IN THE PINK

How the latest coatings keep ships in full health SMART

FIT

Why artifical intelligence is a trusted option on board CALLS TO ACTION

Stay ahead of the latest environmental regulations

How the latest coatings keep ships in full health SMART

Why artifical intelligence is a trusted option on board CALLS TO ACTION

Stay ahead of the latest environmental regulations

Stay ahead. Stay compliant. Stay efficient.

Compliance should not disrupt your business. Partner with us to navigate regulatory challenges and optimize the performance of your fleet. Whether you are investing in new builds or retrofits, with Ecospray’s EGCS and Carbon Capture solutions, you can reduce pollutants and lower your carbon footprint.

Turn compliance into a long-term advantage with our Service and Training programs that ensure your team operates with confidence and efficiency.

Decarbonization

Carbon Capture with Amine | Carbon Capture with Calcium Hydroxide | MCFC Pollution Containment

EGCS | DeNOx SCR | Methane slip reduction | WESP Discover our Technologies for the Planet

Sandra Speares Editor, Clean Shipping International

Safety continues to be one of the most important elements of the onboard maritime experience. It is essential that those on board do not lose sight of the correct ways of working, ensuring the safety of all crew. Today, artificial intelligence (AI) is being employed to improve onboard safety, as well as the eco-friendly performance of vessels.

In this edition of Clean Shipping International, we speak to Osher Perry, CEO of maritime tech company ShipIn about the role that AI plays in the shipping industry (see page 62). India, for example, is one country that has fully embraced the role AI can play and has put in place systems on board its vessels to improve safety procedures.

There are plenty of well-documented incidents at sea where seafarers find themselves in high-risk situations, in cases where they may be overloaded with work. With that in mind, one of the most important factors is ensuring that any AI systems are serving the crew and not obstructing them when they are trying to do their job.

With safety comes improved environmental performace. In addition to the role of AI in the maritime industry, we take a look in this edition at how environmental efficiency is being enhanced within the various sectors of shipping, including alternative fuels, wind power, paints and coatings, and the handling of ballast water in a safe manner.

We hope that you enjoy reading this edition of Clean Shipping International

With a mission to create cleaner air by developing innovative green solutions, we aim to set new standards for sustainability towards a cleaner and purer atmosphere.

ME Production has for more than 10 years been a pioneering force driving global change towards a cleaner and healthier future. Our solutions cover exhaust gas cleaning, waste heat recovery and green propulsion all supported by our worldwide services operating out of Denmark, Panama, Singapore and Shanghai.

Clear Smart Emission Guard - our next generation carbon-capture ready scrubbers systems available for both retrofit, new building and conversions.

HeatSmart - our waste heat recovery solution is an eco-friendly upgrade to all vessels aiming to eliminate the use of oil-fired boilers in port.

Hybrid Marine Gearbox - our flexible, cost-efficient and safe gearbox solution offering best in class environmental and operational benefits.

Superior Service - Our “Time-2-Service” concept ensures second-to-none service quality offering high quality reporting and reliable delivery times.

Editor: Sandra Speares speares1@aol.com

Project Director: Jonathon Ferris jonathon.ferris@ cleanshippinginternational.com

Sub-editor: Samantha Robinson sam.robinson.journalist@ gmail.com

Publisher: Bill Robinson production@ cleanshippinginternational.com

Designer: Justin Ives justindesign@live.co.uk

Published by Maritime AMC, Clean Shipping International supports Clean Shipping Initiatives.

The views expressed in Clean Shipping International are not necessarily those of Maritime AMC unless expressly stated as such and disclaim any responsibility for errors or omissions or their consequences or for advertisements contained in this magazine and has no legal responsibility to deal with them.

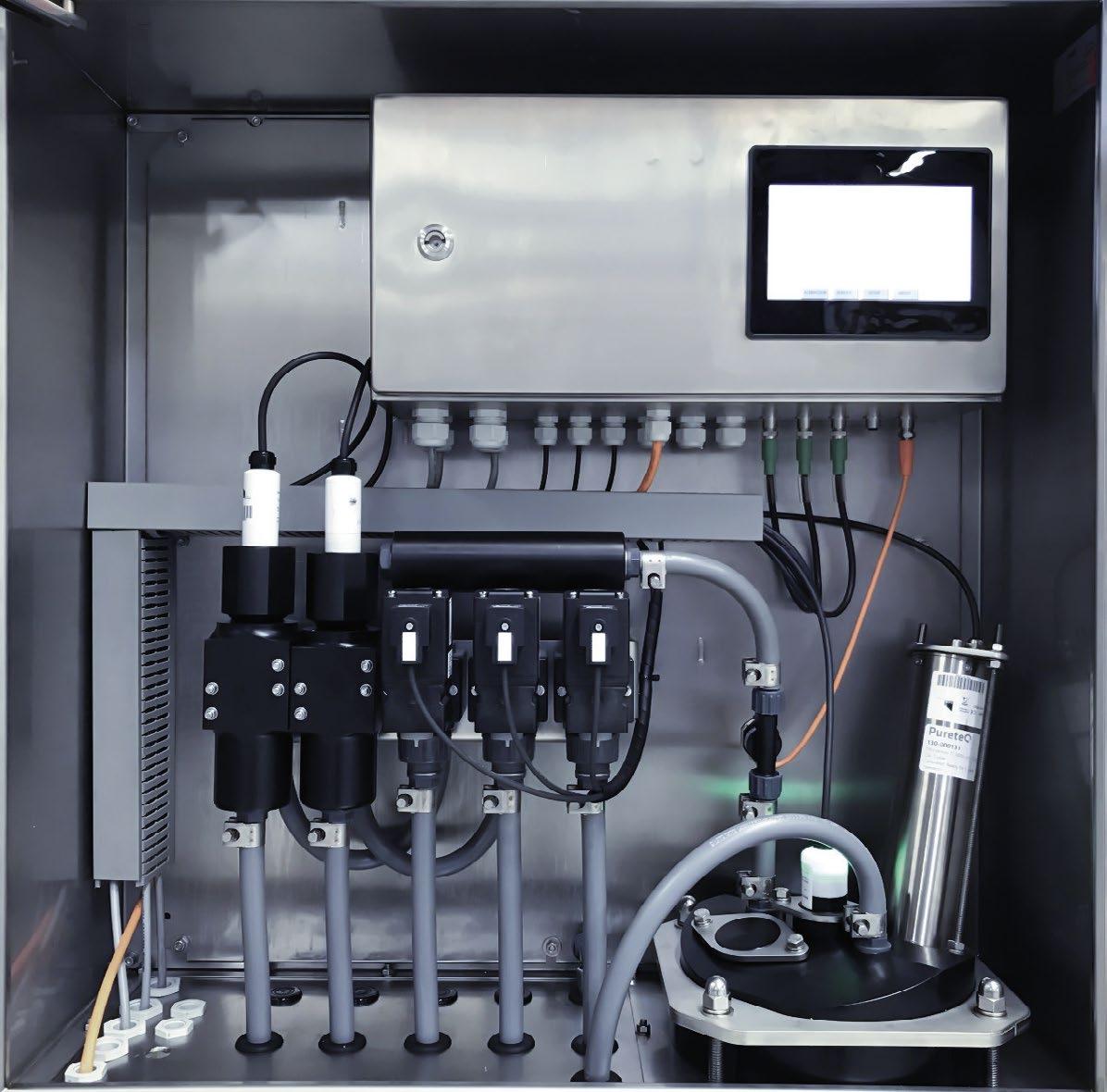

maintaining built-to-fit maritime scrubbers including automated control and monitoring systems with remote accessibility and an energy optimisation programme.

The PureteQ WMS013 Water Monitoring System is designed for simple installation and operation with only one central monitoring cabinet, reducing sensor maintenance costs significantly. The control system and related software ease retrofitting to any existing EGCS/EGR.

ClassNK and BV approved.

» p12

» p37

» p49

» p53

Sandra Speares on how artificial intelligence is enhancing safety and environmental performance

Don Gregory, Director, Exhaust Gas Cleaning Systems Association

All the latest news and views from across the globe

Further regulation relating to the use of open loop scrubbers has been introduced by various countries, notably in Scandinavia

Paints, coatings and hull cleaning devices have a major role to play in improving the efficiency of shipboard operations

The US Navy is carrying out trials on French company BIOUV Group’s state-of-the-art ballast water treatment system

39 Viewpoint: Gary Rogers, CEO of Magnomatics

If nuclear power was a nonstarter politically in the past, it is now established as an alternative fuel in the shipping sector

The latest high-tech solutions not only limit emissions, but save shipowners and operators time and money

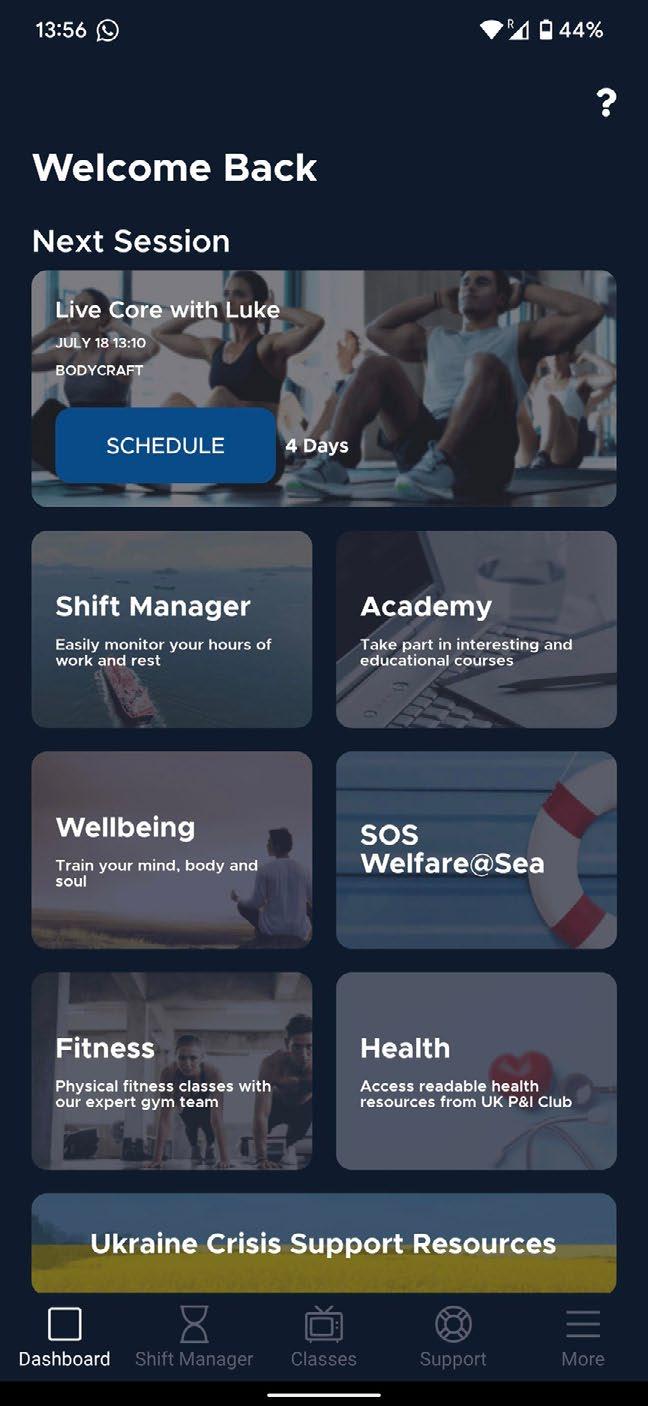

The latest Seafarers Happiness Index has revealed a drop in seafarers’ happiness – a reminder of the persistant challenges that industry workers face

