Amid the uncertainty created around the world following the outbreak of COVID-19

PUMPS

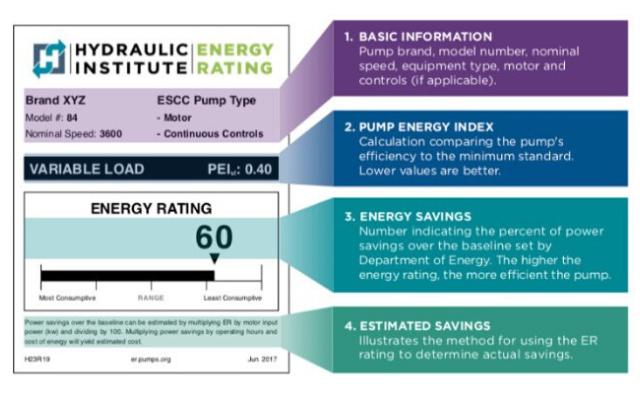

It can feel like sustainability initiatives have taken a back seat. However, energy efficiency and cost savings are often intrinsically linked. The Hydraulic Institute, the global authority on pumps and pumping systems, maintain that utilities in countries remain uniquely positioned to gain energy efficiencies in their operations while launching incentive programs that encourage other companies to seek more energy-efficient clean water pump systems. Pumps, says Edgar Suarez, manager of technical programmes at the Hydraulic Institute (HI), are a good and cost-effective (and proven) measure to help one fill out commercial and industrial programme portfolios. To support energy-efficient pump incentive programs, the HI launched a collection of tools and educational materials that can drive the development and implementation of incentive programs that advance pump system energy savings. Such programs, says Suarez, can help utilities meet regulatory goals and provide other value-adds to customers. HI’s utility resources build upon the Energy Rating Programme the organisation launched earlier which underpins incentive programs by streamlining the way pump manufacturers and distributors communicate energy efficiency. Pump systems may account for 40% of industrial energy usage, but they don’t have to. Paving the way towards more energy-efficient and reliable

pumping systems starts with training, says Suarez. The HI advocate that training is a top priority as it is critical for teaching first and foremost pump system fundamentals, but also system optimisation and assessment. It also instituted a certification programme for a certification program for Pump Systems Assessment Professionals (PSAP). This program sets the standard for the discipline of pump systems assessment and the use of pump system optimization techniques. Following these developments, the organisation implemented its Lab approval programme to ensure higher efficiency and compliance to test standards. Delivered through a third-party audit it provides pump test labs with the opportunity to demonstrate compliance to their established quality programme, procedures, instrument calibration to ISO 17025 and pump testing to HI 40.6 methods for rotodynamic pump efficiency testing that is referenced to the US Department of Energy requirements. Most recently it launched its energy rating programme – a metric, label, database and utility resources that advance the use of energy-efficient pumps. According to Suarez, while energy and cost savings will vary depending on a variety of factors for different settings, the reality is that by properly selecting pumps and ensuring they have an HI Energy Rating Label savings can be

1. BASIC INFORMATION Pump brand, model number, nominal speed, equipment type, motor and controls (if applicable). Brand XYZ

ESCC Pump Type

Model #: 84

- Motor

Nominal Speed: 3600

- Continuous Controls

VARIABLE LOAD

PEl vt: 0.40

ENERGY RATING

3. ENERGY SAVINGS Number indicating the percent of power savings over the baseline set by Department of Energy. The higher the energy rating, the more efficient the pump.

60

Most Consumptive

RANGE

Least Consumptive

Power savings over baseline can be estimated by multiplying ER by motor input power (kw) and dividing by 100. Multiplying power savings by operating hours and cost of energy will yield estimated cost.

H23R19

8

er.pumps.org

2. PUMP ENERGY INDEX Calculation comparing the pump’s efficiency to the minimum standard. Lower values are better.

Jun 2017

Pipes, Pumps and Valves Africa - Mar/Apr 2021

4. ESTIMATED SAVINGS Illustrates the method for using the ER rating to determine actual savings.