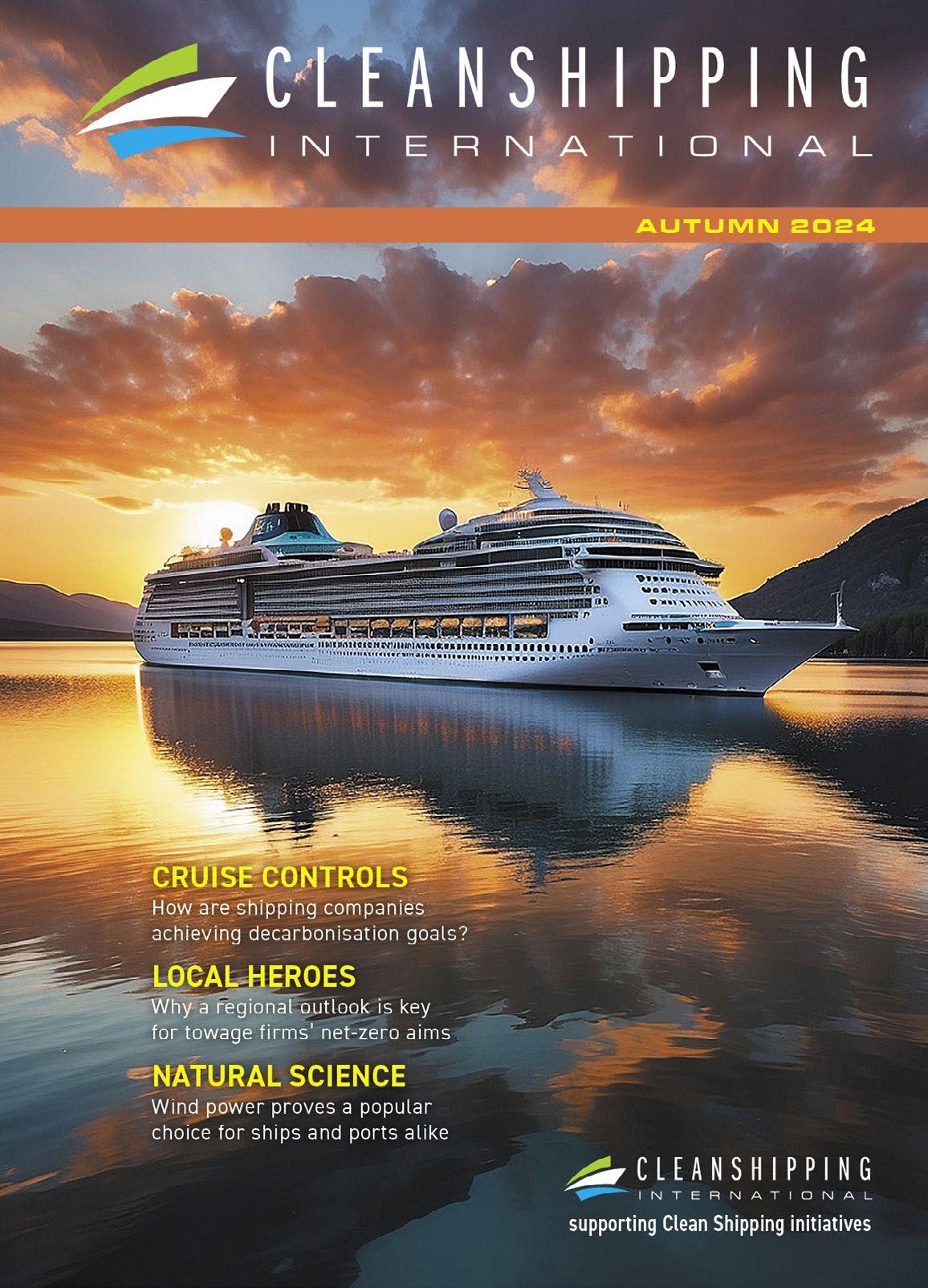

CRUISE CONTROLS

How are shipping companies achieving decarbonisation goals?

LOCAL HEROES

Why a regional outlook is key for towage firms’ net-zero aims

NATURAL SCIENCE

Wind power proves a popular choice for ships and ports alike

How are shipping companies achieving decarbonisation goals?

Why a regional outlook is key for towage firms’ net-zero aims

Wind power proves a popular choice for ships and ports alike

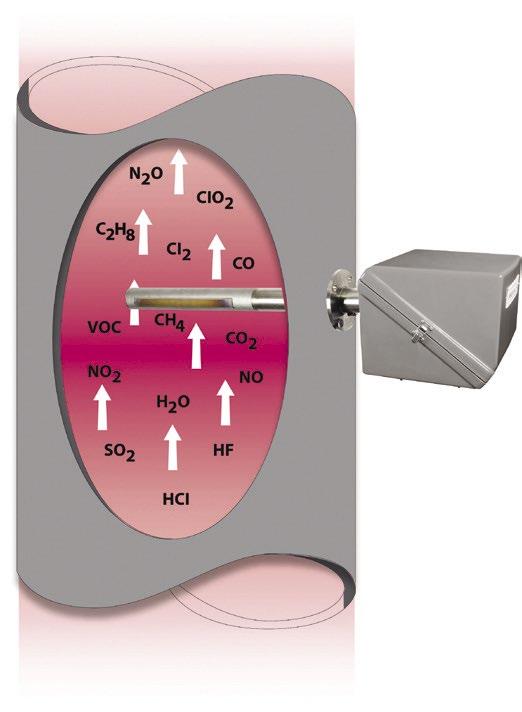

Protea manufacture the equipment and supply qualified engineers to carry out the on board testing.

Emissions Testing using the latest Protea Transportable FTIR

• Know your ship gaseous emissions

• Verify your continous emission monitoring system

• Verify your Exhaust Gas Cleaning Systems (EGCS) performance

• Data contributes to engine efficiency checks

• Emissions Testing

UK Maritime and Coastguard Agency

European Commission Directive 2008/67/EC of 30th June 2008, amending Council Directive 96/98/EC on marine equipment (4th Amendment) Annex 2, A2/2.1On board NOx monitoring and recording devices, MARPOL 73/78 Annex VI regulation 13 and the NOx Technical Code.

ATEX Protea P2000

Certficate Number:

Baseefa 18 ATEX 0060X

Markings: II 2 G Exdb IIBT* Gb

Certificate of Design Assessment

Protea P2000

RINA Rules for the Classification of Ships - Part C “Machinery, Systems and Fire Protection”, Chapter 3, Section 6, Tab.1 and IMO Res. MEPC.259(68) Chapter 6 “Emission Testing” as well as the relevant requirements of Revised MARPOL Annex VI and NOx Technical Code 2008.

Lloyd’s Register - Type Approval Certificate

Protea P2000

T6 Ta -20˚C – +40˚C

T4 Ta -20˚C – +60˚C

IEC Protea P2000

Certificate Number:

IECEx BAS 18.0040x

LR Rules & Regulations for the classification of ships (July 2014) LR Test Spec No.1 (2015)

Markings: Ex db IIB T*Gb

IMO Resolution MEPC 184(59) - 2009 Guidelines for exhaust gas cleaning systems

IMO NOx Technical Code (2008)

International Association of Classification Societies

Concerning Electrical InstallationsIACS E10 Test Specification for Type

MCERTS Protea P2000

MCERTS Performance Standards for Continuous Emission Monitoring Systems

Product Conformity Certificate No: Sira MC 050060/12

Speares Editor, Clean Shipping International

Innovative approaches to tackling emissions continue to be a challenge for the industry and there have been a number of new initiatives in recent times to try and ensure that companies and trade organisations meet their targets. We have some interesting views in this edition of Clean Shipping International from industry players on how they deal with the challenges, particularly when considering issues such as salvage or tug operations in ports around the world.

Much of this, of course, places the onus on ports to ensure their facilities are up to scratch and they can handle demands placed on them. For example, manoeuvrability is an important issue, given recent accidents involving ships in restricted areas. We take a look at port operations such as towage of vessels and how close-quarter situations can potentially prove dangerous – not to mention fatal – if not properly handled. There have been a number of incidents within harbour bounds that have had serious consequences in terms of dangers to individuals in the port area –including bystanders as well as crew members.

The ability of vessels to move safety within ports has, in some cases, been compromised by insufficient power being available on board to get out of potentially dangerous situations. Some of this has been driven by moves to reduce energy consumption by fitting less powerful engines.

We also look at some of the other issues relating to emission reductions, including which green fuels are currently available – and which will be available in the future. Companies need to take a practical approach to their fuel selection, which takes into account availability and practicality in the short term against what may be available in greater quantities in 10 or 20 years’ time, but for which infrastructure is currently lacking.

Shipowners and operators also need to consider the financial demands of meeting green fuel deadlines. They must not leave it too late and risk missing the boat. At the same time, governments across the globe need to consider how they can help companies reach their targets.

More natural approaches to powering vessels, such as the use of wind, are also proving a popular choice with companies and there are plenty of innovations playing out in this sector.

