TASK 1 Research one of MMC

2D primary structural systems

Pre-Manufactor

Pre-Manufacturing (2D primary structural systems) is defined as: 'A systematized approach using flat panel units for the basic floor, wall and roof structures of varying materials which are produced in a factory environment and assembled at the final workforce to produce a final three-dimensional structure. The materials used are mass-engineered timber, hot-rolled steel and pre-cast concrete.

HOW ITS ASSEMBLED

The creation of 2D panelised and framing systems away from the site that is assembled on-site to create the structure of a building. There is a wide range in the extent of pre-manufacture between the three sub-categories with the systems utilised in category 2c incorporating significantly more consolidation of materials than 2a. Typically utilises timber and steel as the core component, with concrete solutions also available although generally these are used less in residential development.

MATERIALS USED

A systemised approach uses flat panel units for the basic floor, wall and roof structures of varying materials produced in a factory environment and assembled by the final workforce to produce a final three-dimensional structure. The most common approach is to use open panels, or frames, consisting of a skeletal structure only, with services, insulation, external cladding and internal finishing installed on-site.

HOW ITS ASSEMBLED

More complex panels – typically referred to as closed panels –involve more factory-based fabrication and include lining materials and insulation. These may include services, windows, doors, internal wall finishes, and claddings. The system includes structural performance for primary walls and all floors (note that this excludes unitised or composite external walling systems, not load-bearing included in Category 5).

https://www.designingbuildings.co.uk/wiki/Pre-manufacturing_(2D_primary_structural_systems)#:~:text=productivity%20 %2F%20assurance%20improvements.-,Category%202%20%E2%80%93%20Pre%2DManufacturing%20(2D%20primary%20 structural%20systems),a%20final%20three%2Ddimensional%20structure. https://www.buildoffsite.com/content/uploads/2019/04/MMC-I-Padbase_GOVUK-FINAL_SECURE-1.pdf https://www.wbdg.org/resources/structural-insulated-panels-sips

WHAT ARE SIPS

Structural insulated panels (SIPs) are high-performance building panels used in floors, walls, and roofs for residential and light commercial buildings. The panels are made by sandwiching a core of rigid foam plastic insulation between two structural facings, such as oriented strand board (OSB). Other skin materials can be used for specific purposes. SIPs are manufactured under factory controlled conditions and can be custom designed for each project. The result is a building system that is extremely strong, energy-efficient and cost effective. Building with SIPs will save you time, money and labor.

HOW ITS ASSEMBLED

The structural characteristics of SIPs are similar to that of a steel I-beam. The OSB facers act as the flange of the I-beam, while the rigid foam core provides the web. This design gives SIPs an advantage when handling in-plane compressive loads. SIPs are used for high wind designs in excess of 180 mph and are approved for Florida’s strict High Velocity Hurricane Zones (HVHZ). The loadbearing area of SIPs is equivalent to building with 2 x 10 framing at 16 inches on center.

https://www.sips.org/frequently-asked-questions-about-sips#:~:text=Structural%20insulated%20panels%20are%20one,and%20helps%20save%20 natural%20resources.

TASK 2 Research cross-

laminated timber (CLT)

HISTORY

Cross-laminated timber (CLT), a type of wood product, was first made available in Austria and Germany in 1990, and since then, both domestic and non-residential buildings throughout Europe have begun to use it more frequently. It's a pricey, wood-based option that compliments the heavy timber and light frame options already available. It is appropriate for some applicants currently using masonry, steel, concrete, and other construction materials. CLT has helped lots of impressive buildings around the world, but it showed that it can be used competitively to handle mid and highrise buildings. CLT has helped many amazing structures all over the world, but it also demonstrated that it can be used in a competitive manner to manage mid- and high-rise structures.

DEFINITION

Multiple layers of timber boards are stacked crosswise (typically at a 90-degree angle) and glued together on both their broad and, occasionally, their narrow faces to create CLT panels. The sections can also be joined together with nails or wooden dowels in addition to glue. The CLT cross-section has three glue layers of board placed in a right-angle position to the rest of the layers. The timber panels used in the stacking are 22m in length and 3.5m in width. The main use of CLT is as part of a hybrid structure or as a sole building material. CLT timber is mainly used for walls, roofs and floors. The thickness of the CLT timber allows it to stay versatile, which makes it better than concrete as it handles building weight and allows for extra floors in a building.

