Sports Field Forum: October 29 at SNHU

Sports Field Forum: October 29 at SNHU

For nearly 30 years, POLYON® controlled-release fertilizer has been used with confidence for its predictable performance and labor-saving benefits. Industry proven, trusted by sports turf managers everywhere. If your goal is safe, durable and beautifully playable turf – season in and season out – no fertilizer feeds your success like POLYON® fertilizer.

Choose POLYON® fertilizer and you will get guaranteed results backed by our POLYON® Guarantee.

For more information, visit www.polyon.com or contact your Territory Manager today!

JIM FAVREAU MASSACHUSETTS jfavreau@harrells.com (978) 227-2785

MIKE KROIAN RI, MA mkroian@harrells.com (401) 265-5353

TOM LOPEZ CT tlopez@harrells.com (860) 488-2649

JIM WIERZBICKI CT, RI jwierzbicki@harrells.com (860) 424-7250

KENT LEMME NORTHEAST klemme@harrells.com (413) 281-8087

TOM HOFFER NORTHEAST thoffer@Harrells.com (401) 871-2916

IAN WILLIAMS NORTHEAST iwilliams@harrells.com (781) 664-4519

LANCE BLASS NORTHEAST lblass@harrells.com (570) 956-0974

CONNOR CINQUE NORTHEAST ccinque@Harrells.com (603) 930-1861

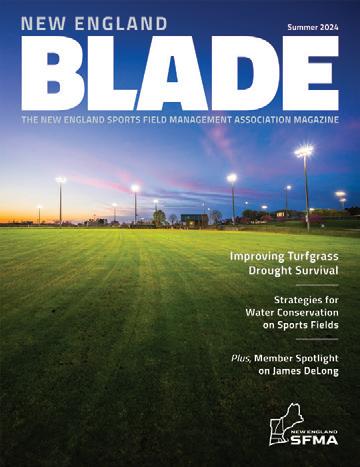

The official publication of the New England Sports Field Managers Association (NESFMA), the New England Blade is dedicated to educating, advising, and informing members of the profession and furthering the goals of the Association. The New England Blade carries news and features related to the sports field management profession. Publisher is not responsible for unsolicited material and reserves the right to edit any article or advertisement submitted for publication and to refuse advertising not in keeping with the goals of the Association. Publisher assumes no responsibility for the validity of claims in connection with items appearing in the New England Blade. Mention of a commercial product does not imply endorsement by the New England Blade, NESFMA, or Leading Edge Communications, or preference over similar products not mentioned. The New England Blade is published quarterly. Subscriptions are complimentary to members of NESFMA. Presorted standard postage is paid at Jefferson City, MO. Printed in the U.S.A. Advertising: For display and classified advertising rates and insertions, please contact Leading Edge Communications, LLC, 206 Bridge Street, Suite 200, Franklin, TN 37064, (615) 790-3718, Fax (615) 794-4524.

Officers

President

Art Goodhind Town of Natick Natick, MA

President Elect

Ryan Bjorn Gillette Stadium Foxborough, MA

Treasurer

Andrew Carlisle, CGM Worcester Technical High School Worcester, MA

Past President

Chris McGinty

Framingham Parks Department Framingham, MA

Directors

Tom Barry, CSFM Greens Farms Academy Greens Farms, CT

Bryan Conant Nashua Parks & Recreation Nashua, NH

Brendon Connor Holy Cross Worcester, MA

Adam Ferrucci

Read Custom Soils Wareham, MA

Scott Lagana Turf Products Corp. Holden, MA

Christopher Lilly

Blackstone Valley Regional Technical Vocational High School Upton, MA

Michael Malvoso

Needham Parks & Forestry Needham, MA

Scott Vose

Tom Irwin Advisors Tyngsborough, MA

Board of Trustees

Mike Lueders Medfield, MA

Edward Olsen

Needham Parks & Forestry Needham, MA

Victoria Wallace University of Connecticut Storrs, CT

Management Team

Virginia Wood Executive Director

Charissa Sharkey

Membership Manager

Peggy Benjamin

Bookkeeper

Technical Editor

Victoria Wallace University of Connecticut Storrs, CT

New England Sports Field Management Association, Inc. 67 West Street Medfield, MA 02052 (508) 653-1241 NE-SFMA.org

