MANUFACTURING PRODUCTION

INTERVIEW

MPE MAGAZINE SPEAKS WITH ANNE-MARIE, CEO OF STEMETTES

TECHNOLOGY

SUSTAINABILITY BEYOND THE FACTORY FLOOR

MARCH 2023

MANUFACTURING PRODUCTION

ENGINEERING

Pentagon, pro-actively supporting you from the early stages of design assistance right through to mould tool manufacture and repeat production of your injection moulding project. Your new or existing plastic injection moulding project will benefit from years of technical moulding experience!

DESIGN DEVELOPMENT MOULDING TOOLING BEYOND THE MOULD

UK Manufacturing services delivering ease of communication and a smooth supply chain www.pentagonplastics.co.uk | websales@pentagonplastics.co.uk Tel: +44 (0) 1403 264 397 |

invests £100,000 into new ‘Recycle’ offer to support greener packaging solutions Interview - MPE Magazine speaks with Anne-Marie, CEO of Stemettes News - Outsourcing could solve industry’s ‘people puzzle’ predicts PP C&A chief Exhibition - Records broken at successful Southern Manufacturing & Electronics 2023 Technology - Responding to the future: empowering manufacturing with tech innovation

Editors Note

Welcome to the latest edition of Manufacturing & Production Engineering Magazine.

We have two upcoming shows at the end of this month which we are looking forward to attending. Both IntralogisteX and Robotics and Automation are taking place on 28th & 29th March at NEC Birmingham. It is always exciting to see new innovations and to speak with leading names in the industry regarding their applications.

In this edition we have several articles focusing on sustainability, always a topic at the forefront of a company’s decision making. We hear from Umair Ejaz, from Visual Components, who tells us what steps that are being taken in the manufacturing industry to help reduce the carbon footprint.

We hope you enjoy this issue and as always, if you have any news that you would like to feature, please email details to editor@mpemagazine.co.uk

Every effort is made to ensure the accuracy and reliability of material published in Manufacturing & Production Engineering Magazine however, the publishers accept no responsibility for the claims or opinions made by advertisers, manufactures or contributors. No part of this publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including photocopying) or stored in any information retrieval system without the prior consent of the publisher.

03 Manufacturing & Production Engineering Magazine CONTENTS Editor Paul

editor@mpemagazine.co.uk Senior

Francesca

editorial@mpemagazine.co.uk Features

Harry

editorial@mpemagazine.co.uk

Laura

Charlotte

Alex

Richard

accounts@mpemagazine.co.uk

Leo

subs@mpemagazine.co.uk

Maria

maria@lapthornmedia.co.uk Lapthorn Media Ltd 5-7 Ozengell Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB Tel: 01843 808 117 08 28 36 47 50 Lesters

08 50 36 28 47

Attwood

Editorial Assistant

Amato

Editor

Peters

Production/Design

Whitehead laura@lapthornmedia.co.uk Sales Manager

Chapman charlotte@mpemagazine.co.uk Sales Executive

Costa alex@lapthornmedia.co.uk Accounts

Lapthorn

Circulation Manager

Phillips

Publishing Director

Lapthorn

Attwood Editor @mpemaguk mpemagazine.co.uk

Paul

Midtherm lasers in on growth after £1.2m machine investment

A specialist sub-contract laser cutting and forming specialist is reaping the operational and environmental benefits of a £1.2m machine investment.

Midtherm Laser, which employs 45 people at its factory on Peartree Lane in Dudley, has increased its capacity and speed of processing thanks to the installation of a new Bystronic Bystar Fiber 12kW laser with part automation.

One of the largest purchases in its 23-year history introduces the next level of power in fiber laser cutting and will help the company deliver high cutting dynamics and thin to thick

cutting capabilities to a customer base that spans aerospace, automotive and decorative work to food processing, agricultural and conveyors.

It has also made a massive difference to the firm’s environmental performance, with the Bystronic model replacing two older CO2 machines and is already delivering a 50% energy saving – the equivalent of powering 2100 average homes every month.

Midtherm was originally established in 1968 by Ray Andrews and operated through sister companies offering powder coating, enamelling and UV flues. There was a laser cutting machine that was occasionally being used at one of the factories and the decision was taken in 2000 to put it to better use by creating a ‘laser’ business that initially employed just three people.

With orders starting to take off, Ray’s son Richard Andrews moved the business to its current 20,000 sq ft factory on Peartree Lane in Dudley in 2004, with the next big milestone taking place in 2018 when Mark Hannon replaced Dean

Midtherm was originally established in 1968 by Ray Andrews and operated through sister companies offering powder coating, enamelling and UV flues.

Cockayne as Director and took over the operation alongside Richard and Kate Birt.

Today, Midtherm Laser works with more than 500 companies across 20 different sectors, cutting or forming various sheet metal from 0.5mm to 30mm to a +/- 0.25mm tolerance. It is also the only sub-contract laser provider that can offer the cutting of non-ferrous materials without the risk of cross contamination for industries, including food processing and chemical manufacture.

For further information, please visit www.midthermlaser.co.uk

SHD Group announce new factory in Slovenia

SHD

d.o.o. relocate to new 1500m² manufacturing premises.

SHD is delighted to announce that as part of their Group’s ongoing growth plans, and absolute commitment to the highest levels of quality and service in

the prepreg industry, SHD Composite Materials Europe d.o.o. has relocated to new manufacturing premises.

The new factory is a short distance from the original site in Krsko, Slovenia, however the 1500m² factory provides a major increase in

capacity and facilities which creates a substantial foundation for SHD to further expand in support of its dynamic customer base across Europe.

This expansion will immediately double production capacity, enabling the company to maintain its short leadtimes and providing significant scope for longer term growth. The SHD team moved into the facility in September, successfully commissioning all new equipment and have received quality certification following the Group annual AS9100 audit.

Steve Doughty, Managing Director, said: “We are very proud of our new Slovenian plant and the highly skilled team that are based there. Our customers know very well of our 100% focus on excellence in service and quality. This new facility means we now have a solid foundation to support our customers for the foreseeable future. Please feel free to come and visit the plant to see what we do.”

Company News 04 Manufacturing & Production Engineering Magazine

Composite Materials Europe

Wire specialist completes MBO and sets sights on record year

One of the UK’s leading manufacturers of round, flat and profile wire has completed a management buy-out, as it looks to target £15m annual sales for the first time in its 77-year history.

Alloy Wire International (AWI)’s senior management team, comprising Managing Director Tom Mander, Technical Director Andrew Du Plessis and Finance Director Adam Shaw, has purchased the business from the current owners, cementing the Black Country firm’s long-term future.

The deal will see all 33 members of staff become shareholders in the business, reinforcing a company-wide commitment to each other and its 6000-strong global customer base.

The trio have also pressed the button on a near £1m investment drive that will see new wet drawing and single hole dry drawing machines arrive during the course of the year, along with an annealing line spooler and several hundred tonnes of raw material.

Alloy Wire International manufactures round, flat and profile wire in over 60 Exotic alloys, such as Inconel, Monel, Hastelloy, Nimonic and Waspaloy.

Founded in 1946 by John Stockdale in an old ambulance station in Old Hill in the Black Country, the company’s founding principles of ‘manufacturing quality, delivering reliability’ has stood the test of time and remains a crucial part of how it deals with its international customer base.

Today, the firm continues to operate across 15 different market sectors and, despite global supply chain disruption, is still delivering material in just four weeks from the order being placed.

Mark Venables, who led the previous MBO in 2013, is delighted that the new owners have come from within the company.

Alloy Wire International has been supported in the MBO by Andy Wyeth, Corporate Relationship Director at HSBC Corporate Banking’s West Midlands Team, with the company’s existing accountant, BSN Associates, helping structure the deal.

Legal representation for the owners and buyers was by FBC Manby Bowdler and George Green LLP respectively.

For further information, please visit www.alloywire.com

headcount

Manufacturo, a SaaS provider of a cloud-based manufacturing execution system (MES) designed to help manufacturers optimize and synchronize production processes in complex manufacturing industries, announces 360% growth in revenue year-on-year. As well as significant revenue growth, Manufacturo has also nearly doubled the size of its innovation department to continue investing in enhancing its solution’s functional and technical capabilities.

In what is a record year, the company has celebrated significant milestones, including winning deals with new clients in the aerospace, laser communications, and renewables sector, and expanding the Manufacturo product portfolio to 12 applications.

