Volume 13 Issue 4 | Fall 2019

A Quarterly Publication of the Professional Logging Contractors of Maine

Cover: Logan Malm of Caribou working the forwarder this summer in Coplin as a student in the 3rd Mechanized Logging Operations Program Class. Graduation story page 35. PLC Staff Executive Director Dana Doran ▪ executivedirector@maineloggers.com Membership Services Coordinator Jessica Clark ▪ jessica@maineloggers.com Safety and Training Coordinator Donald Burr ▪ safety@maineloggers.com The Logger’s Voice Editor and Designer Jon Humphrey Communications and Photography ▪ jehumphreycommunications@gmail.com Advertising Jessica Clark ▪ jessica@maineloggers.com Email news, notices, and correspondence ▪ jehumphreycommunications@gmail.com IN DEPTH: Why are longstanding family logging businesses shutting down in a strong economy? 10 Supporting Member Spotlight Chalmers Insurance 24 Also Inside 4 Calendar and Updates 6 President’s Report 7 New Members 8 Executive Director’s Report 18 Log A Load Golf Tournaments 20 Trucking 29 Safety 35 MLOP Graduation 36 Maine Forestry Direct Link Program 38 PLC News Briefs 40 ALC Updates 43 Master Logger 44 Congressional Updates Board of Directors Jim Nicols, President Tony Madden, 1st Vice President Chuck Ames, 2nd Vice President Will Cole, Secretary Andy Irish, Treasurer Scott Madden, Past President Aaron Adams Kurt Babineau Donald Cole Tom Cushman Brent Day Marc Greaney Steve Hanington Duane Jordan Robert Linkletter Randy Kimball Ron Ridley Wayne Tripp Gary Voisine Aquarterly publication of: The Professional Logging Contractors of Maine 108 Sewall St., P.O. Box 1036 Augusta, ME 04332 Phone: 207.688.8195 www.maineloggers.com

Event Calendar

PLC Office, Augusta

4 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

8, 2020

ME

PLC Office, Augusta

May

Bangor,

5 The Logger’s Voice ▪ Fall 2019 Updates Do you have news to share? The PLC is always seeking news from our Members that showcases our industry’s professionalism, generosity, and ingenuity. Send ideas to jonathan@maineloggers.com

From the President

By Jim Nicols

Hello Everyone,

I hope everyone’s summer and early fall is going well. PLC’s third Mechanized Logging Operations Program (MLOP) class recently concluded with the graduation on September 19th. Fifteen students graduated this year including two female students. The class was a huge success. Fifteen is the maximum number of students we can take per class. This year’s students were chosen from a pool of over 50 applicants. While we are retiring more people each year than we are graduating, it takes time to rebuild the workforce. Each year the class continues to evolve and improve. Next year hopefully we can hold two twelve-week programs. I believe that all the students have had interviews and most will have been hired by the time this article is published. Dana brought many people in for tours while the class was going on and all came away very impressed from start to finish. It takes a lot of people and businesses to make something of this magnitude happen.

Thanks to all of our sponsors and partnerships involved to have these classes happen. Without them it would not be possible. A special thanks to Donald Burr and his group of instructors. They do a great job keeping things organized and moving forward day to day.

I believe one of the reasons for the success of the program is the grass roots effort of the loggers in recognizing the need and developing the program to fit their needs. Who knows what is needed more than the loggers themselves? PLC’s support continues to also be a very important part of the class’s success.

Labor will continue to be a challenge in the near future and beyond as it is in many small businesses. We must continue to work hard as an industry to promote the jobs that are available in logging. Through collaboration, education and communication within the industry to our young people, schools, and educators we can work towards this common goal. Trucking and drivers should also be included as there is a shortage of CDL drivers out there.

In order for our companies to produce wood fiber, we must work hard to meet these employment needs so we can supply future needs of all of the mills and upgrades that they have added or project in the future. This will be one of the contractors’ biggest challenges in the years to come, but a challenge that I think we can overcome.

Over the summer PLC moved into its new offices beside the building that we were operating out of. If you get a chance stop by and check it out, Dana or Jess would be glad to give you a tour.

I would like to take a minute to thank our legislators and the administration. While we didn’t always agree on all of the issues, we did try to find common ground where we could communicate and have an open door to listen to each other. For that we are thankful and we are looking forward to the next session.

As of September, it looks like PLC members are working relatively safe. We should know in the next quarter what the numbers look like. We should always work towards zero incidents. That should be our main goal. The safety committee will meet later this fall. Everyone is invited and encouraged to attend. A date, time and place will be sent out shortly.

Have a safe and dry fall.

Jimmy

6 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

Welcome New Members

Charette Family Investments, LLC., of Crystal, ME joined the PLC as a new Affiliated Contractor in July of 2019. The company is Master Logger certified and has a professional staff of four. For more information contact Cyndi Mullen at 538-1142 or email madchemist4@hotmail.com.

Hinds Selective Wood Harvesting of Wayne, ME joined the PLC as a new Contractor in September of 2019. The company has a professional staff of two. For more information contact John Hinds at (207) 242-6267.

KA Tuttle & Sons of New Limerick, ME joined the PLC as a new Contractor in September of 2019. The company is Master Logger certified and has a professional staff of seven. For more information contact Kevin Tuttle at (207) 538-5884.

Mark D. Nelson Trucking, of Dexter, ME joined the PLC as a new Contractor in July of 2019. The company has a professional staff of 14. For more information contact Mark Nelson at 270-1528 or email mdntrucking@yahoo.com

Timber Down Logging Inc., of Fort Kent, ME joined the PLC as a new Contractor in July of 2019. The company is Master Logger certified and has a professional staff of eight. For more information contact Craig Thibodeau at 316-8953 or email craig.thib@gmail.com

BMR Logging of Jackman, ME joined the PLC as a new Affiliated Contractor in July of 2019. The company has a professional staff of one. For more information contact Bruce Rich at 399-0884 or email brich6600@yahoo.com

Deprey Harvesting Inc., of New Canada, ME joined the PLC as a new Affiliated Contractor in July of 2019. The company has a professional staff of one. For more information contact Joey Deprey at 592-4147 or email jdeprey80@gmail.com.

Grady Forest Products of Whitefield, ME joined the PLC as a new Affiliated Contractor in July of 2019. The company is Master Logger certified and has a professional staff of 2. For more information contact Steven Grady at (207)-549-3170 or email gradyforestproducts@gmail.com

JBR Logging Inc., of Mapleton, ME joined the PLC as a new Affiliated Contractor in July of 2019. The company is Master Logger certified and has a professional staff of three. For more information contact J.D. Hummel at 2276708 or email jdhummeljr@hotmail.com

J. Soucy Logging Inc., of Fort Kent, ME joined the PLC

as a new Affiliated Contractor in July of 2019. The company has a professional staff of three. For more information contact Jared Soucy at 316-9915 or email jsoucylogging@gmail.com.

JLO Logging, of Fort Kent, ME joined the PLC as a new Affiliated Contractor in July of 2019. The company has a professional staff of two. For more information contact Joshua O'Clair at 231-4106 or email josh.oclair@hotmail.com.

C&C Trucking of Lincoln, ME joined the PLC as a new Forest Contractor Member in August 2019. The company has a professional staff of nine. For more information contact Carl Carr at (207) 403-0984 or email carlpattie.carr@gmail.com.

Aroostook Partnership of Caribou, ME joined the PLC as a new Nonprofit Supporting Member in August of 2019. The Aroostook Partnership is a nonprofit private/public partnership speaking with one voice and engaging the private sector leadership, talents, and resources in the region to ensure the economic survival and growth of Aroostook County. The partnership is concerned with all things economic development-related in Aroostook County with a strong emphasis on expanding our natural resource based economy. For more information contact Paul Towle at (207) 551-6601 or email ptowle@aroostookpartnership.org.

Barbara Bush Children's Hospital at Maine Medical Center of Portland, ME joined the PLC as a new Nonprofit Supporting Member in July of 2019. The hospital is a nonprofit organization benefiting from generous community support. From routine check-ups and immunizations, to the treatment of life-threatening illnesses and injuries, it provides comprehensive, family-centered healthcare for all of northern New England. With 116 beds, including 31 Level III NICU beds, 20 Level II Continuing Care Nursery beds, and 8 PICU beds, it is Maine's premier referral hospital, offering services not available elsewhere in the state. For more information contact Kate Richardson, Philanthropy Manager at (330) 697-2861, email Richak4@mmc.org, or visit the hospital website at www.mmc.org/bbch.