XStatic Benefits Include:

• Reduce static buildup on synthetic or artificial turf athletic fields

• Diminish off field migration of crumb rubber, cork and other infill mixes

• Improve field aesthetics and playability

• Protect your investment

I hope this message finds you all well and that your summer was successful, fun and relaxing. As I write this message, I am soon leaving for my annual summer vacation to the Finger Lakes Region of New York state. I always look forward to the slower lifestyle pace and the beautiful landscape that the region provides.

This summer I had the pleasure of visiting another beautiful landscape at the UMass Turf Day in Deerfield, MA. As always, this event is a rewarding and education packed day on the turf plots. I also enjoy this day for another reason, reflection on the past. Not only am I an alum of UMass and the Stockbridge School, as a kid my grandparents would take me up to the top of Mount Sugarloaf (a butte for those who remember from soils class) which overlooks the turf plots. I like to look up at the summit, remember those simpler days in life, and catch up with my grounds crew friends from Amherst College, the place where I was first introduced to Sports Turf Management.

As much as I was inspired back then, I know the Mark DeWolf Golf Tournament was a success and inspired two folks in the industry. Thank you to all those who participated and congratulations to our scholarship recipients Tessa Hospod and Trent Levesque. I find comfort in knowing we are inspiring a new generation of professionals and honoring the legacy of our friend Mark DeWolf.

As we conclude this year’s golf tournament, your Board members remain hard at work preparing for our next event and publication. Please mark your calendars for the Sports Field Forum on October 29 at Southern New Hampshire University. We are excited to share the opportunity to tour this campus and learn about the schools’ newest renovation projects. Thank you to James Gassman for hosting our community.

In this issue of The Blade, a special thank you to Scott Vose for his efforts to bring us an in-depth look at certified turfgrass seed production. We plan to bring more member specific content to future issues of The Blade. If you have a special project or something else you feel we would all benefit in learning about please share!

Cheers,

Art Goodhind

NE-SFMA President

These companies support NE-SFMA with their membership investment and involvement. Please be sure to thank them for their support of our industry as you do business with them throughout the year.

A-OK Turf Equipment – aokturfequip.com

A.R.Plante Materials & Earthworks, LLC –arplantematerials.com

Activitas, Inc – activitas.com

BASF – basf.com/us/en

Brock USA – brockusa.com

Championship Turf Services – turfchamps.com

Covermaster Inc. – covermaster.com

Finch Turf – finchturf.com

Franklin Paint Company – franklinpaint.com

G.P.S. New England – Greg Albanese

Game Ready, Inc – Gamereadyfields.com

Golf Course Management, Inc. – Michael Hightower

Greenhaven Turf Care – greenhaventurf.com

Harrell’s – harrells.com

Hayner Swanson Inc – hayner-swanson.com

Kaestle Boos Associates – kba-architects.com

Liberty Landscapes, LLC –libertyathleticfieldcontractors.com

Mainely Grass – mainelygrass.com

MJ Cataldo Inc. – mjcataldo.com

Mountain View Landscapes & Lawncare –mountainviewinc.com

MTE, Inc. – mte.us.com

Natural Tree & LawnCare – naturaltree.com/about New England Pro Greens & Turf – turfinstaller.net