The Manufacturo cloud-based MES solution was designed by a team of SpaceX alumni who have immense experience building software that streamlines the production of rockets, satellites, and user terminals. Manufacturo provides highly configurable and out-of-the-box applications for multiple manufacturing modelsfrom fully automated high-volume

innovation

production to complex manual operations - to efficiently optimize and synchronize production processes at scale. Ultimately, Manufacturo offers end-to-end traceability, rich process planning, and operations synchronization.

VP of Solutions at Manufacturo, James Montgomery, said:

“2022 was a massive year for Manufacturo, as it saw us secure six new key customers, each of whom we consider true partners, as well as expanding the software’s capabilities considerably. Our goal is to make manufacturing processes more efficient for hightech emergent players – many of whom are start-ups or SMEs – and our mission is to enable them to bring their products to market quicker and speed up the time it takes to manufacture at scale.

Andea developed the initial concept of its modern manufacturing SaaS solution in 2018. Two years later, after significant effort spent on concept refinement, design, and testing and with tremendous input and vision from James Montgomery and Kenzo Takai, Andea started building Manufacturo, a solution geared for the rapidly growing, high-tech emergent manufacturing markets.

05 Manufacturing & Production Engineering Magazine Company News

Manufacturo doubles

team

and increases revenue by 360%

GIC and Stourgarden celebrate 21 years of working together

Packaging machine manufacturer GIC and Stourgarden are this month celebrating 21 years of working together, in which time one of the UK’s leading suppliers of onions has seen demand grow by over 500 per cent!

Stourgarden was established by brothers Bill and John Rix in 1995 when they won a contract to supply Tesco.

Today, the third-generation family business still grows onions on the Essex and Suffolk border, as well as sourcing onions locally and from around the world to ensure a year-round supply.

In 2002 Bill approached GIC for a quote to add a vertical form fill and seal packaging machine to Stourgarden’s single packing line. At that time, just 45 tonnes per week were leaving Stourgarden’s site near Colchester. Today, that volume has increased to more than one million packs per week.

The first GIC machines – two VFB2000s – were bought in August 2002 and installed at Stourgarden’s Lodge Farm packhouse in early 2003. Both

VFB2000s featured maintenance-free full servo drive systems, Markem Smartdate coder, discharge pack elevator and a stainless steel drip tray.

As demand for Stourgarden’s onions increased, the company upgraded the VFB2000s to VFB8000s in 2007. Two years later, Stourgarden added a third packing line and ordered another VFB8000. All three machines were upgraded in the summer of 2016, with three GIC8000s being installed. The GIC8000 is a high-speed continuous motion vertical form fill and seal packaging machine capable of handling 65 packs of onions per minute.

The latest generation features maintenance-free Allen Bradley Rockwell servo motor drives for all machine movements, including film feed, crimp jaw opening and closing, and crimp jaw vertical motion.

The ten-inch operator-friendly HMI colour touch screen controls are complemented by tool-free size changing, a fully-integrated coder station, reel run-out detection, and an

glasses, polymers, compounds, composites and other materials to meet the research, development and specialist production requirements of science and industry.

expansion

One of the UK’s leading manufacturers of specialist metals and materials has signed a new commercial agreement with Advanced Energy Minerals (AEM) to support its growing order book in the academic and research sectors.

Goodfellow Ltd, which recently delivered materials to the Lawrence Livermore National Laboratory for the Nuclear Fusion Breakthrough that shook the world, will work with the Canadian company to build high purity alumina powders into its growing range.

The transatlantic deal gives the Huntingdon-based firm exclusivity for sales denominations of up to 20kg per line, covering nine high purity alumina powders, 5 gamma powders and 4 alpha powders.

Goodfellow is a leading global supplier of metals, alloys, ceramics,

Located on Ermine Business Park in Huntingdon, the company has an extensive range of 150,000 catalogue products in multiple forms available off the shelf, most subject to free delivery within 48 hours and with no minimum order quantities.

It also offers a comprehensive range of bespoke processing services, effectively operating as an

out-of-tolerance temperature sensor on the Heat Seal Crimp Jaws.

Such is the build quality of GICs machines that all of the VFB models supplied to Stourgarden are still operating at other food manufacturers today.

As well as supplying the machines, GIC has also serviced them for 21 years, ensuring that the machines operate efficiently and with minimal downtime.

Currently, Stourgarden is supplying Tesco with over a million onions every day. However, in the pandemic’s first week, this reached over two million per day!

For further information: www.gic.uk.net

extension of a customer’s production team to develop custom-fabricated components in any quantity required.

Mark concluded: “Our in-house team comprises fellow scientists and engineers with extensive knowledge of materials and processing.

“Through their technical expertise, and a supporting range of specification tools, we have built an unrivalled reputation for finding solutions to the most challenging of research problems.”

For further information, please visit www.goodfellow.com

Company News 06 Manufacturing & Production Engineering Magazine

International deal paves the way for Goodfellow’s scientific industry

Lesters invests £100,000 into new ‘Recycle’ offer to support greener packaging solutions

One of the UK’s leading large packaging specialists is introducing a new service that will help companies improve their environmental footprint and their bottom line.

Lesters has invested more than £100,000 into creating its dedicated ‘Recycle’ offering that sells used cardboard boxes to existing and new clients looking for a greener and more cost-effective way of transporting their products.

The Burntwood-based company, which now employs 60 people after a recent recruitment drive, is already working with customers in the home and commercial removals and manufacturing sectors and expects sales to double in this area to more than £500,000 over the next twelve months.

Bosses at the family-run firm believe an increasing number of companies will tap into the sustainable benefits of reusing high quality boxes

for moving their goods, with the cost of each box typically 50% less than buying a brand new one.

There is also a host of environmental benefits attached to this approach and these can be factored into a business’ commitment to becoming Carbon Neutral or Carbon Negative.

Interest in this latest offer from Lesters has surpassed initial expectations and the company is now actively looking to buy back boxes it has sold whilst also purchasing used boxes manufactured by other firms.

A new marketing and social media campaign is being launched to raise awareness and educate other businesses on the benefits of looking at alternative packaging options.

It has been a whirlwind period for Lesters over the last two years, with fifteen staff taken on across production and in admin/support, whilst a second shift has been introduced to keep up with demand.

This has helped support the design and manufacture of a growing range of products, including octabins, pallet boxes, heavy duty packaging, bespoke die cut units, corrugated cartons, and retail ready packaging.

The ‘large packaging’ specialist is also keen to innovate the materials it uses, as well as looking for new applications outside the world of packaging.

For further information, please visit www.lestersrecycle.co.uk

Tugdock Limited has announced a partnership with Sarens, the global leader and reference in crane rental services, heavy lifting and engineered transport. To support the further growth of Tugdock, Sarens have invested in the start-up company, which is based in Cornwall, UK. The partnership will enable the two companies to offer a novel solution to the fast-growing floating offshore wind industry.

Lucas Lowe-Houghton, Director of Business Development for Tugdock, explains: “The floating offshore wind

sector is expected to continue to grow rapidly. However, very few of the world’s ports have sufficient water depth and assembly quay space to build the huge turbine floaters required and conventional dry docks are not wide enough as they were originally designed for ships. Tugdock’s patented marine buoyancy bag technology solves this issue. It allows floating dry docks to be delivered by road in modular form and assembled at the port to dimensions far wider than most of the world’s existing dry docks.”

Lucas continues: “Our submersible floating dry docks can operate with as little as 5 metres draft, enabling more efficient wind turbine floater construction. The platform is then towed to deeper water for launching of the turbines. More than 8% of the total cost of a floating offshore wind farm is accounted for by assembly and installation. So, any innovation that allows this process to be carried out more efficiently and quickly will have a big impact on profitability for developers.”

Floating offshore wind turbines are located in areas where there is deeper water and higher winds than fixed wind turbine structures, enabling them to generate higher levels of power. This means they are expected to play a key role in the transition to net zero. Over 20 gigawatts of floating offshore wind power is expected to be commissioned globally

by 2035, requiring over 2,600 wind turbines.

Carl Sarens, Director of Technical Solutions, Projects & Engineering at Sarens, said: “Through this partnership with Tugdock, we are able to streamline the solution we offer to developers.

“By significantly reducing time and costs, our alliance will deliver a step change for wind turbine construction. In addition, Tugdock’s flexibility and reusability is useful to global developers as the units can be reused from one port or project to another regardless of changes in turbine size or foundation weight.”

Shane Carr, CEO of Tugdock, said: “Working in partnership with a large multinational such as Sarens will accelerate our development, enabling further innovation to keep us at the forefront of the floating offshore wind industry.”