We hope you enjoy reading all about them in this edition of Clean Shipping International

BY MEPRODUCTION

Convert to a smart scrubber solution

ClearSmart Emission Guard is our next generation of high quality, carbon-capture-ready scrubber systems, which are available for retrofit, newbuilding and conversions. The system is designed for reliability and come outfitted with a cutting-edge sensors package, and intuitive controls to ensure maximum performance, reliability, and environmental compliance. Choose between open, closed or hybrid loop configuration, and in-line or u-type construction.

The smart systems toward a better future

The ClearSmart Emission Guard system is part of ME Productions newly formed smart collection of sustainability technologies for the maritime sector - now covering exhaust gas cleaning, waste heat recovery, power optimization, and green propulsion. The entire set of technologies are supported by ME Productions worldwide, world-class service, and network for extreme peace of mind.

CELEBRATING 10 YEARS OF SUSTAINABLE SOLUTIONS

Editor: Sandra Speares speares1@aol.com

Project Director: Jonathon Ferris jonathon.ferris@ cleanshippinginternational.com

Sub-editor: Samantha Robinson sam.robinson.journalist@ gmail.com

Publisher: Bill Robinson production@ cleanshippinginternational.com

Designer: Justin Ives justindesign@live.co.uk

Published by Maritime AMC, Clean Shipping International supports Clean Shipping Initiatives.

The views expressed in Clean Shipping International are not necessarily those of Maritime AMC unless expressly stated as such and disclaim any responsibility for errors or omissions or their consequences or for advertisements contained in this magazine and has no legal responsibility to deal with them.

PureServ, a cerertified service organization by PureteQ A/S, provides maintenance services for all brands of scrubbers and sensors worldwide.

PureteQ offers inspections that assess all components and structural conditions, creating a work scope for the yard, crew, suppliers, and stakeholders well before the scheduled drydocking. Scrubbers installed around 2018 have operated for thousands of hours, making motors, dampers, sensors, and moving parts due for overhaul or replacement, some of which can have long lead times.

Sandra Speares on why shipowners and operators must not miss the boat when it comes to green fuel choices

Don Gregory, Director, Exhaust Gas Cleaning Systems Association

All the latest news and views from across the globe

Why improper use of exhaust gas cleaning systems can result in fines for unwary shipping companies

A number of new vessels have been launched using wind power as a solution to the challenges of meeting emissions targets

There are plenty of opportunities to invest in green fuels – but which are the most practicable in the short to medium term?

New regulations are looming for BWMS, which may lead to further scrutiny for shipowners and operators

Shipping firms are undertaking a range of adjustments, installations and innovations to ensure they achieve decarbonisation goals

Interview: Gareth Prowse, Head of Decarbonisation, Svitzer

Viewpoint: Cathy Stevenson, Managing Director, Wärtsilä Water and Waste

In the race to adhere to new regulations, a number of innovations are helping shipowners in their journey

A strong culture is vital across the supply chain as the industry grapples with a huge range of potential threats

Anemoi Marine Technologies (Anemoi) is committed to accelerating the maritime industry’s transition to zero emission shipping by delivering market-leading wind technology.

Forward thinking vessel owners and charterers are installing Anemoi Rotor Sails to reduce fuel consumption and harmful emissions by up to 30%. Our proven technology has been uniquely designed to work alongside complex vessel operations, making it suitable for most ship types as retrofit and newbuild.

Use the free and unlimited power of wind to limit ship emissions now.

Don Gregory Director,

You will probably be reading CleanShipping International soon after the International Maritime Organization’s (IMO’s) MEPC 82 meeting in London has completed its work. The committee has a broad standing agenda related to all the Annexes of MARPOL. Recently, topics pertaining to greenhouse gas (GHG) emissions reductions have taken over the wide agenda and absorbed almost all the administration’s attention. Could there be a serious risk of work overload leading to misinformation being nodded through in other parts of IMO’s work?

Despite all the rhetoric, it is pretty clear that the only two options during the next 30 years for merchant ship prime movers (PM) is either a nuclear energy source or the marine diesel engine.

For the moment, nuclear is not on the agenda as a realistic commercial solution. So the challenge is where to source around 250Mt/year of zero fossil carbon energy that is suitable substitute for the current diesel and fuel oil used in marine diesel engines.

The 250Mt/year of marine bunkers equates to 10.5TJoules (T=1012) of energy that needs to be substituted for zero fossil carbon energy. That does not take into account shipping growth that may need more energy. According to the International Energy Agency in 2022, wind provided 7,560,000 TJoules of energy globally, solar voltaic 4,658,400 TJoules. World total energy consumption in 2022 was 600,000,000 TJoules. Note that renewables equate to just over 15m TJoules compared with 600m TJoules of total global consumption, sourced from all energy including coal, gas, oil, and renewables, etc.

Assuming the world’s merchant marine needs to secure a liquid fuel for at least the next 20 years, each alternative fuel seems to come with some significant bear traps. Some are extremely toxic, and/or combust with an invisible flame, or have significant fugitive leaks from well to wake that cancels out the reduced fossil carbon content, or the lifecycle analysis (LCA) reports a picture of increased GHG emissions. There are actually a lot more weaknesses to the alternative fuels than what has been just listed above, including unknown pollution emissions.

Traditionally, the drivers for the selection of heavy residual fuels and diesel as the marine bunker of choice include:

» Price – the energy cost of a ship can be more than 60% of the daily operating cost. Higher fuel costs, drives higher transport costs and consequently a higher cost of living.

» Availability – the majority of ships operate globally and need to be able to source fuel in virtually any port. Carrying more fuel than optimal inevitably reduces the vessel’s cargo carrying capacity. Less cargo means more ship voyages to transport and inevitably more emissions.

» Safety – any type of fuel presents a possibility of almost instantaneous release of energy that needs to be able to be managed on board ship. It also has to be handled by the crew.

There is also energy content, energy density, suitability for long term storage on board ship, suitability for the PM fuel handling and injection and, of course, suitable combustion characteristics.

It seems that the hunt for alternative fuels ignores these desirable and, in many cases, essential characteristics of a marine fuel. What is becoming increasingly evident to many shipowners is that energy sources containing little or no fossil carbon are a challenge or probably unrealistic. In the meantime, there are huge opportunities to mitigate and minimise fossil carbon emissions through many practical measures. These include hull and machinery efficiency, vessel scheduling, ocean currents and much more. One group of ship operators have chosen to reduce CO2 emissions by between 10% and 20% through the continued use of high sulphur fuel oil (HSFO), and the installation of exhaust gas cleaning systems (EGCS) to comply with sulphur emission regulations. The fleet represents about 30% of the total annual marine bunker consumption.

According to an non-governmental organisation (NGO) that has been calling for a ban on EGCS, the use of HSFO has saved operators using EGCS in excess of $8bn in fuel cost. The NGO argument centres around an assertion that the savings have paid for the capital investment in the EGCS and

therefore a ban on use would be at no loss to the operators. The NGO is either not aware or chooses to ignore the lower CO2 emissions from running on HSFO or that the $8bn lower operating cost might have fed back into a lower cost of transport – important facts that are being hidden or ignored and do have serious consequences for the long-term impact of IMO regulations.

IMO requires evidence to introduce new regulations. In their misdirected efforts to protect the marine environment, NGOs have focused on attempting to identify harm caused by the use of EGCS and have turned to unscientific claims of harm caused by EGCS discharge water.

Fortunately for EGCS designers, manufacturers and ship operators, there has been no evidence in more than 50 years of EGCS operation of any significant impact on the marine environment from EGCS discharge water. This is especially evidenced in ports and local waters where many studies have been conducted, including power stations and oil refineries operating in local waters for decades.

In the absence of any compelling evidence of harm, a paper was presented to IMO purported to propose a method to consistently evaluate the risk posed by EGCS discharge water in territorial waters, ports and even attempting to extend the jurisdiction beyond the Exclusive Economic Zone.

The paper was discussed at IMO and converted into a circular letter entitled Guidelines MEPC.1/Circ.899. In order to implement this circular letter, it requires for the process of risk assessment various standard information, (data sets). One such data set is known as the emission factors, (EFs).

The purpose of the EFs is to enable a sea area to be modelled for the input of quantities of compounds from EGCS without the need to measure the concentrations actually in the body of water. In simple terms, if the concentrations of one or more compounds exceeds a limit value, then there is cause to consider what mitigation steps can be taken or to decide to ban the EGCS discharge.

However, simply using EFs and multiplying the value by the number of ships passing the sea area only gives the value of concentrations at the

ship’s discharge. There is another very critical step in the evaluation process known as the fate of the compounds. Some compounds break down, some evaporate and some are persistent and build up in the sediments, and then there is the dispersion of the discharge and loss of concentration down to infinitely minor values through dilution.

The starting point remains the EF. It is important that these factors, used to model total ship side discharges, that the development of the EFs is undertaken in a rigorous and scientific way.

