WORK GROUP & COMMITTEE BULLETIN

By Tanner Perrine, Project Executive, Oregon

A Building for Future Builders: Inside Lane Community College’s ITEC Project

Twenty years ago, fresh out of Oregon State University and entering the construction industry, I noticed an alarming trend: fewer young people were joining the trades. Today, this problem is even more pronounced, with aging workers retiring and not enough new talent stepping in to fill critical roles like electricians and plumbers.

In response to this growing workforce gap, Lane County voters passed a $121 million bond in 2020, funding enhancements at Lane County Community College (LCC). The centerpiece of this investment is the Industry and Trades Education Center (ITEC), a cutting-edge, 55,000-square-foot facility designed to train future generations in construction, mechanical, and advanced manufacturing trades.

Opening this winter, ITEC is more than just a training center. It represents a shift in how we approach skilled labor, challenging misconceptions about the trades and offering career pathways to underrepresented groups. With its state-of-the-art equipment and flexible learning spaces, ITEC will empower students to enter the workforce ready to succeed. Lewis and our trade partners are proud to be part of this transformative project. With construction nearing completion, we’re excited to see how ITEC will shape the future of Oregon’s workforce.

Southwest corner of LCC’s Industry and Trades Education Center earlier this summer

By Maks Goldenshteyn, Communication Manager

Did You Know: Lower-Carbon Concrete Mix Testing

In addition to delivering more energy efficient buildings for our clients, Lewis is working to minimize jobsite construction waste, exploring how we might phase out gas-powered trucks and equipment in favor of the all-electric kind, and making infrastructure improvements at our equipment yard to support those changes.

But we also recognize that our organization’s greener business practices and jobsite operations are only part of the equation.

The biggest opportunity resides in reducing the embodied carbon impact of the structures we put in place. This covers emissions related to extracting, manufacturing, and transporting the building materials we ultimately use, as well as the impacts of construction and disposal.

This year, Lewis became the first regional contractor to commit to reducing embodied carbon from its established baseline by 5% for the concrete placed on all our projects. We’ve met with major local concrete suppliers and structural engineering partners to discuss opportunities to use lowercarbon mixes that minimize the amount of cement with little-to-no increased costs.

We’re also developing test cases for the use of cement replacements—or supplementary cementitious materials (SCMs)—including high volumes of typical industrial byproducts like fly ash and slag and new SCMs being added to the market. In addition, we are testing mixes with alternate materials like biochar that would otherwise release carbon and methane, currently captured in concrete. We’ve received approval to use these non-standard mixes on active projects. We continue to test new low-carbon mixes to better understand their viability in standard construction applications.

By Ben McLean, Communication Specialist

Building Trust Before Breaking Ground

Superintendent Dustin Zyph and his Northshore School District team are renovating and expanding Maywood Hill Elementary School, a project that balances construction deadlines with community needs. Understanding the school’s central role in the lives of students, staff and the surrounding community, Dustin approaches the project with a focus on transparency and collaboration.

From the outset, the team has prioritized communication. They actively engaged with school faculty and nearby residents, providing regular updates about the construction process. “We try to over-communicate with the neighbors and provide venues for them to share their concerns. They have my phone number. I am here to address their concerns,” Dustin said. This level of openness is crucial to building trust and minimizing disruption.

Dustin’s team delivers unwavering commitment to safety on their jobsite. With students returning to the campus while work was still underway, the team worked closely with the school to create safe pathways for children, ensuring drop-offs and pickups were as smooth as possible. Viewing windows along the construction fences were also added, allowing students to safely observe the progress, sparking curiosity without compromising safety. “If we don’t feed their curiosity, we’re going to see children coming into the site, but if we give them a view into what is going on, we help satisfy that curiosity,” says Dustin. Regarding the safe return of students, principal Sonja Hoeft shared, “It has gone remarkably well. Dustin and his team have worked with us on every detail to keep students safe and facilitate a smooth start to the school year.”

By integrating thoughtful community outreach and focusing on the students’ experience, Dustin demonstrates that construction is not just about buildings but about enhancing the environments that shape young lives. His team’s ability to build trust early and maintain lines of communication have paved the way for a successful project at Maywood Hills and positions Lewis for future success with the Northshore School District.

Maywood Hills Elementary

Dustin Zyph standing in front of the jobsite viewing window

By Maks Goldenshteyn, Communication Manager

Passion for his Craft

About a year ago, foreman Jeremy Paschich came to work at one of Lewis’ Meta jobsites with a well-crafted wooden American flag, a find from a local farmer’s market. He was excited to show carpenter Bill Donovan, knowing Bill’s passion for woodworking.

Bill, who’s been with Lewis for 20 years, admired the craftsmanship and asked if he could buy one too. But the merchant’s husband had passed away and she didn’t have any left. Jeremy insisted Bill keep it.

