L et ’s fi l l

o u r wo r l d

w i t h b e a u t y

L et ’s fi l l

o u r wo r l d

w i t h b e a u t y

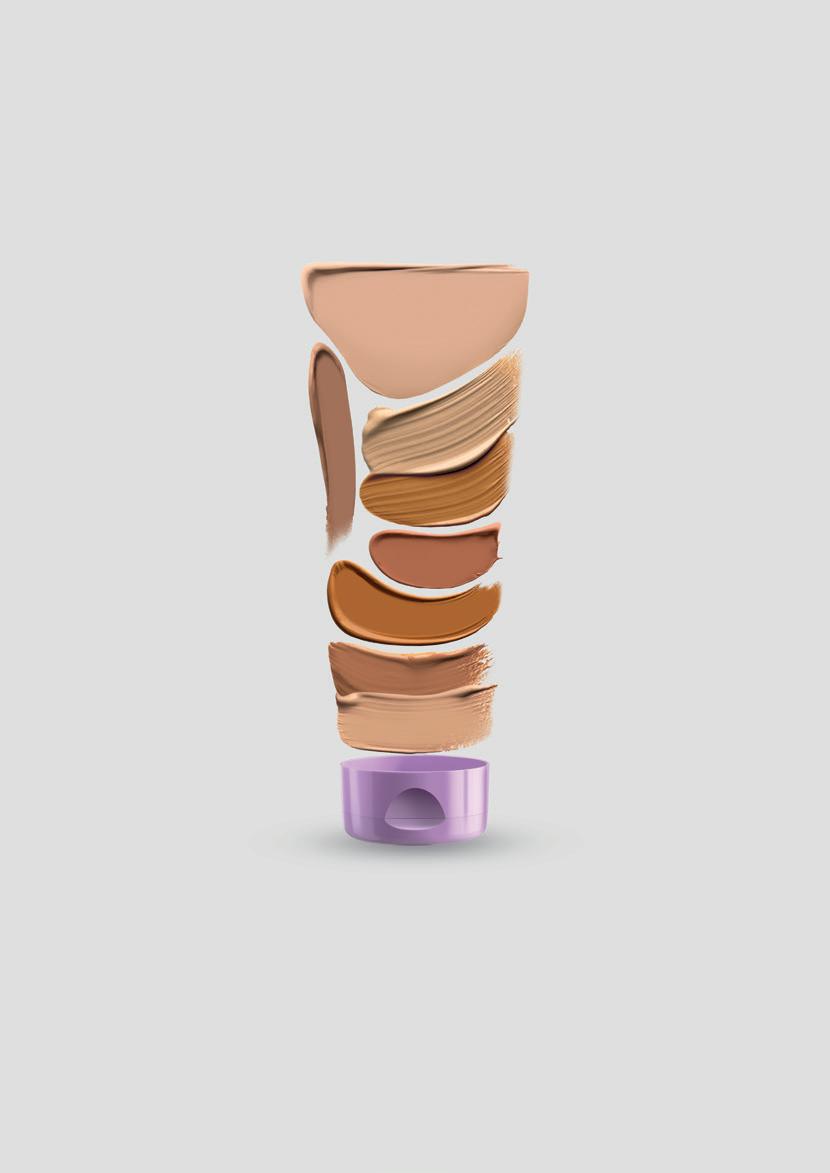

We produce machines and lines for the processing and packaging of cosmetic products. We are committed to responding promptly to every type of request - from laboratories and small businesses to extensive companies - in order to fulfill our common purpose: filling the world with beauty.

With 50 years’ experience in the packaging industry, Marchesini Group offers a complete range of machines for the cosmetics industry, designed and tailor-made to each client’s individual specifications.

Group Beauty is a leading company in producing complete lines and machines covering the entire packaging process for the cosmetic industry.

The solutions available include machines for processing creams, filling, capping and sealing jars, tubes, mascaras, lip-glosses, lipsticks, sachets and many other products, as well as cutting-edge automatic cartoners, wrappers and labelling machines. We also provide sterile solutions for dermo-cosmetic products and thermoforming applications for the personal care industry.

With the launch of the company’s dedicated Beauty Division, Marchesini Group is fast becoming a reference point in the rapidly growing cosmetics and personal care packaging market both in Italy and abroad.

Now that the Group has also added the extraordinary expertise of brands such as Axomatic, Cosmatic, Dumek, Rejves Machinery, Vibrotech and V2 engineering, the Group solutions have never been so complete.

We provide a complete range of machines for the entire cosmetic packaging process.

Compact-sized machines take up minimum space while maintaining efficient output.

Customer Care Service is guaranteed for the entire liftetime of the machine.

Our machines handle even the most delicate product with care.

Accessible and ergonomically designed machines ensure a positive operator experience in terms of machine management, inspection and service. Skilled staff and constant investment in R&D personalise your project and find the machine solution to suit your needs.

Fast and simple changeover

offers great flexibility in adapting product size and shape in our machines.

We satisfy the requirements of cosmetics customers rapidly and efficiently.

Featured Model TURBO-MEK 10

Vacuum turboemulsifiers suitable for processing liquid and creamy products for laboratories, pilot plants and very small-scale productions.

• Lifting lid.

• Tilting vessel.

• Vessel insulating jacket.

• Vessel equipped with jacket for heating by electric resistances and cooling.

• Integrated melter (option).

• Vacuum circuit.

• Slow mixer with counter-rotating movement having a speed regulated by inverter.

• Turbine positioned on the vessel bottom having a speed regulated by inverter.

• Base entirely realized in AISI 304 stainless steel.

• 12” Touchscreen.

• D-connect for connection and remote service with dedicated App (option).

RANGE

3 - 5 - 10 - 15 litres

Featured Model AXOBLADE 5

Turboemulsifiers model “AXOBLADE” especially designed to produce stable emulsions, creams, gels, balms, lotions, and make-up all with extremely small particles for laboratories and small-scale productions.

• Special mixing system “ALL IN ONE”

• Fast homogenizer by BLADES adj. speed from 300 up to 3000 RPM.

• Special anchor for slow mixing with adj. speed from 5 up to 15 RPM.

• Special mechanical seals to avoid air in the product.

• Perfect temperature control.

• Vacuum efficacy.

• Easy cleaning.

