Cover photo: Kevin Gibbs operates an SDR Logging Inc. harvester in Sebec in June, 2024.

Cover photo: Kevin Gibbs operates an SDR Logging Inc. harvester in Sebec in June, 2024.

Do you have news to share?

The PLC is always seeking news from our Members that showcases our industry’s professionalism, generosity, and ingenuity. Send ideas to communications@plcloggers.org

Hello everyone,

By Chuck Ames

This is my first shot at this, so hopefully it's all good.

First of all, I want to thank all the staff at PLC for doing a great job putting together a great Annual Meeting and all of the generous folks who made the annual auction for Log a Load total $186,007. Wow, that's a new record that is going to be very hard to match!

Now some food for thought, are we the last generation of loggers? I hope not, but it’s beginning to look that way.

The average age of loggers in the State of Maine is 57 years old. The executive committee of PLC averages roughly 62 years old and if you're like my brother who is 61 and I who am 62, we have no one to take over when we hang it up.

Almost everyone I’ve talked with who are owners of logging companies have downsized, not because of lack of work, but lack of workers we can afford to hire. My company used to run five mechanical crews, now we are running one processor crew because of no help. Unless we can start to offer the same wages and benefits other professions can, we are going to be the last of the loggers.

One of the other problems we are facing is we can’t afford to buy new equipment. New equipment costs have gone up significantly. I bought a new fellerbuncher in 2021, the price was $460,000. Now they are close to $600,000. How can we handle that kind of increase when we can’t pass our costs along to those we work for?

Our company has been in business since 1980, went mechanical in 1988, so we have some equity to be able to continue. If you are a logger just starting out, there is no way you're going to make it without the financial backing of a family member who understands the business. Why would you want to spend $1.5 to $2 million just to make 3% on your investment? And you need everything to go really well to make that work. I can make 5% on my money in the bank doing nothing!

So, what is going to happen in the future? Are we going by the wayside like the shoe companies or

textile mills? How can we attract new people and investment to the industry?

Can we attract a younger generation with the idea of providing an opportunity to work in the forest versus a mill or office environment? What moves us forward and attracts the younger generation? There have been many articles on this subject and below are some of the comments in the articles:

∙ Education and personal development - Forest related education is important to ensure high qualified personnel in the future for high quality management in the forest sector. PLC has developed the MLOFT program which is free to qualified applicants. The program educates students on how to use mechanized logging equipment but is this program enough? Should we start educating students at the high school level on the benefits of a career in the forestry industry and the potential of new markets to expand the industry?

∙ Developing new products - Would the development of new products persuade the younger generation to join our industry? The development of new product lines with higher profit margins would excite the younger generation to learn about our industry and enable current logging companies to invest in employees by providing a more reasonable compensation and benefit package.

∙ Working environment - Good mentors and good role models are essential to create a good working environment. We, as experienced loggers, can be role models and show the younger generation the benefits of working in the industry.

∙ Technological development - The forest sector is experiencing fast technological development both in terms of technical tools and product innovation, e.g., replacing fossil-fuel based materials with wood-based renewables. Education and infrastructure investments are essential to follow the development. Can the PLC or other trade associations assist in developing a program with equipment dealers to finance investment in equipment for new and existing loggers?

If we cannot attract new talent to the industry, will we be the last generation!

Jeff Poczobut Logging of West Rutland, VT joined the PLC as a new Logging Contractor Member in March of 2024. The company has a professional staff of 1. For more information contact Jeff Poczobut at (802) 558-2408 or email loggerjmp@vermontel.net

Michaud Timber Harvesting of Orono, ME joined the PLC as a new Affiliated Contractor in March of 2024. The company has a professional staff of 1. For more information contact Charles Michaud at (207) 231-0560 or email charlesm623c@gmail.com

Coastal Auto Parts of Ellsworth, ME joined the PLC as a new Preferred Supporting Member in May, 2024. Coastal Auto Parts has stores as far east as Machias, as far north as Caribou, and south as Auburn. Coastal Auto Parts has stores dotting the 95 Highway and along coastal Route One. From a single store in 1981, today Coastal Auto Parts has grown to 29 stores and more than 270 employees. The company has transitioned to the next generation by selling the company to their four children who work together to operate it. The future plans of the company are to continue store growth, and explore spinning niche segments of the auto parts business, into full fledged businesses of their own. For more information contact Bruce MacDonald at (207) 240-3157 or brucemacdonald@capnapa.com

Eskuad of Portland, ME joined the PLC as a new Preferred Supporting Member in April of 2024.

The company builds mobile forms and workflows for field operations. Eskuad captures data regardless of connectivity without draining your battery. For more information contact Max Echeverria at (207) 449-5674, email max@eskuad.com, or visit https://eskuad.com/

Transaxle, LLC of Westbrook, ME joined the PLC as a new Enhanced Supporting Member in March of 2024. The company is a premier remanufacturer of transmissions, axles, hydraulics, differentials, steering gears and steering pumps for on and off highway heavy equipment. The company is also an authorized service center for Eaton Road Ranger, Eaton Hydraulics, Char-Lynn Vickers, andAllison on and off highway applications. It is also a warranty center for Eaton Hydraulics, Muncie Power Products, and Dana Off Highway. For more information contact Rob Fortier at (207) 951-2443 or rfortier@transaxle.com

Bob Williams of Laurel Springs, NJ joined the PLC as a new individual member in February 2024. Bob is a forestry consultant. For more information contact Bob Williams at (609) 2210211, email bob@pinecreekforestry.com or visit www.pinecreekforestry.com

Senio Forestry of Passumpsic, VT joined the PLC as a new Industry Service Provider Member in June of 2024. Senio Forestry is a consulting forester business serving the Northeast Kingdom of Vermont. For more information contact David Senio at (802) 274-8761 or email senioforestry@gmail.com

From the Executive Director

By Dana Doran

Happy summer everyone. It’s 95 degrees outside and the wet weather of the last 24 months seems to be a distant memory. In typical New England fashion, just wait awhile and it always changes.

Speaking of weather and climate, earlier this week, I attended a meeting of the Maine Climate Council. I know, I know, you’re probably cringing as I say that. Just part of the job of playing nice in the sandbox.

After four years of being a member of two subcommittees of the Council (Transportation and Working Lands), I had a pretty good idea what I would hear at the meeting. Likely, it would make most in the room feel good, but very little of it will actually move forward. Why do I believe this? Just take a look at the original list of recommendations from December 2020, and you will know why.

The 2020 Report, “Maine Won’t Wait”, singled out keeping forests as forests as one of the most important tools for carbon sequestration for climate benefits. However, keeping forests as forests, ultimately comes down to the value proposition for all stakeholders that could play a role in their management, as well as their benefits.

As we know, one major stakeholder for keeping

forests as forests is the logging/trucking community. There is probably no one that knows more about the impact of climate on the forests as well as their value than the community that has worked in them longer than any other segment of our population. That said, loggers/ truckers need only look in the rear-view mirror at the last 24-48 months to know that inconsistent weather, inflation and challenging markets can impact the value proposition

more than anything.

In the 2020 Report, “Maine Won’t Wait”, on page 78, there is a specific reference to the role that loggers could play, but also to what needs to be done to help the logging community continue to play a role if we will succeed in keeping forests as forests.

Incentivizing high-quality on-the-ground performance by loggers and facilitating the use of low-impact timber-harvesting equipment would also support progress toward achieving climate goals.

As a member of the group that came up with this recommendation, I took great pride in getting this included. However, it wasn’t just the PLC supporting it, there was also unanimous support from a diverse group of environmentalists, landowners, mills, conservationists and governmental officials.

So, as I sat in the meeting earlier this week, it irritated me to no end that yes, this great recommendation was included in the report, but nothing, and I mean nothing has been done by the executive or legislative branches of Maine state government in almost four years to move this forward, despite every effort from our organization to do so.

And what’s in the latest set of recommendations that was presented earlier this week? Essentially the same darn recommendation. Want to take bets on whether something will happen over the next two years before the current administration leaves to move this forward? If it hasn’t happened in the past four years, what are the odds that it will happen in the next two?

In Vermont, the PLC and it’s membership there had what I would describe as a very successful first legislative session pushing for policies that would help. The general takeaway was that both the executive and legislative branches want to help but they don’t always know what the answer should be. However, they’re willing to listen and work to find solutions that are amenable to contractors and to the public sector. The logging community in VT is just as challenged as it is in Maine, but I would say that they have proponents willing to support them more consistently for now.

The list of examples in Vermont might not be exceptionally long, but it is significant:

1. $1 million was included in the state budget to create a new water quality program for logging contractors that would reimburse them for resilience practices such as culverts, gravel, hay, silt fencing. This funding will also provide cost share for contractors to become Master Logger® Certified.

The last four years have been a dog fight for contractors throughout the Northeast. Lost markets, depressed pricing, record inflation, constrained workforce, and weather impacts that never seem to end.

Over the last four years, the PLC has been advocating for contractors in two states and at the federal level for policies that will help achieve the recommendations included in the Climate Council report as well as others that will help those same contractors weather the storm of volatility that they have had to withstand, essentially because there has been very little help from the private sector. Some would argue that the private sector should solve their own problems and government is not the answer. If loggers/truckers were treated like other professional occupations, I would agree, but it’s clear that they are not, so public intervention unfortunately seems to be a necessity.

Comparing the response of state governments in Maine, Vermont and Congress to our requests is fascinating to say the least. Not only is it telling, but it provides insight into those who understand the value proposition and those who don’t.

2. A new loan program was created at the Vermont Economic Development Authority for contractors to purchase equipment at an interest rate that is 2% below prime.

