2 minute read

Five Things You May Not Know About Choosing a Batch Glass Melt Furnace

Source: Deltech

1

Corrosion Resistance Is Essential 2 Elements Need Protection Too 3 Does The Furnace Allow You To Easily Fine Your Glasses?

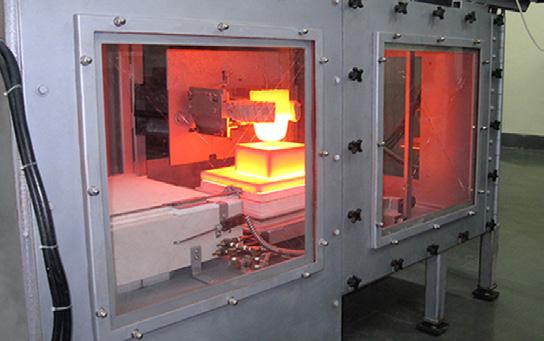

The most important characteristic of any batch glass melt furnace is that the lining be able to withstand the highly corrosive fumes frequently generated by glass chemistry at high temperatures. High alumina ceramic for temperatures up to 1800° C and cast zirconia for temperatures above 1800°C are optimal corrosion resistant materials. In addition, the use of a “spill trap”, rather than a flat hearth plate, to catch spills from broken crucibles or “boil-overs” is highly recommended.

4How To Facilitate High Temperature Pours

If you are pouring the glass at temperature, then the furnace you select should be designed for optimal ease of loading and removal of the melts, and and for maximum operator safety. Pneumatic door operation permits very rapid access to crucibles.

Some glasses, such as those containing significant amounts of sodium, fluorine, or chlorine, will also attack molydisilicide heating elements. In these cases an element protection liner should be used to separate the elements from the furnace hot zone.

5Experience Counts

If you are fining the glass with a stirring apparatus or gases bubbled into the melt, the furnace you select should have a top opening to permit the use of a stirring apparatus or gas supply tube. The opening must be designed to resist heat and any corrosive fumes escaping from the furnace chimney. You may also want the manufacturer to supply the stirring mechanism, or make modifications for your equipment.

Choose a supplier whose glass melt furnaces have been performance proven in the field. Ask your colleagues for recommendations and ask manufacturers for references. Do not settle for an all-purpose off-the-shelf fiber lined furnace, which will require frequent relining. Get a furnace designed to withstand glass attack, and that is also custom designed and sized to fit your need. Also, get a control system that matches the level of sophistication you want. Robotic movement of the melts, and remote operation, monitoring, and data logging of any and all parameters desired, are all available options. Visit our website for examples of custom and standard bench top and small production models. Call us to discuss how our 45 years of experience in customer driven glass furnace design can serve your application requirements.