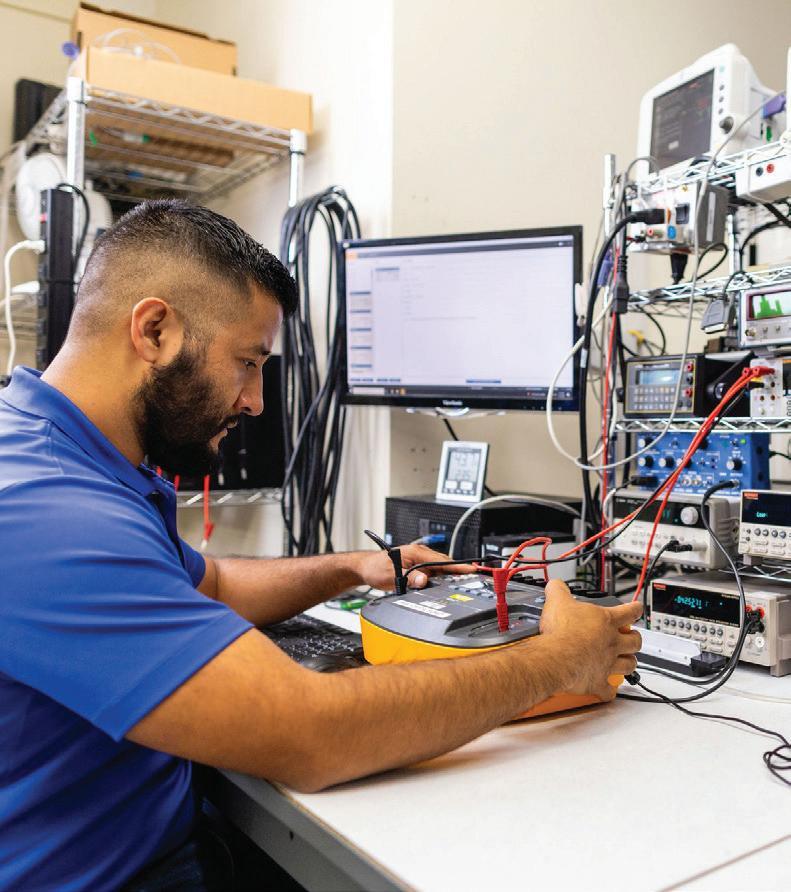

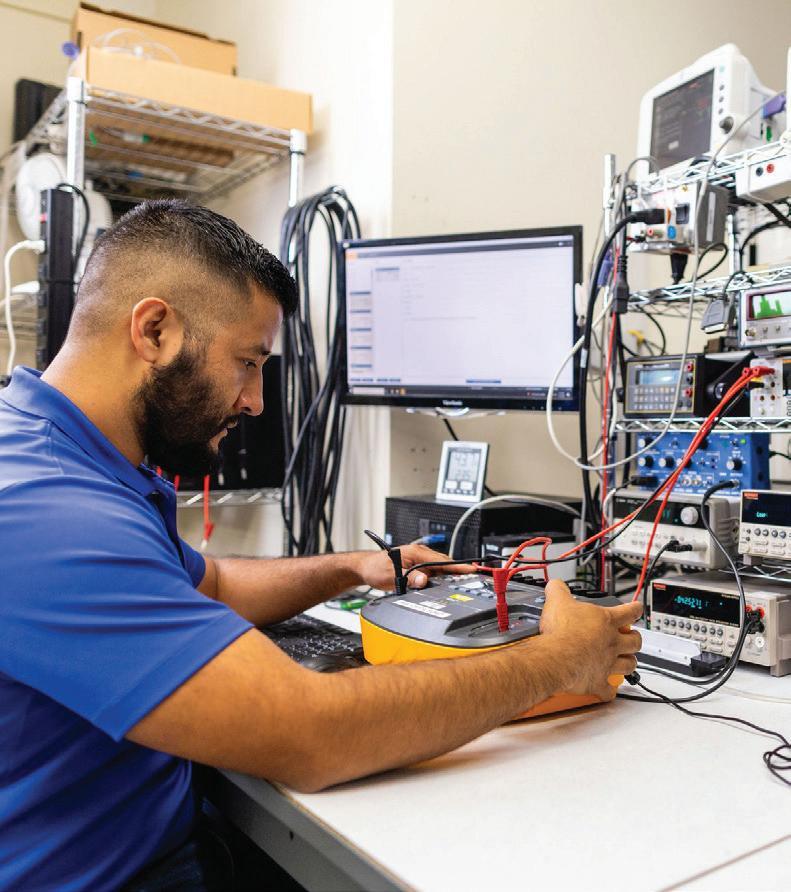

Our test equipment calibration service will:

• Eliminate shipping costs and damage

• Reduce downtime from weeks to hours

• Increase productivity

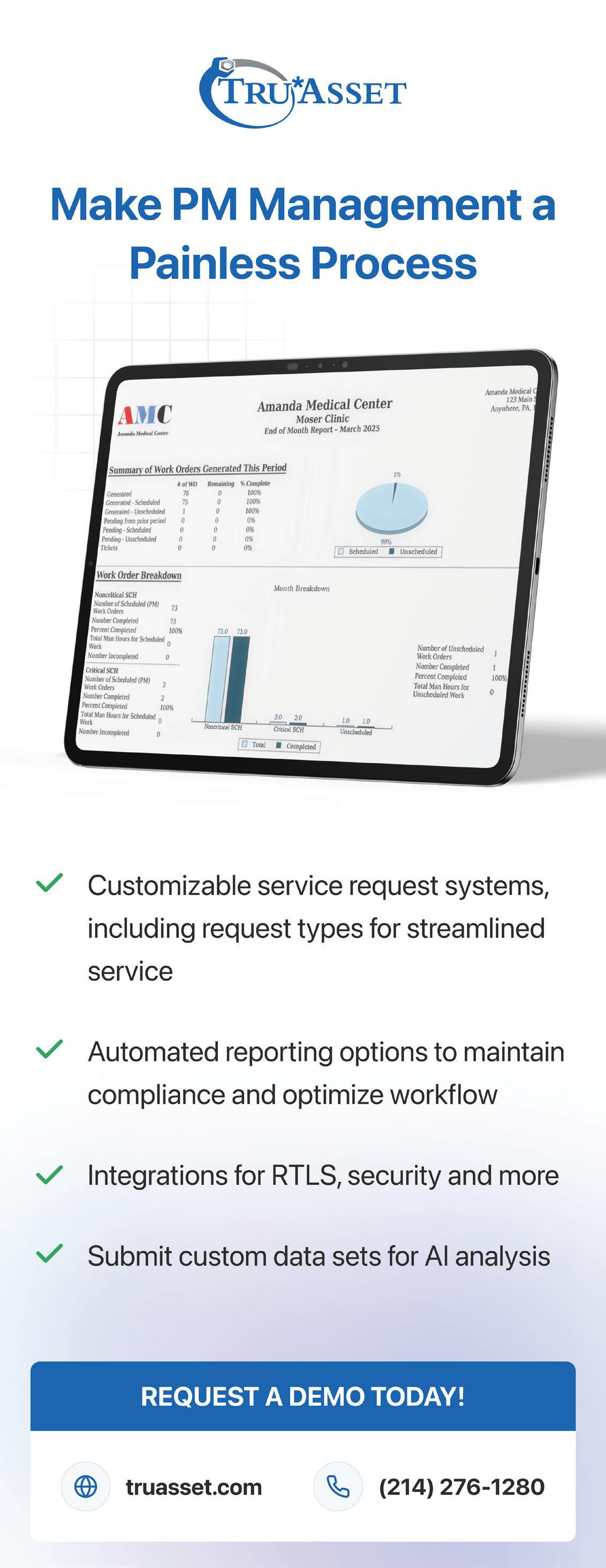

Our calibration management software will:

• Allow us to identify and notify you when your equipment is due for calibration

• Provide an online history of calibration and repair services performed on your test equipment

Let's meet at booth 203 at the Imaging Conference and Expo Feb. 20 - 22

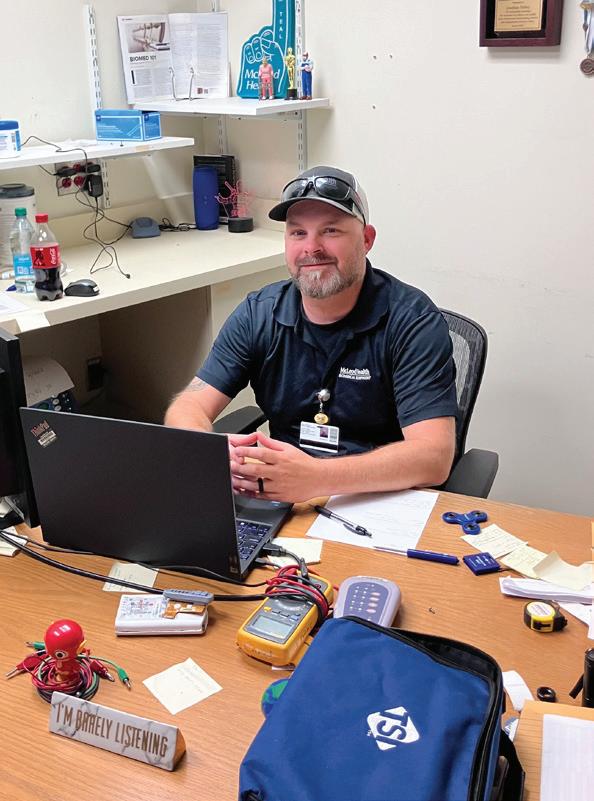

P.12 SPOTLIGHT

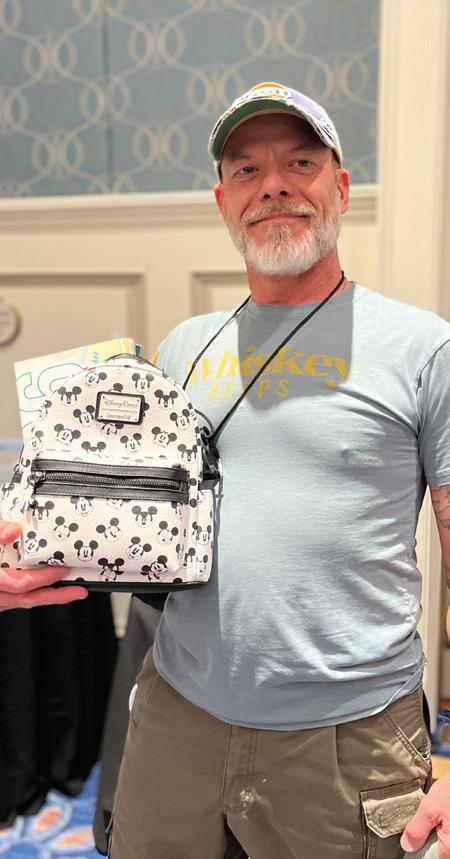

p.12 Professional of the Month: Chris Shores

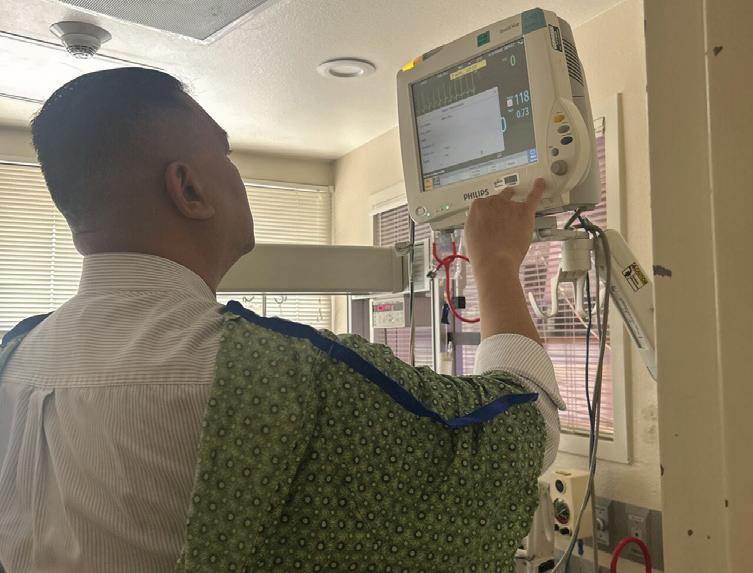

p.14 Department of the Month: The Emplify Health Biomedical and HTM Department

p.16 Next Gen: Kierra Morrow

p.18 Association of the Month: Michigan Society For Clinical Engineering (MSCE)

