Do you have news to share?

The PLC is always seeking news from our Members that showcases our industry’s professionalism, generosity, and ingenuity.

Send ideas to communications@plcloggers.org

Hello everyone.

Back in 2001 I took my family to California. We spent a week in Yosemite National Park. Being a logger, I wanted to see the big trees. One particular stand of redwoods stood over 300 feet tall and was so large that our entire family holding hands could not go around them. They were truly magnificent.

I could easily see why someone would be opposed to cutting trees after that experience. The park does give the public an appreciation for nature. But as we traveled around in different areas of the park, I noticed everything was about preservation as opposed to conservation. Man was not allowed to manage the forest, just look at it from the sidelines. Most signage was warnings about how our presence is harmful. Don’t get too close to the roots because it causes erosion. Don because it disturbs nature. Over and over the theme was the same. Man is bad for the environment.

I witnessed no sawn stumps, only rotted ones and courses of dead wood (fuel load) decaying on the ground. From the park’s perspective this was proper management. Leave it alone and keep man on the edges.

One of the last days we came upon a viewshed turnout, so I pulled in. It was a 60,000 acre burn that had happened a few years before. The sign was a tribute to the benefits of the burn saying how the forest would regenerate and wildlife would thrive. I couldn’t help but wonder if all those charred stumps had been sawn off and the timber utilized instead of burned to the ground would the sign have read the same? “Doubtful.”

Why? I would suggest to you it’s a worldview that is shifting in our country. A worldview in simple terms is the lens you see and understand the world through.

America was founded on a Christian worldview. That worldview understood man was placed in the garden (world) to work it and harness it’s potential. That’s why America prospered. We captured potential by farming the land, building dams, cutting timber, and mining products and incentivizing work by offering equal opportunity (not equal outcome). Everyone gets a chance, not everyone gets a check. The Bible teaches “if a man will not work, he shall not eat.” That would solve our labor crisis today, wouldn’t it? Our founding fathers understood these simple yet profound truths. Man was created by God and the world was created for man to steward by design.

Today God has been removed and evolution has become the standard worldview. This view takes design out of nature and makes life accidental. The whole carbon issue is based on the premise that man is the problem and cause of climate change. Keep man out and save the environment.

Why do I bring this up? I believe the carbon sequestration movement is rekindling the view that cutting trees is bad for the environment. I googled how many acres have burned in California in the last 10 years. It claimed over 7 million. I would suggest to you not cutting wood does not sequester carbon. Maine cuts wood and burns the residual for energy instead of wasting it. Who released more carbon? The earth by design needs to be worked to maximize its potential.

Last year I was asked for a quote on the first National Loggers Day. I wrote what I truly believe. “A true environmentalist not only cares about the environment they care for it. Loggers are true environmentalists.”

Science is on our side. Never apologize for what you do. Explain it.

This spring will bring closure to my tenure as president. Whenever I close out a harvest, I always look back and evaluate the results. Did our presence have a positive or negative impact? Have the neighbors become our adversaries or allies? Representation is a two-fold process: word and deed. Our actions either confirm or bring questions to our words. When word and deed align, growth will be the result. In the last two years PLC has grown from 4 to 6 employees and expanded it’s representation to the Northeast. That’s a reflection of progress and I was proud to be a part of it. It has been an honor serving as president of an organization that is creating allies instead of adversaries.

See you in the woods, Will

Blue Hill Land & Timber, LLC of Stowe, VT joined the PLC as a new Affiliated Contractor Member in January of 2024. The company is Master Logger® Certified and has a professional staff of 1. For more information contact Jed Lipsky at (802)-279-3993 or email lipskyjed@gmail.com

Hawkes Tree Service of Phippsburg, ME joined the PLC as a new Affiliated Contractor Member in January of 2024. The company has a professional staff of 23. For more information contact Jarrod Hawkes at (207)-442-7444 or email jarrodhawkes@gmail.com

JMM & Sons Logging, Inc. of Fort Kent, ME joined the PLC as a new Contractor Member in January of 2024. The company has a professional staff of 9 employees. For more information contact Jerod McBreairty at (207)-436-0696 or email jmmlogging@gmail.com

Pine Ridge Logging of St. John Plt., ME joined the PLC as a new Affiliated Contractor Member in January of 2024. The company has a professional staff of 1. For more information contact William Nadeau at (207)-398-4130 or email williamnadeau1@gmail.com

Savage Trucking Inc. of Chester, VT joined the PLC as a new Forest Contractor Member in January of 2024. The company has a professional staff of 5. For more information contact Hanson Savage at (802)-376-6801 or email hansonsavage@hotmail.com

Rowlee Farms Trucking of Reading, VT joined the PLC as a new Forest Contractor Member in January of 2024. The company has a professional staff of 2. For more information contact Dylan Rowlee at (802)-291-3548 or email rowleefarms@yahoo.com

Pete’s Equipment Sales & Rentals Inc. of Morristown, VT joined the PLC as a new Preferred Supporting Member in January of 2024. The company is a family-owned and operated equipment dealership founded in 1974 carrying a fine selection of agricultural, forestry, and construction equipment from various premium brands, and is the exclusive dealer for Metavic logging equipment in the United States. To learn more contact Jason Couture at (802)-888-5138 or email jason@petesequipmentvt.com

Waldo Solutions of Chassell, MI joined the PLC as a new Preferred Supporting Member in January of 2024. The company connects everyone in the logging industry by providing real-time job and load information through a chain-of-custody platform and mobile app enabling seamless communication for improved planning, control, transparency, security, and reporting. To learn more contact Brady Bekkala at (906-231-1420) or email brady@waldologs.com

Britton Lumber Company, LLC joined the PLC as a new Enhanced Supporting Member in January of 2024. The company is a forest products and building materials business. It was founded in 1946 in Hartland, VT. The company currently operates two divisions: Manufacturing, which produces Eastern White Pine boards with a sawmill, dry kilns and planer mill in Bath, NH; and Wholesale Distribution, which sells building materials from warehouses in Fairlee, VT, and Gray, ME. To learn more contact John Moses at (603)-838-5504 or email jmoses@brittonlumber.com

Maine Energy Systems, LLC of Bethel, ME joined the PLC as a new Supporting Member in January of 2024. The company builds and distributes the world’s finest fully automated wood pellet boilers and furnaces for residential, commercial and industrial use throughout North America. The company also delivers bulk wood pellets to many of the Northeast states. To learn more contact Ben Otten at (207) 824-6714 or email ben@maineenergysystems.com

From the Executive Director

From the Executive Director

Welcome to mud season everyone, or did mud season never end?

As I sit down to write this article, the largest snowstorm of the season just took place on Saturday, March 23. I’ve lived in Maine my whole life and I don’t think we have had such a large storm so late in the winter since the 1980’s. Based upon the winter of 2023-24 that never really happened, I guess we should just call this

normal and it’s probably very appropriate that the focus of this quarter’s magazine is on the weather.

As I say all too often, you can’t look forward if you don’t look back. Looking in the rear-view mirror, it’s not just the past winter that has been abnormal, but more like the last 18 months have produced probably the most unreliable operational conditions that our membership has ever seen, regardless of state in the Northeast.

The warm winter of 2022-23 continued with rain for the entire summer and fall of 2023 and then finished off the year with a major catastrophic wind and rainstorm on December 18th. January 2024 started about the same with two back to back rainstorms and a lack of frozen ground. I guess we did end up having a winter for about four weeks between mid-January and mid February 2024, but it was short-lived as most of the membership has been

shut down since around March 1st.

I would call this living on the edge at this point and it’s not just about the weather.

At the end of December, we finished renewals for 2024. I’ve been in this job for 11 years now, but I’ve never seen such a reduction in both capacity and membership in just one year. Our entire membership is living on the edge and that is not a good sign.

Doran Continued from Page 96

The lack of consistency of market, pricing, weather, inflation and availability of employees is causing a majority if not all to question their future. If this isn’t the edge, then I don’t know what is.

We know that the economy ebbs and flows as do markets for forest products. This ebb and flow has existed for as long as there has been an economy. This same ebb and flow has also followed fairly normal patterns with respect to weather. Contractors could count on 44-48 weeks of normal operational weather each year. Winter would start in November and end in mid to late March, if not early April. However, what logging contractors are going through now is not just ebb and flow, based upon simple supply and demand and normal weather patterns.