IMO is being presented with document MEPC 78/9/3 that purports to have developed a set of EFs based on sampling of EGCS discharge water. After carefully reviewing the document and all the papers referenced as the sources of the resultant EFs in the document, it has been found the paper is not scientific or rigorous and is misleading. IMO has also been presented with document MEPC 82/5/1, which systematically evaluates the EF document and explains why the EF are unscientific and often incorrect.

Given the climate change agenda is focusing minds, will this misleading information be accepted by IMO or will there be enough resource within administrations to spot the concerns and not accept the EFs?

Here are some examples of how the EFs have been incorrectly derived and are not valid for current EGCS, or the data has been incorrectly processed, or in many cases the samples are simply not assured as a valid sample of EGCS discharge water.

Many of the samples were taken prior to 2020 when EGCS were still evolving and improving. Today, many EGCS have variable speed pumps that reduce the amount of water discharged on low loads. Most of the samples do not have information on the method of sampling and transport to the lab. This is essential as poor sampling will give inaccurate results. A sample taken from an oily sampling point will inevitably have oil in the sample increasing the EF for oil discharge. Bear in mind the concentration limits are usually in low ppm or in ppb.

Some compounds were only reported in a few samples analysis. So, for example of 100 samples, all were analysed and reported for the Iron content, but only two samples were analysed and reported for nickel. Despite the low number of nickel results, the values have been accepted as statistically valid. So the average of just two sample results is used in the EF calculation.

It was found that there were wide variations in analysis methods. Many samples were not analysed in accordance with International Organization for Standardization or Environment Protection Agency analysis methods. The level of detection of a compound varies significantly between analysis methods.

The environment risk assessment community has over the past 30 or so years evolved a norm for the treatment of what are known as non-detects, (ND). This means that the compound was not detected in the analysis. One could assume that if it is not detected it is not present.

However, this presents a possible risk. Instead of reporting zero, the ND is reported as 50% of the analysis method detection limit. If the detection limit is 400ppb then the sample is reported for ND as 200ppb.

In order to produce an EF value part of the calculation is to add all the reported values for a compound and divide by the number of values to get an average value. In the case of ND, the average value can and has been distorted. As an example, two labs analysed for a compound. Both labs reported ND. The limit of detection of lab A was 4ppb whilst the limit of detection for Lab B was 400ppb. So, the labs reported 2ppb and 200ppb respectively. The average value to be used in the further EF calculations was (2 + 200) / 2 = 101ppb. Clearly this is a gross distortion of the likely amount of compound to be found in the discharge water if any at all is present.

The evaluation of the document MEPC 78/9/3 took many days of work. Reading, cross referencing and then evaluating the science of the document. How can IMO function to be the international arbiter for coherent, sound and durable regulations and solutions if it is receiving mis-leading or unscientific information?

Protea Ltd manufactures an extensive range of gas analysers for use in both continuous emission and process monitoring. This enables Protea to select the product best suited to the application without compromise. Protea operates two modern facilities incorporating application development, production and aftersales support.

Our customers are supported by a worldwide partner company network employing factory trained service personnel, supported by our service team. Protea is dedicated to working with our customers to develop state-of-the-art solutions to meet the requirements of critical industrial/marine sectors to meet their environmental goals. Protea’s proven in-situ technique is both cost effective and reliable.

Protea’s fixed and portable analysers can monitor emissions from many classes of vessel, (for example cruise ships to platform support vessels.) This is an ideal solution that complies with International Maritime Organization regulations. Proteas P2000’s are used to monitor/report emissions from vessels with and without exhaust gas cleaning systems/ scrubbers and have been developed to meet the requirements of multifuel vessels.

Robust and with proven reliability, up to six gases can be measured including sulphur, carbon dioxide and nitrogen oxides. The Protea 2000 emissions monitoring system comprises up to eight exhaust-mounted analysers, each with automatic verification facilities.

For more information, contact:

Hempel data provides in-depth insight into the correlation between hull coating and emissions performance

For all vessel owners and operators, deciding which tools, technologies and techniques to adopt to reduce emissions across their fleets is a significant, if not primary, business concern. To meet regulatory requirements with the fuels currently available requires a careful calculation of potential cumulative gains – working out which combination of emissions reduction solutions will deliver the best returns for a vessel.

Thankfully, hull coatings are a known quantity; a tried-and-tested method for lowering fuel requirements by reducing frictional resistance below the waterline. The fuel savings a highquality hull coating or anti-fouling solution can deliver immediately to Carbon Intensity Indicator (CII) and Energy Efficiency Existing Ship Index (EEXI) ratings should not be underestimated. Crucially, the right hull-coating can go a long way in helping owners and operators to hit the first updated International Maritime Organization (IMO) updated Greenhouse Gas (GHG) Strategy

‘indicative checkpoint’– a 20% reduction in total GHG emissions by 2030 – as well.

Understanding how to calculate the return on investment in both emissions reductions and operational costs before making any investment is a complex equation. This is particularly true given that there are so many potential additional variables to consider, such as route-specific costs including EU Emissions Trading Scheme (EU ETS) payments, which will influence how suitable each solution might be.

This is why Hempel, as a leading coatings manufacturer and trusted advisor to the industry, recommends that owners and charterers take a vessel-specific approach to determining which coating system and hull maintenance strategy best meets the commercial and operational needs of their business. Each coating system offers its own unique benefits and restrictions, so it is crucial that these are explored carefully before investing in a product that should serve a vessel for five years or more.

To do this with necessary rigour, a robust decision-making procedure is

paramount. Hempel has developed a framework that can enable owners and operators to establish the impact of any energy efficiency measure on both vessel performance and cost before they make a purchase decision. The framework considers environmental, sustainability and regulatory requirements against total cost overall and payback, resulting in a ship-specific impact assessment that can support effective investment decisions.

Hempel is able to do this with confidence because its data is reliable. For Hempaguard X7, our silicone-based low-friction anti-fouling solution that has been applied to more than 4000 vessels, has been third-party certified by leading classification society DNV, which has verified the emissions savings it delivers.

DNV’s verification objectively confirms the solutions’ outstanding performance when it comes to the reduction of CO2e emissions and confirms our claim that the solution can deliver fuel savings of up to 20% and average speed loss of 1.4%.

Building on the success of Hempaguard X7, Hempel has invested in further developing its cutting-edge innovation Hempaguard Ultima. Launched in late August this year, Hempel’s Hempaguard Ultima represents a revolution in hull coating systems, delivering unmatched performance including up to 21% fuel savings.

Hempaguard Ultima combines the tried-and-tested performance of Hempaguard X7 with Hempel’s revolutionary new biocide-free silicone topcoat, Hempaguard XL, preventing growth of marine organisms while ensuring long-lasting hull protection.

With its minimal speed loss of only 0.9% on average and increased out-of-dock speed of 6%, Hempaguard Ultima is an obvious choice for all vessels. Its unique formula also means

it maintains a smooth surface into the fourth or fifth year of a dry-docking cycle, removing the need for expensive mid-cycle cleaning. This happens because the Hempaguard XL topcoat acts as a modulator for the release of biocide from Hempaguard X7, allowing a lower biocide amount per square metre to last longer. Vessels protected with Hempaguard Ultima can also benefit from 160 fouling-free idle days, providing operators with enhanced operational flexibility and the choice of operating in all water conditions.

What this means in a real-world scenario can be illustrated by applying the decision-making framework to the case study of a typical 60,000 DWT bulk carrier, as Hempel has done. In this case study, three scenarios were tested: two using self-polishing antifouling coatings with and without annual hull and propeller cleaning; and one using Hempaguard Ultima accompanied by an annual propeller polish. The scenarios were assessed for their impact on the ship’s required power, fuel consumption, fuel costs, and total CO2 emissions over a fiveyear docking cycle.

The first step, a required power change assessment, traces the power needed to deliver a specific ship speed. Compared with the baseline of a clean hull coated with a self-polishing coating (SPC), the Hempaguard Ultima scenario implies 6% less main engine power initially, i.e. freshly coated and out of dock, with the power gap to scenario one or two gradually increasing towards the end of the

study period, in accordance with the guaranteed speed-loss. The result is that the Hempaguard Ultima option always generates a net saving against self-polishing coatings, when including fuel costs.

The silicone-based coating scenario, i.e. Hempaguard Ultima, offers far lower fuel consumption across the five-year cycle – a difference of up to 9,000 tonnes, or around US$5m (based on a fuel price of US$575/tonne). That is more than enough to outweigh the higher initial cost, delivering a fast payback compared with the SPC option in less than one year.

Specifically for this case study, assessing the impact of the measures on the vessel’s IMO CII attainable rating – another crucial calculation for any efficiency measures – shows that only the Hempaguard Ultima option leaves the shipowner with a CII rating that does not require corrective measures by the end of the study period. CII is not the only measure that demands an impact assessment beyond the cost of purchase and maintenance. EU ETS, for example, imposes an extra cost on GHG emissions in the form of EU Allowances that need to be purchased to cover emissions on voyages to, from and between European Economic Area ports. Assuming an EUA price of $90 per tonne of CO2e emitted, over five years the Hempaguard Ultima option’s greater fuel savings lead to a total saving of around $2.5m in EUA purchases compared to the base self-polishing option.

