RFID

This special editon of LP Magazine is sponosored by the following partners:

This special editon of LP Magazine is sponosored by the following partners:

Just before the end of World War II, Averill Harriman, the US ambassador to the Soviet Union, received a gift from the Young Pioneers, a Soviet youth organization. Their “gesture of friendship” was a beautifully carved wood replica of the state seal of the United States, and it was promptly hung in the study of the ambassador’s residence in Moscow. What the Americans didn’t know was that it contained a listening device, which the Soviets used to monitor conversations for several years.

The genius of the Soviets’ device was that it was entirely passive,

relying on electromagnetic signals from an external source to be activated. When sound waves, such as those produced by a person speaking, reached a tiny membrane in the device, they were converted to radio waves that were then transmitted to a receiver on the Soviet side. The device’s passive design allowed it to be very small, lightweight, and nearly impossible to detect. It was a pioneering achievement in the use of transponders, which would lead in a few decades to the radio frequency identification (RFID) technology of today.

The idea of a passive device that responded to radio waves held obvious potential for all kinds of uses. By the 1960s, electronic article surveillance (EAS) equipment was being developed to help retailers reduce merchandise theft. This simple version of RFID used a one-bit tag, which was either on or off depending on whether the item had been paid for or not. Other RFID research exploded in the ‘70s, with important advances coming from companies such as Raytheon and RCA, as well as academic institutions such as the Los Alamos Scientific Laboratory, Northwestern University, and the Microwave Institute Foundation. In these early stages, RFID technology was used primarily for tracking vehicles, tagging animals, and collecting tolls on bridges, highways, and railroads.

The introduction of low-voltage complementary metal-oxide semiconductor (CMOS) circuits enabled RFID tags to be smaller and less expensive. Eventually, an RFID tag could be as inconspicuous as a small sticky tag attached to a car windshield or other object. Multiple use RFID tags also became available; a consumer might use a single tag to pay a highway toll, access a business parking lot, and enter a gated community. The technology began to be applied to a wider range of uses. Car owners could use RFID-enabled electronic keys to open their car doors remotely. Microwave ovens were equipped with RFID readers that could respond to tags on microwavable meals.

These innovations in RFID marked a notable improvement on the earlier barcode technology. Barcodes require a line of sight between the components to function; because RFID uses radio waves, no line of sight is needed. As long as a tag is within the range of the reader, it is scannable. This one feature vastly expanded the versatility of the new scanning technology. RFID tags could be hidden within an object or under surface layers. And whereas barcodes must be scanned one at a time, an RFID reader can process hundreds of items at once. Today’s RFID readers have the impressive capability to scan over a thousand tags per second.

The development of ultra-high frequency (UHF) RFID in the early 1990s vastly extended the potential range of readers while allowing

for faster data transfer. And the introduction of writeable tags further enhanced the versatility of the technology. Initially, RFID tags were read-only; once the information was embedded it could not be changed. Making tags writeable allowed users to amend the data on them to adapt to changing needs.

Also in the ‘90s, two professors at the Massachusetts Institute of Technology (MIT), David Brock and Sanjay Sarma, hatched the idea of connecting RFID tags to the internet. The tags would be equipped with an identifying number which would link them to a database with more extensive information. This development opened up a wealth of new possibilities: items could be tracked remotely from their inception through their entire lifecycle. And the amount of data associated with an item was potentially limitless. Instead of being used as a standalone data storehouse, the RFID tag was now a component in a vast networking system that was accessible to multiple users.

“As RFID begins to unravel the who, what, when, and where of retail theft, it’s one of the most significant advancements in asset protection strategy I’ve observed over the past 25 years.” Joe Coll

These developments made RFID especially attractive to manufacturers, who could now monitor individual products through the manufacturing process and their entire journey through the supply chain. Small, inexpensive tags could be attached to large numbers of items, and each one could be tracked with accuracy in near real time.

In retrospect, RFID would seem a natural fit for the retail industry, but a number of factors made its adoption by retailers a relatively slow process. One was cost; initially, the software and, especially, the readers, were more expensive than they are today. Larger retail stores typically needed multiple readers, which increased the

cost dramatically. To be most effective, an RFID system should be applied to a store’s inventory. This requires collaboration with suppliers to equip products with RFID tags. Additionally, employee training is essential for the successful implementation of the system, which is an investment in time. Initially, many companies found the projected return on investment to be unattractive. However, today’s RFID technology is more cost-effective, quicker to deploy, and offers a wider range of use cases compared to its early versions in the 2000s.

In 2005 Walmart went live with its RFID systems, enlisting more than 100 suppliers and partners in the effort. Before long the number of those participants had tripled. The retail giant found that the technology allowed it to replenish out-of-stock items three times faster than before. As the

“It is too bad that brands and retailers who have adopted RFID are not more public about the benefits that they are getting, such as inventory accuracy, inventory visibility, labor savings, improved omnichannel experiences, loss detection, and customer experience.”

Jonathan Aitken

world’s largest retailer, Walmart has the capacity to shift entire industry trends. And while Walmart paused their RFID program, many other retailers moved forward including Amazon, Target, Macy’s, Zara, Kohl’s, Decathlon, lululemon, adidas, Nike, Best Buy, Gap, H&M, Urban Outfitters, Nordstrom, Burberry, Gap Inc., and too many more to list.