Last week, I had several dozen members reach out to me when they got a text message from a major pulp producer early in the morning, telling them that their payments were going to be delayed. This had happened before with an infamous biomass electric company (Stored Solar) that landed in the state around 2017, but this has never happened in the realm of reliable markets. Folks were extremely troubled by this, again questioning what their future would look like. Two days later, it looks like the company realized that the shockwaves they delivered were not a good public relations move, and they quickly did an about face, sending out a new message that payments were made, contractors were made whole, and casting a rosy picture for the summer, even though at the same time, they were laying off 100 plus people from the mill. The damage was done though as the edge seems to have inched forward.

I guess the new normal is abnormality and contractors are just supposed to take it, but it just doesn’t seem right to me. Contractors have always been quiet, hardworking folks, who have understood their role, rolled with the punches and understood the risks for their rewards. But, I can tell that folks are getting restless, more so than they ever have over the last 11 years. What does the future really look like and is the sacrifice really worth it is what I’m hearing more and more.

road ahead and drove straight off the road and into a pond losing his life likely almost immediately.

While Mr. Drolet is Canadian, he is still a human being and still a hardworking member of the logging and trucking industry. He may have been delivering wood from one of our members’ harvest sites within Maine and probably knew many of our members since this community is very small.

This is extremely sad news for our industry because it could have happened to any one of our members. This tragedy should be a reminder to all of us how precious human life is and how it can be taken in the blink of an eye.

Based upon the time of year, the lack of winter conditions and the time of day the accident took place (2 am), the driver was likely pushing the limit as so many in this business do. However, does it really need to be this way? Does everyone really need to operate on the edge to be successful?

Most of this industry is pushed to the edge because they don’t get paid unless wood crosses the scale, which generally passes much of the risk to them and not the other way around. This unfortunate fatality is something that could happen to any one of our members at any time as a direct result of the edge that all of you are forced to work on at all times. The weather is inconsistent, markets are inconsistent, and pricing for the work you do is inconsistent. The edge is always getting closer and the limit is always getting pushed. There’s always one more risk and one more chance to take because there doesn’t seem to be another option if one wants to be successful in this industry.

There’s always one more risk and one more chance to take because there doesn’t seem to be another option if one wants to be successful in this industry.

Mr. Drolet went to work on March 21st to make ends meet and put food on the table for his family, but didn’t deserve to lose his life, trying to do his job. No one that sacrifices the amount that loggers and truckers do should be put in a similar circumstance. Rest in peace Mr. Drolet and our collective heart is with you and your family.

Also this past week, there was another snowstorm, a trucking accident and an unfortunate fatality by a Canadian truck driver who was likely trying to deliver pulpwood to a market in Central Maine. The wood looked like hardwood pulp and was likely from a Maine forest along the Canadian border that was then making it’s way south to a Maine market.

The driver, Pierre Alexander Drolet, of SaintZacharie, Quebec was only 35 years old. From news reports, he experienced white out conditions from a snowstorm while driving south on US Route 201 between the Forks and Bingham. Mr. Drolet likely couldn’t see the

As we move forward with mud season and take a collective breath of fresh air, I challenge those that you work for to start thinking about what it is they make you do and why they make you do it. There must be a better way and there must be a return to normalcy, because without a collective press of the reset button, things like this are going to continue to happen and more and more of you are going to head in another direction. After all, it doesn’t have to be this way and the edge should not be so close.

My best to all of you for some rest in recovery this mud season and I truly do hope things change for the better once conditions improve and you go back to work. Please stay safe, be well and stay in touch.

Weather has always been a challenge in logging, but what happened in many parts of Maine on Dec. 18, 2023, was much more than that.

Mid-December has traditionally been a time of frozen ground, snow, and good logging conditions in Maine. However, as that day began much of the state was in the 50s, a warm wind began to blow and strengthen until it reached hurricane force in some locations, and the rain fell at rates unusual even for summer thunderstorms,

melting snowpack to the bare ground in hours.

The resulting damage from wind and flooding would paralyze much of the state for days, knocking out power to half of all Mainers and forcing the closure of nearly 100 roads and more than 20 bridges. Losses to logging companies in many areas from disruptions to trucking and harvesting were severe.

Three months later loggers affected are still counting their losses and grappling with additional issues

from the second unusually warm winter in a row. Mud season is weeks early. As spring begins, many are asking, what’s next?

The town of Rangeley received more than 5 inches of rain in the Dec. 18 storm and was isolated by flooding and washouts after it ended, with no passable roads in or

out. Rangeley was not the only town in that situation, Farmington being another important crossroads that was cut off, while Rumford-Mexico suffered similar effects.

Among the most significant damage for the logging industry was a washout of the Route 16 bridge on Nash Stream, which severed the primary east-west route for wood moving between Rangeley and Stratton for three weeks, affecting loggers throughout the region.

It wasn’t just paved routes that were damaged -

Weather Continued from Page 15

washouts of culverts and bridges on woods roads were everywhere, some so bad it may be months before access is back to normal.

Peru logger Andy Irish of PLC Member Irish Family Logging reported extensive damage to logging roads and woods bridges in his area, and major travel disruptions in the days following the storm due to floodwaters closing major routes.

“You couldn’t get out of Dixfield, Mexico or Rumford, on Route 17 the Swift River came over its banks and went right down the road.” Irish said in early January.

“We had to move jobs, we lost a whole week of trucking. Our spruce goes to Stratton now and we’ve got 40 or 50

ice and other hazards they encountered at the end of the day. Their pickup went into a washout and was nearly wrecked. They were able to limp it into Oquossoc but were unable to get south and ended up stranded there until the next day when they found a route home. That was the beginning of a rough few weeks for the company, Gavin said.

“We missed the lion’s share of the week after the rain and then we added 82 miles roundtrip per trip to get to the mill in Stratton, so we got to eat that, not only the expense of it but the loss of production because the trucks individually were losing a load a day, they just couldn’t get enough hours in the day to get their load counts where they

loads of spruce sitting in the woods and we can’t go up Route 16, so we’ve got to haul it all the way around and up through Carrabassett.”

PLC Member CTL Land Management Inc. of Washington, ME, co-owned by Kyle Overlock and Gavin McLain, had a job going on the Parmacheenee Road near Rangeley the day of the storm, but kept most of the crew out of the woods due to the forecast. Kyle and his son did go in to cut wood and were caught off guard by the glare

should be,” Gavin said. “Every truck that was capable of doing four loads a day instantly went to three and those doing three were down to two.”

In the wake of the storm, the Professional Logging Contractors (PLC) of the Northeast surveyed its member companies in Maine on losses due to the event. More than 50 responded, estimating losses exceeding $2.6 million. Applying a multiplier for the industry utilized by the

University of Maine and the Margaret Chase Smith Policy Center in a recent logging economic impact study for Maine, the total loss to the Maine economy just from the impacts on this group of companies was pegged at more than $5.5 million.

And so began the winter of 2023-2024.

Maine is by no means the only state in the Northeast where loggers have been impacted by severe storms and warm winters in recent years. Neighboring Vermont has also been slammed by floods and persistently warm winter temperatures, and the losses for loggers there are as deep as those elsewhere.

In testimony provided on Jan. 5 before the Vermont Senate Agriculture Committee and the House Agriculture, Food Resiliency, and Forestry Committee, Melanie Gilman, co-owner of PLC Member Stephen Montgomery Logging Inc, of Royalton, provided a dire example of what logging contractors in the state are facing due to weather challenges, estimating the company lost 88 days of production and suffered another 60 days of reduced production in 2023 due primarily to unusually muddy conditions.

“All of this has resulted in our 2023 logging revenue being down by 30% and our trucking revenue down by 55%. This is compounded by higher fuel consumption and crippling increased costs for parts, services, fuel, employee costs and employment taxes,” Melanie said. “To keep our business going we have exhausted our reserves, had to hold off on some equipment maintenance, reduced equipment refreshes for 2023, we have used most of our personal savings and we are relying on some new short-term lines of credit. Our biggest concern is that with all this we do not have the cash reserves that we rely on to get through the normal ‘mud season’ shut down from April-May 2024.”