Overall, the silicone-based coating delivers a saving of more than US$5m compared with the baseline selfpolishing coating, with a payback period of around 8 months. The saving becomes $7.5m when the savings in the EU ETS carbon cost are included, which lowers the effective payback period even further

It is clear that this calculation will vary depending on the other energy efficiency measures considered, the vessel operating profile and the resulting exposure to regulatory regimes. But with a rigorous decisionmaking framework such as the one described above, owners can make effective investments for each vessel in their fleet.

With so many potential emissions reductions technologies now available, making sense of which solutions to apply to any vessel is a complicated undertaking and taking a chance on new innovations can feel like a gamble. Applying rigorous methods to analyse all of the variable factors that will impact on the emissions and cost savings and understanding both total cost of ownership and return on investment means owners and operators can effectively plan their sustainability strategies for the immediate and near-term.

As the case study makes clear, relying on verifiable data and proven technologies by applying the correct combination of coatings offers a simple and affordable solution to mid-term compliance, and a fuel cost saving that can deliver strong return on investment for any vessel.

By Mads Bertelsen. Director, Data and Technology, Hempel

The International Maritime Organization (IMO) has been inviting expressions of interest from developing countries for support to create National Action Plans (NAPs) to reduce greenhouse gas (GHG) emissions from shipping.

The International Maritime Organization (IMO) has been inviting expressions of interest from developing countries for support to create National Action Plans (NAPs) to reduce greenhouse gas (GHG) emissions from shipping.

This technical support, provided through the GreenVoyage2050 programme, offers a unique opportunity for eligible developing countries to develop tailored NAPs that address their specific maritime challenges.

A NAP outlines a country’s strategies to reduce GHG emissions from ships. These plans can include various measures, such as enhancing institutional and legislative frameworks, promoting energy efficiency, researching and adopting low-carbon and zero-carbon fuels, accelerating port emission reduction strategies, and developing infrastructure for green shipping.

The implementation of NAPs, and policy actions identified therein, can facilitate the step change needed to significantly reduce ship emissions and support achieving IMO’s GHG mitigation commitments.

IMO’s 2023 Strategy on Reduction of GHG Emissions from Ships (resolution MEPC.377(80)) sets ambitious goals, including achieving net-zero GHG emissions by or around, i.e. close to, 2050 and ensuring the uptake of alternative zero or near-zero GHG emission technologies, fuels, and energy sources by 2030.

The GreenVoyage2050 programme has been actively supporting partnering countries in the process of developing a national maritime emission baseline to inform evidence-based policymaking and highlight priority actions. The development of a NAP requires significant coordination across various ministries and stakeholders.

TheGreenVoyage2050 programme facilitates these dialogues to ensure effective NAP development and implementation. Selected countries will receive technical assistance, including targeted capacitybuilding and training, the provision of expert personnel, assistance with data analysis, technical guidance, stakeholder dialogue facilitation, and administrative support.

Astrid Dispert, GreenVoyage2050 Manager, says: “National Action Plans are essential for every country looking to tackle maritime GHG emissions effectively. Our programme not only offers technical support but also promotes collaboration among stakeholders, ensuring that these plans are practical, actionable, and tailored to each country’s unique needs.

“By supporting the development of these plans, we enable developing countries to build a sustainable and resilient maritime future.”

Over the past five years, the New International Land-Sea Trade Corridor has expanded its reach to 523 ports in 124 countries and regions.

With its operational hub based in southwest China’s Chongqing Municipality, this trade corridor connects global ports via railways, sea routes and highways through southern Chinese provincial regions such as Guangxi and Yunnan.

According to recent data released by the coordination centre for logistics and operation of the New International Land-Sea Trade Corridor, more than 30,000 ChinaEurope freight trains have operated via the corridor.

From 2019 to 2023, the annual freight volume through the trade corridor from Chongqing increased by 50%, 45%, 54%, 32% and 21% year-onyear, respectively.

Over the past five years, the variety of goods transported through the trade corridor has expanded from more than 80 types to more than 1,150 types, covering a wide range of categories, including electronic products, vehicles and components, machinery, small household appliances and food. The trade corridor has now achieved a near balance of shipments between inbound and outbound.

The export of new energy vehicles from these western regions has accelerated, with local auto enterprises establishing factories in Southeast Asian countries.

Oceanic and V.Ships, an integral part of V.Group, have donated a recycling structure to the Limassol Municipality in Cyprus. The donation will enable more sustainable practices among the local community by recycling waste and minimising the impact on the environment of single-use plastics.

The donation is part of Oceanic and V.Ships’ environmental, social and governance (ESG) strategy to encourage sustainability not just across fleets, but also in the communities in which they operate.

The recycling structure was developed in close partnership with Studio 8, School of Art and Design and Scenography, based in Limassol. Its design is inspired by both the sea and marine life to serve as a reminder of the impact our actions can have on the wider ecosystem.

Kyriakos Hadjikyriakou, Managing Director, Oceanic, says: “The idea of donating a recycling structure was driven by our ongoing efforts towards reducing our carbon footprint and promoting sustainable practices, including the elimination of singleuse plastics both at sea and onshore. Seeing the significant impact of plastic waste on our world, we identified a prime opportunity to further our environmental initiatives.

The findings of the latest Seafarers Happiness Index report by the Mission to Seafarers reveal a mixed but increasingly positive picture of seafarers’ wellbeing, with the happiness index increasing slightly to 6.99 in Q2 2024, marginally up from 6.94 in Q1 of this year.

However, the survey results reveal concerns over the emergence of two classes of life at sea for seafarers. There are suggestions of a ‘digital divide’ when it comes to accessing the benefits of modern communications and connectivity at sea, as well as different levels of training and preparedness for new fuels and new technologies for crew on different types of vessels.

The Seafarers Happiness Index (SHI) is a quarterly survey undertaken by the Mission to Seafarers, delivered in association with Idwal and NorthStandard and supported by Inmarsat. The survey offers vital insights into the sentiments and experiences of the men and women who serve at sea.

According to the feedback from the Q2 report, the positive shift in seafarer wellbeing is a testament to improvements in several critical areas, including shore leave, wages, training, crew interaction, and workload.

Although this modest improvement in an otherwise stable set of results is welcomed, the picture is slightly more complicated than meets the eye. Vessel type can significantly affect the wellbeing of seafarers, with seafarers on tankers reportedly feeling well-prepared, qualified and ready to tackle the challenge of new fuels. In contrast, those on dry cargo and container vessels feel left out of crucial technologies and developments emerging in the industry.

Those serving on vessels with upto-date communications technology comment on how it is transforming the social and emotional landscape of life at sea, as it is critical for connectivity and links to home. Many seafarers express profound gratitude for maintaining regular contact with loved ones. However, for those who do not have those means of communication,

life on board can be challenging; many are facing limited data, slow connections or no access at all.

Similarly, shore leave, a crucial aspect for maintaining mental and physical health, is often restricted for seafarers due to tight port schedules, regulatory barriers, and inconsistent practices across different ports and companies. While access to recreational facilities like gyms is essential for maintaining health, the quality of equipment and safety standards often need to be improved. Additionally, cost-cutting measures can lead to monotonous meals, adversely affecting crew morale.

The multicultural nature of crews presents both opportunities for enriching cultural exchange and challenges in managing social dynamics, highlighting the need for practical, social activities to foster crew bonding. Bureaucratic burdens add another layer of stress, with increasing paperwork and regulatory requirements despite the push for digitalisation.

Workload varies widely depending on the type of ship, company policies and schedules, exacerbating these challenges. Finally, some seafarers often report feeling unrecognised and unsupported when ashore, underscoring the urgent need for greater respect and acknowledgement of their contributions to global trade and the economy.

Andrew Wright, Secretary-General, The Mission to Seafarers, says: “Although there are still plenty of areas of growth that need attention, our report reveals an encouraging trajectory of steady recovery and stabilisation after what has been a tumultuous year for seafarers. I’m heartened that those responsible for our seafarers are taking measures to ensure the enhancement of wellbeing.

“However, reports of a distinction between the ‘haves and have-nots’ of welfare standards on board are worrying. Every single seafarer deserves access to the fundamentals that are needed to support a safe and rewarding life at sea, including access to shore leave, decent connectivity,

good onboard facilities, and regular training.

“It is critical that the industry continues to support and bolster seafarers to maintain this positive momentum. Our job is to raise the profiles and voices of seafarers by building a maritime industry that truly values seafarers’ living standards, welfare, and happiness across the globe.”

Thom Herbert, Key Account Manager (Asia) and Crew Welfare Advocate, Idwal, comments: “The latest Seafarers Happiness Index findings present a nuanced picture of life at sea, with the slight increase indicating gradual improvement, but also highlighting persistent challenges. At Idwal, we’re particularly concerned by the emerging ‘two-speed’ industry revealed in this report, especially the ongoing issue around connectivity and, also, the readiness for new technologies, where the disparity in experiences between tanker crews and those on dry cargo vessels is striking.