3. A timber trespass statute was enacted that will hold bad actors accountable for timber theft and timber trespass. If contractors are convicted of theft on two or more occasions, they will lose their ability to operate and could have their equipment liquidated. A task force that will include the PLC will also meet over the next six months to review other measures for enforcement.

4. A biomass energy statute was updated to ensure that contractors are paid for fiber within seven days of delivery.

5. The PLC will apply for funding from the US Forest Service to create a crane mat program for contractors in VT. This is a collaboration with the Dept. of Forests, Parks and Recreation in VT where the PLC will be the grantee and will run the program while collaborating with state government to ensure it is successful.

At the federal level, we can also point to some significant wins and accomplishments in the recent past as a result of the collaboration of a unified delegation in Maine and one in Vermont that is starting to take shape.

In 2021, as a result of leadership from the Maine Congressional delegation, the Pandemic Assistance for Timber Harvesters and Haulers was implemented. This provided one time assistance in the form of income replacement for contractors during the pandemic.

In 2022, the Maine delegation was able to secure $1 million through an earmark, also known as Congressionally Directed Spending, to double the size of the Mechanized Logging Operations Program at the Maine

Community College System and also provide commercial driver license training.

Lastly, earlier in 2024, the Maine delegation, along with Senator Peter Welch from Vermont, introduced the Loggers Economic Assistance and Relief Act, which would establish a new fund at the US Department of Agriculture to support loggers with income support when they are unable to work because of natural disasters. We are hopeful that this essential legislation makes it across the finish line later this year and lands on the President’s desk.

In all of these cases, the delegations from both states have demonstrated leadership, but also an understanding of the value proposition for the forest industry and for contractors. If contractors cannot operate or they can’t hire qualified employees with necessary skills, the entire value chain will fall apart. Without a logger and trucker, there is no value for landowners and there are no value added products that all Mainers and all Americans require.

Which brings me back to the state of Maine and what appears to be legislative and executive branches that may have lost touch with reality and the very value proposition that built this state. Yes, the forest products economy is probably the longest and most durable of any of Maine’s heritage industries, but that has potentially become a curse rather than a blessing.

When I sat at the Maine Climate Council meeting earlier this week and noted that nothing has been done to move the recommendations forward from 2020, and as I now doubt that any of the new recommendations will move forward, you will understand why I feel this way.

Since the pandemic and the federal funds have dried up, the level of support for contractors at the state level in Maine has become paltry. Without federal money to hand out, even despite the fact that there has been record inflation, loss of markets, and major market retraction, it feels like there is no criticality and very little leadership.

Here are just a few examples from the past two years that point me in this direction:

1. In early 2023, the PLC asked the Maine Forest Service to support a grant application to the US Department of Commerce to help with equipment purchases for contractors, to expand the Master Logger program and provide training to contractors on climate related impacts. This was exactly what was recommended by the Maine Climate Council. The Maine Forest Service rejected this request.

2. In 2023, the PLC introduced legislation to create a logger relations position at the Maine Forest Service that would work with the logging community. The Maine Forest Service opposed this idea as did the Legislature.

3. In 2023, the PLC introduced legislation to ensure a paper Forest Operations Notification was available as an alternative to the online system. The Maine Forest Service and the Legislature opposed this idea.

4. In 2023, the PLC learned that the Maine Forest Service was working with the Sustainable Forestry Initiative (SFI) to create a new online training database which would track the employees of contractors for SFI purposes. The PLC pushed back and told them this had no foundation in law and should not occur, not to mention the privacy, confidentiality and due process issues it raised. The Maine Forest Service moved forward with it anyway. Google ABC Collaborative/Maine Forest Service and you will see for yourself.

5. In 2024, the PLC tried to work with the Maine Forest Service to make changes to the Direct Link Loan Program to help contractors invest in lower cost equipment, which is exactly what was recommended in the Climate Council report. The Maine Forest Service opposed the idea and no changes were made.

6. In 2024, the PLC supported legislation that would make the purchase of log trucks and trailers sales tax exempt. The legislation failed because the Legislature adjourned and it had not been funded.

7. In 2024, the PLC supported legislation that would provide income replacement for contractors as a result of significant storms in late 2023 and early 2024. The Legislature didn’t fund it and instead only provided funding for coastal landowners and business owners.

8. In 2024, the PLC supported legislation that would protect the privacy and confidentiality of contractors as well as ensure timely payments for service contractors. The Maine Forest Service opposed this legislation and the Legislature failed to move it forward before adjournment.

The last four years have been a dog fight for contractors throughout the Northeast. Lost markets, depressed pricing, record inflation, constrained workforce, and weather impacts that never seem to end. During that timeframe, we have also lost about 40% of the harvesting and trucking capacity that will likely never return.

The value proposition in Maine is important, but how important is it? Why does it seem that since there is no more federal money to hand out, the industry doesn’t seem as valuable as it once was?

I can’t fathom what it’s like to be in business right now, knowing that the industry you hold so dear seems to be hanging on by a thread. And oh by the way, those taxpayer servants in Maine at least, the ones that have their salaries paid by you, seem to believe that you work for them, rather than the other way around.

The value proposition for most is still well understood, but perhaps it’s time for recognition across the board instead of just giving away free money and the expectation that all will be okay.

Please stay safe, be well and stay in touch.

