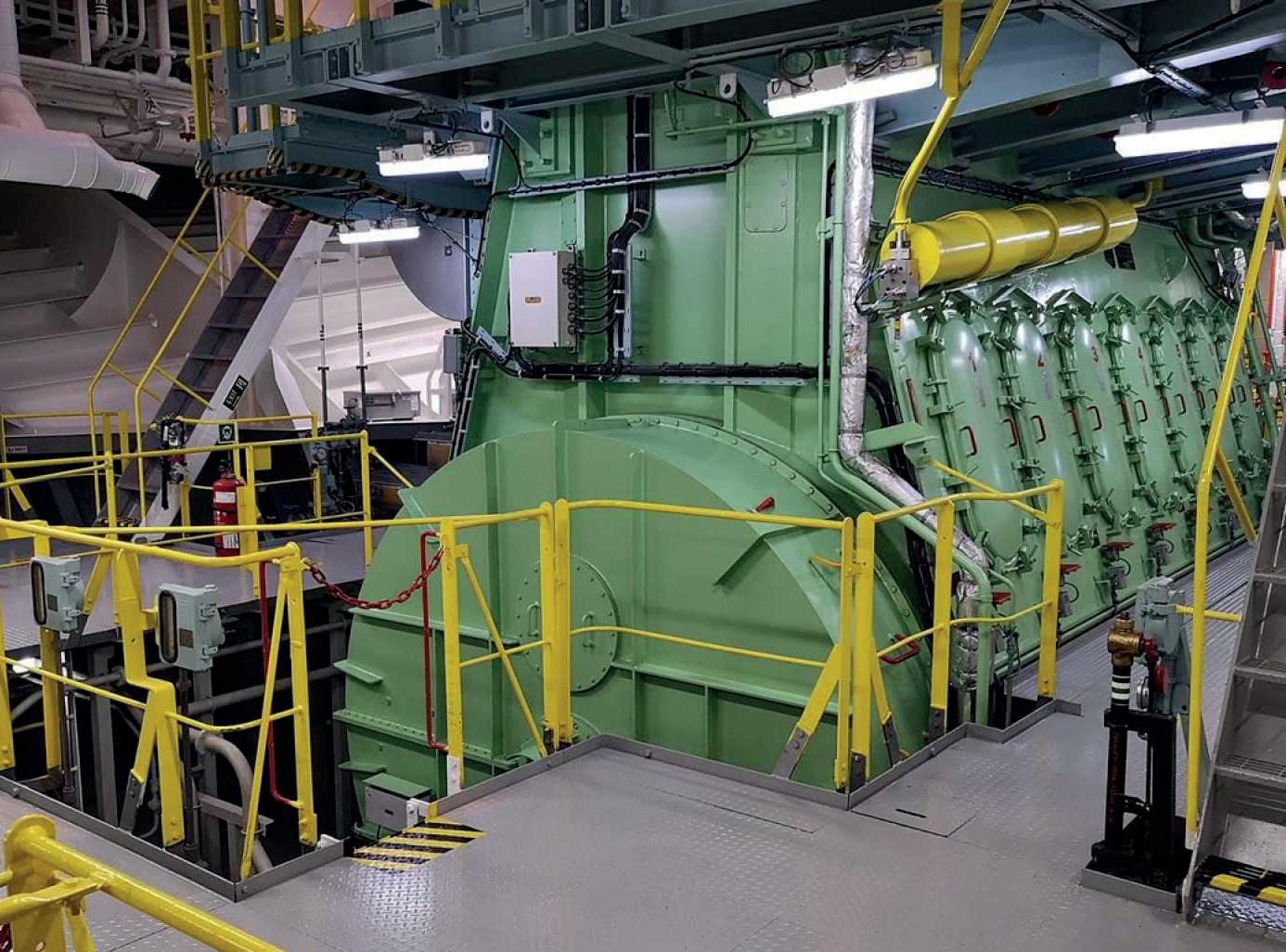

MAN Energy Solutions has delivered its fi rst methanol-fuelled engines equipped with its water in methanol LGIM-W solution following successful shop tests for two engines equipped with the solution at a Korean licensee earlier this year.

The company’s fi rst ME-LGIM-W system has been installed aboard a newbuilding at a shipyard in South Korea, Peter Quaade, Head of Dual Fuel Technology group at MAN ES told The Motorship in an exclusive interview. In all, 12 engines are on order, with the fi rst two vessels due to undergo sea trials by the fi nal quarter of 2021.