North Turf Inc. – Northturf.com

Northeast Nursery Inc – northeastnursery.com

Osborne Organics, LLC – osborneorganics.com

PBI Gordon – pbigordon.com

Pioneer Athletics – pioneerathletics.com

R.A.D. Sports – radsports.com

Read Custom Soils – readcustomsoils.com

Replay Maintenance USA – replaymaintenanceusa.com

S & D Landscapes, LLC – facebook.com/LandscapeVermont

Sherwood Sportsturf – Chuck Sherwood

Silico Turf LLC – silicoturf.com

SiteOne – siteone.com

Sodco, Inc. – sodco.net

Specialized Turf Services, Inc. – sportsturfspecialties.com

Sports Fields Inc. – sportsfieldsinc.net

Sports Turf Specialties, Inc – sportsturfspecialties.com

Syngenta – greencastonline.com

Target Specialty Products – TurfFuel.com

Tartan Farms LLC – tartanfarmsri.com

The Charles C. Hart Seed Co. – HartsTurfPro.com

Tiny Mobile Robots – tinymobilerobots.com

Tom Irwin Advisors – tomirwinadvisors.com

Tom Irwin, Inc. – tomirwin.com

Tuckahoe Turf – tuckahoeturf.com

Turf Products Corp – turfproductscorp.com

Turf Robotics – turfroboticsllc.com

Turface Athletics – turface.com

US Playground Surfacing – USPlaygroundSurfacing.com

Welch Mechanical – Welchmechanical.com

Participation is limited, so please be sure to sign up early at NE-SFMA.org!

Interested in sponsoring? Contact Charissa Sharkey at Csharkey@NE-SFMA.org.

Join NE-SFMA for an intensive, case study-based forum designed for sports field professionals looking to gain insights into every phase of baseball field renovation. From initial planning and budgeting to design, construction, and post-project evaluation of an actual project at SNHU, industry experts will provide the tools and practical knowledge needed to manage successful ballfield renovations that meet the highest performance, safety, and sustainability standards.

Whether you are an athletic field manager, groundskeeper, facility manager, or athletic director, NE-SFMA’s Sports Field Forum at SNHU is an opportunity to enhance your knowledge and skills. Stay ahead of industry trends and learn from the best as you continue to ensure the safety and performance of your athletes and your fields. Sign up by October 15 and save! NE-SFMA.org

UMass Turf Program announced that Evan Mascitti, Ph.D. has joined the UMass Stockbridge School of Agriculture faculty. In a new position entitled Urban Managed Landscapes, his role builds off the legacy of longtime Turf Agronomist Dr. Scott Ebdon.

As a geologist turned groundskeeper, Evan comes with a strong academic background, including M.S. and Ph.D. degrees from Penn State, complimented by significant experience in industry. His career has taken him to prestigious sports venues from Citi Field to PNC Park, maintaining turf, coordinating renovations, monitoring irrigation, and optimizing cultural practices. In his most recent position, at Biocore LLC, he honed his research skills in surface testing as it relates to athlete injury and performance.

Evan will serve as the primary instructor for the Introduction to Turfgrass Management course and develop additional courses for turf and horticulture students in the Stockbridge School of Agriculture. His research program will broadly address current issues relevant to urban landscapes, including sustainable management of lawns, golf courses, sports fields, and other green spaces. This research will serve as the foundation for Extension and outreach activities to New England stakeholders and will include establishment of trials at the Joseph Troll Turf Research Center.

By Gary Sykes, Executive Director, NERTF, Inc.

is a big year for turfgrass research here in New England and with the New England Regional Turfgrass Foundation (NERTF). We recently finished our 28th annual turfgrass conference and show and we are delighted to report that attendance was up, and we experienced a nice increase in sold booth space. The conference and show are what fuels our capability to invest in turfgrass research. The Live Auction and Tee-Up New England also bring in important revenue to help expand research opportunities.

In the New England area, we have three universities that can do active turfgrass research and educate the future generation of turfgrass professionals. Over these 28 years the NERTF has secured $2,787,000 in research funding. In 2025, the foundation, feeling a little behind on funding since Covid, decided to expand funding this year to cover all the research proposals that were submitted for 2025. This added $130,513.00 to an already committed $68,073.00 for funding this year. This boosted the total funding for 2025 to a total of $198,586.00. This will be our largest funding year in our history. One reason the foundation could commit to this amount was the generous donation of $10,000 from the RIGCSA to the foundation helping to underwrite a joint proposal written by Dr. Nathaniel Mitkowski (URI) and Dr. Geunhwa Jung (UMass) on the traits and identification of a possible new Dollar Spot pathogen.