7 The Logger’s Voice ▪ Fall 2019

Not a member but interested in joining the PLC? Contact Jessica at (207) 688-8195 or email jessica@maineloggers.com

Ceiling vs. the Floor

By Dana Doran

In October of 1994, 45 loggers from 20 states descended upon St. Louis, Missouri to discuss the formation of a national organization which would provide a “forum which allows groups, organizations, agencies or lawmakers to grasp a “national sense” of how independent loggers feel about proposals which might dramatically impact our profession.” On behalf of loggers from the state of Maine, PLC founding member, Harold Bouchard, President of HO Bouchard/Comstock Woodlands attended that meeting to discuss a rebuttal to the American Forests and Paper Association’s roll out of a program now known as the Sustainable Forestry Initiative (SFI). That meeting eventually led to the formation of the American Loggers Council (ALC) later that year and the organization of the PLC in 1995. Loggers from Maine and across the country felt strongly that the logging community had to organize to push back against prescribed working and training requirements which were conditions of employment. Conditions that led to additional work requirements without compensation.

In a press release published on

October 4, 1994, it was announced that, “delegates from 20 states took major steps towards uniting members of the logging community,” according to Lisle Brist, a conference participant and President of the Montana Logging Association. “Advancing the professional image of independent loggers, providing a unified voice on logging issues, and working with public, industrial and other private landowners towards sustainable forestry practices were among the topics discussed,” said Brist. He added, “the council endorsed VOLUNTARY, state by state, professional training and education designed by loggers, for loggers and the council emphasized the need for strong support from public, industrial and private landowners to encourage, reward and recognize loggers committed to the pursuit of professional standards.”

Twenty-five years later, I think it’s important to reflect on where loggers stand today with the advent of the ALC, the PLC and other work over that timeframe. Have working conditions improved over the last 25 years for loggers, do loggers now receive the respect they deserve and are they free to

8 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

From the Executive Director

take advantage of “voluntary” education and training which is for loggers and by loggers. What still stands in the way of true success and why?

As I reflect back on this timeframe, and ponder the question of positive progression, I equate this to the analogy of a ceiling vs. a floor.

With the ceiling, loggers are told what they need to do to be successful, they are spoken for and they are told how good they are based upon the training program they are told to complete.

In the case of the floor, loggers are able to control their destiny. They are respected for the experience and investment they bring to the table. They speak on their own, their organizations and projects are endorsed, and they can move forward as equal partners with lower friction costs.

The floor is the springboard and the ceiling is the limitation. As much as loggers have made significant progress in busting through the ceiling, even today, there are still many obstacles in their way to move off the floor, up the stairs and to the next level.

In 1999, the PLC created the Master Logger (ML) program as a voluntary, floor-based performance standard to recognize the exceptional harvesting practices that logging contractors had been invested in for

years. We realized that it was the consumer who wanted a certified product and that point of harvest chain of custody was a significant component of harvest practices certification. Rather than fight against the ceiling in the world of logger training, we decided to lead our way up the stairs rather than follow.

This leadership was vital in moving the recognition of loggers forward. We could not let others define this profession and define who loggers were and what they knew. ML was created to tackle this problem so that loggers could define themselves and determine what their destiny would be.

Over the last 20 years, ML has become one of the PLC’s crowning achievements and something that all loggers in Maine should be proud of. From that point in time, ML has evolved, it has grown and it has shown what can be done when loggers are willing to put themselves out there for the world to see.

In 2005, ML became 3rd party certified by the Rainforest Alliance through their creation of the SmartLogging Certificate. In 2007, the Northeast ML Program was expanded to include loggers from the seven states in New England and New York. Today there are 120 companies in this region who can call themselves Master Loggers. Close to home, logging companies in

Doran Continued Page 14

9 The Logger’s Voice ▪ Fall 2019

The economy is strong. Demand for wood is high. After years of decline, Maine pulp and paper mills are reinvesting and expanding. New markets for wood fiber are emerging, and Maine’s vast forests are an accessible and reliable source for that fiber in a world of shrinking forestland.

Why then, are well respected, long-standing family logging businesses in Maine shutting down?

Every story is different, but when you talk to loggers who have made the hard decision to end those businesses that their families have poured decades of hard work into, you’ll find it really boils down to one thing; the profits just aren’t there anymore.

There was a time not long ago when these businesses thrived, when good money could be made to justify the challenges and effort that goes into making a logging business successful. Solid profit margins meant these logging companies could offer good wages and benefits and that in turn ensured they could attract good workers and expand when they needed to. It also provided the money to operate newer, safer and more efficient equipment and to build for the future when, if they were lucky, they could pass the business on to the next generation as their fathers and grandfathers did before them. No more.

Over the last two decades the picture has changed dramatically. Costs to operate have risen steadily, with expenses for everything from equipment to fuel to health insurance for employees rapidly climbing. The recession and broader global market shifts led to mill shutdowns and cutbacks. Trucking costs went up and drivers grew scarce as haul distances grew longer. Skilled logging operators began reaching retirement age, with too few young operators

10 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

Why loggers are shutting down in a strong economy

to replace them. And long-standing relationships between mills, contractors and landowners were shaken by major sales of commercial timberland to new owners that had their own profit margin to manage rather than ensuring the health of the logging workforce those profits depend on. Although the economy has rebounded and most links in Maine’s forest products chain have seen the benefits of that, in many cases those benefits have not made their way down to the logging industry on which the entire chain depends.

Bruce Marquis, owner of Robinson Lumber Co. and a PLC Member since 2002, has been a logger for 45 years. He turns 64 this year, and two years ago he had to make the decision to shut down his logging operations. This spring, what was left of the business in road building and maintenance and excavation was shut down too. Except for buildings, land, and equipment - and on paperwork including a substantial outstanding loan – after

more than seven decades, Robinson Lumber Co. no longer exists.

Bruce’s father came from Fort Kent to St. Pamphile on the Maine-Canada border in 1947 to begin building the business logging in Maine’s north woods. Bruce was born there in a small house on the Maine side of the border next to where the Robinson Lumber Co. garage now stands, within 100 feet of Canada. For 13 years, he worked alongside his father before taking over the business himself. It was a family business then, and even now his sister, Jackie is still with him working to close it down. Logging has always had ups and downs, but there were many good years for the business. Working on commercial timberland feeding wood to the mills and markets was a boom industry. At one time Bruce can remember 34 employees on the payroll and 24 skidders in the woods. Production was big too. “One year we cut 153,000 tons for Seven Islands,” Bruce recalled.

The Logger’s Voice ▪ Fall 2019 11 IN DEPTH Continued Page 12

Photos: Opposite, Bruce Marquis watches a log truck pass by his garage next to the border crossing at St. Pamphile where his own logging business, Robinson Lumber Co, is now shut down after several decades. Top: Three generations of Poulins two years ago. Today Gerard Poulin & Sons is out of business.

IN DEPTH Continued from Page 11 16

The decline of the company was a familiar story and one many former loggers across Maine would recognize. Shrinking profits leading to cutbacks in employees and new purchases. Aging equipment, debt rising rather than falling, uncertainty in the markets, increasing difficulty finding enough workers, a slide down that no amount of hard work seemed able to stop. Bruce’s father paid him a salary when he was working for him. When Bruce took over he didn’t raise it. In the latter years, he had to cut it. He has not drawn a paycheck since April of this year.

There was a time when he thought of passing the business on to the next generation, but although one of his sons had an interest he did not encourage that and today he is glad his children chose other careers. “I saw what was coming,” Bruce said.

Months after shutting down, Bruce and Jackie continue the job of selling off equipment, spare parts and other assets. The land and the buildings will eventually go too if there is a buyer. At the end of the whole process Bruce is hopeful the outstanding debt can be settled and a bit of money will be left over, because he has no pension or other retirement, just Social Security.

Both Bruce and Jackie smile and laugh as they talk about the company, they’re not asking for sympathy or suggesting what happened to Robinson Lumber is something to be depressed about, but even for people so obviously upbeat as these it is clear the loss of a family business is a very hard thing.