“In tandem with the Seafarers’ Happiness Index, through our vessel inspections and Social Impact Report, we continue to advocate for consistent, high standards of living and working conditions for all seafarers. It’s crucial that the industry addresses the digital divide and ensures equal access to training opportunities across all vessel types. Only by treating seafarer welfare as a non-negotiable priority across all sectors can we build a more resilient and sustainable maritime industry.”

Yves Vandenborn, Head of Loss Prevention Asia-Pacific, NorthStandard, adds: “At 6.99/10, Quarter 2 of 2024 marks a small increase from 6.94/10 in Q1 2024. This rise is a reflection that seafarers’ happiness is stabilising and attests to the ongoing efforts and attention to enhance seafarer wellbeing. This quarter also registered a higher female participation rate at 15% from 9% last quarter.

“Although the data indicates improvements across several areas, there remains room for improvement in satisfaction levels for connectivity, health and fitness. NorthStandard will continue to work alongside international organisations to

advocate for seafarers worldwide and play our part in maintaining this positive momentum.”

Finland’s Groke Technologies is supporting calls made by flag states and shipowners for the International Maritime Organization to withdraw MSC/Circ.733 and other circulars, allowing for the reintroduction of trials in which a ship’s Officer of the Watch (OOW) acts as the sole watchkeeper in periods of darkness.

Groke’s support follows the submission of documents by the Netherlands, Germany, and the International Chamber of Shipping (ICS) that propose the revocation of MSC/Circ.566, MSC/Circ.733 and MSC/ Circ.867 that prohibit such trials so that the maritime autonomous surface ship (MASS) regulatory framework keeps pace with rapidly evolving technology.

Prior to publication of MSC/ Circ.733 in June 1996, ship operators were permitted to carry out trials in accordance with the requirements set out in MSC/Circ.566, adopted in 1991.

However, while the results of initial trials onboard thirty or so ships indicated that a sole watchkeeper provided “at least the same degree of safety and pollution prevention” as traditional night-time watchkeeping arrangements, Administrations were called upon to discontinue the trials indefinitely.

“We are of the same view as that put forward by the Netherlands, Germany, and the ICS, said Groke Technologies’ founder and CEO Juha Rokka. “Initial concerns that only one watchkeeper adversely affects navigational and environmental safety have been disproven with today’s advanced AI-based situational awareness technology.”

In the MSC 107/5/5 document submitted in March 2023, it states “new means of detection technology have emerged which may possibly surpass human detection capabilities”.

The Netherlands, Germany and the ICS further that new technologies may well serve as alternative methods of performing specific duties or satisfying

the arrangements prescribed by the STCW Convention, which would provide at least the same degree of safety, security and pollution prevention as provided by STCW regulation I/13.

“Navigational safety technology has advanced significantly in the 25 years since MSC/Circ.733. We now need to address whether an additional watchkeeper at night is required or not,” Rokka says. “With current technology, the OOW could have far greater all-round visibility, day and night, that may not be picked up by the human eye. Further studies and trials are required.”

All parties believe that continued prohibition of solo watchkeeping trials could hamper MASS trials and prevent the adoption of new technology.

The current requirement for an additional watchkeeper at night also has an impact on seafarer wellbeing, according to Niels van de Minkelis, Nautical and Technical Affairs Director at the Royal Association of Netherlands Shipowners.

“Our members believe the introduction of new technology capable of supporting the Officer of the Watch not only helps improve navigational safety by mitigating risks associated with human error, but replacement technology that surpasses human detection capabilities in periods if darkness also provides another crew member available for daytime duties, which will reduce seafarer stress and increase their overall well-being

A one-man bridge operation during periods of darkness was also supported in a separate document submitted by Liberia in September.

The Maritime Safety Committee has instructed the HTW Sub-Committee to consider the documents as a priority when it meets in February 2025.

The International Association of Dry Cargo Shipowners (INTERCARGO) has submitted proposals to the International Maritime Organization (IMO) calling for a review of the Carbon Intensity Indicator (CII) at the 82nd session of the Marine Environment Protection Committee (MEPC 82), being

held between 30th September and 4th October at the IMO Headquarters in London.

Drawing on extensive studies that analysed data from over 5,600 bulk carriers, INTERCARGO has highlighted several key issues with the current CII system:

Impact of idle time: The studies show a clear correlation between increased idle time and poorer CII ratings, particularly for smaller vessel sizes. This idle time, which includes periods in port or at anchorage, is often beyond the vessel’s control.

Perverse incentives: The current CII framework may inadvertently encourage ships to run their main engines unnecessarily, for example when waiting at anchorage, potentially increasing overall emissions while improving their CII rating.

Inconsistent efficiency indicators: Vessels with E ratings often have lower average CO2 emissions compared to those rated A to D, suggesting the CII does not accurately reflect a vessel’s true efficiency.

Size-based disparities: Smaller bulk carriers, especially in the Handysize and Supramax/Ultramax segments, show a higher percentage of D and E ratings compared to larger vessels.

In light of these findings, INTERCARGO has proposed that the IMO:

Review and adjust the CII to better reflect a vessel’s true energy efficiency, rather than, by implication, reflecting the efficiency of a port or other factors outside the control of a ship.

Implement a system that further incentivises overall GHG emission reduction, rather than potentially resulting in encouraging behaviour that improves ratings but increases total emissions.

Consider a multi-phased approach to refining the CII, starting with solutions based on current data and progressing to more refined measures as additional data becomes available.

Dimitris Monioudis, vice-chairman of INTERCARGO’s Technical Committee, emphasised the rigour of the analysis underlying these recommendations: “Our proposals are grounded in a comprehensive examination of verified

IMO Data Collection System data from 2022. This wasn’t just a cursory review – it involved meticulous analysis of over 5,600 bulk carriers, conducted in collaboration with three major classification societies: ABS, Bureau Veritas, and DNV. This level of scrutiny provides a robust foundation for our recommendations and underscores the urgent need for a review of the current CII system.”

INTERCARGO chairman, Dimitris Fafalios, added: “The current CII framework, while well-intentioned, may be leading us down a path which contradicts our ultimate goal of reducing overall emissions. We’re seeing situations where ships might actually increase their total emissions to improve their CII rating. This is clearly not the outcome we’re aiming for so it is crucial that we refine this system to ensure it truly incentivises energy efficiency and emissions reduction across our industry.”

INTERCARGO has urged the MEPC’s Working Group on Air Pollution and Energy Efficiency to examine how the CII can be adjusted to better align with the IMO’s decarbonisation goals for global shipping.

The Blue Sky Maritime Coalition (BSMC) has released a new report titled, Navigating the Complex Landscape of Onboard Carbon Capture Solutions, which offers insights on carbon capture technologies as well as the potential adoption of onboard carbon capture in the North America market. BSMC’s Technology, Infrastructure & Fuels Workstream conducted desk research and authored this comprehensive report.

The latest report serves as a high-level roadmap, helping navigate industry through the complex landscape of evaluating onboard carbon capture solutions. It underscores the urgency of addressing carbon emissions in maritime operations and presents onboard carbon capture as a promising but underdeveloped option that requires collective action for technological advancement, infrastructure setup, and policy support.

“We believe that carbon capture will be a critical component of maritime decarbonization in North America,” said David Cummins, BSMC President and CEO. “This publication serves as a call-to-action to industry, detailing the foundational elements needed as well as describing what technical and commercial success looks like for onboard carbon capture.”

The report addresses three important questions around the evaluation and implementation of onboard carbon capture solutions:

» What are the prerequisites for successful implementation of onboard carbon capture in the North American maritime sector?

» What does success look like for companies that implement onboard carbon capture?

» How do we make onboard carbon capture a reality?

The report goes further to outline three crucial prerequisites for the successful implementation of carbon capture, utilisation and storage in the maritime sector: technology readiness; availability of storage; and market incentives. It considers the need for both infrastructure and technology to progress in parallel.

To read more, download a copy of the report at: bluesky-maritime.org

For more information, contact: technology@blueskymaritime.org

Daphne Technology and Williams have announced collaboration on the US Department of Energy’s (DOE) Methane Emissions Reduction Program (MERP) grant. This partnership underscores both companies’ commitment to reducing methane emissions.

As part of this collaboration, Daphne Technology and Williams will leverage their combined expertise to advance methane abatement technologies that align with MERP’s goals. The programme, designed to reduce methane emissions in the exhaust of natural gas engines (aka ‘slip’), aims to drive innovation and deploy cutting-edge solutions to significantly reduce greenhouse gas emissions.

As the primary applicant on the MERP grant, Daphne Technology commits to provide its SlipPure system for field demonstration on Williams’ natural gas engines at multiple locations across the United States. In addition to providing access to their natural gas engines, Williams will install and operate the SlipPure systems.

“As demand for natural gas accelerates, Williams is dedicated to advancing the decarbonization of our industry through various initiatives, including the use of innovative technology,” said Vice President of Williams New Energy Ventures, Jaclyn Presnal. “We are excited to partner with Daphne on this grant and are optimistic we will have the opportunity to pilot this technology and eventually adopt it across our business to help meet our climate goals and those of our customers.”