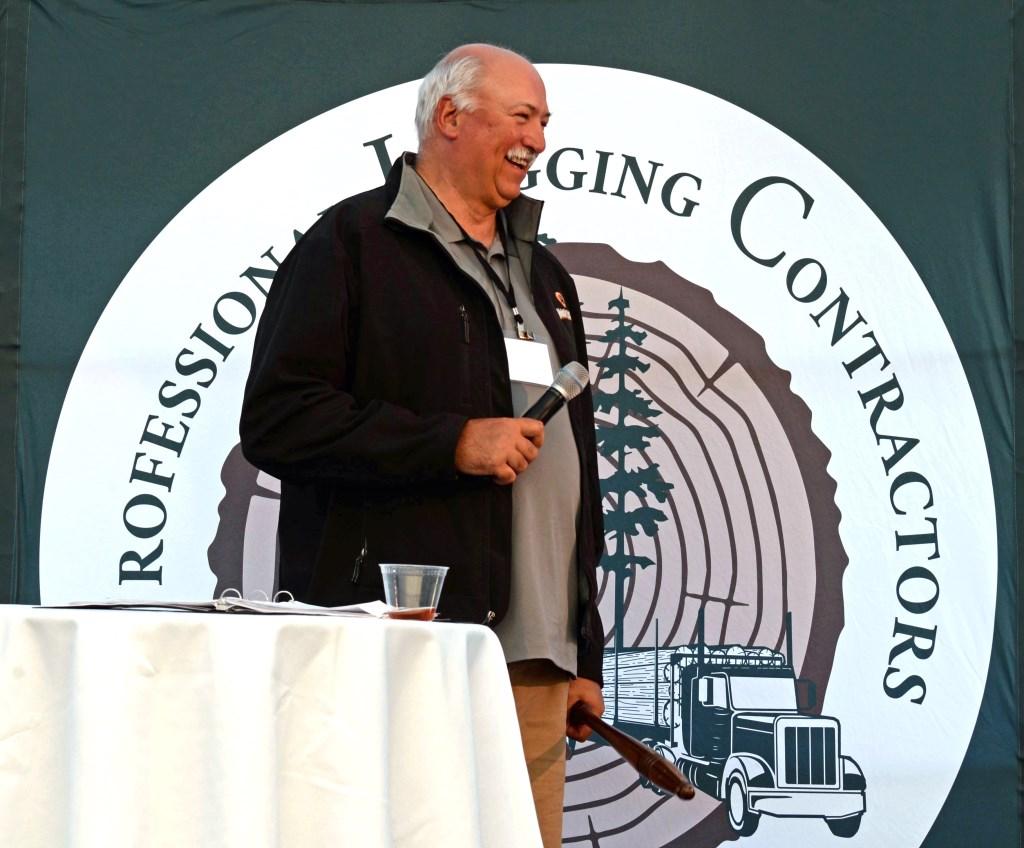

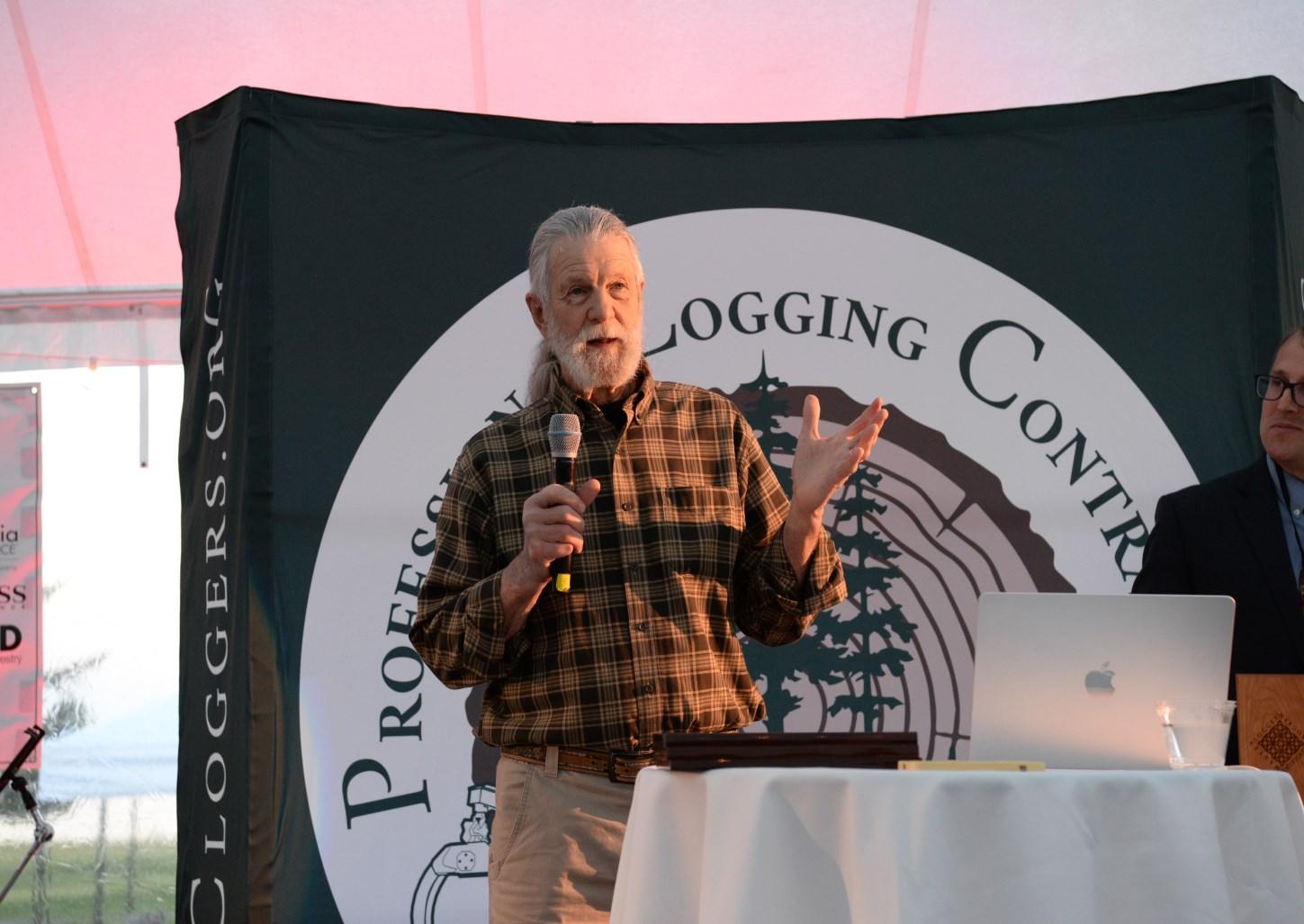

ROCKPORT, ME – The Professional Logging Contractors (PLC) of the Northeast held its 29th Annual Meeting May 9-10, raising a record $186,007 for Log A Load For Kids and presenting awards to businesses and individuals from across Maine and Vermont for their contributions to the logging industry.

The meeting was held at the Samoset Resort in Rockport, ME., with more than 250 attending the main events Friday. Special guests at the event included former NASCAR driver and Maine native Ricky Craven. This was

the first annual meeting of the PLC since its expansion in 2023 from a Maine organization to a regional one serving loggers and forest truckers across the Northeast.

The annual meeting is the PLC’s largest event and highlighted by the Log A Load for Kids Auction raising money for Children’s Miracle Network (CMN) Hospitals.

“Each year this special group has come through for the families served by our Children’s Miracle Network hospitals in Maine, and we could not be prouder that this year we have added Vermont to the effort,” Dana Doran,

$186,007

Executive Director of the PLC, said. “These are very difficult times for the logging industry in the Northeast, with unprecedented market and weather challenges, and that makes this record-setting total for our auction even more impressive and inspiring. We are so grateful for the generosity shown here, and we know the families and kids are grateful as well.”

The Annual Meeting spanned two days, beginning Thursday which featured a bus tour of PLC Supporting Member Robbins Lumber’s Searsmont Eastern White Pine

sawmill, lunch in Belfast, a tour of the midcoast and an evening social gathering at the Samoset Resort.

The second day, Friday, included a business meeting and presentations for all PLC Member contractors in the morning, with board and officer elections. A panel discussion followed with equipment manufacturers John Deere, Komatsu and Weiler represented followed by a presentation by the Ruffed Grouse Society of Maine. A noon luncheon featured Jon Godfrey of Godfrey Forest Products.

Annual Meeting Continued from Page 13

The evening events included the traditional Log A Load for Kids Auction, dinner, and the PLC awards ceremony. PLC’s special guest for the evening, Ricky Craven, a former NASCAR driver and racing broadcast analyst who is a Maine native, took part in the auction and donated items including autographed racing memorabilia to help boost the total.

*Awards were presented to the following individuals and organizations during the evening portion of the event:

PLC Logger of the Year Awards: Timber Harvesting of Randolph Center VT, and Madden Timberlands of Old Town, ME.

PLC Community Service Award: & Son Inc of Waltham, ME.

PLC Supporting Member Award: Peterbilt of Maine.

PLC President’s Award: Laurie Palow.

Acadia Safety Award: Madden Sustainable Forestry of Milford, ME.

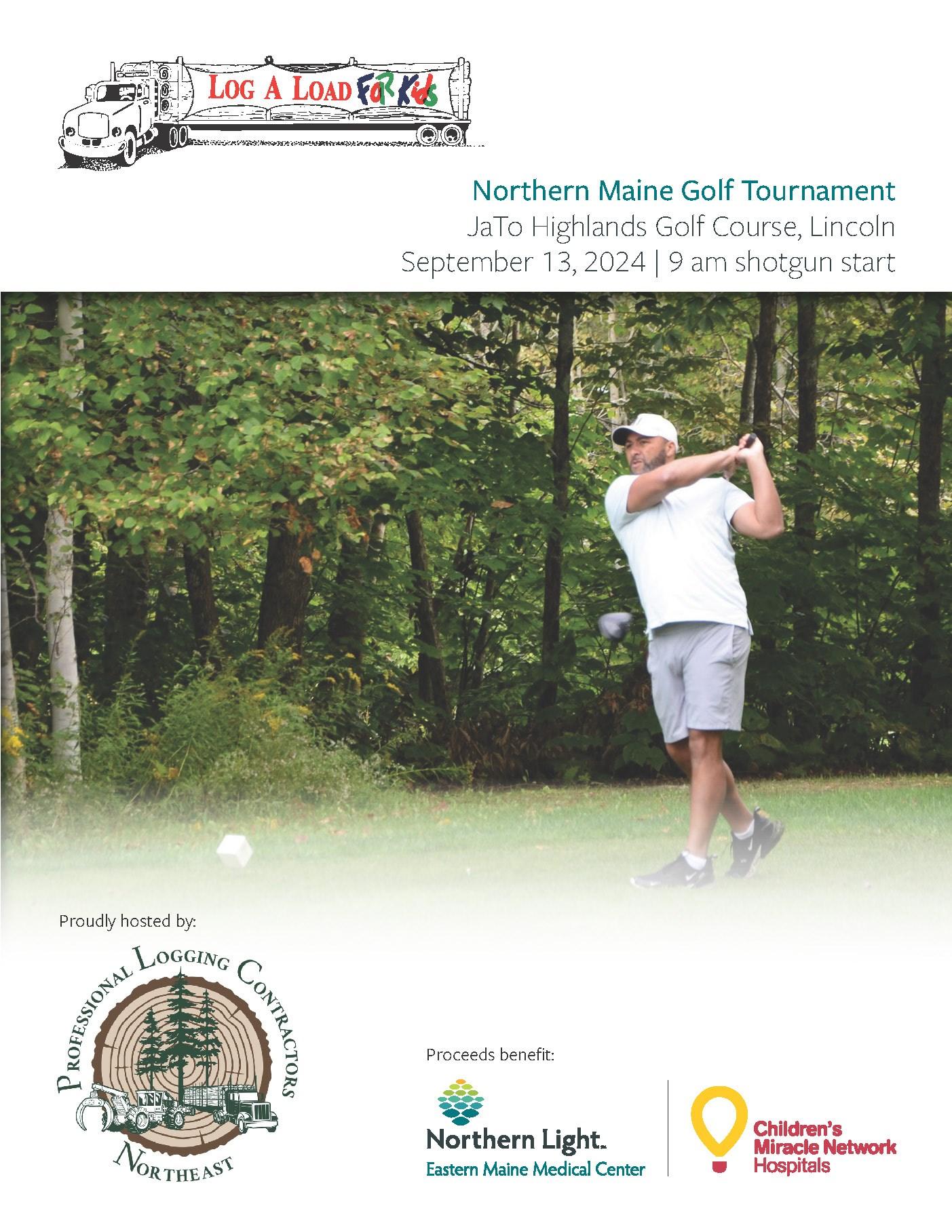

The Annual Meeting is one of the PLC’s major fund-raisers to benefit CMN hospitals. Last year the PLC raised a record $287,691 by the end of 2023 for the cause, including $127,723 at the auction. The PLC’s two Log A Load golf tournaments this year will be held in August and September.