Managing and understanding regulation in the industry is of utmost importance when addressing climate change

60 Viewpoint: Majeure

We talk to Osher Perry, Chief Executive of maritime tech firm ShipIn on the role of AI in the industry

Dates for your calendar

Telephone:

Protea manufactures equipment and provides qualified engineers for onboard testing, ensuring accurate emissions monitoring, system verification, and engine efficiency analysis.

UK Maritime and Coastguard Agency

European Commission Directive 2008/67/EC of 30th June 2008, amending Council Directive 96/98/EC on marine equipment (4th Amendment) Annex 2, A2/2 1On board NOx monitoring and recording devices, MARPOL 73/78 Annex VI regulation 13 and the NOx Technical Code.

ATEX/IEC Protea P2000

Certificate Number:

Baseefa 18 ATEX 0060X / IECEx BAS 18.0040x Markings: II 2 G Exdb IIBT* Gb

Lloyd’s Register - Type

Approval Certificate

Protea P2000

LR Rules & Regulations for the classification of ships (July 2014) LR Test Spec No.1 (2015)

IMO Resolution MEPC 184(59) - 2009 Guidelines for exhaust gas cleaning systems

IMO NOx Technical Code (2008)

ABS- Certificate Of Product Design Assessment

Certificate Number: 24-0170173-PDA

Marine and Offshore Application continuously monitors the concentration of exhaust gas emissions from ships

Certificate of Design Assessment

Protea P2000

RINA Rules for the Classification of Ships - Part C “Machinery, Systems and Fire Protection”, Chapter 3, Section 6, Tab 1 and IMO Res. MEPC.259(68) Chapter 6 “Emission Testing” as well as the relevant requirements of Revised MARPOL Annex VI and NOx Technical Code 2008

Don Gregory Director,

Systems Association

The United Nations Conference of Parties has been meeting annually since 1995. Despite 30 years of meetings and tens of nations and thousands of people coming together at each COP, little seems to have been achieved.

Back in 2002, a graph was available that projected the total CO2 emissions per year in billions of tonne under several different socio-economic pathways. In two of the scenarios, it showed that if there was no net increase in CO2 from developed countries by 2050 the trajectory for CO2 emissions per year was nevertheless skywards off the graph.

One of the reasons is the clause that described everyone’s responsibilities, but then noted that those who had historically contributed most to CO2 emissions would have to take on the greatest obligation to reduce those emissions. Meanwhile, developing nations had a greater right to increase their net CO2 emissions in order to allow them to catch up with developed nations.

This COP’s clause was something akin to a statement used in apartheid South Africa where the arguments for segregation included the idea that different ethnicities should be allowed to develop separately. The COP version of the apartheid segregation is “Common but differentiated responsibilities” (CBDR). This is the principle of international environmental law establishing that all states are responsible for addressing global environmental destruction, yet not equally responsible.

Has this approach been part of the problem in the lack of progress with the net-zero target? Is targeting CO2 the wrong target? Certainly, there is an increasing voice being given to scientists who do not agree that there is a direct link between CO2 emissions and subsequent concentration in the atmosphere and climate change.

One of the basic arguments put forward by the doubters of the link between CO2 and climate change is that the United Nations Framework Convention on Climate Change’s (UNFCCC’s) data is never properly scrutinised or challenged by any government. It has become a sort of group think, with studies aimed to reinforce the belief rather than scrutinise the models and predictions against real-world effects.

We increasingly observe this behaviour of group-think with many environmental non-governmental organisations (NGOs) that consistently mislead the public with claims that are shallow, sensationalist and often with little or no evidence, in order to reinforce their own beliefs.

In the world of ship diesel engine exhaust emissions, sensation rather than fact has ruled the messaging from International Maritime Organization environment NGOs, as well as the EU Commission. Their actions have contributed to the implementation of regulations often on the back of false or ill-informed information that has resulted in an acceleration of climate change indicators, such as higher sea surface temperatures through the loss of ship emissions ”radiation umbrella’ effect. It has also led to a net increase in shipping CO2 emissions, due to the switch to more intensely processed fuels.

So, there should be a concern that the ambition to simply drive down the emissions of fossil carbon may not result in halting climate change and the actions being taken may also be counterproductive due to unintended consequences.

Another element that the net-zero ambition fails to address is the impact on people. The cost of many of the measures being sought to be introduced are severely impacting people’s standard of living. The argument that doing nothing will be more costly is frankly of little interest to a family who cannot afford to pay their bills and

eat healthy food. Some politicians have at last recognised this and are openly stating in conflict with UNFCCC goals (stabilise greenhouse gas concentrations at a level that would prevent dangerous human-induced interference with the climate system), that the 2050 target is unobtainable and damaging to economies.

In shipping, the EU maritime carbon taxes or penalties are forecast to cripple sea transport. On the other hand, the crippling EU regulations may be a useful driver to questions we should be asking about the current netzero ambitions.

Are carbon emissions the problem that needs solving? Are attempts to limit CO2 emissions as a singularity the wrong target to address climate change?

Back in 2000, the then Chief Executive of BP, Sir John Brown, initiated the reinvention of BP with the slogan ‘Beyond Petroleum’. But key to Sir John’s vision for BP was that he had not lost track of the reason for and the need for the existence of BP. This was explained by its corporate statement that BP is an energy company, providing heat, mobility and light.

Oil companies through the past 50 years have contributed to the

growing wealth and standards of living by ensuring energy (oil) was discovered, harvested and delivered for use/consumption at an increasingly efficient cost.

History shows that development has always succeeded where natural resources have been utilised to increase productivity and standards of living. One could add in the word ‘sustainably’ such that natural resources are used sustainably, meaning they continue to be available or re-utilised.

History also records that prohibition and stifling growth are counterproductive and always eventually fail.

Is there another approach that takes into account that CO2 may or may not contribute to climate change, but would implicitly reduce emissions of CO2 and other greenhouse gases (GHGs) while encouraging the development of lower cost energy and simultaneously ensure that available energy is effectively allocated and not wasted?

Is there an example from the shipping industry? Over many decades shipping has strived to reduce energy costs by a combination of efficiency and use of lowest cost

and practical energy sources. We can observe the latest incarnation of that continuous drive on energy cost with the take-up of exhaust gas cleaning systems and the use of high sulphur fuel oil. It has resulted in a lower cost of transport and a somewhat lower CO2 emission when compared with some of the prescriptive alternatives, such as low sulphur fuel oil or marine gas oil.

Should we look at a model that gradually encourages the continued use of less energy while also gradually billing emissions of GHGs to atmosphere? It sounds complicated. It surely will require much thought and testing to develop the framework for incentivisation.

On the other hand, the principles align with the long-term successful approach of sustainable use of resources and re-use of resources to drive increased productivity and consequent rise in standards of living.

Is it time to re-think the net-zero ambition and transfer to a human behavioural approach? As support for net zero wains, it is probably something that we should all put our minds to, to seek a framework that we can all find acceptable and willing to support.

BRITISH RED ENSIGN

SAME DAY & OUT OF HOURS REGISTRATION WORLD CLASS TECHNICAL EXPERTISE REMOTE SURVEYS

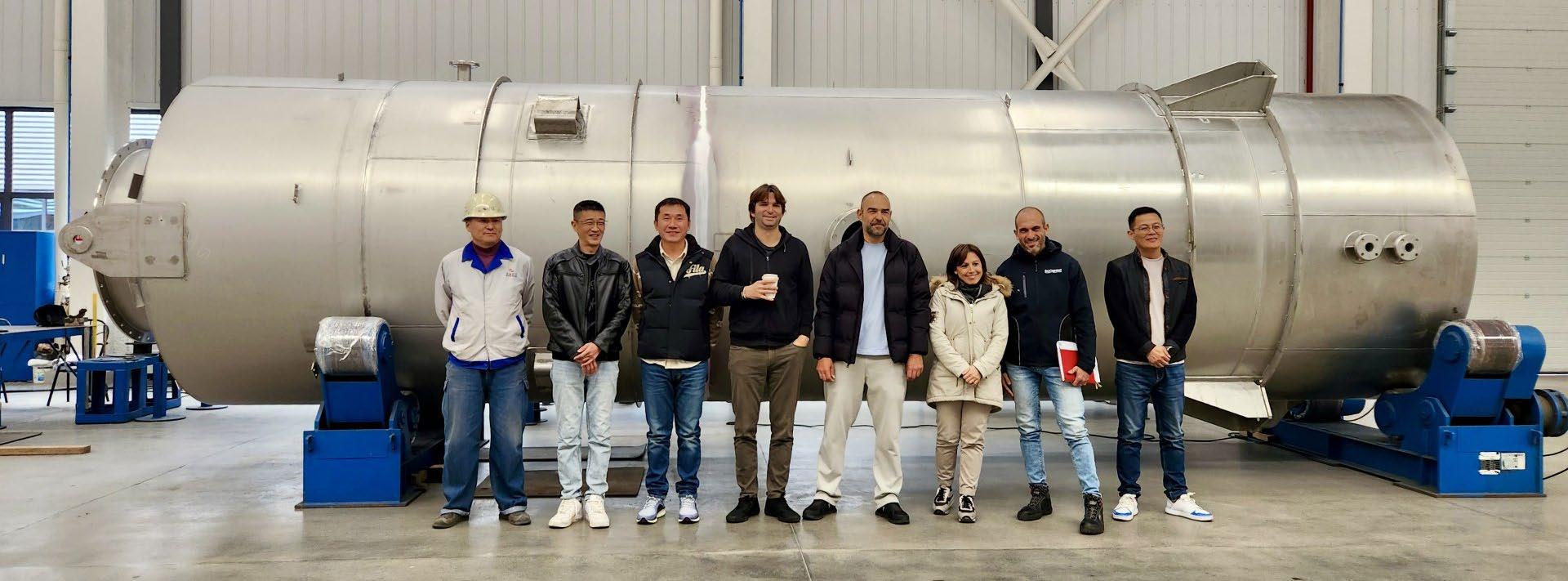

The shipping sector is evolving rapidly, driven by the need to adopt sustainable strategies in line with the 2050 targets. In this context, the leading companies are strengthening their global presence by focusing on innovation and strategic partnership to face the industry’s future challenges.