Although its potential uses in retail were just beginning to be explored, it was clear that RFID technology was here to stay.

Fast forward to the 2020s in a post-COVID-19 world where Walmart

has announced a mandate requiring suppliers to utilize RFID tags on certain product categories like electronics, toys, soft home, and automotive by 2024. This policy expansion builds on an initial requirement set in 2019 for apparel, signaling a pivotal shift in how inventory is tracked and managed. Retailers see benefits not only in streamlined inventory management and significantly reduced labor costs, but also enhanced supply chain robustness and product tracking.

Now, retailers routinely use RFID to track inventory from the point of origin to the sale, and beyond. Here are some of the obvious benefits:

• Stores can know when items they’ve ordered leave the manufacturer or distributor, where they are in the shipping process, and when they can be expected to arrive.

• When the items do arrive, entire pallets can be scanned at once, greatly reducing onboarding time versus blind receiving or only inspecting 10 percent or less of items.

• Retailers can pinpoint the exact location of items in the store, as well as their price, color, the date of delivery, and any special features. When a customer orders an item online, it can be located immediately and prepared for delivery or pickup. Employees spend less time looking for items.

• The store can know in real time when an item is out of stock or inventory is low.

• For retail chains with multiple stores, shifting inventory between stores becomes much more efficient.

• When items are subject to a manufacturer’s recall, stores can locate them quickly and remove them from the shelves.

• RFID technology can be employed for anti-theft and investigative purposes, such as monitoring exits, bathrooms, and high-theft areas. Asset protection teams can use this technology to track items and receive real-time notifications, along with linked video footage, for forensic investigations.

• RFID technology enhances EAS systems, allowing retailers to modernize their anti-theft measures with contemporary overhead RFID readers. These advancements provide a more effective means to deter and detect shoplifting, a concept previously considered unachievable. “The integration of RFID technology in retail asset protection

has effectively reduced bias and empowered data-driven decision making, ultimately yielding improved results,” said Macy’s VP of Asset Protection Joe Coll. “As RFID begins to unravel the who, what, when, and where of retail theft, it’s one of the most significant advancements in asset protection strategy I’ve observed over the past twenty-five years.”

Emerging technologies, including RFID, continually evolve, bringing significant advantages as they mature. While the implementation of RFID’s full suite of features may currently challenge some users, the benefits it offers are substantial. For one, the adoption of RFID technology can streamline operations and enhance efficiency, simplifying procedures for employees once they are familiar with the new system.

Despite common misconceptions about the security of RFID tags, they are generally secure. While skilled cybercriminals could exploit vulnerabilities to manipulate tag information, such incidents are very rare due to ongoing improvements in encryption and security protocols. Hacking an RFID is akin to reprinting a barcode. For retailers, adopting RFID technology offers significant improvements in inventory management and reductions in shoplifting losses, outweighing the perception of security threats

Furthermore, there is a misconception that RFID can track a consumer’s actions even after purchase, raising privacy concerns. However, this concern is often exaggerated and misunderstood, and the majority of RFID tags today are removable as part of the price tag. Aside from these concerns, the benefits of RFID in tracking inventory would by themselves make it a worthwhile investment for most retailers. But its potential to revolutionize the shopping experience for consumers has opened vast new realms of possibility. Enhancing engagement with online customers became a more urgent priority with the arrival of the COVID-19 pandemic, which permanently changed shopping behavior. Stores had to quickly accommodate more online purchases for shipping—and devise pickup systems that didn’t require customers to enter the store. Since retail marketing has always relied heavily on the shopper’s in-store experience,

that called for the development of new marketing tools. RFID technology was a perfect vehicle for meeting that challenge.

“Many brands and retailers who are not using RFID do so because they have old and erroneous information about RFID; cost, performance, outdated information about Walmart,” said Jonathan Aitken, chair of the RAIN RFID Alliance and director of RFID partnerships for Avery Dennison. “It is too bad that brands and retailers who have adopted RFID are not more public about the benefits that

“The integration of RFID technology in asset protection has effectively reduced bias and empowered data-driven decision making, ultimately yielding improved results.”

Joe Coll

they are getting, such as inventory accuracy, inventory visibility, labor savings, improved omnichannel experiences, loss detection, and customer experience.”

Learn about specific ways retailers are using RFID to make the shopping experience more efficient and consumer-friendly, and how RFID could change the future of retail, in part two of this story at LossPreventionMedia.com ●

Tom Meehan is retail technology editor for LP Magazine as well as president of CONTROLTEK.

Previously, Meehan was director of technology and investigations with Bloomingdale’s, where he was responsible for physical security, internal investigations, and systems and data analytics. He currently serves as the chair of the Loss Prevention Research Council’s (LPRC) Innovations Working Group. Meehan recently published his first book titled Evolution of Retail Asset Protection: Protecting Your Profit in a Digital Age. He can be reached at TomM@LossPreventionMedia.com.

By Dave Sandoval

By Dave Sandoval

Ican remember starting my career in retail product protection thirty years ago and hearing about a future technology that would allow a retailer to view their inventory levels in real-time throughout the entire supply chain while securing it in the stores prior to sale.

At the time, it was thought this mythical creature called RFID resided deep in the jungle where few dared to venture. For many years, RFID seemed an imaginary creature, impossible to capture, and many times, even discussing it would cause your head to spin. It is my hope to take the journey with you, deep into the jungle to learn more about RFID and realize that it is now out in the open and available to all.