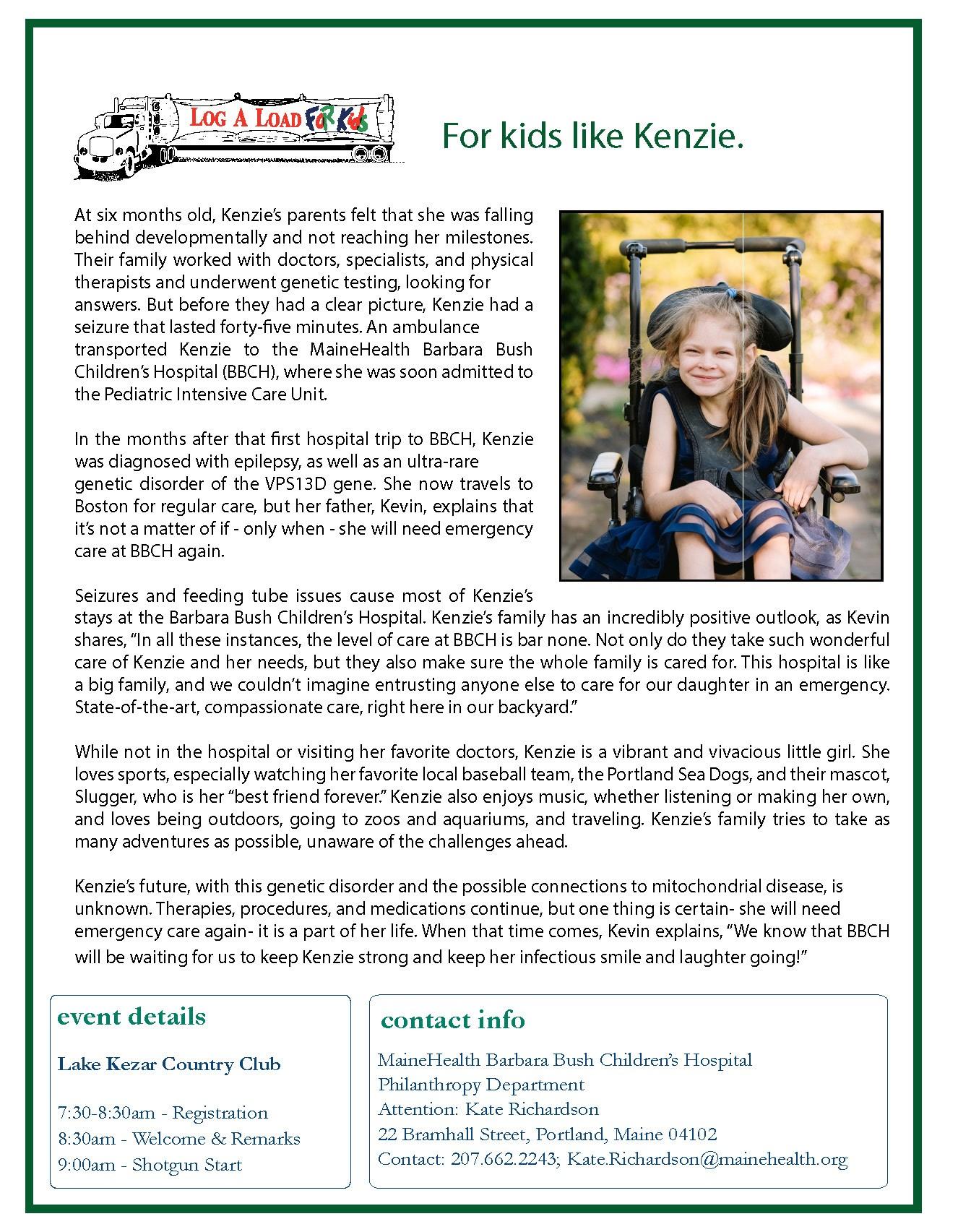

The PLC partners with the Barbara Bush Children’s Hospital (BBCH) and Northern Light Health Foundation in Maine for its annual Log A Load fund drive and this year for the first time is partnering with the University of Vermont Children's Hospital in Burlington, Vermont as well. All are CMN hospitals.

The PLC and the Northern Light Health Foundation (formerly Eastern Maine Health Systems Foundation) have partnered in the Log A Load fundraising effort since 1996. BBCH joined the Log A Load

Our special guest Kenzie (center) at the Log A Load for Kids Auction with her parents (back) and Mike Conway of Barry Equipment (at right).

effort in 2019 and all donations have gone to support research and training, purchase equipment, and pay for uncompensated care, all in support of the mission to save and improve the lives of as many children as possible. BBCH and Northern Light in Bangor both have Neonatal Intensive Care Units that have received support for years from the PLC’s Log A Load efforts.

The PLC’s Log A Load efforts have now raised more than $2.38 million since 1995.

*For more on the 2024 PLC Awards turn to page 18.

“These are very difficult times for the logging industry in the Northeast, with unprecedented market and weather challenges, and that makes this record-setting total for our auction even more impressive and inspiring. We are so grateful for the generosity shown here, and we know the families and kids are grateful as well.”

PLC Annual Meeting photos, left to right:

Top: PLC Members and Supporting Members on the Splinters and Spirits Tour gather at Marshall Wharf Brewing Company in Belfast; The morning contractor meeting.

Middle: PLC Members touring PLC Supporting Member Robbins Lumber’s White Pine sawmill in Searsmont during the Splinters and Spirits Tour; Former NASCAR driver Ricky Craven kicking off the Log A Load for Maine Kids Auction; Auctioneer Scott Hanington, at left, firing up the crowd at the auction with the help of PLC Executive Director Dana Doran, center, and PLC President’s Award recipient Laurie Palow, at right.

Bottom: PLC staff members Renee’ Wright, at left, and Vanessa Tillson auctioning off racing uniforms donated by Ricky Craven to benefit Log A Load for Kids; PLC President Chuck Ames shortly after accepting the President’s gavel from outgoing PLC President Will Cole; PLC Board Member Molly London and her youngest daughter onstage during PLC Award presentations.

memorial scholarship fund is joined by PLC Board Member Steve Hanington, center, and PLC Executive Director Dana Doran at right; Right, the Mallet

Bottom: Log A Load Auctioneer Scott Hanington, at left, with PLC Executive Director Dana Doran during the announcement of the new memorial scholarship fund.

It’s been two months since the PLC’s 2024Annual Meeting in Rockport, Maine and I would like to take this opportunity to thank everyone who attended and sponsored this special yearly event. I would also like to express my sincere gratitude to all those who stepped up in support of our LogALoad for Maine KidsAuction and our scholarship fund in memory of lost members of a very special PLC family.

Each year we are amazed by the support and generosity of PLC Contractor and Supporting Members and 2024 was certainly no exception. I am proud to let you know that as a result of your support we were able to raise over $186,000 for our hospital partners in each state. Your commitment to the PLC and our LogALoad for Kids efforts is greatly appreciated.

We are not done yet, our two LogALoad for Kids golf tournaments are coming up onAug. 23 and Sept. 13, and I encourage you all to support the kids by attending, sponsoring a team, or donating to the events.

Again, thank you for your support of the PLC. If you have any questions or need further information, please do not hesitate to contact me at (207) 688-8195 or Dana@plcloggers.org.

Dana

The PLC Logging Contractor of the Year awards recognize PLC Logging Contractors for their commitment to the sustainability of the industry and logging as a profession. This year for the first time there are two awards, one for Maine and one for Vermont. The recipients are Lincoln Farm Timber Harvesting of Randolph Center VT, and Madden Timberlands of Old Town, ME.

Both of these companies received multiple nominations and it is easy to see why. Each is a key member of the PLC in their respective states, and the organization would not be where it is today without them. Both are also outspoken advocates for the logging industry and highly visible members of the PLC. We can always count on them when someone needs to step up, whether that is to testify before legislators, talk to the press, lead a harvest tour, or – much as they dislike it - sit in a meeting instead of the cab of a machine.

words from PLC’s Vermont loggers and Vermont steering committee members Matt McAllister, Craig Hammer, Zach Emerson, and Everitt Thurston describing Sam Lincoln.

PLC Board Member Jack Bell of Vermont presented the award to Sam at the Annual Meeting, and said, “Like Matt, Craig, Zach, and Everitt, I know I would not be here tonight if not for Sam. After laying the groundwork with Dana for the possible expansion of PLC to VT, Sam worked tirelessly to recruit VT loggers one by one to join the effort. I remember clearly one of many phone conversations with Sam on a Saturday in the fall of 2022 when he was once again calling to see if I would come to the first PLC introductory event in Barre, VT. I’ve dragged my feet on lots of things like this over the years – no great excuse, just the usual - but Sam’s sheer persistence wore me down until I simply said, ‘Sam, you clearly think this is a good use of time and energy, I trust you, and I’ll come to the event.’ No doubt this pattern has repeated with many others in VT and is continuing today as Sam works to build PLC’s VT membership.

“Sam is so good at this, at organizing and bringing people together to get things done, it’s almost possible at times to forget that he is also what my younger daughter once called “a real logger - you know dad - the kind that cuts down trees,” Jack added. “Unfortunately, I have to admit that she said this right after having told me I was a ‘phone call logger’. Kids. They call it like they see it. Make no mistake, Sam is a real “tree cutting” logger.”

Sam’s family has been farming and logging for generations and his sons are now building their own careers working the land in Vermont. Sam started logging more than 25 years ago and over thousands of hours in the woods he has built an outstanding reputation for professionalism and integrity with landowners, foresters, other loggers, and the general public.

Lincoln Farm Timber Harvesting was one of the first companies in Vermont to become Master Logger® certified and as Sam came to the attention of organizations including the PLC and the American Loggers Council, his voice grew in importance on issues facing loggers in our region.

Never one to sit on the sidelines when things need to get done, Sam was appointed in 2017 by Governor Phil Scott to be the Deputy Commissioner of the Vermont Department of Forests, Parks, and Recreation and served through 2020.

“Dedicated, selfless, determined, without his leadership, the PLC would not be in VT.” These are a few

Jack said, “I recently spoke with Mike Synder, the former Commissioner of Forests, Parks, and Rec who Sam worked closely with during his time in state government. When I asked Mike what some of Sam’s key accomplishments were, his first emphatic comment was, ‘Sam immediately made me a better commissioner.’ He then went on to speak passionately about how his years

teamed up with Sam were his best years as Commissioner. ‘I knew what life was like before, during, and after working with Sam and hands down the very best of it all was during Sam’s tenure. I cannot overstate my gratitude and support for Sam. His involvement with the industry in VT is the best development in decades.’”