• Hydraulic lifting of the cover.

• Vessel tilting up to 95 degree.

• Small hopper for additive, perfumes.

• Observation window with screen and lamp.

• Removable spout on the vessel for product conveying when tilting.

• All parts coming into product contact are realized in stainless steel AISI 316L mirror polished.

• Control panel with multi-coloured touch screen of 15”, suitable for Industry 4.0.

• Possibility to record recipes.

• Ethernet connection for remote assistance.

• Optional available on request: CIP system, steam heating, etc..

• Full Atex version (option).

RANGE

5 - 300 litres with intermediate capacities

Featured Model AXOMIX 10

Turboemulsifiers especially designed to produce stable emulsions, creams, milk, gels, balms, lotions, and toothpastes all with extremely small particles for laboratories and small-scale productions.

• Optimum mixing system for raw materials.

• Special geometry of the turbine and its high rotation speed (3000 rpm).

• Special sealing gaskets guarantee the impossibility to have air in the product.

• Perfect temperature control.

• Vacuum efficacy.

• Easy cleaning.

• Fast homogeniser (adj speed up to 3000 rpm).

• Adjustable speed of the Slow mixing, by inverter.

• Hydraulic lifting of the cover.

• Manual hand wheel for vessel tilting.

• Small hopper for additive, perfumes.

• Observation window with screen and lamp.

• Removable spout on the vessel for product conveying when tilting.

• Control panel with multi-coloured touch screen of 10”, suitable for Industry 4.0.

• Possibility to record recipes.

• All parts coming into product contact are realized in stainless steel AISI 316L mirror polished.

• Ethernet connection for remote assistance.

• Optional available on request: CIP system, data printing, steam heating, etc..

• Full Atex certification (option).

RANGE

3 - 50 litres with intermediate capacities

FILLING RANGE

• 2 - 2500 ml - pneumatic version also available.

• Wi-fi remote control with a dedicated APP.

FILLING RANGE

• 10 - 1100 ml with all the intermediate capacities.

• High dosage accuracy.

FEATURES

• Manual machine without electricity or compressed air.

• Max. tube diameter: 42 mm.

FEATURES

• Codes 4 tubes simultaneously for production cycle

• Max. diameter: 50 mm (coding option).

FEATURES

• Hot air sealing device for plastic and laminated tubes.

• Max. tube diameter: 50 mm coding and trimming station.

FEATURES

• Suitable to check the fitting of the stick in the packaging.

• Equipped with a disk for one size of packaging.

FEATURES

• Laboratory equipment suitable to the production of lipstick samples.

FEATURES

• Labo unit for filling cosmetic products up to 130°C.

• Minimum dosing 0,2 ml and maximum dosing unlimited.

• The dosage is constan, accuracy +/- 0,5%.

• One filling nozzle with manual adjustable height.

• The level is kept constant through a bin fed by a pump.

• Manufacturing in Anticorodal material.

• Full electric operation (not pneumatic).

Featured Model TURBO-MEK 2000

Vacuum turboemulsifiers suitable for processing liquid and creamy products for large scale productions.

• Lifting lid.

• Tilting vessel (option, up to 3000 litres).

• Base entirely realized in AISI 304 stainless steel.

• Vessel equipped with jacket for heating and cooling.

• Electric or steam vessel heating system.

• Vessel insulating jacket.

• Turbine positioned on the vessel bottom having a speed regulated by inverter.

• Slow mixer with counter-rotating movement having a speed regulated by inverter.

• Vacuum circuit.

• 12” Touchscreen.

• CIP and SIP systems with possible storage tanks.

• Staircases and mezzanine in AISI 304 stainless steel.

• Product recirculation line with 2 stage turbine system (option).

• Slow mixer with double-planetary blades (option).

• Vessel emptying by pressure (option).

• Set up for inside vessel washing (option).

• Ancillary melters (option).

• D-connect for connection and remote service with dedicated App (option).

• Full Atex certification (option).

RANGE

25 - 10000 litres with intermediate capacities

Extremely flexible and customisable machine which, thanks to the motor on the bottom of the container, can fit a variety of quickly interchangeable anchors and mixing blades, making it versatile in processing raw ingredients.

• Electric vessel heating system.

• Product temperature thermo-regulation.

• Vessel insulating jacket.

• Base on braking casters, or palletised.

• Main motor installed on the bottom for improved access

• Quick & Easy. interchangeable slow mixer anchor shaped (Flex option).

RANGE

100 - 300 litres with intermediate capacities

Featured Model AXOMIX 500

The Axomix turboemulsifier is especially designed to produce stable emulsions, creams, milk, gels, balms, lotions, ointments and toothpastes, all with extremely small particles for the cosmetic, chemical and food industries.

• Machine body covers and electrical cabinet completely made in Stainless Steel AISI 304L with proper glazing type “Scotch Brite” TM.

• Manual Piston Suction/Discharge centrally positioned on the bottom of the mixer.

• Fast mixing electronically adjusted by inverter.

• Ethernet port to have remote assistance and diagnose any software problem.

• Hydraulic lifting and lowering of the cover and of the vessel.

• Heating system by thermoregulated heating elements positioned in separated tank.

• Vacuum system: powerful “Liquid Ring” vacuum pump, equipped with solenoid safety valve on the water inlet.

• CIP system by spray balls.

• Check-Weigher.

• Technologically advanced HMI, with Ethernet port to download the main machine process data and record of recipes.

• New generation PLC and advanced T&S, with Ethernet connection and USB port, for remote assistance and in compliance with Industry 4.0 .

• External product recirculation (optional).

RANGE

100 – 10000 litres

Accessories for vacuum turboemulsifiers, useful to complete the production process and available in different solutions for mixing, dispersion or storage.

• Machine body covers completely made in Stainless Steel AISI 304L mirror polish finished (inner and outer).

• Expansion hopper for the compensation of the oil volume during the heating phase.

• Temperature controlled by a thermoregulator and probe positioned directly on the base of the tank for an accurate reading of the real temperature of the product.

• Cover divided in two parts to better control the process.

• Easy oil discharge for machine maintenance.

RANGE

20 - 5000 litres with intermediate capacities

Model TRESOR 1000

• Its versatility and ease of changeover enable it to handle a wide range of bottle sizes.

• High production rates.