The current cycle of weather-related logging losses in Maine and Vermont began more than a year ago. January 2023 was the second warmest January for the Northeast since records began being kept in 1895, leading to early road postings and shutting down logging operations in some areas weeks before they would normally have halted. That warm winter was followed by heavy rains and severe flooding in areas of Maine and Vermont in the early summer that washed out roads and bridges and made for challenging conditions in general for loggers seeking dry ground on which to operate.

As summer gave way to fall and conditions improved hopes were high for a productive winter season.

December’s storm and similar storms in early January 2024 put an end to that.

Consistently cold temperatures were hard to find in January and were quickly followed by rains in February and a lack of snow and frozen ground in many areas. By March, conditions were so poor that even in far northern Maine the Can-Am Crown International Sled Dog Races had to be canceled for lack of snow.

Working on the Maine coast in Castine during the third week of February, Derek Madden, owner of PLC Member Madden Sustainable Forestry, surveyed a salvage harvest that included some trees knocked flat by the Dec. 18 storm. On what should have been a cold, midwinter

Road and bridge warnings and closures continued to hinder movement of wood through large portions of the Northeast two weeks after the Dec. 18 storm as this early January screenshot shows.

morning, the ground was bare, the sun warming the logging road surface quickly, and the final truckload of wood had already left to avoid what was coming.

“This is frozen right now, but by 3 o clock in the afternoon there’ll be at least a foot of mud,” Derek said.

“

We can truck in the morning but come afternoon we can’t, so they’re starting at 2 or 3 in the morning and getting done by noon.”

Derek has been logging for two decades, long enough to remember when Maine had more predictable seasons, including longer and colder winters that were ideal for logging. He has certainly noticed more erratic weather in recent years.

“There were a handful of years where it was super dry in the summertime, the winters were still pretty warm but manageable, but then I’d say for the last three years we haven’t really had any winters here, the last two years for sure, and this one here is right up there with the worst,” Derek said.

Weather Continued from Page 17

At that point in late February Derek estimated his company had already lost at least two to three weeks of production due to the weather and he was trying to figure out where his company could still cut given the conditions.

“You can’t go to your winter lots because winter didn’t come, so now you’re trying to do what you can on some of them – like this is a winter lot because there’s a lot of swampy ground, so you try to do what you can but a lot of it you just say you can’t do it, it’s too wet,” Derek said.

Madden Sustainable Forestry does a lot of work on the Maine coast but works in other areas of the state as well, but going north or into the mountains no longer seems to be a guarantee of better winter conditions.

“I think mud season has already started here,” Derek said. "but I don’t think it’s a lot different anywhere in the state, we were way up north a couple weeks ago and there was more snow but other than that it was not much different.

”

Mission impossible

Rangeley is Maine’s highest elevation town, and the mountainous region surrounding it is normally one of the most dependably snowy and cold areas of the state. Yet even here logging is becoming difficult in winter.

For CTL Land Management Inc. things had gotten back to something resembling normal in the wake of the December storm by the second half of January. There, working a job on the Lincoln Pond Road northwest of Oquossoc, the crew at least had frozen roads most days, snow, and the restoration of the Route 16 bridge in their favor. But it didn’t last. The rains began again by midFebruary, temperatures got warm, and they stayed warm.

By the end of February, it was over. With the roads thawing to mud CTL had to shut down and move about 40 loads of wood onto gravel along with seven machines. On March 7, as rain poured down, the wood and the machines remained stranded in the woods with the company unable to get to either with trucks. Gavin was back in Washington debating the company’s next moves. “So now its mud season so you can’t truck wood and I’m not sure you can cut wood, I think the saturation levels are going to box things out for a while,” Gavin said. “We’re sitting here today in the office going over cash flow and effective next week we have cash flow concerns, so I don’t know where that leaves us as a company. We’re a month early so we’re going to miss four weeks of operating here and I don’t have to tell you what that represents in gross receipts at 50 loads a week, that’s a lot of money that isn’t going to go through our checkbook here in the next month.”

CTL Land Management Inc. worked for years in the region surrounding Washington, but more recently moved most harvesting operations to the Rangeley area due to a combination of increasingly warm winters in the

Average winter temperature data for Maine and Vermont since 1900 shows the number of years above the mean for the 20th century (in red) increasing since the 1980s. Winters are also getting wetter in both states.

Midcoast area and the need for more commercial-scale jobs to better suit its mechanized logging crews and remain profitable.

With the Rangeley area shut down due to an early mud season, options for the company to find dry lots to continue operating on closer to home were slim.

“I’ve logged here my whole life, and so for all intents and purposes we’ve logged through all the high ground that we have available in the Midcoast region,” Gavin said. “It’s almost like a mission impossible right now, so we don’t know what we’re going to do, we’re going to wait out the week and then reevaluate and see what makes sense.”

Weather has always been unpredictable and severe weather events have always been part of the challenges in logging. Until recent years however, loggers could at least plan with some confidence on the general conditions to

expect in each season. That included knowing approximately when mud season would begin and end, when the ground would freeze and thaw, and when generally dry conditions would be the norm. In recent years that confidence has been shattered. Heavy rain can now be expected in every month of the year. Frozen ground - if it occurs at all - may thaw at any time due to sudden unseasonably warm temperatures.

Weather data available from the Northeast Regional Climate Center (NRCC) in Ithaca, NY, shows 2023 had record warmth for Massachusetts, New Hampshire, and Vermont, and ranked as the second warmest year on record for Connecticut, Maine, Maryland, New York, and Rhode Island.

Jessica Spaccio is a climatologist with the NRCC. Speaking on Feb. 29, she said she expected more winter temperature records to be broken in 2024 and added that while the Northeast’s current warm wet winter was being affected by El Niño, that alone does not account for the record-breaking weather. She said the best way to measure trends for the region is to examine weather data long-term,

The graphic above shows the shrinking portion of the Northeast experiencing a full traditional winter logging season from the 1980s to the 2010s. It is taken from a 2019 study, Climate Adaptations in the Northeast’s Forest Products Supply Chain: A Vulnerability Assessment for the Primary Forest Products Sector. The study has not been updated but the years since it was completed have included record warm winters for the region.

over a period of decades.

For example, looking at average annual temperatures for the entire 20th century in Maine and Vermont, you can calculate a mean temperature for the century for each state, and then on a graph plot where the average temperature for every individual year since 1900 falls in relation to the mean. Doing that, the pattern that can be seen since the 1980s in both states shows far more of the years falling above the mean temperature than below it.

“We're seeing this trend where there's more and more of these warmer winters and that is the challenge,” Jessica said. “It's not that we're not still getting some cold days, but it's also the warm-up in between them that would be big for the loggers as well, deciding if the roads are staying frozen enough for those heavy trucks to drive on.” Weather data for the region also supports the general perception that severe storms are more common and winters wetter than they used to be. For loggers, more heavy rainfall versus snowfall in winter is particularly troubling.

“We're seeing more precipitation fall in these intense rainfalls, coming down quickly and not as useful as if it would just happen in a slow fashion and soak into the ground,” Jessica said. “I can say without specific numbers that we're expecting the current trend to continue, that our winters will continue to be warmer, precipitation is also expected to increase a little, but the biggest change will be when and how we see it – we’re expecting to have our winters be a little wetter and more of that coming as rain

than snow.”

It may well be that as 2024 proceeds more normal weather patterns will return to the Northeast and that some reliably cold winters lie ahead, but after what the region has experienced in recent years, no one is counting on a long-term return to traditional weather patterns. If not, the question of how the logging industry can adapt is a critical one to answer.

The PLC is currently working on multiple fronts to explore what options may be available to offset the financial losses loggers are suffering as they work to protect water quality and forest health in the face of a changing climate. Loggers are not compensated for the extra time and money that goes into the culverts, road repair work, timber mats and other measures they are taking, and that is contributing to their losses.

In early January, PLC Executive Director Dana Doran was among a group of representatives of agricultural stakeholders who met with U.S. Department of Agriculture (USDA) Secretary Tom Vilsack in Portland to discuss the impact of recent storms and warm rainy winters on the state’s farms and the logging industry, and to make the point that so far loggers are being left out of most relief efforts.