Optimisation work

The introduction of the water in methanol solution is the result of significant optimisation work since 2019, when The Motorship interviewed Stefan Meyer of MAN ES in 2019 about the company's development of an emulsification-based solution. At the time, MAN identified the significant commercial advantages that the solution offered to customers seeking to comply with upcoming Tier III IMO NOx emission limits.

Peter Quaade outlined progress with the pilot fuel ignition concept, which has been a key area of focus for MAN ES during the development of the LGIM-W solution. The waterfuel blends demonstrate weaker ignitability, but environmental standards have focused attention on pilot fuel consumption. “This has also been a competitive parameter for charterers and owners during the dual fuel era,” Quaade noted. Given the multiple constraints, as well as the need to ensure engine stability, the team has made significant progress in delivering a solution that can meet pilot consumption limits “by quite a margin”.

“We like to be within the limits that we have promised on pilot consumption,” Quaade noted, adding that the optimisation work had also led to improvements in fuel consumption. Quaade noted that the fuel penalty introduced by the solution has been “significantly” lowered since 2019, when it was estimated at 2-6g/kWh, without providing further details.

As previously discussed, the design of the injector As previously discussed, the design of the injector nozzles required modification to increase the nozzles required modification to increase the fuel mixture flow without extending the length fuel mixture flow without extending the length of the injection, while the methanol-water of the injection, while the methanol-water fuel mixture also introduces some changes to fuel mixture also introduces some changes to the fuel’s characteristics. The proportion of the fuel’s characteristics. The proportion of water required for the mixture to reach Tier water required for the mixture to reach Tier III at 100% load has been established at III at 100% load has been established at between 10-15% of the mixture, depending between 10-15% of the mixture, depending on the engine load, with proportions of on the engine load, with proportions of water up to 40% permitted at lower engine water up to 40% permitted at lower engine loads. In response to a query from loads. In response to a query from The Motorship about potential about potential volumetric constraints for the volumetric constraints for the injection of the mixture at injection of the mixture at higher loads, Quaade noted higher loads, Quaade noted that the ECS (Engine Control System) could "manage the injection of the relatively larger volume within the injection window”. The management of the water plant and the admission of water would be handled automatically, while the engine could default to pure methanol operation in the case of an unforeseen water plant outage.

The Motorship also asked about the initial experience of operating methanol-fuelled engines on methanol-water mixtures, and the potential effect of operation on cylinder liner condition, for example.

Once again, Quaade noted that the initial results of operating test engines on methanol/water solutions were broadly similar with early pure-methanol results during the development of the methanol engine. Peter Quaade confirmed that the LGIM-W afterPeter Quaade confirmed that the LGIM-W aftertreatment system offered particular advantages for treatment system offered particular advantages for engines operating on methanol, owing to the engines operating on methanol, owing to the smaller footprint of the LGIM-W system and the smaller footprint of the LGIM-W system and the lower operational cost compared with SCR lower operational cost compared with SCR solutions. solutions. MAN ES had received 23 orders for LGIM MAN ES had received 23 orders for LGIM engines in late June 2021, of which 11 engines engines in late June 2021, of which 11 engines were in service. Cumulatively, MAN ES' LGIM were in service. Cumulatively, MAN ES' LGIM engines had accumulated 90,000 operating engines had accumulated 90,000 operating hours running on methanol. hours running on methanol.

8 MAN ES is

considering extending the range of LGIM engines to include additional bore sizes beyond its existing G50ME-C9.6-LGIM and S50ME-C9.7LGIM options

Economic advantages Economic advantages

As the solution offers Tier III compliance without As the solution offers Tier III compliance without requiring the installation of exhaust gas requiring the installation of exhaust gas recirculation (EGR) or a selective catalytic recirculation (EGR) or a selective catalytic reduction (SCR) after-treatment solution, it reduction (SCR) after-treatment solution, it offers significant reductions in engine offers significant reductions in engine footprint as well as lower installation costs footprint as well as lower installation costs for shipyards. for shipyards.

8 Peter Quaade,

Head of Dual Fuel Technology group at MAN Energy Solutions

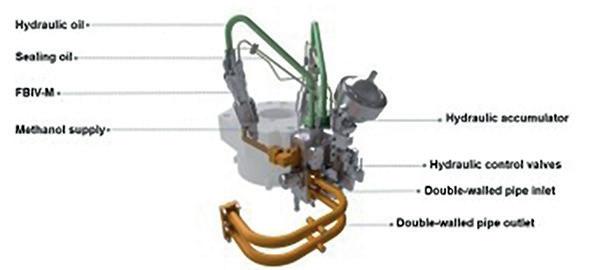

Hydraulic oil

Sealing oil

FBIV-M

Methanol supply

Credit: MAN ES

Hydraulic accumulator

Hydraulic control valves Double-walled pipe inlet

Double-walled pipe outlet

Peter Quaade confirmed that the emulsification offered particular advantages for engines operating on methanol, owing to the smaller footprint of the LGIM-W system and lower operational cost compared with SCR solutions.