Inspired by the flag, Bill decided to create his own. Since first tinkering with the design, he’s produced 106 custom flags from the workshop in his home garage. Variations include a centennial flag and those with bicentennial commemorative one-dollar coins bearing President Dwight D. Eisenhower. Each flag, which stands 13 inches tall and two feet wide, takes about three hours to complete. Bill starts by laminating pieces of pine or maple together. He then applies wooden stripes to the back to stiffen the form. Grinding it gives the flag a wavy look (like it’s been caught in the wind). Sanding and staining come next before the stars are stenciled. Then comes the paint. Three coats of clear gloss finish are added next. Lastly, Bill burns his name and “Made in the USA” into the wood with a heat stencil.

Bill has gifted the flags to his son and fellow service members, all of whom are currently deployed on a U.S. Navy carrier in the

Given the Navy’s at-sea manning shortages, the hours are long and the work grueling. Sending flags is Bill’s way of showing his gratitude to the men and women who sacrifice for our country each day.

“If I can bring a smile to someone’s face—my son, and his wife who’s raising their kids at home—then it’s all worth it,” he says.

He’s also presented flags to Vietnam War veterans he’s met at car rallies benefiting veterans. Other recipients include FUSION, a Federal Way nonprofit that provides housing to mothers and children. FUSION has auctioned some of the flags off to support FUSION’s mission.

Without any marketing, word about Bill’s handcrafted flags has spread—so much so that he’s been struggling to keep up with demand. One Lewis colleague has purchased seven.

As for the flag that started it all—the original one Jeremy gave Bill—it now hangs proudly on Bill’s porch. Last Christmas, Bill returned the favor by giving Jeremy one of his own handcrafted flags.

South China Sea.

Bill Donovan in his wood shop

By Ben McLean, Communication Specialist

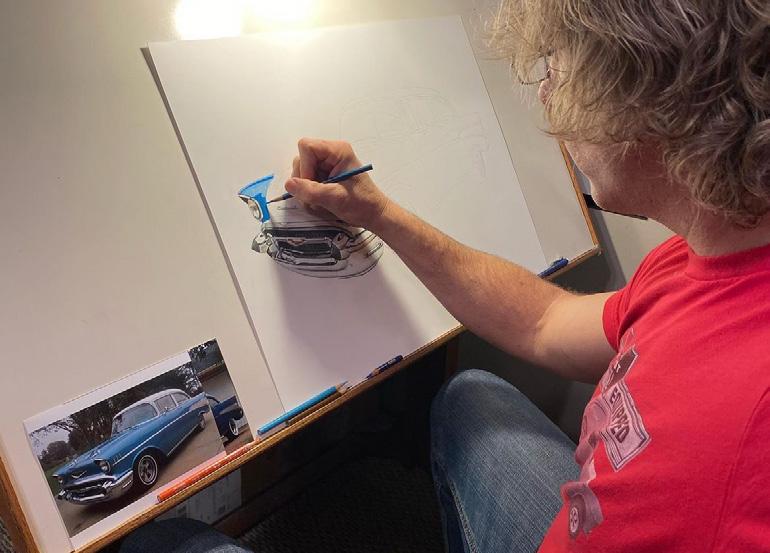

Finding Balance Through Art with Chris Olney

For Chris Olney, superintendent at Lewis’ NTT HI2 project, art isn’t just a hobby—it’s a crucial outlet that helps him find balance in his life. As a lifelong lover of illustration, Chris has found that creating art brings a sense of calm and fulfillment to his often high-pressure job.

“I’ve always been interested in drawing since I was a little kid,” Chris recalls. Inspired by his older brother and supported by a passionate high school art teacher, Chris developed a deep appreciation for colored pencil illustrations. Today, his art reflects his admiration for mechanical objects, with much of his work centered around classic cars and motorcycles. He notes, “I’m a complete car nut,” often blending his passion for vehicles with his creative expression. One of Chris’ endless muses is his 1967 Chevelle, which he’s had since he was 18 and continues to work on, drive and sketch. Chris’ art also allows him to meet people in the classic car world through his print sales and commissions.

For Chris, art represents a form of mental reset. “It keeps me home,” he says, referring to how working on art in his personal space fosters quality time with his family, including his wife and son, who are both artists. It’s also a way to stay to an element of playfulness that reminds him of his childhood and helps him stay grounded in adulthood. “I am just a big kid with a coloring book,” Chris says.

Chris’ meticulous approach to his artwork mirrors his methodical style as a builder. Both roles—artist and superintendent—require patience, planning and attention to detail. He draws a parallel between the two, saying, “You’re creating on both ends... There’s an order to it, there’s a method to it.” His ability to shift between building large-scale construction projects and working on fine details in his illustrations offers a powerful reminder of the value of having outlets beyond work that can absorb some of the jobsite stress in a positive way.

Art provides Chris with a sense of fulfillment, both personally and professionally. This fulfillment makes him a more engaged and present leader at work, a sentiment he echoes about his team: “Working with fulfilled team members creates a positive and productive work environment.”

For Chris, having art as an outlet is not just about creating something beautiful—it’s about achieving a deeper sense of balance and well-being, which, in turn, enhances his ability to lead, connect, and enjoy life.

Chris Olney displaying some of his favorite pieces