Although retailers have been questioning the viability of RFID as an alternative to more established electronic article surveillance (EAS) technologies for the past 20-plus years, the current landscape of retail security shows an increase in the trend of integrating RFID with EAS systems. RFID has come a long way to fit in the retail environment and even though it offers much broader functionalities beyond pure loss prevention, EAS remains the preferred solution to deter shoplifting.

In this article we will explore together the functionalities of each technology, their strengths, weaknesses, historical development, and the considerations involved in offering a hybrid approach.

RFID uses radio waves to track and identify tags and labels that contain information stored electronically which can be read from a distance of several feet. These tags are comprised of both a microchip, which contains the information, along with an antenna to allow communication with the reader. Currently, RFID is used in various applications including, but not limited to, asset tracking, contactless payments, inventory management, and supply chain transparency.

The RFID concept dates to World War II when the Allies used this technology to differentiate between friendly and enemy aircraft. It became commercially viable with the advancement of microelectronics in the ’70s and ’80s during the push for smaller, better, faster, and cheaper.

EAS focuses on deterring shoplifting through the use of hard

tags or labels that are applied to items, triggering an alarm when unauthorized removal attempts occur at the store entrance or exit or when an item is tampered with.

EAS can be traced back to the 1960s and is credited to Arthur Minasy, who sought to fight shoplifting in his family’s Ohio store. Since then, EAS has emerged as a cornerstone in retail loss prevention with many studies supporting its simple yet effective success in reducing theft.

The relationship between RFID and EAS technologies is complex yet symbiotic.

There are two main varieties of EAS. Acousto magnetic (AM) utilizes magnetic and acoustic (sound) energy to communicate between the specially designed tags or labels and the systems. The sound waves are disrupted when a tag or label passes through the field, causing the system to alarm. Although this is the more expensive of the two, it provides superior performance in environments with metal and liquid items—both of which can

be troublesome to alternative technologies. AM also experiences greater success when dealing with “body de-tuning” or shielding of tags or labels.

Radio frequency (RF) uses radio waves for the tags or labels to communicate with the systems. Like RFID, RF has trouble in environments with metal and liquid items. Even with its limitations, RF is a viable alternative for those looking for a more economical solution that uses a flat label and is easier to install.

Both AM and RF technologies are wonderful tools to help control shrink. Deciding between the two can be driven by many factors such as the products being protected, budget constraints, and additionally, the retail environment. It is important to consider the differences in order to select the best option for your specific loss prevention needs.

I often get asked if RFID can be used purely as EAS. Although RFID was not specifically designed

For many years, RFID seemed an imaginary creature, impossible to capture, and many times, even discussing it would cause your head to spin.

The RFID concept dates to World War II when the Allies used this technology to differentiate between friendly and enemy aircraft. It became commercially viable with the advancement of microelectronics in the ’70s and ’80s during the push for smaller, better, faster, and cheaper.

for EAS, it can be adapted to be used as such. However, before committing to this technology there are some limitations to consider. The cost to implement an RFID system for EAS is higher than a traditional solution using RF or AM. RFID does struggle in a high-metal environment and the tags or labels are body de-tunable, unlike AM.

Despite these challenges, using RFID for EAS is still attractive. The technology can lead to an increase in customer service and tracking as it offers enhanced security features, such as improved inventory visibility and the ability to track the movement of individual items throughout the store.

In a perfect world you could implement a “hybrid” solution using AM and RFID. This would leverage the strengths of both technologies by providing the advanced inventory management capabilities of RFID combined with the enhanced security features of AM. This offers retailers

a powerful tool to enhance both operational and security efficiency. This approach facilitates a smoother transition for those looking to upgrade their systems over time without having to overhaul their entire infrastructure at once. However, the cost of upgrading tags and potentially replacing cash wrap technologies can be prohibitive for some.

In conclusion, we covered the origins of RFID and EAS, we familiarized ourselves with the different technologies that are prevalent in today’s retail environment, and finally, we delved into using RFID as a hybrid solution along with AM or RF as well as the option of having it supplant them completely.

The relationship between RFID and EAS technologies is complex yet symbiotic. As retailers strive to enhance security and improve inventory management in this ever-changing environment, the

integration of these technologies presents a promising avenue. The hybrid solution, despite its challenges, stands as a testament to the industry’s innovation, offering a glimpse into the future of retail operations where efficiency, transparency, and security go hand-in-hand considering that RFID is already EAS, with some limitations. ●

Dave Sandoval is president and founder of Industrial Security Solutions with thirty years of experience in securing the profits of all size retailers. Dave uses that expertise to create cutting edge custom solutions for product protection across all sectors. Dave earned an MBA at Pepperdine University and a Bachelor of Science Degree in Economics from CSULB. He can be reached at dave@isscorpus.com.

In the last twelve months, RFID technology has received significant praise from influential leaders in the retail industry’s LP community.

“RFID gives retailers capabilities they have wanted for decades,” says noted criminologist Dr. Read Hayes, managing director of the Loss Prevention Research Council, a think tank and research hub with over ninety different retailers among its members. The technology provides a much

more complete picture of specific theft incidents, including whether employees were involved, and to Hayes, this is quite exciting.

