SMART

MANUFACTURING

‘Tech bro’ culture stifling startup sector.

SMART MANUFACTURING

How Industry 5.0 is redefining manufacturing.

SOUTHMACH 2025

Manufacturing fuels the present.

THE LAST WORD

The Skills Shortage Smokescreen. 12 13 15

MANUFACTURING

‘Tech bro’ culture stifling startup sector.

How Industry 5.0 is redefining manufacturing.

SOUTHMACH 2025

Manufacturing fuels the present.

THE LAST WORD

The Skills Shortage Smokescreen. 12 13 15

By Ben Speedy, ASB’s General Manager Commercial Banking and Business Strategy

In February this year, the New Zealand Government released ‘Going for Growth’, setting out its approach to enable economic growth, to deliver more jobs, higher incomes and money to invest in services like healthcare, education, and infrastructure. Put simply, the current Government is focused on lifting New Zealand’s productivity and rightly so.

Productivity in NZ has been steadily falling behind other OECD countries as we have struggled to lift the value of the goods we export.

We are a country of small to medium-sized, often family-owned businesses and, contrary to popular belief, our businesses mainly focus on domestic rather than export markets.

Unlocking productivity is essential to help us scale growth and enable greater redeployment of resources into high value products and services.

In recent years, primarily due to economic environment and immigration settings, productivity has largely focused on addressing cost challenges and labour issues. However, if we want to succeed as a country, we must turn our focus to growth.

Our research with the New Zealand Institute of Economic Research (NZIER) has found that investing in innovation now will unlock benefits and choice for NZ, with the potential to raise real GDP to $500 billion by 2045.

NZ Manufacturing is pivotal to our success, but we must continue to evolve, focusing not only on producing high value products, but leveraging new technology, and creating unique IP to enable us to

compete on the world stage.

Work undertaken by economist Richard Fabling for the Productivity Commission found that firms operating at their respective industry frontiers, invest twice as much capital to improve productivity and generate three times the revenue per worker.

Banks have a very important role to play. Interestingly, our research with NZIER indicated that while competitive lending was critical, capacity to borrow was the more significant consideration for investment.

Relative to NZ, small advanced economies have greater access to capital, more active capital markets, and greater willingness of firms to leverage capital outside bank debt.

Banks therefore need to support businesses improve their capacity to borrow and provide innovative solutions to support growth.

Banks can help businesses to consider the right form of capital to support growth and take appropriate leverage to manage risk and reward.

With NZ’s economic recovery in motion, supported by easing inflation, lower interest rates and stronger

exports, we think now is a good time for businesses to be investing in capital.

According to ASB’s economists, we can expect a more pronounced recovery in the latter half of 2025, as lower interest rates steadily boost domestic activity.

For businesses, capital investment in machinery, technology, buildings, and processes is not just a financial decision; it’s a strategic move towards future-proofing operations.

By channelling resources into capital, businesses can leapfrog from traditional, labour-intensive practices to more efficient, technology-driven processes.

Buckley Systems, a manufacturer of precision electromagnets and vacuum chambers, is a great example of a company that has seen the importance of investing in automation and technology to lock in future growth.

continued on Page 11

Secure supply of energy and data to moving industrial equipment.

• Large size range

• Vertical travels

• Energy tubes

• Hygienic chains

• Solutions for long travel

• Guide troughs

• Readychain

• Robotic, 3D

• Circular movement

HUGE range of high quality flexible cables

• Control cables

• Single cores

• Data cables

• Sensor/Actuator

• Intrinsically Safe

• VSD/EMC cables

• Halogen Free cables

• High temperature

• Harsh Conditions

• Crane cables

• Profibus cables

• Bus/DeviceNet

• Solar cables

• Instrumentation

• Flat cables

• Curly cords

Largest range of flexible conduits for cable protection

• Conduits

• Conduit fittings

• Divisible systems

• Jumbo systems

• Conduit Accessories

• Braided cable protection

• Fire barrier solutions

• Food and beverage

• EMC systems

• Ex, ATEX, IEC EX

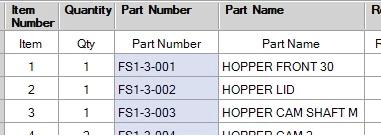

Industrial connectors for many industries

• Rectangular multipole connectors from ILME

• Single pole Powerline connectors from TEN47

• EPIC connectors from Lapp Group

• M23 circular connectors from Hummel

• Circular connectors specifically for the entertainment/stage lighting industry from Socapex

Safety engineering solutions from EUCHNER

• Multifunctional Gate Box MGB

• Transponder-coded safety switches

• Electromechanical safety switches

• Magnetically coded safety switches

Sensor technologies for automation

• High-Precision Laser Distance Sensors

• Ultrasonic Sensors

• Inductive Sensors

• Fluid Sensors

We invite you to attend the

In conjunction with SouthMACH 2025 - May 28, 2025 – Wolfbrook Arena, Addington, Christchurch For our conference this year we are taking a different approach. The primary target audience will be operational leaders – operations, production and manufacturing managers, but also, and quite specifically, team leaders – especially those with ambitions to take on greater responsibility. That doesn’t mean top-level managers and business owners aren’t welcome, but substance and form of the conference programme will be tailored to engage with the

target audience. What that means:

• Emphasis on contributions ‘from the coal face’ – war stories from those with scars on their backs

• Emphasis on tangible outputs –what worked, what didn’t, and what are the measurable results?

• Most presenters will have been directly involved in the work they will report on

• We’ll create opportunities and encourage the audience to interact with the presenters throughout each session. For our workshops we have chosen three related topics:

1 Leading through change, keeping hearts and minds onboard

2 Improving productivity through raising levels of engagement

9:00 – 10:00 SouthMACH

3 Using digital tools to improve productivity on the shop floor Investment – includes catering and Social Hour function:

• Top-tier leaders (MD/CEO/GM): $485+GST

• Tier-2 leaders (operations, production, manufacturing managers, etc) $340+GST

• Tier-3 leaders (team leaders and equivalent) $220+GST

• Full Paid-up members of MAKE│NZ receive a 15% discount on the above – click here to register

• For more than four registrations per company, please contact us for a special offer: dieter@makenz.org

SouthMACH opens at 9 a.m. – Feel free to come in early and see the exhibits at SouthMACH 9:00 – 10:00 Check-in and day registration

10:00 – 10:10 MC

Theme 1: Leading through change

10:10 – 11:10 Rebecca Phillips & Ben Rae (Comfort Group)

11:10 – 11:40 Tony Smale (FORTÉ Management)

11:40 – 12:10 Panel discussion – Convenor: Natalie Smith (Kiwicare)

12:10 – 13:00

Theme 2: Raising levels of engagement

13:00 – 13:30 Lucien Thiele & Natalie Smith (Kiwicare)

13:30 – 14:00 Sara Ogier & Michael Anderson (Wyma Engineering)

14:00 – 14:30 John Eatwell (Strategic People Group)

14:30 – 15:00 Panel discussion – Convenor: Rebecca Phillips (Comfort Group)

15:00 -15:20

Theme 3: Making the boat go faster

15:20 – 16:20 Aaron Haines (Energyline) Nathan Hay (Argus ManuTech)

16:20 – 16:50 Carl Broxup, (CHC Engine Centre)

16:50– 17:20 Panel discussion – Convenor: Ben Bainbridge, CHCEC

Welcome and introduction

The Comfort Group is in the middle of a major move -shifting its operations from Auckland to Ohinewai (Waikato). Ben & Rebecca will share their experience with managing that transition

Motivating people – how to get it right in different cultural contexts

On the Panel: Natalie, Rebecca, Ben and Tony

Lunch Break and ability to see the exhibits at SouthMACH

Improving engagement at all levels – how we got that to work, and what the impacts on our business are

Achieving and maintaining high levels of genuine engagement – the Wyma experience

Engagement. What is it really about?

On the Panel: Rebecca, Lucien and Natalie, Sara and Michael, John

Afternoon Tea and networking (with presenters)

Argus and Energyline have both recently put a lot of effort into adopting digital tools that help them to improve productivity. They will share how they got there, and what mistakes to avoid

Getting ERP to work with lower-level manufacturing process management software – we FINALLY got it to work!

On the Panel: Aaron, Ben, Carl & Nathan

17:20-17:30 MC Wrap Up

17:30- 18:30

Social hour – Drinks and Nibbles

Unlocking business growth

BUSINESS

The art of investment.

Why banking competition matters. Ransomware incidents highlight security blind spots.

EMA

Is New Zealand’s Health and Safety reform enough to prevent workplace harm?

SMART MANUFACTURING

‘Tech bro’ culture stifling startup sector. Hydrogen electric flight prepares for lift off in New Zealand.

How Industry 5.0 is Redefining Manufacturing.

Remanufacturing 101: Reviving parts, reclaiming value.

SOUTHMACH 2025

Manufacturing fuels the present.

ANALYSIS

Navigating the tariff maze.

SUSTAINABILITY

Double materiality: What it is and why it matters to manufacturers.

TRAINING

How learning drives manufacturing performance.

WORKSHOP TOOLS

Alfa Laval expands hygienic valve portfolio. Clad composite wire combines multiple properties.

Acoustic imaging camera locates smaller compressed air leaks faster.

ANALYSIS

Article 2: The Crucial Role of System Integrators in Industry 4.0 and Automation. Manufacturing sector doing a lot.

DEVELOPMENTS

Engineering: the invisible high-demand career.

THE LAST WORD

The Skills Shortage Smokescreen.

Ian Walsh Ian Walsh is a leading expert in designing and implementing transformational improvement programmes, with over 30 years of experience helping businesses drive operational excellence and long-term success. A Six Sigma Master Black Belt, he has worked with both New

Zealand’s top organisations and global multinationals including Kimberley Clark, Unilever, Guinness to unlock productivity, reduce costs, and optimise business performance. Ian has been at the forefront of operational improvement, working at all levels—including Boards—to deliver high-impact change. Ian continues to play a key role in advancing business excellence, supporting Auckland University and The Icehouse with expert insights on productivity, operational improvement, and best-practice methodology.

Dr Barbara Nebel CEO thinkstep-anz

Barbara’s passion is to enable organisations to succeed sustainably. She describes her job as a ‘translator’ – translating sustainability into language that businesses can act on.

Mark Devlin

Having owned food manufacturing and distribution businesses for a decade, Mark Devlin now runs Auckland public relations agency Impact PR. Mark consults to several New Zealand manufacturing firms including wool carpet brand Bremworth, aircraft exporter NZAero and cereal maker Sanitarium.

Errey

Insa’s career has been in the public and private sectors, leading change management within the energy, decarbonisation, and sustainability space. Insa holds a Chemical and Biomolecular BE (Hons) from Sydney University. She is a member of the Bioenergy Association of NZ and has a strong passion for humanitarian engineering, working with the likes of Engineers Without Boarders Australia.

Insa is a member of Carbon and Energy Professionals NZ, been an ambassador for Engineering NZ's Wonder Project igniting STEM in Kiwi kids and Engineers Australia Women in Engineering, increasing female participation in engineering.

Jane Finlayson is Head of Advanced Manufacturing at the EMA, and has 25-years’ experience in business and economic development. She is passionate about empowering businesses to grow, innovate and embrace Te Ao Māori.

Copyright: NZ Manufacturer is copyright and may not be reproduced in whole or in part without the written permission of the publisher. Neither editorial opinions expressed, nor facts stated in the advertisements, are necessarily agreed to by the editor or publisher of NZ Manufacturer and, whilst all efforts are made to ensure accuracy, no responsibility will be taken by the publishers for inaccurate information, or for any consequences of reliance on this information. NZ Manufacturer welcomes your contributions which may not necessarily be used because of the philosophy of the publication.

PUBLISHER

Media Hawke’s Bay Ltd, 121 Russell Street North, Hastings, New Zealand 4122.

MANAGING EDITOR

Doug Green

T: 027 625 6166

E: publisher@xtra.co.nz

CONTRIBUTORS

Holly Green, EMA,

Business East Tamaki, Ian Walsh, Adam Sharman, Mark Devlin, Nicholas Russell, Jane Finlayson, Chris Penk, Paul Jarvie, Frank Phillips, David Altena, Rob Bull, Ben Speedy

ADVERTISING

T: 027 625 6166

E: publisher@xtra.co.nz

DESIGN & PRODUCTION

:kim-jean:

E: kim.alves@xtra.co.nz

WEB MASTER

Julian Goodbehere

E: julian@isystems.co.nz

PUBLISHING SERVICES

On-Line Publisher

Media Hawke’s Bay Ltd

DIGITAL SUBSCRIPTIONS

E: publisher@xtra.co.nz

Free of Charge.

MEDIA HAWKES BAY LTD

T: 027 625 6166

E: publisher@xtra.co.nz

121 Russell Street North, Hastings NZ Manufacturer ISSN 1179-4992

Vol.17 No.3 April 2025

The future of manufacturing is with us every day. We plan for it, living in the present, making things, being innovative, maximising the opportunities…for tomorrow.

Some of these opportunities may materialise for you if you are visiting SouthMACH 2025 in May, sharing stories and experiences with your peers who are there to listen to speakers and observe the latest in technology, products and services that may assist in enhancing your business performance.

The first of our two SouthMACH 2025 Previews is on Page 15 of this issue.

Recent regulatory changes by the Reserve Bank of New Zealand (RBNZ) may mark the beginning of a new era - one where increased banking competition and AI-driven financial services could significantly benefit manufacturers. Says Mark Devlin in his article (Page 7), ‘Why banking competition matters for New Zealand manufacturers.’

In our lead story, Ben Speedy, ASB, says that productivity in NZ has been steadily falling behind other OECD countries as we have struggled to lift the value of the goods we export.

He reflects on how. in recent years, primarily due to economic environment and immigration settings, productivity has largely focused on addressing cost challenges and labour issues. However, if we want to succeed as a country, we must turn our focus to growth.

You can also read about ‘Remanufacturing’ (Page 14); ‘New Zealand’s Health and Safety Reform’ by Paul Jarvie of EMA (Page 10); ‘Navigating the tariff maze’ with Adam Sharman (Page 21) ; Argon and Co (Page 13) talks the journey ‘From Automation to Augmentation: How Industry 5.0 is Redefining Manufacturing’, and amongst other great reading, Martin Fryer from thinkstep-anz (Page 22) shares his thoughts on ‘Double materiality: What it is and why it matters to manufacturers.’

You can also read about Remanufacturing, New Zealand’s Health and Safety Reform by Paul Jarvie of EMA, Navigating the tariff maze with Adam Sharman, Argon and Co (Page 13) talks the journey From Automation to Augmentation: How Industry 5.0 is Redefining Manufacturing, and amongst other great reading, Martin Fryer from thinkstep-anz (Page 22) shares his thoughts on Double materiality: What it is and why it matters to manufacturers.

Doug Green, Publisher

Lego, instruments, classic cars and baseball cards are among the alternative investments University of Auckland finance lecturer, Gertjan Verdickt, discusses in his new book The Passion Portfolio: Investing in Style.

Co-authored with Jürgen Hanssens (senior manager at KPMG Belgium and an avid Lego collector) the book details the mechanics behind the world of ‘passion’ investing.

The researchers offer readers an understanding of how the prices of passion investments evolve, along with the factors that drive these changes.

“We want to help people navigate these often opaque markets, where transactions are infrequent, and where in some instances, exclusivity, rather than transparency, is both the norm and the value driver,” says Verdickt, whose investment portfolio includes wine.

Verdickt and Hanssens discuss the pros and cons of various investments: wine, Lego, whisky, watches, bags, jewellery, art, stamps, instruments, vintage cars, precious metals and baseball cards.

They provide average historical annual returns by examining at least twenty years of data for each object.

Of all the investment options, whisky comes out on top with an average annual return of 17.52 percent. In second place is baseball cards, which posted an average annual return of nearly 13 percent compared to the stock market’s 10 percent.

Research suggests that adding collectibles like whisky, baseball cards, or Lego to an existing stock

portfolio can reduce overall portfolio risk, says Verdickt.

Each chapter of his book follows a structured approach, examining the advantages and risks of different asset classes, their historical returns and key factors that influence their value. Readers can learn about the authentication process, assess long-term investment potential, and gain insights into platforms that track pricing.

While passion investing can be lucrative, it’s also less regulated than traditional markets, increasing the risk of fraud. As such, Verdickt and Hanssens discuss how to spot counterfeit goods. They also explore arbitrage - where investors can take advantage of pricing discrepancies across different markets.

A well-documented provenance and pedigree, says Verdickt, can significantly increase the value of an alternative investment and, in turn, boost its likelihood of being sold.

The finance expert says passion investments require patience and expertise. “Unlike stocks, which can be sold at the click of a button, luxury assets are illiquid. A work of art is resold only once every nine years on average. Wine appreciates over decades. These are long-term investments that demand both knowledge and time.

“Lego, on the other hand, is accessible to everyone,

with relatively low initial capital required compared to many other collectibles.”

Because demand for Lego sets remains high, while supply is relatively limited, it’s a more liquid investment than most other alternative assets, he says.

“The book is for investors looking to diversify beyond traditional securities,” says Verdickt. “It’s also for people who are keen to put their money into something they love, something that’s tangible.”

Mark Devlin, Managing Director, Impact PR

New Zealand’s manufacturing sector has long faced challenges in securing financial services that are both efficient and cost-effective. The dominance of a few major banks has resulted in high fees, outdated systems and a lack of tailored solutions for businesses looking to scale.

However, recent regulatory changes by the Reserve Bank of New Zealand (RBNZ) may mark the beginning of a new era - one where increased banking competition and AI-driven financial services could significantly benefit manufacturers.

The RBNZ’s decision to allow greater access to New Zealand’s Exchange Settlement Account System (ESAS) is a critical step forward. ESAS is the backbone of the country’s financial transaction system, enabling real-time settlements between banks.

Previously, only major banks had direct access, forcing smaller financial players to go through them as intermediaries. This restriction has stifled competition and innovation in the banking sector for years.

Now, with non-bank financial institutions permitted to participate directly, manufacturers may soon see more competitive financing options, faster payment processing, and AI-driven banking solutions tailored to their needs.

The impact of these reforms extends beyond just banking competition. Fintech companies like Emerge are poised to introduce AI-driven financial tools that could streamline business operations for manufacturers.

Emerge co-founder Jovan Pavlicevic says that traditional banking services have failed to keep pace with the needs of modern businesses.

“It’s staggering that in 2025, opening a business bank account in New Zealand can still take months.

“Many of our customers report waiting three to four months just to get an account set up. Meanwhile, international fintech solutions are providing instant

onboarding, real-time fraud prevention, and AI-driven financial insights,” he says.

Emerge is working towards embedding artificial intelligence at the core of its banking platform, offering manufacturers real-time financial tracking, automated reconciliation, and proactive fraud detection.

AI-powered banking could also optimise cash flow management - an issue that continues to be a pain point for manufacturers dealing with supply chain disruptions and fluctuating demand.

Manufacturers are among those who stand to benefit the most from increased banking competition.

The sector is heavily reliant on access to working capital, trade finance, and seamless international transactions. Under the current system, high banking fees and slow processing times add unnecessary costs to doing business.

Pavlicevic highlights how manufacturers will benefit from fintech-driven solutions.

“Our system allows AI-powered facial recognition for secure transactions, while automated fraud prevention tools analyse transaction histories to flag unusual spending patterns before they become an issue. These innovations could save businesses significant time and money,” he says.

AI-driven banking models could also democratise financial insights. Previously, businesses needed a team of financial experts to manage cash flow, reconcile transactions, and detect anomalies. With AI, manufacturers will have real-time access to insights that allow them to make better financial decisions without requiring an in-house finance team.

Despite these advances, significant regulatory and financial barriers remain for challenger banks. In the UK, fintechs can launch a banking entity with just £1 million in capital. In New Zealand, they need between $30 million and $50 million just to enter the conversation with regulators. Pavlicevic describes this as an “impenetrable wall” for new competition. However, if New Zealand can overcome these regulatory constraints, the potential for AI-driven banking innovation is immense. AI could reduce reconciliation time, automate expense tracking, and improve financial decision-making for manufacturers.

With open banking and ESAS reform, the manufacturing sector may finally gain access to the efficient, cost-effective financial services it needs to compete on a global scale.

As the financial landscape shifts, manufacturers should keep a close eye on the rise of fintech solutions. Increased competition in banking could mean lower fees, faster transactions, and smarter financial tools - all of which will play a crucial role in helping New Zealand’s manufacturing sector remain competitive in an increasingly digital economy.

By Barracuda Networks

IT security teams are bombarded daily if not hourly with security alerts and events.

They need to cut through the noise to piece together the puzzle of potential threats and anomalous or suspicious activity to decide whether they are looking at legitimate actions or intruders with malicious intent. What happens when one or more of the puzzle pieces are missing?

Two different, real-life ransomware incidents targeting manufacturing companies and mitigated by Barracuda Managed XDR highlight what can happen to a company when their security cover is incomplete.

The security blind spots: compromised domain admin credentials, unprotected server not visible to security cover, the misuse of legitimate, commercially available IT tools

At approximately 1:00 a.m. on a Tuesday night, attackers exploited the credentials for a domain admin account to breach an unprotected remote desktop server belonging to their target. The lack of security cover meant that the anomalous activity on the domain controller went unnoticed.

The attackers then tried to establish persistence by installing a remote monitoring and management application on the unprotected server so that they could control their target from a distance.

The attackers used commercially available tools to try to obtain a list of credentials and move laterally through the network. This activity brought them to the attention of security tools which promptly killed the malicious activity. The attackers then tried to disable and manipulate security measures and delete copies of files – a common precursor to the release of ransomware. This activity was also detected and blocked.

At 3:20 a.m. the attackers tried to execute Play ransomware and encrypt several devices. By 3:23 a.m. this attempt was shut down when the targeted endpoints were isolated from the network.

With full security cover the attack could have been neutralised hours earlier.

The security blind spots: unprotected devices on the network, a VPN without multifactor authentication (MFA), a ‘ghost’ account created for a third-party vendor and not deactivated when the vendor left

At some point before the main attack – another middle of the night incident –the attackers got hold of the credentials to a ‘ghost’ account that had been set up by the target for a vendor and not deactivated when the vendor left. The attackers used this to connect to the target’s network via an open VPN channel that didn’t have MFA in place.

The attackers were spotted as they tried to move laterally across the network using information stealer malware and a hacking method that can circumvent passwords to gain access to a computer system. The malicious activity was blocked, but the attackers carried on. When they realised that endpoint protection was deployed on devices throughout the network, they tried to disable the endpoint security.

After this failed, they shifted the focus of their attack to an unprotected server from where they planned to launch the rest of the attack, well away from the visibility and restrictions of the installed endpoint security. The attackers were able to elevate their privileges to administrator-level and leverage that to execute the ransomware stage of the attack an hour later.

The attackers first executed the ransomware on the unprotected server and then tried to remotely encrypt devices they could reach through the network. Security tools quickly spotted the attack and isolated the targeted devices. Within four minutes it was all over for the ransomware.

These incidents illustrate how cyberattacks have become increasingly multi-stage and multi-level, with attackers ready to pivot and adapt to changing or unexpected circumstances, hunting down and exploiting any areas that are left unprotected and exposed.

Incomplete security cover can help attackers gain access to networks and remain under the radar until they decided to move laterally. It can enable them to prepare and launch different phases of the attack from devices that can’t be scanned and monitored by security tools.

The best protection against such attacks is comprehensive, layered defenses with integrated and extended visibility. This should be accompanied by a robust focus on cybersecurity basics. For example:

• Always enforce MFA, especially on VPN accounts that are accessible externally.

• Implement a password policy to rotate credentials regularly to avoid stale passwords.

• Regularly audit active user accounts and disable any that are no longer in use.

The integration of network, endpoint, server, cloud, and email security through XDR enables an unprecedented level of threat detection and response capability. With a comprehensive XDR solution, every corner of the IT infrastructure, and from emails to cloud applications, is monitored and protected with advanced security measures, a full spectrum of defensive tools, combined with proactive threat hunting and response strategies.

This allows for swift action and minimises the window of opportunity for threat actors.

Planned amendments to New Zealand’s Health and Safety at Work Act represent a shift towards reducing compliance burdens and offering businesses clearer guidelines.

However, while these changes may streamline processes and alleviate some administrative stress, they fall short in addressing the deep-rooted issues that contribute to New Zealand’s unacceptably high rates of workplace harm.

On the week of March 31, Minister for Workplace Relations and Safety, Brooke van Velden, announced the following proposed changes:

Reducing general H&S requirements on small businesses

• Small, low-risk businesses will only need to provide basic facilities and manage critical risks in their health and safety practice.

• Notifiable incident requirements will be restricted to significant workplace events such as serious injury, illness, death and incidents (including those on the Schedule 2 ACC list).

• Over-zealous and over-compliant health and safety practice can be reported to a hotline.

Freeing up landowners from liability in third-party recreational activities

• Landowners or managers who allow public access to land for recreational activities will not be liable for injuries.

• Health and safety responsibilities will fall on the organisation running those activities.

Directors to focus on governance and oversight, not day-to-day management of health and safety risks

• A clear distinction will be made between health and safety governance and operational management.

• There will be a reduction in overcompliance of health and safety policies and duplication of plans.

• Compliance with an Approved Code of Practice (ACOP) will become the same as compliance with the Health and Safety At Work Act in many cases.

• The definition of what ‘reasonably practicable’ means in specific industries will become clearer.

• Industry organisations will be allowed to initiate work on ACOPs, with final approval reserved by the Minister.

The EMA has been heavily involved in recent work with ACC to co-design a Harm Reduction Action Plan for Manufacturing, so we know the issues and complexities businesses face in navigating the health and safety landscape.

The simplification of the Health and Safety At Work Act, such as exempting small, low-risk businesses from extensive reporting requirements, will undoubtedly ease the strain. The reduction of ‘tick-box’ exercises, which often detract from addressing genuine safety risks, is a positive development.

Additionally, the clarification of responsibilities between directors and managers is a positive change. By delineating governance from day-to-day operational oversight, the reforms empower managers to better focus on immediate safety concerns, while directors are freed up to concentrate on strategic decisions.

This clarity should reduce confusion and make it easier for businesses to allocate resources effectively.

For industries such as manufacturing, where risks evolve quickly, the introduction of Approved Codes of Practice (ACOPs) offer flexibility, allowing businesses to develop industry-specific guidelines that adapt more rapidly to changing circumstances.

But while these reforms may reduce administrative burden, they do little to tackle the deeper, systemic issues that continue to plague New Zealand’s workplace safety record.

Despite being based on Australian and UK legislation, both of which have much stronger records in reducing workplace injuries and fatalities, New Zealand still suffers from alarmingly high levels of harm.

Our workplace injury and fatality statistics remain among the worst of the developed nations, with twice the rate of Australia and four times that of the UK.

Clearly, something more profound is needed.

The fundamental question remains: will these reforms genuinely reduce harm or are they simply a band-aid solution to a much deeper problem?

The root cause of high workplace injury and fatality rates in New Zealand is the lack of clarity in regulations and the failure to address key areas like enforcement, education, and multi-employer workplace coordination.

Without a modern regulator that is there to help, the reforms run the risk of becoming another set of guidelines that businesses pay lip service to, without

making any real changes on the ground.

It’s not enough to merely simplify compliance, we need to foster a culture of safety that goes beyond paper compliance and drives practical, meaningful change.

For instance, while the introduction of ACOPs tailored to industry subsectors is an innovative approach, it assumes that businesses have the capacity and resources to develop and implement them effectively.

In manufacturing, there are more than 70 subsectors, each requiring either industry or business associations to engage and create these practical guidelines if they are needed.

This argument assumes we have the economies of scale within subsectors to resource these ACOPs.

I’ve been involved in the drafting of ACOPs in the past – they come in and out of fashion – and they were a process of endless meetings and wordsmithing.

Some useful ACOPs came out of this process. There are currently 23 existing ACOPs on areas such as asbestos removal, but there was a real lack of resourcing to successfully build on these and, in many subsectors, they weren’t completed.

In reality, the lack of economies of scale in smaller subsectors means that resources for drafting, updating, and enforcing these codes are often insufficient.

In practice, the absence of a well-resourced and coordinated effort by government agencies such as WorkSafe means that some subsectors will continue to be underrepresented, leaving workers at risk. Moreover, the government’s budget for health and safety enforcement remains a point of concern. The announcement of an additional $2.7 million in funding for new inspectors is a step in the right direction, but it’s worth remembering that the annual cost of workplace harm in New Zealand is estimated at $4.9 billion.

This raises the question: is $2.7 million enough to reverse years of underinvestment in workplace safety?

The situation is made more urgent by the recent

restructuring of WorkSafe, which has seen the reduction of core roles and functions.

Imagine you’re driving down a straight road with your pedal to the metal. If you look in your rearview and there’s a police car, what do you do? Of course, you’ll slow down and drive more carefully.

If you see that police car then pull off the road, you’ll be more inclined to keep travelling as you were. Consider the millions spent on road safety to get the driving public to become confident and competent. The argument is, should we need a police force to monitor our driving? Law only ever prescribes the minimum requirements for a particular issue.

The EMA believes New Zealand needs more detailed health and safety regulations, similar to those of Australia and the UK, and we need a national strategic plan to make workplaces both safer and healthier.

WorkSafe NZ needs to be stabilised and given a clear mandate to work with businesses on making the workplace safer. It needs to be a modern regulator, not one focussed solely on non-compliance and enforcement.

New Zealand has to accept that, as a country, we are not doing workplace health and safety well.

Discussions with the Minister and her team at MBIE indicate that there are more health and safety changes in the pipeline, which is welcome news. We need not reinvent the wheel but rather learn from countries with strong health and safety regulations and implement known and successful interventions.

continued from Page 1

One of the many ways they have done this is through investing in and using artificial intelligence in the production of training videos, which have been used as part of the multi-language training materials accessible through kiosks placed throughout their workshops.

Supporting growth is a priority for us at ASB as we endeavour to sustain our position as being the leading supporter of NZ business, a position we have held for the past 5 years.

We are committed to backing brilliant businesses take on the world. In the first half of the year, we have increased international trade finance lending

by nearly $150m, supporting business with our fully subscribed $30 million clean tech and $20 million food and fibre accelerator funds.

We are continuing to support exporters and innovators with capital and global network opportunities, as well as boosting our internal capability in the critical food and fibre and manufacturing sectors.

With tailored financial products and advisory services, banks can empower NZ businesses to innovate and grow, ultimately driving economic development. Business must own our future as a country, and ASB wants to help make this happen.

Copy Deadline – 5 May 2025 Advertising – For bookings and further informa

Stralis Aircraft, Fabrum and Ara Ake are collaborating to advance hydrogen-powered aviation by designing, developing and testing liquid-hydrogen storage tanks and a fuel system for Stralis aircraft.

The partnership aims to enable Australasia’s first liquid-hydrogen-powered flight - and support the transition toward zero-emission aviation.

Australian company Stralis Aircraft, which develops high-performance, low-operating-cost hydrogen-electric propulsion systems, will integrate Fabrum’s tanks and fuel system into its aircraft.

New Zealand company Fabrum, which specialises in zero-emission transition technology, will provide lightweight composite tanks and dispensing systems, essential enablers for hydrogen-powered aircraft.

The project is supported by Ara Ake, New Zealand’s future energy centre, and aligns with Fabrum’s recently announced hydrogen testing facility at Christchurch International Airport.

“Our hydrogen liquefier provides readily available liquid hydrogen onsite, allowing the capability to access the critical fuel source to prove and test the tanks and fuel system we are developing for Stralis and their fixed-wing fuel-cell electric aircraft,” said Christopher Boyle, Managing Director of Fabrum.

“With Ara Ake support, we are excited to be delivering our light-weight composite tanks and fuel system for Stralis to advance the future of hydrogen-powered flight.”

The collaboration also aims to strengthen industry ties between New Zealand and Australia. The project will build expertise in

liquid-hydrogen storage refuelling, and aircraft integration, contributing to New Zealand’s growing role in hydrogen aviation.

“This project is a strong example of Ara Ake’s role in connecting leading organisations across countries to advance real-world clean energy solutions,” said Cristiano Marantes, CEO of Ara Ake.

“By enabling this initiative, we’re supporting the first hydrogen-electric demonstration with liquid hydrogen and positioning New Zealand as a global testbed for sustainable aviation innovation.”

Stralis’ fuel-cell technology is significantly lighter than existing alternatives, potentially enabling aircraft to fly ten times further than battery-electric solutions at a lower cost than fossil-fuel-powered planes. The company is already testing its hydrogen-electric propulsion systems with a team that has deep expertise in electric-aircraft development.

“This project is a significant step forward for Stralis as we test and refine our hydrogen-electric propulsion technology and build our liquid hydrogen capability,” said Stuart Johnstone, co-founder and CTO of Stralis Aircraft.

You might have heard the term ‘tech bro’ – a shorthand for the hypermasculine culture synonymous with the startup world. But while it’s often associated with Silicon Valley, that same culture is alive and well in New Zealand’s innovation scene too, say researchers Professor Anne de Bruin and Dr Janine Swail. Entrepreneurial ecosystems: the networks, organisations, and funding systems that support startup ventures, might seem open to all. But they’re far from gender neutral, the researchers say.

“The strong association of masculine traits with entrepreneurship persists, hindering gender equity,” says de Bruin.

In a new paper, de Bruin and Swail examine how gender dynamics shape startup ecosystems, and how feminist theories can be used to make them more inclusive and equitable.

“If you think about Auckland’s startup sector, it’s still pretty ‘tech bro’,” says Swail. “We need to rethink what it means to be inclusive in entrepreneurship.”

She says this starts with challenging the norms that shape entrepreneurial culture – norms that can make women and non-binary people feel unwelcome.

“Imagine you’re a female deep-tech entrepreneur looking for a lab or an accelerator programme,” says Swail. “You walk into a space that feels overwhelmingly masculine; in-jokes, blokey language, a boys club. It can be difficult to feel like you belong, let alone thrive.”

One of the biggest barriers? Unacknowledged gender bias baked into the structures and language of entrepreneurship. De Bruin points to New Zealand’s finance ecosystem, where most venture capitalists are men.

“The way people communicate and operate in that world is often coded in a very masculine way. Language matters, and when we start to unpack it, we see how women and others are often excluded, even unintentionally.”

If New Zealand wants to develop a genuinely diverse startup sector, we need to question who it’s built for, and who’s being left out.

Feminist theories argue for a shift from accepting the status quo to actively creating gender-equitable ecosystems.

One international organisation the researchers point to doing just that is Coralus (originally SheEO). Formerly led in New Zealand by Dame Theresa Gattung, Coralus was launched in Canada in 2015 as an experiment in more equitable funding for women and nonbinary people.

Since then, it has flipped the traditional funding

“We look forward to advancing hydrogen-electric aviation and fostering new partnerships in New Zealand.”

Green hydrogen is produced through electrolysis of water using renewable electricity. With an energy density three times higher than sustainable aviation fuel (SAF), and over 100 times greater than batteries, hydrogen can offer a credible alternative for aviation[1].

The support from Ara Ake has enabled Stralis and Fabrum to accelerate the development of this technology, with the goal of achieving Australasia’s first liquid-hydrogen-powered flight.

This collaboration represents not just a technical milestone, but a pivotal step toward making zero-emission aviation a commercial reality in Australasia and beyond.

model favouring male-led ventures and distributed nearly $19 million to more than 190 femaleand non-binary-led ventures using a collective decision-making model.

“By challenging traditional funding structures, Coralus reimagines what an entrepreneurial ecosystem can look like,” says Swail. “Even the name change – from SheEO to Coralus – reflects a broader, more inclusive vision.”

If New Zealand wants to develop a genuinely diverse startup sector, we need to question who it’s built for, and who’s being left out, says de Bruin. “We can create new pathways and build a future for entrepreneurship that’s more inclusive, more equitable, and ultimately, more innovative.”

The landscape of manufacturing is undergoing a significant transformation as we transition from the principles of Industry 4.0 to the emerging focus of Industry 5.0.

While Industry 4.0 emphasised automation and the integration of digital technologies into manufacturing processes, Industry 5.0 shifts the spotlight towards augmentation, fostering a harmonious collaboration between humans and machines.

Industry 4.0 brought a revolution by embedding automation and data exchange into manufacturing through cyber-physical systems, the Internet of Things, and cloud computing. The central aim was to streamline operations, reduce human intervention, and enhance efficiency.

However, as we pivot to Industry 5.0, the emphasis broadens to include the critical role humans play alongside machines, leveraging the unique capabilities of both to drive innovation and adaptability.

The shift from automation to augmentation marks a fundamental change. Automation focuses on machines performing tasks independently, effectively reducing human involvement in repetitive and labour-intensive activities.

In contrast, augmentation enhances human capabilities. It is about empowering workers with intelligent systems, using machines to support and elevate human decision-making and creativity rather than replace it.

The synergy between humans and machines in Industry 5.0 offers numerous benefits. It enhances problem-solving capabilities by combining human intuition with machine precision and data processing power.

This partnership can lead to more innovative solutions and a more flexible production environment. Moreover, it increases operational efficiency as machines handle repetitive tasks, allowing human workers to focus on more strategic roles that require creativity and complex decision-making.

Real-world examples of successful augmentation in manufacturing often involve collaborative robots, known as cobots, working alongside human workers on production lines.

These cobots are designed to assist with precision tasks, reducing the physical strain on workers and lowering the risk of human error.

In some factories, augmented reality tools are used to provide workers with real-time data overlays, enhancing their ability to assemble complex products accurately and efficiently.

Recent innovations led by major players within the AI industry is enabling the deployment of short run, cost effective robot solutions.

Nvidia the leader in AI compute technology with their market leading Cosmos world model is enabling robots at small scale with the creation of synthetic data for training.

Humans are a critical component in this process as the technology evolves.

The rise of Industry 5.0 heralds significant implications for the workforce. While there is concern about machines replacing jobs, the focus on augmentation offers a more optimistic outlook.

It suggests a shift in job roles rather than outright displacement, with new opportunities emerging in managing and optimising machine-human interfaces.

This transformation can lead to an upskilled workforce, where employees are empowered to engage in higher-level tasks, fostering job satisfaction and productivity.

For productivity, the combination of human creativity and machine efficiency promises a more resilient and adaptive manufacturing environment.

This integrative approach can lead to faster innovation cycles and a more responsive supply chain, ultimately benefiting businesses and consumers alike.

In conclusion, Argon & Co.’s expertise, particularly through its IRIS practice, positions it uniquely to guide organisations through this transformative phase.

By understanding and addressing the challenges involved in the transition to Industry 5.0, businesses can fully realise the potential of human-machine collaboration, ensuring a competitive edge in the ever-evolving manufacturing sector.

If you’re ready to embrace the future of manufacturing, contact us today to explore how we can help you navigate the transition to Industry 5.0 and unlock the full potential of human-machine collaboration.

The remanufacturing market unlocks opportunity across sectors for higher margins, affordability, and supply chain resilience.

Remanufacturing, the process of restoring used parts to give them a second life, has propelled into the spotlight in recent years by attempts to mitigate supply chain shortages, reach new customers through affordability, and search for high-margin alternatives for parts.

Both independent remanufacturing companies and remanufacturing arms within OEMs have proved essential for efficiently restoring parts and creating a way to lower expenses while making operations more efficient.

These players provide value across multiple industries, from the well-established space in the automotive sector to more emergent opportunities across sectors such as medical devices and electronics.

All of these sectors can benefit from reduced dependence on raw materials, extended product life cycles, and more.

But remanufacturing is an inherently complex process, and the industry faces unique challenges.

For example, remanufacturers grapple with the unpredictable availability, quantity, and quality of incoming used parts (referred to as “core”), complex pricing due to the volume and long tail of SKUs, and a high volume of unstructured, text-based data generated by product warranty claims.

Remanufacturing is the process of restoring core to give it an entirely new life.

The core, the starting point for the remanufacturing process, is typically a high-value part that requires technical expertise to be restored to its original function.

Within the automotive and industrials industry, parts that can be remanufactured include engines, transmissions, hydraulic components (such as bucket lifters), and drivetrain components (such as clutches and axels), as well as turbochargers and superchargers.

Historically, the automotive and industrial equipment industries have had the most use cases for remanufacturing, but a growing number of use cases are emerging in industries such as medical devices, furniture, electronics, and aircraft components.

The remanufacturing process typically involves seven primary steps (exhibit).

Prior to the remanufacturing process, raw materials travel through the product process, which begins

with the extraction of raw materials, followed by product manufacturing, and product use.

The product can then travel onto one of the three final phases: the end of its life cycle in a landfill, recycling, refurbishment or repair, or the remanufacturing process.

The remanufacturing process is comprised of seven steps: disassembly, cleaning, inspection and sorting, reconditioning, replacement, reassembly, and testing.

Once the product is remanufactured, it enters back into produce use and cycles through the three final phases.

1. Disassembly. A worn part is completely disassembled into its subcomponents.

2. Cleaning. Sandblasting, hot water treatments, ultrasonic cleaning, and other methods are used to thoroughly clean each component.

3. Inspection and sorting. All parts are inspected to determine which are reusable and sorted.

4. Reconditioning. Reusable parts are reconditioned through processes such as grinding or galvanizing.

5. Replacement. If a component does not meet quality standards, it is replaced with a new part.

6. Reassembly. The part is reassembled to meet or exceed the original specifications for function.

7. Testing. The part is rigorously tested for performance so that it meets or exceeds the original quality standards.

Remanufacturing offers several benefits for OEMs and remanufacturing organizations, including the following:

Cost-effectiveness. Remanufacturing can reduce

costs by 40 to 60 percent, directly boosting margins versus newly manufactured parts.

Faster availability. From 2020 to 2023, 33 percent of players across industries had “very significant” supply chain disruptions due to material shortages, according to McKinsey analysis, though disruptions have begun to improve. Remanufacturing makes parts available more quickly by using less raw material than new product manufacturing.

Reaching new customers through affordability. By extending product life cycles, product prices can be 45 to 65 percent lower,2 giving remanufacturers the opportunity to grow organically and, in many cases, reach a new set of customers.

Remanufacturers face a unique set of challenges, including the following:

Complex product pricing. Remanufacturing players manage substantial volumes of SKUs (sometimes over a million), which complicates SKU pricing. In addition, remanufacturers often manage a long tail of SKUs with low volumes, making it difficult to measure elasticity and arrive at an appropriate price.

Furthermore, each product may have a wide variety of different product vintages, status codes, and life cycles. Remanufacturers also need to balance the dynamics of different tiers of product (for example, OEM-grade, tier-two, and remanufactured parts).

Variable core availability and difficulty in core forecasting. Several factors make it difficult to predict when players will receive core, including the varying lifespans of different parts and macroeconomic conditions that may cause companies to keep their old equipment running longer.

Because remanufacturers cannot always predict the arrival and condition of the core, they sometimes incur excess operating costs, such as overtime shifts or expedited shipping for urgent orders.

Warranty management. Warranty claims often include high volumes of unstructured text data for every product in the portfolio, causing OEMs to struggle with identifying patterns of information, making improvements to their products, or reducing warranty costs.

Without a way to synthesise this valuable information, companies often let it go to waste.

Remanufacturing undoubtedly makes logistics, pricing, and operations more complex. But companies that pursue it reap the benefits of lower costs and prices, new customers, and supply chain resilience.

- Doug Green, Publisher

Fisher and Paykel Healthcare, Gallagher Industries, Buckley Systems, Rocket Lab, Rakon, Skellerup Holdings, Particle Systems, Scott Technology…are just a few examples of successful companies who have found markets for their ‘home grown’ products and services. And they keep moving ahead in challenging times.

They are members of the Creative Class – to which so many of us belong – who help drive the economy. They are the people who role their sleeves up and get stuck in, in their workshops or studios, to make ‘the next best thing’ and find new markets for their unique products.

At present, it is not only tariffs we need to keep an eye on, Generative AI (GenAI) is set to reshape manufacturing, driving innovative integration, operational efficiency, and data insights, transforming productivity and revenue.

Distribution leaders will need to adopt AI, robotics, and IoT to enhance industry-specific processes, data, and ways of working.

Ian Walsh, Partner, Argon and Co is big on Lean. And others don’t just talk Industry 4.0, they also talk Industry 5.0

These are all required for the efficiency of manufacturing. And of course, there is the urgent need to raise the levels of Productivity. This cant just be a never-ending conversation piece – we need to

do something about it!

Manufacturers will have to be prepared for the continued rise in competition from lower-cost production countries in Asia, including Vietnam, Thailand and China, along with more technologically advanced nations in Europe.

The world and its markets are changing and our manufacturers need to adapt and move forward.

Research the TIN Network, or the EMA, HERA, the Hutt Valley Chamber of Commerce, the Southland

Business Chamber, Make NZ or the Northland Chamber of Commerce. Join, find out what is going on and work with aspirational companies like your own for better business.

Trade shows, such as SouthMACH 2025, are an opportunity to become better informed of products and services available to make New Zealand manufacturing better. To make your company more efficient and successful.

SouthMACH 2025 puts you in the same room as the Creative Class; innovative businesses who are following their dream to achieve on local and world markets. And even though at present we are all facing the challenge of tariffs imposed by an inept regime, we need to plan ahead and continue to focus on where the opportunities are.

In April and May issues of NZ Manufacturer magazine we profile SouthMACH 2025. Because manufacturing and technology trade fairs such as this one, are few and far between. Best wishes for a rewarding experience.

Get ready to see tne latest in Robotics, Automation, IOT, Electronics, Education & Training, Materials, Composrtes, Industrial Macninery, Manufacturing Tools, HVAC, 30 Printing and more from leading New Zealand and International suppliers!

Caliber Design is turning 10—and we’re marking the occasion at SouthMach 2025 with a celebration that reflects who we are: practical, people-focused, and project-driven.

Visit us at Booth 135 for a slice of birthday cake and go in the draw to win a $1,000 Christchurch Adventure Park voucher. While you’re there, we’d love to talk about how we can help you scale your mechanical engineering capacity, flexibly and efficiently.

We’re not a consultancy. We’re not a contractor. Caliber is something different—a secondment-based engineering firm with a growing team of over 60 mechanical engineers working with businesses across New Zealand. We embed engineers directly into your team, on-site or remote, to provide the horsepower you need to get projects across the line.

Whether you’re navigating a peak workload, filling a short-term skills gap, or moving a major capital project forward, our engineers are there when and where you need them. From machine design and product development to FEA and project engineering, our team has deep, practical experience across a wide range of industries—from automation and manufacturing to food processing, aerospace, and advanced materials handling.

What sets Caliber apart isn’t just our model—it’s our people. We carefully select engineers who bring the

right mix of technical ability, communication skills, adaptability, and professionalism. We back them with systems, mentors, and processes that ensure they deliver value quickly. And we stay involved— checking in regularly, monitoring progress, and making sure the secondment is working for everyone.

When you engage a Caliber engineer, you don’t just get that one person—you tap into the entire Caliber network. That’s 350+ years of collective experience, shared knowledge, and access to a powerful library of proven templates and systems.

As one client put it, “Caliber engineers don’t just fill a role—they take ownership, solve problems, and bring fresh thinking to the table.”

Over the past 10 years, we’ve helped some of New Zealand’s most innovative businesses move their ideas from concept to reality.

From supporting HamiltonJet in developing state-of-the-art marine propulsion systems, to helping Fabrum advance hydrogen technology … and working with Wyma on world-leading post-harvest agricultural equipment and Daifuku on complex airport luggage handling systems, our engineers are helping scale production, bridge resourcing gaps, and build better, faster, and smarter.

We’ve also played a quiet but critical role in keeping the industry connected. Our model means we’re

*The BusinessNZ Performance of Manufacturing Index (PMI) decreased to 53.2 in March 2025, down from 53.9 in February.

*Production reached 54.2, its highest since December 2021

*Employment rose to 54.7, the strongest since July 2021

*New orders in contraction at 49.6, reflecting continued demand challenges.

Finished stocks surged to 56.3, suggesting manufacturers are building inventory.

uniquely positioned to see what’s happening across the country—in big OEMs, niche R&D firms, and busy production facilities.

We share that insight. We connect people. And increasingly, we’re being asked to help clients not just fill roles, but solve broader engineering and delivery challenges.

We’re proud of what we’ve built—and excited about what’s next. We’ll continue to grow our mechanical engineering capability, and we’re actively exploring how we can support clients in related disciplines.

We’re also investing heavily in learning and development, ensuring that every Caliber engineer gains exposure to world-class projects, expands their skillset, and contributes meaningfully to the New Zealand industry. It’s good for them. It’s good for you. And it’s good for engineering in Aotearoa.

Let’s talk at SouthMach

If you’ve worked with us before, come say hi and have some cake. If you haven’t yet, stop by and find out why over 240 New Zealand companies have trusted us with their engineering resource needs.

�� Booth 135

Birth day cake + prize draw

Win a $1,000 Ch ristch urch Adve n ture Park vouch e r

Here’s to the next 10 years.

Convex, an innovative New Zealand plastic packaging company, sees staff training not just as a strategy, but as a vital driver of success. During the Covid-19 pandemic, the company actively invested in upskilling its people to stay agile through the crisis.

Now, with New Zealand businesses facing fresh economic challenges, Convex continues to lead by example — showing how ongoing training builds a stronger, more resilient workforce.

Convex Operations Manager Aaron Collett says agility and adaptability have been the key to thriving in an industry as competitive as plastics packaging.

“Upskilling is a necessity to being and staying competitive, and for us competition is not just local, it’s global,” says Aaron. “Manufacturing is under pressure in New Zealand from imports and staying competitive in the packaging business is tough. A lot of what we do is highly specialised, capital intensive, and relies heavily on skilled trained staff.”

He says while training is a non-negotiable at Convex, it must also be scalable through tough times.

“Investment in training changes depending on the need, but for us it has always been important to continue upskilling our people, it’s just ‘the where’ and ‘the how’ that changes,” says Aaron.

“As a business we certainly have been tested, firstly during Covid and more so recently with the economic

downturn. In recent years we’ve had to navigate a new landscape in reduced demand so all areas of the business have been reviewed and training has been reduced in some non-core areas to reduce costs – but apprenticeships and appliance training maintains status quo and we’ve boosted training around HR, mental health and resilience as well as group training utilising the expertise of key suppliers.”

One clear benefit of this sustained investment is agility. Trained employees can maximise production efficiency, adapt to new technologies, and take on different roles as needed. Around 15% of Convex’s 105 employees are actively engaged in training, many through Competenz, working towards qualifications in printing, engineering, and manufacturing apprenticeships, as well as health and safety programmes.

“A sound level of training gives staff the ability to maximise the setup and speeds which machines can be run at, and cross-training in certain areas gives us flexibility to move staff around as the work changes,” says Aaron.

The majority of Convex’s workforce has completed foundational manufacturing training. This not only enhances individual skills but also strengthens the company’s ability to retain staff and build long-term careers.

“Over the years we’ve put over 70 percent of our staff

through basic manufacturing levels with Competenz as it gives them scope, confidence and the ability to learn new skills whether they use it at work or for personal growth.

‘Frontline management courses for staff becoming supervisors has definitely paid dividends, giving staff structure and confidence to supervise effectively, and there has never been a time when we haven’t had a printing apprentice,” Aaron adds.

“Like any manufacturing business, you can’t be doing what you did yesterday. Having the continuous improvement notion and attitude ingrained in a business is gold and that’s hard to do. You train to future proof.

“Any training you give staff where they are empowered to participate and contribute will benefit both the business and the individual staff member. We have been through testing times but training has helped us be more agile and reactive as the industry landscape has changed.”

Training requires commitment, resources, and a willingness from employees to embrace new challenges. In a period where many businesses are cutting costs to navigate financial pressures, Convex’s ongoing commitment to upskilling staff stands out as a forward-thinking approach to economic resilience.

continued on Page 27

Adam Sharman, CEO LMAC Group APAC

As trade tensions escalate globally, through the introduction of heavy tariff from the U.S. New Zealand manufacturers find themselves navigating increasingly complex waters.

The United States is one of New Zealand’s key export markets worth approximately NZ$9 billion annually, and New Zealand products provide key components in other countries’ supply chains into the USA.

The ripple effects of U.S. tariff changes extend far beyond simple price adjustments. When tariffs increase, manufacturers face immediate margin pressure, but also longer-term strategic questions about market positioning and investment priorities.

For New Zealand’s primary sector, dairy processors, which have developed specialised ingredients for U.S. food manufacturers, tariff increases could undermine carefully cultivated market positions. Similarly, premium meat exporters who have invested heavily in sustainability certifications and farm-to-table traceability to command premium pricing, could see their value propositions challenged. The impact extends beyond agricultural processing. New Zealand’s high-tech manufacturing sector, including medical device manufacturers and precision agricultural equipment producers, faces similar challenges.

For organisations that have established niches in specialised global supply chains where even modest tariff increases could significantly alter competitive dynamics, a focus on IP protection and maintaining certifications required for market access, for example in aerospace, pharmaceuticals and defence help protect market position, and reduce price sensitivity.

While tariff increases present challenges, they also create strategic opportunities. As tensions escalate between the United States and other major trading blocs, particularly Europe and China, New Zealand manufacturers could benefit from “tariff arbitrage” – situations where Kiwi products become relatively more competitive due to higher tariffs on competitor nations.

Exporting organisations are required to think differently about their global market positioning, both in terms of direct market tariffs and the relative position with respect to global trade dynamics.

Whilst this is not a new concept, the volatility introduced through the USA’s latest tariffs require organisations to develop both risk and opportunity response plans that maintain market position and capitalise on market opportunities create by trade tensions between other, competing regions.

For example, with higher tariffs on European meat products into the U.S. market, New Zealand dairy producers should be ready to step in with expanded production and distribution capabilities as New Zealand products become relatively cheaper by comparison.

This requires maintaining production flexibility and strong relationships with American distributors who may suddenly seek alternative suppliers.

Even given the potential opportunities created by shifting trade dynamics, margin erosion is a likely consequence for exporting New Zealand manufacturers as price pressure for their produces in market increase and cost of materials increase.

With geographic isolation already imposing a “distance tax” on exports, companies must double-down on operational efficiency to maintain margins even when facing tariff headwinds.

Successful manufacturers are those taking a holistic approach to efficiency. Organisations that focus on all aspects of their operation from material use and product design to production and logistics to optimise productivity when cash flow is constrained, and big plays are out of reach will be those that are running whilst others are crawling as the markets settle.

This means, optimisation of production efficiency to maximise capacity and reduce cost to manufacture, optimisation of supply chain efficiency to reduce material cost and stock held, and optimising process quality to minimise waste and rework. Whilst these focuses should be a continual focus, it is easy to let them slip when demand is high. However,

an unrelenting focus on operational efficiency is a critical foundation for agility and resilience in an uncertain world.

U.S. tariff policies represent just one aspect of what business strategists increasingly describe as a VUCA (Volatile, Uncertain, Complex, Ambiguous) or BANI (Brittle, Anxious, Non-linear, Incomprehensible) operating environment.

For New Zealand manufacturers, success increasingly depends on developing organisational capabilities, flexibility and efficiency that foster resilience regardless of specific trade policy outcomes.

The manufacturers who will thrive are those building adaptive, resilient organisations who can move quickly to respond to price fluctuations and changing market access requirements.

This means cultivating scenario planning capabilities, maintaining robust market intelligence functions, and developing diverse sourcing strategies. It also requires closer collaboration throughout supply chains to ensure rapid response to market shifts. Fundamentally, it means being as efficient as possible in production to maintain margin in good times and bad, to ensure capacity and resource levels that allow for a rapid response.

As Kiwi manufacturers navigate this complex landscape, the most successful will maintain their traditional strengths – quality production, innovation, and supply reliability – while rapidly developing new capabilities focused on agility and adaptation.

Those who view tariff challenges as opportunities to build more resilient organisations may ultimately emerge stronger, regardless of how specific trade policies unfold.

Leading New Zealand e-waste company, Echo, achieved the‘Climate Positive Business Operations’ certificate with Ekos, providers of national environmental auditing services.

This certification signifies Echo goes beyond neutralising its carbon footprint, actively removing more carbon from the atmosphere than they generate.

In achieving this certification, Echo carried out Greenhouse Gas (GHG) emissions reporting in partnership with Ekos, in which they:

• Identified and classified the different sources of emissions (Scope 1, Scope 2, Scope 3)

• Measured and calculated these emissions through in-depth data capture

• Reported on emissions following the GHG protocol

• Ensured these emissions have been verified and undergone external auditing

• Offset any emissions generated by business operations with verified carbon credits

• Are implementing a reduction plan to decrease their CO2 emissions.

Echo’s CEO Patrick Moynahan says: “Our carbon positive certification highlights Echo’s market-leading dedication to going beyond, driving

meaningful environmental change.

The certification takes our ongoing commitment to the environment even further, ensuring our operations not only reduce environmental impact, but also actively contribute to a greener future for all in Aotearoa New Zealand.”

With approximately 120,000,000 kgs of e-waste generated every year in Aotearoa, with only 2% of this diverted from landfill and recycled properly, Echo’s carbon-positive commitment indicates a doubling down on this mounting issue.

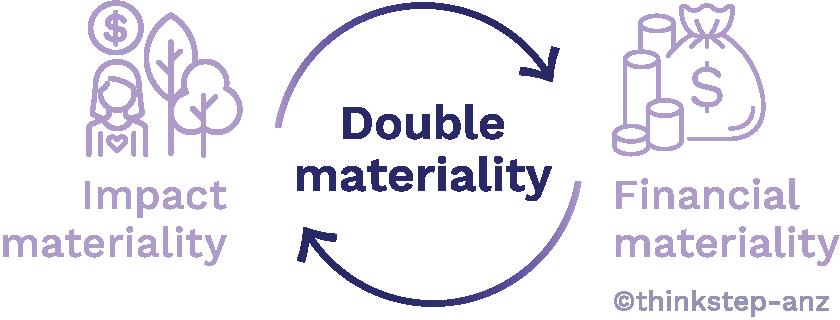

Sustainability isn’t just about ticking boxes for your next report. It’s about seeing the big picture - how the world is affecting your business and how your business is affecting the world. That’s the idea behind double materiality, and it’s something manufacturers across New Zealand should start paying attention to.

This approach goes beyond compliance. It can help you build a more resilient business, unlock opportunities and manage risks - whether you’re exporting food and beverages, building homes or making parts for machinery.

Double materiality means looking at sustainability from two perspectives:

Impact materiality: how your activities affect the environment, society and economy.

Financial materiality: how environmental and social issues affect your financial performance, risks and long-term success.

This approach is already required in some parts of the world. For example, the European Union’s Corporate Sustainability Reporting Directive (CSRD) mandates it. Even if you don’t export to the EU, it’s likely your customers or investors will start asking for the same level of transparency.

Why does this matter in New Zealand?

Even though New Zealand’s reporting regulations currently focus more on financial materiality, there’s growing interest in taking a broader approach. Why? Because it makes business sense.

Le t’s look at a fe w e xample s:

1. Food an d be ve rage man ufacturin g

Impact materiality: The way you source ingredients matters. Are you contributing to deforestation, water stress or unethical labour practices?

Financial materiality: If global retailers tighten their supply chain standards (as many already have), you could lose access to key markets unless you can prove your practices are sustainable.

What you can do: Use certified ingredients, invest in traceability, or switch to regenerative farming partners. These changes reduce your impact and protect your bottom line.

2. Te xtile s an d con sume r goods

Impact materiality: The fast fashion model creates waste and pollution, with many textiles ending up in landfill.

Financial materiality: Growing consumer demand for sustainable products is shifting the market. Products that aren’t seen as responsible may struggle to sell or fetch lower prices.

What you can do: Offer circular solutions - repair, reuse or recycling options. Use organic or recycled fibres and communicate these benefits clearly to customers.

3. Plastics an d packagin g

Impact materiality: Non-recyclable or single-use

plastics contribute to environmental harm.

Financial materiality: New Zealand’s product stewardship schemes and bans on certain plastics are already affecting what’s allowed on shelves.

What you can do: Redesign your packaging to be reusable, compostable, or easier to recycle. It can improve your brand image and reduce regulatory risk.

4. Wood proce ssin g an d furn iture man ufacturin g

Impact materiality: If you’re sourcing timber from unsustainable forests or using toxic adhesives and finishes, your products could contribute to deforestation and indoor air pollution.

Financial materiality: Customers (especially in export markets) increasingly want certified sustainable products. Failing to meet these standards can result in lost contracts or reduced sales.

What you can do: Shift to FSC-certified or locally sourced timber, reduce the use of harmful chemicals, and promote your sustainability credentials to gain a competitive edge.

5. Dairy proce ssin g an d e xport

Impact materiality: Emissions from dairy farms and wastewater from processing plants can contribute to climate change and water pollution.

Financial materiality: International buyers are tightening their sustainability criteria. Supermarkets and distributors may drop suppliers who can’t meet new climate and water standards.

What you can do: Work with suppliers to improve environmental performance, invest in cleaner technologies, and monitor your footprint to meet export requirements and avoid reputational risk.

Double materiality isn’t just about reporting

While many frameworks use materiality to guide sustainability reporting (like GRI or CSRD), the real value for manufacturers comes from using it to inform business strategy.

Set meaningful sustainability goals

Prioritise where to invest time and resources

Build stronger relationships with suppliers and stakeholders

Understand what’s coming down the track—before it’s urgent

Show leadership in your industry

Think of it as a radar system. It shows where your business might be exposed (e.g. through emissions, water use, or social risks in the supply chain) and where there’s opportunity to innovate or lead.

Many companies still treat materiality as a one-off exercise. But the world doesn’t stand still, and neither should your approach.

To get the most value, make your double materiality process dynamic. That means:

Reviewing it regularly (e.g. annually, or when major changes happen)

Engaging internal teams and external stakeholders