Besides making Mike Synder a better Commissioner, Sam got a lot done in just a few years including:

∙Removing sales & use tax from logging equipment.

∙Securing funding for skidder bridges.

∙Helping to develop the AMP smartphone app.

∙Passing Right to Conduct Forestry Operations (right to log) legislation.

And last but not least, with creativity and moxie, Sam got it done with the toughest nut to crack of all where many had tried and failed – workers

Sam has not slowed down in his industry efforts since he completed his time as Deputy Commissioner. As he and other Vermont loggers began to see the need for a loggers-only organization to represent them, Sam was one of the first to commit to the idea, which eventually led to where we are today, with PLC’s expansion to the Green Mountain State.

This past year, Sam became one of the first PLC Board members from Vermont. In that role he is still regularly making the trip to Montpelier to speak before legislators and the governor’s administration as well as traveling around the state to talk to other key groups and individuals as the PLC fights for loggers’ interests. He serves a vital role on the VT steering committee for the PLC. He is actively recruiting more members for the organization. He has also worked tirelessly to educate the public and the media about our issues and to push for action that can help our industry. When all that is done, he still has time to cut wood once in a while.

lucky to have members like Sam Lincoln to lead the way. It is with great pleasure that we congratulate Sam as the first Vermont Logger of the Year.

PLC’s 2024 Maine Logging Contractor of the year Scott Madden of Madden Timberlands, at right, onstage with his grandson, Holden Harnum, who helped present the award May 10.

Scott Madden, owner of Madden Timberlands, is a man that needs no introduction in Maine’s logging industry.

Fellow Master Logger® and PLC Board Member Gabe Russo said of Sam, “Sam has dedicated his life to continuous improvement and exemplifies the logging contractor of the year.”

Master Logger® Heath Bunnell, who works extensively in Vermont as well as New Hampshire, says, “I have never seen another logger offer up so much of his time for the industry. At the state house as well as out in the field. He truly is a steward of the land and has a passion for the industry. He probably wishes this wasn’t so but whenever I have a question in Vermont, I call Sam Lincoln.”

Everyone involved in Northeast logging knows things are very, very tough out there right now. Logging needs leaders and role models at this moment more than it ever has before. The PLC and the industry are extremely

Scott has been with the PLC from the very beginning, as a founding member. In the many years since, he served on the board of directors for more than two decades, and as PLC president from 2016 to 2018, but whether he had a title or not, he has always been a leader for the industry.

From the halls of Maine’s state house to the annual Log A Load Live Auction, Scott has always stepped up for the PLC and logging causes. We’ve seen him literally go toe to toe with legislators over issues affecting the logging industry at the state house and bring that same passion to the task of raising funds for Children’s Miracle Network Hospitals.

Scott started his business in 1977, but as part of one of the largest logging families in Maine he started working in the woods long before that. He and the rest of the family are dedicated to preserving the profession for Awards Continued Page 20

Awards Continued from Page 19

future generations, and this spring during the Safety Training at Randall Madden’s garage what a pleasure it was for us to see four generations of Maddens from eight logging companies together with the upcoming fifth generation.

Madden Timberlands has hosted multiple Safety trainings, press conferences and events for the PLC over the years. This past year the company also hosted MLOFT trucking training and has regularly donated equipment and expertise to MLOFT over the years as a key partner in that program. The company is also Master Logger® certified and was one of the first companies in Maine to achieve that certification.

So much of what the PLC stands for today and what it has accomplished over the years has been influenced by Scott and his passion for this business. Former PLC President Tom Cushman said of Scott, “Scott has worked tirelessly for decades to improve professionalism and logging and is always the first to volunteer especially with safety and the MLOFT program.”

during the award presentations to talk about his grandfather and help present the award.

Holden said of Scott, “I've been working with my Bampie in the logging business for four or five years now. He's a great boss, he works so hard and he is patient. He is excited to teach me and other kids about the business so I can be a logger. He has also been really involved in PLC and Log A Load for Kids and I'm really proud of him and Madden Timberlands. Family is the most important thing to him, but logging is a really close second. He shows up for logging and he wants to make sure logging keeps going in Maine.”

“Congratulations to my grandfather and the entire crew at Madden Timberlands. They deserve this award and I can’t wait to see him smile with me up here tonight,” Holden added.

It is with great pleasure that the PLC congratulates Scott with the 2024 PLC Maine Logger of the Year Award.

PLC Community Service Award

Tom also noted Scott’s efforts on behalf of Log A Load. Scott has always been a big part of the PLC’s annual Log A Load events, and we’ve lost count of how many times we’ve watched him convince members who hate to spend more than $5 a gallon on diesel spend thousands of dollars for the cause. In 2023 we watched Scott convince former Patriot Pete Brock to literally donate the shirt off his back to the auction, and we’ve seen him accomplish similar wins every year from Maine Sen. Angus King and some Jimmy Buffett tickets to Maine Rep. Jared Golden purchasing some very pricey fishing flies. If we knew exactly how much extra money Scott has raised for Log A Load over the years we’d love to tell you, but we don’t. We just know it’s a lot.

PLC Board Member Molly London said of Scott, “I personally have firsthand experience of all the ways Scott has advocated for loggers even in less public settings. In my time as a forester for AFM, I read countless long emails from Scott (usually one long sentence) that explained all of the complexities of our harvests for the logger and what worked and didn’t and why. I spent hours around meeting tables and walking the mountain sides of Willimantic as Scott tirelessly fought to help me understand what was operable or how much things would really cost. When we decided to buy logging equipment, Scott was my first call to ask if we were REALLY as stupid as everyone was saying –‘welcome to the dark side!’ he said. Over the last few very hard years, Scott has offered himself as a sounding board and has been willing to help in any way possible to keep us and others in the logging business.”

Scott’s grandson, Holden Harnum, went onstage

PLC’s 2024 Community Service Award winner Duane Jordan of Elliot Jordan & Son, at right, onstage with PLC Executive Director Dana Doran, who presented the award, on May 10.

In 2015, to celebrate the 20 years of the PLC and its commitment to giving back to the State of Maine, the PLC started a new tradition by presenting a Community Service Award. This award is given annually to a PLC member, Supporting Member or affiliated organization that has demonstrated a significant commitment to giving back to their community. Members of our industry in the State of Maine are notorious for their significant generosity in giving back to their local communities and good causes. Examples of this are everywhere, but often the people and organizations doing the best work don’t seek the limelight or credit for it. Consistent with this theme, the 2024 winner is Elliot Jordan & Son Inc.

Elliot Jordan & Son is a fourth-generation family logging business that over the years has branched into other businesses including construction and blueberry harvesting, but no matter what else the family does, owner Duane Jordan and his sons, Brian and Adam, are loggers at heart.

The company is deeply connected to and involved in its own community as well as the larger logging community. Anyone who knows Duane knows he is not the sort to seek attention or credit for himself, but it is because he and his family deserve some that the PLC presented this award to finally say thank you for everything they have done.

Elliot Jordan & Son has been a PLC Member for many years and has quietly but consistently stepped up for the organization in many ways, including hosting safety trainings every year since they began. Duane has been an active board member for many years as well, and the PLC knows it can count on him at any time. The company is Master Logger® certified and has a well-deserved reputation for professionalism.

Many PLC Members and Supporting Members know all this, but what they may not know is how dedicated Duane and his family are to the Log A Load cause, because so many of the donations they have made over the years are made anonymously. We apologize to Duane for even mentioning those donations, and we’ll leave it there, but we sincerely thank him for them.

At our annual meeting last year many PLC Members spent an entire day with Duane and his family during PLC’s Log A Load and Lobster event. This was a first-ever addition to the Annual Meeting, and it could not have been more successful.

For those unable to attend, the day included a bus tour of Elliot Jordan & Son renewable energy and blueberry fields, a visit to Duane’s fully off-grid home, a stop at Big Rock in Waltham which is located on Jordan land (and yes it is a really big rock, a glacial erratic to be exact), and finished up with a lobster feed with all the fixings at the garage that included guests from Children’s Miracle Network Hospitals. Duane’s entire family

contributed to the success of this event and all proceeds went to support PLC’s Log A Load for Kids. What many may not know is Duane and his family paid for this entire event. That’s right, all of it.

We often say how amazed we are at the generosity of the people involved with the PLC who step up year after year in support of Log A Load no matter how tough things are in the logging business. Duane and his family are a wonderful example of that.

So, thank you, Elliot Jordan & Son for all you do. The PLC is proud to have you as a Member, and it is with great pleasure that we present the 2024 Community Service Award to Elliot Jordan & Son.

John Whited of Whited Peterbilt of Maine, at right, onstage to accept PLC’s 2024 Supporting Member of the Year Award with PLC Executive Director Dana Doran, who presented the award, on May 10.

The PLC Supporting Member of the Year Award is presented annually to a PLC Supporting Member who has demonstrated an unprecedented commitment to the organization as well as to PLC contractors. The 2024 recipient is PLC Preferred Supporting Member Whited Peterbilt of Maine.

Whited Peterbilt of Maine has been serving loggers

Awards Continued Page 22

Awards Continued from Page 21

from its very beginning, and there are many loyal customers of the family owned and operated company in the PLC today.

The roots of the business date back to 1985, when Bob Whited founded Bangor Ford with John Linnehan. What started out as a Ford truck dealership soon began expanding into a major commercial truck and trailer sales and service center, with Bob Whited buying out Linnehan in 1991 and adding locations in Presque Isle in 1994, and Auburn in 2001.