The Motorship previously reported that while the operational costs of running an LGIM-W system were competitive with EGR systems for methanol/water mixtures, the system would reduce the requirement for auxiliary equipment. The emulsification solution introduces an additional requirement for a water tank, but as there are no miscibility issues between methanol and water, it eliminates the need for a separate surfactant reservoir.

“The reduced investment costs to achieve Tier III compliance are an obvious attraction,” Quaade noted, adding that it demonstrated the advantages of MAN ES's ability to develop simple solutions for a range of different fuels.

ME-LGIM 1.3

Quaade also outlined a number of additional refinements that had been developed for the ME-LGIM engine platform.

Several of the changes related to the sealing oil system. Quaade explained that the replacement of a u-type seal with an o-ring seal reflected operational experience. It was intended to simplify the task of maintaining the seals for crew members, and had already accumulated 1,500 hours. “After we saw some, let's say assembly issues, we said okay, this could actually be done smarter.”

Quaade noted that the simplified design had substituted the previous seal oil swashplate pump with an accumulator. This elegant solution marginally reduced the system’s footprint, and would also help to simplify the maintenance requirements.

As the accumulator uses static pressure, it does not require constant operation, Quaade added, noting that this would reduce the unit's energy consumption by almost twothirds. “While that's not much by itself, if you add up all the energy consumers, then they become relatively large.”

The operation of a small heating tank used in the sealing oil system has also been optimised, so that it can equalise temperatures more rapidly. Finally, the operating system controlling the sealing oil system has also been upgraded, Quaade noted, adding that “you could say the sealing oil system has undergone a major update.”

Engine development plans

Quaade concluded by providing an overview of the market for methanol-fuelled engines. Quaade noted that the engine development programme for the ME-LGIM had developed very quickly since the engine demonstration event was held in 2015 at MAN's research centre in Copenhagen.

However, the potential market for methanol-fuelled engines had also developed rapidly in recent years. While initial orders for LGIM engines came from the methanol

8 The design of

the injector nozzles has been modified to increase the fuel mixture flow without extending the length of the injection

8 Rendering of

a MAN B&W 6G50ME-LGIM engine

tanker market, what had originally seemed like a niche market has developed significantly in recent times.

“We are seeing interest in methanol-fuelled engines from the container market and the tanker market,” Quaade said, speaking before A.P. Møller–Maersk announced an order with Hyundai Mipo Dockyard for a series of methanol-fuelled 2,100 teu container feeder vessels. MAN licensee HHI-EMD will build the MAN B&W 6G50ME-LGIM type engine.

Quaade confirmed interest in methanol-fuelled engines was not just coming from smaller sized vessels, but also from larger vessels. As a result, MAN ES is understood to be considering extending the range of LGIM engines to include additional bore sizes beyond its existing G50ME-C9.6-LGIM and S50ME-C9.7-LGIM options.

The interest in methanol as a fuel was also coming from potential fuel suppliers, Quaade said, and as importantly, it was coming from a range of different regions.

“Fuel availability is the key question - and as ever for new fuels, it is a chicken and egg type question,” Quaade said, adding that the growth of interest in methanol as a fuel is reminiscent of the early stages of development of LNG as a fuel.

Some of the interest was coming from ship owners or producers seeking to position a little bit, amid continuing uncertainty about the medium-term outlook for the market. “Definitely some fuels look more interesting, such as methanol. We also have LPG coming up, which is attracting huge interest, and a little bit further out, ammonia. While a lot of people are putting their money on ammonia, I think it is extremely hard to predict, actually.”

JUNE 2022 21 23 TO

Southampton United Kingdom

Seawork is open for business – all year

Reserve now for 2022. Make the most of marketing & PR support from Seawork and our leading commercial marine magazines, in print, online, eNews and via social media.

Europe’s leading commercial marine and workboat exhibition.

Show your latest innovations in vessels, equipment and services to over 7,700 maritime professionals. 12,000m2 of exhibition halls featuring 600 exhibitors. Over 70 vessels and fl oating plant. E uropean Commercial Marine Awards (ECMAs) and Innovations Showcase.

Co-located with: Also returning in 2022 Speed@Seawork

For more information visit: seawork.com contact: +44 1329 825 335 or email: info@seawork.com

Media partners: