www.nzmanufacturer.co.nz

BUSINESS NEWS

What we are seeing in NZ Manufacturing.

Blending artistry with automation for strategic advantage.

Adoption of smart practises by manufacturers across New Zealand.

6 10 14 22

in the trades.

www.nzmanufacturer.co.nz

BUSINESS NEWS

What we are seeing in NZ Manufacturing.

Blending artistry with automation for strategic advantage.

Adoption of smart practises by manufacturers across New Zealand.

6 10 14 22

in the trades.

New Zealand’s manufacturing sector stands at a unique crossroads in its AI journey. The recent Callaghan Innovation survey showed that AI is the second-most desired technology, overtaking data and analytics among those already implementing technology.

The country already possesses some advantages, including one of the world’s highest rates of AI adoption among workers and a reputation as a global test-bed for innovation, with generative AI expected to add $76 billion to New Zealand’s economy by 2038 (Generative AI expected to more than double New Zealand’s productivity: report – New Zealand News Centre).

However, comparatively low digital maturity is eroding potential returns and putting New Zealand’s competitiveness at risk.

The infrastructure foundation is strengthening rapidly. Digital infrastructure is about to receive a huge boost with the opening of Microsoft’s hyperscale cloud region in 2024, and other datacentres promised over the next few years.

This development addresses one of the key barriers to AI adoption that many New Zealand manufacturers have faced—access to the computational power and data storage capabilities required for sophisticated AI applications.

For New Zealand manufacturers, the message is clear: the opportunity is significant, but the window for competitive advantage is narrowing.

Local manufacturers who act decisively to build their AI readiness now will be best positioned to capture their share of this transformative economic opportunity.

The Path Forward

Preparing your manufacturing business for AI success requires a holistic approach that addresses data infrastructure, strategic planning, workforce development, and technological readiness.

The companies that invest in building these foundations today will be best positioned to capitalise on AI’s transformative potential tomorrow.

The key is to start with a clear vision of how AI will support your business objectives, then systematically build the capabilities needed to achieve that vision.

This isn’t about implementing the most advanced AI technology available— it’s about creating an organisation that can effectively leverage AI to drive measurable business results.

The manufacturing landscape is evolving rapidly, and AI adoption is no longer optional for companies seeking to remain competitive.

By taking a strategic, comprehensive approach to AI readiness, manufacturing leaders can ensure their organisations are prepared to thrive in an AI-driven future. exerted from article on Page 19

Buy it and own it, no subscripon or cloud. Most cost affecve 3D CAD program to own.

www.baycad.xyz 0274847464 www.formtech.co.nz

Secure supply of energy and data to moving industrial equipment.

• Large size range

• Vertical travels

• Energy tubes

• Hygienic chains

• Solutions for long travel

• Guide troughs

• Readychain

• Robotic, 3D

• Circular movement

HUGE range of high quality flexible cables

• Control cables

• Single cores

• Data cables

• Sensor/Actuator

• Intrinsically Safe

• VSD/EMC cables

• Halogen Free cables

• High temperature

• Harsh Conditions

• Crane cables

• Profibus cables

• Bus/DeviceNet

• Solar cables

• Instrumentation

• Flat cables

• Curly cords

Largest range of flexible conduits for cable protection

• Conduits

• Conduit fittings

• Divisible systems

• Jumbo systems

• Conduit Accessories

• Braided cable protection

• Fire barrier solutions

• Food and beverage

• EMC systems

• Ex, ATEX, IEC EX

Industrial connectors for many industries

• Rectangular multipole connectors from ILME

• Single pole Powerline connectors from TEN47

• EPIC connectors from Lapp Group

• M23 circular connectors from Hummel

• Circular connectors specifically for the entertainment/stage lighting industry from Socapex

Safety engineering solutions from EUCHNER

• Multifunctional Gate Box MGB

• Transponder-coded safety switches

• Electromechanical safety switches

• Magnetically coded safety switches

Sensor technologies for automation

• High-Precision Laser Distance Sensors

• Ultrasonic Sensors

• Inductive Sensors

• Fluid Sensors

www.australianmanufacturingnews.com

The New Zealand Manufacturing Landscape BUSINESS NEWS

What we are seeing in NZ Manufacturing. Kiwi garage start up one of largest dual market export operations.

The genius myth.

ANALYSIS

Blending artistry with automation for strategic advantage.

Businesses remain trapped between health mandates and employment rights.

Adoption of smart practises by manufacturers across New Zealand.

NZ to be a global leader in superconducting magnet technologies for space.

Turning low-carbon ambitions into real-world results.

Let’s seize this chance to fix vocational education.

SUSTAINABILITY

Carbon claims: Get the language right and the facts straight.

ANALYSIS

Building the Foundation: Preparing Your Manufacturing Business for AI Success.

TRAINING

Shining a light on female talent in the trades.

WORKSHOP TOOLS

IAI Modular Cartesian Robot Systems: Space-Saving precision and flexibility. igus expands D1 motor control.

ANALYSIS

Article 5: The Role of Selectors & Optimisers in Industry 4.0 and Automation.

DEVELOPMENTS

World first waste upcycling tech to reduce dependence on imported foods.

New food safety combi unit launches at Foodtech Packtech.

THE LAST WORD

Leadership from the top.

Ian Walsh

Ian Walsh is a leading expert in designing and implementing transformational improvement programmes, with over 30 years of experience helping businesses drive operational excellence and long-term success. A Six Sigma Master Black Belt, he has worked with both New

Zealand’s top organisations and global multinationals including Kimberley Clark, Unilever, Guinness to unlock productivity, reduce costs, and optimise business performance. Ian has been at the forefront of operational improvement, working at all levels—including Boards—to deliver high-impact change. Ian continues to play a key role in advancing business excellence, supporting Auckland University and The Icehouse with expert insights on productivity, operational improvement, and best-practice methodology.

6 7 10 12 18

Dr Barbara Nebel CEO thinkstep-anz Barbara’s passion is to enable organisations to succeed sustainably. She describes her job as a ‘translator’ – translating sustainability into language that businesses can act on.

Mark Devlin

Having owned food manufacturing and distribution businesses for a decade, Mark Devlin now runs Auckland public relations agency Impact PR. Mark consults to several New Zealand manufacturing firms including wool carpet brand Bremworth, aircraft exporter NZAero and cereal maker Sanitarium.

Errey

Insa’s career has been in the public and private sectors, leading change management within the energy, decarbonisation, and sustainability space. Insa holds a Chemical and Biomolecular BE (Hons) from Sydney University. She is a member of the Bioenergy Association of NZ and has a strong passion for humanitarian engineering, working with the likes of Engineers Without Boarders Australia.

Insa is a member of Carbon and Energy Professionals NZ, been an ambassador for Engineering NZ's Wonder Project igniting STEM in Kiwi kids and Engineers Australia Women in Engineering, increasing female participation in engineering.

Jane Finlayson is Head of Advanced Manufacturing at the EMA, and has 25-years’ experience in business and economic development. She is passionate about empowering businesses to grow, innovate and embrace Te Ao Māori.

PUBLISHER

Media Hawke’s Bay Ltd, 121 Russell Street North, Hastings, New Zealand 4122.

MANAGING EDITOR

Doug Green

T: 027 625 6166

E: publisher@xtra.co.nz

CONTRIBUTORS

Holly Green, EMA, Business East Tamaki, Ian Walsh, Adam Sharman, Mark Devlin, Nicholas Russell, Jane Finlayson, David Altena, Rob Bull, Chris Penk, Scott Adams

ADVERTISING

T: 027 625 6166

E: publisher@xtra.co.nz

DESIGN & PRODUCTION

:kim-jean:

E: kim.alves@xtra.co.nz

WEB MASTER

Julian Goodbehere

E: julian@isystems.co.nz

PUBLISHING SERVICES

On-Line Publisher

Media Hawke’s Bay Ltd

DIGITAL SUBSCRIPTIONS

E: publisher@xtra.co.nz

Free of Charge.

MEDIA HAWKES BAY LTD

T: 027 625 6166

E: publisher@xtra.co.nz

121 Russell Street North, Hastings

NZ Manufacturer

ISSN 1179-4992

Vol.17 No.6 July 2025

There are insights into the current state of manufacturing and the economy in this issue. Going on about the state of things is not always great; however, we need to keep looking ahead to a better future. Simply, what is not going well needs to be sorted.

Johnathan Prince, Founder, Caliber Design says the recent SouthMACH and Fieldays have added optimism about where things are heading (Page 6).

Scott Adams, Argon & Co believes that manufacturing companies in New Zealand often lack artistry, passion and flair (Page 10).

Paul Jarvie, EMA, presented to the Royal Commission of Inquiry into Covid-19 and believes the restrictions on business operations during the lockdowns were too restrictive (Page 11).

Sean Doherty believes manufacturers are increasingly recognising the value of advanced technologies as essential tools for growth and resilience, with nearly 40 percent of the workforce implementing Industry 4.0 technologies (Page 14).

Adam Sharman discusses the AI revolution and how to prepare business for success (Page 19).

David Altena and Rob Bull want government to reflect on what it asks of business (Page 29).

*Finally, on a business trip, I travelled on the Tokaido Shinkansen Bullet Train between Tokyo and Nagoya and was taken by the number of apartments along the side of the track, at Bullet Train speed.

And they all had one thing in common on their balcony: a dog kennel, a satellite dish, plants and clothes lines. Nowhere to walk, no ground level space to kick a ball around.

The thinking around large apartment buildings close to the new Auckland railway stations is it to ensure trains have patronage and the huge spend on the developments justified.

The Government wants Auckland Council to make apartments possible. “Ensuring that Auckland takes economic advantage of this transformational investment in the city.” I wonder how many Government ministers will move there?

The economic advantages for engineers, architects, developers, interior decorating consultants and so on will be great.

Apartment living can bring problems – lots of people in a built-up area without social cohesion, finding ways to get into each other’s way and an over familiarity with one’s neighbours which does not necessarily lead to a quality of life.

Why not move to the regions where there are greater choices, competitively priced housing and lots of space where the kids can play?

By Jonathan Prince, Founder – Caliber Design

At Caliber, we get a decent sense of what’s happening across the industry. With more than 60 mechanical engineers embedded in client teams around the country—working across sectors like aerospace, energy, medtech, agritech, and manufacturing—we’re fortunate to see a broad cross-section of projects and perspectives.

Two recent events, SouthMach and the Fieldays Innovation Awards, have only added to that sense of optimism about where things are heading.

At SouthMach earlier this year, there was a noticeable shift in energy. The foot traffic may have been a little lighter than usual, but the conversations were deeper—full of optimism, insight, and a sense that momentum was building.

One that stood out was with Leonard Wiegersma and Saskia van der Geest, who spoke about everything happening in Southland. Leonard’s team of 30+ electrical engineers is flat out, and the vibe was clear: things are happening.

A few weeks later, Fieldays Innovation Awards attracted more than 60 entries—clever, technically sound ideas spanning everything from methane-reducing pills and shelf-stable functional proteins to advanced sensors for precision agriculture.

We’re seeing stronger product development, deeper understanding of market needs, and greater technical maturity across the board.

It’s also encouraging to see the next generation of talent coming through. The Young Innovator Award went to KiwiPrune, a device developed by high school students to remove clips from kiwifruit vines, improving productivity and reducing strain. This was an example of classic kiwi innovation—well considered and practical.

Of course, not everyone is feeling buoyant. There are still manufacturers doing it tough; navigating economic uncertainty, cost pressures, and cautious customers. But even within that context, we’re seeing lots of development going on. That quiet persistence is one of the defining strengths of New Zealand’s engineering sector.

From aerospace and medtech to heavy industry and food processing, there’s a consistent drive toward smarter, more efficient, and more sustainable

the day-to-day of New Zealand engineering. That means we see the challenges, and all the good stuff, up close. It’s not always smooth sailing. Resources are tight, deadlines are tighter, and innovation often has to happen on the fly. But what keeps us fired up is the calibre of people in this industry. Practical, sharp, and not afraid to get stuck in.

The engineers quietly doing great work. The companies backing themselves to tackle world-leading challenges. The teams pulling

A Kiwi company that began as a West Auckland garage start-up nearly three decades ago has grown into one of NZ’s largest dual-market export operations, and is set for further expansion with the construction of a new $115m biotech manufacturing facility in China underway.

Manukau-based Alpha Group is a vertically integrated nutraceutical exporter at the international forefront of fermentation technologies. The company produces patented fungal and plant-based bioactives, with integrated research and manufacturing operations across New Zealand and China.

The new 60,000m² facility in Ningde will support New Zealand’s fermentation export capabilities by integrating advanced R&D, testing, treatment and production.

Once complete, it is expected to generate more than NZ$225 million in annual revenue and expand Alpha’s transnational footprint to over 119 hectares.

To date, the company has invested over NZ$830 million in developing this global infrastructure.

Alpha Group was founded in New Lynn in 1998 by Professor Yihuai Gao, a globally recognised researcher in medicinal fungi and honorary fellow at Massey University’s Riddet Institute.

Mike Arand, Alpha Group senior business advisor, says the new facility is the physical realisation of Alpha’s long-term dual-market strategy, which combines New Zealand’s scientific and natural resource strengths with China’s demand, scale and infrastructure.

He says the development bridges lab-to-market

pathways, turning New Zealand-led research into commercial outcomes that drive export growth and reinvestment into local R&D.

“This facility unlocks exponential growth potential for New Zealand’s fermentation sector.

“By integrating R&D and processing in one hub close to our largest export market, we can boost output, reduce lead times and increase demand for Kiwi-derived ingredients.

“It’s about creating a transnational innovation ecosystem where New Zealand science drives offshore commercial outcomes, which then feed back into local jobs, R&D and raw material demand,” he says.

Alpha Group has already attracted global attention for its patented fermentation method that grows Ganoderma Lingzhi mycelium.

Used in traditional medicine for immunity, cardiovascular health and anti-inflammatory support, it now grows in under 10 days compared to the six-month growth cycle in the wild.

Approved by New Zealand’s Environmental Protection Authority, the technology enables consistent bioactive yields at scale and is the first of its kind to be commercialised in this country.

The innovation was developed six years ago by Professor Gao in collaboration with Callaghan Innovation and Massey University. It is seen as a flagship example of New Zealand’s growing strength in natural health and functional food technology.

Ganoderma Lingzhi has been used in traditional

Chinese medicine for over 2,000 years, but this lab-based approach opens the door to a new class of high-value, environmentally stable food and health exports.

Professor Gao says the breakthrough represents a turning point in how New Zealand can grow and export natural therapeutics.

“Fermentation is one of the most exciting global food technologies today. It offers us a way to produce clean, bioactive-rich compounds from fungi and plants in a controlled environment free from soil, weather or climate volatility, or without requiring large tracts of land or disrupting native ecosystems.”

“Ganoderma Lingzhi is one of the most revered mushrooms in traditional Chinese medicine, used for thousands of years to support immunity, cardiovascular function and overall wellbeing. But growing it traditionally is slow, unpredictable and difficult to scale.”

“Our fermentation method not only replicates the active compounds found in the wild species, but it does so in days instead of months under precise conditions that ensure consistency, purity and potency.”

“What we have built with Lingzhi is a platform that can be adapted to other medicinal fungi, plants and marine compounds, and now not only can we unlock new export streams from organisms that are difficult or impossible to cultivate here, we can dramatically accelerate research into other plants and fungi that support human health.

“That opens the door to a whole new category of science-led exports for New Zealand,” he says.

A curious history of a dangerous idea

Unsettling, amusing, and prescient; a much-needed audit of a consuming idea.

This is a study of how the measurement and indulgence of “genius” has changed over time. Over the past couple of centuries, the boundaries of genius have been used to justify eugenics, consolidate power, and excuse eccentric and even morally egregious behaviour.

This, Helen Lewis argues, grew from a shift to a secular world, wherein brilliance is no longer the guarded realm of religious authority or divine inspiration, but instead anchored in the fullness of the individual.

Her book offers a sweeping, entertaining, and at times disconcerting read of the new scaffolding of mythology that genius now demands. She moves in three parts, from its identification, measurement, and, sometimes, weaponisation by “genius hunters”; through the creation of and care for dominant archetypes of genius, such as lone rebels and tortured artists; to the extreme veneration of “hardcore”

genius in the modern market- and tech-driven world—personified by Elon Musk.

Along the way she interrogates the obsessions of Great Man theory, inherited greatness, and IQ tests, and she pokes with wry humour at the self-justification, oversimplification, hubris, male dominance, and fetishisation surrounding her case studies.

While her examples—including Galileo, the Beatles, Hollywood biopics, and the anti-establishment pseudoscience unearthed by the Covid-19 pandemic—are drawn from her own interests, Lewis only hints at her own ideas of genius, its limits, and the purpose it might legitimately serve.

Instead, her argument focuses on undermining the persistent idea that geniuses constitute a special class of people, exempt from the social norms and moral expectations of the rest. By illustrating the stakes of this shift, Lewis issues an effective call for a more carefully tempered understanding of

genius in our precarious times, one that celebrates creativity, innovation, and achievement rather than idolising a maker’s rarity and eccentricity.

How an elite athlete system could unlock new levels of productivity in NZ manufacturing

New Zealand’s manufacturers have long punched above their weight. Despite our relatively small domestic market and geographic isolation, Kiwi businesses have found ways to innovate, adapt, and produce world-class products. But there’s one area where we continue to fall behind global benchmarks, and that is workforce productivity.

In a sector where efficiency, speed, and output are constantly under pressure, how we support and develop human performance should be central to every productivity conversation.

Yet all too often, manufacturers focus their investment on new machinery, process automation, or software upgrades, while overlooking the untapped potential within their people.

That is why a new system, originally designed to help elite athletes deliver peak performances under pressure, could represent a game-changing opportunity for our industry.

Vantaset, a New Zealand-based performance company, has developed a science-backed workplace platform that helps individuals and teams consistently deliver their best.

It was created by Craig Steel, a performance expert whose research into the psychological breaking point of athletes led to a repeatable framework now used in both public and private sector organisations.

This is not a motivational workshop or a leadership seminar.

-Mark Devlin, Impact PR

It is a codified, platform-based performance system grounded in decades of data and testing.

Developed by a team that includes a former All Blacks manager and two Olympians, the Vantaset framework was originally designed to help elite athletes deliver peak performance on demand.

It has since been refined into a platform-as-a-service (PaaS) model that organisations can implement across their entire workforce.

What makes this particularly relevant for manufacturers is the platform’s focus on helping people function effectively in high-pressure environments. Unlike many workplace performance tools that are reactive-used to manage poor results or resolve personnel issues-Vantaset’s system is designed to proactively lift output and engagement.

This approach is especially powerful for manufacturers, where operational rhythm, human reliability, and sustained mental focus can mean the difference between profit and loss.

The system was developed over seven years at a cost of around $7 million and has already helped over 100 organisations and 30,000 employees improve their performance.

An earlier version of the framework was credited with supporting one of the most successful transformations in the New Zealand public sector, when it was used by the New Zealand Police under former Commissioner Mike Bush.

Bush attributed the system to helping reduce crime rates by over 20 percent, while also improving engagement and trust within the organisation.

The results were not coincidental-they were the product of a replicable performance process designed to bring out the best in people regardless of the environment.

The reason this system is so relevant to manufacturing today is because our sector is at a crossroads. Global

competition is rising. Margins are tightening. Labour shortages are ongoing. And many of our traditional productivity levers have already been pulled. What remains is the human factor. How well do we engage our teams? How consistently do we enable them to perform at their best? How well do we support their decision-making, me

Labour shortages are ongoing. And many of our traditional productivity levers have already been pulled.

Steel argues that most organisations default to risk mitigation. In manufacturing, that can mean rigid internal controls designed to reduce mistakes or enforce compliance. But this mentality often stifles initiative and slows down innovation.

By contrast, elite athletes are trained not to avoid failure, but to pursue exceptional outcomes. Their systems are designed to amplify strengths and bring out consistent top-level performance, even under pressure.

The Vantaset model applies that same principle in a business context. It offers leaders a structured way to support individual and team effectiveness by focusing on what drives high performance.

The goal is not just to avoid problems, but to create a culture where excellence becomes the norm.

For manufacturers, this could be the edge we need

continued on Page 16

Manufacturing companies in New Zealand are most often owned, managed, and operated by engineers and therefore they often lack artistry, passion, and flair.

I readily, and happily, accept there are exceptions to this statement, but for every exception there are 10 more that focus on precision, performance, and cost.

Is this a problem? Sometimes it is, because we miss the opportunity of producing something wonderful rather than something utilitarian, but also because it limits opportunity and commercial outcomes.

If we build a low-cost focused, and therefore often automated, manufacturing capability without creativity then it is very difficult to be innovative with product design and it therefore limits our ability to adapt to a changing market or to create opportunity in a new market.

I frequently hear that the only reason a product has changed is because the client required it.

This is satisfactory for many of our smaller national or regionally focused manufacturing companies as there are significant obstacles to change: there is not enough space, inflexible machinery, or people are scared to try something different.

But if we were to examine a list of the NZ manufacturing companies that have been successful globally and nationally, it would be full of companies that have blended artistry with automation, admittedly in industry sectors where that combination is encouraged, which is generally high-value niche products. Another smaller list of successful companies will show they have primarily focused on the artistry.

However, we have very few low-cost automation manufacturing companies producing volume that have been successful, primarily because there are too many barriers to be globally, let alone nationally, successful due to our small population and high labour costs.

So, if there are benefits in blending automation with artistry then what steps would I take? I’d argue that it’s relatively straight forward.

Firstly, it is entirely dependent on your industry. It is much easier to be innovative with furniture than it is with plastic washers that must meet specific engineering requirements.

So, if you are making plastic washers for NZ you might want to skip to the videos at the end if you still have some time left in your lunch break!

Secondly, we humans need to recognise that we are in control of our destiny, and we need to recognise that we are very good at product design, innovation, defining goals, and reviewing quality and results.

If we are doing anything other than this, we should question the value we are adding. So you should assign the machines to the repetitive and back-breaking work, assign the IT Systems to the data-driven business management and process control, and assign AI to the complex and detailed analysis.

Thirdly, use all the recently created available spare time to consider whether you can reinvent your business to produce the most beautiful or best designed and made product, or even the most wanted product on the planet. Got it?

Regardless of whether you have got it or not these are the steps in the correct order to be applied.

1. Differentiate your product –recognising that you can still automate its manufacture to ensure precision and consistency, but will now blend in artistry to make the product unique, desirable and filled up with emotional value. Greenest country in the world if you don’t check too thoroughly.

2. Customisation of automated products is very feasible. It sounds costly and risky but if you have a product in high demand that can be tailored for your clients it will be very appealing.

3. Speed up your innovation process so that you can rapidly prototype new designs for testing in the market to always be a little bit ahead.

4. Balance efficiency with identity so that automation cuts costs and ensures production levels can be met, and is balanced with making sure the product is authentic and has a feel-good story like Patagonia clothing.

5. Shift your people from repetitive to higher skilled and creative roles where they can manage systems, processes, technology, and other people.

6. Focus on a sustainable and ethical approach to how you source raw material and manufacture.

With a will it can be done. We can leverage our New Zealand advantage for clean design, sustainability and craftsmanship, and enable it with efficient automated production.

While researching for this article I found three YouTube clips that each offer a different perspective on this theme of blending artistry with automation. I particularly like the comment

made that “we make the most beautiful guitar possible that will last forever.”

The first is the crafting of an ancient Chinese stringed musical instrument called the Guqin. It takes years to prepare the materials, and weeks to make, and reflects the patience, beauty, and effort to produce a beautiful work of art.

The second is the manufacture of guitars in South Korea. They have been making a standard acoustic guitar that has had good reviews for over 50 years. The manufacturing process is a mix of automation and manual with a focus on volume, and you will get the vibe without watching it all.

https://www.youtube.com/ watch?v=0JSnvUaBUTc

The third is Taylor Guitars who expertly blend automation with artistry, but with a more modern approach using robotics where it makes sense.

https://www.youtube.com/watch?v=Q_ m1w7GRj_U

By EMA Employment Relations and Safety Manager Paul Jarvie

I recently presented to the Royal Commission of Inquiry into Covid-19, outlining the impacts on the business sector of the extended lockdowns and vaccine mandates.

In the EMA’s submission, we argued that from a business perspective, the restrictions on business operations during the lockdowns were too restrictive. Public health measures and employment law are like oil and water. Currently, they just don’t mix. I told the commission that businesses struggled to implement mandates while being bound by employment law processes.

The question was put to me during the inquiry as to what could be done about the impasse. I suggested that a caveat could be created under employment law that allows for certain public health measures (such as vaccine mandates), under exceptional and clearly defined circumstances (such as pandemics).

But it’s truly a can of worms. You have employment law on one side, but running parallel to that is the Bill of Rights in which people have the right to say “yes” or “no” to treatment. And treatment includes injections.

Businesses that were mandated to have vaccines immediately faced legal issues. If someone doesn’t want to get vaccinated, what do you do with them?

The difficulty here is plain for all to see. Legal cases involving workers being fired for refusing to get vaccinated continue to rumble through the courts. In early July, a Qantas pilot won his case in the Employment Court, as a result of the company’s unwillingness to provide “leave without pay” and the fact that he was let go after refusing to get the Covid-19 vaccine.

Having a caveat for exceptional health circumstances would at least give businesses some clarity around their roles and responsibilities. Obviously, there’s a lot of ground that needs to be covered before anything like this becomes a reality.

And, as I mentioned, the Bill of Rights would need to be taken into account. But so, too, would the Health and Safety at Work Act. Allowing a person to opt out of treatment, such as a vaccine, then return to the workplace is a safety hazard, which business have a responsibility to mitigate.

During the pandemic and its various lockdowns, the EMA worked with government to help businesses navigate the various Covid regimes in their efforts to get back to work. We provided numerous Covid related webinars and employment checklists as a means to find a way through unchartered territory. We handled thousands of calls a month on the Covid mandates between 2020 and 2023, underlining the

confusion and frustration that businesses faced. Since that time, the number of Covid-related calls from businesses to our AdviceLine has reduced to a trickle, but the gulf between public health measures and employment law remains.

Those remaining calls relate to an issue that continues to be a persistent strain on businesses and causes serious employment law headaches.

They relate to the estimated 38% of infected people for whom the effects of Covid have lingered, based on recent overseas research.

Measuring the impact of long Covid, as it has come to be known, on businesses and the wider community was not included in the relatively narrow terms of reference of the Royal Commission.

We find this difficult to understand given the continued social and workplace challenges.

Long Covid brings a host of debilitating symptoms, including brain fog, chronic fatigue, joint pain, and respiratory issues. For New Zealand, this translates to between 207,000 and 405,000 people potentially affected.

I wanted the Royal Commission to know that alongside the legislative issues of balancing public health and employment law lies a persistent employment issue that is simply not going away.

Sandra Lukey

Sandra Lukey is the founder of Shine Group, a consultancy that helps science and technology companies accelerate growth. She is a keen observer of the tech sector and how new developments create opportunity for future business.

Sean O’Sullivan

Has a B Com (Hons) Otago University. In 2000 - 2001 introduced PCs on the workshop floor and job and staff tracking and a productivity software App to Fletcher Aluminium Group and 100 manufacturers NZ nationwide.

Founding Director Empower Workshop Productivity & Scheduling Software App.

Johnathan Prince

Jonathan Prince is a Director at Caliber Design, a project-based mechanical engineering consultancy with engineers all around the country. With a background in product commercialisation, sustainable design, and business strategy, Jonathan is passionate about helping Kiwi companies turn ideas into reality and building engineering capability within New Zealand Inc.

Adam Sharman

Is CEO at LMAC for the APAC region. With a background in technology implementation, manufacturing and strategy, Adam and the team at LMAC are on a mission to transform manufacturing productivity by combining expertise in operational excellence, manufacturing digitisation and strategy definition and delivery.

Patrick McKibbin

CEO – Hutt Valley Chamber of Commerce

Patrick joined the Hutt Valley Chamber of Commerce in September 2021. His passion is identifying and connecting with manufacturing & technology businesses, other businesses, local government, central government and industry associations.

By EMA Advocacy and Stakeholder Engagement Lead Joanna Hall

New Zealand’s vocational education and training (VET) system stands at a defining crossroads.

After years of sweeping reforms, financial pressures and structural upheaval, the Education and Training (Vocational Education and Training System) Amendment Bill now before Parliament offers a rare opportunity to rebuild confidence, lift quality, and finally deliver a system that serves both learners and employers.

But to get there, we must face some uncomfortable truths about the current state of play, especially for manufacturers who continue to shoulder some of the heaviest burdens of our skills challenges.

At the Employers and Manufacturers Association (EMA), we represent small family manufacturers through to major exporters.

Despite their diversity, they all face a similar challenge: securing the skills and talent they need to grow.

For too many manufacturers, the promise of vocational education remains unfulfilled. They tell us the current system often does not meet their needs, forcing them to look for alternative training that better matches industry standards – even if that means absorbing extra costs or investing in programmes that fall outside formal NZQA credentials.

Nowhere is this disconnect more stark than with apprenticeships. Employers desperately want to grow their own talent, bringing young people into well-paid, sustainable careers. But they frequently encounter barriers that make the process far harder than it should be.

Many manufacturers highlight the heavy administrative burdens involved in taking on apprentices, from paperwork to managing assessments, which can overwhelm especially smaller firms.

Others point to persistent quality and consistency issues. Too often, graduates or trainees arrive on site without the foundational skills, work readiness, or familiarity with modern equipment that manufacturers expect.

Underlying all of this is a more systemic problem: a vocational education system that has often developed qualifications and delivery models in isolation from the industries it is supposed to serve.

The new Bill now before Parliament is a critical opportunity to reset these relationships. But if we are to truly deliver a system that meets both learner aspirations and labour market needs, it will demand a far stronger, more genuine partnership with industry than we have seen to date.

The proposed creation of Industry Skills Boards (ISBs) could be a positive step, but only if they are given clear mandates, robust funding and real influence. We need ISBs that are not just passive advisors but active participants in workforce planning. They should bring together deep insights into emerging skill requirements, feeding this intelligence into schools, tertiary education, immigration settings and careers advice.

This is a great opportunity to develop an integrated workforce skills strategy, looking across all levels of education/training and all industries, to ensure as a country we understand what skills are needed, how we’re going to train and hire for these, and how we communicate future opportunities within industries

like manufacturing to our young people and job-seekers.

Without such alignment, we will continue lurching from skill shortage to skill shortage, never addressing the root causes.

Manufacturers also want to see far stronger quality assurance and monitoring of training providers. It is critical that providers are held accountable not just for ticking boxes, but for delivering graduates who are truly ready to step onto factory floors, work safely and contribute productively.

This is particularly urgent given how rapidly manufacturing is evolving. Digital systems, automation, advanced materials and precision engineering are transforming workshops across New Zealand.

We need a vocational education system that is nimble enough to keep up and is continuously updating training content to reflect new technologies and practices.

At the same time, proposals in the Bill, such as lowering thresholds for imposing compulsory industry training levies, risk alienating businesses at precisely the moment we need them on board.

Many manufacturers already invest heavily in upskilling their people. Imposing levies without clear benchmarks for broad industry support could undermine goodwill and further disengage employers from a system they already view with scepticism.

Our message to policymakers is simple: work with us, not around us. Use the expertise that sits within industry to shape qualifications, delivery and pathways that are genuinely fit for purpose.

Recognise the vital role that industry bodies like the EMA can play – not just as advocates but as partners in areas like training, support, industry engagement and advice.

This is also a time for realism. The sector has been through near-constant flux over the past decade, breeding deep uncertainty for both learners and employers.

The changes now proposed are ambitious, timelines are tight, and many practical details are still missing. Without careful planning and authentic collaboration with industry, we risk repeating the mistakes of the past and squandering yet more employer trust.

At the EMA, we stand ready to work with government, educators and other partners to build a system that is collaborative, responsive, and focused on quality outcomes.

This is not just about manufacturers’ interests, it’s about opening up meaningful, future-focused pathways for New Zealanders into secure, rewarding careers. It is about boosting productivity and lifting our nation’s prosperity.

We cannot afford to get this wrong. Let’s seize this moment to finally create a vocational education system that truly works for both industry and learners.

Manufacturers are ready. We hope the system will be too.

By Chris Penk, Minister for Small Business and Manufacturing

Being the Minister responsible for advocating for New Zealand’s magnificent manufacturers comes with the benefit of being welcomed into factories around the country for tours and meetings.

From racing car seats and top-grade pharmaceuticals to steel, bread, and plastic containers, there’s a wealth of products made right here in our backyard beyond what the average Kiwi could even imagine.

Time and again, when visiting these businesses, I hear two consistent messages: they need skilled workers to grow, and they need fewer obstacles when selling their world-class products internationally.

That’s why I’m proud to share two recent wins that directly respond to those calls and aim to give the manufacturing sector a real boost, helping it grow and build confidence—something very welcome amid the tough global and economic climate.

First, we’re tackling one of the most persistent challenges facing the sector: skills shortages. Welders, fabricators, machinists, panel beaters – these are the roles that keep factories running and businesses growing. Unfortunately, in too many regions, there simply aren’t enough people to fill them.

With thanks to my colleague, Immigration Minister Erica Stanford, I sincerely hope this pressure is about to ease. Starting in August, ten additional manufacturing and trades roles will be added to the Green List’s Work to Residence pathway.

Eligible migrants working in these roles will be able to apply for residency after just two years of experience

with an accredited New Zealand employer. This practical change will help fast-track the talent manufacturers need to keep moving. Whether it’s a vehicle painter in the Far North or a pressure welder in the deep south, these roles are crucial to daily operations, and the Government appreciates that bringing in the right people is crucial in providing the stability businesses need to stay productive.

Some readers will likely share my determination that we don’t lose sight of the importance of local recruitment. I believe the skilled labour shortage needs a relatively fast fix, however – one that can support a longer-term, industry-led solution.

When businesses have the skills they need, they’re better able to take on local apprentices and help train the next generation of Kiwi tradespeople. This is how we build a stronger, more resilient workforce over time, with a steady pipeline of skilled people entering the industry for years to come.

Alongside workforce development, we’re also focused on expanding New Zealand’s global footprint by strengthening international relationships. I’m excited to share a major step forward for our cosmetics and skincare manufacturers. Thanks to a smart new certification scheme announced by the Prime Minister in Shanghai, New Zealand-made health and beauty products can now be sold in stores across China – not just online.

This change removes a longstanding trade barrier and gives exporters a government-backed

Taking steps to become more energy efficient and making the switch to clean energy can have plenty of benefits for your bottom line. It doesn’t have to be costly to implement, either.

EECA provides free tools and advice to help your business take the next step – including energy efficiency checklists, energy calculators and advice on the best clean and clever tech on the market.

Discover more at eeca.govt.nz/manufacturing

certification that meets Chinese regulatory requirements. That means faster, more credible access to a consumer market worth $200 billion and one of the fastest-growing in the world.

It also highlights the innovation, quality, and sustainability Kiwi businesses are known for. Our ban on animal testing remains firmly in place, and this blend of ethics and excellence continues to set New Zealand products apart.

These recent initiatives – like smarter immigration settings and expanded trade access – are part of our ongoing commitment to support manufacturers across New Zealand, whether they’re exporting cosmetics or building high-tech equipment. I understand how important it is for this sector to know it has the Government’s full backing.

And on that final note, while times have been tough for many in the past few years, I remain confident we can turn things around together.

The Government is working hard to strengthen the economy and create the conditions businesses need to feel secure and grow with confidence.

Intervengine is reshaping the future of healthcare by delivering faster, more effective, and more affordable preventive health solutions—without relying on traditional investment.

This New Zealand-based company has taken a self-funded path, growing through strong customer traction and strategic partnerships.

Rather than seeking early-stage capital, Intervengine has embedded its clinically validated digital health interventions into employee assistance programs (EAPs), digital health start-ups, primary care, and allied health, while seeking traction with health insurance platforms.

By offering white-labelled digital architecture, the company enables other digital start-ups to bypass costly development, saving millions while creating a recurring revenue stream to fund its own operations.

At its core, Intervengine blends behavioural science, AI-driven technology, and human coaching to tackle whole-of-health challenges. Its high-engagement mobile platform delivers daily health insights, activity scores, and AI-generated tips—working seamlessly

Zenno Astronautics, Wellington UniVentures, and Paihau—Robinson Research Institute have formalised a collaborative partnership to advance the development of superconducting magnet technologies for space, and further strengthen New Zealand’s position as the global centre in this critical field.

This collaboration marks a major step forward for New Zealand’s sovereign space capabilities. It brings together Zenno’s industry-first invention and commercialisation of superconducting systems for space, Wellington UniVentures’ expertise in research translation, and Paihau—Robinson Research Institute’s globally recognised leadership in high-temperature superconductivity and applied electromagnetics.

Together, the three organisations represent a significant opportunity for New Zealand to advance superconducting space technologies with a wide range of applications.

Zenno is building core technologies that underpin in-orbit mobility and advanced space operations and is a leading IP holder, with patents awarded for conduction cooled superconducting magnets in space in New Zealand and worldwide.

In December 2023, Zenno became the first company in the world to launch a superconducting magnet to

space, marking a major step in the deployment of superconducting hardware in orbit.

Max Arshavsky, CEO of Zenno Astronautics, said, “At Zenno, we’re focused on building technologies that are simple, reliable, and highly scalable, creating a foundation the space industry can thrive on. Our goal is to develop systems that reduce the industry’s dependence on “Earth-based resources, such as onboard fuel or traditional radiation shielding. Superconductors offer transformative potential in addressing these challenges and have the promise to become one of the core pillars of space infrastructure in the years ahead.

“Robinson Research Institute is a world-leading superconductivity research institute. I’m genuinely excited about the opportunity to work with this level of capability and deep expertise. It represents a tremendous win for New Zealand, placing us firmly on the global stage as a leader in space-based superconducting applications,” Arshavsky added.