In January, at the National Retail Federation’s Big Show in New York, Hayes called RFID “a game changer,” saying it is now essential for effective loss detection and loss prevention.

“RFID has unlocked a level of data that we never thought possible,” says Joe Coll, vice president of asset

protection at Macy’s. Coll has been using RFID for nearly a decade and he too calls RFID a game changer.

Why are they raving? Let’s go through some basics and then we can tie it all together.

An RFID label is essentially a serialized barcode that can be read via radio waves, without line of sight.

The chip within the RFID label does not contain any personally identifiable information, meaning there is no risk to consumer privacy. When activated by an RFID reader, the label relays back its serialized product information. Unpaid items concealed in knapsacks, shopping bags, or tucked inside a shoplifter’s clothing can typically be detected by a reader when the RFID labels are still present.

Stickers, paper tickets, and fabric tags are the most common forms of RFID labels. When a consumer returns an item with an RFID tag, it can be easily identified and authenticated as a product originally purchased in the store. Store personnel can also easily and quickly create a new tag.

The factory is typically where the RFID label is applied to the product or its packaging. Alternatively, distribution centers can apply an RFID label to any product that needs one.

Using handheld RFID scanning devices, an entire store’s inventory can often be counted in 20-60 minutes. For every SKU in the store, RFID gives a separate view of the store’s sales floor and stockroom inventory positions. This helps employees keep the store properly stocked. It also creates cleaner and richer data for enterprise systems, enabling better decision-making.

Stationary readers—often called Smart Exits—can be used at a store’s doors. They detect when a serialized RFID label leaves the store.

The software enables alarming if unpaid items exit the store. Logic-driven rules for a store’s alarms can be set (e.g. no alarm unless the cumulative value of the stolen goods exceeds $50). Theft events can be cross-referenced with video footage to identify perpetrators.

Retailers use RFID readers at their POS terminals to distinguish between sold and unsold merchandise. These readers can speed up checkouts considerably, which positively impacts the retailer and improves the shopper experience.

Some retailers have begun using inconspicuous overhead RFID readers that continuously monitor each item’s

presence, location, and movement inside the store.

GAME CHANGER #1

Did my product show up?

Asset protection teams work with imperfect information. This starts from the moment a shipment arrives at the store from the distribution center. Since it’s rarely practical or economical to do an itemized check of each piece of merchandise received by the store, retailers often rely instead on what is known as an “assumed receipt” or “blind receipt.”

RFID scanning can be performed promptly upon the arrival of a shipment or at any point thereafter, even after the goods have been unpacked and stocked. The first RFID scan of an item—regardless of whether the item is sitting in the stockroom or on the sales floor—serves as confirmation that the item arrived.

GAME CHANGER #2

Is my product still here?

RFID-enabled Smart Exits are designed to reveal theft immediately. Many retailers have installed these special readers at the doors of their stores and sometimes even at employee exits.

But even without Smart Exits, the regular RFID scans of the entire store— which are performed primarily for the benefit of store operators and merchants—expose the absence of merchandise. This is immensely valuable. With RFID, many retailers perform these counts weekly, and some do them daily, significantly improving inventory accuracy and on-shelf availability.

GAME CHANGER #3

Exactly when did my product go missing?

In the ideal scenario, the store has installed Smart Exits and gets a more precise answer to this question. The ability to narrow down the window of time in which an item disappeared will help an LP team identify who they are after and also allow them to adjust a store’s defensive tactics.

GAME CHANGER #4

Who took my product and how?

When a retailer uses a Smart Exit—especially when the serial numbers of purchased goods are captured at POS—it becomes much simpler to pinpoint theft incidents. You can time-stamp the moment the stolen item left the store and cross-reference it with

video footage. Once the perpetrators’ identities are known, additional footage of their time inside the store can be immensely helpful.

Behaviors can be studied carefully. The identified thief might routinely use a fitting room before leaving the store. Their accomplice might strategically deposit the soon-to-be stolen items within a section of the sales floor where it is easier for the thief to stash the goods discreetly. Or perhaps the accomplices deliberately distract store personnel while their friend conceals merchandise.

RFID may help investigators link the activity of one thief with another. Thieves sometimes get help from dishonest employees, including highly trusted store managers and other long-tenured frontline team members.

GAME CHANGER #5

How often have the thieves hit my store?

Software, artificial intelligence, and video technology can significantly accelerate investigations. What might have taken over six months to complete can now be done in a matter of weeks.

Proof of serial criminal behavior can also help demonstrate that a specific individual requires more serious intervention, whatever the appropriate remedies.

GAME CHANGER #6

What’s the dollar value of the merchandise the thieves have stolen from my company?

The ability to aggregate a person’s shoplifting events is critical to “packaging up” cases of sufficient strength and monetary value to attract and maintain the interest of busy prosecutors and legislators.

It’s not just about the likelihood of favorable verdicts in the cases that prosecutors choose to pursue. Low-level criminals are more likely to be persuaded to disclose critical information about people higher up the food chain when faced with more serious charges. The aggregation of case value using RFID serialization is convincing courtroom evidence and hard to dispute—as close to product DNA as we may get.

GAME CHANGER #7

Who’s helping to fence my stolen product?

RFID labels are serialized, and radio waves can read through walls.