Below is a chart of information on the current research funding for 2025

We are also delighted to tell you that currently the total funding toward turf research since 1998 is $2,942,826.00 and will be well

Current NERTF Research Funding 2025–2026

over $3M when we total the figures in 2026! Our universities are a great resource for our industry here in the northeast. Our industrial community receives the benefits of diagnostic services, Extension Services, consultation, continuing education, formal opportunities for education resulting in interns and graduates. We have a great responsibility and need as an industry to keep our schools viable through research funding and education support. These schools will help to grow our industry today and as we look to the future.

The NERTF was formed in 1996 to bring together all the turfgrass industry in New England to support our turfgrass education and research programs at state universities and to encourage greater support to the turfgrass industry in New England as a whole. The foundation is proud to make two statements: 1) We are a Turfgrass Foundation that supports all types of turfgrass managers. 2) That the foundation is truly a regional organization designed to prioritize the turfgrass needs of all the New England and surrounding states here in the Northeast. Those needs might include turfgrass research, education, networking, consulting, etc. Our conference and trade show are the center of the turfgrass industry activities. Currently, the foundation is preparing for its 29th turfgrass conference and show to be at the Rhode Island Convention Center in Providence on March 3-5, 2026.

The foundation is governed by the following associations:

• Connecticut Association of Golf Course Superintendents (CAGCS)

• Golf Course Superintendents Association of Cape Cod (GCSACC)

• Golf Course Superintendents Association of New England (GCSANE)

• Maine Golf Course Superintendents Association (MGCSA)

• Massachusetts Association of Lawn Care Professionals (MALCP)

• New England Sports Field Management Association (NESFMA)

• New Hampshire Golf Course Superintendents Association (NHGCSA)

• Rhode Island Golf Course Superintendents Association (RIGCSA)

• Vermont Golf Course Superintendents Association (VtGCSA)

Editor’s Note: Members Mike Buras and Ben Polimer are NE-SFMA’s representatives to the NERTF board of directors. We appreciate their hard work on behalf of the sports field profession in New England.

PROJECT NAME 2025 2026

Investigating the Efficacy of Fluazinam Fungicide as a Tool for Managing Fungicide Resistance Dollar Spot Populations, Dr. Geunhwa Jung, UMass

A Chemical Scent Lure to Attract Bumble Bee Queens to Nest in Irrigation Valve Boxes, Dr. Steve Alm, URI $12,573.00 $12,573.00

Pure Urea Fertilizer (46-0-0) in Granular Form as a Fungicide Alternative to Control Turfgrass Diseases Including Dollar Spot and Brown Patch, Dr. Geunhwa Jung, UMass

Insect Biodiversity and Management in the Grassy Natural Areas on New England Golf Courses, Dr. Olga Kostromytska, UMass $9,500.00

Autonomous and Conventional Mowing Strategies Impact on Mowing Quality, Turfgrass Quality and Disease Incidence in Four Turfgrass Species Dr. Jason Henderson, UConn $41,426.00 $42,421.00

Evaluating Factors Impacting the Winter Survival and Spring Recovery in Cool-Season Turfgrasses, Dr. Michelle DaCosta, UMass $26,138.00 $27,054.00

Identifying Key Factors Contributing to the Increased Aggressiveness of Dollar Spot in Early Fall*, Dr. Nathaniel Mitkowski, URI, Dr. Geunhwa Jung, UMass $34,000.00** $0.00

Management of Yellow Ring Symptoms Associated with an Emerging Turfgrass Pathogen, Dr. John Ingugiato, UConn $28,949.00 $27,274.00

*The RIGCSA has agreed to share $10,000 of the cost of this research proposal. ** URI-$2,000.00 & UMass $32,000.00 Funding Split $198,586.00 $109,322.00

Itwas a perfect summer morning as nearly 100 players teed off for NE-SFMA’s annual DeWolf Memorial Golf Tournament. Members and friends enjoyed a great day of golf, camaraderie, and friendly competition—all in support of the association’s Scholarship and Benevolence Fund.

After a round on the scenic course, players gathered for a barbeque lunch, prize presentations, and a special highlight of the day: awarding the first-ever DeWolf Outdoor Education Scholarships. Congratulations to recipients Tessa Hospod and Trent Levesque, two promising students preparing for bright futures in the sports field management industry.