Simon Cheeseman of the Offshore Renewable Energy Catapult (the UK’s leading technology innovation and research centre for offshore renewable energy) said: “Tugdock have created a brilliant innovative solution to enhance port capacity and meet one of the most significant infrastructure challenges facing the fast-growing floating offshore wind industry. Their partnership with Sarens will accelerate use of this solution by floating offshore wind developers across the world.”

Company News 08 Manufacturing & Production Engineering Magazine

Pioneering partnership to deliver innovative solution for floating wind industry

Galvanizing process futureproofs leisure centre

A multi-million-pound, state-of-theart leisure centre has been unveiled in Helensburgh which will withstand the elements – being located right next to the sea.

Hosting a swimming pool and gym, the main contractors responsible for the project, Heron Bros Ltd, commissioned Walter Watson to create the structure of the large building. They created the framework using steel, but due to its seafront location, sought assistance from Scottish Galvanizers Ltd to ensure the components would be protected against rust and corrosion for years to come.

The steel was fabricated in sections –some of which were up to 11.6m long –before being sent to Scottish Galvanizers to be hot-dipped in its molten zinc galvanizing bath. As no other coating process has the ability to cover all areas of the steel and without the need for regular maintenance, galvanizing offers the greatest resistance to damage and corrosion – crucial to endure the sea air.

Trevor Irvine, General Manager of the Structural Division at Walter Watson, said: “This was an extremely exciting project, and a facility we hope will be enjoyed by the local community for many years. To ensure this, we wanted to guarantee that the steel framework would be protected from the elements and called on our long-standing partners, Scottish Galvanizers, to assist. We’ve worked with them many times, and can always rely on Paul and his team in Glasgow. Despite the issues and delays the construction industry has faced over the past few years, they always deliver on time and to the highest of quality”.

Paul Tait, Sales Manager at Scottish Galvanizers Ltd, added: “It’s been a great pleasure to be involved and play a part in this project. We’re sure the leisure centre will be enjoyed by many people within the local community for years to come – and, thanks to the galvanizing process, it’s fit for purpose”.

Scottish Galvanizers Ltd is part of Wedge Group Galvanizing Ltd, the largest hot-dip galvanizing organisation in the UK with a history dating back over 150 years. With 14 plants strategically placed across the country, the firm offers a truly national galvanizing service.

For further information please contact Wedge Group Galvanizing on 01902 601944 or visit www.wedge-galv.co.uk

09 Manufacturing & Production Engineering Magazine

Call 01664 567226 for more information www.dualpumps.co.uk UK Official Distributor Since 1983 celebrating 40 Years Your trusted partner since 1975 Follow / Like / Subscribe Dependable Under Pressure Company News

More than 8% of the total cost of a floating offshore wind farm is accounted for by assembly and installation.

Compressed Air Pumps & Valves

Achieving Pneumatic Cylinder Longevity in Harsh Environments

By Japh Humphries, UK Sales & Commercial Manager, Matara UK Ltd

Pneumatic cylinders are an efficient, reliable and clean solution for moving loads in a linear direction (back and forth or up and down), with good levels of force and speed.

Pneumatic cylinders use compressed air as the input source to move a load. There are various pneumatic cylinder types, including single-acting, double-acting and rodless. Most contain a piston inside the cylinder, and the compressed air is pushed in at one end of the cylinder and acts upon the piston within the contained environment to translate the energy into movement, using a rod to move the external load. In the case of rodless cylinders, these are engineered to perform as a self-contained linear actuator with the piston moving within a cylinder bore, for improved flexibility.

Unlike a hydraulic cylinder which uses fluid and therefore comes with a risk of leakage or cross-contamination, a pneumatic cylinder relies solely on air, making them suitable for use in a vast array of mechanical applications (although generally in fixed installations as moving large air compressors around is not ideal or easy!).

At the heart of a linear motion system

Cylinders are often the most important component of a linear motion system. If the cylinder fails, the linear motion system is unable to function and, in most instances, the machine it is part of and even the entire production line is out of action until the cylinder can be replaced.

This downtime is undesirable in any setting, but in a harsh environment where contaminants are heavily present,

standard cylinders are going to fail all the more frequently, resulting in greater downtime. Cylinders can be contaminated internally from the air supply or externally from the operating environment. In the case of the latter, seals become damaged from particles and corrosive elements in the immediate atmosphere, which are then able to enter the main workings of the cylinder, reducing the effectiveness and life of that cylinder.

What environmental factors impact cylinders’ longevity?

Airborne particles in the form of dust and grit are the most obvious threat to cylinders. If this penetrates a nose seal, it builds up and sits in seals and bearings with a similar effect to sandpaper. In a normal environment, with regular preventative maintenance, standard cylinders can cope well with basic levels of dust, but where these contaminants are prevalent, such as flour mills, mines and quarries, a more robust cylinder must be considered.

Water may not be deemed a contaminant in the usual sense, but when it comes to pneumatic cylinders it is very much a problem as where there is compressed air, there is water vapour. Furthermore, there are a number of industries, including food and pharmaceutical, where washdowns are conducted regularly and very thoroughly. In these situations, the water collects within system components where it can block the flow of air through orifices, dilute or adulterate lubricants, corrode the barrel or rod finish and, of course, freeze in cold weather.

Contamination from synthetic oils used to lubricate the air compressor can have a similar impact on cylinders to water, in that it can block orifices, as well as causing seals to swell. In harsh environments, greater quantities of lubricant are often used, which makes the contamination situation worst.

In applications where extreme heat is used, and/or where chemicals, paint or weld splatter are present, the piston rod and rod-seal are prone to damage.

10 Manufacturing & Production Engineering Magazine

Cylinders are often the most important component of a linear motion system.

- Japh Humphries

So, these are the problems, but what are the solutions?

Selecting a cylinder for harsh applications

First and foremost, invest in cylinders that are manufactured and sealed to a high quality from a well-established, recognised manufacturer. You really do get what you pay for!

However, for really harsh environments you will need to look to a more customised cylinder. The good news is, most of these customisations are relatively straightforward and represent a good ROI.

Let’s start with the cylinder seals, these being one of the most important means of preventing the ingress of dirt and water. Standard seals can be replaced with specialist versions to meet the needs of your specific application. Viton™ - a fluoropolymer elastomer and synthetic rubber compound - seals, for example, have been designed for use in some of the harshest environments,

where temperature extremes and chemical interactions are common. These can readily be used in Matara’s standard rod type pneumatic cylinders and rodless pneumatic cylinders.

Moving further into the cylinder construction, with rod type pneumatic cylinders a rod seal/wiper can be incorporated to both stop contaminants from entering the inner body of the cylinder, with the wiper removing larger particulates from the rod. For added protection the rod can be fitted with a rod bellow/gaiter which keeps contaminants away from piston rods.

When it comes to corrosion prevention, then you may need to consider going further than just swapping out seals for more tougher versions. For corrosive environments, including those where regular washdowns are conducted, the choice of rod material may need to be reconsidered. Standard rods are mostly manufactured from chrome, but swapping to stainless-exercised steel rods and fasteners, or even a stainlesssteel rod, will provide extra protection against corrosion. This will impact the cost, usually by an additional 10% of the overall cost of the cylinder. For complete corrosive protection, Matara offers a range of 100% stainless steel pneumatic cylinders.

The other option is to stick with existing materials but use specialist coatings or epoxy paints. There are a good range of options here, including Armoloy TDC® coating, which we use on our linear rail and ballscrews for maximum longevity in

demanding applications and locations. Armoloy TDC® is a hard (78Rc), thin, dense chromium coating with a micronodular surface texture which provides corrosion protection equal to 440 series stainless steel.

Maintenance matters

Having selected the right cylinder type for your environment, it’s important to conduct basic preventative maintenance to a regular schedule. This should include the regular cleaning of external parts of the system so that visual inspection of seals and other parts is straightforward; inspection for wear and tear; draining of air line filters and checking that the water traps are operating as they should; lubrication of the cylinder, rod seal, piston seals and surfaces; checking for air leaks and resealing where required; and last, but not least, replacement of air filters.

Harsh environments make for difficult operating conditions, but by selecting quality pneumatic cylinders customised to your specific site, you can costeffectively prolong the service life of a cylinder and reduce costly downtime.

Matara designs and manufactures pneumatic and linear automation products, which are available from stock or can be custom built to order.

11 Manufacturing & Production Engineering Magazine

www.matara.com Compressed Air Pumps & Valves

Invest in cylinders that are manufactured and sealed to a high quality from a well-established, recognised manufacturer.