Investigators now have a new way of identifying stolen goods in flea markets, hair and nail salons, and other notorious “fence locations.” For example, law

enforcement can put RFID to work when a search warrant is obtained to open and search a storage locker

When stolen goods are located, they can be traced back to the stores they were stolen from or even traced to specific incidents of cargo or delivery theft. This sheds greater light on the network of criminals working together. It also makes it much simpler for law enforcement to return goods to brands and retailers, which today is a cumbersome challenge.

GAME CHANGER #8

Is that online seller selling my stolen product?

The ease with which stolen goods can be sold online has played a large role in the rise of retail theft. Retailers, consumer brands, and law enforcement agree that online marketplace owners could be doing much more to prevent the sale of stolen merchandise.

A new way for a retailer to prove that a seller in an online marketplace is selling stolen items is to have its investigators make purchases from suspicious sellers and compare an item’s serialized RFID label to the retailer’s serialized transaction logs. Or the item can be proven to have been stolen cargo.

Macy’s is among an expanding group of retailers who have fully integrated RFID into their LP toolbox over the past ten years. These teams have seen for themselves that a whole new set of opportunities is unlocked when RFID is added to their existing mix of technology solutions and protection measures.

A growing group of LP leaders have recognized the game-changing nature of RFID. The tech has already changed the way many retailers operate their stores. Now, it’s time for the rest of the LP community to catch up with them. ●

Marshall Kay is the global director of retail transformation services at Avery Dennison. He helps retailers and consumer brands make good use of RFID and other Intelligent Label technology. He writes for Forbes as a retail contributor and is a member of the Loss Prevention Research Council’s Product Protection Working Group. In 2024, Marshall was named a Top 100 Retail Technology Influencer by UK-based Retail Technology Innovation Hub and a Top Retail Expert by RETHINK Retail.

Founded in 1929, Nedap is the global leader in RFID-based retail solutions. Nedap helps retailers achieve perfect inventory visibility, zero waste, and no losses with innovative EAS systems, streamlined POS solutions, and the iD Cloud platform.

iD Cloud, a cloud-based RFID platform, simplifies multi-store retail and supply chain management. The platform gives retailers real-time item-level insights into stock levels and can even pinpoint the exact location of each item. The platform consists of three software solutions: iD Cloud Store, for accurate stock data, iD Cloud Supply Chain, for supply chain visibility, and iD Cloud Loss Prevention, to detect, quantify, and prevent losses.

iD Cloud Loss Prevention, the latest addition to the iD cloud suite, utilizes AI to detect suspicious events automatically.

Specifically, it can detect bulk theft and sweet-hearting and discover high-theft items or high-theft sales floor locations. Retailers can then utilize these insights to report theft and enact policy changes to prevent future loss

With iD Cloud and Nedap’s portfolio of RFID-based Electronic Article Surveillance (EAS) systems and Point of Sale (POS) solutions, Nedap offers fashion retailers an integrated approach to enable seamless shopping experiences—without shrink.

Nedap has operations in APAC, EMEA, and the Americas. Together with their global business partner network, Nedap has successfully deployed EAS and POS systems in more than 400,000 stores worldwide. ●

While theft remains one of retail’s biggest barriers to success, or even survival, advancements in technology are riding to the rescue.