When Ford rebranded its big truck division with the Sterling name in 1998, Whited Peterbilt of Maine became the dealership that buyers across the region turned to for the classic brand. Then the recession prompted Sterling’s parent company to discontinue Sterling in 2008 and Whited Peterbilt of Maine built up its used truck division as it looked for a new direction. Finally, in 2009 the opportunity arose to become the northern New England dealer of Peterbilt trucks and the company seized it.

Today, Whited Peterbilt of Maine has locations in Bangor, Presque Isle, Auburn and Saco. It is the largest Peterbilt dealer in New England. The company has built a strong reputation for sales, service, and quality parts and accessories with customers. Many PLC Member logging contractors are among them.

Whited Peterbilt of Maine was one of the first Supporting Members of the PLC, joining more than 22 years ago. As a Preferred Supporting Member, the company has been a strong supporter of the organization and its members ever since.

could not be successful without them. This award is long overdue, and the PLC is pleased to present Whited Peterbilt of Maine with the PLC’s 2024 Supporting

Whited Peterbilt of Maine has stepped up repeatedly for the PLC. The Fleet trainings so many PLC contractors attended this spring were sponsored in part by Whited Peterbilt of Maine. The Social Hour and Log A Load Auction at the Annual Meeting were also sponsored in part by the company, and these are both things the company has stepped up to do repeatedly over the years. You will find the company’s logo as a sponsor on PLC’s Log A Load golf tournament banners going back many years. They always participate as a team as well – last year Whited sent teams to both tournaments. Open the Logger’s Voice magazine and you will find the large ads Whited has purchased. In short, when the PLC calls, Whited Peterbilt of Maine has always answered.

In the years since Whited Peterbilt of Maine joined the PLC this organization has grown tremendously in every way. The PLC now has more events and larger events, new programs, bigger fund-raising goals, and now in the past year a major expansion of its geographic reach. As it has grown, Supporting Members like Whited Peterbilt of Maine have been critical to meeting the challenges that come with that growth.

The PLC depends on its Supporting Members and

PLC’s 2024 President’s Award winner Laurie Palow, at left, onstage with PLC Executive Director Dana Doran, after accepting the award May 10.

The President’s Award is a discretionary award that is given by the current PLC President to recognize an individual or business that has had a major impact upon the PLC and the logging industry in Maine. The recipient of the 2024 President’s Award is Laurie Palow.

As most PLC Members and Supporting Members know, Laurie recently retired as Senior Commercial Lines Underwriter at Acadia Insurance after three decades in the business, and she was already with Acadia when the PLC was founded in 1995.

Logging is a rough business, and it can be hard on equipment and people. Having the right insurance can make or break a business, and for 30 years Laurie has been working to make sure logging businesses had what they needed to operate effectively and safely.

Laurie took on Acadia’s logging clients at the start of her career and it did not take long for her to begin growing that book of business for the company.

Brent Wittman, Acadia’s Director of Middle Market Sales Underwriting, said Laurie very quickly established herself as the logging expert at Acadia, and is largely responsible for the impressive growth in Acadia’s logging business over the years.

Brent said, “She developed a quick rapport with the PLC, with the loggers themselves, and is primarily responsible for building the book and the relationship up to where it is today. She takes a lot of pride in the book and is always a great advocate for the loggers and the programs and the coverages they need.”

He added, “I’d been a coworker of hers before becoming underwriter director and that’s when I started getting involved with logging and what struck me going to the PLC meetings and the equipment shows was how she couldn’t walk two feet without somebody seeking her out and saying hello, she just knows everybody at a personal level as well as understanding what they do professionally and that’s very unique for a lot of insurance companies, particularly those that aren’t direct underwriters. We have programs that allow us to sometimes get out in front of customers, but Laurie took that to a whole new level just with her involvement and support, she is the go-to expert in this field, bar none and the mutual respect between Laurie and the loggers is quite unique in the industry.”

Laurie was closely involved in the development of and the success of the PLC Safety Dividend Program with Acadia Insurance, which has distributed more than $14 million in safety dividends to eligible PLC Members since 1999.

Laurie has been a reliable supporter of and participant in PLC safety meetings and trainings. She has always attended our events, including our Log A Load golf tournaments. She has been a valued member of an Acadia Team that is one of PLC’s strongest partners. To say we will miss her would be an understatement.

Throughout her entire career Laurie was a friendly face and a steadying force for our industry. She made our businesses safer and more profitable, provided sound advice, and most importantly of all, she cared.

Thank you, Laurie, for all you have done for us over the years. We’ll let you retire, but we still expect and hope to see you at our meetings and our golf tournaments. We wish you and your family all the best.

Brent Wittman described the way Laurie and Ted Clark in Acadia’s loss control division worked together as phenomenal. Ted himself told us Laurie had a passion and commitment to the logging business that is unsurpassed by anyone he has ever worked with in his life, but because she worked primarily behind the scenes most people don’t know she would lose sleep, miss holidays, and be stressed worrying about the loggers, or how passionately she advocated for the logging industry.

Ted said, “within Acadia, Laurie was known as the loudest voice supporting Maine loggers. She and I would often be on the phone at 4:30 in the morning, discussing how we could better serve the logging community with our products. The pride she had in her work with loggers was infectious and I think I speak for Acadia and the logging community when I say that I am proud to call her a colleague and a friend.”

The PLC would like to congratulate PLC Member Madden Sustainable Timberlands for winning the 2024 Acadia Insurance Safety Award!

The award is presented to a logging contractor with an outstanding commitment to maintaining a safe workplace and a culture of safety. It is well deserved.

Accepting the award, at right, is Derek Madden of Madden Sustainable Timberlands. The award was presented at the PLC Annual Meeting on May 10 by Acadia Insurance’s Ted Clark, at center, and Scott Peill-Meininghaus, at left.

Congratulations!

The PLC spent May 3-4 at The Northeastern Forest Products Equipment Expo in Essex Junction, Vermont.As always, this was a great opportunity to catch up with current and prospective Members and Supporting Members, and thank you to all who stopped in at our booth!

The PLC would also like to thank the many logging contractors from across the region who attended the Northeast Logger Reception May 3 at the Expo (photo above). This gathering was jointly hosted by the PLC, the Northeast Master Logger® Certification Program and PLC Preferred Supporting Member Milton CAT - sponsor for the event!

We are already looking forward to seeing everyone at next year’s Expo in Bangor, ME!

Check out the equipment and job opportunities our members have listed on the PLC website at the LOGGING ZONE!

If you have equipment for sale, are looking to buy, are looking for employees, or are looking for employment - check it out!

As Part of DOT’s Push to Bring Traffic Deaths to Zero, Biden-Harris Administration Sends Every State Funding for Commercial Motor Vehicle Safety...

June 3, 2024,

WASHINGTON, D.C. Today, the U.S. Department of Transportation’s Federal Motor Carrier Safety Administration (FMCSA) announced approximately $480 million in Motor Carrier Safety Assistance Program grant awards from President Biden’s Bipartisan Infrastructure Law to fund initiatives aimed at preventing crashes, fatalities, and injuries involving commercial motor vehicles. As FMCSA’s largest grant program, the Motor Carrier Safety Assistance Program awards funding to all 50 states, the District of Columbia, American Samoa, Guam, the Northern Mariana Islands, Puerto Rico, and the U.S. Virgin Islands.

Funding through the Motor Carrier Safety Assistance Program supports safety inspections of large trucks and buses, investigations of motor carriers in response to safety concerns, and audits of new truck carriers and bus companies to reinforce responsible operation and ensure the safe movement of goods and passengers. The funding also promotes outreach and education efforts that help combat human trafficking, distracted driving, and other roadway safety concerns. The program’s funding amounts are determined by a formula and awarded annually to the lead agency of each state or territory upon completion of an FMCSA-approved Commercial Vehicle Safety Plan.

FMCSA Removes Two Devices from List of Registered ELDs...

May 21, 2024,

WASHINGTON – Today, the U.S.

Department of Transportation Federal Motor Carrier Safety Administration (FMCSA) removed BLUE STAR ELD and ELD MANDATE PLUS devices from the list of registered Electronic Logging Devices (ELD). FMCSA placed these ELDs on the Revoked Devices list due to the companies’ failure to meet the minimum requirements established in 49 CFR part 395, subpart B, appendix A. The removals are effective May 21, 2024.

FMCSA will send an industry-wide email to inform motor carriers that all who use these revoked ELDs must take the following steps: Discontinue using the revoked ELDs and revert to paper logs or logging software to record required hours of service data.

Replace the revoked ELDs with compliant ELDs from the Registered Devices list before July 20, 2024.

Motor carriers have up to 60 days to replace the revoked ELDs with compliant ELDs. If the ELD providers correct all identified deficiencies for their devices, FMCSA will place the ELDs back on the list of registered devices and inform the industry of the update.

For more information on ELDs, visit FMCSA’s ELD website

The Professional Logging Contractors (PLC) of the Northeast has completed its 2024 Logger and Fleet Safety Training series, providing training in March, April and May to more than 1,300 loggers and forest truckers at a dozen sites in Maine and Vermont.

Reaching employees of more than 130 companies, the training covered topics including first aid, bloodborne pathogens, CPR, fire safety, electrical safety, managing stress, radio communication, roadside safety, properly securing loads on trucks, throwing straps, and federal trucking safety rules. Training was delivered by veteran instructors who have worked in or with the logging industry for many years and was focused on the unique needs of the industry.

The PLC launched the training series several years ago and it has quickly grown into the largest effort of its kind in the region.

“This training is unmatched in the Northeast in terms of its scale and quality and the numbers of loggers and forest truckers it reaches,” Dana Doran, Executive Director of the PLC, said. “This was the first year the training has been offered in multiple states and it has proven to be our most successful year yet. Safety is the top priority at the PLC for this industry, and our focus will always be to ensure our members’ employees go home safely each night.”