Pierre Malou, CEO of Wellington UniVentures, said, “This development highlights the critical role that deep tech research and commercial collaboration play in solving complex challenges in the space sector.

“Robinson Research Institute’s superconducting

for both wearable and non-wearable users.

This hybrid care model triples the caseload capacity of health coaches and delivers outcomes up to three times faster than traditional approaches.

With licensed, evidence-based interventions from global experts like Professor Judy Moskowitz of Northwestern University, Intervengine’s programs have demonstrated over 20% improvements in wellbeing.

With 40% of its revenue now coming from offshore markets and a growing reputation built through global partnerships and conferences, Intervengine proves that impactful, export-ready health tech can be built sustainably—and independently—from Aotearoa.

research is internationally recognised, and we’re excited to be part of a collaboration that enables these capabilities to reach practical application.”

Professor Nick Long, Director, Paihau—Robinson Research Institute, added: “We see this as an exciting opportunity to contribute to New Zealand’s space industry ambitions by working together to solve some of the most difficult problems of using superconductors for space operations.”

This partnership supports New Zealand’s ambitions to grow a sovereign, high-tech space industry, delivering commercial, scientific, and strategic value. It aligns with national priorities around advanced manufacturing, research commercialisation, and global innovation leadership.

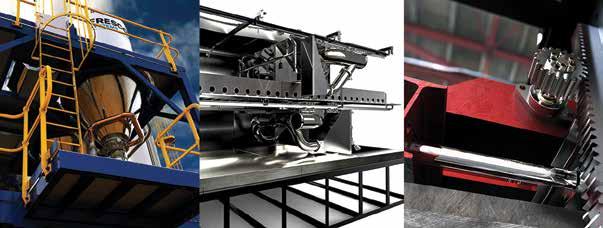

New Zealand’s manufacturing sector has stepped firmly into the fourth industrial revolution, with a 10.5 percent increase in the use of advanced manufacturing technologies since 2023, as shown in the final Industry 4.0 Insights Survey by Callaghan Innovation.

The Industry 4.0 programme was launched to build awareness and educate New Zealand’s manufacturing sector about the powers of digitisation and connectivity in manufacturing.

And, while it’s achieved this goal with 80 percent of Kiwi manufacturers aware of the programme, for Sean Doherty, Industry 4.0 Product Manager at Callaghan Innovation, the real impact has been how quickly that awareness has turned into action.

“What seemed experimental five years ago, has

quickly become business as usual for many Kiwi manufacturers,” he says.

“Manufacturers are increasingly recognising the value of advanced technologies as essential tools for growth and resilience. We now have nearly 40 percent of the workforce implementing Industry 4.0 technologies.”

From AI and robotics to real-time data tracking, manufacturers are turning to smart technologies to lift productivity, improve quality and modernise operations. It’s already seen that Industry 4.0 technologies such as AI, digital twins or cloud technology are able to increase productivity by 15-30%.

Supporting this momentum, the recently introduced Investment Boost scheme offers manufacturers an

immediate 20 percent tax deduction on eligible machinery and equipment purchases.

“Capital investment often presents a significant challenge for manufacturers,” says Doherty.

“This incentive helps lower that barrier to entry, making it more feasible for businesses to invest in automation, AI and other advanced tools. It’s a promising development and will help keep momentum built through Industry 4.0.”

However, Doherty stresses that “technology alone isn’t enough, investing in people and company culture is critical for lasting success.”

To view the full Callaghan Innovation Industry 4.0 Insights Survey report, visit: https://www. callaghaninnovation.govt.nz/assets/documents/ Industry-4-0/2025_Industry4_Insights_Survey_FINAL.pdf

An unwavering commitment to upskilling its people has helped keep tool maker Sutton Tools (NZ) out in front despite a string of setbacks including an earthquake, a pandemic, and in 2022, a fire that gutted their Kaiapoi factory.

Now though, the future looks brighter than ever with a brand-new factory in Rangiora and a forward-focussed masterplan that will drive expansion and power up their knowledge base.

Sutton Tools manufactures its high-quality cutting tools in Rangiora, as well as at two sites in Victoria, Australia before exporting them globally.

Adopting a proactive approach to training has been a critical factor in their success, and a long-standing partnership with industry training organisation Competenz has been pivotal to this work.

For over 30 years, Competenz has collaborated with Sutton Tools, offering apprenticeship and traineeship opportunities to enhance skills and engagement.

Production Manager Brian McCallum has spent just shy of 25 years with the company and in that time, he has completed a string of Competenz programs including a New Zealand Certificate in Workplace Health & Safety Practices (Level 3), a National Certificate in Competitive Manufacturing (Level 4), and a National Certificate in Manufacturing (Metal and Related Products) (Level 3).

Currently he’s working towards his NZ Apprenticeship in Mechanical Engineering (Trade) (Level 4) – Fitting and Machining.

“I went to Sutton for work experience when I was 17 and I never left,” says Brian. “In that time, I’ve been given lots of opportunities and done lots of different things within the company, including gaining qualifications and temporarily relocating to Australia after the fire to help with running one of the manufacturing plants in Melbourne.”

With a myriad of development and career prospects - and a highly supportive, encouraging employer - he can’t see a reason to ever leave.

“I love the company culture here and the way they respect and value their employees. It sounds cheesy, but we’re like a family, and that filters down. People feel valued when they’re getting these opportunities, and that adds to our output as well. People want to come to work, sick days are reduced, and productivity increases.”

Sutton Plant Manager Glenn Morgan has been with the company for 32 years and is a driving force behind the company’s workforce development. For him, it’s not just good business – it’s personal.

“To me it’s all about personal growth,” says Glenn. “I look at a person like Brian who is extremely intelligent and can achieve anything, and this is a way to upskill him.

“He’s a production manager now and he’s been a team leader and everything else, but if the place fell over and he didn’t have a job – not that it’s going to – he needs qualifications to back up his experience. For me it’s about ‘how can we help this guy in life’?

“It’s such a shame to see untapped potential. In some companies, people do such a good job in one area that it’s just easier for their employer to keep them there, but that’s not what I’m about. We want good people here, so the more we can accommodate them and make them happy, the better.”

In the 30-plus years Sutton has been working with Competenz, Glenn says they have trained hundreds of staff through Mechanical Engineering apprenticeships and training in Manufacturing, Competitive Systems and Practices, Distribution, Workplace Health & Safety and People Management. Competenz Training Advisor Euan Main supports Sutton Tools with their apprenticeship training and it’s a role that is particularly dear to his heart.

“I have a close connection with Sutton because that’s where it all started for me as an engineer. Back in the 1980s I worked there as a fitting and machining apprentice, so now I’ve come full circle,” says Euan.

“Sutton Tools is a real success story – they’re an export company that sells to the world, yet they come from a small town. They’ve adapted and kept pace with the markets and they have a great team environment.

“Many people are not aware of what this company does or produces for New Zealand, but their new factory is state-of-the-art in terms of engineering and they’re always open to upskilling and advancing people’s careers. In fact, two of my current apprentices already have degrees in engineering!”

But apprenticeship training is just one piece of the puzzle. Competenz Account Manager Denise Burton also collaborates with the organisation to identify traineeships that align with operational needs and employee development goals.

A traineeship is a short, structured programme that combines practical and technical training to provide people with a formal qualification. Typically taking six to 24 months to complete and ranging from entry level to advanced, traineeships can address general business and workforce needs, like leadership or health and safety, or key technical skills required by industry.

Denise enrols learners into relevant programmes, provides pastoral and academic support, and maintains regular communication with workplace supervisors to ensure smooth progress.

“Traineeships provide a valuable alternative to apprenticeships, delivering foundational knowledge and skills that can also serve as a stepping stone to higher-level qualifications,” says Denise.