- Japh Humphries

Sustainability high on Manufacturing SMEs’ agenda despite economic headwinds

• 81% of the UK’s Manufacturing SMEs are actively moving to become more sustainable

• 77% believe their firm already behaves sustainably

• 73% say being a sustainable business is important

The message about needing to move towards a more sustainable future is being heard by the UK’s Manufacturing SMEs as they actively plan for a ‘greener’ way of doing business, according to the latest independent research from Close Brothers Asset Finance and Leasing.

The data reveals that 73% of those polled state being a sustainable business is important to them while a further 81% believe their firm already behaves sustainably.

Over four in five firms are actively enacting plans to become more sustainable, while 60% have set goals to make their firm greener and more efficient, providing hope that the ‘green revolution’ is beginning to gain traction among the UK’s smaller firms who aren’t waiting for larger businesses to take the lead.

According to the CBI, the UK risks falling behind Europe, the US and Asia in the race towards investing in green technology if more action isn’t taken soon; however, according to the research, 63% of firms have already invested in technology to help them become more sustainable. This finding

clearly demonstrates the willingness of business owners to spend capital on green technology in spite of the many challenges they face, including inflation, interest rate hikes and subdued demand.

“These results make for very encouraging reading,” said Steve Gee, CEO of Close Brothers’ Industrial Equipment Division. “The message about the need to move to a greener way

of living has landed and is being heard loud and clear.

“Every business has a clear duty to act responsibly towards the environment and we are working with firms across the UK on renewable energy projects, from onshore wind farms, solar energy installations, battery storage projects and landfill CHP projects, to name a few. Clearly, action needs to be taken across the board but, speaking with our customers, there is a huge amount of innovation taking place.”

Myles McCarthy, Group Head of Sustainability at Close Brothers added “With the rising cost of energy and a clear trajectory for a more sustainable UK economy, it has never been more important for UK businesses to unlock the benefits energy efficiency and renewable energy can deliver. Savings in energy use not only help financially but also demonstrate to a company’s stakeholders (including its customers and staff) that it is meeting its climate goals and responsibilities.”

For more information, please visit: closeasset.co.uk/manufacturing

12 Manufacturing &

Engineering Magazine

Production

Asset Finance

Close Brothers Asset Finance is a trading style of Close Brothers Limited. Close Brothers Limited is registered in England and Wales (Company Number 00195626) and its registered office is 10 Crown Place, London, EC2A 4FT. Our team of experts can help you defeat the mounting cost of doing business. We offer a range of flexible options that can allow you to: • Unlock the value of existing assets • Invest in new equipment • Create positive cash flow Our quick lending decisions and industry knowledge, enable our customers to unleash the value in their business. Contact us today to find your superpower. closeasset.co.uk/mpe Combat rising costs

Record year delivers a perfect 30th birthday present to Spillard Safety Systems

The UK’s largest specialist safety equipment provider is celebrating thirty years in business by securing a record sales boost and drawing up plans for a new facility.

Spillard Safety Systems, which was founded by Vic Spillard in his garage in 1992, has just completed its best-ever 12 months, with the launch of the pioneering Spillard Live platform driving orders past the £7m mark.

The intuitive cloud-based platform captures and streams real time video and analytics simultaneously from multiple cameras fitted to plant equipment and commercial vehicles, reducing risks, protecting lives, and saving industry millions of pounds.

AF Blakemore, Lomas Distribution, Carlsberg Marston’s, Flannery Plant Hire and Severn Trent have already signed up to the technology, joining over 300 other companies and 12,000 vehicles connected to Spillard Live.

The surge in demand has seen the company take on ten

CGTech Celebrates 35th Anniversary

CGTech, developer of VERICUT CNC machine simulation software, is proud to celebrate 35 years of growth and innovation in CNC simulation and optimisation in 2023.

new people across all areas of the business and put in place plans to expand into an additional 27,000 sq ft site later this year.

‘Spillard Live’ is based on an award-winning Internet of Things (IoT) platform that can track a vehicle in real-time with live video and analytics.

It captures, processes, and learns from multiple sources and has been designed so that it is compatible with any device capable of transmitting datasets.

The data received is analysed using complex algorithms to improve driver behaviour, so much so that audible alerts can be sent to notify employees that their actions are being recorded - a feature that has been proven to have a positive effect on their behaviour.

This all helps companies with their compliance and accountability, two increasingly important features of doing business.

For further information, please visit www.spillard.com

“Whether it’s milling, turning, millturning or any other CNC-machining, VERICUT® is the industry standard to simulate CNC machines, as well as optimise and verify NC programs,” says Margaret Schmitt, President of CGTech.

“For 35 years, CGTech’s technology leadership and experienced team have helped VERICUT evolve together with our customer base.

“CGTech’s solutions are deeply entrenched in the aerospace industry’s history, and adopted today across industries ranging from oil and gas to Formula 1 racing.

“People are at the heart of CGTech’s success and have made it what it is today: an innovative software company driven by team spirit and customer care.”

CGTech was founded by Jon Prun in 1988, when he recognised the need to verify NC tool path programs without taking valuable machining time to prove-out a part. VERICUT was the first widely available method to test machine tool paths in a virtual environment. The software has grown to be the leader in the NC program verification space and has since expanded its original capabilities to include physics-based optimisation with its Force module, composites programming and simulation, as well as additive and hybrid processes.

VERICUT is 100% developed in-house by software engineers and leaders experienced in manufacturing and the CAD/CAM space.

Improvements are made with each release to support complex multi-axis kinematics, further reduce cycle times, increase tool life, and further optimize the simulation. New features are also continuously being developed, including live CNC machine monitoring features, tool performance optimisation, and more.

Events & Awards News 14 Manufacturing & Production Engineering Magazine

Science and Technology

Nuclear Science and Technology

MSc - 1 year full time

time part time Certificate for CPD

MSc - 2 or 3 year part time

MSc - 1 year full time

PG Diploma • PG Certificate

MSc - 2 or 3 year part time (Taught and Distance Learning)

PG Diploma • PG Certificate

Designed

Short Courses for CPD

generation of nuclear engineers skills to secure a sustainable

Key

Designed

Short Courses for CPD info.ntec@manchester.ac.uk

Key features:

For

•Flexibility

•Short-course format

For more information:

of nuclear engineers and

a

and

for

to create a generation

scientists with the skills to secure

sustainable

safe future

nuclear energy.

or visit

Register at: Course delivered by: The University of Birmingham • University of Central Lancashire • The University of Leeds • The University of Liverpool The University of Manchester • The University of Sheffield • The Nuclear Department of the Defence Academy

www.ntec.ac.uk

features: Demand-driven • Breadth of learning • Delivered by experts • Flexibility • Short-course format

nuclear energy.

Register at: Central Lancashire • The University of Leeds • The University of Liverpool University of Sheffield • The Nuclear Department of the Defence Academy

more information: email: info.ntec@manchester.ac.uk or visit www.ntec.ac.uk

learning • Delivered by experts • Flexibility • Short-course format

Breadth of

to

a generation of nuclear engineers and scientists with the

to secure a sustainable and safe

for nuclear energy.

create

skills

future

info.ntec@manchester.ac.uk

email:

or visit www.ntec.ac.uk

•

Demand-driven •Breadth of learning •Delivered by experts

delivered by: University of Birmingham • University of Central Lancashire • University of Leeds • The University of Liverpool • The University of Manchester • The University of Sheffield • The Nuclear Department, Navy Command

Courses

Creating efficiencies in your automotive processes from the start

The automotive industry is in the middle of a shift towards conventional vehicles with internal combustion engines. The move towards hybrid vehicles has rapidly picked up pace over the last few years and plug-in hybrids are becoming even more popular. The future is battery electric or fuelcell electric vehicles, referred to as NEV – New Electric Vehicles. These changes in the automotive industry require new types of components, including electric motor housings, new types of gear housings, new examples of covers and all accessories related to E-mobility. There will be increased demand for re-tooling, new tooling and processes to produce these components. High volume will remain key to the industry, and cycle time – cost, seconds and pennies – will always be a concern, so it’s important to get things right from the very beginning.

Getting it right from the start

Every step in the process – engineering, design, CAM programming and machining – should be inspected, verified and optimised. Simulation software ensures programs are error free and all operations work together as intended, and optimisation ensures the whole process is operating as efficiently as possible to save time and money. Developed by CGTech, VERICUT is an independent CNC machine tool simulation, verification and optimisation software that enables users to link all the machining operations end-to-end

to evaluate and improve the entire manufacturing process.