“I worked all my life, I have nothing left,” Bruce said. “I hate to see it go out like this.”

Two hundred miles south of St. Pamphile in Readfield, Larry Poulin has a lot in common with Bruce Marquis.

Larry’s father, Gerard, started logging more than 60 years ago and moved his young family to Readfield in 1959 where he eventually founded Gerard Poulin & Sons. His sons grew up in the business and for three decades beginning in 1980, the company worked on big commercial timberlands in the Eustis area, cutting right-of-ways for roads, harvesting thousands of acres for major landowners, and running multiple crews that included many members of the Poulin family in addition to many employees.

In 2011, the company finally returned to working closer to home, primarily on smaller private lots. As recently as the early summer of 2019, Larry, his brother Gerry, Larry’s son Dana, and the brothers’ nephew, Andrew were still working together in the woods together, but no more.

The money just wasn’t there anymore.

“We were as efficient as we could possibly be, and if we can’t make any money, I don’t know how to do it, and I’ve been doing it all my life,” Larry said. “I’ve always solved the problem, but this problem can’t be solved.”

The challenges for the company had been building up for years, most of them very familiar to loggers

everywhere in Maine. Gerard Poulin & Sons faced all the same issues mentioned by Bruce Marquis in St. Pamphile including rates for wood, worker shortages, and rising operational and equipment costs, but Larry also pointed to unpredictable weather leading to more extended mud seasons, uncompensated expenses associated with cutting small private lots for aesthetics as much as timber, and mounting stress from working harder than ever for diminishing returns.

“When you’re making good money, there’s a lot of things you can overlook, but when you’re just scraping to get by it makes the whole atmosphere just an awful place to work,” Larry said.

Larry had been positioning the business for his son, Dana to take over so he could retire. They had started the process, but he finally woke up one night and realized the profit just wasn’t there to keep the business going, and it wouldn’t be there for Dana either. So, the company cut its final lot in early summer, got the last checks for loads of wood a few weeks later, and is out of business going through the process of selling equipment and assets. Gerard Poulin & Sons was a PLC Member and a Master Logger company.

Three generations of Poulins worked in the business, and Dana’s young sons were already expressing an interest in logging, but if they go that route they won’t be in the family business.

He’ll always have good memories of his life in the woods, but, “It just didn’t end the way it was supposed to,” Larry said.

Not every logger who has gotten out of the business wants to talk about it, and many who are still in it don’t want to go on the record because they are still trying to make a go of things and feel that speaking out publicly could hurt their business. Still, off the record they all talk

12 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

Bruce Marquis speaks with PLC Executive Director Dana Doran in St. Pamphile in early September.

about the same issues that led to the demise of companies like Robinson Lumber Co. and Gerard Poulin & Sons, and agree that if something doesn’t change, the day of reckoning won’t be long in coming for Maine.

The breakdown in the traditional relationship between the mills, the contractors, and landowners has been a huge factor in the decline of the industry, some say, and it seems this three-legged stool, as it is known in the industry, won’t stand much longer if the contractor leg fails.

The difficulty in turning a sufficient profit in Maine’s logging industry is glaringly apparent in a recent employment availability and wage analysis prepared by the Maine Center for Business and Economic Research at the University of Southern Maine. The study found wages for logging equipment operators and log truckers in Maine are lower than those for comparable jobs in competing industries in the state, and that although capital expenses in the logging industry have risen across the board, rates for wood harvesting and trucking have not.

“This analysis simply confirms and reinforces what many in the industry have known for a long time,” Dana Doran, Executive Director of the Professional Logging Contractors of Maine (PLC), which commissioned and partnered with the Center on the study, said. “The root of Maine’s vital forest products economy – the logging industry – must be able to offer higher wages to compete for existing workers and attract new ones at a time when they are desperately needed to support a resurgent forest products industry.”

The heart of the problem is declining financial health for logging contractors as costs of doing business have risen, limiting the ability of contractors to raise pay for workers and limiting their ability to reinvest in their own companies. Small business in the logging industry does not mean, “non-profit”, but for the majority, this is what it has become, said Doran.

The remedy for declining profits in Maine logging has always been, “lower costs and become more efficient,” raise the returns, or some combination of both that leads to a healthier balance sheet. While there are things that can be

done everywhere from tax breaks to reduced regulation to help profits by lowering the costs of logging, loggers agree that there is no more meat to be cut from the bone on the efficiency side. The real fix lies on the side of the returns; if the cost of harvesting wood has risen, that cost must be passed on, it cannot simply be absorbed by the logging companies.

No one blames a wood buyer for trying to get a good price on wood. That’s the free market, and that’s the system most loggers believe in. The logging industry once employed thousands more than it does today, but as technology changed and the move to mechanization began cutting into those numbers, there was excess contractor capacity and it became easy for buyers to leverage that into keeping the prices they paid low because if a logger told you, “I need more money,” you could always say, “I’ll find somebody else who can do it for less.”

For years it worked, and contractors on the edge of profitability couldn’t make it and shut down. Contractor capacity steadily shrunk. Companies remaining in business often did so by surviving on equity and resources that had taken generations to build. Debt climbed. More businesses failed.

Now the day of reckoning is fast approaching as demand for wood climbs while the contractor force continues to shrink, and the point where the supply chain on which Maine’s entire forest products industry depends can no longer keep up is either close or already here. Bruce Marquis and Larry Poulin have no doubt of this.

At the end of the day, contractors want landowners, land management companies and mills to succeed so they can succeed. The pie doesn’t need to get bigger; it really just needs to be redistributed so every business can succeed.

Higher wood prices for loggers could change the outlook for those contractors who are still in business, but continuing down the same path will not end well for the businesses and industries that depend on logging contractors for their raw material, Bruce said.

“They’re running out of time,” Bruce said.

“They’re running out of, ‘somebody else.’”

13 The Logger’s Voice ▪ Fall 2019

Doran Continued from Page 96

Maine are now receiving the benefits and recognition they deserve, including lower workers comp rates, an opportunity to set themselves apart through marketing and advertisement, and opportunities for low interest loans and benefits from certain mills and landowners that see the value in what they do.

Back to where I started, in 2000, the ALC recognized Maine’s Master Logger program as a preeminent opportunity for logging companies across the country to recognize their harvest practices when it endorsed the program to be used as a tool for its membership Since that point in time, Master Logger is now recognized in 20 states, in Canada and Japan.

However, as much as ML has grown and has provided tangible benefits to loggers across the globe, the ceiling is still attempting to keep it from succeeding.

Over the last two years, the PLC’s sister organization, the Trust to Conserve Northeast Forestlands (TCNEF) has been working on marketing the ML program on behalf of the ALC This work was incredibly beneficial for the brand and for the respect that logging companies deserve. From 2000 to 2017, the ALC did not have a concerted effort to market the ML brand and encourage states to adopt it as an opportunity for progress. At the end of this year, that work will come to an end and so will the support of ALC for ML.

At the ALC Annual Meeting on September 28, 2019 in Orange Beach Alabama, a majority of the ALC Board voted to suspend its endorsement of the ML program moving forward. The action taken states specifically that those who have the program currently will need to run their programs on their own and do so without the formal support of the ALC. The action also stated that there would be no more formal movement or encouragement of new ML programs in other ALC states.

Those of us from the PLC in attendance were disappointed by the action of the ALC. Not only was this a rejection of the principles and progress of ML, but

it was a rejection of 20 years of ALC commitment to ML.

It was clear from the discussion against ML not only at the Board meeting, but over the last two years by those in the dissenting category, that ML was viewed as a threat to their logger training programs, logger training programs that were created to support and service SFI. This is quite ironic since the ALC was formed in 1994 to push back against top down ceiling-based requirements. It seems that 25 years later, the ceiling is now acceptable.

The recent action by the ALC is surprising, but not unexpected if you really think about it. There are numerous instances, some on a daily basis, where others, even those who are supposed to represent loggers, relish the opportunity to suppress them because that’s how it’s always been or because without it, they couldn’t move their own agenda forward. After all, as PLC Board Member Randy Kimball and his wife Chrissy always say, the stigma of the “Dumb Logger” cannot be forgotten. How could a “dumb logger” think for themselves, speak for themselves or push through that ceiling by standing on the floor.