In her remarks, Tessa expressed gratitude for the association’s support, noting the importance of mentorship in her academic journey. She also shared her commitment to “pay it forward” to the next generation of professionals—a sentiment that captured the spirit of the day.

Thanks to all who participated, volunteered, and sponsored this memorable event. We can’t wait to see you back on the course next year for the third annual DeWolf Memorial Golf Tournament! •

August 13 DeWolf Memorial Golf Tournament provided an opportunity to celebrate the future of our industry. NE-SFMA Treasurer Andrew Carlisle presented the inaugural Mark DeWolf Outdoor Education Scholarships, honoring the legacy of Mark DeWolf, a lifelong sports field manager and passionate outdoorsman. Each scholarship provides $1,500 to support students pursuing careers in turfgrass and environmental sciences.

Tessa, graduate research assistant at UConn under Jason Henderson, is studying the agronomic benefits of turfgrass maintained by autonomous mowing. A recent NE-SFMA member, Vice President of the UConn Turf Club, and volunteer on the Softball Little League World Series agronomy team, she credits mentorship for her success and plans to “pay it forward” to the next generation of sports field professionals.

Contest Sponsors Tournament Tees

Trent, a recent graduate of Cape Cod Regional Technical High School, has gained hands-on experience at landscape companies and farms while actively competing in FFA statewide competitions in turfgrass, nursery, and landscape construction. Passionate about ecosystem restoration, sustainability, and renewable energy, he will begin studies this fall at UVM’s School of Environment and Natural Sciences, aiming to “improve life for people and the planet.” •

linkedin.com/company/theturfzone

x.com/theturfzone

Associate Athletic Director -

Southern New Hampshire University

Manchester, New Hampshire

How did you get your start in the sports field industry?

I studied sports management at Springfield College. I loved the business side of college athletics but also worked on the maintenance side at Baker Hill Country Club over the summers. After four summers at BHCC, I graduated and started coaching and working as a Second Assistant Golf Pro at Lake Sunapee Country Club managing the pro shop, corporate outings, cart barn and helping with maintenance when needed.

Where did you go from there?

Looking for a full-time job, I started my master’s at SNHU in athletics in 2006. After completing my master’s degree, I was promoted to a full-time position of Equipment Manager, which then turned into the Assistant Athletic Director, and then Associate Athletic Director.

Who was your mentor when you were first starting out in the industry, and why?

One of my mentors growing up in the sport industry was Bob Turcott at Baker Hill Country Club, as well as Marty Brown at Kearsarge Regional High School. Bob showed me so many areas of the maintenance side of working the golf course, and the fine details that went into everything. Marty showed me the athletics world, and that work isn’t too bad when your job revolves around athletes and competitions.

What’s the best business advice you’ve ever received?

To be a good leader, you need to have great employees: treat them with respect, give them space, but also help when needed. Working in athletics, we have so many areas that we have to account for and knowing when to grind and when to rest is a critical part. I give my operations staff all the credit for the facilities and events we run, as they are the boots on the ground all the time with managing our fields, game operations, student workers, coaches, etc.

What is the next “game-changer” you see on the horizon for the sports turf industry?

I have seen some information on the management of artificial turf. Smart technology: from monitoring the temps of the turf/ moisture levels, as well as maintenance needed in specific areas. This would assist in the need to treat specific areas for grooming, saving the hours of staff grooming full fields/facilities when specific work can be concentrated to extend the lift of synthetic fields. Additionally, the ability to find ways to cool the synthetic fields to assist in the health and wellness of the athletes/coaches that are on the fields.

What’s your favorite / most useful piece of equipment?

I enjoy the 1st Products Turf and Field AERA-Vator, and all the versatility it has with the attachments and maintenance abilities. I find it a great piece of equipment that helps all our natural grass fields, whether freshly sodded or an infield grass area. We can really show each area the attention it deserves all year. Additionally, our pro turf pusher is one of the most beneficial pieces we have. Having the ability to keep our two synthetic fields cleared from snow, we have been able to get in more outdoor practices/games, as well as host local colleges and high school practices/games.

What advice would you share with people starting out in sports field management today?