• It is suitable for products with unfavorable barycenters.

OUTPUT

Up to 600 pcm

Tracks: 1

Position: vertical axis

PRODUCT RANGE

Product diameter: 15mm - 200mm

Product height: 35mm - 400mm

Tresor mechanical feeding system is designed primarily for feeding bottles of all sizes. It consists of circular unscrambler and linear belt conveyor.

• Estimated size changeover in 15 minutes.

• Possibility of integration: inkjet printing station, cleaning station.

Vibroflex TPR is a flexible feeding system for handling tray products equipped with a robot, vision system, vibrating hopper, and vibrating plate that can process multiple products such as bottles, brushes and caps, and stems of all kinds.

• The hopper doses the products on the plate and is designed not to overload the vibrating platform, which operates the product handling.

• The vision system processes the images captured by the camera and send the coordinates of the pickable products to the robot.

• The robot pick up the products and deposit them oriented toward the destination. The station is prepared to accommodate different types of robots (anthropomorphic, SCARA, Delta) and from different producers.

• It is suitable for products with unfavorable barycenters.

• Handling of delicate products sensitive to scratches, possibility of distinction by internal details, and possibility of discarding nonconforming products.

• The system features ultrarapid format changeover managed by software.

• Possibility of inserting caps or brushes directly on already filled bottles.

• Possibility of using multiple stations to increase production rates.

Up to 30 pcm deposit in pre-filled bottle

Up to 40 pcm deposit on accumulation guide

Up to 50 pcm double pick-up with deposit on accumulation guide

Product diameter: 10mm - 100mm

Product height: 10mm - 150mm

Vega is a robotic feeding system for handling tray products such as dispensers, caps, bottles or other products in both plastic and glass.

• The operator manually loads full trays and the trays are unloaded and collected outside the system.

• Dedicated software processes the images captured by the camera and sends the robot the coordinates of the products that can be picked from the tray.

Up to 40-60 ppm

Tracks: 1

Position: variable depending on the product

PRODUCT RANGE

Product diameter: 20mm - 120mm

Product height: 20mm - 120mm

• Radial orientation of products.

• Bottles can be deposited on a conveyor belt or in godets.

• Caps can be deposited directly into the filled bottle.

• The station is designed to accommodate 2 Scara robots.

Prism 60 is a robotic feeding system for handling bulk products. It can process different product types such as bottles, jars, tubes, caps, brushes, flexible and delicate packaging products in different materials, excluding glass objects.

• The system consists of a rotating sorting disc, a belt (or vibrating) hopper that doses the products onto the rotating disc, a vision system that detects the products to be picked, and a Delta-type robot that picks up the products and deposits them at the outlet.

• High efficiency: all products loaded on the sorting disc are brought to the exit without recycling with secondary systems.

OUTPUT

Up to 60 pcm

Tracks: 1

Position: variable depending on product

PRODUCT RANGE

Product diameter: 20mm - 120mm

Product height: 20mm - 250mm

• Gentle product handling: the system avoids repetitive strain on the products and thus damage to them. It is therefore particularly suitable for delicate cosmetic packaging.

• Functional design and compact footprint.

• Format changeover time zero without mechanical parts for similar products.

• Robot gripper format changeover only for different product.

• Optional extras that can be integrated: deposit of products in godet and automatic emptying of products onto the disc.

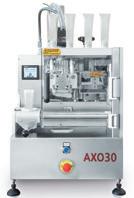

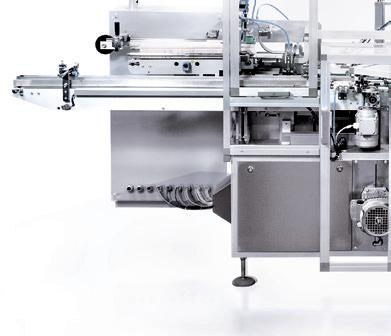

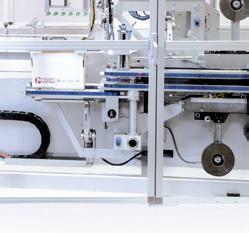

The machines of the Axo Series (models from 800 to 3600) are automatic filling and closing machines for metal, laminated and plastic tubes.

• Machine body covers, electrical cabinet completely made in Stainless Steel AISI 304L with easy access, to all machine devices.

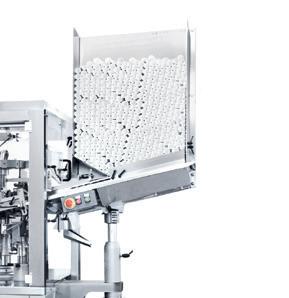

• Automatic tube infeed from the magazine (option ergonomic jumbo loader) from model AXO1000.

• Accurate automatic tube print registration, by registration mark scanner.

• Diving Nozzle for bottom-up filling (130 mm stroke adjustable) for AXO 800 fix 70mm.

• Simple and Quick format changes and adjustment without tools.

OUTPUT

Up to 220 tubes/min

PRODUCT RANGE

• New generation PLC and advanced T&S, with Ethernet connection and USB port, for remote assistance and in compliance with Industry 4.0.

• Machine predisposed for simultaneously fitting of both closing heads, for plastic and metal tubes (option).

Metal tube diameter: 13.5 mm - 42 mm (50 mm option)

Plastic tube diameter: 13.5 mm - 50 mm (60 mm option)

Tube Length, cap included: 70 mm - 250 mm

Filling range: 3 ml - 250 ml (450 ml option)

From single-channel to four-channels linear automatic filling and closing machines for metal, plastic and laminate tubes.

• Linear balcony structure.

• Parts in contact with product made with SS 316 L.

• Servo adjustment of tube length for versatile machine configuration.

• Dedicated trolley available for wet parts changeover while still assembled.

• Combined hot air and metal folding closing systems.

OUTPUT

Up to 320 tubes/min

PRODUCT RANGE

Metal tube diameter: 11 mm - 40 mm

Plastic tube diameter: 11 mm - 50 mm

Tube length, cap included: 50 mm - 250 mm

Filling range: 3 ml - 350 ml

• Each machine movement is obtained by a dedicated servo motor.

• Quick and easy size parts changeover without use of tools.

• Touch screen control panel for machine management, with self-diagnosis and help functions.