INDUSTRY UPDATES

p.20 News & Notes

p.25 TechNation Pulse

p.27 Ribbon Cutting: FDM Enterprises

p.30 AAMI Update

p.32 ECRI Update

p.34 Dental Update Revolutionizing the Way We Manage Devices

P.36 THE BENCH

p.36 Biomed 101

p.38 Webinar Wednesday

p.39 Tools of the Trade

P.42 FEATURE ARTICLES

p.42 Roundtable: RTLS

p.50 CORPORATE PROFILE: USOC

p.54 Cover Story: AI & HTM Revolutionizing the Way We Manage Devices

P.60 EXPERT ADVICE

p.60 The Future

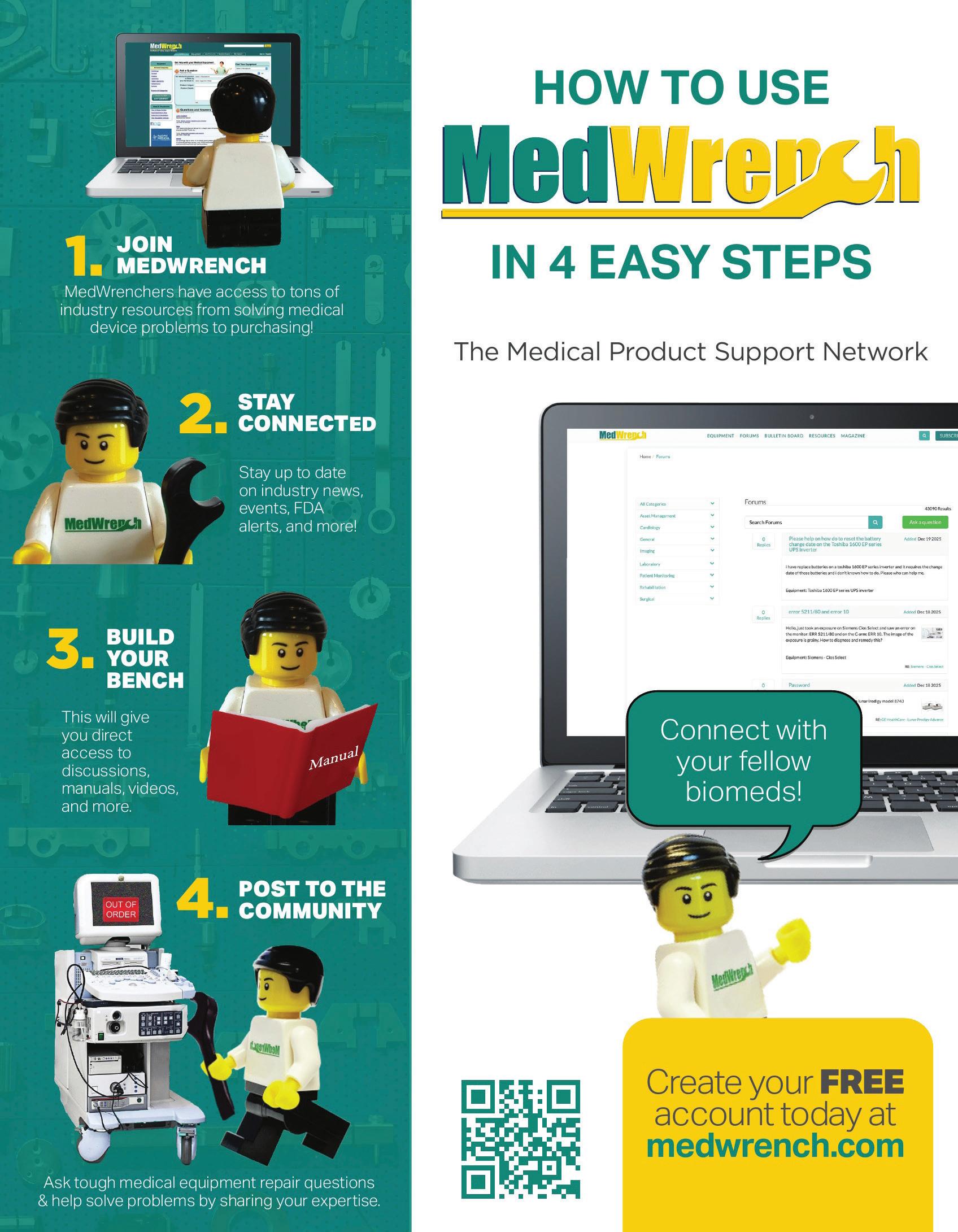

p.62 MedWrench Guru

p.64 The Massey Method

p.66 Networking Notes

p.68 Cybersecurity

p.70 Right to Repair

PUBLISHER John M. Krieg

VICE PRESIDENT Kristin Leavoy

VICE PRESIDENT Jayme McKelvey BUSINESS DEVELOPMENT

EDITORIAL John Wallace

CONTRIBUTORS

K. Richard Douglas

Joie Marhefka

Steven J. Yelton

Garrett Seeley

Nathan Proctor

Carol Davis-Smith

Eric Massey

Gay Gordon-Byrne

Dave Francoeur

Andrew Whyte

James Linton

Christopher Walters

ACCOUNT Megan Cabot

EXECUTIVE

ART DEPARTMENT Karlee Gower

Taylor Hayes

Alicia Brown

DIGITAL SERVICES Cindy Galindo

Kennedy Krieg

Haley Harris

EVENTS Kristin Leavoy

Sydney Krieg

WEBINARS Linda Hasluem

HTMJOBS.COM Sydney Krieg

ACCOUNTING Diane Costea

CIRCULATION Joanna Manjarrez

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Nadia ElKaissi, CHTM, Biomedical Engineer, HTM, VA Central Office (19HTM)

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Earl Morris Jr., BMET, Director of Clinical Engineering, Harrison County Hospital

Leticia Reynolds, Clinical Engineering Operations Manager at UCHealth Parkview Medical Center

p.72 Word Search

p.72 [Contest] What’s on Your Bench?

p.73 Biomed Brainbuster

p.74 FBS Scrapbook

p.76 HTMA-NTX Scrapbook

p.79 The Social

p.80 Service Index

p.83 Alphabetical Index

p.84 Preferred Vendors

College of Biomedical Equipment Technology, we are setting standard for excellence in HTM.

Our nationally recognized programs include Biomedical Equipment Technology (BMET), Biomedical Equipment Support Specialist (BESS), and the Dental Repair Technician (DRT) Certificate. Each is designed to equip you with the advanced skills needed to thrive in today’s evolving healthcare and dental technology landscape.

nationally recognized programs include Equipment Technology (BMET), Equipment Support Specialist (BESS), Dental Repair Technician (DRT) Each is designed to equip you with the skills needed to thrive in today’s healthcare and dental technology Courses

Networking

Infection Control*

BY K. RICHARD DOUGLAS

More than 20 years ago, mission trips to two developing countries sparked an interest in HTM for one biomed.

“When I was in my 20s, I used to go on mission trips all over the world, remembers Chris Shores, a clinical engineering tech II in the Department of Clinical Engineering at Fairview Hospital in Cleveland, Ohio. Fairview Hospital is a part of the Cleveland Clinic system. Back in 2004, we went to a small village not far from Guatemala City. They [had]

year and that sparked my curiosity. As time moves on, electronics or power when In 2006, I went to Ghana.

countries, but who repairs them? He told me they don’t have too many people, if any, to work on them. He shared that they need help in those regards.”

Shores went on to get his formal training to enter HTM and transition from his former occupation.

“In 2013, I received my degree in electrical engineering technology. Before that, I was a state tested nursing assistant for 15 years at a nursing home and a patient care nursing assistant for three years at Cleveland Clinic Hospital,” he says.

Since entering HTM, Shores has been advancing with a goal to continue to reach new heights.

“I started as a tech I and now I’m a tech II. I’m currently trying to be the next work leader for the West Region of Cleveland Clinic,” he says.

Shores says that he has a focus on dialysis as an area of specialty.

“I’m the only one in the West Region Cleveland Clinic who works on dialysis. I take care of echo, EKG, lab, pharmacy, multi-specialty, neurology, cardiac rehab and cancer departments (radiation oncology, hematology oncology, breast health, breast surgical, chemo infusion suite),” he says.

malfunctions?’ I know donated medical equipment from other

Many biomeds had their mettle tested during the COVID-19 pandemic when circumstances required resourceful thinking, out-of-the box ideas and stamina. Shores was involved in preparation and overflow management during this period.

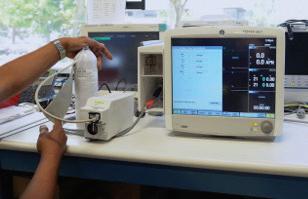

“During the pandemic, I played a key role in ensuring our hospital was ready for patient surges. This included overflow planning: coordinated setup of additional patient care spaces to handle increased volume, monitor preparation: I configured and deployed extra patient monitors on mobile stands for rapid deployment in overflow areas,” he says.

He was also involved with IV pole procurement in which he ordered and distributed additional IV poles to support expanded treatment zones and equipment readiness where he ensured all devices were tested, calibrated and ready for immediate use in critical care environments.

Beyond pandemic-related projects, Shores has kept busy with other projects.

“I was involved in the shadow box project, Philips telemetry upgrades, new dialysis department relocation and expansion. I was involved in relocation of the clinical engineering supply room as well as Environmental Services’ storge relocation. Philips monitoring upgrades in OR, dialysis, and ICU. In charge of leading the West Region monthly Leader Guided Discussion (Avon Hospital, Lutheran Hospital and Fairview Hospital). I oversaw the phone upgrades for our department,” he says.

The shadow box project involved walk-throughs across the hospital and placement of shadow boxes which shows patient room and vital signs without breaking HIPPA.

“[I was] involved with Philips with what’s needed for the monitors. Making sure they all function properly and educating the rest of the clinical engineering team on purpose and repair. Worked with other third-party vendors on installation,” Shores says.

Away from work, Shores is most comfortable with a pair of drumsticks in his hands.