Be open to hard work. In this industry, there is so much more than just games to manage. The hours that go into the prep of a field, gym, facility for practice, scrimmage, game, or tournament is planned and managed on so many levels. Being able to manage the day-to-day, weekly, monthly, and seasonal needs is hard to really understand when new to a role. Getting to know what you are passionate about, and what you need help with, also will make this industry a much more manageable experience.

Can you share a bit about your family life and / or what you enjoy doing in your free time?

My two very active daughters (10 and 7 years old) who play flag football, basketball, and softball. We also ski, boat, and hike in our “free time”. I enjoy coaching them in their sports, as well as sitting on the boards for flag football, basketball, and softball. I try to give a little insight into options for uniforms and gear, as well as fundraising opportunities, helping the town with field

maintenance, and training local parent/coaches on how to drag/ line fields. I also run a local softball camp in Hooksett, NH as well as sit on the Town Facilities sub-committee board for the local schools in Hooksett. The facilities at SNHU have become a second home for the girls, allowing them to come in and shoot hoops, run the fields, use the gyms, or just run around with their friends. Seeing their interest in college sports has been great.

What have you enjoyed most / find most beneficial about being a NE-SFMA member?

I really enjoy the ability to learn from and network with people in the region on what works for their facilities and fields. Meeting great local companies, many of whom we have purchased equipment from. I have been a part of national committees through work, and been a part of Division I seminars, but with their budgets and locations, many of those areas do not correlate with what we do. Knowing we have to manage four seasons, with many climate changes, the local NE-SFMA has been an incredible resource. •

Editor’s Note: James and his team at SNHU will be hosting NE-SFMA’s Sports Field Forum on Wednesday, October 29, 2025. We appreciate their support of this popular educational session.

By Jason Lanier, University of Massachusetts

Q: What exactly is an “enhanced efficiency” nitrogen fertilizer? Are these essentially the same as “slow-release” sources of N?

A: A great question for this time of year, which is the most important time for fertilizing cool-season grasses. The short answer? No, not really.

Nitrogen (N) is the most important essential nutrient for most cultivated plants, including turf. One of the reasons we fertilize with N is that plant growth is very responsive to N levels. Higher N availability translates to more growth. While we like the idea of vigorous growth and deep green color, a lot of growth can be too much of a good thing. Overstimulation of growth can promote succulent, less resilient plants, stunted root systems, and lots of mowing, which is the most time consuming and costly input for most management programs.

Too much N can also cause problems beyond the turf system. Nitrogen is typically very transient and mobile in the environment, and N that is not quickly taken up by plants is subject to potential loss. Some forms of N readily move with water, either across the soil surface with runoff, or below the reach of the root system with gravitational drainage (leaching). This movement of N into the environment can impair both surface and drinking water.

Some N sources are also prone to conversion to a gaseous form after application, which is subsequently lost to the atmosphere; a process called volatilization. Volatilization losses can be significant under certain conditions (especially warm and damp). While concerns around N volatilization are not as acute as N loss involving water, it contributes to inefficiency and waste. There is also increasing evidence that some gaseous N compounds in the atmosphere can play a role in the greenhouse effect, along with more general impacts on air quality.

Slowly available or slow-release nitrogen (SRN) fertilizer materials (as opposed to readily available, water-soluble N sources, WSN) include water-insoluble N (WIN) materials and various engineered slow-release N technologies sometimes referred to as controlled release nitrogen (CRN). These slowly available sources, which “meter out” the N contained in them, offer valuable opportunities for tailoring N availability to plant needs and reducing “surge growth” and losses via runoff and leaching promoted by excess N availability. Read more about the utility of slow-release N for fertilizer programming in and around Table 12 in Chapter 7 of UMass Extension’s Lawn BMP document.

In contrast, the term enhanced efficiency fertilizer (EEF), by strict definition, most often refers to stabilized N sources. The stabilization process yields fertilizers that behave differently compared to SRN or WIN materials. There are two current stabilization technologies found among nitrogen EEFs for turf:

• Urease inhibitors – Prevent N conversion to the gaseous form, thereby reducing volatilization loss. While these sources can reduce N movement to the atmosphere and improve plant use efficiency of applied N, they don’t necessarily mitigate the potential for runoff or leaching losses of N as described above.