Automatic intermittent motion rotary machine, for filling and capping glass or plastic jars with creams, gels or liquid products.

• Working star-wheel to transfer and position jars into the different machine stations.

• Touch screen control panel for machine management, with self-diagnosis and help functions.

• Brushless capping station with integrated torque control.

OUTPUT

Up to 65 jars/min

PRODUCT RANGE

Jar diameter: 35 mm - 85 mm (100 mm option)

Cap size: 35 mm - 85 mm (100 mm option)

Filling range: 3 ml - 250 ml (500 ml option)

• Pick & Place for under cap plugs feeding and positioning.

• Welding/pouching system for under cap liner sealing.

• Manual or automatic jars/plugs/caps feeding system.

Automatic sachet machine (4 sealed sides) for filling Powders, Granules, Liquids, Creams or Solids.

• The unit is equipped with a control panel (soft touch screen) incorporating a PLC controlling the various machine’s functions including:

sealing temperature, safety devices, length of bags, motor’s speed, cutting, centered printing, etc.

OUTPUT

Up to 4000 sachets/h

Alternate movement automatic filling and capping machine with transport wheel for stable and not stable bottles with pucks, for liquid and cream products.

• Very compact monobloc solution.

• Manual loading of the container from the operator, directly on the belt.

• One volumetric dosing pump group, mechanically driven.Sigle filling head for bottom-up filling with mechanical adjustable

OUTPUT

Up to 25 pieces/min

PRODUCT RANGE

Stable containers diameter: 20 mm - 90 mm

stroke up to 160 mm.

• Capping system for capping head movement and spinning, by Servo-motors.

• Simple and quick format changes and adjustment without tools.

Stable containers height: 40 mm - 285 mm (cap included)

Alternate movement automatic filling and capping machine with transport wheel for stable and not stable bottles with pucks for liquid and cream products.

• Machine frame completely realized in AISI 304L.

• Manual loading from the operator, directly on the belt.

• Filling unit with volumetric dosing pump and linear movement by servo motors.

• Filling nozzle with “No Drop System”.

• Diving nozzles for bottom-up filling (200 mm stroke adjustable) driven by servo motor.

• Depucker system for product unloading.

STANDARD PERFUME

OUTPUT

Up to 40 pieces/min

PRODUCT RANGE

Diameter: 20 mm - 100 mm (110 mm option)

Height: 40 mm - 285 mm (300 mm option)

OUTPUT

• Screwing unit driven by servo motor.

• Dosing system for liquids and thick products.

• Simple and quick format changes and adjustment without tools.

• Alphanumeric machine functions display touch&screen 10’’ suitable for Industry 4.0.

• Robotic cap pick and place (option).

• Full Atex certification (option).

• More optionals available on request.

Up to 40 pieces/min

PRODUCT RANGE

Diameter: 20 mm - 100 mm (110 mm option)

Height: 40 mm - 285 mm (300 mm option)

Intermittent motion machine for filling and capping plastic and glass bottles in various formats and sizes.

• All the parts in contact with the product made of 316 L Stainless Steel.

• Compact-sized machine, with small footprint.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Easy and fast tool-free changeover.

• Central starwheel, equipped with safety clutch, for bottle transport to different operating stations.

• Vibrating bowls positioned on the operator side for easy closure loading.

STANDARD

OUTPUT

Up to 50 pieces/min

PRODUCT RANGE

Filling range:

5 ml - 500 ml

Bottle diameter:

70 mm

Bottle height:

160 mm

CONTAINERS

OUTPUT

Up to 50 pieces/min

PRODUCT RANGE

Filling range: 5 ml - 20 ml

Bottle diameter: 70 mm

Bottle height: 160 mm

• One through tabletop conveyor for bottle inlet and outlet, with adjustable guides, allowing Bypass function (upon request).

• Possibility to install peristaltic pump group or Mass Flow Measuring Systems, Rotary Piston Pump.

• Possibility of partial filling or filling in one cycle.

• Different closing units available to handle a wide selection of closures, with one or more units fitted at the same time.

• Wide range of options available.

PERFUME

OUTPUT

Up to 50 pieces/min

PRODUCT RANGE

Filling range: 5 ml - 500 ml

Bottle diameter: 70 mm

Bottle height: 160 mm

OUTPUT

Up to 120 pieces/min

PRODUCT RANGE

Filling range: 1 ml - 3 ml

Bottle diameter: 10 mm

Bottle height: 55 mm

Whatever your closure needs, we’ve got you covered. Whether mechanical, hybrid, electronic, rotary, or linear, our capping machines deliver 100% in performance, reliability, and efficiency.

• Rotary Capping Machines: Rejves Machinery’s capping machines are extremely flexible and versatile, capable of handling various styles of closures.

• Customizable Free-Standing Cappers: Our free-standing cappers are fully customizable to meet customer requirements, whether

OUTPUT

Up to 150 pieces/min

INDUSTRIES

Cosmetic

Nutraceutical

Personal Care

PRODUCT RANGE

Bottle diameter: 100 mm

Bottle height: 240 mm

CONTAINERS

integrated into a new production line or an existing one.

• Versatile Container Handling: Our capping machines can handle different types of containers, from the smallest used in the cosmetic and pharmaceutical industries to the largest bottles for oil or detergents used in home care and industry.

• Closure Compatibility: Our machines can work with a wide range of closures, including dispenser pumps, atomizers, mini-triggers, and any type of screw caps, available in mechanical, hybrid, or electronic versions.

Our Linear Monoblock combines fast changeovers and ease of use with high performances and flexibility.

• The filling section of the REJBLOCK can be enhanced with our latest technologies: Magnetic Flow Meters, Mass Flow Meters and servo controlled Volumetric Pistons.

• Capping Section: Can be configured

REJBLOCK 360

OUTPUT

Up to 120 pieces/min

INDUSTRIES

Cosmetic

Nutraceutical Personal Care

PRODUCT RANGE

Filling range: 30 ml - 1000 ml

Bottle diameter: 100 mm

Bottle height: 240 mm

CONTAINERS

depending on the required output speed and flexibility.

• Compliance: The machine can be supplied in food-grade and ATEX versions.