The priority in automotive production is increasing output, while minimising costs. Manufacturers typically have very high volume, so cost per unit and cost control are extremely important. Focus is on planning production efficiently from the start.

Mistakes can be costly. Consider the production environment – the machines, their automation, the required floor space, raw materials and invested capital – and the initial information required for accurate process planning – machining operations, required tools, the cycle time, production rate and requirements. This is where VERICUT comes in to play. It has the ability to analyse the process before any machining takes place or before cutting material – in essence, it reduces prove-out time.

Prove out

The major challenges facing automotive

manufacturers when proving-out parts on a machine for the first time can range from scrapped parts, broken tools and holders, to fixture or spindle repair, or replacement. Ultimately, this can result in machine down-time, schedule disruption, insufficient capacity and lost contracts. VERICUT simulation and verification can resolve these issues and eliminate factors that are going to cost downtime, money and safety on the shopfloor.

VERICUT becomes part of the process once the NC code has been created, but prior to any machining on the shopfloor. The engineer or programmer, who is offline from the machine, can perform a virtual prove-out and identify potential issues in the NC program. VERICUT verifies post-processed G-Code instead of the CL data. This is the exact same G-Code that runs within the NC system of the machine, enabling the software to carry out a comprehensive machine simulation based on the same data that will operate the machine. Any errors will be highlighted in the VERICUT logger, which when clicked on will link directly back to the line of NC code where the error occurred. Simultaneously, rather than sitting idle, the machine can be producing parts, thus removing the wait time from the machining process. Valuable machine time is therefore not wasted and machinists can be confident that the program will deliver accurate parts without collisions or disruption.

Simple set up

The machine features, components, fixtures and stock in VERICUT are identical to the physical process. Setting up VERICUT is simple. With direct interfaces to all leading CAM systems, configured data can be quickly imported into VERICUT, which is another time saver. Likewise with tooling, smart tools can be imported from the cloud and other online databases – already configured for VERICUT’s use. VERICUT will identify tool related errors, for example, where it is engaged in material but the spindle is not on, and instances when the tool is going too fast or not being used efficiently.

Using measurement and inspection capabilities within VERICUT, the user can also compare the machined model to what was intended. The cut stock can

16 Manufacturing & Production Engineering Magazine

Machines & Machinery

VERICUT simulation and verification can resolve these issues and eliminate factors that are going to cost downtime, money and safety on the shopfloor.

be measured at any time with X-Caliper including hole depths, volume removal, model thickness, air distance, diameter/ radius, centre of gravity and many more. The simulated model can be compared with the original model using AUTODIFF, identifying any gouges or excess material. This reduces the time it takes to cut the first production-worthy part.

Make parts more efficiently

Simulation and verification address the obvious elements of machining, and once complete the process is error free, safe and will deliver the parts as intended. However, there are also hidden opportunities to make components more quickly – issues include inefficient programming and suboptimal feed rates caused by the CAM system’s inability to adjust cutting feed rates for varying cutting conditions. VERICUT Force addresses these. The goal for efficient CNC machining is to achieve a constant chip thickness that meets manufacturing standards. Maintaining a tool’s ideal chip thickness through an operation ensures that the tool is being used to its full potential, which in turn reduces machining cycles, increases tool life, and makes programs safer.

VERICUT Force is a software module within VERICUT that uses a physicsbased optimisation method to determine the maximum reliable feed rate for any given cutting condition based on four factors: force on the cutter, spindle power, maximum chip thickness, and maximum allowable feed rate. It calculates ideal feed rates by analysing tool geometry and parameters, material properties of the stock and cutting tool, detailed cutting tool edge geometry, and VERICUT cut-by-cut contact conditions. Shifts in market demands in the

automotive industry have already seen, and will continue to see, the need for new components and the processes to produce them. Simulating, verifying and optimising machining processes from the start using verification software, such as VERICUT, will ensure that these processes deliver accurate parts, as efficiently and quickly as possible, without collisions and downtime. Ultimately, automotive manufacturers will achieve high-volume production goals, while reducing costs and maintaining quality.

17 Manufacturing & Production Engineering Magazine Machines & Machinery R TECH FOR RELIABILITY! Monitoring Solutions since 1983 Web: rotechsystems.co.uk Email: sales@rotechsystems.co.uk Tel: +44 (0)151 356 2322 Protecting Your Plant Instant Shutdown Before Things Go Wrong food glass coal textiles fertilisers steel mills utilities coal water treatment mines grain glass ash fertilisers roadstone offshore fertilisers aggregate power generators food sand stone… dock installations RotechMotion Sensors can be used whenever information or monitoring of shaft rotation, position, direction, speed, slip etc, is required,for indication, control, interlocking, protection, sequencing, alarm initiation, and many more functions. Wherever materials are transported or processed by Conveyors, Elevators, Screws, Crushers, Mixers, Etc, there are applications for Rotech Motion Sensors gravel ore …and many more! cement Motion Sensor’s for all industries

Micrometric Celebrates 40 Years of Laser Material Processing

Lincoln-based manufacturing firm Micrometric is continuing to lead the way in micro laser manufacturing and multi-process services during its 40th year of business.

With this special anniversary, Micrometric is reflecting on the evolution of services it provides in a range of sectors including medical, aerospace and automotive. Micrometric began by cutting sheet metal using CO2 lasers in January 1983 and had a turnover of only £50 in its first month but this soon started growing.

Neil Main, Managing Director of Micrometric, remembers contracts that changed the services provided by Micrometric: “We were asked by the Atomic Energy Research Establishment at Harwell if we could make radiation sensors for detecting alpha radiation. They needed small rectangles cutting with each having a unique letter, number and error code. At that time our competitors were not able to do this, so we rose to the challenge and successfully output the parts using the large CO2 laser (DE) and BBC Micro.”

By 1990, Micrometric was a precision laser processor, and several industries

were asking them to make parts: gas turbines, food manufacturers and medical. Most medical items were for instrumentation but Micrometric was asked to make one part for a prostate cancer remover.

In 1994 the company moved into a new purpose-built factory on Doddington Road, Lincoln. With more space Micrometric invested in new hi-tech lasers including its first Bystronic which was fast, flexible and precise.

After Neil purchased Micrometric in 2004, he faced a great challenge: their biggest customer bought its own laser. Company revenue declined, and it resulted in redundancies.

Recovery took a while before Micrometric was able to invest in new equipment. However, technological advances meant that new lasers were state-of-the-art and Micrometric was able to produce better quality components more quickly with a higherskilled workforce.

Over the past five years, Micrometric has invested £1.5m in new equipment to meet demand for precision components, including the Coherent Starcut tube cutting machine which works with extremely high precision, and a new Lasercube machine which delivers on quality and efficiency. These developments will allow the team to continue producing high-quality components for multiple industries.

When looking forward Neil is positive: “We have seen so much change in just the last three years, but customers are still asking for new parts and processes. We are always looking for new ways of expanding our services so there is huge potential for growth.”

Micrometric are AS9100 accredited and are members of the Midlands Aerospace Alliance (MAA), The Manufacturers’ Organisation (MAKE UK), Association of Industrial Laser Users (AILU), The Welding Institute (TWI) and Motorsport Industry Association (MIA).

18 Manufacturing & Production Engineering Magazine

& Machinery

Machines

Find out more about Micrometric on the website or call on 01522 509999.

We are always looking for new ways of expanding our services so there is huge potential for growth.

Neil Main, Managing Director of

Micrometric

LEFT: Left to right, Chris Waters (Commercial Director), Rosie de Smit (Finance Director) and Neil Main (Managing Director)

Laser Lines Ltd – Total Solutions Provider

Laser Lines began in 1975 supplying lasers for science and research, and for the past 30 years has been the UK’s leading retailer of 3D printing and additive manufacturing (AM) technologies. Find out more about the exciting technologies and solutions they can offer.

3D Printing solutions

A Platinum Partner of Stratasys, and representing Makerbot and Xact Metal in the UK, Laser Lines offers a vast range of 3D printing technologies including FDM, Polyjet, SLA, P3, SAF and Metal. Of these, Stratasys’ FDM F370 and Polyjet J55 Prime 3D printers are proving to be the ideal solution for many design and small-scale production applications.

The Stratasys F370 is the perfect additive manufacturing machine for more demanding projects. With support for two model materials and two support materials, it can be left to run for extended periods. This feature can be used to guarantee overnight, unattended printing by installing matching spools in advance. The perfect combination of class-leading performance and offering a generous build envelope of 355 x 254 x 355mm, the F370 is incredibly quiet and can be used with industry-leading FDM materials, including PLA, PC-ABS, ABS-CF10 Diran 410MF072 and FDM TPU 92A.