• Nitrification inhibitors – Work to keep more of the N in the fertilizer in the ammonium form. Ammonium is preferred by plants, and is less susceptible to loss routes like leaching relative to other forms of N.

Be aware that recommendations and regulations can sometimes conflate these different N sources and blur the lines between their distinct and varying attributes. Be sure to read labels and endeavor to gain a better understanding of the nuances, benefits, and potential drawbacks of these materials. The take home is that there is a range of fertilizer technologies available today, with bearing on how the N contained in them behaves relative to plant and soil health as well as human health and natural resource protection. It is important to have a sound management plan, and to have a good understanding of how these tools can enable maximum turf performance as well as good environmental stewardship. •

Jason D. Lanier is Extension Turf Specialist and Group Leader in Commercial Horticulture at the University of Massachusetts-Amherst. Reprinted from Hort Notes September 2024.

• De-compaction of Infill

• Deep Grooming

• Rejuvenation

• Magnetic Sweep

• Vacuuming

• Surface Cleaning

• Rotary Brushing

• Add Infill

• Seam Repair

• G-Max Testing

By Scott Vose

hether you’re building new athletic fields, refurbishing a public park, or creating a new campus environment, you want that green space to provide beauty, enjoyment, and recreation for years to come, meeting the needs of today’s generation while protecting those of the future. This is only possible if your project delivers on all three dimensions of sustainability: Community, Environment, and Economy. Maintaining a successful, sustainable greenspace always begins with carefully selecting the right seed for your property. There are many variables that will determine the outcome of your seed after it is sown, but starting with the highest quality seed gives you the best chance at success for years to come. As Dr. Leah Brilman says, “Don’t plant your problems.”

I was very fortunate to join a trip with my colleagues at Tom Irwin, Inc. in August of 2023 to gain more insight into the process of certified seed production. Our hosts from Vista Seed Partners and DLF led us on tours of their facilities from field to bag and everywhere in between, and it is a much more intensive process than I could have ever imagined. The care and attention to detail that their process requires, before a single seed ever makes it into a bag, is truly remarkable. They feel it is their duty to ensure that the turf managers who end up planting and maintaining their grass seed will be successful.

Growing and harvesting turfgrass seed in the Willamette Valley of Oregon yields very desirable commercially available seed. As much as 80% of grass seed in the world is grown annually in this

valley; 400–500,000 acres are dedicated to Perennial Ryegrass seed production alone! In recent years, more production operations have started in Minnesota as well as other parts of the world like Canada and the Netherlands. Canadian/European labeling and testing follow a different process and set of guidelines, and quality of establishment to the end-user may be affected compared to the rigorous testing carried out in Oregon.

It all starts in the field – which we all know as turf managers requires not only experience and specialized equipment, but also a bit of luck with Mother Nature after the seed is sown. Weather is critical from overwintering to pre-harvest, having a direct impact on yield, which drives pricing from year to year. For example, record setting yields occurred in 2021 when weather was

ideal, however the following two years had overly wet winters and long drought periods during the growing season which significantly reduced seed yields.

Marissa McDowell of Vista Seed Partners led us on the tours of two turf seed production farms. She explained how if everything goes to plan and the turfgrass matures to produce a seedhead, the harvest timing is determined by scouts, not the farmers. Both farmers we spoke with said that even after 40+ years of harvesting grass seed, they have never had the same harvest date as the seed scouts predicted. The harvested plants need to dry in the field for ten days before being combined. Harvested seed is blown into bags or bins before cleaning occurs; some of the bins we saw housed 250,000 lbs. of raw seed!

A thorough cleaning process is carried out on the raw seed. We walked a multi-level Carter harvester using six screens to sift out weed seed and vegetative material. Between screening different seed varieties, it takes an entire day to clean the harvester/cleaner. Certified turf seed gets inspected by state regulators, who randomly probe bags, therefore each batch (55,000 lbs.) of seed must go to a lab to be checked multiple times throughout the cleaning process. If testing fails, they run through the screener again, always losing a bit of desirable seed on second cleaning.