“I’m a percussionist! I teach two drum lines, I give private drum lessons and I drum at church. The first drum line I co-coach with my older brother, Ivan. The organization is called ‘The Deputies Club.’ It’s a baton and drum corps. This organization has been around for 44 years. We’ve performed in multiple countries, Cavs NBA games, parades, churches, Walt Disney, etcetera,” he says.

Shore met his wife, Rachel, in high school.

“She was in the KACP drum line with me back in the ’90s. We were reacquainted back in 2019. She’s a nursing supervisor for a rival hospital. She has two daughters and I have two sons. Her girls are 19 and 16 and my sons are 18 and 16. We raised our kids to be drummers; go figure. We have a three-year-old dog named Pearl,” Shores says.

He says that he loves working as a biomed. His mother was a nurse in a hospital, and Shores spent a lot of time around the hospital environment growing up. He actively tries to introduce the profession to young people.

“Hard work pays off and I’m still pushing forward to be an example for my children and anybody else who wants to pursue a career in saving lives through technology. I currently bring in high school students to see what I do and encourage the youth at the different drum lines I teach,” Shores says.

He has been a biomed for nine years, in healthcare for decades and has been drumming since he was seven. Shores has been an example of why practice and experience pay dividends with perseverance and focus.

FAVORITE BOOK: Holy Bible

FAVORITE MOVIE:

“War of the Worlds” with Tom Cruise

FAVORITE FOOD:

Seafood boil

HIDDEN TALENT: Empathy

FAVORITE PART OF BEING A BIOMED?

Saving lives through technology and bringing smiles to clinicians’ faces.

WHY DO YOU READ TECHNATION?

Informative and encouraging

BY K. RICHARD DOUGLAS

As the nation’s top producer of cheese and milk, Wisconsin rightly owns the moniker “The Dairy State” and has capitalized upon that fact for years. While the term “cheesehead” is commonly known, the historical fact that the ice cream sundae was born in the state is less well known.

A major healthcare provider, with headquarters that span Wisconsin from east to west, is Emplify Health.

With 729 licensed beds, Emplify Health is a major provider of healthcare services. The medical device inventory of such a large provider requires an equally robust HTM department.

Headed by Enterprise Director Melissa Wilke, CBET, BSHA, ITDS, the Emplify Health Biomedical and HTM Department has a total of 43 team members. There are three supervisors. Supervisors Josh Bachim and Darren Budde are positioned in La Crosse. Supervisor Jessica Paul is positioned in Green Bay. Jason Young is the enterprise manager.

“Emplify Health is a not-for-profit, patient-centered, community-focused healthcare network with headquarters in Green Bay and La Crosse, Wisconsin. Formed by a merger between Bellin Health and Gundersen Health System, Emplify Health has nearly 16,000 employees, including more than 1,400 clinicians, in 11 hospitals and more than 100 clinic locations in Wisconsin, Minnesota, Upper Michigan and Iowa,” Wilke says.

She says that with community partners, Emplify Health strives to lead – with love – a local, regional and national healthcare transformation to inspire people’s best lives at every stage.

“Biomed team members are assigned to specific departments, equipment or applications. OEM training is provided for team members to adequately and efficiently support both equipment and departments. Some areas of specialty support include linear accelerators, dialysis, nuclear medicine, anesthesia, NICU, respiratory therapy and mammography. Additionally, Emplify Health Biomed has several technicians that support rural critical access hospitals. This makes each of them especially unique as their strength is adaptability and flexibility to support a multitude of departments and equipment,” Wilke says.

She says that the biomed department has been working for the past several years to align service contracts under the

biomed accounting unit. This ownership of service contracts brings responsibility and opportunity. The advantage of centralizing contract ownership is the ability to create a standard workflow.

“It is crucial to involve team members as it leverages their expertise in service and support of equipment to identify the actual needs without any fluff,” Wilke says.

The convergence of HTM and IT integration operations happen under the CIO.

“As new equipment is evaluated and inventoried, collaboration with IT ensures that all devices meet rigorous security standards and are seamlessly integrated into the existing network infrastructure,” Wilke says.

New construction and facility update projects can often mean additional challenges for biomed departments. Extra care is demanded to provide quality healthcare to the tiniest of patients.

“One of the most transformative projects the team has supported is the development of the Emplify Health Family Integrated Neonatal Intensive Care Unit (NICU) in Green Bay, Wisconsin, which opened in 2022. This unit introduced ‘couplet care,’ which is a model that allows mothers and their newborns, who require intensive care, to stay together in the same room. Emplify Health is the first hospital in Wisconsin to offer this approach,” Paul says.

She says that from the beginning, the biomed team was deeply involved in the planning and implementation of this innovative care model. The team ensured that each room could safely support maternal and neonatal intensive care needs, integrating advanced monitoring systems, neonatal ventilators, maternal care equipment and secure data connectivity – all within a single, family-centered space.

“Currently, the team is proud to be supporting the next phase of this journey: transitioning from a Level II to a Level III NICU designation. This upgrade involves expanding clinical capabilities, increasing equipment complexity, and ensuring readiness for higher-acuity neonatal cases. Biomed is actively working on equipment evaluations and compliance with regulatory standards to meet the rigorous requirements of Level III care,” Paul adds.

She says that this transition has also created exciting opportunities for professional growth. The biomed team has been training in a range of new technologies, including the

Giraffe Shuttle, which allows seamless transitions between rooms without interrupting patient care. The team is also preparing for neonatal transport with integrated systems –including an incubator, gas blender, ventilator, suction and vitals monitor – and scheduling training on new oscillators to support advanced respiratory care.

“ It’s been a rewarding experience for biomed, knowing that their work directly contributes to seamless, high-quality care during a vulnerable time for families. This project exemplifies how biomed professionals not only support clinical excellence but also help create environments where healing and connection can thrive,” Paul says.

The HTM team has also demonstrated its problem-solving skills in conjunction with its IT colleagues and a vendor.

“ When one of the hemodynamic monitoring systems began crashing, it became an ‘all-hands-on-deck’ situation between biomed, IT and the vendor. Biomed provided in-room support, initially assisting the cath lab team in navigating the errors and completing the current case. We then began troubleshooting the problem and calling in other IT teams,” Bachim says.

H e says that it became apparent that a network security issue was corrupting the system and ultimately required the hard drive to be replaced.

“ Biomed worked with the vendor to get a replacement hard drive shipped overnight. After installation, biomed partnered with the IT network security team to ensure the system was correctly assigned to the appropriate organizational unit (OU) and configured with the correct security permissions,” Bachim adds.

H e says that after sitting through several days of patient cases actively monitoring the system, the team was confident the issue was resolved.

Away from the work setting, team members remain active in the HTM community.

“ The Emplify Health Biomed and HTM Department is an active participant in the Wisconsin Biomedical Association (WBA). There are several team members who currently serve on the WBA Board of Directors. This includes Darren Budde and Ladd Dafoe. I serve as the treasurer. Outside of attending annual WBA conferences held across the state of Wisconsin, attending HTM Mixers in Milwaukee have been highlighted events. The team always enjoys these incredible events in their own backyard,” Wilke says.

In The Dairy State, the HTM professionals at Emplify Health are making a difference in the lives of patients and supporting clinical colleagues.

Lead Biomedical Equipment Technician

Kierra Morrow grew up in Buffalo, New York, full of wonder regarding the world around her with an early interest in science and how things work. Her curious nature continues to thrive as an adult working at Buffalo General Hospital where a colleague nominated her as a member of the Next Gen of HTM.

TechNation discovered more about this rising star in a recent Q&A

Q: WHERE DID YOU GROW UP?

A: Born and raised in Buffalo, N.Y., I grew up with a strong interest in the world around me, fascinated by how things functioned and how science might help others. That early desire for exploration affected the direction I take today.

Q: WHERE DID YOU RECEIVE YOUR HTM TRAINING/ EDUCATION?

A: I began my journey with a degree in biotechnology, graduating in 2022. That foundation opened the door to the world of healthcare technology management, where I further developed my skills and earned my CABT certification through AAMI.

Q: How did you first discover HTM?

A: I originally learned about healthcare technology management while looking for a job that would combine my passion for science with a practical, significant influence. Clinical engineering quickly captivated my heart. It provided an ideal blend of technology, innovation and patientcentered treatment.

Q: WHY DID YOU CHOOSE TO GET INTO THIS FIELD?

A: I chose HTM because I wanted a career where my work would truly matter. Where I could help bridge the gap between life-saving technology and the patients who depend on it. Every device I touch, every system I support,

is part of a greater mission to improve and save lives. That’s what drives me every day.

Q: WHAT DO YOU LIKE MOST ABOUT YOUR POSITION?

A: What I love most about my role is the opportunity to lead, teach and grow – not just within myself, but within my team. Mentoring new technicians and seeing their confidence bloom reminds me why leadership in this field is so powerful. We aren’t just fixing equipment; we’re building the future of healthcare technology.

Q: WHAT INTERESTS YOU THE MOST ABOUT HTM?

A: What draws me most to HTM is the way it constantly evolves. Technology never stands still and neither do we.

I love the challenge of staying ahead, learning new systems and finding innovative solutions that directly enhance patient care.

Q: WHAT HAS BEEN YOUR GREATEST ACCOMPLISHMENT IN YOUR FIELD THUS FAR?

A: One of my proudest moments was earning my CABT certification and being promoted to lead technician. Stepping into a leadership role, where I guide and support BMET technicians, felt like a true turning point. It is proof that hard work, passion and perseverance can create real change.

Q: WHAT GOALS DO YOU HAVE FOR YOURSELF IN THE NEXT 5 YEARS?

A: In the next five years, I see myself advancing further into leadership, taking on greater challenges and continuing to mentor the next wave of HTM professionals. I also plan to pursue additional certifications, broaden my technical expertise, and help shape the future of healthcare technology through innovation and education.

FAVORITE HOBBY:

When I’m not working with cutting-edge medical technology, I’m deeply immersed in the world of herbalism. I’m currently working towards creating my own apothecary, blending my love for science and natural healing to make a positive impact in new and meaningful ways.

FAVORITE SHOW OR MOVIE:

“The Office”

FAVORITE MEAL: Green curry

WHAT WOULD YOUR SUPERPOWER BE?

Reality warping – the ability to transform ideas and dreams into reality

1 THING ON YOUR BUCKET LIST?

To study in a monastery for six months

SOMETHING YOUR CO-WORKERS DON’T KNOW ABOUT YOU:

I initially pursued my education with the goal of becoming a dentist.

BY K. RICHARD DOUGLAS

The state of Michigan covers a lot of ground from its southern border with Ohio and Indiana to Traverse City in the northwestern portion of the lower peninsula and to Copper Harbor in the far northern portion of the upper peninsula. Surrounded by the Great Lakes, the state is a mecca for boaters, fishermen, hunters and more.

The state is also home to the Michigan Society for Clinical Engineering (MSCE), the statewide biomed organization that unites the state’s HTM professionals.

The group’s mission is to promote professional development, advance the development of excellence in patient care in hospitals and related healthcare facilities and to provide a forum for the exchange of information among the members and organizations.

Officers in MSCE include President Eric Ebejer, Vice President Jahan Azizi, Secretary Jason Walewski and Treasurer John Crissman. Members of MSCE Board of Directors include Jay W. Hall, M.S., P.E.; Kyle Farrell; Thomas

Brown and Bill Fox. Lindsey Peterson serves as the MSCE webmaster.