The Stratasys J55 Prime is a fullcolour Polyjet 3D printer that you can add to your organisation, without the need for a specialised operator or a dedicated room for it. For anyone that wants to cut down the time it takes to prototype a product, the Stratasys J55 Prime can print models efficiently, in over 500,000 colours. The compact 3D printer fits into any standard office, classroom or studio space with ease. With no unpleasant smell, toxic fumes or noisy machinery to deal with, you

can work as normal – even if sat right next to it.

If you are looking to print metal parts, the XM200C metal powder-bed fusion 3D printer from Xact Metal, is ideal. A compact and affordable system, it can produce quality metal parts from a variety of metal powders at a low cost, bringing a new level of price and performance to metal 3D printing for entry-level operators for the first time. The XM200C is perfect for universities, prototyping laboratories and small to medium enterprises that require multiple machines. Supporting metal powders such as Stainless Steel, Super Alloys, Tooling Steels, Aluminium, Titanium and Bronze, the XM200C is ready to make your part in a fraction of the time it takes using traditional casting. Plus, its open platform means that qualified users can develop their own printing parameters or use their own powder. It is simple to use with an easy touchscreen user face, which makes it easy to load files, set up build and monitor jobs

Industrial Laser Solutions

Laser Lines also supplies a complete range of lasers, laser systems and

accessories, providing solutions for industrial processes such as marking, engraving, drilling, welding, soldering, brazing and cladding. Key systems include Synrad CO² lasers in the power range of 10W to 400W, Datalogic laser markers, DPSS, fiber and CO² laser technologies, all for integration. Complete systems include Laserline high power diode sources to 45kW and Sisma pulsed YAG welding and cutting systems. Also available are beam delivery solutions including conventional process heads and galvanometer scanning systems.

The company offers their own range of standard and bespoke laser marking solutions of which there are four options. Lasermark PRIMARY, is Laser Lines’ entry level laser marking system. This unit perfectly matches safety, functionality and a small footprint with value for money and potential for an excellent return on investment. Suitable for install with a variety of lasers from our DPSS and Fibre ranges, this system presents the very best in value for small laser marking applications. The Lasermark PROJECT system is a unique system devised for your specific application. Understanding that the best option for your business may not be an ‘off the shelf’ solution, Laser Lines has a wealth of experience in designing bespoke marking solutions. The Lasermark PRESTIGE system is specifically designed with the industrial laser user in mind. With free standing and benchtop versions available this system offers a full range of customisable features and options.

The Lasermark PREMIUM combines all of the benefits of the Lasermark PRESTIGE system but with a larger footprint and working area. Designed for applications that require extra space for larger or longer parts.

For more information, please visit: www.laserlines.co.uk

20 Manufacturing & Production Engineering Magazine

The Lasermark PREMIUM combines all of the benefits of the Lasermark PRESTIGE system but with a larger footprint and working area.

Machines

& Machinery

Supplying Total Solutions for nearly 50 Years - and counting!

We

THE

Nearly

www.laserlines.co.uk

50 years’ experience helping companies reduce manufacturing and development costs.

TOTAL SOLUTIONS PROVIDER

Laser Lines offers a comprehensive portfolio of 3D printers, additive manufacturing systems and industrial laser solutions.

has amassed over 100 years of experience selling and

the products

supply. In

Laser Lines offers a bureau facility and certified training courses to

you get the best out of your investment

The team

supporting

they

addition

ensure

us today to discuss your

or arrange for a demonstration.

672500

LASERS

are keen to help our customers with their purchasing or up-grade decisions, and offer competitive leasing options as well as generous Trade-in packages where available. Contact

application

01295

3D PRINTERS

IntraLogisteX 2023: Improve Efficiency, Reduce Costs, Exceed Targets

28th & 29th March 2023, NEC Birmingham

The largest intralogistics show of this year is almost here. Now in its ninth year, IntraLogisteX is not only UK’s biggest and best factory and warehouse logistics event, but it also features the most advanced industry innovations and solutions – everything you need to create the factory or warehouse of tomorrow, today.

IntraLogisteX offers visitors the chance to discover how the latest intralogistics, robotics, automation, and packaging technologies can improve their business efficiency, reduce costs, improve sustainability, and give them a competitive advantage. By attending IntraLogisteX, engineering and manufacturing professionals can condense weeks of online research into just a few hours, all while networking and sharing ideas with their peers.

Manufacturing companies make up a significant portion of the event’s visitors. As well as most of the major car producers, such as Hyundai, Toyota, Aston Martin, Bentley, Ford, Arrival, and BMW, a vast range of manufacturing giants like Sony, Airbus, Perkins Engines, Caterpillar, Bosch, Lego Group, and Tata Steel are all sending delegations to the event.

Visitors can meet industry-leading exhibitors who will be showcasing solutions in factory and warehouse automation, robotics, materials handling, storage, racking, sortation, picking, barcode scanning, labelling, packaging, software, facilities management, and more!

The event organisers, Akabo Media, are introducing a number of important changes for this year’s event. Following on from last year’s sold-out event, the organisers have announced that the 2023 edition will take place on 28th–29th March 2023 at the UK’s leading live events venue – the NEC Birmingham.

This exciting move not only offers a wider range of services and transport links to exhibitors and visitors, but also allows IntraLogisteX to grow after its 2022 event sold out the Coventry Building Society Arena. IntraLogisteX can now

offer its guests an unrivalled selection of nearly 200 exhibitors.

The move isn’t the only good news for automation and manufacturing professionals. This year, IntraLogisteX will be co-locating with Robotics & Automation Exhibition – the UK’s largest dedicated robotics and automation exhibition. This follows the huge success of Robotics & Automation’s 2022 event, held at the Coventry Building Society Arena last November. This co-location gives visitors access to a wide range of leading robotics and automation organisations such as Geek+, Zebra Robotics, Locus Robotics, Brillopak, Dexory, KNAPP, OnRobot, Orion, and many more!

According to Stephen Brooks, owner and Managing Director of Akabo Media, the decision to co-locate gives both shows an immediate gain in number of exhibiting companies and number of qualified professional visitors – more than 4,000 buyers are expected!

The synergy of the two shows is obvious, and visitors’ passes will grant them access to both, meaning they have an

even bigger opportunity to discover the solutions to their current and future factory and warehouse challenges.

On top of all these new features for the 2023 event, IntraLogisteX is once again providing its visitors with a truly world-class conference programme. Featuring over 60 expert speakers, the IntraLogisteX conference will span over both days of the exhibition and will offer visitors practical insights in the latest industry innovations. Visitors will be able to hear directly from industry leaders as they share real world examples of their solutions in action.

Topics covered in the outstanding conference will include decarbonisation and efficient solutions in the automotive industry, growth via investment in automation and technology, and the importance of inclusion within the logistics industry.

22 Manufacturing & Production Engineering Magazine

IntraLogisteX 2023 is a totally free exhibition and is your best chance to see an unmissable showcase of the latest solutions and innovations in intralogistics! Visit their site to register now: www.intralogistex.co.uk Show Preview

28TH & 29TH MA R CH 2023, N E C BIRMINGHAM #ILX23 DISCOVER THOUSANDS OF WAYS TO www.intralogistex.co.uk Improve Efficiency, Reduce Costs, Exceed Targets Visit the UK’s Largest Warehouse and Factory Logistics Exhibition! IMPROVE YOUR BUSINESS Discover thousands of manufacturing, production and engineering innovations! RECRUITMENT Robotics & Innovation Robotics & Innovation Exhibitors: FREE TO ATTEND

Automation: the key to sustainable warehousing

The way to sustainable warehousing is through automation, says

Creating more sustainable logistics operations is a priority for businesses, governments and increasingly, consumers. The warehouse is the beating heart of the supply chain, but it may not be immediately obvious that investment in warehouse automation can significantly contribute to sustainability goals.

On the face of it, automation may appear resource heavy, requiring metals, plastics and electrical power. How can this be more sustainable than resource- and energy-light manual processes?

However, sustainability isn’t just about the headline issues of rare earth metals and carbon emissions, important though these are. We need sustainability in land use and water management, in transport capacity, in the reduction of waste in all its forms, in enabling the goods and packages we handle themselves to be more sustainable. Further, labour and money are also finite resources, which need to be managed sustainably. Automation, of physical processes and of control systems, can contribute to achieving sustainability goals in all these areas.