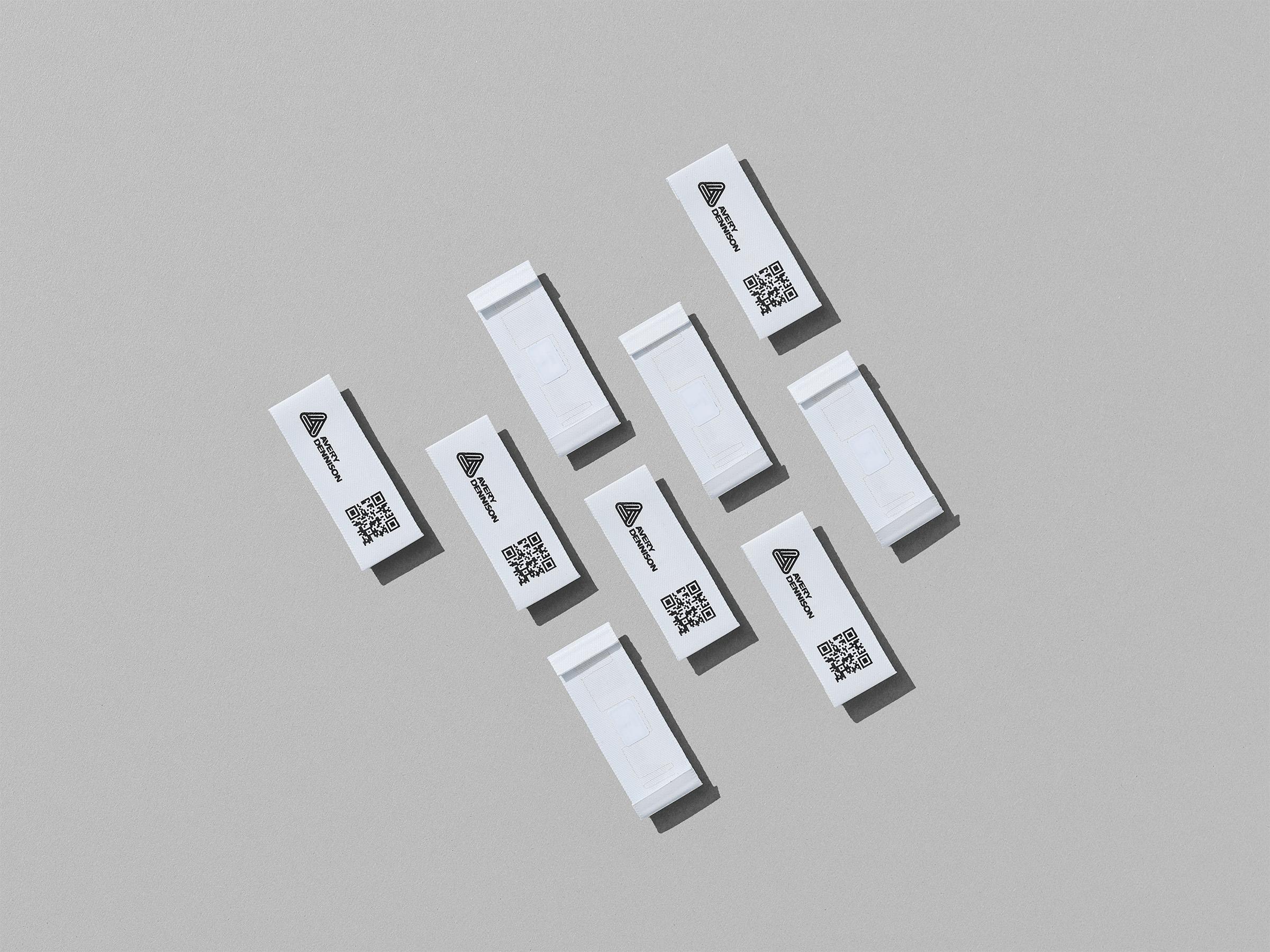

Dennison is helping retail brands unlock a smarter future with its AD TexTrace™ integrated RFID solutions for connected textiles. With these solutions, loss prevention technology in the form of small, soft, and flexible RFID inlays can be built into every garment, meaning there is no need for hard tags, saving time and money.

And because the RFID labels are integrated into the garment, they can’t be removed or switched with another label. Meaning, retailers can reduce fraud at POS, self-checkout, and in the returns process. The big win is detecting and deterring theft cost-effectively and intelligently through item-level, accurate data.

AD TexTrace™ takes RFID to the next level, integrating the technology into garments at the manufacturer stage. With item-level connectivity, loss prevention teams can easily analyze data, spot spikes and trends, and make informed decisions.

“With RFID already embedded into the garment, inventory management and loss prevention become more efficient for the store personnel,” says Mathieu de Backer, vice president, innovation and sustainability, Avery Dennison. “Thanks to integrated RFID technology, if a product gets stolen from a store the retailer knows exactly what has been taken. That item can immediately be replenished from the stockroom, meaning the sales opportunity is not lost. This is not possible with a hard tag because it does not identify the specific item it was attached to.”

RFID technology also enables interactive shopping experiences, such as smart shelves, smart dressing rooms, and interactive displays. Item-level

identification with RFID creates the opportunity for a true frictionless self-checkout experience, meaning less queuing for busy customers and fewer missed sales for retailers.

With a unique identifier embedded into the garment, AD TexTrace™ can now exploit the full potential of RFID at every stage of the value chain. A single integrated label combines all the benefits of RFID and EAS functionality, with a frictionless and engaging shopping and checkout experience as well as fast returns handling, significantly improving the customer experience.

Looking further ahead, connected garments could be vital for futuristic smart devices in the home, such as smart wardrobes and smart washing machines. “Imagine a future where your smart washing machine recognizes the clothes you have put in and advises which wash cycle and temperature to put it on based on the information stored within the RFID label,” says de Backer.

AD TexTrace™ can help retailers progress their much-needed circularity efforts too. Since the RFID inlay is part of the product, it can be used to harvest useful information on the materials used, the supply chain journey, and an item’s carbon footprint. In addition, the technology will soon be able to last for the entire lifecycle of the product, enabling circularity through resale and recycling. ●

Unlock a more intelligent future for your retail business with AD TexTrace™ integrated RFID at bit.ly/AveryDennison-RFID

The promise of RFID in retail has been a long and winding road going back at least to the late 1990s when the Auto-ID Center was launched at the Massachusetts Institute of Technology (MIT).

Walmart was an early adopter of RFID in the early 2000s, seeing the

benefits of RFID in tracking inventory moving through the supply chain. As part of their initiative, they worked with the University of Arkansas to set up an RFID Lab in 2005 to focus on retail use cases. In 2014, the RFID Lab moved to Auburn University in Alabama, where it remains today.

In the past two decades, the RFID Lab has become the global go-to authority on implementing RFID solutions in multiple industries, including retail. Brand Elverston, who has been involved with RFID throughout his loss prevention career with Walmart and now as principal at Elverston Consulting, sits on the Lab’s advisory board. He calls the Lab “the epicenter for RFID technology. There are other entities out there, but nobody nearly as robust and engaged with industry as Auburn’s team.”

One of the major functions of the RFID Lab is to bring together RFID inlay manufacturers (the companies that produce the RFID tags), suppliers who work with end users to deploy RFID systems, and end users like JCPenney, Bloomingdale’s, and Dillard’s to help ensure that the RFID tags needed for the retailers’ programs meet the necessary performance and quality levels.