The examples of this I see in this position are astonishing, but I guess in the end, that’s why the PLC exists; to push back and speak on behalf of loggers rather than being spoken to. This is the strength of this organization and why it has been successful for almost 25 years.

In a recent organizational newsletter here in Maine, there was a discussion on legislation this past session that had a provision in it to provide equal representation for good contractors. The article went on say, “This bill would disadvantage the majority of loggers in the state”. When the PLC asked to discuss this statement and seek clarification, the group didn’t respond.

I find it rather hypocritical that certain groups can advocate for themselves and receive preferential

14 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

treatment in law without a challenge from the logging community, but when there’s something that could benefit the logger, they are suddenly the voice for loggers and know what’s in their best interest. Again, it’s just another example of one group’s thought that they can speak on behalf of loggers because in the end, they know what’s best for them.

Lastly, in a recent meeting I attended, there was discussion on logging road conditions in a certain part of the state. Evidently, there have been more complaints than ever to the state regarding the condition of the roads and something needed to be done because it was creating an environment for sediment in water bodies and could cause serious harm.

There are certainly numerous reasons why this happened and blame can be apportioned to a multitude of stakeholders. Landowners have not invested in road construction and maintenance over the last few years. Contractors have not built or maintained the roads to the standards required. Regardless, the issue exists and there is plenty of blame to go around.

However, in this meeting, it was simply described as a contractor issue. The contractors need better training and because of the lack of training, this must be the reason why these roads have deteriorated in such a rapid fashion.

I find it hard to believe that it’s the grader operators’ fault for all of these issues and the subsequent complaints. However, this has always been the norm, place the blame on the contractor because in the end, someone has to be at fault and that is the path of least resistance.

It has to be the contractor’s fault because they are the one in the machine and if we train our way through it, the problem will either go away or be forgotten. This is exactly the type of conversation that solidifies the ceiling vs. floor mentality that pervades this industry on a consistent basis and must change if we are to move forward in a positive way.

I can go on and on with example after example of conversations like this that happen every day in our office, within our membership and between stakeholders whereby the logger is at the bottom of the value chain and must be kept there at all costs. Essentially, the perception is if we keep them there, or speak on their behalf, or place blame on them, or make sure they receive training that meets someone else’s standard, all will be right in the end. This perspective is not healthy and as long as it exists, it will contribute to more contractor erosion than stability.

As we move forward in a very challenging environment these days, with workforce development challenges, investment apathy and a constant reduction of contractors, I would like to challenge all stakeholders in this industry to try to take a different approach when it comes to what’s in the best interest of the logger. This industry is a chain and the chain is only as strong as its weakest link. The logger is not always the weakest link. In fact, in a world of constant evolution, the logger is probably one of the strongest links and the most committed to the cause.

In the end, positive and productive companies, economic sectors and industries must be based upon strength within the chain. To achieve this, decisions must be made as a team and that team can’t exist without trust and relationships. Trust and relationships take time, but the strongest ones come as result of mutual respect and sharing of responsibility, resources and profits over a sustained period of time.

The ceiling is ever present and perhaps it is just the way it has always been, but it doesn’t mean that this is the way it has to be. One day, I hope that the floor is the starting point and there is no ceiling pushing down. When this has happened, the examples of success are limitless.

I hope the fall is productive and successful for all of you and move onward and upward!!!

15 The Logger’s Voice ▪ Fall 2019

New PLC Office in Augusta!

The PLC's office has moved to our permanent home at 108 Sewall Street in Augusta! We are easy to find as our new three-level brick building, purchased and renovated by PLC this spring, is located right next to the old office. This is a great move for PLC; for the first time in the organization’s history, we will not be renting space and Maine’s Professional Loggers will have their own permanent presence in the state's capital, within sight of the Maine State House and with ample parking, a conference and meeting

A Higher Standard

16 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

You know your company holds itself to a higher standard of timber harvesting Prove you are a cut above with Master Logger Certification masterloggercertification.com

23rd Annual Log A Load for Maine Kids Golf Tournaments

The Professional Logging Contractors (PLC) of Maine held its 23rd Annual Log A Load for Maine Kids Northern Maine Golf Tournaments in September, raising $77,336 for Children’s Miracle Network Hospitals in Maine and pushing its annual fund raising effort to a new record total.

This year for the first time the PLC held two Log A Load golf tournaments, with a new Sept. 6 southern Maine tournament at the Kezar Lake Country Club in Lovell, Maine in addition to the northern Maine tournament Sept. 20 at JATO Highlands Golf Course in Lincoln, Maine.

The new tournament has been added as the PLC seeks to expand its annual fund-raising efforts on behalf of Children’s Miracle Network Hospitals in Maine, and has partnered with the Barbara Bush Children’s Hospital at Maine Medical Center in Portland in that effort.

The southern tournament raised $25,236, and when added to the $52,100 raised at the northern tournament and a record $51,866 raised at the PLC Annual Meeting the effort has now raised more than $129,000 for the year. Last year the PLC raised a total of $122,500 for Log-A-Load, with the bulk of funds coming from the annual golf tournament and PLC Annual Meeting.

“The generosity of the PLC’s members, friends, and supporters is more inspiring each year, and with the new tournament we are expanding participation and the positive impact we can have for Maine families in need,”

PLC Executive Director Dana Doran said. “This group always comes through for these families and continues to devote an incredible amount of time, effort, and resources to the Log A Load cause, and our efforts this year are something we should be very proud of.”

The PLC and the Northern Light Health Foundation (formerly Eastern Maine Health Systems Foundation) have partnered in the Log A Load fund-raising effort since 1996. Donations, which have now surpassed $1 million, have gone to support research and training, purchase equipment, and pay for uncompensated care, all in support of the mission to save and improve the lives of as many children in Maine as possible. Eastern Maine Medical Center in Bangor is a Children’s Miracle Network Hospital and includes a Neonatal Intensive Care Unit that has received support for years from the PLC’s Log A Load efforts.

Funds raised from the Lincoln golf tournament will go to Northern Light/Eastern Maine Medical Center and the funds from the Lovell golf tournament will go to the Barbara Bush Children’s Hospital at Maine Medical Center. The funds from the PLC Annual Meeting are split between the two hospitals.

Many thanks to our partners in this effort, our generous sponsors, our members and supporting members, friends, donors, and families that made this year’s effort a great success!

14 Professional

Contractors of Maine LoggersServingLoggersSince1995

Logging

$77,336 Raised!

JATO Highlands Golf Course

The Logger’s Voice ▪ Fall 2019 19

Kezar Lake Country Club

20 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

C&C Trucking Inc. truck at Treeline Inc. in Chesterville.

OWNER: Carl Carr

YEAR FOUNDED: 2004

ADDRESS: PO Box 481, Lincoln, ME 04457

PHONE NUMBER: (207) 403-0984

EMPLOYEES: 12

TRUCKS: 14

AREA OF OPERATION: Within 100 miles of Lincoln.

SERVICES PROVIDED: Hauling of logs and chips. Excavation and other dirt work.

Trucking Industry News...

FMCSA Opens Registration for Commercial Driver’s License Drug and Alcohol Clearinghouse ...

WASHINGTON – The U.S. Department of Transportation’s Federal Motor Carrier Safety Administration (FMCSA) has announced that registration is now open for the Congressionally-mandated Commercial Driver’s License Drug and Alcohol Clearinghouse. Commercial driver’s license (CDL) holders, employers, medical review officers, and substance abuse professionals can now visit: https://clearinghouse.fmcsa.dot.gov and register to create a secure online user account.

“As this Congressional mandate is enacted, FMCSA’s goal is to ensure drivers, employers, and everyone who will be using the clearinghouse are registered as efficiently and effectively as possible. FMCSA is here to be helpful during this implementation, and we strongly encourage all CMV stakeholders to get registered in the clearinghouse now,” said FMCSA Administrator Raymond P. Martinez. Registration is required to be able to access the clearinghouse once it is fully implemented on January 6,

2020. To access the clearinghouse, authorized users must register.

These users include:

▪ Drivers who hold a commercial driver’s license (CDL) or commercial learner’s permit (CLP).