Consider, for example, Automated Storage and Retrieval Systems (ASRS) in all their variety. By using high-density storage right up to the eaves and in very narrow aisles, the required building footprint, with its associated impact on hydrology, can be reduced – along with the amount of steel and concrete that goes into construction. ASRS can save energy too, as lights-out operations are often possible, and less empty space is being heated, air-conditioned, or refrigerated.

Automated processes, perhaps combining ASRS, conveyor runs and Autonomous Mobile Robots (AMRs), can greatly reduce or even eliminate the requirement for carbon-emitting forklift trucks – with all the health and safety benefits of a reduced exposure to the possibility of collisions, back injuries and repetitive strain grievances. And as labour is a scarce resource in itself, freeing people up for more thoughtful, dexterous tasks.

However, automation can offer even more. The automated loading/unloading of vehicles reduces waiting time and thus the yard space required, enables more efficient vehicle utilisation, and again has safety benefits. Automated handling can also reduce waste through lowering stock damage, and with the latest packaging innovations can facilitate the use of ‘greener’ packaging solutions, with less waste of cardboard as a result of more compact packages.

These benefits can be amplified through the appropriate use of automated planning, management and control systems. Warehouse simulation, together with tailored Warehouse Management Systems (WMS), can optimise layout and activities to minimise movements and thus energy consumption – for example, by minimising the number of movements in and out of cold stores.

A well-attuned WMS can also contribute to more efficient and sustainable use of transport, making it is easier to plan and assemble full loads for a destination within the necessary timescale. Automated goods-to-person

order picking using, increasingly more affordable mobile robots combined with pick-to-light technology, or voice with human operators, can reduce mispicks, and thus waste and returns.

Meanwhile, environment management systems can save on heat, refrigeration, and turn the lights off when an area of the warehouse is free of workers. Management systems for AGVs and AMRs can, within limits, plan for vehicle recharging off-peak, which is both cheaper and may reduce the demand for fossil-based energy generation.

Finally, machine monitoring systems informing preventative maintenance procedures can ensure that equipment is operating at peak energy efficiency as well as contributing to safe and healthy operation, while the general use of digital systems can greatly reduce the operation’s consumption of paper.

These are just some of the automation options which, sensibly combined, can make a real contribution across the whole range of sustainability goals of the business, from climate change to human welfare and, yes, sustainable profitability.

24 Manufacturing & Production Engineering Magazine

On the face of it, automation may appear resource heavy, requiring metals, plastics and electrical power.

Automation

- Craig Whitehouse

More on smart warehouse automation at www.invargroup.com

Craig Whitehouse, Managing Director of Invar Integration.

SAVINGS

As energy prices continue to rise, can your business afford not to know how much compressed air your system is wasting? Isn't it time you found out what happens behind closed doors?

Automating Energy Saving

Festo’s combination of a field bus node, flow and pressure sensor, proportional pressure regulator and stop valve in one intelligent service unit component. Integrated

www.thorite.co.uk Visit our website More information 0800 034 5850

MSE6 - E2M Energy Efficiency Module

Leak detection,

and

to the minute comparative data reporting

of

MANUFACTURING SOLUTIONS We’re Exhibiting! visit us at Stand G70 EFFICIENCY &

measurement

reporting Up

Automated shut-off & start-up

idle machines

COMBINED

93 new hires drives global growth for MEP design firm

A global MEP engineering design company is continuing to grow rapidly as its global workforce expands. In the last 12 months, UK-headquartered Black and White Engineering (B&W) has become a 380+ strong global team, a 34% increase since the end of 2021. UK and Europe headcount has increased by nearly a third (32%) and the firm now employs a UK team of 100 with offices in Newcastle, Edinburgh and London as well as multiple locations globally.

Globally, B&W is currently a 30-million-pound revenue business due to an expanding client base and is now focused on strengthening its team of engineering design experts by recruiting up to 100 more specialists over the next 12 months. The company delivers innovative sustainable

MEP design services across a number of industries, with a particular specialism in data centre MEP design.

Current global projects include a number of data centre developments across the UK and Europe, Middle East and APAC as well as high rise projects in the Middle East and buildings projects in the UK.

Electrifying growth for Sellectronics with managing director recruitment

Rapid growth and forecast expansion for Sellectronics, has seen the Falmouth based contract electronics manufacturer, recruit a new Managing Director.

Jon Hurrell joins as Managing Director, strengthening the senior management team with a wealth of experience and expertise gained in a variety of manufacturing environments.

Started by Dean Haney and Jason O’Connell over 14 years ago, Sellectronics has been

at the forefront of the UK’s electronic engineering with its specialist printed circuit board (PCB) manufacture sitting at the epicentre of numerous electronic applications.

Specialising in managing quick turn-around prototype assembly and low volume/high mix production demands, the company develops strategies to support external and in-house test requirements for high level reliability and performance of PCBs and sub systems.

The PCB industry has seen massive growth and Sellectronics is mirroring industry trends with the PCB global market valued at 78 billion USD in 2021 and forecast expectations of growth to 128 billion USD in 2030.

Recognised for their innovative, high-quality PCB assembly, Sellectronics offers a range of services from small cable forms, to complex multi-level surface mount circuit board assembly, developing superior products based on individual requirements.

Working with specialist talent partner and recruitment specialists, Talentheads, B&W is looking to recruit across a number of roles including senior and principal engineers, BIM coordinators and managers, design engineers, power systems engineers, and document controllers. The firm has created opportunities from entry and graduate level through to senior leadership roles. Investment in young people across different regions is prioritised with B&W supporting government and industry initiatives to attract more emerging talent to the MEP design sector, playing a key role in developing future generations of global MEP engineers.

For more information about the roles available at B&W engineering, visit: https://www.bw-engineering. com/careers/

People On The Move 26 Manufacturing & Production Engineering Magazine

Interview: Anne-Marie, CEO of Stemettes

Firstly thank you for speaking with us! I wondered if you could please tell us more about the Stemettes and the main company goals.

I created Stemettes in 2013 to ensure girls, young women, and non-binary young people know that technical fields are for them. The Stemettes’ mission is to engage, connect and inform the next generation of women & nonbinary people into Science, Technology, Engineering, Arts and Maths (STEAM) by showcasing a diversity of people working in STEAM. We have changed the lives of more than 60,000 young people across the UK, Ireland and parts of Europe with our ‘Free, Fun, Food’ ethos. We run more than 50 activities each year - a mixture of intersectional programmes, impactful events and inspirational content platforms. These free opportunities improve perceptions of STEM, raise awareness of options within STEAM, grow the network these young people have and improve their self and STEM confidence.

The Stemettes recently marched across London’s Waterloo Bridge to raise awareness about women in STEM; could you tell us some more about the event?

Hundreds of Stemettes and our supporters walked across London’s iconic Waterloo Bridge - the ‘Ladies’ bridge’ - on Monday 13 February 2023 to raise awareness about women in STEM who are excluded from the

UK curriculum after a Stemettes commissioned survey*, supported by the British Science Association, shows that 1 in 3 young people say they haven’t or don’t remember being taught about a woman scientist in the past 2 years.

What events do you run and how can people get involved?

We run a range of events including panel and networking sessions with our STEM partners; hackathons where participants work together to develop an idea around a theme and professional certification programmes where people can gain qualifications in agile methodologies or Python coding certifications. Anyone who is interested should visit Stemettes.org/events to sign up.

How important is it to encourage and support more girls, young women and nonbinary young people into a career within the STEM industry?

It’s super important - the STEM industry’s output shapes society and how it operates. Where the intention is to solve problems, we end up creating new ones through a lack of

28 Manufacturing & Production Engineering Magazine

Interview

Manufacturing and Production Engineering Magazine speaks with Anne-Marie, CEO of Stemettes

consideration for members of society that aren’t reflected in the industry. Having a breadth of experiences, identities and perspectives allows us to prioritise better, create better products and build with an inclusive set of assumptions.

Is more encouragement needed within educational environments?

Yes. Seeing is believing and we need more women in STEM role models on the curriculum. We recently commissioned a survey with the British Science Association which found that 70% of young people think it is important for schools to include information about women STEM role models in their lessons (boys are just as likely to agree with this statement as girls).

We also found that older students (aged 17 -18) are more likely to feel that their identity is reflected in the STEM curriculum and classroom than younger students so yes, more encouragement is required in the early years.

Do you think the pandemic has affected progress?