”Partnering with Williams on the MERP grant will not only help us accelerate commercialization of our SlipPure product, it also allows us to work with a company on the forefront of methane emission reduction,” said Jamie Brick, Managing Director North America at Daphne Technology. “It is great working with Williams. Their expertise and commitment to the environment and innovation is impressive. “

When cars, planes, ships or computers are built from a material that functions as both a battery and a load-bearing structure, the weight and energy consumption are radically reduced.

A research group at Chalmers University of Technology in Sweden is now presenting a world-leading advance in so-called massless energy storage – a structural battery that could halve the weight of a laptop, make the mobile phone as thin as a credit card or increase the driving range of an electric car by up to 70 percent on a single charge.

“We have succeeded in creating a battery made of carbon fibre composite that is as stiff as aluminium and energy-dense enough to be used commercially. Just like a

human skeleton, the battery has several functions at the same time,” says Chalmers researcher Richa Chaudhary, who is the first author of a scientific article recently published in Advanced Materials.

The research group has further developed its concept to increase both stiffness and energy density. The previous milestone was reached in 2021 when the battery had an energy density of 24 watt-hours per kilogramme (Wh/kg), which means roughly 20 percent capacity of a comparable lithium-ion battery. Now it’s up to 30 Wh/kg. While this is still lower than today’s batteries, the conditions are quite different. When the battery is part of the construction and can also be made of a lightweight material, the overall weight of the vehicle is greatly reduced. Then not nearly as much energy is required to run an electric car, for example.

“Investing in light and energyefficient vehicles is a matter of course if we are to economise on energy and think about future generations. We have made calculations on electric cars that show that they could drive for up to 70 percent longer than today if they had competitive structural batteries,” says research leader Leif Asp, who is a professor at the Department of Industrial and Materials Science at Chalmers.

When it comes to vehicles, of course, there are high demands on the design to be sufficiently strong to meet safety requirements. There, the research team’s structural battery cell has significantly increased its stiffness, or more specifically, the elastic modulus, which is measured in gigapascal (GPa), from 25 to 70. This means that the material can carry loads just as well as aluminium, but with a lower weight.

“In terms of multifunctional properties, the new battery is twice as good as its predecessor – and actually the best ever made in the world,” says Leif Asp, who has been researching structural batteries since 2007.

There is still a lot of engineering work to be done before the battery cells have taken the step from lab manufacturing on a small scale to

being produced on a large scale for technology gadgets or vehicles.

“One can imagine that credit card-thin mobile phones or laptops that weigh half as much as today, are the closest in time. It could also be that components such as electronics in cars or planes are powered by structural batteries. It will require large investments to meet the transport industry’s challenging energy needs, but this is also where the technology could make the most difference,” says Leif Asp, who has noticed a great deal of interest from the automotive and aerospace industries.

Structural batteries are materials that, in addition to storing energy, can carry loads. In this way, the battery material can become part of the actual construction material of a product, which means that much lower weight can be achieved on, for example, electric cars, drones, handheld tools, laptops and mobile phones.

The developed battery concept is based on a composite material and has carbon fibre as both the positive and negative electrodes – where the positive electrode is coated with lithium iron phosphate. When the previous battery concept was presented, the core of the positive electrode was made of an aluminium foil.

The carbon fibre used in the electrode material is multifunctional. In the anode it acts as a reinforcement, as well as an electrical collector and active material. In the cathode it acts as a reinforcement, current collector, and as a scaffolding for the lithium to build on. Since the carbon fibre conducts the electron current, the need for current collectors made of copper or aluminium (for example), is reduced, which reduces the overall weight even further. Nor are any socalled conflict metals such as cobalt or manganese required in the chosen electrode design.

In the battery, the lithium ions are transported between the battery terminals through a semi-solid electrolyte, instead of a liquid one, which is challenging when it comes to getting high power and for this more research is needed. At the same time,

the design contributes to increased safety in the battery cell, through reduced risk of fire.

The research has been funded by the Wallenberg Initiative Materials Science for Sustainability (WISE) programme.

Daphne Technology, a leader in climate deep tech, announces the approval of its pioneering carbon credit methodology by Gold Standard. This milestone directly targets reducing methane emissions from internal combustion engines using any methane-rich fuel.

Methane is a powerful greenhouse gas (GHG) with a global warming potential (GWP) 28 times that of carbon dioxide (CO2) over a 100-year period. It is responsible for at least a quarter of the current global warming. Unlike CO2, fossil-origin methane has a much shorter atmospheric lifetime, with a GWP of 82.5 over a 20-year period, so reducing methane emissions can result in quicker climate benefits. Therefore, reducing methane emissions has gained increasing attention in recent years.

Daphne Technology’s methodology targets this critical area, focusing on reducing methane emissions to help achieve climate goals and limit the rise in global temperatures.

Key Features of the “Methodology for Reducing Methane Emissions from Combustion Engine Exhaust” Carbon Credit Methodology: Advanced Methane After-treatment: Methane emissions from combustion

emissions are abated using an advanced after-treatment such as Daphne’s SlipPure technology.

Real-Time Measurement: The methodology requires high-accuracy, real-time measurement before and after the abatement system ensuring a robust monitoring of the greenhouse gas emission and its reduction. Daphne’s PureMetrics is one such measurement system ensuring a robust verification of the GHG emission and its reduction.

United Nations Framework Convention on Climate Change (UNFCCC) Approved Methodological tools: The Clean Development Mechanism (CDM) of the UNFCCC developed many carbon credit methodologies. In the process, they also developed a number of “Methodological Tools” that can be used as building blocks to simplify other methodologies. Several CDM methodological tools are used in this methodology. For example, Tool 8 is used to calculate the exact dry tonnes of CO2e emitted and abated. The use of a CDM Tool ensures that the calculation of GHG emissions abated is based on a widely recognised model that is well accepted by the international community and well understood by the scientific community.

Quantification and Verification: Provides a robust framework for quantifying, monitoring, and verifying methane emission reductions, adhering to principles of transparency and integrity.

Economic Incentives: Enables companies to generate carbon credits, which can be traded in global markets, providing financial incentives for adopting greener practices.

Broad Applicability: Designed for use in maritime and land-based applications involving internal combustion engines, ensuring wide-scale impact on methane emission reductions.

The Gold Standard ensures that carbon credit projects deliver genuine and measurable climate and sustainable development.

When maintained in good operational condition, a scrubber system will not only serve you well throughout the lifetime of your ship, but also reduce operational expenses.

PureteQ specialises in designing and maintaining scrubber systems. With established offices in Europe and Asia and extensive expertise in exhaust gas cleaning, PureteQ is a leading service provider for all brands of scrubbers worldwide. PureServ, the certified service organisation of PureteQ, assists shipowners and operators in safeguarding the continuous operation, reliability, and MARPOL compliance of scrubbers with its team of experienced marine engineers.

While PureteQ Maritime Scrubber Systems are known for their high energy efficiency, even less efficient ones can be fine-tuned to lower electrical consumption caused by excessive scrubbing.

To support this effort, PureteQ offers all service agreement clients access to Pure-SPOT, a web-based Scrubber Performance Optimisation Tool that plays a crucial role in reducing energy consumption on all scrubber systems.

Data is automatically uploaded to a cloud-based platform for optimising and reporting environmental performance across ships equipped

with scrubbers to assist shipowners and operators in making their operations more environmentally friendly, lowering operational expenses, and enhancing the Carbon Intensity Indicator (CII) rating.

To combat climate change and facilitate the transition towards a more sustainable and low-carbon future, lowering the carbon intensity of the shipping industry is key. Most ships are forced to lower their speed by derating engines, which in turn means less trade and more focus on saving costs. Cost of energy in any form is very high and cost of lowcarbon fuel even higher.

Furthermore, it may take years before alternative fuel and onboard carbon capture technologies become available for shipping. In the meantime, we must be energy efficient in every way possible.

A PureteQ Service Agreement is all you need to realise the full potential of your scrubber system. Based on the ship’s operational pattern and crew proficiency level, it is tailor-made to meet specific needs. Included (but not limited to) are:

» 24/7/365 hotline service

» Spare part management

» Training of crew on-site or remote via our Internet for Remote Assistance Services (IRAS) – a complete hardware and software installation for ship-wide wifi access and real-time support

» Operational advice and reporting

» Certified calibration and sensor replacement programme

*Note that a scrubber’s pH sensor requires calibration every three

months, while gas analysers need calibration once a year. Through our sensor replacement programme, you will be notified well in advance of when calibration is due. You will receive a newly calibrated sensor before sending the old one to us for refurbishment.

Scrubbers installed around 2018 have operated for thousands of hours, making motors, dampers, sensors, and moving parts due for overhaul or replacement.

The most economical approach is to inspect, replace, or refurbish these parts. Some parts have long lead times, so arranging a pre-drydocking inspection well before the scheduled drydocking is prudent.

This inspection assesses all components and structural conditions, creating a work scope for the yard, crew, suppliers, and stakeholders. PureteQ offers these inspections for any scrubber system globally, tailored to the shipowner’s convenience.