Ecospray, the specialist in integrated solutions for the sustainable reconversion of marine and land industries, has entered into a partnership with Chinese manufacturer Jiangsu Zhenhua Environmental Protection Technology (Zept), with the aim of improving competitiveness with Eastern manufacturers.

Under the agreement, Ecospray oversees the design, engineering and supply of critical system components, such as spraying nozzles, PLC and software, and water analysers. Meanwhile, Zept produces and purchases locally additional equipment and components, following Ecospray’s specifications and design guidelines.

This partnership enables Ecospray to provide its well-established, highquality exhaust gas cleaning systems (EGCS) – recognised for their top-tier materials, design and performance –at a competitive price for the Far East market.

Thanks to Zept’s robust equipment manufacturing capabilities in China and its ability to provide prompt, local support during installation and commissioning, Ecospray strengthens its foothold in the Asian market while ensuring the highest standards for its EGCSs.

Ecospray’s product portfolio includes a wide range of scrubber

solutions tailored to various needs, from open loop and hybrid systems to inline and u-type configurations. These technologies are available in multiple sizes, ranging from 1,800-5,000mm in diameter, and are designed for engine power ratings between 5 and 80 MW.

The agreement with Zept has enabled Ecospray to continue its longstanding collaboration with one of the leading dry bulk shipping companies: having already equipped the majority of the fleet with its EGCS and undertaken multiple joint R&D initiatives, Ecospray will deliver to the Greek-based shipowner five systems to be installed on new vessels under construction at a Chinese shipyard.

These vessels will be fitted with open loop EGCSs for both main engines and auxiliary systems.

The first part of this order has been completed with the successful conclusion of the Factory Acceptance Test (FAT) for the first two DeSOx towers at Zept. The tests reported results in line with Ecospray’s quality management standards.

The other EGCSs are expected to be ready between September 2025 and January 2026.

Moreover, Ecospray’s business development activities in the region are progressing. In parallel, within the framework of its collaboration with Zept, another project has taken shape and has been completed – with a different Greek shipowner – to equip a liquefied petroleum carrier with an EGCS.

Equipping a vessel with an EGCS is a proactive step toward decarbonization and a strategic move in preparing for the next generation of maritime sustainability solutions. While scrubber technology is currently essential for reducing emissions, it also plays a crucial role in enabling future advancements such as onboard carbon capture.

The presence of the EGCS as pre-treatment of the exhaust gas reduces the pollutants (for example sulphur oxides and particulate matter) and part of the uncombusted and hydrocarbons, so as not to affect the performance and lifetime of the carbon capture technology installed downstream.

Furthermore, a key advantage of scrubbers is their ability to cool exhaust gases – a necessary step for carbon capture, which requires temperatures below 50°C. This integration eliminates the need for additional cooling stages, simplifying the process.

Onboard carbon capture presents the biggest opportunity for reshaping the shipping industry.

To be ready for this sustainable transition, Ecospray has already designed, developed and tested two carbon capture technologies – based on chemical absorption with amines and calcium hydroxide – specifically for the maritime sector.

At the same time, the company is continuing to invest in developing molten carbonate fuel cell technology. This initiative is at the core of CapLab, the joint research laboratory established by Ecospray and the University of Genoa.

Given the paramount importance of decarbonization, the company is developing multiple solutions in order to be able to adapt them to different operational contexts. Factors such as ship size, type, route and onboard space significantly influence the selection of the most suitable technology.

Ecospray is ready to provide technologies to the market, but the widespread adoption of onboard carbon capture solutions depends on the acceleration of regulatory framework. The viability of investments in this technology, essential for the ecological transition, will ultimately be determined by the establishment of clear and consistent international regulations.

To support the sustainable transition, it is essential to develop a diverse range of technologies. For this reason, Ecospray continues to invest in R&D across multiple areas. In particular, there are two technologies that the company already offers and which are crucial for air pollution control: the DeNOx systems use selective catalytic reduction (SCR) technology to remove nitrogen oxides from diesel engine exhaust gases.

Moreover, the methane slip reduction system represents another key area of action for Ecospray. This solution uses catalytic oxidation technology to remove methane slip from dual fuel engines. It is designed to reduce emission levels up to 95%, using oxidation catalyst substrates with platinum group metal to oxidise methane.

From research to development, Ecospray specialises in the creation of integrated solutions for the sustainable conversion of marine and land-based industries, as well as for the reduction of dependence on fossil fuels. Founded in 2005, Ecospray, market leader in EGCS for marine diesel engines, has been part of the Carnival Group since 2013.

The company operates worldwide, providing a wide range of technologies, including gas cleaning and exhaust gas treatment (DeSOx, DeNOx, methane slip reduction), carbon capture technologies, low-carbon fuel production (CH4 liquefaction, eNG liquefaction) and waste-to-energy solutions (CO2 liquefaction, flare gas recovery, liquefied natural gas and natural gas liquid separation).

For more information, contact: Marcello Vercellino, Sales Manager Ecospray Technologies Via Circonvallazione, 14/14A 15050 Alzano Scrivia (AL) Italy Email: marine@ecospray.eu ecospray.eu

All the latest news, views, partnerships and reports from across the world of shipping

Baltic Exchange, the world’s only independent source of maritime market information for the trading and settlement of physical and derivative contracts, and Veson Nautical, a global leader in maritime data and freight management solutions, have joined forces to launch the latest version of the official Baltic99 questionnaire for the dry bulk sector.

The questionnaire, which remains the industry standard for collecting and collating detailed information about the global dry bulk fleet, is designed to help owners and charterers share common data requirements to speed up the vetting process when a vessel is put up for hire, facilitate faster trades and ensure smarter pre-fixture decisionmaking.

It is also a vital tool to ensure owners and operators supply the data they need as part of their commercial and vetting criteria to ensure they are in line with regional, national and International Maritime Organization (IMO) regulations.

The latest version of the questionnaire, available as of today, has expanded its criteria to cover an increasing cadence of requests for safety and sustainability information about bulk carriers. As a result, the Baltic99 Questionnaire has been designed to help move the global maritime industry move forward on a number of key issues, such as reducing carbon emissions, increasing operational safety standards in the dry bulk trade, and ballast water treatment systems.

In addition, respondents to the Baltic99 Questionnaire are also asked for their vessel’s greenhouse gas (GHG) data, energy and consumption ratings and NoX emissions compliance data.

The enhancements in this latest version of the questionnaire incorporate suggestions from the Baltic Membership Council, industry partners and subscribers to Veson Nautical’s dry bulk information management service, Q88 Dry.

“Using Q88 Dry to complete the Baltic99 Questionnaire with integrated certificate management makes it easy for owners and operators to share vessel particulars and certificates with your charterers and brokers,” Tor-Arne Berger, Senior Product Manager at Veson Nautical says.

“The Baltic99 Questionnaire remains the industry leading questionnaire for commercial fixtures in the dry bulk industry,” notes Janet Sykes, Chief Commercial Officer at Baltic Exchange. “This latest revision includes several key developments linked to important emissions-related data and enhanced safety requirements to ensure charterers are hiring the right vessel for their needs and expedite the vessel acceptance process.”

“We are pleased to once again partner with Veson Nautical on the Baltic99 Questionnaire as we all work together to drive the maritime industry forward to a more sustainable and efficient future,” Skyes adds.

Both companies are now urging owners and operators to verify that their vessel data is accurate, complete and up to date.

The new version of the Baltic99 Questionnaire can be found at: veson.com

Baltic Exchange has also introduced a series of green fuel options to its FuelEU voyage and compliance cost calculator as more shipowners, traders and charterers seek to understand the commercial implications of this regulation on their voyage costs.

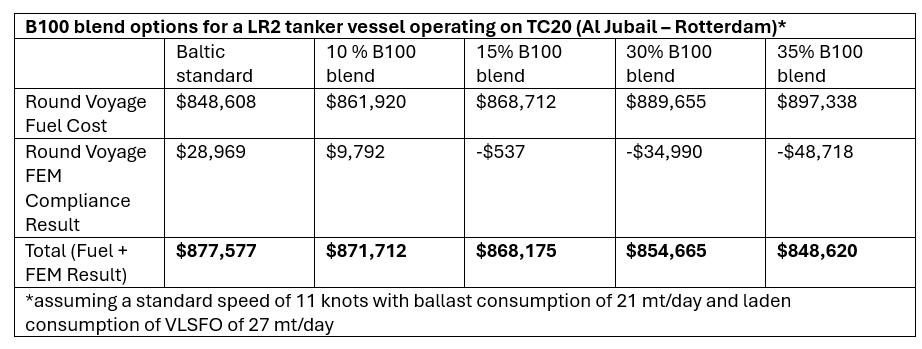

Biodiesel, bio-liquefied natural gas, bio-liquefied petroleum gas, green methanol, green hydrogen and green ammonia have all been added to the calculator, either as green fuel or blend options. Baltic Exchange’s FuelEU Maritime calculator provides an overview of the cost implications for the selected option relative to the Baltic standard for that route. This will enable the market to factor any change in fuel selected or contemplated into their voyage cost estimates.

“Green fuels are expected to be very expensive initially, so will likely be blended into fossil-derived fuels initially, to achieve compliance with the new FuelEU Maritime regulation. For this reason and based on industry feedback, we have added a blend capability to Baltic Exchange’s FuelEU compliance and fuel cost calculator,” says Martin CrawfordBrunt, Emissions Lead at Baltic Exchange.

“Baltic Exchange is assisting the market by cutting through the considerable complexity of these regulations by providing a simple decision-making tool that estimates the voyage costs of the many fuel and blend alternatives quickly and simply,” he adds.