“Keeping loggers and truckers employed is the biggest challenge that we have, and I will tell you there are no programs, federal or state, that help logging businesses

through this,” Doran said, pointing to things that could be done such as assisting logging companies with the costs of repairing critical woods infrastructure such as roads, bridges, and culverts, as well as aiding logger efforts to protect water quality from extreme weather events in harvest areas. “Those are things that are going to have to happen in order for contractors to continue to be able to work.”

In Vermont, the PLC has met with a wide range of legislators, state agencies, and representatives of Governor Phil Scott’s administration seeking support for relief efforts to assist the state’s timber harvesting and hauling sector. The focus is primarily on two efforts:

1. Income replacement in response to the floods in 2023 to be included in an appropriations bill. That bill is awaiting action in the Legislature.

2. H. 624, An Act Relating to Providing Financial Assistance to the Forest Economy. The bill, which includes $1 million for climate resilience measures and Master Logger scholarships, is currently working its way through the state’s legislative process and looks like it will get included in the FY 25 Budget for the Dept. of Forests Parks and Recreation. One-time funds would incentivize logging contractors to implement best management practices to enhance water quality protection measures during forest operations. Currently the cost of such efforts is borne entirely by the logging contractor.

In Maine, the PLC is advocating for passage of LD 2191, An Act to Provide Relief to Small Businesses Affected by Severe Weather-related Events. The amended bill includes a one-time General Fund appropriation of $50 million in fiscal year 2023-24 to the program with assistance to loggers for income replacement and dedicated funding to establish a Wood Salvage and Reclamation Program in the Department of Economic and Community Development to provide grants to landowners and contractors affected by the recent severe weather events.

other relief measures that may emerge for the logging industry, it seems clear that changes in weather patterns must now be factored into every Northeast logger’s planning for the future. Wood markets, worker shortages and the high cost of everything from equipment to fuel are bigger challenges if you ask most contractors what is keeping them awake at night. But in an already tough industry, there is no doubt the loss of operating time and the increased cost of dealing with extreme and unpredictable weather is taking a toll.

The industry is nothing if not adaptable, and if any group can survive the changes, it will be loggers.

Watching the rain fall on March 7 with his woods crews idled and uncertain where or when they would be able to cut again, Gavin McLain was not wasting time wishing the weather were better, he was actively looking

Northeast loggers are responsible stewards of the land who invest large amounts of their own time and money to protect forest health and water quality during timber harvests. Recent warmer and wetter conditions in the region have increased the amount of uncompensated work loggers are doing at a time when they cannot afford it. PLC Executive Director Dana Doran, at far right, made this point during a meeting in early January with U.S. Department of Agriculture (USDA) Secretary Tom Vilsack, third from left, to discuss the impact of recent storms and warm rainy winters on Maine farms and the logging industry.

And at the federal level, the PLC is working with Congressman Jared Golden and Senator Susan Collins to create a national income relief program for logging contractors that are impacted by storms where a federal disaster relief designation is declared. The program will be modeled after the Pandemic Assistance for Timber Harvesters and Haulers program that was created in 2021 and the intent is to have legislation introduced in the near future.

Whatever the outcome of the PLC’s efforts and any

for solutions while keeping as many of CTL’s employees working as possible at the company’s other operations.

“ For us it’s going to be sawmilling and firewood for the foreseeable future, if it weren’t for that there wouldn’t be anything,” Gavin said. “I think we’re going to endure some pretty tough times financially for the next couple months there’s no doubt about it, but it’s what we do and we’ll come out on the other side somehow.”

In 2020, HAIX®, a global leader in top quality specialty footwear, was working to develop a high slip resistant boot for use by operators of heavy equipment, especially during the icy months of the year. The project prompted HAIX® to focus on conditions in the Northeast United States, and particularly Maine. There, working in partnership with the Professional Logging Contractors (PLC) of Maine (today PLC of the Northeast), Acadia Insurance and MEMIC,

HAIX® developed the Airpower® XR23, a tough, waterproof and breathable work boot able the handle the harsh demands of Northeast winters and the region’s logging industry while meeting durability and comfort demands of mechanized logging operators.

The boot has gone on to great success thanks to top-notch durability, utility, and a design specifically geared toward moving safely and comfortably on equipment and in and out of the cabs of machines in all

weather conditions.

The PLC’s Mechanized Logging Operations and Forest Trucking (MLOFT) training program was an early beneficiary of the new design, with HAIX® supplying XR23s to students and instructors in the training program in 2021 through a combination of donations and hugely discounted sales.

“I’m still wearing mine,” and Training Consultant, said three years later. “Even the laces have not worn out, they are good boots.”

HAIX® traces its roots to Bavaria, where in 1948, shoemaker Xaver HAImerl began making hiking and work boots. His son, Ewald Haimerl, developed the area’s first leather fire boot in 1992. HAIX® North America was established in 2003 in Lexington, Kentucky and today the company stocks over 60,000 pairs of shoes ready for distribution in the United States and Canada. In 2022 HAIX® crafted 1.67 million pairs of shoes. The company has grown from a few hundred employees when Ewald Haimerl took over in the 1990’s, to 1,400 in 2017, to just over 2,300 employees worldwide today. HAIX® is proudly a 3rd -generation family-run company.

for the Northeast region and mechanized logging, it is not the only product HAIX® offers geared toward the logging industry. HAIX® Class 1 and Class 2 chainsaw/cut protective footwear designed for groundwork and climbing is also utilized by loggers worldwide. Models include the Airpower® XR200, Protector Prime, and Protector Ultra, which is available in three color variations (Signal Red,

HAIX® joined the PLC in 2022 as a Preferred Supporting Member and has been a strong partner for the organization and supporter of the logging industry ever since. That has included offering a special discount for PLC Members - $35 off any boot $224 or more, use code “PLC”. Order online at haix.com

The company has plenty of fans in the logging industry, including PLC Members like Ron Ridley of L&A Ridley Logging Inc. in Jay, ME.

“

Above: Some of the 2023 graduates of the Mechanized Logging Operations and Forest Trucking Program. HAIX® has supplied boots to many students and instructors in the training program through a combination of donations and hugely discounted sales.

HAIX® main headquarters are located in Mainburg, Germany but the company serves customers all around the world, selling its products through dealers, contracts and directly from its online web shop at haixusa.com. Headquarters for HAIX® North America is located in Lexington, Kentucky.

HAIX® owns its own manufacturing facilities throughout Europe and uses only the highest quality materials that are 100% sourced in Europe, including more durable bull hide leather. Hand-made uppers, attention to detail, and craftmanship set the company apart from other safety footwear manufacturers. HAIX® also emphasizes sustainability at their plants, headquarters and in their leather tanning processes. Their primary leather manufacturer has the TerraCare® designation which means they have 100% transparent raw material origin, 100% clean auxiliary materials, at least 97% recycling/reuse of cut materials, at least 40% less water consumption than other tanneries and at least 30% less CO2 emissions during production. HAIX facilities in Europe utilize green energy for vehicles, including forklifts and other warehouse equipment. They also power headquarters using solar energy, with 80% used at buildings and at least 20% fed into the local power grid.

While The XR23 boot was designed specifically

I am on my fourth or fifth pair of their boots, very pleased with them,” Ron said. “We still do some chainsaw work but spend most of our time in a machine cutting trees. Can wear them year-round and no more twisting ankles. We have gotten several other loggers in our area to try HAIX® boots. HAIX® makes a high-quality boot. Very satisfied!”

The relationship with the PLC and the region’s logging industry is important to the company.

“Working with the PLC has been an absolute pleasure. With their open, honest, and sincere passion for logging, it aligns with our own philosophy at HAIX®,” said Tracy Cline, Forestry Brand Ambassador for HAIX® North America Inc. “The PLC allows us a platform to share the importance of proper footwear and educating folks on how the right type can make their job easier and safer.”

Check out the equipment and job opportunities our members have listed on the PLC website at the LOGGING ZONE!

If you have equipment for sale, are looking to buy, are looking for employees, or are looking for employment - check it out!

The PLC provides Members with regular email updates and alerts on important issues. If you are not receiving these emails please reach out to our office at 207-688-8195 or email communications@plcloggers.org so we can correct the issue!