▪ Employers of CDL drivers. This includes those who employ themselves as CDL drivers (owneroperators), typically a single-driver operation.

▪ Consortia/Third-Party Administrators (C/TPAs).

▪ Medical Review Officers (MROs).

▪ Substance Abuse Professionals (SAPs).

22 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

There is no cost for registration. Commercial drivers are not required to immediately register for the clearinghouse, but will need to register to respond to an employer’s request for consent prior to a pre-employment query or other full query being conducted.

FMCSA’s clearinghouse website contains important resources, including user brochures and instructional aids with step-by-step registration instructions for all users. Users can visit https:// clearinghouse.fmcsa.dot.gov to access these resources and to start the registration process.

The clearinghouse will be a secure online database that will allow FMCSA, CMV employers, State Driver Licensing Agencies, and law enforcement officials to identify – in real-time – CDL drivers who have violated federal drug and alcohol testing program requirements, and thereby improve safety on our nation’s roads.

U.S. Department of Transportation Awards Over $77 Million in Grants to Improve Commercial Motor Vehicle Safety…

WASHINGTON – The U.S. Department of Transportation’s Federal Motor Carrier Safety Administration (FMCSA) has announced that it has awarded $77.3 million in grants to states and educational institutions to enhance commercial motor vehicle (CMV) safety.

“Safety is the Department’s top priority and these grants will further assist state and local officials in their efforts to prevent commercial motor vehicle crashes,” said U.S. Transportation Secretary Elaine L. Chao.

FMCSA announced:

$43.3 million in High Priority (HP) grants to enhance states’ commercial motor vehicle safety efforts, as well as advance technological capability within states.

$32 million in Commercial Driver’s

License Program Implementation (CDLPI) grants to enhance efforts by states to improve the national commercial driver’s license (CDL) program.

$2 million in Commercial Motor Vehicle Operator Safety Training grants to sixteen education institutions to help train veterans for jobs as commercial bus and truck drivers.

23 The Logger’s Voice ▪ Fall 2019

BRIDGTON - Bob Logan grew up in a family business - R.G. Johnson Co. - that has relied on local loggers for the raw material to make custom wooden baseball bats for nearly a century, so his job as Logging Insurance Advisor for Chalmers Insurance Group comes naturally to him.

“We leaned heavily on the local logging community to provide us with quality white ash, rock maple, and yellow birch, and so that just drew me in from the insurance side to want to jump on board and start working with these guys that I’ve known for a very long time,” Bob said.

Chalmers Insurance Group is a Preferred Supporting Member of the Professional Logging Contractors of Maine (PLC) and a strong supporter of all the organization’s efforts on behalf of Maine loggers as well as PLC’s Annual Log A Load for Maine Kids events and PLC Safety Trainings. Joining the PLC was a natural fit for the agency, Bob said.

“If it wasn’t for these loggers I can’t imagine how our economy would be in this area, so from an insurance standpoint I think it was pretty important to Chalmers to try to do what they could to keep those businesses thriving

and safe and bring a good risk management perspective to them,” Bob said.

Chalmers Insurance Group is a fourth-generation family-owned and operated business founded in 1857, proudly serving businesses and individuals from eight offices throughout Maine and New Hampshire. The fourth generation of the Chalmers family took the reins of the company in January 2018 when Bruce and Bill Chalmers transferred ownership of the Chalmers Insurance Group to cousins Jim Chalmers and Dottie Chalmers Cutter, who have joined President Stephen P. Cote in leading the agency.

For logging businesses, Chalmers Insurance Group offers general liability and umbrella liability coverage, worker’s compensation coverage, equipment and fire suppression coverage, commercial auto insurance, and employee benefits coverage. The agency also offers claims advocacy, risk management, and expert advice.

Chalmers company culture is guided by these four simple values SHIP:

*We work hard to deliver excellent Service to our clients.

24 Professional Logging Contractors of Maine LoggersServingLoggersSince1995 PLCSupportingMemberSpotlight:

ChalmersInsuranceGroup

*We are trusted insurance advisors and pride ourselves on being Honest.

*Community Involvement is integrated into everyday life.

*As Passionate professionals, we share our values with co-workers, clients and partners.

“Chalmers Logging Insurance is committed to helping clients implement sound risk management practices and control costs. Being a family owned business ourselves, we enjoy guiding and supporting business owners’ efforts for thoughtful succession planning, continuous training and offering competitive employee benefits packages to assist with building and retaining a strong team,” President Cote, said.

The agency has expanded over the years, and one of the key moves that led to its current strong relationship with Maine loggers was the 2007 acquisition of the Lovejoy Agency Parsonfield office.

“Here at Chalmers they already had a good number of logging accounts on the books prior to that acquisition, but Phil Lovejoy and Scott Lovejoy, his son, were really the ones who had the largest line of PLC contractors, that was something that was a really big part of their family agency, just getting involved with the loggers and helping that community grow stronger,” Bob said.

When Bob became an agent for Chalmers based in the Parsonfield office serving local loggers he asked them what he could do to help them out, and with typical directness most said, “lower my insurance costs.”

Not long after he began working in the industry, Bob met PLC Executive Director Dana Doran and Membership Coordinator Jessica Clark at Woodsmen’s Day at the Fryeburg Fair and after talking with them quickly realized that the work the PLC was doing and its focus on safety could in fact help his loggers lower their costs. He approached the leadership at Chalmers to suggest joining PLC, to which they quickly agreed.

The Logger’s Voice ▪ Fall 2019 25

Chalmers Continued Page

26

Photos: Opposite, Bob Logan, Logging Insurance Advisor for Chalmers Insurance Group.

Above: Cousins Jim Chalmers and Dottie Chalmers Cutter are the fourth generation to lead Chalmers Insurance Group.

Chalmers Continued from Page 25

“

For Chalmers, it was a no brainer to step up and support moving forward with that so we could really help our contractors be better risk managed and have fewer claims and keep insurance costs down for everybody,” Bob said.

PLC Member R.C. McLucas of Porter is a client of Chalmers, and speaks highly of the agency.

"They're also family-owned, and they've treated us accordingly, like family and friends," said Gayla McLucas. "They're also very savvy about all aspects of insurancebusiness and personal."

Chalmers Insurance Group is committed to its clients and their communities, and the company admires the similar commitment by PLC logging contractors, who are generous hard-working community members and community supporters.

“By being a Supporting Member I would say it really gives us the opportunity to hear their voice, and it really allows for us to gain additional knowledge of the industry and try to build our program in a way that stays out ahead of things to be more pro-active rather than reactive,” Bob said. “I’m excited every day to come to work to try to find ways to give back to them to help their businesses thrive to keep their employees safer and just be a helpful part of the whole process.”

Chalmers Insurance Group is headquartered in Bridgton, Maine with other Maine offices in Fryeburg,

Learn more about Chalmers Insurance Group at www.chalmersinsurancegroup.com or call Bob Logan at (207) 625-3262. 26 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

Gorham, Norway, Parsonfield and York and New Hampshire offices in North Conway and Ossipee.

28 Professional Logging Contractors of Maine LoggersServingLoggersSince1995 Check out the PLC Online Store! Looking for great PLC items and apparel? Gifts? First Aid packs, safety items and more? You will find them at the new PLC Online Store on our web site. Ordering is easy. Check it out at the link below! Go to: http:// maineloggers.com/ product-category/ products/ Above: Some of the items currently available at the PLC Online Store. More will be added. Christmas is coming!

Acadia Insurance to Distribute Premium Dividends to Eligible PLC Safety Group Members

WESTBROOK, Maine (9, 2019) Acadia Insurance, a W. R. Berkley Company®, recently announced that it will pay over $890,000 in premium dividends to eligible policyholder members of the Professional Logging Contractors of Maine (PLC) Safety Group. Since 1999, Acadia has distributed over $10 million in premium dividends to eligible participants of this safety group.

Founded by Acadia Insurance, the PLC Safety Group dividend program rewards logging companies and sole proprietors for having a safe workplace by refunding a portion of their insurance premium if certain measures are met by the entire safety group. In addition, Acadia Insurance, in coordination with the PLC, provides risk management and mitigation expertise to members to help ensure the long-term sustainability of the logging industry in Maine.