To that end, the Lab created what they call “the ARC Program,” which is a test system and database that stores comprehensive performance data of in-development as well as currently available RFID tags.

Starting with end users, ARC identifies the performance and quality requirements (which the Lab calls a Spec) that an RFID tag needs to meet to perform reliably in a particular use case and deployment. As an example, a retailer’s use case may require RFID readers to be placed at a specific distance or angle to the RFID-tagged products to record the information.

These requirements are used to identify acceptable RFID tags and tagging practices within the ARC database to ensure that they will perform reliably in the deployment.

The requirement will help the suppliers who install the RFID systems clearly understand what end users are expecting. Suppliers are provided with information on RFID, lists of approved RFID tags, and proper tagging practices to ensure compliance.

Inlay manufacturers send new tags to ARC before they are released to the market. ARC measures the tag’s performance in its ARC chamber test environment, compares it to all the Specs, and adds it to the approved

tag list if it meets a particular Spec’s requirements.

The ARC testing methodology is open and has been established through industry collaboration. The methodology is clearly defined, but continual assessment and enhancement input into the testing process is encouraged and incorporated in evolving revisions.

No vendor is excluded, but all vendors must have a certified quality manufacturing system (QMS) to be included in the program. The Lab does QMS audits for every new inlay manufacturer to ensure that they can deliver consistent quality products before their tags are tested.

Part of the mission of the Auburn RFID Lab is to communicate their research in RFID solutions to the industries they service, which are primarily retail, aviation, shipping, and quick service restaurants (QSR).

“[The Auburn RFID] Lab is the epicenter for RFID technology. There are other entities out there, but nobody nearly as robust and engaged with the industry as Auburn’s team.” Brand Elverston

Another long-time RFID Lab advisory board member, James “Jamie” Kress, RFID solution sales and strategic consulting executive with Sensormatic Solutions, explained: “Early on, a lot of retailers were questioning whether RFID even worked, as opposed to how they would attain the value of RFID in their environment.”

He added, “The Auburn RFID Lab was a place where we could take customers to show them that there was a consistency of thought across how RFID could be deployed. It

wasn’t a question of does it work, but how is it best deployed for each individual use case.” Kress believes that was a pivotal moment within the retail industry.

The first significant retail use case was accounting for inventory accuracy. Suppliers like Sensormatic Solutions, Checkpoint, Avery Dennison, and Zebra could take their customers to Auburn to speak to the Lab directors to hear how other retailers were using RFID to simplify and increase inventory accuracy. This became an even more compelling use case as retailers evolved to omnichannel marketing.

“[RFID] unlocked for us a level of data that we had never thought was, A, possible or, B, our teams could consume and make actionable strategies based on the data.” Joe Coll

At this point, according to Kress, a visit to the Lab provided retailers with a playbook for how to tag, which type of tags to use, and the ideal placement of tags for each product category.

“Those playbooks became a really important tool for retailers to leverage so that their suppliers knew exactly how to deploy RFID tags on items,” he said.

A relatively newer application is the use of RFID with “smart exits” for loss prevention. The Auburn Lab is looking at all the issues related to making sure tags on products are easily accessible for point-of-sale accuracy and speed and that tags are well read at the exit either by a pedestal or in the ceiling. This is essential for validating that the products exiting the store went through the point-of-sale station.

At the 2024 National Retail Federation Big Show conference, Macy’s Vice President of Asset Protection Operations and Strategy

Joe Coll talked about his team’s experience with RFID readers deployed at their stores’ customer and employee entrances: “That unlocked for us a level of data that we had never thought was, A, possible or, B, our teams could consume and make actionable strategies based on the data.” Coll added that had his team been invited to the table earlier in Macy’s RFID journey, they would have likely had significantly greater benefits earlier on.

“Having LP involved in the initial stages of an RFID deployment is really critical,” said Kress. “Even if loss prevention is something you might not get to for eighteen or twenty-four months, make sure an asset protection professional is at the table because you don’t want program design decisions now that will adversely affect your future loss prevention use case.”

Both Kress and Elverston believe the Auburn RFID Lab will play an important role going forward, helping retail asset protection teams consider the next use case that could benefit the retail enterprise.

Currently, there are over fifteen retailers working with the Lab, including Nordstrom, DICK’S Sporting Goods, H&M, Lowe’s, and T-Mobile, in addition to the other retailers mentioned in this article.

The Auburn Lab hosts annual meetings besides individual supplier or retailer visits. The two-day meetings include a one-day advisory board meeting with fifty-plus participants. The second day is a supplier source-tagging workshop with upwards of 300 attendees.

For more information about Auburn’s RFID Lab, contact Justin Patton, the RFID Lab director, at rfidlab@auburn.edu. Or visit the Lab’s website at rfid.auburn.edu. ●

Jack Trlica is the cofounder and former editor-in-chief of Loss Prevention Magazine He retired from full-time work in December 2022 but continues to observe the industry from his homes in Charlotte, North Carolina, and Manzanillo, Mexico. He can be reached at jack.trlica@gmail.com.