Stemettes grew exponentially over Covid. There was A LOT of demand for online learning opportunities. We pivoted quickly and used our digital skills to meet the demand. However there was a return to 1950s style living for so many working women - unpaid labour, changes to the workplace and reprioritisation meant that so much DEI work disappeared. We have to

intentionally build an industry that works for everyone and values difference.

What challenges do women still face within the industry and the workplace, and what more in your opinion can be done to ensure gender equality is present within the workplace?

Challenges (and opportunities) abound - from the social norms that inform poor recruitment, retention and promotion practices to the gender pay gap and a lack of progressive and inclusive workplace policies. We have to see more allyship and willingness to change from folks at all levels - from the C-Suite to middle managers and beyond. I’m personally for quotas that recognise where existing practices fall short, and companies taking an iterative approach to evolving their cultures. Also - we need to normalise men stepping into caring responsibilities and so much of the unpaid labour typically done by women in society. Finally, we need to ensure we’re all aware of the herstory that has got us to this point. It’s not good enough to hold onto outdated stereotypes of women not being technical whilst using GPS and WiFiwe have Gladys West and Hedy Lamarr to thank for such everyday tech!

(The stats speak for themselves. “Research undertaken by STEM Learning indicates that 89% of STEM businesses have found it difficult to recruit staff with the required skills in the last 12 months, leading to a current shortfall of over 173,000 workers –an average of 10 unfilled roles per business.” - IET June 2021. If we want to equip young people with both

aptitude and an interest for STEM, we need to act when folks are in their formative years. Employers need to realise that without the diversity of thought that different groups bring, they are doing their businesses a disservice in solving the problems of tomorrow.)

What are your plans for Stemettes for this year?

This year we’re organising so many celebratory free STEM and STEAM events around the UK for people of all ages. We’re shining a spotlight on Herstory missing from the National STEM Curriculum and continuing our normal work to edit social norms for the next generation. We’ll be hosting roundtables and festivals in the North East, West Midlands and London areas. We’re continuing to give young people the chance to make an informed decision on their relation to STEM & STEAM careers.

STEAM*: Science, Technology, Engineering, Arts, Maths. The arts include the humanities, language arts, design and so on demonstrating the importance of an interdisciplinary approach to future STEM careers.

29 Manufacturing & Production Engineering Magazine

Interview

It’s not good enough to hold onto outdated stereotypes of women not being technical whilst using GPS and WiFi - we have Gladys West and Hedy Lamarr to thank for such everyday tech!

- Anne-Marie

Advantages of optical sensors in coordinate measuring machines

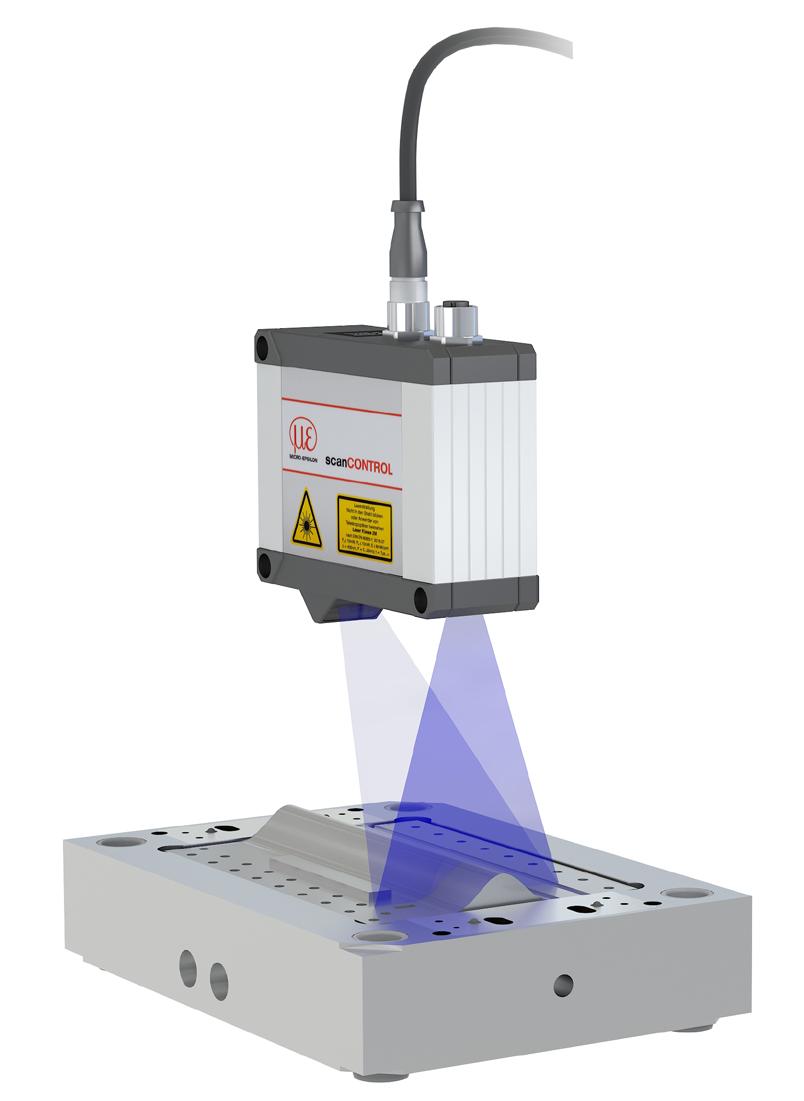

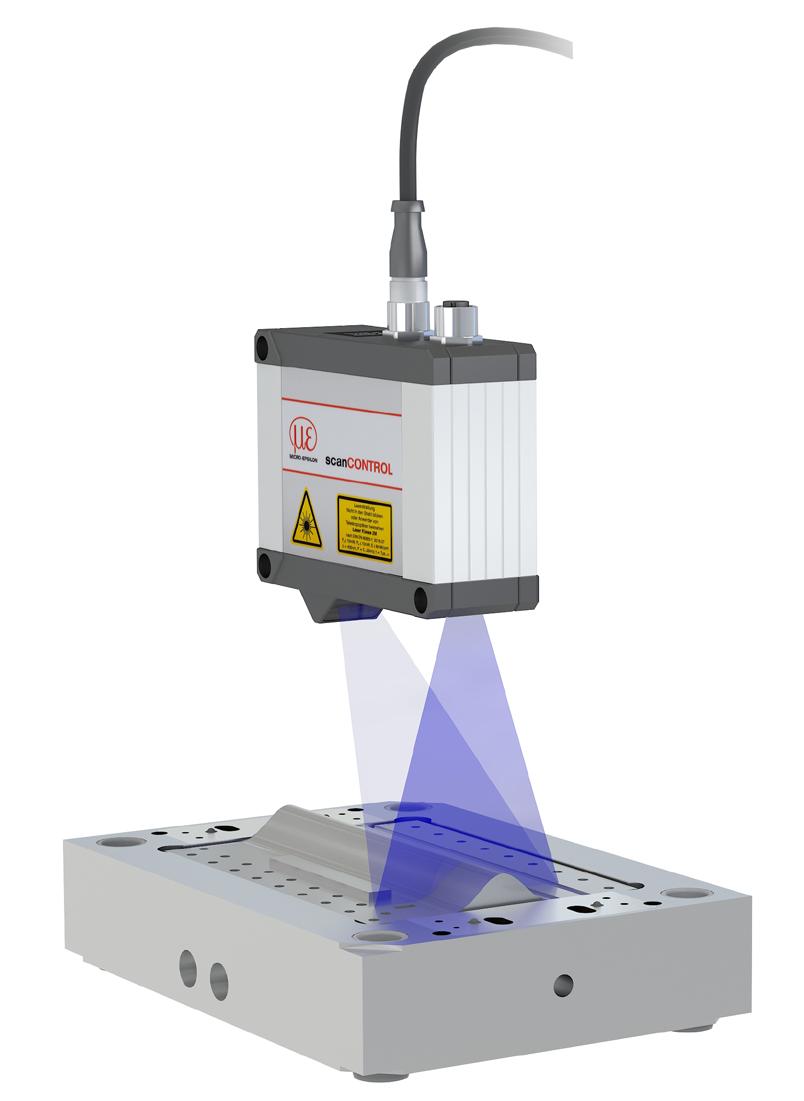

Coordinate measuring machines are used for high precision quality and parts inspection. Optical distance sensors are increasingly being used for this purpose to replace conventional mechanical gauges. There are numerous reasons for using non-contact sensors: the measurement is reactionless, fast and offers high resolution. Modern optical sensors such as laser triangulation sensors, laser scanners and confocal sensors are particularly suitable for this purpose, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.