These results of the calculations are all presented relative to the Baltic standard ship and route types, which is generally considered to be burning very low sulphur fuel oil (VLSFO) in navigation outside Emission Control Areas and marine gas oil for waiting and port consumption.

The output from these calculations shows the cost differential for the fuel under consideration with the entered speeds and consumptions of the test ship versus the market standard.

For example, a 115,000 dwt LR2 clean tanker operating on the TC20 Baltic route (Al Jubail – Rotterdam), assuming a standard speed of 11 knots with ballast consumption of 21 mt/day and laden consumption of VLSFO of 27 mt/day, stands to save nearly $30,000 in fuel costs if using a 35% B100 blend option.

Despite an increase in overall fuel costs, the amount saved for being in compliance with the FuelEU Maritime regulation will offset those costs and provide additional savings compared to burning purely VLSFO.

According to Baltic Exchange’s FuelEU Maritime Calculator, in this example, the vessel stands to save increasing amounts of costs on fuel as the ratio of biodiesel to VLSFO increases.

In addition, the table below shows the voyage cost outcomes for the same vessel and route depending on which green fuel is blended into VSLFO at 10%. These calculations are made with the assumption that these green fuels cost twice as much as their fossil-derived versions, which make up the remainder of the fuel burned on the round voyage.

In this example, bioLNG offers the most cost-effective option as a fuel blend. While it has a higher overall cost compared to ePLG or B100, the FuelEU Maritime-related savings of using bioLNG results in more than $400,000 in overall cost savings.

“With the latest update to Baltic Exchange’s FuelEU Maritime Calculator, users now have the ability to experiment with any green fuel blend percentage taking into account the assumed green fuel cost premium and the expected wellto-tank emissions profile for the specific green fuel blend selected,” Crawford-Brunt notes.

“Regulations like FuelEU Maritime and EU Emmisssions Trading System will have an increasing impact on voyage costs to and from the EU. All contracting parties, their brokers and traders need to be able to estimate these additional costs quickly to avoid facing high financial penalties.

“Baltic Exchange is pleased to be able to offer these vital emission resources and tools to its members and the wider market as we all strive for a more sustainable future for shipping,” he adds.

Ocean Network Express (ONE) and Yusen Logistics have announced a new agreement for sustainable shipping solutions through ONE’s green shipping service, ONE LEAF+ (low emission-able freight).

This collaboration demonstrates how the industry can advance sustainable supply chain practices and marine transportation to deliver environmental benefits. Under this agreement, ONE will use sustainable biofuels for propulsion, achieving up to 84% reduction in well-to-wake CO2 emissions compared to VLSFO. As a freight forwarder, Yusen Logistics will offer this green shipping option to customers, enabling them to simultaneously reduce their Scope 3 greenhouse gas (GHG) emissions.

Gilberto Santos, Senior Vice President, Global Commercial and Service Management, ONE, says: “This collaboration with Yusen Logistics represents an important step in expanding the availability of green shipping solutions in Asia. Through ONE LEAF+, we are offering customers the flexibility to

reduce their supply chain emissions while maintaining the reliability they expect from ONE.

“Together, we are advancing our shared commitment to sustainable shipping and supporting the industry’s decarbonisation goals.”

Kohei Omura, Head of Ocean Freight Forwarding Group, Yusen Logistics, says: “We are very pleased to sign an agreement with ONE as the first logistics company in Asia and aim to build a more sustainable future through the provision of eco-friendly shipping solutions together.

“By utilising ONE LEAF+, we are proud to offer our customers more sustainable choices and contribute to the reduction of GHG emissions.”

ONE LEAF+ offers customers the opportunity to proactively manage their own emissions and minimise environmental impact across the value chain. The service currently uses UCOME (used cooking oil methyl ester), a non-toxic and biodegradable biofuel derived from food production. Customers can choose flexible CO2e savings from approximately 10-80% and receive independently verified emissions reduction certificates to track their environmental impact.

Under current and prospective policies from the International Maritime Organization, EU and US, the business case for green shipping corridors could improve markedly – but not sufficiently – according to a new report published by maritime consultancy UMAS, UCL and the Global Maritime Forum (GMF).

Titled Building a Business Case for Green Shipping Corridors, the report looks at the significant commercial challenges associated with green shipping corridors, how these could change under future regulation and what additional support may be needed to ensure the viability of such projects.

Green shipping corridor projects – which focus on initiating the maritime value chain for scalable and sustainable fuels such as hydrogen-derived e-ammonia and e-methanol – have thus far faced an insurmountable cost gap.

Against the backdrop of an evolving global and regional policy landscape, the business case for such first mover initiatives will begin to improve, but targeted support will be needed to ensure uptake of e-fuels.

The report emphasises the important role of regulation in enabling shipping’s energy transition and the wider implications for the industry operating under a future compliance regime where fleet and bunkering strategies will need to become more sophisticated. Policies such as the IMO’s new global fuel standard, the EU’s Emissions Trading System (ETS), and the US Inflation Reduction Act (IRA) will play a critical role in reducing costs for green shipping corridors but fall short of fully bridging the gap between the cost of e-fuels and the cheapest solution to meet compliance.

The report explores the potential opportunities and options that could be available for green shipping corridors

in three different shipping sectors—gas carriers, container ships and bulk carriers—to highlight how public and private efforts could accelerate early adoption of e-fuels.

The scenarios explored reveal that while biofuels and blue ammonia are lowest cost options over the near term, scalable e-fuels such as e-ammonia are expected to become increasingly competitive as production costs fall and compliance requirements tighten, indicating that targeted support would only be required over the short term.

With 62 green shipping corridor initiatives already announced, support for these early mover projects could enable significant strides to be made in the development of sustainable fuel production and in investment in the storage, bunkering, and port infrastructure required to decarbonise the wider shipping industry later in the transition.

Deniz Aymer, Senior Consultant at UMAS, comments: “Upcoming regulation will shift the business case for green shipping corridors – as well as shaping how the wider shipping industry approaches compliance. To fully bridge the cost gap, however, targeted support for e-fuels is needed. But this short-term support will pay future dividends by ensuring that scalable and sustainable fuels are available to the wider industry when needed.”

Dr Nishatabbas Rehmatulla, Principal Research Fellow at the UCL Energy Institute, states: “The findings of this study make it very clear that without clear demand signals and additional public support over the near term, closing the cost gap on e-fuels will be challenging.

“Without this support and guardrails on fuels, some of the announced green shipping corridors are at risk of failing to fulfil their crucial role as first movers, and stalling before implementation or gravitating towards least-cost compliance options.”

Jesse Fahnestock, Director of Decarbonisation at the Global Maritime Forum, comments: “The most important role green corridors can play is to coordinate and kick-start the value chain for tomorrow’s shipping fuels. Participants in corridors will need to be creative in how they leverage a range of regulations, but it’s clear from this work that the scale of their impact will depend on policymakers delivering targeted support for e-fuels.”

To accelerate progress, the report outlines actionable solutions for industry and policymakers. It highlights how business models will need to adapt under incoming regulation and how long-term commitments from cargo owners and ship owners and operators can help de-risk investment and drive e-fuel adoption.

Strategic partnerships across the value chain will be essential for sharing risks and rewards, ensuring a more equitable cost distribution while advancing green shipping corridor projects.

Despite this, the business case for green shipping corridors will remain challenging without targeted measures to support the uptake of e-fuels. Mechanisms such as Contracts for Difference (CFDs), e-fuel auctions, and/or multipliers for overcompliance with e-fuels will be crucial to the short-term viability of these initiatives. Economic support could be underwritten by the IMO through revenues raised

by a levy on shipping industry emissions. In the absence of a global levy, however, national governments may need to step in to directly support corridor projects.

To download a copy of the report, visit: tinyurl.com/CSIGreenCorridors

The Nigerian National Petroleum Corporation (NNPC) Shipping, Stena Bulk and Caverton Marine have recently announced the signing of a new joint venture that will transform Nigerian maritime transportation.

The agreement, signed in London last month, will create a new tanker operation serving Nigeria and West Africa’s regional and global crude oil, refined product and liquefied natural gas shipping requirements.

The joint venture partners will create a new company whose objective is to provide top quality, reliable and efficient maritime transport. The partners will explore options to create a modern and efficient fleet of tankers, comprising both new and existing tonnage depending on market factors and commercial opportunities in the region.

The companies will evaluate opportunities for both vessel acquisitions and long-term charter arrangements, with a focus on maintaining competitive operating costs while meeting the highest standards of safety and sustainability.

This fleet will primarily serve the logistics needs of NNPC, including crude, clean and LNG/LPG transportation.

Additionally, the new company will cater to other oil producers and traders, offering the strategic advantage of a modern fleet, strong financial backing, and maritime pedigree and heritage.

Speaking on the announcement, Panos Gliatis, Managing Director, NNPC Shipping, said: “This strategic partnership marks a significant milestone in NNPC’s commitment to modernising Nigeria’s maritime infrastructure. By combining our expertise with Stena Bulk and Caverton Marine, we’re creating a robust platform that will enhance our domestic refining, import and export capabilities and strengthen Nigeria’s position in global energy logistics.”

Erik Hånell, President and CEO, Stena Bulk, added: “We’re excited to partner with NNPC and Caverton Marine in this groundbreaking venture. This collaboration aligns perfectly with our pragmatic strategy of expanding our presence in key growth markets while maintaining our high standards of operational excellence and sustainability. Nigeria’s energy sector is undergoing remarkable transformation, and we’re proud to be part of this journey.”

Johan Jäwert, Head of Stena Bulk USA and Pool Manager SSSP, said: “We look forward to developing shipping activities locally with Caverton and benefiting from NNPC’s strong position in the oil market. Combined with our know-how across all aspects of commercial and technical shipping, we will create a world-leading shipping company providing firstclass service to the energy market.”

Bode Makanjuola, CEO, Caverton Offshore Support Group, said: “This joint venture – the result of many years of planning – marks a significant stride in enhancing Nigeria’s

maritime capabilities. By combining local knowledge with international best practices, we are establishing a worldclass operation that will benefit not only Nigeria but the entire Sub-Saharan Africa region.”

This joint venture comes at a time when Nigeria is asserting its position as Africa’s largest economy. The country’s strategic location, growing population, and ambitious infrastructure developments are creating new opportunities for shipping companies. By establishing this world-class tanker operation, the partners are not only meeting immediate logistical needs but also contributing to Nigeria’s long-term economic diversification and growth.