The society has a long history going back to 1977. The same year that “Star Wars” hit theaters an initial focus group meeting was held in Lansing, Michigan, at the Michigan Hospital Association. It was at that meeting that a steering committee was established to consider how best to interact.

The steering committee had its first meeting two months later. By January of 1978, the core group had developed the new organization’s bylaws and structure. Those bylaws were approved in September of 1978. It was decided at that meeting that members of the newly formed organization should hold a degree in engineering or the life or physical sciences and work in healthcare. The bylaws were later amended to allow anyone actively employed in the field to become a member.

In 1982, incorporation papers were submitted to the state of Michigan and the society was officially recognized as a nonprofit society.

The new group’s first officers included President Tom Bauld, Vice President Chuck Jones and Secretary Dale Petty. One of the original board members – Jay Hall – remains an active board member today. While he is retired from the industry, he still has an active and welcome voice in the MSCE.

The society continued to develop and gain membership

throughout the coming decades. In July of 1999, MSCE launched a new website designed by George Award.

While education is one element of the organization’s focus, Ebejer says that its goals are multifaceted.

“While our meetings are educational in format, the purpose of the MSCE is to promote the professional development of the membership, advance the development of excellence in patient care in hospitals and related healthcare facilities and provide a forum for the exchange of information amongst the members and with other organizations. With many boomers soon to retire in the HTM community, there are strong undertones of the MSCE trying to place graduates in these positions,” he says.

Ebejer adds that at every meeting MSCE takes time to announce any new job openings and provides information from the employers as to where someone can apply.

Those meetings include eight to 10 monthly meetings annually, February through November. MSCE also hosts an annual golf outing in July.

As Ebejer mentioned, MSCE is active in helping to replenish the ranks of HTM in the state and has partnered with some local biomed college programs, both in Michigan and in nearby Canada.

“The MSCE has been working closely with Schoolcraft College in Livonia, Michigan for years and even one of our current board members –Secretary Jason Waleski – is an instructor/teacher at the school,” he says.

Ebejer also says that MSCE has built a strong relationship with James Linton and the BME program at St. Clair College in Windsor, Canada, over the past year.

“Many of their students attend our meetings since they’re right across the border from Detroit, Michigan in hopes that they could also find employment here in Michigan and the U.S.,” Ebejer adds.

Many biomed organizations were impacted by the pandemic. Those restrictions caused MSCE to shift gears to continue operations.

“The pandemic halted any/all MSCE meetings but has allowed us to more easily hold meetings remotely or have presenters present from a remote location,” Ebejer says.

While MSCE does not hold an annual conference, it does host a fun event each summer that has become a tradition.

“The closest thing the MSCE has to an annual conference/symposium is our annual golf outing which invites any/all HTM professionals, vendors, suppliers and MSCE board members that want to get together in a casual setting on the golf course which has been taking place for at least 20 years. I’m looking into organizing an annual conference/symposium (ETA 2027) as I know the HTM community in Michigan could and would support it,” Ebejer says.

He says that the group’s attendance declined in recent years because of the COVID pandemic, but it is growing again.

“I’m currently in the process of lining up manufacturers, suppliers, service providers, etcetera, for next year’s MSCE monthly meetings. The annual golf outing will be held, as usual, in July,” Ebejer says.

In the Great Lakes state, the state’s biomeds have plenty of recreational activities, but they also can stay plugged into the profession through MSCE.

Repair.org recently announced that Binseng Wang, recently retired from Sodexo, has agreed to join its board of directors.

“Binseng will not be bored as we push state legislation in support of the right to repair for medical equipment,” The Repair Association Executive Director Gay GordonByrne wrote in an email announcing the appointment. “His first task will be to help us answer questions in Vermont where H.160 is underway. More state legislators are seeing the need for better access for repair materials which are necessary to keep medical equipment up and running.”

“Please join us in welcoming Binseng to the Right to Repair team,” she added.

The IAM Union (International Association of Machinists and Aerospace Workers) is calling on Philips Healthcare to reach a fair first contract with 17 field service engineers (FSEs) in San Diego who voted to join the IAM, according to a news release. These highly trained engineers are responsible for maintaining and repairing hospital imaging and diagnostic systems across San Diego and the Inland Empire, the release adds. This equipment is critical to patient care and lifesaving diagnoses.

“The bargaining committee has been in negotiations since January 2025. Philips continues to resist negotiating in good faith to help IAM members establish industry-standard wage structures, safety protections, and training commitments for maintaining the operation of CT, MRI, X-ray, ultrasound and other diagnostic systems at hospitals and clinics throughout the region,” the release posted on the IAM Union website states.

Workers are seeking “fair pay” that reflects the advanced skills required to service various types of imaging equipment, as well as improved compensation for overnight and emergency calls. They also want paid training, stronger safety protections, predictable schedules and fair reimbursement for the travel their jobs require.

“These improvements will help prevent burnout and support the essential work field service engineers do to keep hospital imaging systems running safely for patients,” the release reads. “IAM leaders warn that delays at the negotiating table are creating unnecessary tension and instability in a workforce

essential to the region’s medical infrastructure.”

“These engineers are the invisible backbone of our healthcare system,” said IAM Union Western Territory General Vice President Robert “Bobby” Martinez. “Without them, hospitals cannot diagnose strokes, detect cancers or deliver timely emergency care. Philips must recognize their skill, respect their critical role and negotiate a contract that protects both workers and patients.”

The IAM will continue to amplify this issue and organize actions to raise awareness about the delay in receiving a first contract after nearly a year of negotiations.

“Philips has the opportunity right now to be a leader in patient safety, worker retention and healthcare quality,” said IAM Union District 725 Assistant Directing Business Representative Justin Mauldin. “We are urging the company to come to the table with real solutions so these workers can continue performing their life-saving roles without being stretched thin.”

The IAM Union is one of North America’s largest and most diverse industrial trade unions, representing approximately 600,000 active and retired members in the aerospace, defense, airlines, shipbuilding, railroad, transit, healthcare, automotive and other industries across the United States and Canada, according to the news release.

LANDSTUHL, Germany | A team from Landstuhl Regional Medical Center (LRMC) once again demonstrated its exceptional skill and readiness, securing a top position in the demanding Europe Best Medic Competition. The brutal, multi-day event, held Dec. 9-12 in the Rhineland-Palatinate training areas, is a stark simulation of battlefield conditions designed to identify the most resilient, technically proficient, and mentally tough medics in Europe.

For many, the event is also a tribute.

Sgt. Alredo Martinez, a biomedical equipment technician at LRMC, noted the competition is dedicated to Cpl. Wilson, a combat medic who saved soldiers’ lives even while injured.

“This competition assesses your physical and medical knowledge, along with your ability to collaborate with a partner,” said Martinez. “I am not a medic; I am an equipment operator. By participating in this competition, I have learned basic medicine and how to save lives.”

The annual competition pushes military medical personnel to their absolute limits.

The LRMC competitors faced a grueling sequence of events from the start. The first day began with a combat water survival event, immediately followed by the Expert Physical Fitness Assessment. With little time to recover, participants then zeroed their M4 weapons before their medical knowledge was challenged with a comprehensive written exam. The day concluded with a demanding land navigation course and the task of establishing a battalion aid station, requiring quick thinking and flawless execution under fatigue.

Day two tested the medics’ composure with a stress shoot, followed by a resupply mission and tactical lanes. The

challenges continued with late-night land navigation that stretched into the early hours of the third day. Afterward, the weary participants donned 35- to 45-pound rucksacks for an unknown-distance foot march. The final day’s trials concluded with a critical test of their skills in chemical, biological, radiological, and nuclear (CBRN) operations, a vital component of modern military readiness.

The event, which began in Grafenwoehr in December 2023, is a key measure of medical readiness across Europe.

“Competitions like this are beneficial for the Army because they are a way to assess soldiers’ capabilities, and they are not part of our daily routine,” said 1st Lt. Donovan Hinton, a medical officer with the 2nd Cavalry Regiment and the 2025 EBMC winner.

The impressive performance by the LRMC team is a direct reflection of the high standards of training and dedication at the medical center. These competitions are more than just a contest; they are a critical tool for building courage, fostering professionalism and ensuring that every medic is prepared for the unpredictable nature of combat. As one leader remarked, “You need people that will stand up and say, ‘Let me challenge myself.’ ”

The LRMC medics have once again answered that call, serving as an inspiration to their formation. Their success not only highlights their readiness but also prepares them for future representation at the U.S. Army Command Sgt. Maj. Jack L. Clark Jr. Best Medic Competition in the United States. LRMC personnel contributed to the event as both competitors and cadre, advancing mission-critical medical proficiency across the force.

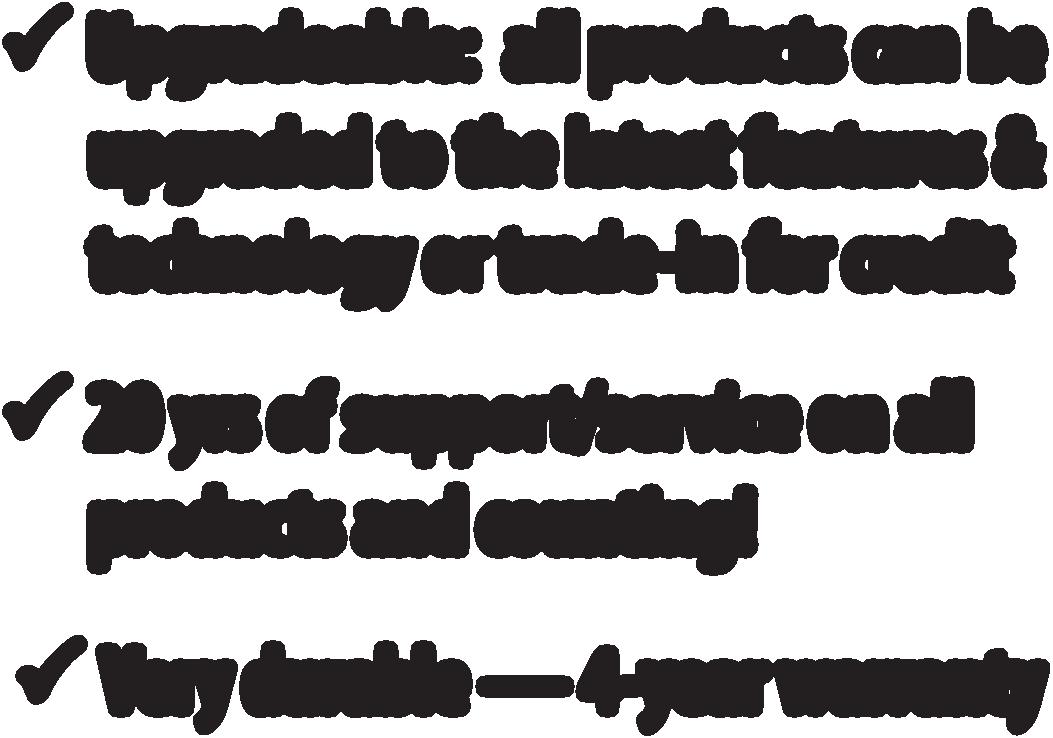

TRIMEDX has launched TRIMEDX-AIQ, a breakthrough AI intelligence offering that sets a new standard for clinical asset optimization, according to a press release.

“Purpose-built for health systems, TRIMEDX-AIQ combines the largest and most comprehensive data set in the healthcare technology management (HTM) industry with next-generation AI capabilities to deliver real-time visibility, predictive maintenance intelligence and supply chain automation – all within a single unified offering,” the release states.