Sponsors for the training series included Acadia Insurance, Cross Insurance, Barry Equipment, United Insurance, O’Connor Motor Company, Chalmers Logging Insurance, Eastman Trucking & Excavation, John Deere, United Construction & Forestry, Cass Insurance, Whited Peterbilt, Anderson Equipment Company, Katahdin Trust Company, Maine Trailer, Farm Credit East, MEMIC, Readfield Insurance Agency, and Sappi.

The logger and fleet training is offered free of charge to all PLC Member companies, prospective PLC Member companies, and to logging companies that are Northeast Master Logger® certified.

The PLC would like to thank all the sponsors, trainers and companies who made this year’s training series another success. See you next year!

ByDonaldBurr PLCSafety&TrainingConsultant

The logging industry is no stranger to the challenges posed by nature, and one of the most formidable natural forces is lightning. When loggers operate heavy equipment in remote and often exposed environments, the risk of lightning strikes becomes a significant concern. This article explores the importance of lightning safety while running logging equipment and provides essential guidelines to ensure loggers' well-being. Lightning is a powerful electrical discharge that can occur during thunderstorms. When it strikes, it can release millions of volts of electricity, which can be deadly if it comes into contact with people or equipment. When a lightning storm comes by, stay in your equipment. The ROPS & FOPS will protect from electrocution. This is called the skin effect, where the lightning goes to the ground around the operator’s cab. When a lighting storm comes in, ground your equipment and don’t touch anything metal, including a radio with an external antenna. Stay shut down until the storm passes by. Lighting can strike 10 miles around the edges of a storm. What do you do if you get caught outside your equipment or pickup truck when a storm rolls in?

1. Don’t panic!

Here are the five ways you can get struck by lighting.

1. Direct strike. This is the most dangerous. 2. Side flash. This is when lightning strikes something nearby and then jumps to you on the way to the ground. This is why you should stand no closer than 20

the ground and hits you. This is why you need to stand with your feet together so that the energy cannot travel up one leg and down the other.

4. Conduction. This is when lighting hits something that can conduct electricity well that you are touching, and you get shocked.

5. Streamers. This is uncommon. This is when a lightning bolt electrifies an area, and sub-bolts develop and strike things around the primary target.

Last thoughts:

Stay informed about weather conditions: Always check the weather forecast before logging operations. Pay close attention to any thunderstorms or lightning warnings. Many weather apps and services provide real-time updates, which can be invaluable in preventing accidents.

Employee training: Ensure that all crew members are well-informed about lightning safety procedures and aware of thunderstorms' risks. Conduct regular safety training sessions to reinforce proper lightning safety protocols and address any questions or concerns.

Meeting

October 2024

Time and location TBD Watch your email for details!

When I started my career in safety I found myself, like most managers do, giving a lot of attention to incidents that occurred on a jobsite. Following an incident, I would spend a large amount of time devoted to the investigation and trying to understand the root cause of the incident that occurred. The goal of finding the root cause was to prevent future incidents from occurring by educating our crews and developing new policies and procedures to reduce the likelihood of the incident reoccurring.

While important, accident investigations can be considered a bit counterproductive in the sense that the incident has already occurred. Through all my investigations into incidents, one thing that became clear was that almost every incident was preceded by numerous close calls that didn’t result in an incident. As I grew in my position as a safety manager, I began to see the value in treating close calls, or “near-misses” the same as I would treat an accident.

Some industry studies have shown that on average for every serious incident that occurs, there are about 600 near-misses leading up to the incident. That is 600 times where nothing bad has happened that we can use as an opportunity to prevent a serious incident. Based on personal experiences, devoting attention to near-misses is challenging initially, but the payoff is substantial when it comes to preventing incidents from occurring.

So, what is a near-miss? A near-miss is simply a close call that, had the events played out slightly different, would have resulted in an incident.

For most of time, culture has dictated that we look at a near-miss when it happens and think,

“phew, that was close, thankfully nothing happened, lets get back to work” and we have carried on without giving it much thought. If your goal is to reduce incidents from occurring, implementing a near-miss program may be one of the most effective things you can do.

Things to consider:

∙ This can be a challenging program to implement because you are attempting to change a culture that has always viewed near-misses as a negative thing.

∙ Learn to view near-misses in a more positive light as a “free” lesson rather than a negative.

∙ Create an environment where employees are encouraged to report near-misses. Consider incentives for reporting near-misses rather than the traditional incentives for things such as not getting hurt.

∙ The only difference between a near-miss and an incident is the outcome. Give near-misses the same attention that you give to incidents. Take the time to investigate the cause, learn from them and implement change to prevent them from reoccurring.

∙ Make sure to communicate the lessons learned with your entire crew so changes can be implemented throughout your organization.

Near-misses do occur, whether they’re recognized or not. In fact, most significant incidents that occur have numerous close calls that led up to that incident. Implement changes based on the nearmiss instead of waiting for an incident to occur. Shifting your mindset to accept this will likely be an effective way to prevent significant incidents within your operations.

Acadia is pleased to share this material for the benefit of its customers. Please note, however, that nothing herein should be construed as either legal advice or the provision of professional consulting services. This material is for informational purposes only, and while reasonable care has been utilized in compiling this information, no warranty or representation is made as to accuracy or completeness. Recipients of this material must utilize their own individual professional judgment in implementing sound risk management practices and procedures.

By Brie Weisman, OTR/L with Maine AgrAbility

Coordinator for Maine Agrability, Bella Ross, and I had the pleasure of conducting a workshop at this year annual PLC Spring Safety Trainings. We were asked to cover shoulder injuries, a common problem in the industry. For workers, a shoulder injury means pain and temporary disability and sometimes even permanent injury, as sufferers often will not recover full range of motion and strength after a serious tear. For business owners, they can result in sizable health and compensation costs and time down. One employer who asked for this workshop said that an employee’s shoulder injury had increased his already high workers rate, and health and compensation costs are threatening to put him out of business.

Workers’ health, always a common sense personal responsibility and business expense, is now also a threat to viability for some smaller logging businesses.

Shoulder injuries are too common an occurrence in logging. Industry truckers are at an especially high risk, with throwing and tightening load straps and hefting chains being major causes.

The good news about shoulder injuries, as with so much I write in this column, is that they are largely preventable by applying responsible ergonomic practices and following a basic strength and stretch program.

Ergonomics: Technique counts. Up to 80% of all shoulder injuries are considered impingement injuries, meaning that soft tissue, muscle or a nerve becomes pinched. It is usually painful, and always results in difficulty or reduced mobility and weakenss. The leading cause of this type of injury is not what you may think–not actual overexertion in, say, throwing a load strap or lifting a tire chain. The true culprit is misalignment of the shoulder while doing a task. Improper posture while lifting or during a physical activity like pulling down while tightening a strap are alignment issues. If we all stood correctly and squared off to our work rather than hastily

doing it at an odd angle, we might actually eliminate most shoulder injuries–eliminate all that pain, personal inconvenience, and lost productivity.

Attempted fall recovery is also, essentially, a misalignment injury. When we reach out in the act of falling at awkward angles, we combine poor positioning with a tense body and a wrenching force. Typically we try to stop ourselves with a single hand, meaning all that force is put on a single shoulder. While we certainly cannot plan for proper posture and weight distribution during a fall, we can take steps to reduce falls in the first place. Be aware of slick and icy conditions, take hold of rails and supports preemptively rather than lunging for them in the midst of a fall. Wear proper footgear. Actively reduce trip hazards. Good practice counts. Remember, even if no single action results in an immediate injury, repeated minor incidents

can result in a chronic injury from wear and tear (in this case, literal micro tears adding up to produce a rotator cuff injury). As always, the best treatment isn’t treatment at all, but prevention.

Strengthening and Stretching: Fortunately, the science tells us a basic, quick exercise routine is all it takes to greatly reduce your chance of injury. As little as three times a week for five minutes! You don’t need to go to a gym if that’s not your scene. A few light weights or exercise bands are all you need for a perfectly effective workout at home.

If you have been relatively inactive for a while or are new to exercise, I would encourage you to talk to a personal trainer at the local gym. If you have some compromising issue such as a previous rotator cuff injury, arthritis, or other pains or restricted mobility, see your PCP for guidance.

Remember, just as the knees of your jeans tear out more easily when the fabric wears thin, so too will your shoulders tear when your muscle mass declines. And just like our jeans, we wear out with age–if we do nothing to prevent it. We begin losing about 1% of our muscle mass a year after age 30, and that loss accelerates to 3% at 65. That means that, if you are the average age of a logger in Maine (45) and haven’t been exercising all along, you’re 15% weaker than you were when The Matrix came out and Faith Hill was topping the country charts with “Breathe”.

Another preventative measure is to work on microstretch breaks throughout your workday. Sitting in the same posture all day is good for no one. Getting out of your seat or work station periodically and simply standing straight and walking about is important. A few simple, quick stretches added to that routine can help open up tight muscles and unkink the body. This need be no more than a couple of minutes. Aside from preventing injury, this simple, healthy practice, done hourly, is proven to increase rather than decrease productivity. The concept is a simple one: do gentle stretches in positions opposite to your work position. If you work seated, do standing, lengthening stretches. Do not push too hard or too fast, slow and steady wins the stretching race. Jerky motions can lead to pain, even injury. As always, if you have specific pains or concerns, talk to your PCP. Maine LogAbility is working on a Yoga for Loggers guide with stretches for both inside and outside a cab. In the meantime, we presently have posters for farmers and fishermen, and many of these same stretches work perfectly for loggers. Check our website for posters and short stretch videos.