REJBLOCK 540

OUTPUT

Up to 150 pieces/min

INDUSTRIES

Cosmetic

Nutraceutical Personal Care

PRODUCT RANGE

Filling range: 30 ml - 1000 ml

Bottle diameter: 100 mm

Bottle height: 240 mm

Lipstick moulding machine SM 600 based on the silicone mould technology.

• Complete with 1 single melting tank (15 liters), with volumetric doser, directly connected with the lipstick machine.

OUTPUT

Up to 600 pieces/hour

DETAILS

Operator: 1

Silicone Moulds: 48

Cooling System: -15° C

• The technological working cycle includes the moulds heating, dosing, cooling up to -15° C by forced air circulation, pick and place and demoulding.

• 48 silicone moulds and 32 bushes for packaging.

• The whole operation cycle of the lipstick moulding machine SM 600 is controlled by Siemens PLC.

Lipstick moulding machine S 2000 N based on the silicone mould technology with belt conveyor and auto-loader for empty bases.

• Complete with 1 or 2 melting tanks 35 liter, stand alone.

• Silicone moulds heating by infrared radiation, short wave (PATENTED).

• Dosing by means of doser with 2 gearing nozzles or volumetric doser.

• Cooling by forced air circulation, double refrigerator inside the machine, temperature -20°C, automatic defrosting.

OUTPUT

Up to 2400 pieces/hour

DETAILS

Operator: 1

Silicone Moulds: 160

Cooling System: -20°

• Pick and place for the pick and place operation of 4 cases by means of grippers to the demoulding group.

• Demoulding by means of mechanical system without membranes (PATENTED).

• Cases store by means of belt conveyor with pallet for cases.

• Controls of the machine by means of colour touch screen with software with manual and automatic menu.

• Easy and quick mould change.

• Fast colour change, moulds cleaning at colour change is not needed.

• Stick perfection, stick shapes and logo according to the customer’s requirements.

Automatic machine with direct filling into the package by top filling for lip balm.

• Dosing table at 864 positions.

• Cooling system by air.

• 120 liters melting tank, stand alone.

• Volumetric doser with 6 filling nozzles.

OUTPUT

Up to 4000 pieces/hour

DETAILS

Operator: 1

• Autoloader for bases.

• Autoloader for caps.

• Ink-jet system to print the code on the bottom of the package.

This machine with 96 metal moulds and small silicone moulds for the tip is suitable to fill sharpenable cosmetic pencils with a minimum diameter of 4 mm.

• Complete with 1 melting tank 15 liters with volumetric doser or gear doser with 2 nozzles.

• With hot wax dosing group.

OUTPUT

Up to 1400 pieces/hour

DETAILS

Operator: 1

Moulds: 96

Cooling System: -15° C

• With silicone spraying system into the empty pencils, with automatic loading and unloading.

• Back filling and a small silicone mould for the tip.

• PLC Siemens.

Rotating filling and capping machine designed according to the highest technological standards to guarantee the maximum productivity and quality.

Operation logic controlled by a IPC provided with a colour liquid crystal 15’’ touch screen display.

Automatic pick up, insertion (with brush guiding device) and screwing system for caps with electronic torque control and parameters which can be set by display.

Dosing group with tri-clamp connections (hopper, filling valve housing, filling valve and nozzle) which can be transferred, still assembled, from the filling area to the washing and sterilization area by a suitable truck.

The dosing adjustment can be set:

• manually by acting on a micrometric screw connected to a digital indicator.

• automatically from display by means of a servo-motor.

OUTPUT

Up to 60 pieces/min

PRODUCT RANGE

Diameter: 10 mm - 30 mm

Lenght: up to 90 mm

Cap height: 20 mm - 50 mm

Filling capacity: 3 ml - 34 ml

OUTPUT

Conveying system of containers with:

• symmetrical shape: with standard size parts.

• irregular shape: in pucks with return conveyor, if any, for the empty pucks back to the load/ unload area.

Up to 60 pieces/min

PRODUCT RANGE

Container diameter: 10 mm - 30 mm

Container height: 50 mm - 120 mm

Filling range: 3 ml - 34 ml

Automatic labelling machine suitable to apply one or two labels on oval, rectangular, round containers, vials and cylindric bottles.

• Orbital centering device for flat and oval formats.

• Automatic reel unwinder by means of independet motor.

• Stabilizing upper belt when labelling flat/oval products.

Up to 120 pieces/min

PRODUCT RANGE

Bottle height: 30 mm -250 mm

Bottle diameter: 15 mm - 90 mm

Reel diameter: up to 400 mm

• Flexibility, versatility and possiblity to integrate on board different types of printing and camera systems.

Automatic high-speed rotary self-adhesive labelling machine for bottles and jars.

• Ergonomic balcony construction for product visibility, maintenance and cleaning.

• Compact-sized machine, with optimized footprint.

• Touch screen control panel for machine management.

OUTPUT

Up to 300 pieces/min

PRODUCT RANGE

Bottle height: up to 220 mm

Bottle diameter: up to 115 mm

Reel diameter: up to 400 mm

• Easy and fast changeover from operator side.

• Up to 4 labelling heads, with non-stop operation option.

• Products can be transported free-standing or inside puck.

• Bottle conveyor carousel produced in different versions, with different number of seats.

• Angular adjustment of the label head for non-standard shapes.

• Micrometric adjustment of the label and overprint position.

Automatic high-speed horizontal self-adhesive labelling machine for mascara, lipstick and lip gloss.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Ergonomic modular design, with easy upgrade to handle new product shape/size or additional functions.

OUTPUT

Up to 200 pieces/min

PRODUCT RANGE

Container height: 80 mm - 200 mm

Container diameter: 10 mm - 30 mm (other dimensions available on request)

• Touch screen control panel for machine management.

• Suitable for products feeding in pitch by the Pick & Place unit or robotic loader.

• Prepared to accept up to 3 labelling heads.

• Wrap-around labels, stickers and bottom/ top labels can be applied on containers with irregular shapes, like mascara, lipstick, lipgloss.

• Containers can be oriented before and after label application.

• Highly accurate label application even on limited or recessed surfaces.

Automatic intermittent motion horizontal cartoning machine.

• Ergonomic construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction reduces maintenance and prolongs machine life.

• Easy and fast change over.

• Touch screen control panel for machine management.