“Acadia Insurance is very happy to issue dividends to eligible PLC members once again,” said Jonathan Becker, Regional Vice President of Acadia Insurance’s Maine office. “The PLC members have been great stewards of the Maine forests and they continue to be vital to Maine’s economy. The PLC members have been dedicated in keeping a safe work environment for many years now. These dividends prove the great work they do every day.”

The PLC of Maine has been serving loggers since 1995 and aims to give independent logging

contractors a voice in the ever changing logging industry. The PLC focuses on advocacy, safety, quality operations and business innovation for loggers. The PLC is a logging organization run by loggers that understands the importance of the logging industry and its impact on the Maine economy.

For more information about the Professional Logging Contractors of Maine Safety Group, please contact Kim Farquhar, Marketing Director, Acadia Insurance, at kimberly.farquhar@acadia-ins.com.

About Acadia Insurance

Acadia Insurance is a regional underwriter offering commercial and specialty property casualty insurance coverages through independent insurance agents with local offices in Connecticut, Maine, Massachusetts, New Hampshire, New York and Vermont. Rated A+ (Superior) by A.M. Best, Acadia Insurance Company is a member company of W. R. Berkley Corporation, one of the nation’s premier commercial lines property casualty insurance providers. Please visit www.acadiainsurance.com.

29 The Logger’s Voice ▪ Fall 2019 Alex Labonville, Sales Manager Cell: 207-233-4801 www.labonville.com Ask about special PLC of Maine member only discounts!

###

Emergency Action Plan

ByDonaldBurr PLCSafety&TrainingCoordinator safety@maineloggers.com

Today we are going over the purpose and need for an “Emergency Action Plan” (EAP).

The OSHA 1910.266 App A standard reads that we need to put an (EAP) into our first aid kits. After reviewing the Northeast Center for Occupational Health and Safety in Agriculture, Forestry, and Fishing (NEC) Maine Logger Study results article, the good news is that over 80% of the loggers surveyed had an emergency action plan. The bad news is that still leaves 20% who do not have plans.

An EAP is essentially a script that you go to when an emergency happens on your job. This way you have the emergency numbers, directions and coordinates for your job at hand and you don’t need to make them up on the spot. I have seen a few different ways these can be written. My nature is to make them simple to avoid confusion as much as possible. I start at a known location like an intersection, fire station or even a street address. Then give the distance to each turn and any road landmarks (ie. bridges, sharp corners, steep hills). I also research which way emergency service will come from so that my directions will make sense to the ambulance, fire department, forest rangers, game wardens or police. The last company that I worked for also gave them to the truck drivers for the first time they come to the job. Occasionally we would write special directions for the trucks from multiple directions.

I include in the emergency action plans the following:

A Title and a Date - So you can always see plainly which job the directions are for in case an old one gets left behind in the 1st aid kit. Remember the old adage “in with the new out with the old”.

Important phone numbers - I generally don’t give more than “911”. Sometimes I add Lifeflight’s direct number 1-888-421-4228. My thought process is that if I can only get one call out “911” connects you to a regional dispatch that can bring resources from multiple agencies including Lifeflight. Many times at incidents we need more hands and a regional dispatch can reach out to game wardens, forest rangers, local fire departments and EMS responders at the same time with the same information.

Lifeflight Landing Coordinates - They can use any coordinate system but they prefer degrees, minutes, seconds. (ie. N 45* 08’ 34.8” / W 070* 25’ 35.1”)

Delorme Map - Page number and grid location. This is so Lifeflight can compare the coordinates with the map page and grid to see if they agree. (ie. Page # 29 / Grid C - 1)

In the example below, you will see how I lay the directions out. I have included a picture of our signs so the person making the call can describe what the signs to our job look like to the dispatchers without relying on their own memory for the description.

The OSHA standard says that these directions need to be in the 1st aid kit but I didn’t stop there. I also made directions for every pickup and I always had them in my machine where I kept the paperwork for the job so I could give directions without digging in the 1st aid kit if I was called on to make “The Call” but I was not close enough to render aid.

The last word on the emergency action plan is to train your employees on the importance of these plans, how to use them and where they need to be stored and managed. We can go through all the work in gathering the data, preparing the plan, printing, and distributing the plan to the crew and having them not know what to do with the plan or where the plan is would be a shame.

30 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

Ted Clark, CLCS, Loss Control Consultant, Acadia Insurance Quarterly Safety Meeting: Hot Work and Fire Watches

One of the leading causes of equipment and garage fires is hot work. According to OSHA, hot work can be defined as, “any work that involves burning, welding, cutting, brazing, soldering, grinding, using fire- or sparkproducing tools, or other work that produces a source of ignition.” While hot work on machinery is typically minimal such as repairing a crack or shortening a chain, there is a significant hazard presented from wood debris build up, hydraulic fluids, and diesel fuel, not to mention the external hazards such as other items in your garage or the woods you are working in. A small piece of slag that falls unnoticed into debris is capable of burying itself into tightly packed debris and smoldering for hours or days until the right combination of heat, fuel and oxygen are present and the fire erupts.

Fires resulting from hot work typically lead to damage ranging from melted hoses and wires up to a total loss of a building. Regardless of how minor, the thing all fires have in common is they result in a frustrating cleanup and significant downtime.

While there are many steps that can, and should, be taken during hot work, this safety meeting will focus only on fire watch, a critical safeguard that is often missed.

What is a “fire watch”?

OSHA requires a fire watch any time hot work is taking place and combustible items, such as debris, cannot be removed from the area.

Typically a person performing hot work is paying such close attention to the work they are executing that they are not able to monitor their work area adequately, allowing for hot debris, such as slag, to potentially enter areas with combustible materials. Think of a fire watch as simply an additional set of eyes that have a full view of the work area and can monitor the combustible materials. If a fire is noticed, the fire watch will be able to immediately summon help and extinguish the fire before it gets too large for a handheld extinguisher.

How do you conduct a fire watch?

*The person should be positioned in an area where they can monitor the entire work area.

*They should watch where the slag is going and ensure that it is not getting into areas such as machine belly pans or trash cans where combustible debris tends to build up.

*They should be prepared to stop the operation if a hazard arises.

*A fire extinguisher should be on hand with the fire watch trained and ready to immediately extinguish a fire if one should occur.

*They should have means of communication available to immediately call 9-1-1 and summon help when necessary.

Conclusion

When a machine or garage catches fire, the flames can grow rapidly to the point where it cannot be extinguished with a fire extinguisher or a fire suppression system. This increases the likelihood that the fire will result in a total loss of a structure and potentially injury to workers. A fire watch, when positioned properly, trained and alert, will be able to provide early warning of a fire hazard, which can significantly decrease the likelihood of a major fire resulting from hot work.

Acadia Insurance is pleased to share this material with its customers. Please note, however, that nothing in this document should be construed as legal advice or the provision of professional consulting services. This material is for general informational purposes only, and while reasonable care has been utilized in compiling this information, no warranty or representation is made as to accuracy or completeness.

sign-in sheet on the back! Cut along dotted line to left to detach this section.

31

*Meeting

*This sign-in sheet is intended to be used with the quarterly Safety Training Topic on page 31. Refer to the cutline on page 31 when removing it from the magazine.

The Northeast Logger Health and Safety Study

*This article by the NEC first appeared in the August 2019 edition of the Northern Logger and Timber Processor. It is reprinted by permission.

The first project of its kind in the Northeast, the Maine Logger Health and Safety Study focuses solely on understanding the health and safety concerns of Maine’s loggers. The study is a project of the Northeast Center for Occupational Health and Safety in Agriculture, Forestry, and Fishing (NEC), which promotes health and safety research, education, and prevention activities in the highrisk areas of logging, farming, and commercial fishing.

Serving a twelve-state region from Maine to West Virginia, the NEC has an extensive track record of conducting research and developing safety and health solutions for a wide variety of occupational concerns. Its Lifejackets for Lobstermen project is currently working to improve lifejacket designs for lobstermen along the coasts of Maine and Massachusetts.