The seed sample testing process at AgriSeed, Oregon State Seed Laboratory and other accredited verification facilities starts with compiling a paper trail tracking the history of crops previously grown on the harvested field, the specific cultivar that was seeded, any applications that had been made through establishment and other growing environment details. This ensures there was quality control through the entire field production process.

A grower sends a sample of a batch of a particular seed variety to quantify the quality, which is a major driver of price. It is an extremely sterile and controlled process where Sifters first go through 50g samples using microscopes and pull out any weed seed with tweezers to identify it - tedious work to say the least! Any batches with weed seed are either re-screened or end up being sold as lower quality seeds in the marketplace. The samples are then chilled in a room for seven days at 8C to simulate overwintering. An adjacent room is set at 15-20C with grow light cycles to simulate germination conditions on special trays for individual seeds. They also perform a TZ Salt (Tetrazolium Salt) test to see if the turf seed embryos can produce food for themselves (if they do not, they are likely not viable). They are also able to test if Perennial Ryegrass seed is contaminated with Annual Ryegrass seed by assessing the florescence under a blacklight. This is all regulated by the State of Oregon, which has much more stringent quality checks than Canadian and European turf seed regulators.

Once the purity of the seed is validated by Agriseed or another verification authority, the producer can have it certified and labeled for premium quality, then the bagging (and coating) process begins. Every seed production representative we spoke to talked about the importance of coated seed. The DLF bagging facility was in the process of accepting parts for a new single room, fully automated coating, blending and bagging production line to reduce contamination potential. This is a significant quality control investment, as seed that is blended post-production will have a greater potential for weed contamination or loss of viability when it is handled incorrectly. The facilities we toured had storage conditions that were closely controlled and monitored in massive buildings, ensuring the seed remains viable before being shipped.

At Oregon State’s Lewis Brown Farm, there were NTEP trials for Tall Fescue, Kentucky Bluegrass and Perennial Ryegrass. Additional research was being carried out to determine how different coating thicknesses affect germination, and to compare establishment timing of raw versus coated seed.

A highlight of the trip was a tour of the DLF Turfgrass Breeding Facility led by Dr. Leah Brilman. It was truly special hearing

Dr. Brilman speak on her home turf as she expressed her excitement for the next generation of cool-season grasses and more temperate warm-season cultivars. She explained in great detail how it can take eight to nine generations to develop a desirable trait consistently in one variety. One generation can take two years, so it could potentially take over 15 years to develop the intended trait fully before production can begin. It is an intricate and controlled process of individual monostand establishment, scouting for desirable traits, cross breeding those plants, and growing consecutive generations until the desirable trait becomes inherent.

As weather patterns shift, it is important that our performance turfgrass varieties continue to evolve. Premium varieties offer the benefits of faster establishment and greater resistance to disease, wear, and drought stress. Secondary certifications on seed blends such as TWCA (Turfgrass Water Conservation Alliance) or ALIST (Alliance for Low Input Sustainable Turf) allow turfgrass managers the opportunity to procure and establish higher performance grasses where there may not be as much supporting infrastructure. Seeding with the right turf species and variety for your property is the first step to successful establishment. Timing for successful seeding is critical

- you want to get it right the first time and certified seed helps to ensure you have the best chance of success and are not introducing future problems to your property.

Of course, the laws of supply and demand apply everywhere today, and the Willamette Valley is no exception. If the demand for hazelnuts or another crop increases, more acreage will be converted to nut production than grass seed production. Nuts are grown predominantly on trees, so it is less likely these areas would be reverted to turf seed production once they are converted. Supporting the quality turf seed industry means preserving a vital agricultural economy, protecting rural jobs, and ensuring the continued availability of premium quality seed for sports fields, parks, and greenspaces across the globe. Bottom line: Eat less Nutella, sow more certified turf seed! •

Scott Vose is the Technical Advisor at Tom Irwin Advisors, Inc. and is a member of the NE-SFMA board of directors. Reach Scott at scottvose@tomirwinadvisors.com or (860) 428-5294. Photos courtesy of author.