The RMT union has welcomed the Climate Change Committee’s (CCC) latest report on decarbonisation, calling for clear guarantees on jobs, pay, and conditions for workers in offshore energy and transport.

RMT General Secretary Mick Lynch says: “We welcome this independent report as decarbonisation is essential, but workers cannot be left behind especially in offshore oil and gas.

“There must also be a greater emphasis on investment to encourage a transition towards public transport, rail freight, and coastal shipping.

“Workers need a guarantee that in the new decarbonised economy the UK maintains an industrial base that can build that economy supporting jobs and incomes, instead of abandoning working-class communities to the international market.

“Too often, transitions like this are used as an excuse to slash and export jobs, cut pay and replace skilled, unionised workers with casualised labour on worse conditions.

“We will not accept a race to the bottom in the name of climate action.

“A genuine just transition must mean protecting wages, skills, and collective bargaining rights across the supply chain.”

More than 2,000 redundancies have hit offshore oil and gas in the past year, with the livelihoods of 1,800 catering jobs under the North Sea Confederation of Offshore Trade Association (COTA) agreement at particular risk.

Seafarers, divers and remotely operated vehicles (ROV) technicians must be protected through funded skills passporting and stronger employment rights.

RMT has welcomed the Labour government’s offshore skills passport, but the appointment of a GB Energy boss from offshore wind, a sector where collective bargaining is resisted, raises concerns about the application of the Make Work Pay reforms across the offshore energy sector.

Only 11.7% of UK seafarer jobs are held by UK-resident workers, a result of P&O-style employment practices and widespread Flags of Convenience. In offshore wind, low pay and exploitative shift patterns are common, with the minimum wage not applying beyond 12 miles from the shoreline.

RMT is demanding an enforceable transition plan that guarantees secure jobs, fair wages, and full collective bargaining rights across transport and energy sectors.

Meanwhile, the RMT has condemned yet another fall in the total number of UK resident seafarers, despite a big increase in the number of seafarer jobs to more than 160,800.

The number of UK resident Ratings working in the UK shipping industry fell three per cent to below 9,900 while the total number of Ratings increased by 7.2% to 134,250. As a result, only 7% of UK resident Ratings hold these jobs.

RMT general secretary Mick Lynch says that most of the increased demand in 2024 was met by Ratings recruited in non-EEA countries.

“These seafarers will be working on P&O style agency contracts that pay below the National Minimum Wage and on rosters that require months at work at sea, with access to shore leave infrequent and poorly regulated, despite this being a core MLC protection.

“While the number of Ratings apprenticeships started in 2024 increased but, at just 60, it is still far too low to reverse this relentless trend of exploiting foreign seafarers at the expense of coastal communities and UK maritime security,” he says.

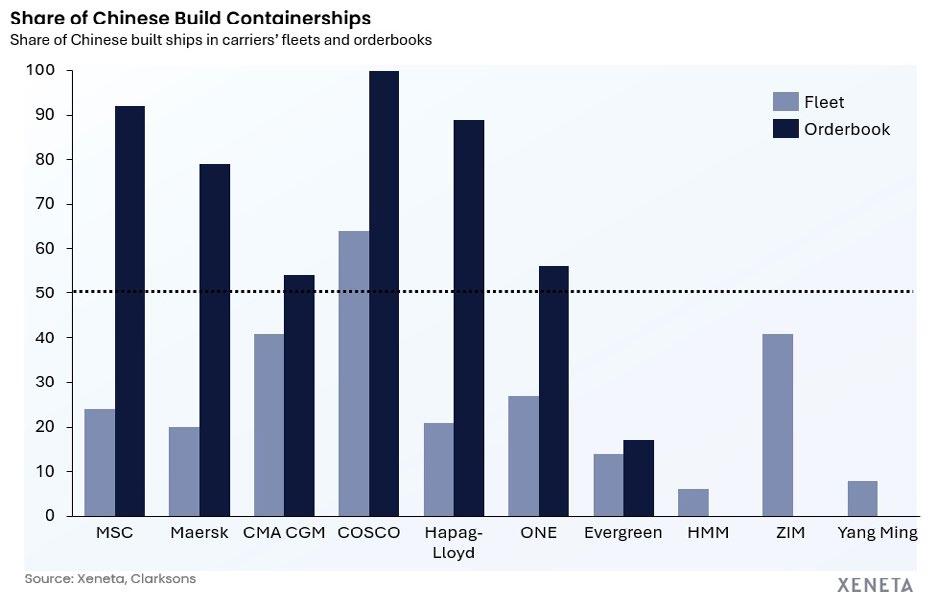

Analysts warn proposed fees on China-built container ships importing goods into the US may have unintended consequences, including port congestion, increasing freight rates and shifts in global trade patterns.

The Trump administration has announced plans for a US$1m fee every time a vessel operated by a China carrier enters a US port. The Federal Notice also threatens further substantial fees for China-built vessels operated by a carrier from any nation. A third section in the notice proposes an additional charge levied against carriers based on the percentage of new ships on order being built in China.

Peter Sand, Chief Analyst at ocean and air freight intelligence platform Xeneta, says: “Ocean container carriers will take action to avoid the fees, such as calling at fewer ports, which could cause major congestion and delays in the US.

“We saw a similar situation last year when carriers cut port calls in Asia and handled more containers per call at Singapore in an effort to offset the impact of the Red Sea crisis and diversions around Africa.

“The intentions were good, but the severe congestion caused by handling more containers in Singapore rippled across global supply chains and saw average spot rates from the Far East to US East Coast spike more than 300%.

“Trump is weaponising trade against China, but you have to wonder if they truly understand the consequences of this policy because there is a high risk it will cause major disruption and make container shipping more cumbersome and expensive for US importers.”

Sand states that shippers could also take action to avoid the fees by importing goods into the US via Mexico and Canada.

Full year imports from China to Mexico in 2024 were up 15% compared to 2023 at 1.42m TEU (20ft equivalent container). Into Canada, imports from China are up 16% at 1.8m TEU.

Sand says: “Shippers have been using Mexico and Canada as a back door into the US to avoid tariffs on imports from China. Trump has vowed to stop this trend by imposing tariffs of 25% on imports from Mexico and Canada and make using these nations as a backdoor less attractive.

“If shippers now face new port fees on top of the tariffs when importing directly into the US, it could change the situation again and fuel further growth in imports from China to Mexico and Canada. Ironically, Trump may be indirectly driving one of the very things he’s trying to guard against.

“We could even see it cause an uplift in goods being shipped into the US by air. The potential repercussions and unintended side-effects of these port fees are impossible to predict with any degree of certainty, which makes it such a challenging situation for both US importers and carriers.”

Data analysed of carrier fleets by Xeneta shows Chinese ship operator COSCO will be hit hard due to it not only being the only Chinese carrier in the global top 10, but also having almost two thirds of its fleet built in China and 90% of its orderbook coming from Chinese yards.

No other top 10 carrier has more than 50% of its fleet coming from China, giving them more options to reallocate ships between trades and adjust schedules to minimise port calls for China-built ships. On the orderbook side, the European carriers (MSC, Maersk, CMA CGM and HapagLloyd) will also be hit, with all having more than half of current orderbook in Chinese yards.

With the exception of Ocean Network Express, the other Asian carriers will not be impacted by the orderbook fee.

Sand says: “The threat of even higher costs to import goods into the US should be taken very seriously, but it remains to be seen whether it becomes a reality due to the impact it will have for US businesses and, ultimately, consumers.

“We understand from talking to Xeneta customers that they are watching and listening to every word that comes out of the US administration, but there is so much uncertainty that they are keeping their options open and being patient before taking any rash decisions on their supply chains.”

West P&I Club has drawn members’ attention to a concerning trend of pollution incidents involving vessels operating within Turkish waters and calling at Turkish ports.

The club has reminded members of the need to strictly adhere to all relevant national and international requirements relating to pollution and the importance of implementing appropriate operational precautions.

This comes at a time when fines by the Turkish authorities for pollution events have been increasing over the past 12 months.

A member’s vessel recently called into a Turkish port to conduct a transfer of slops from the vessel’s slop tank to an adjacent barge. Due to a lapse from the barge and the vessel, a quantity of slops were discharged into the sea because of a leakage that wasn’t immediately noticed. The de-slopping operation was halted soon after and the local Turkish coast guard was notified. This resulted in a significant fine.

The club highlights some key recommendations for vessels transitting Turkish waters when engaging in any operations where there is a risk of pollution.

While the list of recommendations is not exhaustive, it is imperative to comply with all relevant anti-pollution procedures within Member’s Safety Management Systems and ensure crews are fully familiar with these procedures.

A recent edition of TT Talk considers the issue of slot charterers limiting liability.

A container ship caught fire and sank near Colombo in Sri Lanka resulting in a total loss. The owner and bareboat charterer successfully claimed limitation of liability in the English Admiralty Court. The three slot charterers also argued for limitation on the basis they could be considered as shipowners too.

TT Club says “This judgment provides useful confirmation of the MSC Napoli case and applies the earlier judgment to agreements with different names but with basically the same substance. The result is that parties should not be discouraged from part-chartering a ship by the risk that they might be unable to limit under the Convention.” For more information, visit: ttclub.com

The Isle of Man Ship Registry (IOMSR) is playing a key role in the development of a high-tech sail aimed at reducing shipping emissions.

The AirWing was created by engineers in Hull and sea trials are now underway, following a development project that began three years ago.

Developers say it can significantly reduce fuel consumption and carbon emissions and produces 10 times the thrust of a conventional sail. The wing can operate up to wind speeds of 45 knots (Beaufort Force 9) and is built to withstand wind speeds of 100 knots.

Sea trials began in early March following the completion of work to fit the system to the DWT 11051 general cargo carrier Vectis Progress, an IOMSR-flagged vessel operated by Carisbrooke Shipping. Class society trials and certification took place earlier off Hull.

The technology is being tested on trans-Atlantic routes between northern Europe and Canada.

IOMSR worked closely with the development team to ensure the best method of installation and to ensure that the AirWing system is complaint with maritime legislation.

Its expertise has allowed the complex project to move forward at pace and IOMSR will continue its consultancy work.

The wind propulsion system has been developed by UK-based business GT Wings. It utilises fans to improve air flow across the AirWing. The system can be added to new vessels or retrofitted to improve fuel efficiency, cut emissions and reduce tax burdens under new EU emissions regulations.

The project received £3.7m funding after winning a UK government competition aimed at creating green jobs and boosting skills. The

‘We are proud to be playing our part in this truly groundbreaking project’

IOMSR Director Cameron Mitchell

Department for Transport is funding a number of schemes in a £30m plan to decarbonise the maritime industry.