One of the most common questions loggers have is how long to wait before seeing their PCP. If you have a traumatic (impact) injury with substantial pain, go directly to your doctor, emergent care or the hospital. You may have sustained structural damage that can get worse if untreated. If you have a minor soreness from a bump or strenuous use, but you are still able to get your work done

without wincing or flinching in pain, try to rest the muscle by avoiding or minimizing motions and activities that exacerbate the soreness. If the soreness remains after two weeks, it’s time to call your PCP.

Do you have pain in the shoulder with recurrent tasks, especially at night while sleeping on one side? That’s likely a rotator cuff injury. Ask your PCP if you should see a specialist. Remember, the longer you wait for help, the more likely you will injure it further and require more health care, which means it will be more expensive to treat and you will lose more work and quality of life outside of work. In this regard, you are like the expensive equipment you operate: ignoring strange sounds indicating the need for basic maintenance or minor repairs is a mistake that may mean time lost and more expensive repairs. Unlike logging equipment, you are irreplaceable, and have a life outside the jobsite.

For More Information, visit Maine LogAbility, part of the Maine AgrAbility program: https://extension.umaine.edu/agrability/

ByTomGilbert

There are a number of factors to consider when planning for a stream crossing: Where is the straightest, narrowest part of the stream? Are the banks high enough and solid enough to support bridge panels? And most importantly, do I even need to cross it? And if so, what type of crossing structure should I use?

Considerations of planning and installation of stream crossings include the following decision-making hierarchy, ranked from the best option to the least preferred:

1. Avoid creating a crossing.

2. Use a temporary structure, preferably a bridge.

3. Use an open bottom structure that spans or exceeds channel width.

4. Use an embedded culvert that spans or exceeds channel width.

Avoidance - Sedimentation of stream channels originate at crossing structures more frequently than anywhere else at a harvest site. Crossing structures may also create barriers to fish and other aquatic organisms, as they are frequently undersized and/or installed incorrectly. Avoiding a crossing makes the best sense environmentally as well as economically. Planning ahead by reviewing maps and ground truthing with the landowner, logger and forester ensures that you are making decisions based on the best available information, allowing you the opportunity to plan a harvest to avoid a crossing and the costs associated with it.

Temporary crossings - Using portable bridges for temporary stream crossings is one of the simplest and most cost-effective ways to cross streams. In addition, temporary bridges that are properly installed and removed after use do not cause negative impacts to streams such as chronic sedimentation, damage to the stream banks or barriers to the movement of fish and other aquatic wildlife. Keep in mind that a crossing that is in place for longer than seven months is considered permanent and will require a permit by rule application from MFS.

Open bottom crossing structures - Include bridges, arch culverts and open bottom box culverts. Open bottom structures such as these are the best option for a permanent crossing due to their ability to span the stream channel. Staying out of the active channel will provide adequate capacity during large storm events and promote a long-lasting structure that will not create a barrier to

aquatic wildlife. It is recommended that a crossing structure span the stream channel by at least 20% larger than the width of the stream, or 1.2 times the bankfull width of the stream channel.

Embedded culverts - For smaller streams, sometimes a round culvert will provide adequate capacity. As with open bottom structures, it is still important to span the stream channel by at least 20% (1.2 times the bankfull width of the stream channel). These may be considered for small streams, usually no more than 4 ft. wide. Embedding the culvert will keep the stream flow at its natural velocity, avoiding scouring at the outlet and promoting fish passage. Keep in mind that when embedding you will lose some capacity and should size to accommodate this loss.

For additional information, reach out to the Maine Forest Service and/or the Northeast Master Logger® Certification Program.

Students in the 2024 Mechanized Logging Operations and Forest Trucking class on June 25, one day after starting the 20week program at the Kennebec Valley Community College Alfond Campus in Fairfield, ME. The program will run through November, progressing from CDL training to active timber harvesting in the woods at the campus. Those in the photo, from left to right, include Benjamin Smith of Dexter; Aliya Cox of Montville; Andrew McDonough of Palmyra; Daniel Higgins of Masardis; MLOFT Coordinator Donald Burr; Chance Tibbetts of Mercer; Ryan Bean of Troy; Connor Ennis of Millinocket; Levi Bradley of Farmington; Dakota Sutherland of Ashland; Nick Rowe of New Vineyard; and Coltran Austin of Norridgewock. Absent from photo, Mike Coy of Lowell.

Contractors who would like to visit the program, meet the students or be a guest instructor should contact Donald Burr at (207) 356-1541.

On May 10, The Trust to Conserve Northeast Forestlands (TCNEF) held its 2024 annual meeting in Rockport, ME. to elect officers and Board members, and recognize the newest cohort of Master Loggers.

The event at the Samoset Resort was attended by dozens of Master Logger® certified companies from Northeast states.

Paul Miller, a distinguished figure in the Northeast industry, was honored with the 2024 Master Logger® Award, which is presented to outstanding supporters of the Northeast Master Logger Certification Program. This award recognizes his significant contributions to the Master Logger program and to sustainable forestry.

Miller graduated from the University of Maine with a degree in Forest Management in 1972. He gained valuable experience at Sewall Company and Shyka Surveying before embarking on a 24-year career with Great Northern Paper Company. He also served as the forest manager for the Passamaquoddy Tribe and worked with the Small Woodland Owners of Maine (today Maine Woodland Owners) before launching his own consulting business in Washington, ME.

In 2001, Miller began his work with TCNEF as certification auditor. It is estimated that Miller has performed well over 250 audits during his tenure with TCNEF. He also coordinated the distribution of audits based on geographic location, a task that required significant logistical

s dedication to the Master Logger program is clearly

I thoroughly enjoy working with the Master Logger Miller said. “The value the program has brought to this region is immense, and I see it every day in the quality of loggers in this region. I do this work for loggers. I enjoy working with them. They have an incredibly hard job, and I hope my work as an auditor has made a difference.”

From TCNEF’s perspective, Miller’s work has been instrumental in advancing the Master Logger program to its current level as the gold standard for professionalism in the logging industry today.

Congratulations!

Are you a Master Logger® in Maine who is buying new equipment? Take advantage of the Direct Link Loan Program and get an interest rate reduction of up to 2% on qualifying equipment. Details of the program and how you can take advantage of it may be found on the Master Logger® website at masterloggercertification.com/programs/

“What’s Going

”

By ALC President MikeAlbrecht

This 3-word title could end with a period, an exclamation point, or a question mark. For this article, my intent is to stay with an exclamation point.

I’ll set the stage for the “exclamation point” with a few facts as follows.

Currently, over 56% of America’s 760 million acres of forest is privately held by approximately 10 million family forest owners. The vast majority of these private ownerships are east of the Mississippi. (The majority of these eastern forest landowners are well aware of the many western forestry challenges (debacles) and hope they stay . . . west!)

The western loggers might choose the title to read “What’s Going Right?” with a question mark. Regardless, optimism can be found in the fact that the majority of America’s forests are privately owned and cared for by tree farmers across our country who see wisdom in managing for multiple uses, while profiting from a renewable resource . . . trees. I think if we can all “hang on” for a bit longer, America’s trees, and the loggers who harvest them, will soon be more highly valued.

Here’s why I say that. Wood, in the form of lumber, the renewable resource and product we understand, is steadily becoming the world’s preferred building material. Alex de Rijke, director of the London -based cross laminated timber (CLT) firm, dRMM, put it this way, “Timber is the new concrete. … the 17th century was the age of stone, the 18th century was the peak of brick. The 19th century was the age of iron, and the 20th century the century of concrete. The 21st century will be the time for timber.”

Canadian architect Michael Green summarizes it like this: “Climate change and the need for more urban housing collide in a crisis that demands building

wood offers a new way to think about our future.” The fact that architects and builders are embracing CLT as the preferred building product for the future should be viewed by us loggers as a major “exclamation point” to tag onto “What’s Going Right.”

Here are a few more points to consider. The average person can go about 3 weeks without eating. Thank God that we have the world’s best farmers and ranchers feeding America and so many others. That same average person will expire in about 3 to 5 days without water, and in about 3 minutes without oxygen.

Hydrologists estimate that 60 – 70% of America’s water flows out of our forested watersheds. On average, scientists estimate that one acre of trees can produce enough oxygen for 18 people to continually breathe freely. And who is entrusted to work in our forests, watersheds, and airsheds that provide us with the very essence of life? The American logger! That trust is the foundation for this title “What’s Going Right!” To maintain that trust, we must continue to train our logging crews that there are two products that demand our full consideration: What we haul out of the forest, and the forest we leave behind.

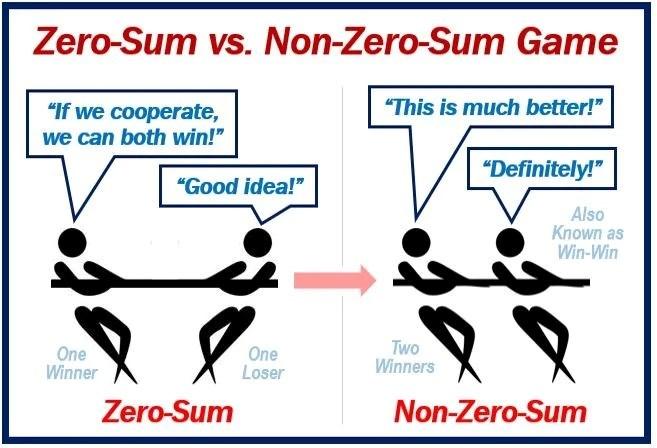

I’ll end with something else going right, maybe the most hopeful thing of all. John Buckley (representing the environmental community in our region) and I (representing the timber industry) fought through the California timber wars of the 1980’s and 90’s. John and I both had our voices, our pens, and our “people” who engaged in the battles with us.