PureServ is a registered trademark and certified service organisation that provides service and support to all scrubbers and sensors including shipment of critical spare parts and replacement of compliance equipment such as continuous emission monitoring systems –CEMS (gas analysers) and water monitoring systems (WMS).

PureteQ A/S, Sverigesvej 13, 5700 Svendborg, Denmark, pureteq.com

CEO Anders Skibdal, anders@pureteq.com (+45) 40 17 14 00

Opsealog, a provider of data integration and analysis services for the maritime and offshore industry, has published a new white paper that underscores the urgent need for data standardisation across the sector.

Analysing ongoing industry initiatives in the marine offshore sector, the report found that data standards can play a central role beyond reporting requirements under IMO and EU regulations and will be essential to maximise the value delivered by onboard digitalisation to boost operational and environmental performance.

Titled Creating Value from Data Standardisation, the white paper calls for the development and implementation of data standards as a much-needed revolution, comparable to how the shipping container transformed cargo handling in the 1950s. It lays out how this change is already under way through industry initiatives such as the Smart Maritime Council and Energy LEAP, which have both made strides

in creating standardised datasets for vessel reporting and emissions tracking, respectively.

Despite these early examples of progress, the research describes persisting fragmentation as a key obstacle, with much of the data currently collected in the shipping and offshore sector not currently creating value due to a lack of standardisation. It also identifies the need for common formats as critical to reducing seafarer workloads amid growing reporting requirements.

The report also highlights how a more standardised data environment is an opportunity to bring about a new level of transparency between owners and charterers that will change the bidding process, support the monitoring of contractual obligations, and improve conflict resolution. Furthermore, as companies face increasing pressure to report their environmental, social, and governance (ESG) performance, unified reporting standards will provide the tools needed to meet these demands efficiently and effectively.

Arnaud

Dianoux, Founder and

Managing Director at Opsealog, said: “Data standardisation is about more than compliance: it is an essential baseline for the industry to fully harness the power of digitalisation. Just as English is the international language of shipping and trade that enables people from all over the world to communicate and collaborate, data standards can become the international language of digital communication and collaboration.

“This is an opportunity not to be wasted, especially as the industry faces growing ESG pressure and new regulatory requirements. Data standards will be the building blocks to enable companies to collect, integrate, and make sense of their data. This paves the way for real-time monitoring, predictive analysis, datadriven decision-making and new fuels analysis, enabling owners to build strong businesses for the green and digital era ahead.”

The full white paper is available for download at: https://opsealog. com/creating-value-from-datastandardisation/

The use of exhaust gas cleaning systems on board vessels has been a popular method in recent times for maritime companies to reduce their carbon footprint

The use of exhaust gas cleaning systems (EGCS) or scrubber systems is not necessarily as straightforward as one might expect and as P&I club West recently pointed out, has resulted in fines for improper use of such systems.

As Dmitry Kisil, Senior Loss Prevention Officer at the club said recently, West has been made aware of cases where vessels were fined by local authorities for improper use of onboard EGCS.

“EGCS is one of the alternative methods of compliance with MARPOL Annex VI regulations. However, it is a timely reminder to the members that many countries and individual ports have banned the discharge of washwater from the use of EGCS in openloop mode in certain waters.

“When the prohibiting measure is national, then the restriction applies to inland and territorial waters as well as to the national ports. However, in other instances, the restriction can be implemented at a port level and would apply to anchorages

and berths only. The ships may be allowed to switch EGCS to the closed-loop mode or have to use a fuel compliant with relevant requirements.

“In rare cases, use of a closed-loop scrubber is also banned, and in others, so-called ‘bleed-off water’ discharge from closed-loop scrubbers may be banned explicitly.

“However, this kind of ship discharges may fall under the definition of contaminated waters and will be prohibited from being dumped overboard along with other illegal discharges,” West says.

Liability for fines imposed on a vessel may not always be covered if the discharge of hazardous substances from the vessel is not considered accidental.

“Given that the requirements on the use of EGCS differ from authority to authority and are subject to change, we recommend that shipowners always clarify with ship agents or local P&I correspondents before calling unfamiliar ports,” the club warns.

Ecospray has signed an agreement with a Greek shipowner to equip five new vessels built in a Chinese shipyard with open loop exhaust gas cleaning systems.

In order to compete with local manufacturers, Ecospray will partner with Chinese company Jiangsu Zhenhua Environmental Protection Technology Co (Zept). Ecospray will design the system and supply sensitive components, while Zept will manufacture and source locally the remaining items to complete the scope of supply.

After equipping the major part of the fleet with Ecospray’s exhaust gas cleaning systems (EGCSs) and conducting several joint R&D projects, this is the continuation of a long-term collaboration with one of the leading dry bulk shipping companies with the aim to reduce emissions from his fleet.

This collaboration will ensure high quality scrubbers at competitive prices for the Far East market and will strengthen Ecospray’s position in Asia. In addition, investing in EGCS solutions remains crucial as a first

step to meeting the great challenge of 2050: scrubbers are a prerequisite and a fundamental starting point for ships that want to embrace new technologies such as onboard carbon capture.

Technology group Wärtsilä has signed a six-year Lifecycle Agreement with Malaysia-based Nautica Ship Management. The agreement covers two vessels, the MTT Saisunee and MTT Senari, and is designed to ensure that the ships’ exhaust gas treatment systems operate at maximum efficiency.

The vessels are feeder container vessels and are fitted with Wärtsilä hybrid scrubber systems.

“It is central to our commitment to sustainable operations that the scrubber systems on these vessels are working with optimal efficiency,” says Azreen Nor Bin Mohamad, Senior Technical Superintendent of Nautica Ship Management. “This enables the ships to comply with the relevant environmental regulations. We know Wärtsilä well, and our experience with their agreements on other vessels in

our fleet has been excellent. It was natural, therefore, that we continue this relationship for these two vessels.”

The scope of the agreement includes remote access capabilities. This feature enables seamless monitoring and troubleshooting of the exhaust gas cleaning systems installed on the two vessels, ensuring prompt response and minimal downtime.

“Our 24/7 service, and especially the remote access feature, gives us the opportunity to provide immediate support and troubleshooting for these vessels, while delivering important cost savings,” comments David Xu, Wärtsilä Area Sales Manager in Singapore.

Wärtsilä’s range of Lifecycle Agreements provide long-term cost predictability and availability by using data-driven technical support and maintenance at every step, from planning to execution. Ship operators benefit from proactive support and recommendations by experts at Wärtsilä Expertise Centres, who help to optimise maintenance intervals according to actual needs while preventing unexpected downtime.

Highest wind yield per square meter

Leading global developer and provider of rotor sails for the shipping industry, Anemoi Mariine Technology offers the decarbonisation technology of choice for shipowners looking for an immediate impact amid an area defined by tightening and looming emission regulations and targets.

With such regulations at the forefront of many shipowners’ minds, vessel efficiency has become one of the primary drivers for shipping players to ensure their vessels are on credible pathways to meet decarbonisation targets.

Carbon reduction targets from the International Maritime Organisation are calling for CO2 emissions reductions to average at least 40% by 2030, with an overall ambition to reach net-zero greenhouse gas (GHG) emissions by or around 2050.