Most work-related hand injuries result from not wearing the proper gloves or not wearing gloves at all. A job hazard assessment performed before work begins determines the appropriate level of hand protection needed for a task.

Workplace hazards that could cause hand injuries include:

∙ Heat

∙ Cold

∙ Chemical

∙ Sharp edges

∙ Vibrations

Types of gloves:

Leather: Made with tanned hides of various animals, leather gloves are a popular choice for tasks that require abrasion, heat, and fire resistance. Liners can be sewn into leather gloves to offer protection from additional hazards.

Cut Resistant: These gloves are designed to protect workers from sharp objects such as knives, glass, and metal edges. They are typically made from materials such as Kevlar, Dyneema, and other high-performance fibers woven together to create a strong and durable fabric that can withstand sharp edges.

Nitrile gloves: These are primarily used for mechanical work, but the same gloves are also used for first aid treatment and to keep people safe from bloodborne diseases.

Welding: The best welding gloves protect your hands from exposure to sharp metal edges, jagged surfaces, red hot metal, sparks, and other hot flying metals. Gloves can also protect hands from the ultraviolet radiation emitted in arc welding.

Insulated: Good insulated waterproof gloves offer

protection from injury. The obvious benefit of thermal waterproof gloves is warm hands.

String Knit Gloves: Thanks to engineered yarn, string knit gloves can offer protection from various hazards. Engineered yarns incorporate the benefits of two or more fibers to make them even stronger. This also allows us to integrate higher levels of protection without compromising comfort or dexterity.

Mechanics Gloves: Mechanics gloves are essentially different layers of materials (natural or synthetic) sewn together to make gloves. This construction method allows us to integrate zoned protection. This means that protection can be localized in areas of the gloves where hands are at high risk of injury.

Protection Against Vibrations: Extended use of power tools such as drills, sanders, or impact wrenches can expose your hands to vibrations, leading to discomfort or even nerve damage over time. Anti-vibration gloves feature padding or gel inserts strategically placed to absorb and dampen vibrations, reducing the strain on your hands and wrists. By minimizing vibration exposure, these gloves help prevent conditions like Hand-Arm Vibration Syndrome (HAVS) and ensure long-term hand health for

the full mechanics and equipment operators who are sometimes mechanics.

In conclusion, wearing gloves while working is not just a precautionary measure but an essential aspect of safety and efficiency. From providing hand protection and improved grip to offering thermal insulation, chemical resistance, and hygiene benefits, gloves are vital in safeguarding your hands and enhancing your overall work experience. Investing in high-quality gloves that are wellfitting and appropriate for your specific tasks and environment can minimize the risk of injuries, work comfortably in various conditions, and prolong the longevity of your hands a crucial asset for any logger.

Following major vehicle incidents on logging roads, a question that always comes up is, “were the involved parties using radios?” This is a reasonable question as radio use is one of the ways loggers have come up with to reduce the hazards associated with travel off road but, from a risk management standpoint, the question is concerning because it indicates a heavy reliance on an inherently unreliable system. In this article I am going to address the reasons defensive driving will always trump use of radios when it comes to preventing incidents on logging roads.

The idea behind radio use to prevent collisions is relatively simple. Call out the road name, location and direction of travel and if both parties are doing this, you should avoid a collision.

“Mile 6. Reality Road. Empty truck. Coming up.”

If those traveling the opposite direction are also calling out their location, you can avoid collision by meeting in a safe location:

“Mile 8. Reality Road. Coming down. Loaded”

“Ok. I’ll wait for you at the wide spot around mile 7.”

An added benefit of the radios is those with radios can communicate for those without radios:

“I met a pickup with no radio about mile 7 headed towards you.”

While this system works great at preventing many incidents, major problems can be created when we rely too heavily on radio communication and we don’t drive defensively.

This problem became inherently obvious to me a few years back traveling out the Michaud Farm Road in Allagash. My radio volume was up and tuned into the proper channel. I was calling every mile marker and I didn’t hear anyone coming my way. Imagine my surprise when I narrowly missed a collision with an empty log truck on a blind corner. The following day I was visiting another

contractor and when I arrived on site I called to them on my MURs radio and got no response. Short story long, it turns out the coax in my antenna was broken so my radio wasn’t projecting or receiving.

This story is just one example of the many ways a radio can fail without our knowledge and why I said in the introduction that the system of radio use is inherently unreliable. We can all learn from this close call by occasionally inspecting and testing our equipment to make sure it is working properly. The primary take away from this lesson is that I THOUGHT I was projecting my location but thankfully I was driving defensively and had pushed way over to the right when I entered the blind turn.

As most people know, I guide hunting trips in the North Maine Woods. On my way in to camp last year I stopped at the gate and I got an updated MURs channel list to have in my truck. When I read down through the list I quickly realized that many of the channels on the list were not the channels that were actually in use. Between the lack of posting the proper channels on the roads, and the inaccurate channel list, it’s challenging to know if you are communicating on the proper channel.

At the end of the day it’s important to remember that although radios are suggested, they are not a requirement to travel on the logging roads. Maine’s working forests provide a recreational attraction to people who enjoy outdoor pursuits and many of them will not have radios installed in their vehicles. We always need to be prepared to meet a motorist without a radio.

While people who don’t use radios get the majority of the attention following an accident, the fact is that radios can fail without the user knowing, rendering it useless. A safety director from a large contractor in the North Maine Woods told me one time, “You should always drive as if you’re going to meet someone without a radio, or on the wrong channel, or with volume turned down, or a bad mic…..” Radios provide a fantastic layer of protection from auto accidents on woods roads but they should never replace good defensive driving techniques.

Acadia is pleased to share this material for the benefit of its customers. Please note, however, that nothing herein should be construed as either legal advice or the provision of professional consulting services. This material is for informational purposes only, and while reasonable care has been utilized in compiling this information, no warranty or representation is made as to accuracy or completeness. Recipients of this material must utilize their own individual professional judgment in implementing sound risk management practices and procedures.

You don’t have to be a sports fan to know that Spring kicks off baseball spring training.

Spring training began in 1886, by Albert Spalding (founder of the Spalding Ball Co.) who was then president of the Chicago White Socks, and Cap Anson, a former baseball player. They chose Hot Springs Arkansas for its warm climate and the therapeutic hot springs that complimented strenuous physical conditioning. After the White Socks’ successful 1886 season the spring training concept gained traction with other teams, and today it is firmly established, with teams migrating each February to Florida and Arizona.

For established players, spring training is a time to get back into the groove of working as a team and prepare physically for the upcoming season. Aside from regular team practices and exhibition games, players have strength and aerobic workouts to prepare themselves for the demands and rigors of the long season ahead.

Loggers would do well to embrace the concept of spring training. Although nearly every logger takes time ahead of the preseason to prepare their machines and gear, I’ve met very few who prepare their own bodies for a long, physically demanding season, although few would argue that mechanized logging isn’t as hard on the body. Just as in baseball, loggers' physical hardships can result in lifelong injuries, and wear and tear can force early retirement for people who have a passion for what they’re doing. Preseason has helped baseball players minimize these risks, and a similar practice can do the same for loggers.

There is some comparison of activity level in terms of fits and starts that both baseball players and loggers perform during work. Baseball has moments of low activity followed by bursts of high activity. A mechanized logging operator sits for most of his day, with occasional getting in and out of his cab, and maybe throwing a strap, or addressing an issue on the machine. This level of predominantly low activity that requires manual dexterity and concentration to get the machines to perform the work often results in poor posture, low back pain, tension in shoulders. So when exiting the cab and doing some manual work, the body is often not ready to engage immediately.

As mud

season demands that loggers wait until roads dry out, loggers often tend to their machines getting them ready for the summer time work ahead. Cleaning, replacing fluids, tightening bolts so the machine is ready for work can make the difference between a safe and productive machine versus a rundown machine. Treating your body like a rundown machine without taking the care to prep it for the season will likely yield increased injuries, and decrease productivity. And worse, you can’t leave this body at work, you take it home with you and quality of life can suffer as a result.

So clean your body by eating healthy foods, at regular meals, in suitable portions. Consider replacing more of your fluids with water to keep yourself hydrated, reduce headaches, and reduce cramping. Most importantly, prepare your body by tightening the muscles to help improve posture, reduce pain and increase endurance. If you have not exercised in a while, it would be ideal to see

your primary care provider to make sure you are not limited in what exercises to engage in.