“With more than 6.1 million device records, 25-plus years of longitudinal insight, and visibility into 90-95% of all active U.S. medical equipment, TRIMEDX has built the industry’s most powerful dataset – refined and AI-ready in ways that cannot be replicated. This scale, combined with over $200 million in recent technology advancements and a national workforce of 3,400 clinical engineering experts, positions TRIMEDX as the only organization capable of delivering an AI offering of this magnitude and insight. This foundation fuels TRIMEDX-AIQ, the only enterprise AI offering that unifies visibility, prediction, security and automation to reduce operational waste, improve medical device uptime and unlock significant cost savings for health systems,” it adds.

Across the country, health systems face a critical opportunity to unlock significant operational, financial and performance gains by tackling longstanding barriers: device inventory records that can be inaccurate by up to 40%, equipment failures that disrupt patient care, rising rental and replacement costs and supply chain inefficiencies that delay critical repairs. Fragmented data, manual workflows and operational blind spots limit visibility and keep teams reacting to problems after they occur. Existing tools – ranging from CMMS platforms to episodic inventory audits and spreadsheet-driven planning – do not provide the predictive intelligence or unified visibility required to solve these issues at scale.

“When these barriers are eliminated, the opportunity is transformative: 10-20% reductions in clinical engineering costs, 25-35% capital expense avoidance and deferral, and equipment uptime reaching 99%. Without that shift, the result is millions of dollars in unnecessary spending and thousands

of hours lost to avoidable downtime every year,” the release states.

TRIMEDX-AIQ combines clinical asset visibility, predictive intelligence and supply chain automation into a single AI-native offering built specifically for the needs of health systems, according to the release. “Rather than relying on disconnected tools and manual updates, TRIMEDX-AIQ provides continuous, automated visibility into the health system’s entire device ecosystem – delivering accurate, real-time asset inventories and resolving the inaccuracies that can reach up to 40% in many health systems today. This enhanced visibility reduces rental overspend, strengthens cybersecurity by identifying unknown devices, and improves capital planning and budgeting by giving leaders a true picture of what they own and how it’s being used.”

“Health systems are facing unprecedented operational pressure, from rising costs to staffing shortages,” says TRIMEDX CEO Neil de Crescenzo. “TRIMEDX-AIQ gives leaders the visibility, predictability and automation they need to run a more resilient, cost-effective operation at scale. It represents the future of clinical asset management, powered by AI and built for the realities of modern health care.”

The release continues:

“TRIMEDX-AIQ applies predictive intelligence to maintenance and repair workflows, equipping clinical engineers with the insights they need to prevent failures before they happen, accelerate turnaround time and work more efficiently. Using TRIMEDX’s multi-vendor dataset in combination with health system data, TRIMEDX-AIQ anticipates likely failures, automates preparation steps such as preventative maintenance kits & parts ordering and synthesizes task lists using generative AI. The result is improved uptime, faster repairs and a more resilient workforce. The offering further strengthens operational resilience by automating supply chain steps that frequently create bottlenecks. By integrating predictive maintenance insights, asset condition data, and repair workflows, TRIMEDX-AIQ ensures that parts and resources are aligned precisely when needed. This reduces delays, speeds up repair cycle and unlocks measurable savings.”

The “Medical Equipment Repair Services Market-Global Forecast 2025-2032” from Research and Markets reports that the market is valued at $44.04 billion in 2024 and projected to grow to $90.49 billion by 2032.

As healthcare organizations depend heavily on the seamless functioning of equipment from MRI scanners to infusion pumps, these services mitigate risks associated with system failures that can lead to postponements and elevated patient safety risks. The industry must navigate challenges such as aging equipment and tight budgets while aligning with regulatory standards, highlighting the importance of strategic planning and risk mitigation in operational decisions.

Navigating the post-pandemic landscape, the medical equipment repair sector is leveraging digital transformations and service delivery innovations to enhance repair dynamics. Remote monitoring and AI-driven predictive maintenance are becoming standard, enabling proactive service interventions that result in improved equipment uptime and reduced service cost. Hybrid service models, combining on-site expertise with centralized support, empower technicians with mobile tools,

thereby improving repair efficiency and competitive advantage Service segmentation shows a growing emphasis on preventive maintenance as foundational to equipment reliability, supported by critical calibration services. The demand for innovative service models highlights a shift toward subscription frameworks, offering predictable costs and driving provider revenue. Equipment segmentation underscores the necessity for specialized services across different equipment types, with hospitals and clinics forming core service customers interested in comprehensive, round-the-clock service commitments.

Global service demand varies significantly across geographies. North America’s mature infrastructure supports advanced predictive services, while Latin America seeks cost-effective repairs. In Europe, the focus is on sophisticated service networks with early adoption of innovative service agreements. In Asia-Pacific, the rapid modernization of healthcare infrastructure, particularly in China and India, presents substantial opportunities for market entry strategies tailored to diverse service maturity levels.

The recent webinar “Laser Safe: The Biomed’s Path to LSO Certification” highlighted the importance of training and certifying biomedical engineers to serve as Medical Laser Safety Officers (MLSO) in a healthcare facility.

Presenters Vangie Dennis, MSN, RN, CNOR, CMLSO, FAORN, FAAN, and Patti Owens, MHA, BSN, RN, CMLSO, CNOR, pointed out that biomeds make ideal candidates for laser safety officer roles in healthcare facilities.

Biomedical engineers should be Medical Laser Safety Officers (MLSOs) because their technical expertise with medical devices, understanding of safety protocols, and familiarity with equipment maintenance and calibration make them ideal for managing complex laser systems and ensuring patient, staff and public safety in healthcare environments. Their technical background directly aligns with the need for precise risk assessment, implementation of control measures, and adherence to strict ANSI standards.

Over 50% of laser-based hospitals and outpatient surgical centers are considered deficient because they lack an MLSO, which puts patients and staff at risk. Without proper credentialing, classified laser systems, updated standard operating procedures, or appropriate protective eyewear, serious injuries can happen. Incidents can quickly lead to costly penalties, regulatory actions and litigation. Ensuring compliance with national regulations, state laws, laser standards and practice guidelines is essential for fostering a culture of safety.

An MLSO is a specially trained professional responsible for

The Healthcare Technology Management Association of Ohio (HTMA-Ohio) will host its 2026 HTMA-OH Conference and Expo on Feb. 5-6, 2026, at the Renaissance Hotel and Conference Center in Westerville.

The two-day event will bring together healthcare technology management (HTM) professionals, industry leaders and solution providers for education, leadership development and networking. The conference will feature a keynote presentation, leadership development workshop, multiple educational sessions, roundtable discussions and an expansive exhibit hall.

The keynote speaker for the conference will be Bryant Hawkins, HTM leader, CEO of Elevate HTM, author and influencer.

Programming begins Feb. 5 with a three-hour leadership development course led by industry expert Carol Davis-Smith, focused on developing effective HTM strategies. Attendees will also have the opportunity to connect with peers during a free Smash Park social outing that evening.

On Feb. 6, the conference will offer 14 educational sessions,

ensuring the safe use of lasers in medical settings such as hospitals, surgical centers, vision clinics or dermatology offices. The webinar reviewed the MLSO role as defined and guided by ANSI Z136.3, the American National Standards Institute (ANSI) standard for the Safe Use of Lasers in Healthcare.

Education to prepare for the role of a MLSO are offered via Medical Laser Safety Officer (MLSO) Excellence live virtual training sessions in 2026. The sessions are designed to prepare healthcare professionals to become a certified laser safety officer. MLSOs can come from a variety of backgrounds. This training is designed for healthcare professionals looking to enhance their laser safety knowledge and improve the quality and safety of patient care at their facility. Professionals who should consider obtaining MLSO certification include laser safety officers, biomedical/clinical engineers, radiation safety officers and surgical technologists.

Find out more and register today at medicallasersafety.com/

a keynote presentation, a roundtable discussion with industry experts, and access to 40 vendor tables showcasing products, services and solutions for HTM professionals.

Additional highlights include free food, a complimentary happy hour, prize giveaways and extensive networking opportunities.

“Whether you are new to HTM or an experienced professional, this conference offers something for everyone,” HTMA-Ohio organizers said. “The goal is to create an engaging environment where attendees can learn, exchange knowledge and build meaningful connections across the industry.”

The Renaissance Hotel and Conference Center is located at 409 Altair Parkway, Westerville, OH 43082.

For more information about the 2026 HTMA-OH Conference and Expo, including registration details and updates, visit HTMA-OH.org

Coming off the largest MD Expo ever, TechNation parent company MD Publishing has announced the addition of a reverse expo to the spring conference.

HTM professionals are invited to register for the MD Expo Baltimore (April 7-9) that is supported by the Baltimore Medical Engineers and Technicians Society (BMETS).

Attendees will connect with industry peers, gain insights into the latest advancements in HTM and expand their professional network.

MD Expo Baltimore will also feature newly popular and older favorites at this can’t-miss event. A few of the offerings include:

• Welcome Reception

• Tech Choice Awards Presentation

• Networking Lunch (open to everyone)

• Lunch & Learn (ticketed event for attendees only)

• Exhibit Hall Grand Opening

• Young Professionals Event

• Hands-On-Training (H.O.T.) Workshops

MD Expo strives to provide healthcare technology management professionals with a unique, intimate and rewarding conference second to none. Clinical engineers, biomedical technicians, directors and managers, procurement/asset managers and others responsible for medical technology will gather in a one-of-a-kind warm and welcoming environment to network with peers, learn the latest technologies and advances in HTM.

As always, MD Expo offers free registration for hospital employees, students and members of the U.S. Armed Forces.

Register today at MDExpoShow.com.

MD Expo has worked with the host hotel to provide a discounted rate for attendees. The deadline to reserve rooms is March 7, 2026 (room block may sell out prior to deadline).

Check out the details at mdexposhow.com/location/

Webinar Wednesday benefitted from amazing presenters, generous sponsors, Tools of the Trade demonstrations and more in 2025.

New in 2026 is a webinar version of the popular monthly TechNation Roundtable article. HTM insiders will come together for a panel discussion where they will add to their responses shared in the article. This is an exciting opportunity to learn more about the latest technology, features and devices in HTM from experts with powerful insights.

The Roundtable webinars are designed to enhance the continuing education TechNation offers the HTM community. Attendees benefit greatly from the free webinars and CE credits from the ACI.

“Webinar Wednesday allows the advancement of knowledge and brings people together in the HTM profession,” said Melissa Jumbo, administrative assistant, Fort Defiance Indian Hospital Board Inc.

“These webinars provide unique insights into our industry and many different ways to advance our experience as well as our careers,” said Larry Hamilton, biomedical services manager, Venture Medical.

“Webinar Wednesday provides valuable information on the biomedical industry. It brings subject matter experts to BMETs all across the nation. With this information, we are all able to learn more and make decisions for our career and industry,” said Isaiah Ledesma, faculty, biomedical engineering technology, St. Philip’s College.

View on-demand recordings of the 2025 webinars and register for upcoming webinars at WebinarWednesday.live.

The Tech Choice Awards shine a spotlight on the vital and outstanding work HTM professionals provide to the nation’s health care industry. These men and women play a role in delivering life-saving care to millions each year.