The impact of this often shorter, job-relevant learning is far reaching, building confidence and reinforcing knowledge for the learner, while improving productivity and workforce capability for the

business, and contributing to a more skilled and motivated workforce for the industry as a whole.

“Partnerships like the one we have with Sutton Tools truly have influence. This is an organisation that is genuinely committed to the development of their staff, and there’s a real culture of care and investment in their people. When employers are actively involved in supporting training, learners thrive.”

Rebecca Hall is one of those learners. The Packing Coordinator is currently enrolled in the NZ Certificate in Business (Introduction to Team Leadership) Level 3, which is delivered through Competenz by their subcontractor Upskills. It’s a qualification that’s giving her the skills she needs to excel in her role –and achieve her goals.

“I’ve always wanted to be a team leader and having this qualification will help me push for it. The course is teaching me so much, deepening my understanding of the role and giving me the tools I need to be good at it. It turns out being a good leader is different than what I thought it was!”

Being encouraged to upskill makes Rebecca feel valued and – just like Brian – she sees herself building her career at Sutton Tools (NZ) well into the future.

“I started working at Sutton Tools when I was 18 and I’ve been here for 12 years. My mum has been here since she was 18 too, and my nana also worked here for a bit. It’s fair to say, it’s a pretty good place to work!”

By Caliber Design

Across New Zealand, companies are making real commitments to reduce emissions.

Coal-to-biomass boiler conversions. Hydrogen technologies. Electrification. Energy efficiency upgrades.

But ambition doesn’t guarantee successful execution. At Caliber, we work inside our clients’ teams to help deliver some of the country’s most ambitious energy projects. We do what our clients need us to do—whether that’s concept development, detailed design, project engineering, or boots-on-the-ground delivery support. And across all sectors, we’ve seen recurring challenges that can make or break a project.

Energy projects are rarely straightforward. They’re retrofitted into existing infrastructure, often while plants continue to operate. The risks are high, the timelines tight, and the expectations significant.

While each site is different, a few issues come up again and again:

• Unclear scope. Projects often kick off before the requirements are fully defined. Early assumptions harden into decisions that are costly to reverse.

• No spare capacity. The engineers who know the site best are already fully occupied. There’s no internal slack to take on a new project—no matter how strategic it is.

• Integration is underestimated. Whether it’s changing fuel type, adding storage, or swapping systems—nothing is ever truly plug-and-play. Real-world constraints surface during detailed design and install.

At Vortex Engineering, we supported a large-scale wood pellet boiler conversion at a milk processing site in Dunsandel. The scope included transporting pellets via

pneumatic blowlines, strengthening existing bins, and coordinating an install in a live, high-compliance environment.

With multiple projects in motion, Vortex forecast a short-term capacity gap. We provided a project engineer to coordinate contractors, manage logistics, and oversee mechanical checks through to handover.

At Open Country’s Waharoa site, we helped convert coal-fired boilers to run on wood pellets. That meant mechanical design, site coordination, and real-time problem solving—supporting a lower-emissions outcome without disrupting production.

With Fabrum, we’ve worked on hydrogen infrastructure—contributing to cryogenic storage systems, mobile refuelling units, and liquefaction equipment. These systems aren’t prototypes. They need to be manufacturable, serviceable, and safe.

Our role has included detailed design, testing support, and integration with existing platforms.

And with Global Bus Ventures, we supported the conversion of a 6x4 truck to a hydrogen fuel cell powertrain. Our engineers tackled structural design, tank integration, and supported the certification process—helping take a strong concept all the way to road-ready.

We’ve also supported a $600K compressed air upgrade for a national food manufacturer—taking the project from feasibility through to commissioning.

At a large industrial site, we delivered a $4M HVAC and fire protection upgrade spanning multiple buildings. And for an industrial gases client, we managed the build and commissioning of a 300 Bar nitrogen filling system, completed in just eight months.

Successful delivery hinges on a few consistent factors:

• Clarity up front. A robust brief and realistic schedule help prevent costly rework down the track.

• Experienced boots on the ground. Projects only move when someone owns the detail—managing suppliers, keeping trades aligned, and making informed calls under pressure.

changes, weather delays, safety audits—it all happens. The key is keeping momentum without losing sight of the bigger picture.

At Caliber, our engineers work onsite inside client teams—bringing extra horsepower when and where it’s needed most. We work across food processing, hydrogen, transport, infrastructure, and more. Our goal is to help companies not only set ambitious targets—but deliver on them.

continued from Page 8

How an elite athlete system could unlock new levels of productivity in NZ manufacturing

to compete more effectively on the world stage. By embedding a scalable performance system that strengthens leadership, sharpens focus, and lifts engagement across the factory floor, we can create workplaces where productivity thrives.

In the past, performance management often meant ticking boxes or documenting weaknesses. Now, thanks to this New Zealand innovation, it can mean empowering every worker to achieve their best and contribute to a culture of excellence.

If a system that helped athletes win dozens of world titles can be used to lift the output of global police forces, then surely it is worth exploring what it could do for our production lines, plant teams, and business leaders.

Productivity is no longer just about processes. It is about people. And in that area, we may be sitting on the biggest opportunity of all.

Singtel has launched its enhanced Multi-Domestic Connectivity solution that enables seamless, secure, and regulatory-compliant global IoT deployments in partnership with floLIVE, a cloud-native IoT connectivity provider.

Through this partnership, enterprises can leverage Singtel as the single, scalable access point to pursue international IoT expansion across more than 190 markets — from China and the Middle East to Europe and the Americas — eliminating the complexity of managing multiple mobile network operator agreements (MNO), SIM platforms, billing systems, and network switching.

As part of this development, Singtel also signed a Memorandum of Understanding with global wireless service provider, Lenovo Connect, to be its channel partner, focusing on IoT industry cooperation. Together, the parties will help Original Equipment Manufacturers (OEMs) expand to overseas markets — faster, more efficiently, and with full compliance — all via a single, unified platform.

For automotive OEMs, building the next generation of connected vehicles or cars equipped with built-in internet access for navigation, safety updates, entertainment, and future-ready autonomous driving — reliable, secure, and scalable IoT connectivity is essential.

This integrated solution combines Singtel’s global IoT network, Lenovo Connect’s device connectivity expertise and floLIVE’s Global Network and multi-IMSI SIM technology — streamlining enterprise operations, reducing time-to-market, and ensuring consistent service delivery across borders.

It also enables the automotive OEMs to enhance or build new features that will improve the driving experience of their customers.

One of the biggest challenges in global IoT connectivity is the fragmented landscape of MNO platforms. Singtel’s Aggregator Connectivity Management Platform (CMP) addresses this by offering enterprises a unified portal that standardises integration, simplifies management, and provides full visibility and control.

Singtel’s new Multi-Domestic Connectivity solution and CMP, augmented by floLIVE’s Global Network enables:

• centrally managed local connectivity with seamless switching between mobile networks via multi-IMSI and the latest eSIM IoT Standards - eUICC (SGP.32)

• enterprises to easily manage and update devices remotely due to the built-in support of the latest global standards for eSIM technology

• end-to-end lifecycle management of SIMs and devices across multiple CMPs

• real-time visibility, control, and diagnostics for superior device performance

Enabling automotive OEMs to go global

The global connected car market is projected to exceed US$250 billion by 2030, with Asia-Pacific among the fastest-growing regions. China is poised to remain the global leader in EV adoption, according to the International Energy Agency’s (IEA)

Robinson Research Institute, a pioneer in high-temperature superconductivity (HTS) research, has received funding of $71million towards setting up and hosting an advanced technology platform in Future Magnetic and Materials Technologies.