Previously, the NEC worked with Mainers to improve ergonomic designs of blueberry rakes and apple buckets. Combining the power of data with the strength of industry partnerships, the Maine Logger Health and Safety Study is the NEC’s first major long-term project in the forestry industry of the Northeast. Nationally, logging is still one of the deadliest professions, with only commercial fishing having a higher fatality rate in 2017, according to the U.S. Bureau of Labor Statistics. The fatal injury rate for loggers is 24 times

higher than the all-worker fatality rate. That said, the logging industry varies throughout the United States, and what is happening in one state or region may not reflect what is going on in Maine. The largest logging state in the Northeast, Maine was the logical place to start our work.

Survey says... To better understand the health and safety needs of loggers in Maine, the study team has been conducting quarterly surveys since spring of 2018. All told, 392 loggers have taken part in an initial survey and 307 continue to provide feedback. These loggers hail from all over Maine. The average age of a participating logger is 48, but some are fresh out of high school, and some have worked over 50 years in the industry. Forty-five percent of the study group have logged for 20 years or less, with the other 55% having more than 20 years of experience. While the vast majority of the group are men, there are some women loggers taking part in the project.

A broad representation of the industry. Different types of logging operations are well represented in the study, with 22% being conventional loggers, 72% mechanized, and another 6% working in both conventional and mechanical logging. The chart on the next page shows the mix of company sizes by number of employees. There are almost 200 unique companies represented in this research. Feedback from such a large and diverse group of loggers strengthens the study findings.

Safety first. The industry’s emphasis on safety is apparent in the project’s initial survey results. Over 80% of loggers report that their company has an emergency action plan, with most reviewing the plan each time a worksite changes. Sixty percent of loggers had safety training in the 12 weeks prior to the survey. There are differences in reported percentages of safety training depending on company size, with workers from sole operations or smaller companies (2-10 employees) having safety training less frequently than larger companies (11 to 50, or more than 50 employees). This isn’t very surprising, as larger companies often have more resources dedicated to training and other human resources needs.

NEC Continued Page 34

33 The Logger’s Voice ▪ Fall 2019

PLC Member Brian Bell (Balanced Forestry) undergoing health screening with Erika Scott, NEC Deputy Director.

NEC Continued from Page 33

Health Report. On the health side of things, initial survey findings show that two-thirds of loggers had an annual checkup in the last year. However, one out of five loggers still does not have health insurance. Of all loggers, two out of every five currently experience musculoskeletal pain. More than one in every 17 loggers report having a work-related injury or illness in the past year.

In addition to learning about Maine loggers through surveys, the project team met over 80 loggers this spring by offering free health screenings around Maine. The researchers and health practitioners who provided the health exams received a warm welcome and learned a great deal by talking to the loggers in person. Loggers received a $25 LL Bean gift card for participating in a health screening, which included the following services free of charge:

*Checkup with a doctor or nurse practitioner

*Blood Pressure

*Cholesterol Test

*Blood Sugar Test

*Hearing Exam

*Lung Function Test

*Carbon Monoxide Test (measures levels of CO from smoking)

*Vision Test

*Height/Weight

Many of the health screenings were set up in logging company garages in conjunction with Professional Logging Contractors of Maine Spring Trainings. Two days of free health screenings at the Logger Expo in Bangor were also offered. The project team will conduct more free health screenings across the state in spring of 2020.

A major part of this project is sharing the data with the logging community and understanding what loggers feel are the most important issues to tackle next. We’ll be holding discussion forums with loggers and industry leaders across Maine to discuss next steps throughout 2020.

You can learn more about this project by visiting http://www.necenter.org/forestry/research/ or searching @MaineLoggerHealthSafetyStudy on Facebook.

Leave us a comment if you have thoughts on the most important health and safety issues for Maine loggers. You can reach out directly to the project team at neclogging@bassett.org or (800) 343-7527.

34 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

Mechanized Logging Operations Program 2019

COPLIN - Fifteen graduates of Maine’s only postsecondary training program for operators of mechanized logging equipment were recognized Thursday, Sept. 19 at an event held in the woods of Western Maine where they spent weeks harvesting timber using sophisticated state-ofthe-art machines like those they will encounter in the logging industry.

Friends and family members of the students were joined by members of the Professional Logging Contractors of Maine (PLC); representatives of Northern Maine Community College including President Tim Crowley; state officials including Commissioner of Maine's Department of Agriculture, Conservation and Forestry, Amanda Beal, and Maine State Forester Patty Cormier; and industry sponsors to share a proud day with the students who completed the program's rigorous requirements.

Graduates included: Travis Merritt of Houlton, Patrick Prescott of Livermore, Garrett Colbath of Exeter, Michael Schools of Littleton, Jaden Castonguay of Livermore, Ahren Harrison of Stacyville, Payton Ross of Rangeley, Cameron Favreau of Pittston, Andrew Cole of New Limerick, Tylar Pickering of Byron, William

Perreault of Chesterville, Tiahna Cyr of Caribou, Corey White of Rumford, Jessica Michalik of Madison, and Logan Malm of Caribou.

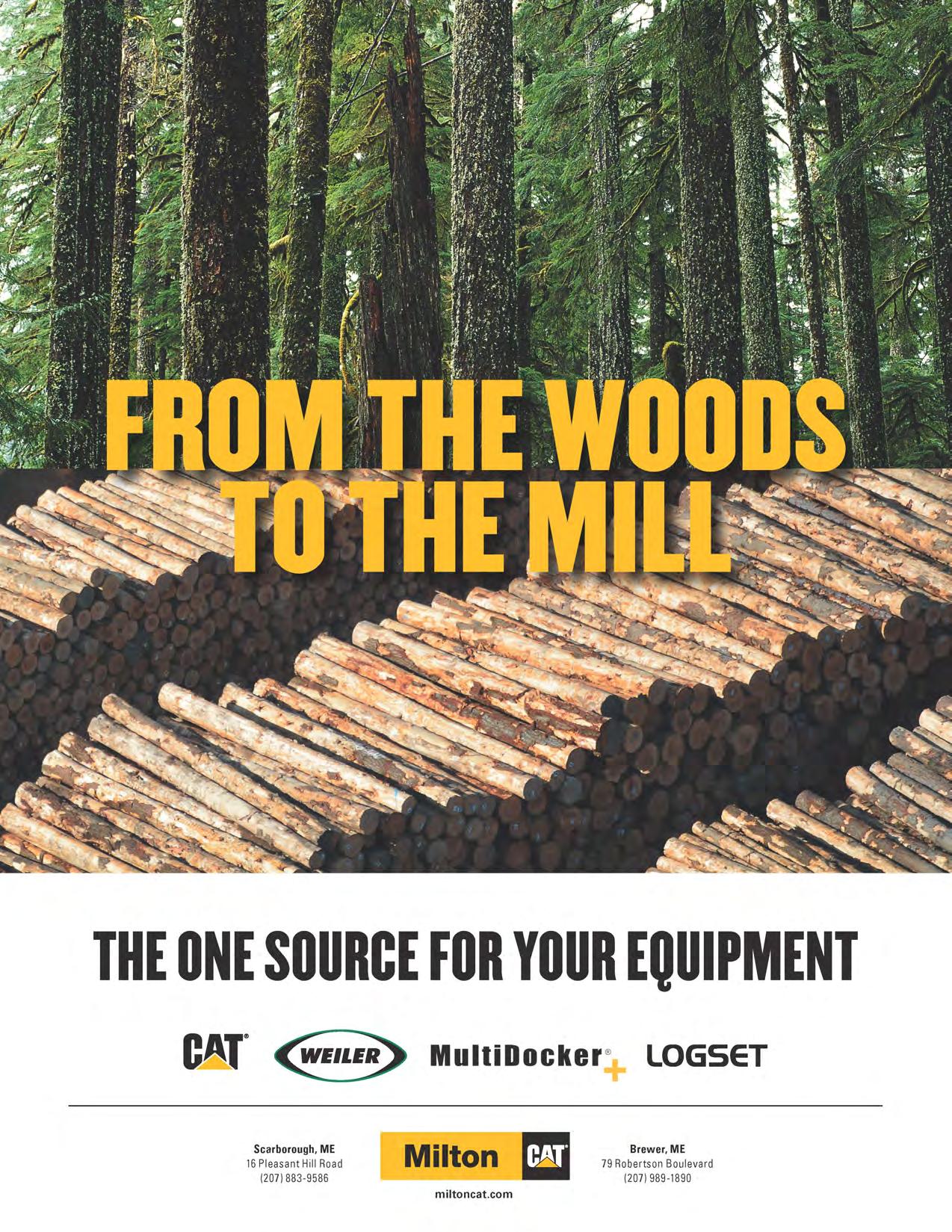

The Mechanized Logging Operations Program (MLOP) was launched in 2017 thanks to a partnership between three Maine community colleges, the PLC, and industry partners including Milton CAT and Nortrax/John Deere. This is the third class to complete the program.