The pressing issue of retail shrink continues to plague the industry, resulting in substantial financial losses for many retailers. The National Retail Federation (NRF) found that retailers lost over $112 billion to shrink in 2022, up $18.2 billion from the previous year. With the organization projecting the annual price tag on shrink will top $140 billion by the end of next year, retailers are continuing to firm up their LP programs to try to curb the impact on their operations and revenue.

For many, that has meant investing in smart LP systems that give insight into how organized retail crime groups and sticky-fingered individuals exploit

blind spots in stores and the best ways to stop them—and for good reason. Though estimates of the impact of theft vary, the NRF 2023 National Retail Security Survey notes that crime (internal or external) is the most expensive single contributor to shrink, accounting for about two-thirds of all losses. What about the other third?

Retailers who leave the impacts of damage, human error, spoilage, and other operational drivers of shrink out of their plans are leaving money on the table—more than $27 billion industry-wide in 2022 if NRF’s estimates are correct.

The fact that one-third of losses might be a result of operational

inefficiencies can be a hard pill to swallow, but it’s also a powerful realization. Retailers have the control and the opportunity to improve their operations. You can’t always control bad actors, but you can control how you do business.

The key to success in this process will likely be shifting our understanding of the issue of shrink. It’s not just about theft but a complex interplay of various factors. LP programs have, for some time, focused on addressing different drivers in isolation from one another, with an emphasis on theft above all else. The reality is much more complicated, and that’s where retail analytics systems can help.

End-to-end intelligence systems help retailers get a holistic view of shrink—one that acknowledges it as the multifaceted and interconnected issue that it is.

End-to-end intelligence systems help retailers get a holistic view of shrink—one that acknowledges it as the multifaceted and interconnected issue that it is. Many retailers are already using these systems, which often leverage cloud-based analytics, electronic surveillance, artificial intelligence, and RFID tools to illustrate the tactics thieves use to execute ORC or individual theft events.

These systems change the game for retailers by giving them an accurate picture of what’s in the store, how products move, and how shoppers interact with merchandise. Item-level RFID inventory tracking is at the heart of the system, automating the tedious task of inventory management to reduce labor spending and improve accuracy.

The item-journey data collected through the RFID system paints a vivid picture of theft incidents, empowering retailers to broaden their understanding of the issue of theft in their stores and home in on the specifics of individual incidents. It can show retailers exactly how

a thief moved around the store and—critically—what they took, something that businesses have traditionally determined through retroactive estimation.

When paired with other intelligent retail tools, retailers can get even more detail, which they can often turn into proactive LP programs. For example, computer vision technology—an AI application used to monitor video feeds—can learn the signs that a theft might be happening and alert teams to incidents in progress. Similarly, these video packages can highlight the way floor elements contribute to risk, identify at-risk items that are not protected, and potentially help law enforcement with prosecution efforts.

However, the scope of these systems stretches far beyond theft and crime prevention when it comes to shrink.

Just as gaining visibility into the events that lead up to retail crimes can help retailers protect high-risk merchandise from theft, getting insight into how inventory moves around the store can help teams identify patterns related to spoilage, damage, or errors. Item-level inventory systems—which many retailers use to improve omnichannel experiences—are designed to ensure staff knows exactly what’s in stock, where it is, and how it got there. Using RFID tags and sensors, retailers can log merchandise’s movement as data, allowing them to analyze operations for anomalies and notify workers.

Abstractly, this can be hard to picture, but let’s zoom in on an example. Let’s say a customer picks up a bottle of cold medicine but decides not to buy it, opting to leave the product elsewhere in the store. This can throw off inventory counts, leading retailers to assume the item has been stolen. If the store uses RFID labels for item-level inventory, staff can reference checkout and exit logs to see if the medication was purchased or stolen. If not, they can assume it’s still in the store and is not yet a true loss.

Over time, this kind of analysis can reveal drivers of internal losses, helping teams to make larger changes to their floor design, processes, or policies that might avoid the situation altogether. For example, RFID data

might show that cold medicine keeps leaving shelves but not the store. By correlating that knowledge with computer-vision-enabled video monitoring and other data streams, the retailer might realize that something about their floor design is leading to this phenomenon, guiding solutions that might fix it

Of course, medication is just one example. This concept applies across retail operations in nearly unlimited ways, allowing retailers to analyze shrink, recognize patterns, identify previously unknown operational issues, and address them.

Given RFID-based capabilities, it’s not hard to see why ORC and theft prevention are two of its most popular retail applications. Because each RFID label is unique to a specific unit, these systems uncover

previously unknown information about operations. The ongoing and integrated data analysis reveals if a fix has made a difference—or if it has inadvertently exacerbated losses in another area. It’s this last step that allows retailers to see how shrink from all sources affects their businesses and how those events interact with one another, empowering them to stop treating symptoms and start finding cures.●

Craig Szklany serves as vice president and product general manager, loss prevention and liability and inventory intelligence at Sensormatic Solutions. In this role, he leads the company’s loss prevention business and is responsible for driving new innovative offerings that will shape the future of loss prevention.

AD TexTrace™ takes RFID to the next level, integrating the technology into garments at the manufacturer. This means every product is RFID-enabled from the start of the supply chain, radically improving inventory management and reducing the time needed for in-store tasks.

The innovative and unobtrusive RFID-based iD Gate Pro increases sales space, achieves >95% detection, and eliminates false alarms and muted labels. Welcome to seamless shopping—without shrink.