HTM professionals generated over 1,500 nominations for the 2026 Tech Choice Awards with the top 5 nominees for each of the 14 categories named as finalists. Voting began on October 1 and closed on January 9, 2026. Votes are being tallied as this report is being written.

The Tech Choice Awards (also known as the Wrenchies) are the people’s choice award for the HTM community. The winners are based 100 percent on the number of votes each finalist received during the voting period. A special thank you goes out to the sponsors who help make the Tech Choice Awards possible. The sponsors do not have any input when it comes to selecting winners.

Wrenchie winners will be announced in the March issue of TechNation with an award ceremony planned for the MD Expo Baltimore in April 2026.

The Tech Choice Award categories are:

1. Professional of the Year, sponsored by Innovative Radiology

2. Large Department of the Year (500+ beds) sponsored by USOC Medical

3. Mid/Small Department of the Year (up to 500 beds) sponsored by USOC Medical

4. ISO Professional of the Year sponsored by Healthmark

5. Young Professional of the Year sponsored by Prescott’s Med

6. Director/Manager of the Year sponsored by MW Imaging

7. Educator of the Year sponsored by MAULL BIOMEDICAL TRAINING LLC

8. Women in Leadership sponsored by Avante Health Solutions

9. ICON sponsored by Renovo Solutions

10. Industry Influencer sponsored by Soma Tech Intl

11. Outstanding Vendor

12. Military BMET of the Year sponsored by College of Biomedical Equipment Technology

13. Association of the Year sponsored by MultiMedical Systems, LLC

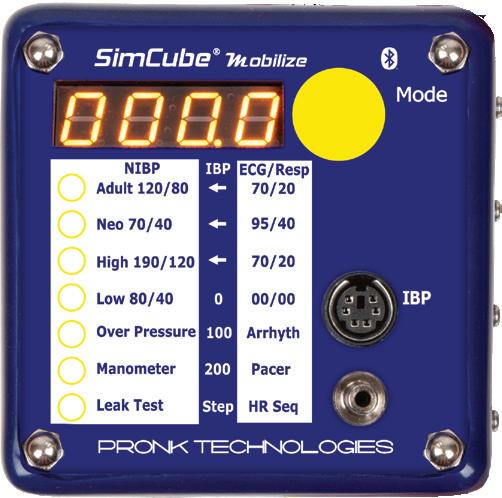

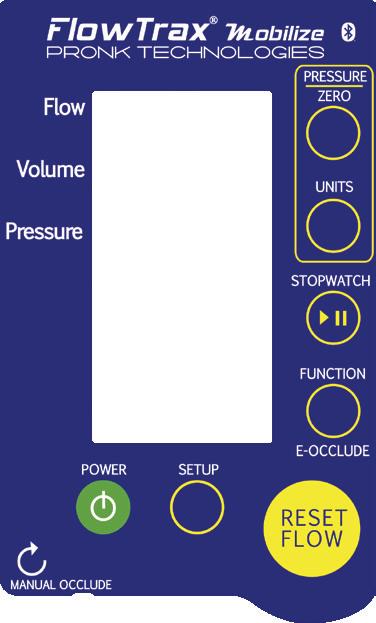

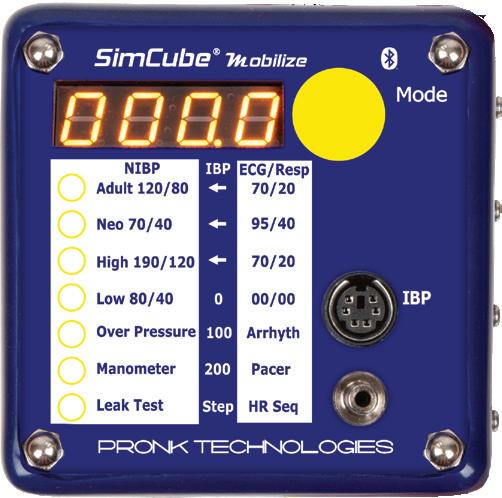

14. Humanitarian of the Year sponsored by Pronk Technologies

TechNation is thrilled to announce that nominations are now open for the 2026 40 Under 40, powered by YP at MD. Now in its third year, this prestigious program shines a spotlight on the next generation of leaders in the healthcare technology management (HTM) industry.

Each year, TechNation honors a diverse group of accomplished young professionals who are driving innovation, excellence and progress in HTM. Last year’s honorees exemplified the intelligence, creativity and dedication that make this field so impactful — and now it’s time to recognize the next wave of outstanding talent!

If you know an exceptional HTM professional under 40, we encourage you to nominate them for this honor. Applications are open now at https://1technation.com/2026-40-under-40/ with a submission deadline of April 24. Help TechNation highlight the best young biomeds shaping the future of HTM!

The YP at MD program, supporting the 40 Under 40, is a dynamic community of young professionals in the HTM field. Members benefit from exclusive networking opportunities at MD Expos, HTM Mixers, and through online platforms, fostering connections and sharing ideas for a bright future in HTM.

For more details about YP at MD, visit 1technation.com/yp. Together, let’s celebrate the talent, hard work and innovation that keep the HTM industry moving forward.

After 25 years in the medical imaging trenches and a career that started in the U.S. Army, Omar W. Jarrah knew there was room to improve how service and support were delivered in the imaging space. It was that idea that inspired him to create FDM Enterprises.

“I’ve spent decades watching big companies forget the little things,” he says. “And in this industry, those ‘little things’ are usually what keep patients waiting, hospitals frustrated and engineers running around in circles.”

His mission to address that frustration fueled the launch of FDM Enterprises – a company dedicated to offering preventive maintenance, troubleshooting, and repair support with the kind of persistence, preparation and precision you would expect from someone with a military background. TechNation recently found out more about FDM Enterprises including what to expect in the future.

Q: CAN YOU TELL US A LITTLE ABOUT YOUR COMPANY?

JARRAH: As a veteran with 25 years’ experience, I started FDM Enterprises to support others in the industry with their MRI, CT and injector service needs. We offer PMs and service support to peers and clients with highly competitive rates. We have been expanding into titanium tools and are looking to offer other services.

Q: HOW DOES YOUR COMPANY STAND OUT?

JARRAH: It comes down to one principle: support

– done better, faster and without the inflated price tag. While many service providers focus on locking in giant contracts and dazzling sales metrics, FDM Enterprises puts its energy into what matters most: customer satisfaction and reduced downtime. Hospitals and imaging centers are often surprised to learn that with FDM, they can get their MRI, CT and injectors serviced in a single service event – a rarity that minimizes disruptions to patient care. We’ve all seen the chaos when three different vendors are needed for three different systems. Why not fix it all at once and let the clinicians get back to doing what they do best?

Q: WHAT IS ON THE HORIZON FOR FDM ENTERPRISES?

JARRAH: In the next five to 10 years, I see FDM Enterprises not just as a service provider, but as a driver of competition and quality improvement in the imaging service industry. My long-term goal is to raise the bar by proving that proactive, customer-focused service doesn’t have to come at premium rates. And at the heart of it all is a very simple philosophy: solve problems, fix things and make life easier for both peers in the industry and the patients relying on those machines. Honestly, the best part of this job is knowing that when I fix something, I’ve played even the smallest part in helping a patient get the care they need. That’s the kind of satisfaction you can’t put a price on.

Q: IS THERE ANYTHING ELSE YOU WOULD LIKE TO SHARE WITH THE TECHNATION COMMUNITY?

JARRAH: Please reach out and connect. Who knows how we may be able to help each other to improve patient care.

For more information, visit fdmenterprises.com .

The Clinical Engineering Association of Illinois (CEAI) celebrated a landmark moment during its 14th annual conference, where record-breaking attendance underscored the growing importance of grassroots associations for professionals in the healthcare technology management (HTM) field. In a series of on-site interviews, Founders Alan Moretti and Joe Bandra, alongside current CEAI President Kelley Harris and Vice President Greg Czajka, reflected on CEAI’s origins, growth and enduring contributions to the profession.

According to CEAI, the run of their annual conference reached its highest attendance figure yet, with more than 215 participants. AAMI’s Danielle McGeary, vice president of HTM at AAMI expressed her gratitude for the chance to take part in the event, noting its vibrant atmosphere and the professional value it provided. “It’s truly remarkable to see

such a dedicated group of professionals come together to share knowledge and build connections.”

The event was marked by an impressive array of presentations, workshops and networking opportunities. Moretti was quick to commend the new generation of CEAI leadership for the event’s success.

“This has been our most attended conference yet,” he exclaimed. “The leadership team, led by Kelley and Greg, truly blew it through the roof. It’s humbling to see how far this organization has come.”

“CEAI has always been about bringing people together, and this event exemplifies that spirit. The turnout is proof of the community’s commitment,” Harris said.

CEAI was founded in 2005 when Moretti and Bandra identified a need to unify Illinois’ HTM professionals. Inspired by an ad hoc meeting at Triton Community College, they organized the first gathering at Loyola University Chicago. While uncertain about the initial turnout, they were thrilled when over 35 attendees arrived.

“That first meeting showed us the energy and need for something like CEAI,” Moretti explained.

This enthusiasm catalyzed 12 additional grassroots meetings in 2005 and 2006, culminating in the formal establishment of CEAI and the election of its first officers in 2007. Today, CEAI has grown into a thriving organization that continues to shape the HTM landscape in Illinois.

One of CEAI’s cornerstones is its investment in education and the development of future leaders. The association has awarded more than $40,000 in scholarships to date, a point of pride for founders and members alike. Several scholarship recipients, who are now working in the HTM field, attended this year’s conference.

Bandra, who personally donated $10,000 to the scholarship fund, shared his excitement. “It’s incredible to see students we’ve supported now excelling in their careers. That’s what CEAI is all about – creating opportunities and building the future of HTM,” he said.

Harris echoed this sentiment, highlighting the importance of mentorship and education. “The scholarship program isn’t just about financial support. It’s about fostering a pipeline of talent and inspiring young professionals to carry the torch forward,” he said.

The success of CEAI has inspired HTM professionals in other regions to consider forming their own associations.

McGeary commended CEAI for its legacy of leadership and community-building. “You’ve created something that not only serves Illinois, but also sets an example for HTM organizations nationwide. The dedication and vision here are inspiring,” she said.

Moretti and Bandra offered practical advice, emphasizing the importance of energy, planning and financial sustainability. “No money, no mission. You need sponsors, exhibitors and committed members to make something like this thrive.”

Bandra noted that building strong digital infrastructure is also key. From the start, “having a well-designed website helped CEAI connect with members and communicate effectively.” In today’s world, that’s not optional – it’s essential, he said.

Reflecting on 14 years of progress, Moretti and Bandra also acknowledged the contributions of collaborators like the late Pat Lynch and Robert Shu, who were instrumental in drafting CEAI’s bylaws and operational framework. “It truly took a village to get CEAI to where it is today.”

As CEAI continues to grow, its focus remains on education, collaboration and leadership succession. This year’s record-breaking conference is a testament to its success and the unwavering commitment of its members. With its strong foundation, CEAI is poised to drive innovation and excellence in HTM for years to come.

Healthcare has yet to realize the benefits of applying human factors engineering (HFE), in part because HFE solutions developed for other high-risk industries have been applied without appreciating the important ways that healthcare differs from those industries.

Like aviation, ground transportation, and nuclear power, healthcare is:

• High-risk – Errors have profound consequences for patients, staff and organizations.