UK Maritime Minister Mike Kane MP praised the team behind the AirWing on a recent visit to Hull to see the project saying: “I’m proud to see this funding boost growth and create jobs throughout the UK.”

Cameron Mitchell, IOMSR Director, says: “We are also proud to be playing our part in this truly ground-breaking project that is driving fresh innovation into the task of decarbonising the shipping industry.

“The initiative also aligns with the International Maritime Organization’s goals, to reach net-zero greenhouse gas emissions from international shipping by or around 2050, goals that IOMSR is also fully committed to, through our industry leading work.”

Captain Simon Merritt, senior fleet manager at Carisbrooke Shipping, describes the installation of the AirWing on the vessel as a “mammoth task”.

He says: “We have worked extremely hard to complete the project to

this stage and we have passed all milestones ahead of target. Testing will continue during the coming weeks.

“It demonstrates the power of collaboration between leading British companies, turning innovative ideas into real solutions to decarbonise the maritime industry while creating job opportunities in the UK.”

And George Thompson, chief executive of GT Wings, adds: “We’re extremely excited about the launch of AirWing, our next-generation, compact wind propulsion technology designed to help even the most challenging ocean-going vessels decarbonise by harnessing wind power.”

The IOMSR is building its expertise in maritime wind propulsion. Last year the world’s most powerful sailing cargo ship went into service under the Isle of Man flag.

Four WindWings were installed on the Berge Olympus as part of dry bulk ship owner Berge Bulk’s ambition to become carbon neutral by 2025. The

cutting-edge technology also uses wind power to reduce fuel and emissions.

The WindWings can save up to 20% fuel, reducing CO2 emissions by 19.5 tonnes per day on an average worldwide route. They were fitted on the vessel by Yara Marine Technologies.

IOMSR believes the maritime industry has a collective responsibility to respond to the climate emergency. It became the first flag state to join the Getting to Zero Coalition, an industry-led alliance working towards decarbonising the international maritime shipping sector.

In another industry leading development, IOMSR become the first flag state in the world to reduce registration fees for ships deploying green technology.

The registry is headquartered in Douglas, Isle of Man, a self-governing British Crown dependency and is a Category One member of the Red Ensign group.

For more information, visit:

Baltic Exchange has launched a new series of chemical and agricultural oil assessments to meet the evolving needs of the maritime freight market and bring its expertise and benchmarking data to the chemical and agri-oil shipping sectors.

The Baltic Chemical and Agricultural Oil Assessments (BCAA) are being produced on a weekly basis. The assessments are designed to serve a segment of the freight market – across owners, charterers, brokers and trading companies – that is increasingly demanding key freight data and sector benchmarks on a more regular basis to make more informed financial decisions.

Known for its knowledge in dry bulk, tanker and gas freight sectors, alongside providing container and air freight data, Baltic Exchange is now set to engage with a broader spectrum of stakeholders, including shipowners, charterers, and industrial producers across the whole chemical, vegetable/agri-oil, and biofuel supply chains.

These industries provide vital products and uses to everyday life, from cleaning/hygiene products to food and cooking, construction materials, transportation, agriculture, clothing, and electronics.

Filling a gap in existing freight assessments, the BCAA will offer insights into a series of trade routes covering ‘easy-chemicals’ such as benzene, biofuels and caustic soda, as well as vegetable oils. The indices, priced in US$ per metric ton and basis 5,000 mt or 10,000 mt shipments (and 40,000 mt for vegetable oils), reflect the unique nature of chemical tankers, which carry multiple cargo types and require specialised handling beyond a traditional oil products carrier.

The trade routes covered by BCAA include:

» EC11: Northwest Europe to US Gulf

» EC22: Middle East Gulf to West Coast India

» EC23: Middle East Gulf to China

» EC34: US Gulf to Far East

» EC35: US Gulf to Northwest Europe

» EC36: US Gulf to Brazil

» EC43: Singapore to China

» EC52: Korea to West Coast India

» EC57: Korea to Singapore

» PO45: Singapore Straits to Northwest Europe

» VG62: EC South America to West Coast India

“Unlike traditional freight indices, chemical tanker operations are highly complex, involving multiple unrelated cargoes with very specific but diverse stowage and handling requirements. However, the chartering market has now become sufficiently mature for us to develop a reference price for these key trade lanes,” says Mark Jackson, CEO of Baltic Exchange.

“The launch of the BCAA underscores our commitment to broadening our services and providing critical transparency in underrepresented markets. By expanding into the chemical and agri-oil sectors, we are offering the freight market much-needed benchmarks for these specialised industries.

“This latest set of benchmarks reflects our dedication to supporting the diverse needs of the global shipping community, and we look forward to continuing to innovate and collaborate with stakeholders across shipping’s most important sectors.”

The EU plans to boost green aviation and shipping fuels, but sends worrying signal on 2040 climate goals, according to green group Transport and Environment (T&E).

New EU plans to lower energy costs by doubling down on deployment of renewable electricity, and to activate more investment and trade instruments to scale clean-tech, have been welcomed by green group T&E.

However, a decision to delay proposing an EU 2040 climate target sends a very worrying signal, the group says.

Other recent announcements included a Clean Industrial Deal that will prioritise the domestic production of renewable fuels for aviation and shipping. However, the EU Commission also rushed out new proposals to weaken the sustainability reporting rules that hold companies accountable for their environmental and social impacts.

The Action Plan on Affordable Energy aims to enable much higher levels of electrification in the economy, which the EU says should rise from 23% currently to 32% in 2030. However, more than one year after confirming that it will publish a 2040 emissions reduction target for the EU, the European Commission has not yet released a proposal as planned.

T&E said any climb-down from the expected -90% target would deprive European carmakers, airlines and shipping companies of the investment certainty that clean technology is here to stay.

T&E welcomed the prioritisation of green fuels in the Clean Industrial Deal. It said the plans for a Hydrogen Mechanism – which will connect hydrogen suppliers and buyers with financing options – and the prioritisation of the shipping and aviation sectors are crucial. But the Hydrogen Bank needs not only matchmaking tools, but also doublesided auctions, which were omitted. The text announced plans for a Sustainable Transport Investment Plan, which T&E said should focus on e-fuels as a priority investment.

Faig Abbasov, Shipping Director at T&E, says: “The Clean Industrial Deal is a step in the right direction, recognising the essential role that green hydrogen-derived fuels play in decarbonising shipping and aviation. But it lacks essential details on how the EU is going to bridge the price gap between fossil fuels and greener alternatives or address the need for larger and longer term offtake commitments. The Sustainable Transport Investment Plan should fill in those missing details or green fuels risk missing the boat and plane.”

The reform of state aid rules outlined recently will not adequately support EU-made clean tech or local supply chains, T&E says. It called for the Clean Industry State Aid Framework, which will be published in the second quarter of this year, to set out how European manufacturing can be

boosted through targeted and strictly conditional state aid. Without ‘Made-in-EU’ requirements or a performance-based approach to aid, Europe will struggle to get its local clean tech industry off the ground.

The Commission also said it would resort to using more trade defence instruments and activating greater EU investment for clean tech. T&E says adding conditions to foreign direct investment is the right step, but financial instruments to support clean tech must be better designed, as the struggling Hydrogen Bank shows. Investment support should be focused on production ramp-up, not pilots, and have local content rules for materials. These proposals need to be put into action quickly given the crisis happening in the local battery sector.

T&E welcomes plans for a labelling system for industrial products that will track their carbon intensity, starting with steel in 2025. The automotive sector consumes 17% of steel in the EU. Other provisions in the Clean Industrial Deal to support cleaner, locally-made products – such as EU content requirements and social leasing – are vague and need to be fleshed out in the forthcoming EU Automotive Plan next week and in an Industrial Decarbonisation Accelerator Act later this year.

Julia Poliscanova, Senior Director for Vehicles and eMobility Supply Chains at T&E, says: “The faltering European battery companies need urgent action to put the trade and investment pledges in the Clean Industrial Deal into action. A green labelling system can play to Europe’s strengths as a more sustainable manufacturer of steel and batteries. But we need to see much more detail about how labelling, as well as local content requirements, will actually work. The plans to overhaul state aid rules also do not go far enough for the EU to build up clean tech manufacturing.”

While there is space for simplification, T&E condemned the so-called Omnibus proposal that actually weakens rules that hold companies accountable for their environmental and social impacts. Companies would only need to look at direct suppliers when doing due diligence checks on their supply chains, under the proposed changes to the Corporate Sustainability Due Diligence Directive. Environmental damages or human rights abuses in raw materials extraction, for example, would therefore not be adequately scrutinised.

The Omnibus also proposes to delay by two years the requirements on companies to report their risks and impacts, under changes to the Corporate Sustainability Reporting Directive. It would also limit the obligations to businesses with more than 1,000 employees and a turnover of €450m. A lack of environmental, social and governance (ESG) information due to a reduced scope of the law would make it very difficult for companies to assess their lifetime emissions across the entire value chain.

Giorgia Ranzato, Sustainable Finance Manager at T&E, says: “The infamous Omnibus package is out. While there is space for simplification, the latest proposal throws Europe into reverse, erasing a decade of gains in

sustainability and global competitiveness. If approved, the new sustainability reporting obligations will only apply to 0.02% of European companies. This risks a disastrous lack of ESG data across the region, creating a nightmare for responsible investors and consumers. This new package guts corporate accountability.”

Baseblue, a provider of marine energy solutions, has launched a new bunker fuel supply service at Point Lisas Port, Trinidad. The service will provide vessels with reliable and efficient fuel options, eliminating logistical challenges and enhancing operational efficiency.

Point Lisas Port, one of the major maritime hubs in Trinidad, comprises four key terminals: Point Lisas Industrial Port Development Corporation (PLIPDECO), Savonetta, Yara Trinidad, and Phoenix Gas. Baseblue’s new supply service will primarily focus on PLIPDECO and Savonetta terminals, where the local supplier’s storage tanks (VLSFO 20,000bbls & LSMGO 10,000bbls) are based. This strategic location ensures seamless fuel delivery through truck-to-ship and pipe-to-ship methods, enhancing convenience and reliability.

The bunker fuel supplied by Baseblue is sourced from leading refineries in the US Gulf, ensuring high-quality and reliable fuel that meets industry standards. Vessels can now access fuel and low-sulphur marine gas oil (MGO) directly at the terminal, mitigating delays caused by weather conditions and logistical bottlenecks commonly experienced in anchorage areas.