Up to 70 cartons/min

PRODUCT RANGE

Width (A): 30 mm - 140 mm

Height (B): 15 mm - 80 mm

Length (H): 90 mm - 200 mm

• Highly reliable positive carton opening ensures erection of square and/or hard carton with low grammage.

• Multiple product feed options (bottles, tubes, lipsticks, mascara, lipgloss, trousses, sachets&stickpacks) as well as different components (leaflets, booklets, etc).

• Wide selection of coding and print systems available (embossing, inkjet, and laser).

• Flexibility for customisation.

• Compact-sized machine, with small footprint.

Automatic intermittent motion horizontal cartoning machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction reduces maintenance and prolongs machine life.

• Easy and fast change over from operator side.

• Touch screen control panel for machine management.

• Highly reliable positive carton opening ensures erection of square and/or hard carton with low grammage.

• Multiple product feed options (bottles, tubes, lipsticks, mascara, lipgloss, trousses, sachets&stickpacks) as well as different components (leaflets, booklets, etc).

OUTPUT

Up to 80 cartons/min

PRODUCT RANGE

Width (A): 30 mm - 140 mm

Height (B): 15 mm - 80 mm

Length (H): 90 mm - 200 mm

• Wide selection of coding and print systems available (embossing, inkjet, and laser).

• Flexibility for customisation

• Compact-sized machine, with small footprint.

Automatic intermittent motion horizontal cartoning machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction reduces maintenance and prolongs machine life.

• Easy and fast changeover from operator side.

• Touch screen control panel for machine management.

OUTPUT

Up to 120 cartons/min

PRODUCT RANGE

Width (A): 25 mm - 110 mm

Height (B): 15 mm - 60 mm

Length (H): 55 mm - 200 mm

• Highly reliable positive carton opening ensures erection of square and/or hard cartons and with low grammage.

• Cartons transport with rubber toothed belts without friction thereby avoiding scratching or marking carton surface.

• Multiple product feed options (bottles, tubes, lipsticks, mascara, lip-gloss, trousses, sachets & stick packs) as well as different components (leaflets, booklets, etc).

• Wide selection of coding and print systems available (embossing, inkjet, and laser).

• Flexibility for customisation.

• Compact-sized machine, with small footprint.

Automatic intermittent motion horizontal cartoning machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction to reduce maintenance and prolongs machine life.

• Easy and fast changeover from operator side.

• Touch screen control panel for machine management, with format size parameter set-up.

• Multiple product feed options as well as different components (leaflets, booklets, spoons, etc.).

• Wide selection of coding and print systems available (embossing, ink-jet, laser etc.).

• High-automated machines to handle a wide variety of products using robotized Pick & Place units.

• Machine layout so that product does not come into contact with carton dust.

OUTPUT

Up to 150 cartons/min

PRODUCT RANGE

Width (A): 20 mm - 190 mm

Height (B): 16 mm - 105 mm

Length (H): 60 mm - 250 mm

Automatic continuous motion horizontal cartoning machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction reduces maintenance and prolong machine life.

• Easy and fast changeover from operator side.

• Touch screen control panel for machine management.

• Highly reliable positive carton opening ensures erection of square and/or hard cartons and with low grammage.

OUTPUT

Up to 180 cartons/min

PRODUCT RANGE

Width (A): 25 mm - 100 mm

Height (B): 15 mm - 85 mm

Length (H): 65 mm - 190 mm

• The high capacity motorized carton magazine is located ata lower level compared to the product transport.

• Multiple product feed options (bottles, jars, tubes, lipsticks, mascara, lipgloss, trousses) as well as different components (leaflets, booklets, etc).

• Wide selection of coding and print systems available (embossing, ink-jet and laser).

• Flessibility for customization.

• Compact-sized machine, with small footprint.

Automatic continuous motion horizontal cartoning machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction to reduce maintenance and prolongs machine life.

• Easy and fast changeover from operator side.

• Touch screen control panel for machine management, with format size parameter set-up.

• Multiple product feed options as well as different components (leaflets, booklets, spoons, etc.).

Up to 500 cartons/min

PRODUCT RANGE

Width (A): 25 mm - 160 mm

Height (B): 15 mm - 110 mm

Length (H): 65 mm - 220 mm

• Wide selection of coding and print systems available (embossing, ink-jet, laser etc.).

• High-automated machines to handle a wide variety of products using robotized Pick & Place units.

• The high capacity motorized carton magazine is located at a lower level compared to the product transport.

• Machine layout so that product does not come into contact with carton dust.

Automatic, vertical intermittent motion cartoning machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction reduces maintenance and prolongs machine life.

• Easy and fast changeover from operator side.

• Touch screen control panel for machine management.

• Highly reliable positive carton opening ensures erection of square and/or hard carton with low grammage.

STANDARD VERSION HIGH SPEED

OUTPUT

Up to 60 cartons/min

PRODUCT RANGE

Width (A): 22 mm - 110 mm

Height (B): 20 mm - 100 mm

Length (H): 40 mm - 200 mm

• Cartons do not come into contact with fixed parts thereby avoiding scratching or marking carton surface.

• Multiple product feed options (bottles & jars in plastic and glass) as well as different components (carton in liners, leaflets, booklets, etc).

• Flexibility for customisation.

• Compact-sized machine.

OUTPUT

Up to 80 cartons/min

PRODUCT RANGE

Width (A): 22 mm - 85 mm

Height (B): 20 mm - 85 mm

Length (H): 40 mm - 200 mm

Featured Model V122LS

Automatic machine for overwrapping cartons and regular-shaped single products or bundled products.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction reduces maintenance and prolongs machine life.

• Easy and fast changeover from operator side.

• Tear tape unit for easy opening.

• Possibility to over-wrap naked soaps, single cartons or bundles in different configuration: stacks or on-edge grouping (feature available in V122-V122MP).

• Touch screen control panel for machine management.

• High quality wrapping.

• Printed film centering device.

• Film trimming unit.

STANDARD VERSION LS VERSION

OUTPUT

Up to 60 cartons/min

PRODUCT RANGE

Width (A): 50 mm - 210 mm

Height (B): 25 mm - 100 mm

Length (H): 80 mm - 300 mm

OUTPUT

• Lateral sealing customisation dedicated for high quality products (feature available only in V122LS).

• Flexibility for customization.