PRODUCTION

The CLT panels are made of so when they arrive at the site, they are ready to use which makes it quicker to place them in position. CLT panels cost slightly more expensive than concrete but it’s five times light which makes the job easier on the construction worker and it has a stronger strength-weight ratio compared to steel and concrete. Even though using CLT is good and better than other materials it makes the job harder for the architect as he has to find a way to use the CLT in his design instead of the traditional concrete and steel that can be covered with a different material. Because of this when an architect has to use CLT panels in his design, it will cost more money because he will have to use panels in all of his design to keep it in shape and strong.

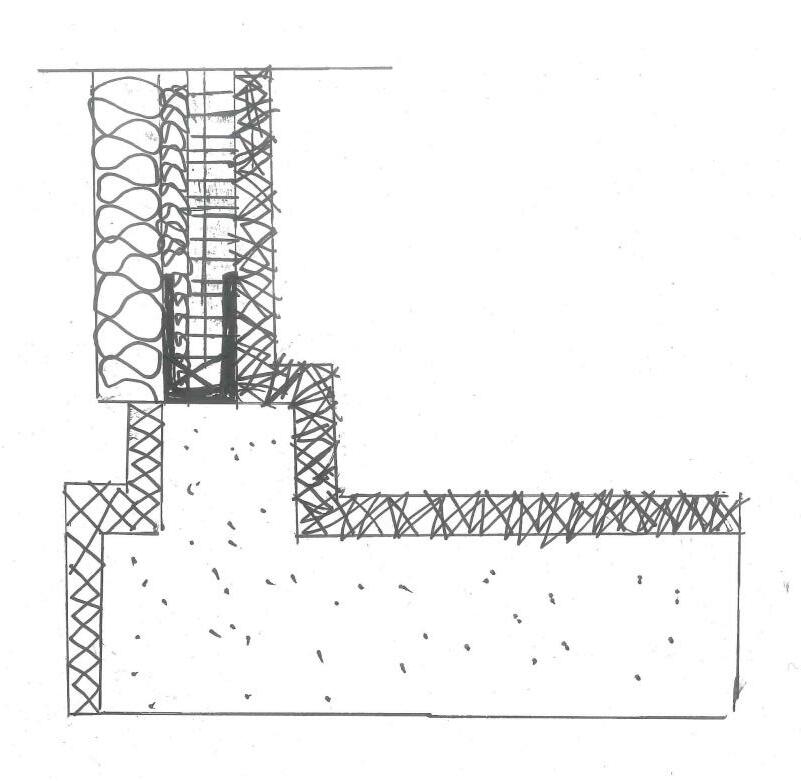

Construction details

1. 200mm CLT structural

2. Vapour control layer

3. 80mm insulation

4. Timber support for drainage

5. DPM

6. 50x50 timber battens

7. Scottish larch timber cladding 20x120

9. 100mm screw

22. Stainless steel supports with holes for drainage

23. 70mm titanium-zinc hidden drainage gutter

Construction details

1. 200mm CLT structural

2. Vapour control layer

3. 80mm insulation

4. Timber support for drainage

5. DPM

6. 50x50 timber battens

7. Scottish larch timber cladding 20x120

9. 100mm screw

22. Stainless steel supports with holes for drainage

23. 70mm titanium-zinc hidden drainage gutter

CLT PANEL INSULATING

WATERPROOFING

RC CURB

BASE INSULATING

RC FOUNDATION SLAB

Galvanized gutter

Roof covering

Wood frame construction

Roof covering

Breather membrane

Wood fibre insulation or glass/ rock wool insulation with wood studs

Clt panel

Mineral/ clay/ gypsum board inner lining

Concrete seed

Clt panel

Reinforced concrete

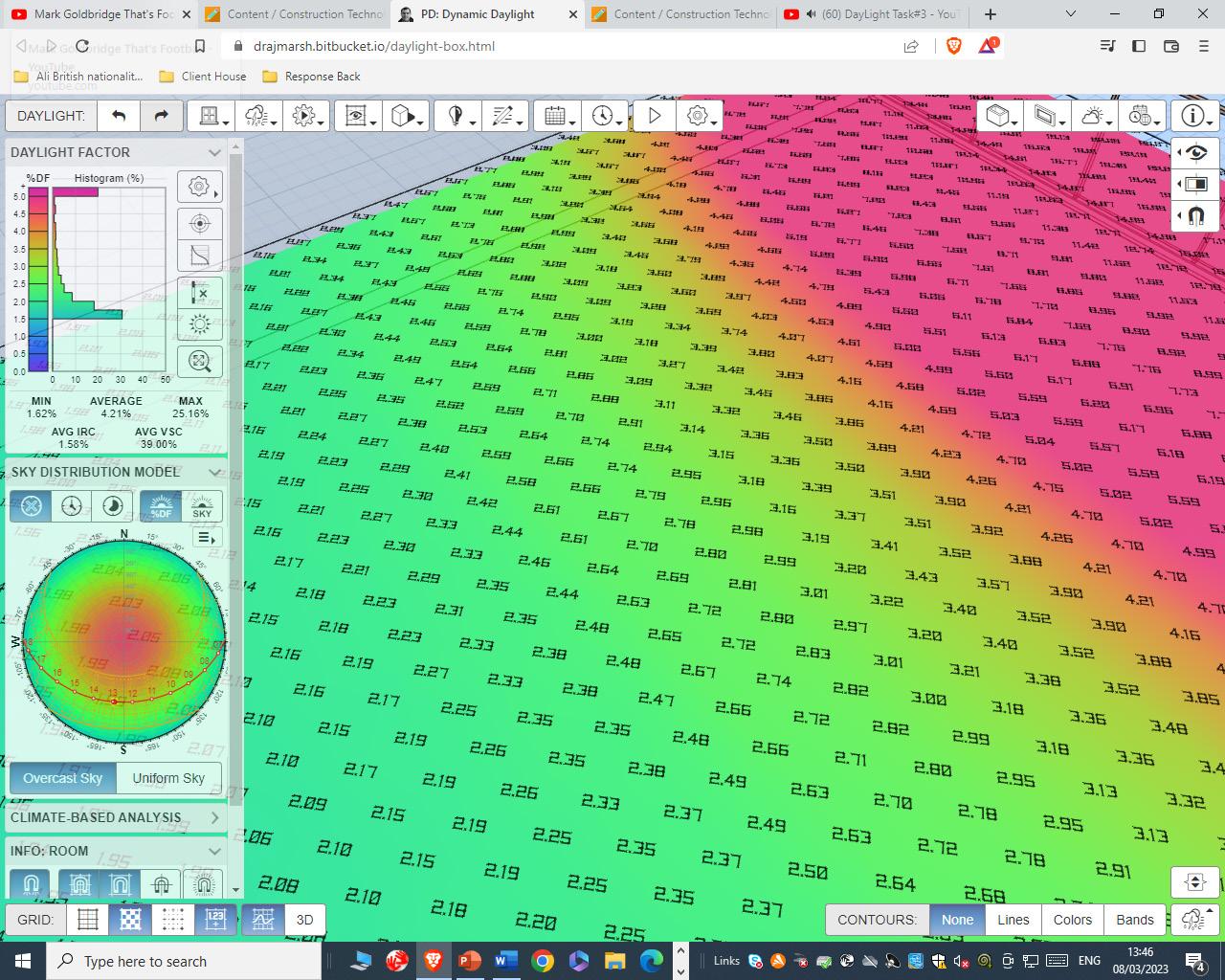

TASK 3 Document an existing daylight space

LUX LEVEL MEASUREMENT

Average light in the room 4.21

