Technical Global Sulphur Cap 2020 (Part 2) The global 0.50% sulphur cap will be introduced in 2020, and up to 70,000 ships may be affected by the regulation according to IMO estimates. There are the following options to ensure compliance with the Global Sulphur Cap: 1. Low sulphur distillate fuels 2. Low sulphur heavy fuel oil 3. Scrubber installation and operation on HSFO 4. LNG as fuel 5. Use of alternative fuels and technologies The first two options were described in the previous Wavelength issue (no. 68).

3. Installation of scrubbers and operation on HSFO - Introduction HSFO will still be an option after 2020. However, to be in compliance, it will require the installation of exhaust gas cleaning technology commonly known as SOx scrubbers. No changes will have to be made to the engines or fuel treatment plant, but the installation of a scrubber could be complex, especially for retrofits. There is a significant investment cost for the exhaust gas cleaning plant and there will also be operational expenses related to increased power consumption and the possible need for chemical consumables and sludge handling. In the scrubber, the exhaust gas is cleaned by water on its way to the funnel. The water is injected into the exhaust gas stream and is discharged from the bottom of the scrubber. The water used in the cleaning process could be either sea water (SW) or fresh water (FW).

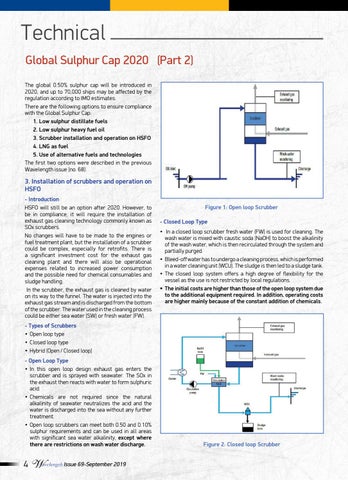

Figure 1: Open loop Scrubber - Closed Loop Type • I n a closed loop scrubber fresh water (FW) is used for cleaning. The wash water is mixed with caustic soda (NaOH) to boost the alkalinity of the wash water, which is then recirculated through the system and partially purged. • Bleed-off water has to undergo a cleaning process, which is performed in a water cleaning unit (WCU). The sludge is then led to a sludge tank. • The closed loop system offers a high degree of flexibility for the vessel as the use is not restricted by local regulations. • The initial costs are higher than those of the open loop system due to the additional equipment required. In addition, operating costs are higher mainly because of the constant addition of chemicals.

- Types of Scrubbers • Open loop type • Closed loop type • Hybrid (Open / Closed loop) - Open Loop Type • In this open loop design exhaust gas enters the scrubber and is sprayed with seawater. The SOx in the exhaust then reacts with water to form sulphuric acid. • Chemicals are not required since the natural alkalinity of seawater neutralizes the acid and the water is discharged into the sea without any further treatment. • Open loop scrubbers can meet both 0.50 and 0.10% sulphur requirements and can be used in all areas with significant sea water alkalinity, except where there are restrictions on wash water discharge.

4

Issue 69-September 2019

Figure 2: Closed loop Scrubber