Ignacio Gaviña Alvarado, Marine Fuel Supply, Baseblue, says: “This new service represents a significant step forward in providing vessels calling at Point Lisas Port with a dependable fuel supply. By delivering fuel directly at the terminal, we are improving operational efficiency, reducing waiting times, and minimising environmental impact.”

The introduction of this service marks a departure from the traditional reliance on barge deliveries, offering a more efficient and environmentally friendly solution. By minimising delays and optimising fuel supply logistics, Baseblue’s service contributes to reducing greenhouse gas emissions and supporting the maritime industry’s sustainability goals, an even more significant advantage with the recent activation of FuelEU Maritime in January, where vessels are mandated to reduce fuel emissions.

Industry coalition SEA-LNG has confirmed its latest board of directors with new representatives from Bernhard Schulte Shipmanagement (BSM), Galveston LNG Bunker Port, MAN Energy Solution, MSC Mediterranean Shipping Company SA, Sohar Port and Freezone and Titan Clean Fuels.

The board of directors includes representatives from each stakeholder sector across the liquefied natural gas (LNG) value chain. Each sector-specific board representative is accountable to the members in their sector. SEA-LNG also had six board seats for voted on by the general membership, Chairperson and five at large board seats. In addition to defining SEA-LNG’s strategy, they ensure members can effectively contribute their expertise to the coalition. All directors will serve a two-year term of office until December 2026.

Peter Keller, Chairman, comments: “As we see record ordering of LNG-powered vessels with over 6% of the global fleet due to utilise LNG, liquified biomethane and ultimately liquefied e-methane, I am pleased that we have been able to broaden the leadership of SEA-LNG. Expanding the number of directors, through two new at large seats, has enabled us to bring onboard industry leaders from around the world.”

The board oversees all SEA-LNG working groups, including investment, regulatory, stakeholder engagement, and emissions working groups. It ensures that these groups consider the perspectives of all stakeholders and identify knowledge gaps that further analysis. This industry grounding leads to research that is practical, credible, and valuable to the shipping industry’s decision-makers.

In addition, the SEA-LNG Board has invited Panos Mitrou, (Lloyd’s Register) to remain as a Board Observer/Advisor given his vital role as Chair of the Methane Abatement in Maritime Innovation Initiative (MAMII)

Keller added: “2025 looks set to be a significant year for shipping decarbonisation, with critical decisions looming at the International Maritime Organization. We are seeking to build on the successes of 2024, and the work of all previous Board members since SEA-LNG’s establishment in 2016. As we look forward, the LNG pathway will only cement itself further, and efforts from SEA-LNG will be critical. Our new board of directors represent key links in the LNG value chain and together we will ensure that we deliver a pragmatic and realistic pathway for shipping to decarbonise and tackle harmful local emissions today.”

A new initiative led by the International Maritime Organization (IMO) and the Kingdom of Saudi Arabia (KSA) aims to address the global seafarer shortage while creating career opportunities for aspiring seafarers from developing nations.

The NextWave Seafarers Project was formally launched with the signing of a Letter of Agreement between Kamal M. Al Junaidi, Permanent Representative of Saudi Arabia to the International Maritime Organization and Jose Matheickal,

Director of the Technical Cooperation and Implementation Division (TCID) of IMO.

The signing was witnessed by IMO Secretary-General Arsenio Dominguez, with senior representatives from the Transport General Authority (TGA) of KSA and Bahri Shipping Line in attendance.

Running from 2025 to 2026, the NextWave Seafarers Project will provide 20 cadets from Least Developed Countries (LDCs) and Small Island Developing States (SIDS) with one year of onboard training through Bahri Shipping Line, one of Saudi Arabia’s leading maritime companies.

The goal is to develop a scalable training model that can be adopted globally, encouraging more countries and shipping lines to participate.

The project aims to:

» Establish a sustainable, onboard cadet-training framework to develop, upskill, and retain future seafarers;

» Address key barriers preventing LDCs and SIDS cadets from entering the industry, including access to training placements and financial support;

» Promote gender diversity by actively encouraging women cadets to join the programme; and

» Showcase the initiative as a pilot model that can be expanded and replicated worldwide.

With 1.9m seafarers ensuring the movement of more than 80% of global trade, the maritime industry faces an urgent workforce challenge, particularly a shortage of officers, as demands on maritime transport grow.

Through its cooperative framework between IMO, member states and shipping companies, the NextWave Seafarers initiative provides a proactive solution by creating a structured talent pipeline and a steady influx of skilled professionals into the sector.

IMO Secretary-General Arsenio Dominguez stressed the importance of strengthening the maritime workforce: “The future of the global shipping industry depends on its people, and this initiative has the potential to transform maritime careers for young seafarers worldwide.”

Kamal M Al Junaidi, Permanent Representative of Saudi Arabia to the IMO, highlighted the Project’s broader vision: “Through this initiative, we aim not only to train the next generation of seafarers but also to lead and inspire other nations and shipping companies to adopt similar programmes.”

The NextWave Seafarers Project invites IMO member states, training institutions, and shipping companies to collaborate in expanding this initiative and building a skilled, diverse, and resilient maritime workforce.

Designed as a proof of concept, the project’s outcomes will be shared with IMO Member States to shape future policy recommendations, enhance global seafarer training frameworks, and contribute to long-term maritime workforce planning.

IMO will issue a circular letter in due course requesting nominations of cadets from LDCs and SIDS through their respective maritime administrations. The circular letter will explain the criteria for selection and mode of participation in the training programme.

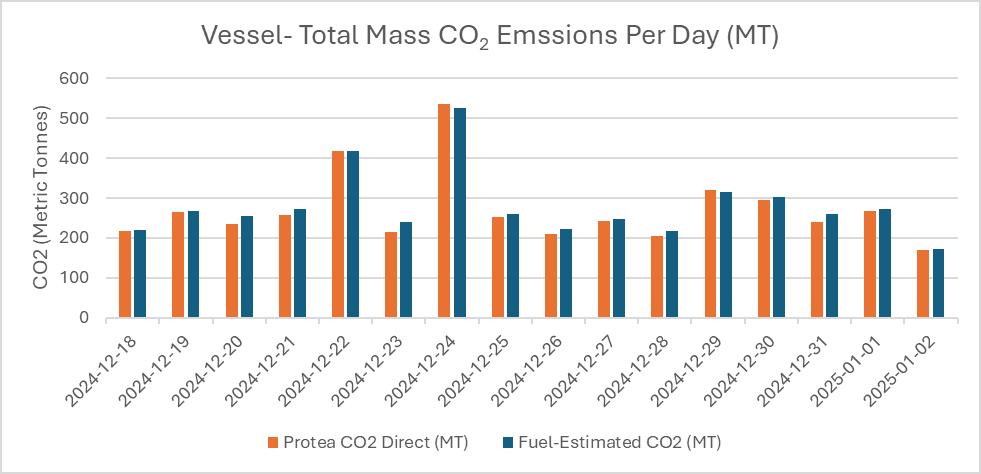

C o m p a r i s o n o f T h r e e M e t h o d s f o r M o n i t o r i n g C O ₂

a n d O t h e r G a s e s f r o m V e s s e l s

A b s t r a c t

T h i s s t u d y c o m p a r e s t h r e e m e t h o d s f o r m o n i t o r i n g C O 2

e m i s s i o n s f r o m v e s s e l s : d i r e c t e x h a u s t m e a s u r e m e n t , f u e l -

b a s e d c a l c u l a t i o n s , a n d e n g i n e l o a d - b a s e d c a l c u l a t i o n s D a t a

f r o m f i v e e n g i n e s o n a c r u i s e s h i p w e r e c o l l e c t e d o v e r s e v e r a l

w e e k s T h e C o n t i n u o u s E m i s s i o n M o n i t o r i n g S y s t e m ( C E M S )

w a s u s e d f o r d i r e c t m e a s u r e m e n t , w h i l e f u e l c o n s u m p t i o n a n d

e n g i n e l o a d p r o v i d e d c a l c u l a t e d e s t i m a t e s R e s u l t s s h o w e d

s t r o n g c o r r e l a t i o n s b e t w e e n m e t h o d s , w i t h d i r e c t m e a s u r e m e n t

o f f e r i n g h i g h e r a c c u r a c y

I n t r o d u c t i o n

M A R P O L A n n e x V I , a d o p t e d i n 1 9 9 7 , a i m s t o r e d u c e v e s s e l

e m i s s i o n s , i n c l u d i n g C O 2 , N O x , a n d S O x M a r i t i m e t r a n s p o r t

c o n t r i b u t e s 2 - 3 % o f g l o b a l C O 2 e m i s s i o n s T h e E U i n t r o d u c e d

R e g u l a t i o n ( E U ) 2 0 1 5 / 7 5 7 t o m o n i t o r a n d v e r i f y C O 2 e m i s s i o n s

S i n c e 2 0 2 4 , t h e E U E m i s s i o n s T r a d i n g S y s t e m ( E T S ) r e q u i r e s

s h i p s t o p u r c h a s e a l l o w a n c e s f o r C O 2 e m i s s i o n s , i n c e n t i v i z i n g

c l e a n e r t e c h n o l o g y D i r e c t m e a s u r e m e n t ( M e t h o d D ) e n s u r e s

a c c u r a c y b u t p o s e s c o s t a n d i m p l e m e n t a t i o n c h a l l e n g e s .