Originally the room’s daylight factor was 2.32% which didn’t meet the requirement of a 5% daylight factor. By adding more windows, I was able to get 4.21%.

TASK 4

Calculate the reverberation time

TASK 5 STRIP SECTION

larch vertical tongue

fascia with ventilation channel behind

soffit ventilation strip

25X35mm battens and counter battens to create a 50mm cavity to roof and wall insulated cavity barrier

172mm SIP panel

18mm OSB floor deck, taken between header and wall plate shaped softwood soffit bearer

vapour control layer joist hanger supporting engineered wood I joist or softwood floor joist to SE design

172mm SIP panel

lintel - or panel header - design by structural engineer

UPVC TRIPLE GLAZED WINDOW FRAME

precast concrete sill with dpc underneath

threshold drain

compressible insulation aircrete block

FFL

damp proof membrane on sand blinding, lapped under door with dpc

25X35mm battens and counter battens to create a 50mm cavity to roof and wall

larch vertical tongue

fascia with ventilation channel behind

shaped softwood soffit bearer

soffit ventilation strip

insulated cavity barrier

172mm SIP panel

vapour control layer

18mm OSB floor deck, taken between header and wall plate

joist hanger supporting engineered wood I joist or softwood floor joist to SE design

172mm SIP panel

lintel - or panel header - design by structural engineer

UPVC TRIPLE GLAZED WINDOW FRAME

WALL

fascia with ventilation

channel behind

header and wall plate shaped softwood soffit bearer

soffit ventilation strip

insulated cavity barrier

joist hanger supporting engineered wood I joist or softwood floor joist to SE design

172mm SIP panel

lintel - or panel header - design by structural engineer

precast concrete sill with dpc

compressible insulation

precast concrete sill with dpc underneath

compressible insulation

threshold drain

aircrete block

damp proof membrane on sand blinding, lapped under door with dpc