A simple exercise routine targeting the abdomen, hamstrings, butt and shoulders can help improve posture, strength and endurance. This can be done at home using the weight of the body alone, but if you want faster results weightlifting will improve conditioning faster. A personal trainer can help select which strength training moves are right for you based on your goals and limitations. The good news is that you don’t have to be a gym rat or dedicate a long period of time to this. If your goal is to improve conditioning it can be achieved in as little as 15-20 minutes a day.

The mechanized logging lifestyle involves a LOT of sitting, and sitting for long periods of time is one of the worst activities we can do. It cuts off circulation to your lower extremities, which explains loggers' complaints of having feet that are swollen, and it impacts sugar regulation and blood pressure. The biggest complaint worldwide is back pain and sitting leads to compressive forces on the spine that are more detrimental than standing. And engaging in poor posture while sitting increases that pressure. Sitting is linked to an increase in chronic diseases like cardiac issues, diabetes and some types of cancers.It is also shown to have a negative impact on mental health.

Of course, just like your machine, it will do better if you attend to it on a regular basis rather than ignore it until there is a problem. In addition, addressing long periods of sitting can be as simple as getting out of your cab more often. Taking a couple of stretch breaks, and a walk around your machine may be all you need to recharge your body. Studies have shown that micro breaks improve productivity, and owner operators I’ve spoken to encourage this.

Baseball season is now in full swing (sorry), having been preceded by two months of spring training through February and March. It was 1886 when Albert Spalding (founder of the Spalding Ball Co.) and president of the Chicago White Socks and former player Cap Anson had the idea for spring training. They brought the White Socks to Hot Springs, Arkansas, chosen for its warm climate and the therapeutic hot springs that complimented strenuous physical conditioning. After the White Socks’ preparation led to a successful 1886 season, the spring training concept rapidly gained traction. Today it is firmly established, with teams migrating each February to Florida and Arizona. Beyond baseball, there is not a major professional sport today that does not have some sort of extended preseason training with the dual purpose of turning a group of athletes into a well-oiled team, and to condition bodies for the rigors of a long season.

Loggers would do well to embrace the concept of spring training. That doesn’t mean having to go to Florida or Arizona for two months (although it doesn’t rule it out, either). Many loggers do have a preseason ritual of sorts,

preparing gear and machinery for the season, but I’ve met very few who actually bother to prepare their own bodies. I don’t mean to suggest that loggers should go into full time training for two months, but to ignore some modest minimal personal preparation is to risk avoidable, potentially long lasting or even permanent injuries.

There is one legitimate comparison between the demands of baseball and logging: both entail longer periods of relatively low activity followed by bursts of high activity. A mechanized logging operator sits for most of his day, with occasional getting in and out of his cab, maybe throwing a strap, or addressing a mechanical issue. The machine operator’s body, then, settles into a sedentary routine that is broken by the exertion of stretching and reaching to climb in and out of cabs, or perhaps some muscles work, literally wrenching, to get the machine running well again.

Outside the cab, logging can be more demanding. Climbing about on slick, uneven terrain, operating hand tools, tossing tie downs–all this is physical work. And I must emphasize that the extent of the effort alone is actually irrelevant; rather, it is the ratio of your personal preparedness to the amount of effort required that matters. Olympians almost never suffer injuries while going all-out to set world records, but every year people suffer the preventable injuries of hurt backs and sprained shoulders, or they even die of heart attacks–all in the modest effort of shoveling their own sidewalk. So, what should a logger do in pre-season?

1. Eat right. Take regular meals in suitable portions. If you’re drinking leans toward either alcohol, sugar, or caffeine, consider replacing some of that volume with water. Develop the habit of keeping hydrated so that it is automatic when you are back in the season.

2. Begin regular, moderate exercise. If you haven’t exercised in a while, it would be wise to talk to your primary care provider about a responsible regimine. A personal trainer can also help select which stretches and strength training moves are right for you. A simple exercise routine targeting the abdomen, hamstrings, butt and shoulders can help improve posture, strength and endurance. This can be done in the convenience of your home, with or without weights–no need to join a gym unless you prefer it for encouragement to stick to it. An effective workout for fundamental strength and health can take as little as 15-20 minutes a day.

3. To take it a step further, schedule in aerobic exercise. Fast walking, jogging, strenuous hiking, and biking are the most common aerobic exercises, but anything that gets your heart and breath rates up does the job. Current recommendations are for 150 minutes/week of moderate activity, or 75/week of vigorous activity. How you divide it up over the week is up to you.

I have said before in this column that too many loggers treat their equipment better than their bodies. The

Logability

Continued from Page 37

best baseball bat in the world doesn’t hit a home run on its own, or prevent an unprepared shoulder from tearing in a swing. Enter the summer season prepared. Not only will you perform better at work and be less likely to suffer injury, you’ll feel better in your leisure hours as well.

For More Information, visit Maine LogAbility, part of the Maine AgrAbility program: https://extension.umaine.edu/agrability/

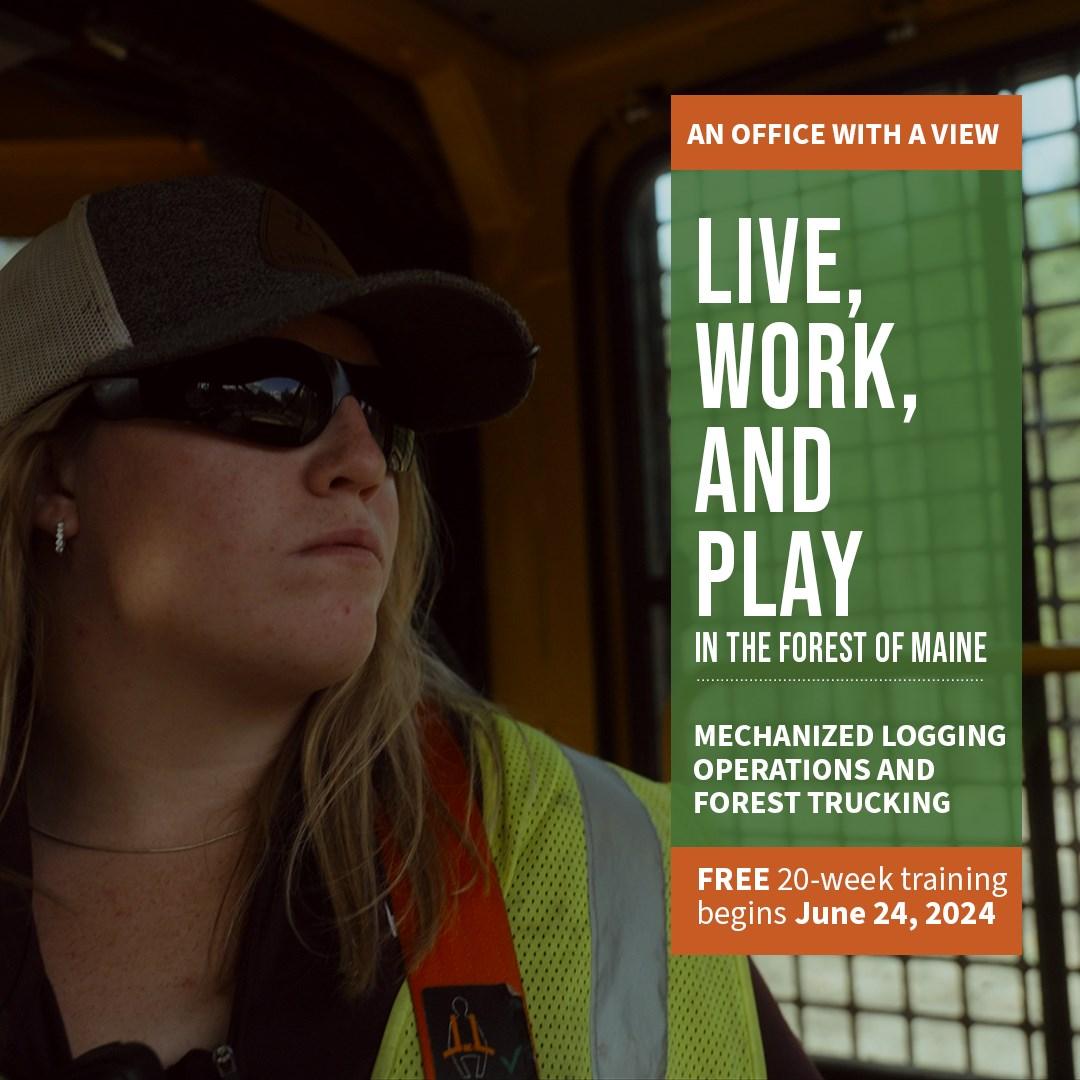

HINCKLEY, ME -The Professional Logging Contractors (PLC) of the Northeast and Northern Maine Community College (NMCC) have announced recruiting is underway for the Mechanized Logging Operations and Forest Trucking (MLOFT) Program, an expanded version of their highly successful logging operations certificate program that now includes Commercial Driver’s License (CDL) training.