“This program provides a direct pathway to a good -paying, exciting career in the Maine woods at a time when there is huge demand for new workers, Executive Director of the Professional Logging Contractors of Maine, said. gain the experience and knowledge you need to become an equipment operator in the logging industry. These students should be proud of this achievement and expect to reap significant professional rewards from it, and the many contributors to the success of this program should be proud that it is affording this opportunity and offering such a quality experience that every student that began the program this summer finished it rate.

MLOP Continued Page 36

35 The Logger’s Voice

Students and instructors in the 2019 MLOP Class

“This program is a great example of how workforce needs can be addressed when education, industry and government work together,” Northern Maine Community College President Timothy Crowley, said. “These students will not only be contributing to the logging industry but also to the economy and quality of life, in Maine.”

The program gives students a broad overview of the most common mechanical systems found in modern timber harvesting equipment, and an understanding of the variables of timber growth, tree species, and markets. It also includes a strong emphasis on safety.

Students who are accepted into the program pay no tuition, but are responsible for transportation, housing, and food costs. Personal Protective Equipment (PPE) is provided by the program. While the logging industry has seen some contraction in recent years due to the loss of pulp and paper mills, the industry is rebounding and the demand for skilled operators of the feller bunchers, harvesters, grapple skidders, forwarders, delimbers, and other mechanized logging equipment that now harvests 95 percent of all timber in Maine is strong. Many current operators are reaching retirement age and the steep costs of training new operators is driving up demand and wages.

The hands-on experience students gain operating equipment for weeks in the woods is something unavailable anywhere else in Maine and neighboring states.

It generally takes at least a year of training and experience before an operator becomes skilled enough to run mechanized logging equipment safely and efficiently. The cost for companies to train these operators themselves is approximately $100,000 each.

It was for this reason that the PLC partnered with the Maine Community College System and industry to create the program. It was jointly developed by the PLC and Northern Maine Community College (NMCC), Eastern Maine Community College (EMCC), and Washington County Community College (WCCC) with generous support from Milton CAT/CAT Forest Products, Nortrax Inc./John Deere, and other industry partners.

The program has been supported since its inception through Maine Quality Centers, a program to develop and support skilled in-demand and high wage occupations in Maine.

More information on the program is available online at http://www.nmcc.edu/industry-customized-training/ mechanized-forest-operations/

Photos:

Top: 2019 Graduates pose for family pictures.

Middle: U.S. Sen. Susan Collins visits the program.

Bottom: U.S. Rep. Jared Golden driving a forwarder during a visit to the program.

36 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

MLOP Continued from Page 35

TheMaine ForestryDirect LinkLoan program

ByTomGilbert WaterResources Specialist

MaineForestService

The Maine Forest Service’s Division of Forest Policy and Management (MFS), Department of Environmental Protection (DEP), and the Maine Municipal Bond Bank (MMBB) have teamed up to offer a mechanism to provide incentive financing to loggers that reduces nonpoint source pollution risk on timber harvests in Maine.

Background

Maine Forestry Direct Link Loan Program utilizes Clean Water State Revolving Loan Funds to provide low-interest rate financing for Forestry Best Management Practices (BMPs). The purpose of providing this financial incentive is to increase the use of BMPs and environmentally friendly logging equipment in the logging

$800,000. This, in turn, will help to protect and improve water quality in and around logging operations.

Program Description

Current Master Loggers are eligible to obtain low-interest financing from participating banks through a Maine Forestry Direct Link Loan Program. MFS will: 1) determine the items that are eligible for financing, 2) ensure that the logger is second or third party certified, 3) ensure that the logger retains, on file, a harvest plan and 4) monitor the improvements and practices of the logger.

The DEP and MMBB will: 1) enter into a memorandum of understanding with MFS to implement the program, 2) work with local banks to participate in the program, and 3) provide oversight within the context of managing the Maine Forestry Direct Link Loan Program.

The table below outlines some of the potential purchases that could be made through the Maine Forestry Direct Link Loan Program. However, equipment purchases will be considered on a case-by-case basis, with eligibility being based on whether or not the equipment is needed to facilitate the implementation of Forestry Best Management Practices. As new technologies become available, they will also be considered for inclusion into the direct link loan program: Low impact forestry equipment such as low impact forwarders, forwarder trailers and low impact harvesters may also be eligible for the DLL program.

37 The Logger’s Voice ▪ Fall 2019

38 Professional Logging Contractors of Maine LoggersServingLoggersSince1995

Great to see so many PLC Members, Supporting Members, Master Loggers, friends, and supporters of our efforts at this year’s Woodsmen’s Day at the 2019 Fryeburg Fair.

Thanks for stopping by to see us!

39 The Logger’s Voice ▪ Fall 2019

As We See It:August 2019

“Crossing the Finish Line”

By Danny Dructor

The American Loggers Council, working with other like-minded organizations such as the Forest Resources Association, have been successful in getting two bills introduced in this Congress that can have a positive impact on the timber harvesting industry and assist with bringing the next generation of logging businesses into the industry.

The two bills are the Safe Routes Act of 2019, S.1509 in the Senate and H.R. 2453 in the House which would allow log trucks to access the Federal Interstate Highway System with state legal tolerances when those safer routes are available to the mills, and the second is the Future Logging Careers Act, S.818 in the Senate and H.R. 1785 in the House, which would allow the 16 and 17 year-old sons and daughters of logging business owners to legally work in their parent’s businesses much like the sons and daughters of farmers are currently allowed to do.

We have received bipartisan support for both bills in the House and Senate and the Safe Routes currently has 7 cosponsors in the House and 2 in the Senate and the Future Logging Careers Act has 16 cosponsors in the House and 7 in the Senate.

We need many more in order to get either of these bills out of Committee and on the floor of the House and Senate for a final vote. In order to do that, we need your help. We have posted action alerts to both our Facebook® page and website (www.amloggers.com) as well as sent out a separate action alert to all of you who have signed on to receive our monthly newsletter, but obviously that still isn’t enough to get the word out.

We are asking you to visit our website and/or American Loggers Council Facebook® page and click on the action alert that will take you directly to a prewritten letter that will go directly to your Congressman or Congresswoman as well as your two Senators

requesting that they support the legislation. We also ask that you help us to spread the need for support as far and wide as possible in order to get more attention drawn to the legislation by your representatives in DC.

If Congress only hears from a few of us, they will not react, but when we are all working together, we will be hard to ignore. Partisan politics has become the status quo for many of our representatives in Washington, DC these days. For those of us outside the beltway who are impacted by the inability of Washington to pass even common sense legislation, one of our few hopes is to convince those members who are playing the political game that their job security rests on satisfying their constituents back home in their districts and States, and not just their allegiance to the “Party.”

If we are to have a chance of getting either of these bills across the finish line, then we have to work together as a unified industry and do our part by contacting our representative directly. The electronic tool that we are providing via our website and social media site only require about 5 minutes of your time to take that action. Please assist us in putting pressure on your representatives to support both of these bills and ask that they cosponsor both pieces of legislation. We are “Loggers Working for Loggers.”

The American Loggers Council is an 501(c)(6) not for profit trade association representing professional timber harvesters throughout the United States. For more information please contact the American Loggers Council at 409-625-0206, or americanlogger@aol.com, or visit our website at www.amloggers.com

We Support Maine Loggers

40 Professional Logging Contractors of Maine

As We See It Sept. 2019 “Success Starts at Home”

By Danny Dructor

The American Loggers Council is described as “loggers working for loggers.” The forest products industry is very broad and diverse in our country, ranging from forest land owners to manufacturers. The ALC works to promote and strengthen the whole industry. However at the end of the day, we are the only organization that focuses on supporting the needs and interests of professional timber harvesters. As loggers, we must stand up, speak out and support each other, because nobody else will.