• Complex and interdependent – Outcomes depend on seamless interaction between people, processes and technologies.

• Decision-intensive – High-stakes choices must be made under time pressure and uncertainty. However, healthcare also has unique challenges, which must be taken into account when designing safety strategies:

• Every patient is different – No two “inputs” are alike. Standardization is limited by biology and individuality.

• Care plans evolve constantly – Decisions are revisited and adapted several times a day.

• Communication is fragmented – Providers often work asynchronously, connected only through electronic health records.

• Outcomes are subjective – “Health” looks different depending on the patient’s goals and values.

• Motivation drives performance – Healthcare relies on

judgment, collaboration and intrinsic commitment so it cannot require or deliver strict controls. These differences mean healthcare organizations cannot simply copy-paste HFE solutions developed for other high-risk industries. Instead, healthcare systems must apply proven HFE principles to develop solutions tailored for their specific system.

The most effective way to improve healthcare safety is to redesign health system environments, tools and workflows to support people to do their best work, even under stress. This is the only way to manage healthcare complexity and prevent inevitable human slips from causing significant harm.

Realizing profound safety improvements requires not only designing systems that make safe care the path of least resistance but also fostering and sustaining environments where staff are empowered to speak up without fear of blame. In other words, great system design and great safety culture are both required to enable healthcare systems to continuously learn from failures and near-misses.

By embracing HFE and applying systems thinking, healthcare systems can become not only safer, but also more compassionate, adaptive and sustainable, leading to better patient outcomes, healthier providers, lower costs, greater efficiency and stronger public trust.

Visit ecri.org to learn more.

BYRANT HAWKINS

HTM Leader, CEO, Author & Influencer

CAROL DAVIS-SMITH

Business Owner, Clinical Engineer, & Expert Strategist

Explore

FEBRUARY

February 5th

3 Hour Leadership Development course

Develop your HTM strategy

Social Outing - hosted at Smash Park

February 6 th

14 Educational sessions

Keynote session

Round table discussion with industry experts

40 vendor tables

Free Food

Free happy hour

Free prizes

Great Networking

BY JOHN WALLACE

Several times in the 2009 American comedy film “The Hangover” Stu states that he is a doctor only to have it pointed out that he is a “dentist.” The gag plays on the belief many hold that a doctor is “not a real doctor.”

Yet, go to any dentist’s office and you will find medical devices and equipment that require regular maintenance and repair exactly like the medical devices found in urgent care clinics, hospitals and surgery centers.

The devices and equipment in dental settings continue to catch the eye and attention of more and more healthcare technology management (HTM) professionals – also known as biomeds.

One example of this growing attention to the dental sector was the 2024 UptimeHealth Dental Fix Summit in Nashville, Tennessee. It was supported by a popular provider of HTM education – the College of Equipment Technology.

The four-day event was designed “to equip independent dental equipment repair technicians and biomedical technicians with the latest technical training, business strategies, and networking opportunities in the dental industry.”

More recently, AAMI decided to spotlight the dental device and equipment sector of technology as this excerpt from a

2025 news release states: “UptimeHealth, a software and services company for outpatient healthcare, has built a strong presence in dental equipment management through its annual Dental Fix Summit. In a bid to bring that resource to the wider HTM community, AAMI has acquired the annual summit, with plans to make it a key feature of the association’s next annual HTM conference in Denver, Colorado, May 29 to June 1, 2026.”

College of Biomedical Equipment Technology President Dr. Richard L. “Monty” Gonzales, an early proponent of the dental equipment management movement, noted that a biomedical equipment technician (or BMET) background provides a strong foundation for transitioning to dental equipment repair.

He pointed out that core competencies, including electronics, troubleshooting, mechanical and pneumatic systems, preventive maintenance, calibration, safety and infection control protocols, as well as imaging, sterilization and IT transfer directly to dental devices and systems.

However, much like a patient would not ask a primary care doctor to perform a root canal, hospital biomeds need additional education and training to service dental devices.

“These types of technical skills align with the proficiencies employers value and enable entry into many unique roles in the dental industry. Success in dental equipment service, however, necessitates targeted additional training,” Gonzales said. “Specialized components require focused expertise, including high- and low-speed handpieces, dental unit waterlines, advanced plumbing, amalgam separators,

clinic-specific utilities, procedural workflows, and digital integrations distinctive to the dental environment. This specialized knowledge is typically acquired through original equipment manufacturer (OEM)specific certifications or dedicated programs, such as those offered by the College of Biomedical Equipment Technology.”

However, there are many similarities especially when it comes to new technology.

“Mirroring the transformation and escalating technological complexity observed in traditional HTM roles – where networked devices, advanced imaging, and integrated software systems increasingly drive service demands – the dental sector similarly experiences robust demand fueled by the rapid adoption of digital dentistry technologies and ongoing needs for dental operatories,” Gonzales said. “Traditional equipment, such as highand low-speed handpieces, dental chairs/ treatment centers, air compressors, vacuum systems, and autoclaves, continue to generate high repair volume due to frequent mechanical wear and daily clinical use.

Like the HTM industry, the dental industry demands timely maintenance and repair services.”

He added that biomeds have an advantage when it comes to expanding their services to include dental equipment saying it is “generally less complex than hospitalbased medical devices, which feature advanced electronics, integrated software, networked connectivity with cybersecurity risks, and life-critical functions requiring rigorous calibration, electrical safety testing, and strict regulatory compliance.”

“In contrast, dental systems – such as chairs, delivery units, and autoclaves – focus on mechanical, pneumatic, and hydraulic components in compact, standalone setups with less emphasis on digital integration,” Gonzales said.

“However, dental equipment introduces unique challenges necessitating specialized training beyond standard BMET/HTM curricula,” he added.

Read what else Gonzales shared about HTM and dental equipment online at 1technation.com/htm-dental.

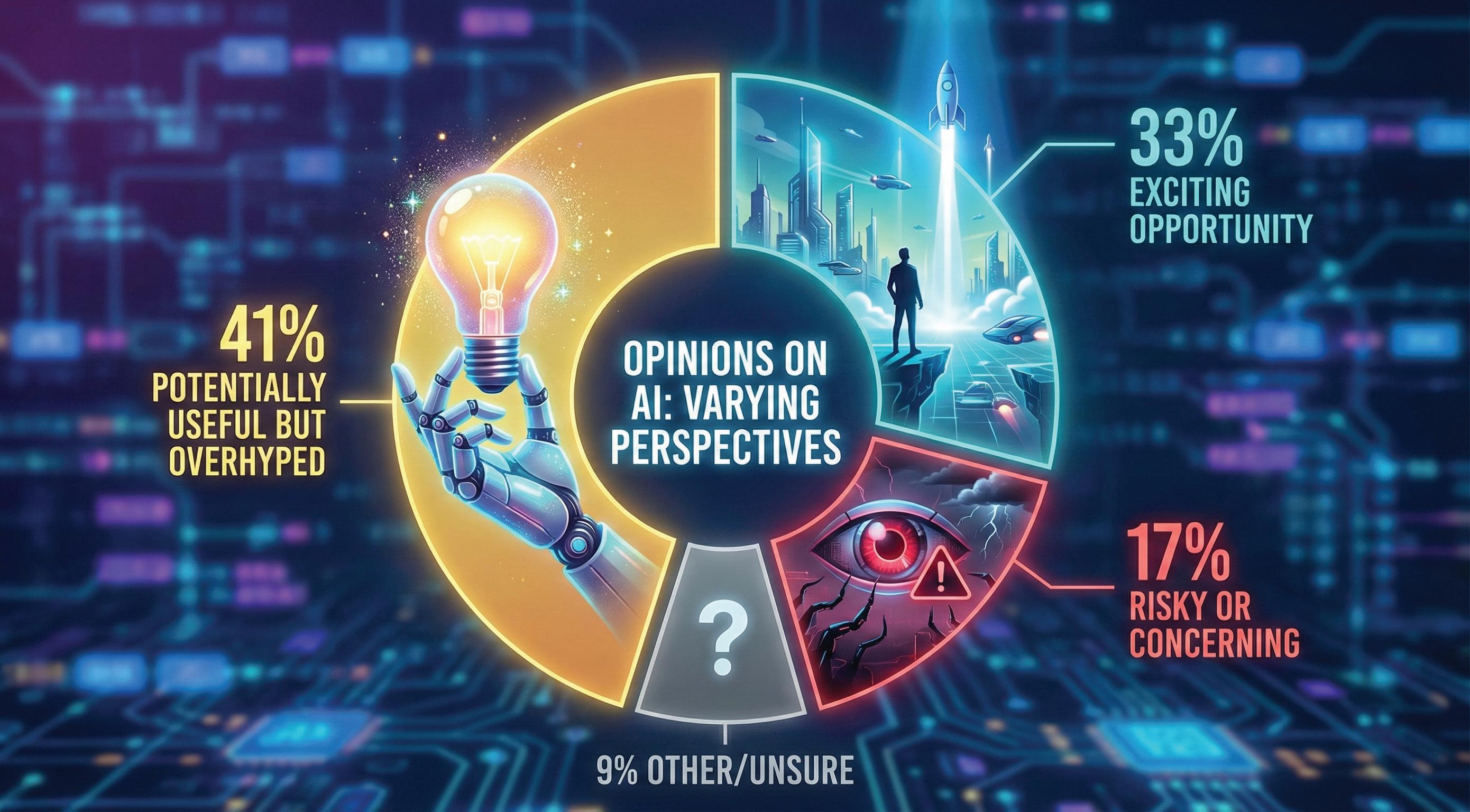

BY RAVIN JANI

he speed at which AI has enveloped our collective consciousness today is astounding, further compounded by the hype that it is the panacea for all that ails healthcare community. This has left patientfocused and financially strapped executives in a quandary.

Investments in enhancing and/or maintaining patient care continue to be the priority of the healthcare community. Allocating limited budgets for nascent back-office technology solutions that haven’t quite demonstrated ROI isn’t on their radar. To remain competitive and to attract and retain talents, these executives are challenged with evaluating the way forward.

Fortunately, the proposition isn’t “Nothing or All-in.” There are incremental steps requiring a fraction of total investment that can get the healthcare community

started on building up their analytical information domains.

Data is the foundation on which information and intelligence is built, which in turn drive our decisions and actions. The healthcare community has access to a wide variety of data including:

• First-party data refers to internal data that is created through daily interactions and transactions, such as patient intake information.

• Second-party data refers to the data that is created in collaboration with trusted partners such as external service providers.

• Third-party data refers to the data that is acquired from external sources and agencies such as compliance and privacy standards.

Every provider in the healthcare community is on various stages of maturity with respect to how and how much they leverage the data they have access to, to complement their decision-making process.

Purpose Descriptive Indicative Predictive Prescriptive Proactive

To understand what happened

To explain why it happened

Output Tools / Processes

Example

Historical insights

Dashboards, reports, spreadsheets

Patient demographics, monthly invoices report

Causation insights

Correlation analysis, data engineering, spreadsheet formulas

Patient re-admission rate increase analysis

Usage of data to inform our decisions and actions has evolved from simply describing the past (descriptive) to anticipating future outcomes (predictive) to recommending a course of action (prescriptive) to executing the best course of action (proactive).

As we move from less mature to more mature evolution stages, each stage progressively enriches the information to enhance our decision making as well as providing better intelligence to drive our actions.