The program will run for 20 weeks, from June 24 to November 7. Classes will take place at an active timber harvest site on the Kennebec Valley Community College (KVCC) Alfond Campus on U.S. Route 201 in Hinckley. Tuition remains free for qualified students.

“This program has a proven track record of addressing Maine’s shortage of qualified logging operators and forest truckers in an efficient and affordable way,” PLC Executive Director Dana Doran said. “Thanks to Maine’s Congressional delegation the program has secured Congressional Directed Spending (CDS) support, and with planned new equipment purchases to support forest trucking for this year’s program, we are well positioned to provide top-notch instruction and hands-on experience for the incoming class.”

“This short-term training is the opportunity of a lifetime for people looking to learn equipment operation and earn a CDL,” stated NMCC Assistant Dean of Continuing Education Leah Buck. “To be able to learn both in a 20-week span is incredible, and thanks to a grant from the USDOL supported by Senators King, Collins, and Rep. Golden we can offer this training at no cost to the 16 students selected to join us this summer. I encourage anyone interested in the program to reach out and fill out the online application without delay. A career working in the woods of Maine is waiting.”

The opportunity to earn a CDL-A permit and receive preparation for the state driving exam was a significant addition to the program in 2023 and has expanded opportunities for graduates while increasing benefits to Maine logging employers who need more mechanized logging operators and truck drivers.

Students enrolled in the post-secondary training program will harvest timber and operate trucks using sophisticated state-of-the-art machines like those they will encounter in the logging industry. The hands-on experience students gain operating equipment is an opportunity unavailable anywhere else in Maine and neighboring states and will prepare them for in-demand careers with logging contractors throughout the state of Maine. A report released by the University of Southern Maine in 2019 documented

that up to 2,000 positions in timber harvesting and trucking will be available in the next decade.

The program includes a strong emphasis on safety as well as giving students an understanding of the variables of timber growth, tree species, and markets. Students pay no tuition or fees, and the program provides all personal protective equipment (PPE).

This project is funded 100% by a $1M grant from the U.S. Department of Labor, Employment and Training Administration.

The program was created in 2017 by the Maine Community College System, the PLC, and industry partners. This year’s class will be the 8th since its launch, and dozens of graduates are working in Maine’s logging industry today.

Approximately 95 percent of logging in Maine now relies on mechanized equipment. The industry also relies almost exclusively on heavy trucks to move wood. With the majority of logging operators and forest truckers at or near retirement age, the demand for new workers in the logging industry is high and most students in the previous certificate program have had job offers before graduating.

Anyone with an interest in the program should contact Holly Grant at Northern Maine Community College at 207-768-2645 or by visiting nmcc.edu to apply. Additional information may be found online at plcloggers.org

industry and we were proud to be involved in helping to secure the grant for the machine and to be represented at the unveiling of the machine by our own Safety and Training Consultant Donald Burr (Fourth from right in photo above)!

The purchase of the multi-purpose TimberPro –which can be run as a harvester and switched over to a forwarder in a short amount of time by swapping out the harvesting head for a grapple head – was made possible thanks to a $946,140 Northern Border Regional Commission (NBRC) grant approved in June 2023.

CTE schools are challenged when it comes to funding heavy equipment purchases and must often run older, less reliable equipment. The TimberPro represents a huge step up in opportunity for the students.

Kevin Lavoie, the director at the St. John, thanked the Northern Border Regional Commission and all those involved in securing the grant for making the purchase of the machine possible.

“This is a major move forward for our forestry program at Saint John Valley Tech,” Kevin said. “It takes us out of the 20th century and brings us right into the 21st century and being able to compete and provide real-world skills to our students who are looking to come into the forestry industry. This is a gift beyond belief, so we thank

Mike Berube, Forest Resource Management and Heavy Equipment instructor for St. John, said the versatile TimberPro makes good sense for the school.

“I was happy to have the machine because it's a new piece of equipment that should run every day,” Mike said. “You just can’t get two new pieces of equipment for that amount of money so I figured we get one that can do everything.”

Supporters of the program like State Rep. Austin Theriault (R-Fort Kent), who worked with St. John Valley Tech on the grant to purchase the machine, congratulated the school on social media.

“Looking forward to seeing the students learn and get good Maine jobs. We need to support kids going into the trades!” Austin posted.

PLC Executive Director Dana Doran is a program advisor for Maine for the Northern Border Regional Commission, and said, "This is a very positive development for logging education in northern Maine. The logging industry of today is technologically advanced and requires a strong educational pipeline to prepare young people for careers in the woods. This machine is desperately needed to give students the hands-on experience with modern logging equipment that they need to be competitive in the industry from day one.”

Vernal pools are ecologically sensitive open water pools found in forested areas, and usually dry up during summer months. Some species of animals, especially frogs and salamanders, can only breed in vernal pools. The breeding season for sensitive vernal pool species in Maine generally begins in late March and ends in late May. Due to their specialized habitat it is recommended that timber harvesting activities protect vernal pools to the greatest extent practical.

Habitat Management Guidelines (HMGs), available from the Maine Forest Service, call for decreasing timber harvest intensity the closer you get to those pools, based on three management zones: the vernal pool depression, a vernal pool protection zone (100 ft), and an amphibian life zone (100-400 ft.), each with a desired management outcome.

The vernal pool depression is where standing water can be seen and is the breeding habitat and nursery for pool-dependent amphibians and invertebrates. To protect this area:

• Flag the pool perimeter during harvest layout and prior to cutting. This could be done during spring break-up when harvesting activities are curtailed.

• Avoid disturbing the basin and surrounding vegetation.

• Prevent slash and sediment from entering the pool.

The vernal pool protection zone (100ft.) is the forest immediately surrounding the pool depression and is critical for maintaining water quality, providing shade and litter for the pool ecosystem, and providing critical upland habitat for pool-breeding amphibians outside of the breeding season. Within the protection zone:

• Flag the boundaries of the protection zone.

• Maintain a well distributed stand of trees at least 20-30 feet tall, with at least 75% canopy cover.

• Minimize soil disturbance and limit harvesting activities to periods where soil is dry or frozen.

• Leave tops and limbs from harvested trees.

The amphibian life zone (100-400 ft.) is needed to support upland populations of amphibians that breed in vernal pools. The zone’s radius includes the range of

habitat used by Maine’s pool-breeding frogs and salamanders during the rest of the year. Within the amphibian life zone:

• Maintain a well distributed stand of trees, at least 20-30 feet tall, with at least 50% canopy cover.

• Limit canopy openings to less than 1 acre.

• Minimize rutting and soil compaction by harvesting during dry or frozen conditions.

• Leave older or dying trees.

To find a copy of vernal pool Habitat Management Guidelines in its entirety, visit the Maine Forest Service website at https://www.maine.gov/ dacf/mfs/ policy_management/ water_resources/bmps.html

Are you a Master Logger® in Maine who is buying new equipment? Take advantage of the Direct Link Loan Program and get an interest rate reduction of up to 2% on qualifying equipment. Details of the program and how you can take advantage of it are below:

1. A Master Logger signs an Agreement with the Maine Forest Service (MFS), the bank submits Agreement to MFS, and it is approved by the MFS for the purchase of a new or new to them piece of qualifying equipment. (Cut to Length Harvesters and Forwarders, Tracked Feller Bunchers, Stroke Delimbers, Mulching Machines, Road Graders; also includes retrofitting of existing equipment like Flotation tires, Bogey wheels, harvester and processor heads; and Miscellaneous purchases like Metal and Wooden Bridges, Bottomless arches, and sediment and erosion control products) Purchases are considered on a case by case basis, with eligibility based on whether the equipment facilitates the implementation of Best Management Practices.