M o n i t o r i n g S y s t e m M e t h o d o l o g y

I n - S i t u G a s A n a l y s e r

T h e P 2 0 0 0 a n a l y s e r m e a s u r e s p o l l u t a n t c o n c e n t r a t i o n s i n

e x h a u s t g a s I t u s e s i n f r a r e d ( I R ) a b s o r p t i o n t o d e t e r m i n e C O 2 ,

C H 4 , S O 2 , N O x , a n d H 2 O l e v e l s

a t m o s F l o F l o w m e t e r

M e a s u r e s e x h a u s t g a s f l o w r a t e t o d e t e r m i n e v o l u m e t r i c

e m i s s i o n s

M a s s E m i s s i o n C a l c u l a t i o n

M a s s e m i s s i o n s a r e c a l c u l a t e d a s :

C O 2 M a s s E m i s s i o n R a t e = F l o w R a t e ( m ³ / h r ) × C O 2

C o n c e n t r a t i o n ( k g / m ³ )

T e m p e r a t u r e a n d p r e s s u r e c o m p e n s a t i o n e n s u r e a c c u r a c y b y

n o r m a l i s i n g d a t a t o s t a n d a r d c o n d i t i o n s

C o m p a r i s o n w i t h S e c o n d a r y M o n i t o r i n g M e t h o d s

M e t h o d C : F u e l - B a s e d C a l c u l a t i o n

C O 2 e m i s s i o n s a r e e s t i m a t e d f r o m r e c o r d e d f u e l c o n s u m p t i o n

u s i n g t h e e m i s s i o n s f a c t o r ( 3 2 0 6 k g C O 2 / k g f u e l ) A

c o m p a r i s o n o f d i r e c t v s f u e l - b a s e d m e a s u r e m e n t s o v e r 1 6

d a y s s h o w e d a s t r o n g c o r r e l a t i o n ( R 2 = 0 9 9 3 )

M e t h o d B : L o a d - B a s e d C a l c u l a t i o n

C O 2 e m i s s i o n s a r e e s t i m a t e d u s i n g e n g i n e p o w e r ( k W ) a n d

e m i s s i o n s f a c t o r s d e r i v e d f r o m I S O 8 1 7 8 - 4 t e s t r e p o r t s L o a d -

b a s e d e s t i m a t e s a l s o c o r r e l a t e d s t r o n g l y w i t h d i r e c t

m e a s u r e m e n t ( R 2 = 0 9 9 8 4 )

R e s u l t s a n d E v a l u a t i o n

O v e r 1 6 d a y s , a l l t h r e e m e t h o d s c o r r e l a t e d s t r o n g l y , w i t h d i r e c t

m e a s u r e m e n t r e c o r d i n g a 3 5 % l o w e r C O 2 o u t p u t t h a n f u e l -

b a s e d c a l c u l a t i o n s T h i s d i s c r e p a n c y s u g g e s t s f u e l - b a s e d

e s t i m a t e s m a y o v e r e s t i m a t e e m i s s i o n s d u e t

c o m p l e t e c o m b u s t i o n

C o n c l u s i o n

D i r e c t m e a s u r e m e n t ( M e t h o d D ) c l o s e l y

c o m p l i a n c e a n d o p e r a t i o n a l d e c i s i o n s I t a l s o a c c o u n t s f o r

v a r i a t i o n s d u e t o a b a t e m e n t t e c h n o

Scrubbers, a proven and longstanding technology, are essential for reducing air emissions. They not only remove sulphur oxides (SOx) from exhaust gases but also tackle other pollutants such as nitrogen oxides (NOx) and particulate matter. Their role extends further as they can mitigate emissions from emerging e-fuels, underscoring their importance in environmental sustainability. Moreover, scrubbers have evolved into efficient carbon capture solutions, crucial in the transition toward lower CO2 and greenhouse gas emissions.

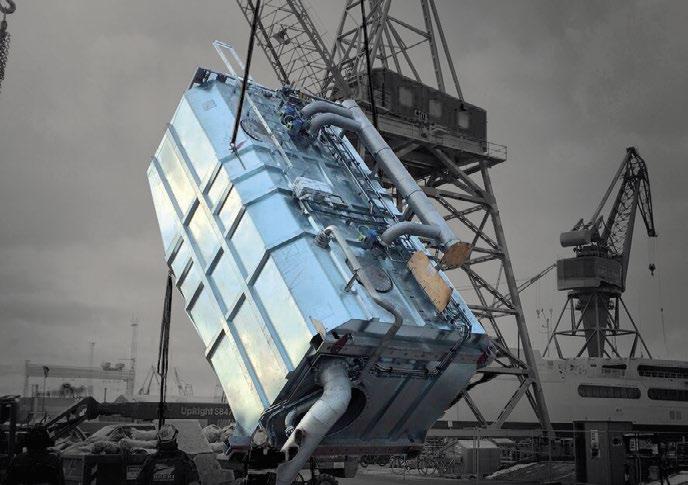

PureteQ is currently installing new scrubber systems on vessels in China and in Europe for European and Asian owners. Nearly all dualfuel new builds now incorporate scrubbers. These systems are driving advancements in carbon capture technology, serving as pretreatment for CO2 capture onboard ships – an important step in reducing global emissions.

Given the projected scarcity and high production costs of green fuels, scrubbers and CO2 capture systems are emerging as vital, long-term and cost-efficient solutions rather than merely interim measures.

Container shipping companies have saved US$13bn since 2020, according to a report by Sea-Intelligence. The report highlights the economic advantages of effective environmental measures, such as scrubbers, which ensure full compliance with stringent environmental regulations.

Sea-Intelligence emphasises the vital role of innovation and technological investment in fostering economic growth and sustainability within the shipping sector.

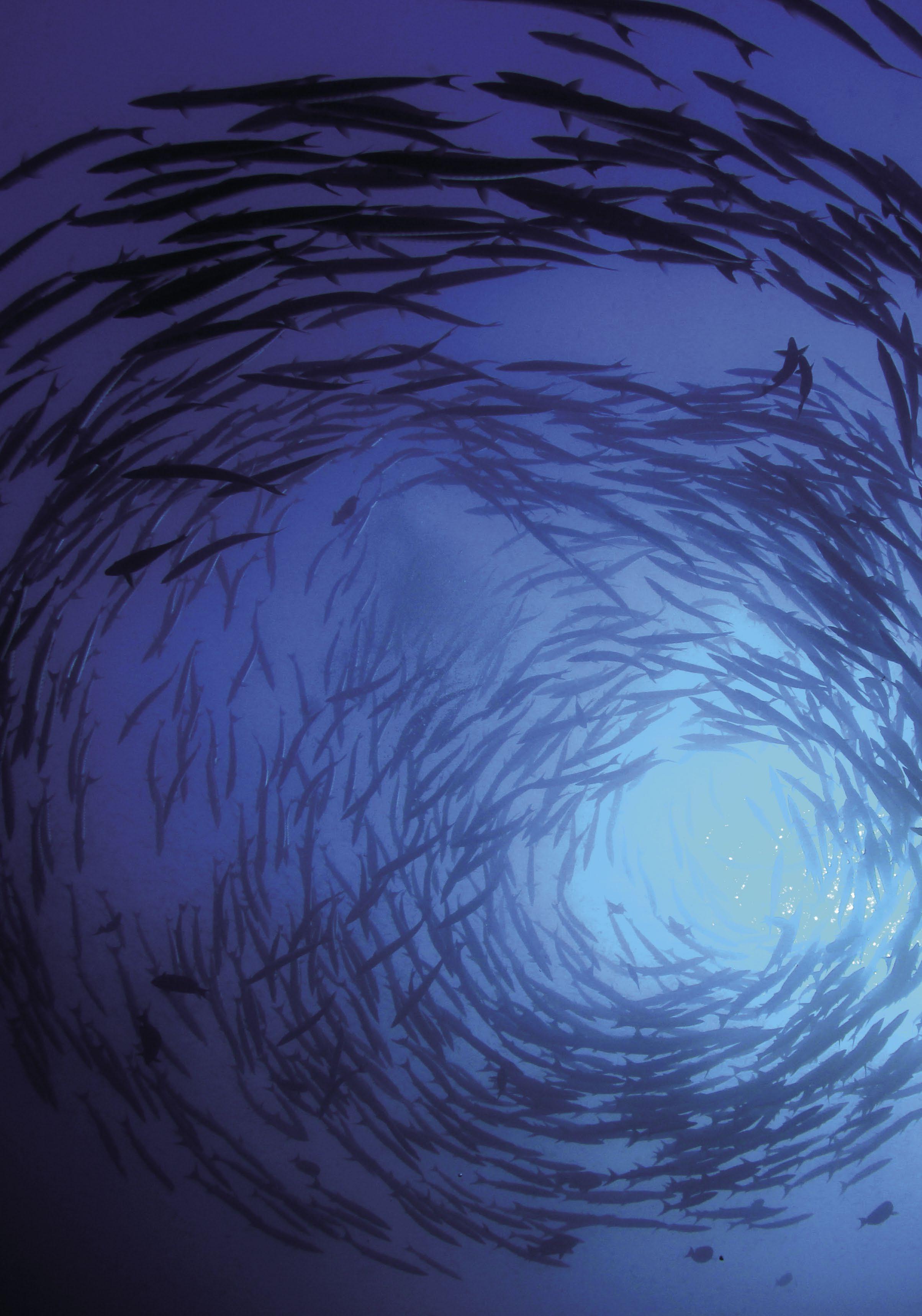

The most common scrubber systems are open-loop scrubbers, primarily due to their lower cost and complexity compared with closed-loop or hybrid alternatives. While cost-effective, open-

loop scubbers face increasing scrutiny due to environmental concerns, particularly regarding their potential impact on marine biodiversity. However, open-loop scrubbers emit only a small fraction of the limits set by

the International Marine Organization (IMO) for washwater discharge.

Recent discussions about the potential negative impacts of openloop exhaust gas cleaning systems in environmentally sensitive areas – such as ports or regions with strict discharge regulations – have prompted the IMO to call for validated sampling data.

In response, Norwegian shipowner Solvang has publicly submitted five years of sampling data from its exhaust gas cleaning systems aboard 13 vessels. Verified by SINTEF, an independent research institute, this data effectively refutes a recent German report that presented inflated figures based on inaccurate emission factors and methodological errors.

Solvang’s validated data, now under review by Norwegian Maritime Authorities and submitted to the IMO for high-level environmental risk assessment, demonstrates that the contamination from exhaust gas cleaning systems is a fraction of the levels reported in the German study.

Globally, the use of closed-loop scrubbers is on the rise. These systems release little to no washwater into the sea when operating in closed-loop mode, making them

ideal for environmentally sensitive regions. Despite being considered future-proof and offering enhanced adaptability, closed-loop scrubbers come with higher costs and greater operational complexity.

To balance cost, compliance, and operational needs, many operators are adopting hybrid scrubbers, which combine both open-loop and closedloop functionalities.

The efficiency of scrubbers depends on their ability to effectively treat exhaust gases under varying loads. This effectiveness is determined by the fundamental design of the scrubber tower and the control mechanisms that govern its operation. Maintaining optimal scrubber efficiency requires continuous monitoring and regulation of the washwater system. Any drop in efficiency results in increased electricity consumption and higher operational costs.

PureteQ scrubber systems are renowned for their high energy efficiency and advanced automation, enabling lower operational costs compared to other brands. PureteQ service engineers can fine-tune even

less efficient scrubber systems from other manufacturers to minimise energy consumption caused by over-scrubbing.

To further enhance energy efficiency, PureteQ offers shipowners access to Pure-SPOT, a web-based scrubber performance optimisation tool.