• Compact-sized machine, with small footprint.

Up to 60 cartons/min

PRODUCT RANGE

Width (A): 50 mm - 140 mm

Height (B): 30 mm - 80 mm

Length (H): 60 mm - 220 mm

Automatic overwrapping machine, designed for the cosmetic market. Suitable to operate with several typologies of products, single or banded together, with thermosealing film.

• The working area is in cantilever (balcony type) layout with easy accessibility and a small footprint.

• Driven by Brushless motors and remotely controlled by a PC, sealing temperatures included. The machine is fitted for a rapid size change over thanks to the employment of the lateral folding unit that allows to minimize

OUTPUT

Up to 80 boundles/min

PRODUCT RANGE

Width (A): 20 mm - 300 mm

Height (B): 12 mm - 150 mm

Length (H): 60 mm - 250 mm

the spare parts reducing the time needed to change the product format.

• Several arrangements and a wide range of customized solutions are available.

• Conformed to the GMP requirements.

• All the group placed in ergonomic positions.

• Operator touch screen interface for machine management.

Automatic horizontal case packing machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction to reduce maintenance and prolongs machine life.

• Compact-sized machine, with small footprint.

• Touch screen control panel for machine management, with format size parameter set-up.

• Easy and fast, tool-free changeover.

• A wide range of personalization options available.

OUTPUT

Up to 7 cases/min

PRODUCT RANGE

Width (A): 140 mm - 520 mm

Height (B): 120 mm - 400 mm

Length (H): 110 mm - 350 mm

Automatic top load case packing machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction reduces maintenance and prolongs machine life.

• Easy and fast changeover from operator side.

• Touch screen control panel for machine management.

OUTPUT

Up to 6 cases/min

PRODUCT RANGE

Width (A): 200 mm - 400 mm

Height (B): 120 mm - 300 mm

Length (H): 150 mm - 300 mm

• Highly reliable positive case opening ensures erection of square and/or hard cases.

• Particularly indicated for products which must be kept in upright vertical position during packaging process such as bottles, jars, bundles, etc.

• Case sealing with tape or hot melt.

• Flexibility for customisation.

• Compact-sized machine.

Automatic top load case packing machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction to reduce maintenance and prolongs machine life.

• Compact-sized machine, with small footprint.

• Vertical magazine case feed, conveniently positioned at the front of the machine, with high loading capacity.

OUTPUT

Up to 12 cases/min

PRODUCT RANGE

Width (A): 140 mm - 420 mm

Height (B): 120 mm - 320 mm

Length (H): 120 mm - 320 mm

• Touch screen control panel for machine management, with format size parameter set-up.

• Easy and fast, tool-free changeover.

• A wide range of personalization options available.

• Particularly indicated for products which must be kept in upright vertical position during packing process.

• Each pick up operation is checked during every cycle to guarantee correct case composition.

Automatic palletizing machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning.

• Reliable and robust mechanical construction to reduce maintenance and prolongs machine life.

• Compact-sized machine, with small footprint.

OUTPUT

Up to 8 cases/min

PALLET

Europallet: 800 x 1200 mm - 1000 x 1200 mm

Height: up to 1650 mm

PRODUCT RANGE

Width (A): 140 - 520 mm

Height (B): 120 - 350 mm

Length (H): 120 - 350 mm

• Touch screen control panel for machine management, with format size parameter set-up.

• Easy and fast changeover.

• A wide range of personalization options available.

• Each pick up operation is checked during every cycle to guarantee correct case composition.

Automatic horizontal case packer palletiser combining in a single, compact monoblock the operations of packaging products in cases then palletising them.

• The machine has been designed and manufactured following the balcony type construction to reduce mechanical maintenance and lubrication.

OUTPUT

Up to 8 cases/min

PALLET

Europallet: 800 x 1200 mm - 1000 x 1200 mm

Height: up to 1500 mm

PRODUCT RANGE

Width (A): 140 mm - 420 mm

Height (B): 120 mm - 320 mm

Length (H): 120 mm - 320 mm

• The mechanical parts are protected against dirt and dust because they are isolated from the working area and the case transport unit.

• The electric panel of the monoblock is included inside a sliding cabinet placed on the case packer rear side, the sliding cabinet makes possible accessibility to all mechanisms.

• All the case packer palletiser motions are driven by servo motors controlled by PC.

• Adjustments for case size change over under ‘B’ and ‘H’ quotes are made through servo motors with command directly from the operator panel. “A” is automatically adjusted by selecting the format from the PC.

• Quick lock size parts with reduced use of tools.

An advanced vision system driven by Artificial Intelligence for automated, in-line lipstick inspection. Integrating top-tier hardware with proprietary software and algorithms, it ensures meticulous quality assessment throughout the manufacturing process.

A-eye lipstick marks a revolutionary stride in quality control for lipsticks, achieved through the incorporation of Artificial Intelligence developed in collaboration with ARGO Vision, a startup specializing in AI that was acquired by SEA Vision in 2020. Our advanced algorithms blend neural, pre-neural, and non-neural technologies, achieving an ideal balance between quality and inspection efficiency.

The system cameras capture 360-degree images of the lipstick, with a particular focus on the tip. Rigorous software analysis examines these images in detail, dissecting various lipstick components, evaluating product attributes, and identifying defects. Users can customize the level of control by adjusting acceptance criteria to meet specific production requirements. The system then communicates with the production machine to automatically reject products that do not meet the defined criteria.

The system improves product quality and boosts production performance by providing automatic, consistent, and reliable control over 100% of your lipstick production.

A-eye lipstick is designed to be intuitive and user-friendly for your operators. The wizard feature simplifies configuration, allowing easy setup for new productions through a step-bystep procedure. Only a few image acquisitions are required to establish the format, minimizing impact on production scheduling.

BODY INTEGRITY CORRECT CAP COLOUR LABEL ORIENTATION

CORRECT CLOSURE ASSEMBLY CAP PRESENCE

SEA Vision is a pioneer of vision systems, offering a complete portfolio of reliable and innovative solutions for the complete control of the correctness of cosmetic products and their packaging.