**Equipment that is NOT eligible: Grapple Skidders, Pull-Thru Delimbers, Tree -Tree Feller Bunchers.

2. The Master Logger loan from a participating bank. (See list below) Example: Loan is for $500,000 at current bank interest rate (ex. 7.00%). Contractor can have multiple loans but can’t exceed the $800,000 aggregate limit allowed by the program.

3. The Master Logger an interest rate subsidy (reduction) of 1.50% (up to 2%) – the same amount as the *CD rate for as long as they continue to qualify for the program.

Example: 7.00% loan interest rate less 1.50% rate

subsidy = 5.50 effective rate.

The following banks participate in the direct link loan program.

Katahdin Trust Company - David Cambridge Farm Credit East - Shannon Webber

Machias Savings Bank - Anita Madden

Acadia FCU

**Note: Maine Municipal Bond Bank buys a $500,000 CD for up to five years from bank for up to 2.00% less than the bank’s going CD rate matching the term of the loan. Ex. 1.50 % - (up to 2%)

Don't see your bank on the list? Reach out and encourage them to get involved.

The Trust to Conserve Northeast Forestlands (TCNEF) has hired Sydney Andersen of Topsham, ME as its new Program Manager.

Andersen started her new position in midJanuary and is looking forward to working with loggers through the Northeast Master Logger® Certification Program to meet their professional needs.

“Sydney brings great experience and a strong professional background to her role and will be a huge asset to the Trust and the Master Logger program,” Ted Wright, Executive Director of the Trust to Conserve Northeast Forestlands (TCNEF) and the Master Logger® program, said. “She will be focused on working with Master Loggers across the Northeast to improve and expand what the program offers and we are lucky to have her on board.”

Ms. Andersen grew up in Oregon, where she graduated from Oregon State University with a bachelor’s degree in Forest Engineering. During her studies, she took the opportunity to study abroad in Belgium, Québec, and New Zealand. While in Québec, Ms. Andersen fell in love with the East Coast. After three years of serving on the Board of Directors for a Soil and Water Conservation District and five years of working in forestry on the West Coast, she decided to pursue a career and livelihood in Maine. She currently lives in Topsham, where she is enjoying the next chapter of her life in Maine.

Ms. Andersen may be reached at (503) 564-9500, at sydney@tcnef.org or at the TCNEF office at 108 Sewall Street in Augusta, ME.

As the American Loggers Council President, I will do my best to help represent loggers at the national level. My best will require continually falling back on quotes from my two grandmas, one from Grandma Ainsworth, and one from Grandma Albrecht. I will share these quotes in just a moment, but I’d like to first better explain who I am.

The “tag line” at the end of my article notes I have a forestry degree from Duke with some past industry leadership roles. Nice, but that doesn’t really explain who I am. The most spot-on characterization I’ve ever received was from an old cat skinner named Roy Paterson. I was in my early 30s on a forest road crew down at Shaver Lake, California. There were about eight of us, a cobbled together crew tasked with getting some logging roads built. The first night at dinner, Roy had us go around the table and introduce ourselves.

A couple of guys were loggers, one was just out of prison, one was Roy’s nephew... I don’t remember the others. Each introduction was short, not eloquent, but sufficient. I was last and proceeded to pontificate about my forestry degree, my previous work as a consultant in North Carolina, and other drivel. When I was done, there was an awkward silence. Then Roy looked straight at me and, in his low, gravelly voice, said, “You ain’t nothin’ but an educated saphead.” The seven other guys guffawed as I turned beet

of roads built.

Over the past 40 years since that humbling beginning, I have been blessed to work with, and learn from, some of the best loggers in California. I was privileged to be hired 35 years ago as general manager of a logging and trucking firm. The owner of that family-run company patiently mentored me, and I became co-owner a few years later. I have always appreciated the great education that my parents worked hard to make possible for me, but my reallife education happened much later in the woods.

I got past Roy’s fairly accurate description, and logging got into my blood as much as, maybe even more than, the love of forest silviculture and management that had brought me there in the first place. Over the years, our company has had as many as 75 employees, with 22 trucks, 2 cut-to-length sides, a mechanized side, 2 chipping sides, and a CAT side. I’ve been to numerous logging truck wrecks, and have transported a few employees to ER, trying to decide whether or not to stop at the stoplights.

We’ve had years that ended with all the bills paid and money in the bank. We’ve had really rough years with one that ended up visiting with a bankruptcy attorney. That served to make us realize that bankruptcy is much worse than the hard work to avoid it. Our company has thinned roughly 75,000 acres of public land on the Stanislaus National Forest. If anything, this “educated saphead” has learned that he is no more than one cog in the wheel we call logging.

Over the past three decades, our logging business has downsized right along with California’s timber industry. I’ve watched logging get rebranded as timber harvesting, then forest thinning, then vegetation management, to the newest moniker, forest restoration. Today, loggers are tasked with producing a product America needs and wants, while trying to protect anything that might get harmed by our operations. Over the years, that has included spotted owls, pine martens, goshawks and a myriad of floral species. I remember a job where we had to protect a “frog crossing.” Loggers have always worked hard to protect forest ecosystems and the creatures that live there, but we

too often see environmental protections designed to “prevent” rather than protect.

Now looms another challenge to “protect” trees. Spurred on by an environmental watchdog group called Environment America, the newest issue confronting our industry is the recent Biden Administration directive regarding “mature and old growth” forests. Here’s where Grandma Ainsworth’s advice would come in handy. As folks considered this topic, she would have advised, “Keep an open mind, but don’t let your brains fall out.”

I’m afraid that on the old growth topic, it may be too late. If some folks’ brains haven’t fallen out, they most certainly are leaking. Under these recently implemented guidelines, any new projects proposing vegetation management that occurs where “old growth conditions exist” must be “submitted to the National Forest Deputy Chief for review and approval.” It often takes years to get forest management projects approved at the Forest Supervisor and Regional Office levels. I can only imagine how long it will take to also clear the Deputy Chief’s office.

Since 2015, 20% of all the mature giant sequoias in the world have been lost to catastrophic fire. This fact inspired Congress in 2022 to pass H.R. 8168, the “Save Our Sequoias Act.” Endorsed by the Save the Redwoods League, the act declares an emergency to expedite work on the ground intended to “save” the sequoias. That work has to include thinning out forests that are now so overgrown that even the fire-resistant old-growth giant sequoias are succumbing to catastrophic wildfire. How work around the giant sequoias will square with the old growth “hands off” edict from the President remains to be seen.

America currently has approximately 112 million acres of Designated Wilderness, 425 National Parks, 6,792 State Parks, and approximately 13,000 miles of Wild and Scenic Rivers. The proposed protections for mature (80 million acres) and old growth (32 million acres) would more than double the amount of American “protected” forestland restricted to minimal or zero production of wood

products.

This is a good spot to update an important fact: America is no longer the second leading importer of lumber in the world. We are now the number one IMPORTER of lumber in the world. So, Congress, US Forest Service, Bureau of Land Management.... as extreme environmental groups lobby you daily and litigate you often, Grandma Ainsworth would remind you, “Keep an open mind, but don’t let your brains fall out.”

I’ll end this message with Grandma Albrecht’s quote. She said these words during the height of WWII just after receiving the news that her oldest son had been killed when the B-17 he piloted was shot down, and her other son (my dad) had just been wounded with a bullet that grazed his head. She said, “God knows, He loves, He cares, nothing this truth can dim.” I share these words for any of you loggers who are facing personal hardship right now, whether with business, employees, family, the challenges of logging, or simply discouragement with the direction our country seems to be taking.

One Sunday afternoon after church, our pastor pulled me aside and said, “Mike, you are called to be an “encourager.” I think I’ve failed that calling with my past few messages, so I’ll tell you now the title of my next message: “What’s Going Right.”