5 minute read

PUMPS

Amid the uncertainty created around the world following the outbreak of COVID-19

It can feel like sustainability initiatives have taken a back seat. However, energy efficiency and cost savings are often intrinsically linked.

Advertisement

The Hydraulic Institute, the global authority on pumps and pumping systems, maintain that utilities in countries remain uniquely positioned to gain energy efficiencies in their operations while launching incentive programs that encourage other companies to seek more energy-efficient clean water pump systems. Pumps, says Edgar Suarez, manager of technical programmes at the Hydraulic Institute (HI), are a good and cost-effective (and proven) measure to help one fill out commercial and industrial programme portfolios. To support energy-efficient pump incentive programs, the HI launched a collection of tools and educational materials that can drive the development and implementation of incentive programs that advance pump system energy savings. Such programs, says Suarez, can help utilities meet regulatory goals and provide other value-adds to customers. HI’s utility resources build upon the Energy Rating Programme the organisation launched earlier which underpins incentive programs by streamlining the way pump manufacturers and distributors communicate energy efficiency. Pump systems may account for 40% of industrial energy usage, but they don’t have to. Paving the way towards more energy-efficient and reliable pumping systems starts with training, says Suarez. The HI advocate that training is a top priority as it is critical for teaching first and foremost pump system fundamentals, but also system optimisation and assessment. It also instituted a certification programme for a certification program for Pump Systems Assessment Professionals (PSAP). This program sets the standard for the discipline of pump systems assessment and the use of pump system optimization techniques. Following these developments, the organisation implemented its Lab approval programme to ensure higher efficiency and compliance to test standards. Delivered through a third-party audit it provides pump test labs with the opportunity to demonstrate compliance to their established quality programme, procedures, instrument calibration to ISO 17025 and pump testing to HI 40.6 methods for rotodynamic pump efficiency testing that is referenced to the US Department of Energy requirements. Most recently it launched its energy rating programme – a metric, label, database and utility resources that advance the use of energy-efficient pumps. According to Suarez, while energy and cost savings will vary depending on a variety of factors for different settings, the reality is that by properly selecting pumps and ensuring they have an HI Energy Rating Label savings can be

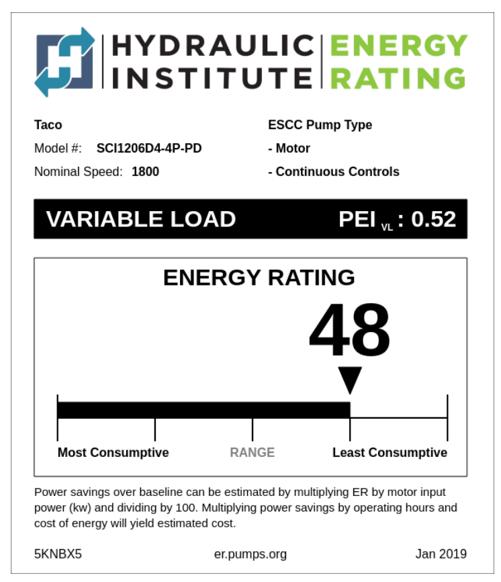

Brand XYZ ESCC Pump Type

Model #: 84

Motor Nominal Speed: 3600 - Continuous Controls

VARIABLE LOAD PEl vt: 0.40

1. BASIC INFORMATION

Pump brand, model number, nominal speed, equipment type, motor and controls (if applicable).

2. PUMP ENERGY INDEX

Calculation comparing the pump’s efficiency to the minimum standard. Lower values are better.

ENERGY RATING 60

Most Consumptive RANGE Least Consumptive

Power savings over baseline can be estimated by multiplying ER by motor input power (kw) and dividing by 100. Multiplying power savings by operating hours and cost of energy will yield estimated cost.

3. ENERGY SAVINGS

Number indicating the percent of power savings over the baseline set by Department of Energy. The higher the energy rating, the more efficient the pump.

4. ESTIMATED SAVINGS

Illustrates the method for using the ER rating to determine actual savings.

increased. “The HI Energy Rating (ER) Label is designed to indicate the power savings obtained from pump system upgrades and changes,” he explains.

Energy Rating

The HI Energy Rating (ER) Label programme is aimed at helping manufacturers differentiate their higher efficiency products and provide ways for commercial and industrial customers to save energy. The rating label identifies energy-efficient pumps and provides a tool for the developers of energy efficiency programs, electric utilities, distributors, and customers to identify energy-saving products. The pumps with the higher ER rating will provide greater energy savings than similar pumps with lower ratings. “With the HI Energy Rating, energy-efficiency program administrators have a new way to encourage adoption of more efficient technology. Through incentives to distributors or rebates to equipment purchasers, programs can encourage commercial and industrial facilities to install more efficient pumps,” says Suarez. “This programme quantifies real savings ultimately paving the way paving the way for pump end-users to be better informed as they purchase pumps and pump systems.” According to Suarez for the process of identifying, understanding and cost-effectively eliminating unnecessary losses while reducing energy consumption and improving reliability in pumping systems, while meeting process requirements, minimizes the cost of ownership over the economic life of the pumping systems, requires one to first see the bigger picture. That means pumps must be selected to meet system requirements. Assessment is another important step as it provides the necessary information required to either further optimize the system or address issues identified. Suarez argues that energy efficiency should be built into the cost assessment. “With the HI Energy Rating, it is possible to capture additional savings when a more efficient motor and/or controls are added to a pump after it has left the manufacturer’s facility,” he explains. This label and certificate respond to the need to identify products that perform more than a representative baseline so that prescriptive incentive programmes can be developed. These programmes will accelerate the adoption of more efficient products into the marketplace and contribute towards broad-based energy savings. Industrial businesses can and do save big over time by implementing these solutions, maintains the HI. Its research has shown that if an industrial plant using 40 pumps operating at an average of 15-hp switched or modified its pumps to achieve an energy rating of 50, that business would save 1.3 million kWh per year which roughly equals R1,7 million ($117 000) in annual savings, more than R18 million ($1,3 million0 in cost savings over an estimate 11-year lifetime of the pump and 114% internal rate of return.

Hydraulic Institute, training@pumps.org, www.pumps.org

FOLLOW US ON :