LABEL PRESENCE TUBES GLASS/ PLASTIC CONTAINERS

LIPSTICKS PENCILS MASCARAS

BUNDLES CASES PALLETS CARTONS LABELS

SEA Vision solutions includes hardware (industrial PC, cameras, light units) and software components (with advanced proprietary algorithms even with AI) perfectly integrated with the Marchesini Group packaging machines. The controls are performed on 100% of the products

Depending on your inspection needs we design and supply a system with multiple cameras that can satisfy all different kind of controls on your product.

On our HMI is possible to select the acceptance threshold depending on the checks enabled on the line. We capture the product while it is moving through the machine.

All the computations are performed at very high speed and the result is communicated to the machine to reject automatically the wrong products without affecting the production speed.

INDUSTRIAL PC TOUCH DISPLAY CAMERAS AND LIGHTS

The end-to-end traceability solution by SEA Vision protects the authenticity of cosmetic companies’ brands, guaranteeing transparency, quality and customer engagement while actively combating counterfeiting worldwide.

SEA Vision develops and supplies an easy-to-use and complete Hardware and Software solution to control the authenticity of the cosmetic product along the entire supply chain: from the production to the end user, whatever is the sales path.

yutrace autogenerates the unique identifier used to trace the product and stores it in a protected database.

tracker manages the in-line identifier printing and verifies its correctness.

reworkapp and pickapp manage reworking and picking operations in the warehouse and distribution centers.

A dedicated brand web page retrieves the information from the distribution database and manages the control along the Supply chain. It can be specifically set up with dedicated functionalities for different users (company agent, retailer, end-user) with the aim of verifying the authenticity of the product once delivered to the market.

There are several ways to apply a unique identifier on your product. It can be directly printed with different printing technologies (Inkjet, Laser,..) and different data carriers like QRcodes, Datamatrix, 1D codes, RFID and NFC tags, that can be implemented depending on your product.

SEA Vision has a proven experience in serialization and aggregation. We are selected preferred supplier of 50% of the TOP10 Pharma companies worldwide with more than 1500 lines deployed.

Link all your production systems (ERP, MES, WMS) and increase your production efficiency with Yudoo, the software suite that brings 4.0 to reality. Launch the production in a fast and automatic way from a centralized platform. Enjoy the benefits of real-time production dashboards that help you find and remove any causes of inefficiencies

Discover more about SEA Vision solutions for cosmetic industry

PO and Master Data Management Unique Identifier application

of Assets / Work-shifts / Workflows

RS Series are automatic inspection and leak test machine designed to combine CMP’s know-how and experience in camera visual inspection with HVLD (High Voltage Leak Detection) system.

• The machines are equipped with 4 leak test stations and a rotation system in order to improve the quality of the control (360° total surface inspection).

OUTPUT

Up to 24.000 pieces/min

PRODUCT RANGE

Ampoules: 1 ml - 25 ml

Vials: 2R - 100 ml

Cartridges: 1 ml - 3 ml

• The productivity, the compact design and the performance level have set these models as leading units in CPM production range.

• RS Series can handle ampoules, vials and cartridges.

• M.E.S. (Manufacturing Execution System) by Auteco provides an effective link between the decision-making tools (ERP, SCM, PLM, …) and the plant itself.

• The system can interface extremely heterogeneous systems both from the hardware and the software perspective in order to optimize the data coordinating engineering, supply chain, traceability, maintenance and processing cycles.

• Auteco software can manage: production planning, management control, production, quality control, maintenance, energy consumption.

BIDIRECTIONAL INTERCONNECTION WITH THE CUSTOMER’S MANAGEMENT SYSTEM

DASHBOARD FOR REAL-TIME PRODUCTION CONTROL AND HISTORICAL DATA ANALYSIS

BIDIRECTIONAL INTERCONNECTION WITH MACHINES IN PRODUCTION

MARCHESINI GROUP BEAUTY

Marchesini Group Beauty excels in the creation of complete lines for cosmetic product packaging. Our solutions for the cosmetics market are designed and produced to meet the needs of all customers, from small companies to multinationals, and to promptly respond to requests for packaging of all types of cosmetic or dermocosmetic products.

In pursuit of delivering ever more integrated and flexible solutions to customers, Marchesini Group Beauty has strategically acquired specialized brands over the years. These brands, while distinct, are simultaneously complementary, making them easily integrable into turnkey solutions.

The company’s approach involves harnessing the collective know-how and expertise of its acquired brands. This synergy allows Marchesini Group Beauty to offer its customers the opportunity to craft personalized solutions. These solutions are meticulously tailored to accommodate diverse production needs, both standard and special.

To facilitate seamless coordination and execution, the Pianoro Headquarters takes charge of overseeing all activities and projects. This centralized control ensures not only rapid delivery times but also upholds consistently high standards of quality throughout the process. Marchesini Group Beauty’s commitment to innovation and adaptability positions it as a leader in the dynamic landscape of cosmetic product packaging, offering clients comprehensive and efficient solutions.

OUR COMPANIES

Marchesini Group Beauty designs jar packaging lines, integrating the entire process from filling to case packaging, delivering unparalleled solutions for your packaging requirements.

Marchesini Group Beauty produces complete lines for filling, closing, and packaging squeezable metal and PE/laminated tubes, ensuring seamless integration throughout the entire process.

Marchesini Group Beauty manufactures advanced bottle packaging lines. Our solutions are designed to deliver unparalleled efficiency for your specific packaging needs.

Marchesini Group Beauty is specialized in crafting cutting-edge lines for secondary packaging, including container labeling and case packaging. Our state-of-the-art solutions ensures precision and efficiency.

RINOVA is a company exclusively specialized in refurbishment and sale of Marchesini Group packaging machines.

Located near the company’s headquarters in Pianoro, near Bologna, Rinova operates from two workshops covering 3,500 m2. Within this space, a 3,000 m2 warehouse is specifically allocated for the refurbishment of primary and secondary packaging machines.

Owners of Rinova machines enjoy the benefits of Marchesini Group know-how and quality, advantageous prices and rapid delivery.

Following the machine delivery and installation, customers have access to Marchesini Group’s Customer Care service, providing qualified personnel for support in servicing, spare parts, and new formats.

Rinova machines rely on the authentic guarantee of the Marchesini Group brand and the unparalleled professionalism of in-house trained technicians.

Rinova offers mechanical and electrical adaptations allowing to supply safe, CE-recertified machines.