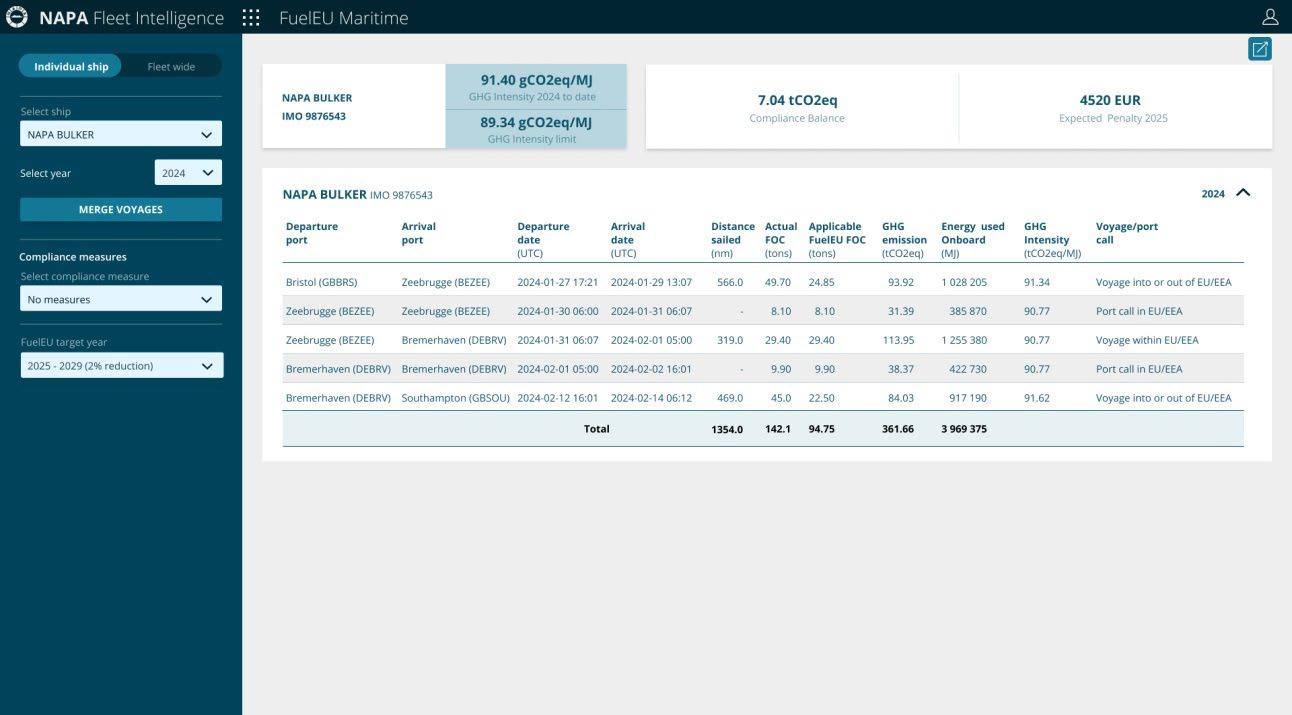

The introduction of FuelEU, the Carbon Intensity Indicator (CII) and the Energy Efficiency Existing Ship Index (EEXI), which will only grow tighter over the coming years, are pushing shipowners to look for immediate efficiency gains to keep their vessels within acceptable levels.

Rotor sails are proving to be one of the fastest-growing technologies for shipowners looking for that immediate improvement in vessel efficiency. These striking and imposing cylinders, also known as Flettner Rotors, have been making headlines as the leading wind-powered alternative propulsion method for commercial vessels owing to their versatility, effectiveness and ability to be tailored to ensure each vessels runs as efficiently as possible.

“With shipowners and managers looking to minimise their carbon emissions while maintaining full operations, rotor sails are an established and proven way of

providing auxiliary propulsion and reducing fuel consumption,” says Kim Diederichsen, Chief Executive Officer at Anemoi.

“Wind propulsion has found its place in modern shipping. With pressure growing on shipowners to go green, rotor sails are a visible and viable decarbonisation technology that enables vessels to save fuel and comply with crucial emissions regulations,” he adds.

Shipping has a well-written history of taking advantage of wind power to move cargo around the world. Although the introduction of dieselpowered engines removed the need for traditional sails, modern rotor sails

have brought the power of wind back to daily vessel operations.

Harnessing the power of an aerodynamic phenomenon called the Magnus Effect, rotor sails utilise wind power during favourable conditions to propel the ship forward, enabling the vessel to limit the use of its traditional engine, allowing it to cut fuel usage and carbon emissions, all while maintaining vessel speed and efficiency.

This type of technology is suitable for almost all commercial vessel types, as well as for both newbuilds and retrofits. Crucially, rotor sails are a compact decarbonisation technology, in comparison to the overall length and tonnage of a traditional vessel, making the efficiency gains and fuel reduction

benefits much more impressive than its counterparts.

“With a rotor sail, for the small amount of power put in, shipowners can roughly get eight to 10 times as much power back through renewable wind energy,” says Luke McEwen, Anemoi’s Technical Director.

Bulk carriers have been harnessing Anemoi’s rotor sails as a means to improve vessel efficiency for a number of years now. This is due to the large areas of unused deck space that bulk carriers have available, alongside the simplicity of installation of Anemoi rotor sails.

However, complementing the rotor sails with a suitable and effective deployment system is just as important as the cylinders themselves. With this in mind, Anemoi offers a flexible array of deployment setups that are tailored to each individual vessel to enable the rotor sails to operate at their maximum efficiency with no impact on day-to-day operations, such as cargo loading/unloading and crew visibility.

First, the rotor sails can be fixed mounted in place to the deck, a setup that is particularly useful for tankers, ferries and ro-ros as their position will not interfere with cargo operations.

Second, a custom rail system can be installed to allow the rotor sails to move along or across the deck when the ship is in port, enabling effective crane access during loading and unloading operations.

Finally, Anemoi offers its bespoke folding deployment system that enables the rotor sails to be folded down from the vertical, limiting impact on portside operations and air draught.

The varying types of rotor sail design, in collaboration with a bespoke deployment system, means there is an ideal combination for each vessel to ensure they can use rotor sails effectively, meet critical decarbonisation targets and ensure that vessel operations are not impeded.

“At Anemoi, we understand that cargo operations are king for vessel owners. However, smart integration methods and tailored setups means we can eliminate any kind of interruption

to daily cargo operations, either at sea or at berth, when utilising rotor sails to ensure the vessel operates at its most efficient,” says McEwen.

It has been a busy few years for Anemoi as demand for its awardwinning rotor sails ramps up.

In August 2023, TR Lady, an 82,000dwt Kamsarmax bulk carrier owned by TR Lady Shipping and chartered by Cargill, was retrofitted with three 24m-tall rotor sails, alongside its rail deployment system.

The vessel, which then underwent its first voyage from China to Australia with the newly installed sails, is expected to save more than 10% fuel and emissions annually following the installation.

In November 2023, Brazilian mining giant Vale announced it was installing five Anemoi rotor sails to Sohar Max, a 400,000dwt valemax VLOC, along with Anemoi’s bespoke folding deployment system, to save up to 6% in fuel and cutting carbon emissions by 3,000 tonnes annually.

More recently, in July 2024, Berge Bulk’s Berge Neblina, a 388,000dwt valemax ore carrier completed its first voyage from China to Brazil following the installation of four Anemoi rotor sails and its bespoke folding system. In this instance, the vessel is expected to save up to 8% in carbon emissions annually directly as a result of the rotor Sail installation and help the vessel comply with CII and EEXI regulations.

Demand for Anemoi’s rotor sail technology is high. As such, Anemoi has upped its production capacity to be able to install up to 50 rotor sails per year.

However, it is not just bulk carriers where Anemoi is looking to improve vessel efficiency. In October 2023, Anemoi signed a deal with HudongZhonghua Shipbuilding Group in China to develop a range of rotor sails designs for liquefied natural gas (LNG) carriers. The project is aimed at boosting the confidence of rotor sail technology for gas carrier owners and enable the smooth introduction of a new generation of efficient and environmentally friendly LNG carrier designs.

With decarbonisation high on shipping’s agenda, the credibility of rotor sails as an off-the-shelf solution to immediately improve vessel efficiency is high. According to the UK’s Clean Maritime Plan, the wind-propulsion technology market is expected to reach £2bn by 2050, a substantial rise from the projected £300m in 2020s.

This level of growth is tied directly to the confidence shipowners have in rotor sails and the ability for their developers, such as Anemoi, to show how their vessels can reap the maximum level of efficiency for minimal investment.

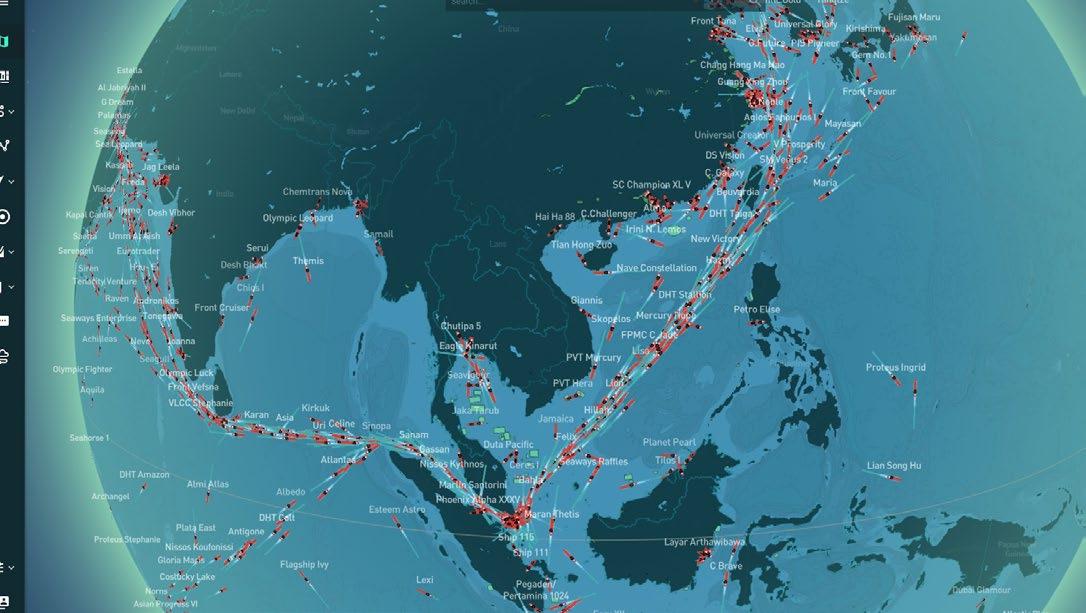

The growing use of data in modern shipping operations to drive decisionmaking is becoming more widespread and Anemoi continues to leverage its extensive datasets to inform customers how to most effectively utilise rotor sails and what setup would be the most advantageous.