The funding for the advanced technology platform was announced by Minister for Science, Technology and Innovation, Dr Shane Reti at Robinson Research Institute’s facility in Lower Hutt, and will operate through the Ministry of Business, Innovation and Employment-administered Strategic Science Investment Fund (SSIF) portfolio over a period of seven years.

In line with the objective to grow New Zealand’s hi-tech exports, the advanced technology platform will apply materials and engineering expertise across a range of sectoral themes including space, electric aviation, critical minerals and technologies for fusion energy.

The platform will play a crucial role in lifting New Zealand’s innovation capacity, enabling companies to take technology to market, and in accelerating the growth of the domestic manufacturing sector.

Professor Nick Long, director, Robinson Research Institute, said “It is an honour for the Institute to receive this strategic funding. At Robinson, our focus has always been on how applications of HTS can be leveraged to address real-world issues, ranging from

propulsion in space to more accessible Magnetic Resonance Imaging (MRI) scanners.

“With proven capabilities in emerging areas like space and advanced aviation, Robinson is well-placed to drive growth in this area. Initially leveraging our capability in magnetics, the Institute has also developed processing methods for critical minerals from New Zealand resources. This funding will enable us to solve some problems with scaling these methods to commercial levels.”

A valued part of the University community, Robinson Research Institute has a strong track record of projects evolving into pilot projects or commercial enterprises. This new platform is a significant opportunity for Robinson to strengthen collaborations with the wider research community, in a way that delivers stronger outcomes for Aotearoa New Zealand.

The objectives of the platform will include developing workforce capability through internships and postgraduate study, and encouraging early career researchers to take their research beyond the laboratory.

Projects from the platform will also enhance local and international research and commercial partnerships, and encourage inward investment into the New Zealand research and development sector.

Global EV Outlook 2025 [1].

Singtel is already a driver of connected car innovation in the region — being the only operator to have powered connected vehicle programs for automotive OEM’s from the United States, Europe, China, and Asia Pacific.

By integrating floLIVE’s capabilities and partnering with Lenovo Connect — whose solutions span secure payment, connection and device management, data collection and computing — Singtel can now offer OEMs a frictionless path to international expansion, with fully compliant and secure in-vehicle connectivity and device orchestration.

This offering is especially timely for OEMs navigating growing demand for real-time services, such as over-the-air updates, smart navigation, diagnostics, and infotainment.

Advertising Booking Deadline – 5 August 2025

Advertising Copy Deadline – 5 August 2025

Editorial Copy Deadline – 5 August 2025

Advertising – For bookings and further informa

Media Hawkes Bay Limited 06 870 9029

Articles to be sent to: publisher@xtra.co.nz

-thinkstep-anz

If you’re sharing your organisation’s carbon footprint, net zero goals or carbon neutral status, it’s vital to communicate clearly and accurately. Getting it wrong could damage your reputation, open you up to legal risk or erode trust with your customers and stakeholders.

Strong carbon claims can show leadership, but only if they’re backed by real action and solid evidence. The good news is: once you understand the terms, it’s much easier to get them right.

Why clarity matters more than ever

In today’s fast-moving policy and regulatory environment, environmental claims are under increasing scrutiny. We’ve seen businesses taken to court for inaccurate or unsubstantiated claims.

To stay on the right side of the law – and the right side of your customers – you need to be cautious and well-informed.

This article explains the key carbon terms and offers practical advice to help manufacturers communicate responsibly.

Your business, product or service has measured its emissions, taken action to reduce them and used offsets to balance what’s left.

➔ You need: a defined scope (e.g. your head office or a specific product line), a timeframe, a verified carbon footprint and a credible reduction plan.

➔ Use offsets only for emissions you genuinely can’t avoid, after reduction efforts.

➔ Standard to follow: ISO 14068.

Example:

A manufacturer measures and verifies its emissions for 2023, reduces what it can and offsets the rest using certified carbon credits. It communicates: “Carbon neutral for our Christchurch site in 2023, certified to ISO 14068.”

This means deep emissions cuts first, and offsets only for what’s unavoidable. It’s typically applied to entire organisations.

➔ You need: to follow the Science Based Targets initiative (SBTi) approach – prioritising genuine emissions reductions. Offsetting alone is not enough. You must reduce most of your footprint through meaningful changes (e.g. cleaner energy, efficient transport).

Example:

A manufacturer reduces emissions by 90% by upgrading equipment and switching to renewable energy. The remaining 10% is offset. That’s a credible net carbon zero claim.

This means no carbon emissions are generated at all across the entire lifecycle. It’s extremely difficult to achieve.

➔ Requires zero emissions from raw material extraction through to end-of-life.

Example:

A wind turbine manufactured and transported using only renewable energy might come close – but most businesses won’t be able to meet this threshold.

These terms mean you’re removing more carbon from the atmosphere than you emit.

➔ Carbon negative is clearer and more accurate.

➔ Carbon positive is used interchangeably but can be confusing, so it is best avoided.

Example:

A timber business plants permanent native forests that sequester more carbon than the emissions from harvesting, milling, and transport. Independent third-party verification supports the carbon negative claim.

What is a carbon credit?

A carbon credit represents one tonne of carbon dioxide equivalent (CO₂e) reduced, removed, or avoided by a certified project. This could be through tree planting, renewable energy or methane capture. What are carbon offset?

A carbon offset is when you buy a carbon credit to balance out emissions you produce. It only works if the offset project is real and measurable.

Here’s how to communicate responsibly and avoid greenwashing:

1. Use accurate, consistent language

Know the difference between net zero, carbon neutral, and climate neutral. Use them correctly and consistently and avoid vague claims. Saying “we’re carbon neutral” isn’t enough. Explain what that means, how you achieved it and what standards you followed.

2. Follow the standards -not just loosely

Look for ISO 14068 for carbon neutrality, ISO 14067 for product footprints, and ISO 14064 for organisational footprints. Don’t say “aligned with ISO”. Follow the relevant standards properly if you want your claims to hold up.

3. Use high-quality offsets and be upfront about them

Offsetting is a useful tool, but only when you’ve done everything you can to reduce emissions first. Share details about the projects and be clear on what they actually achieve.

Make sure offsets are additional, impactful and verified. Check if they’re listed on recognised registries like Gold Standard or Verra.

4. Tell the whole story

Avoid vague promises and future goals without a credible plan and verified data to support them. If you’re just starting your sustainability journey, that’s okay. Be open about what you’ve measured, what you haven’t and what you’re working on. That builds trust.

Even if you’re a small business without certification, you can still tell a credible story. Just be clear and honest about where you’re at.

Want a second opinion?

thinkstep-anz now offers a fixed-price carbon claim review service. It’s designed to help businesses sense-check their claims, avoid risk and communicate confidently. Learn more here.

-Adam Sharman, CEO LMAC Group

The manufacturing sector stands at the precipice of an AI revolution that promises to transform everything from production efficiency to supply chain management.

Yet for many business leaders, the question isn’t whether to adopt AI, but how to prepare their organisations to extract maximum value from these powerful technologies. The answer lies not in the sophistication of the AI itself, but in the quality of the foundation upon which it’s built.

Before any AI system can deliver meaningful insights, your manufacturing operation must first establish a robust data infrastructure.

This begins with conducting a comprehensive audit of your existing data landscape. Map out where data is generated across your operation—from sensor readings on the factory floor to inventory management systems, quality control metrics, and customer order patterns.

Many manufacturers discover they’re sitting on vast amounts of valuable data that remains siloed across different departments and systems.

The key is achieving data integration and standardisation. Legacy systems often speak different languages, storing similar information in incompatible formats.

A machine’s operational data might be recorded in one system while maintenance records exist in another, making it impossible for AI to identify patterns between equipment performance and maintenance needs. Investing in data integration platforms that can unify these disparate sources creates the coherent dataset that AI algorithms require to function effectively.