Regardless of the stage, the reliability of the information output and therefore the intelligence gained is predicated on three critical elements for the underlying data:

• Comprehensive – access to only the first-party data is an information silo. It will provide an incomplete understanding of the situation or the challenge. To gain holistic intelligence, access to second-party and third-party data is also needed.

• Quality – the adage, “garbage-in/garbage-out” holds especially true in this situation. It is compounded by the fact that the healthcare community so far hasn’t had the imperative to refresh technology and data infrastructures.

• Security – given the sensitive and private nature of data healthcare community has access to, it is of paramount

To forecast what is likely to happen

Future forecast

Machine learning, gen AI, regression models, time series analysis

Identifying patients with readmission risks

To recommend what potential actions to take to remedy a situation

Data-driven decisions and recommended actions

To execute a recommended course of action

Executing recommended action based on a specific diagnosis

Advanced ML, learning, gen AI, complex data engineering AI/ML, Agentic AI

Recommending timely interventions for at-risk patients

Scheduling an appointment with pulmonary specialist upon machine identification of irregularity on a patient’s lungs x-ray image

importance that any modernization journey undertaken has well-defined guardrails to safeguard all data.

Before making any significant investment to address the perceived or real gaps in your ability to gain intelligence from the data you have access to, I would recommend going back to the fundamentals and performing an assessment of what requirements you are trying to meet, what are the objectives and ROI of the investment you are making. It may turn out that descriptive and indicative stages are sufficient for what you need now and that the comprehensiveness, quality and security of the data is adequate.

An objective assessment of your requirements and infrastructures is a logical first step. This assessment can be performed internally by the appropriate teams within the healthcare system, their bandwidth and resources permitting. Alternatively, you can engage external independent consultants who have access to appropriate methodologies and toolsets to do so. Regardless of who does it, it is important to understand the baseline before embarking on the next step of the journey.

Ravin Jani is the chief digital officer with Fortuneline Business Consulting LLC.

Watch these webinars on-demand

The TechNation Tools of the Trade LIVE Demo webinar “Laser Safe: The Biomed’s Path to LSO Certification” was presented by Vangie Dennis, MSN, RN, CNOR, CMLSO, FAORN, FAAN, Perioperative Consultants LLC; and Patti Owens, MHA, BSN, RN, CMLSO, CNOR, FAORN, AestheticMed Consulting International LLC. The webinar is eligible for 1 CE from the ACI.

Owens has extensive experience in medical safety programs and laser safety and provides valuable consultation services. She has held significant roles, including president of the AORN eChapter, secretary of the ANSI Z136.3 committee for 12 years, and the safety officer of the American Society for Laser Medicine and Surgery. She has been recognized for her achievements with the Nurse Excellence Award in 1999 and 2014. In 2024, she received the R. James Rockwell Jr. Education Achievement Award. In addition, she was recently designated as a Fellow with AORN for 2026.

Dennis is a consultant for Perioperative Consultants LLC. She is an active member in several professional organizations including the Association of periOperative Registered Nurses (AORN), American Academy of Nursing, and Laser Institute of America. She is a fellow for AORN and the AAN as well as the recipient of the 2026 Award for Excellence in Nursing. The webinar highlighted the importance of training and certifying HTM professionals to serve as Medical Laser Safety Officers (MLSO) in a healthcare facility. Biomedical engineers can be Laser Safety Officers (LSOs) because their technical expertise with medical devices, understanding of safety protocols, and familiarity with equipment maintenance and calibration. These important attributes make them ideal for managing complex laser systems and ensuring patient, staff and public safety in healthcare environments. Their technical background directly aligns with the need for precise risk assessment, implementation of control

measures and adherence to strict ANSI standards.

The presenters also invited attendees to register for a MLSO Excellence training session designed to prepare healthcare professionals to become a certified laser safety officer. Three two-day sessions are planned for the remainder of 2026 with one in April, July and November. More information about the two-day live virtual training sessions is available at medicallasersafety.com/

More than 100 healthcare professionals registered for the webinar with 58 logged in for the live session. A recording of the webinar is available for on-demand viewing at WebinarWednesday.live.

Webinar attendee Scott Williams, a BMET III with Trimedx, correctly answered a trivia question to win a Swiss Force Meister Multi-Tool.

Attendees rated the presentation high and provided very positive feedback via a post-webinar survey that included the question, “What was your single biggest takeaway from today’s webinar?”

“A clearer understanding of the LSO responsibilities and what biomed technicians often overlook in laser safety,” said Navya Sharma, a student at St. Clair College.

“Just an overall introduction on what biomed needs to do to complete an LSO certification,” said Jeff Grubb, a director of biomed with Piedmont Medical Center.

“MLSO certification needs to come from a reputable source. And that it is a valuable certificate for any biomed,” said Laurence Robert, CHTM, CBET, an associate director at the University of Vermont.

“Biomeds make good LSOs because they already have a lot of the technical knowledge that is needed,” said Christina Bottomley, a tech manager and BMET II at Rolling Plains Memorial Hospital.

Check out a recording of this webinar or register for the next webinar at WebinarWednesday.live.

Registration on WebinarWednesday.live

Eligible for 1 CE credit from the ACI.

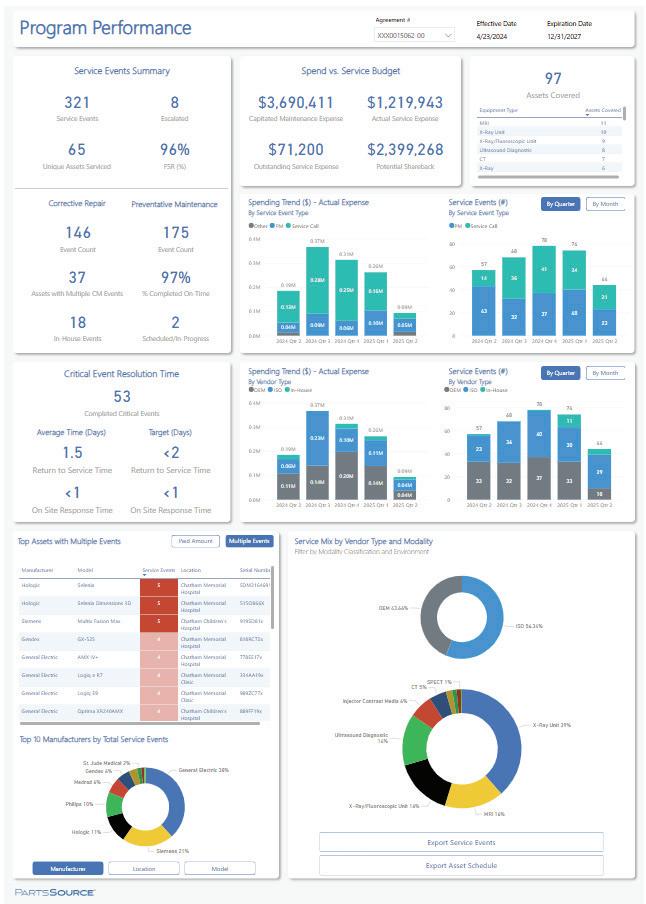

Healthcare organizations face growing pressure to keep critical equipment running while controlling service costs, managing complex contracts, and coordinating dozens of service vendors—all with limited visibility and stretched internal teams. PartsSource PRO Service is designed to solve these challenges by helping hospitals and health systems simplify service management, reduce unnecessary spend, and operate with confidence.

PRO Service gives organizations a clear, enterprise-wide view of their equipment service landscape—what assets are covered, where dollars are being spent, how vendors are performing, and where opportunities exist to improve. By bringing service data, contracts, vendors, and workflows into one centralized experience, PRO Service replaces fragmented processes with consistency, accountability, and actionable insight. The result is fewer surprises, faster resolution, and service decisions that are

guided by data rather than guesswork.

In this Tools of the Trade Live Demo, attendees will see how PRO Service uses a structured, technology-enabled Service Assessment to uncover savings opportunities, right-size coverage strategies, and improve service outcomes. You’ll learn how customers achieve meaningful upfront cost reductions, free up thousands of hours for their HTM teams, and gain the confidence that every service dollar is aligned to organizational priorities.

Trusted by healthcare organizations to manage more than 172,000 service events across 23,000 assets, PRO Service helps teams move from reactive service management to a more predictable, efficient, and cost-effective operating model. Join us to see how PRO Service enables healthcare organizations to spend smarter, work more efficiently, and deliver more reliable equipment performance across the enterprise.

Medical equipment everywhere, yet nowhere?

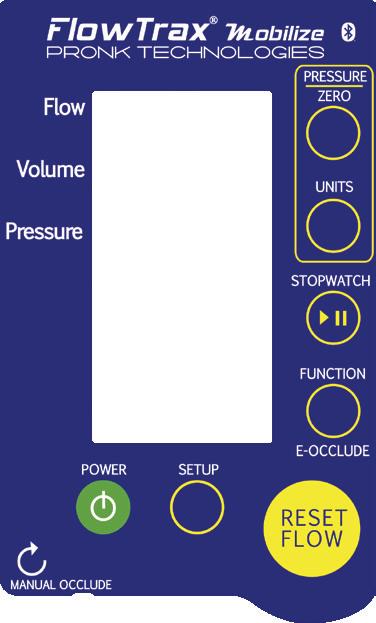

Safe, timely and effective care is jeopardized because the equipment that makes it possible is everywhere … and yet nowhere at the same time. Midmark CareFlow ™ RTLS leverages Bluetooth ® Low Energy (BLE) technology to rapidly and cost-effectively deliver facility-wide visibility—helping biomed and clinical teams locate equipment faster, improve utilization and optimize medical asset inventory.

Learn more at: midmark.com/RTLStracking

Healthcare technology management departments often reply on a real-time location system (RTLS) to help them complete their many tasks and responsibilities. RTLS has evolved over the years matching the rapid advances in technology in the consumer and healthcare markets. TechNation recently spent some time finding out more about RTLS and how HTM professionals rely on it as well as some of the latest trends and newest features.

Participants in this roundtable article on RTLS are:

• Duke Health Senior Director of Clinical Engineering Benjamin Scoggin, MBA, MMCi;

• ECRI Associate Consultant, Device Safety Consulting Dustin K. Telford, AAMIF, CHTM, CBET, CRES, CLES;

• HID Healthcare RTLS Vice President of Sales Kerry Brock; and

• Midmark RTLS Senior Director HT Snowday.

Q: HOW IS RTLS CHANGING THE WAY HTM DEPARTMENTS FORECAST EQUIPMENT DEMAND OR PLAN CAPITAL REPLACEMENT?

SCOGGIN: RTLS has shifted forecasting from anecdotal, and utilization-survey driven to data-validated, defensible planning. Instead of relying on staff perceptions such as “we’re always short on pumps,” we can now evaluate actual utilization rates, dwell times, idle percentages and cross-campus movement patterns. From an HTM standpoint, this directly influences capital replacement decisions by identifying true over- or under-capacity, highlighting assets that appear old but are lightly used, and surfacing newer devices that are over-utilized and approaching functional end of life faster than expected. It also supports fleet right-sizing and redistribution across hospitals and clinics, often delaying capital spend while improving availability and clinician satisfaction.

TELFORD: RTLS doesn’t replace capital equipment replacement planning – it finally gives us the missing data to do it properly. Location states like “in-use,” “standby,” “in-transit,” and “stored” reveal the truth about utilization