www.kyocera-sgstool.co.uk

www.kyocera-sgstool.co.uk

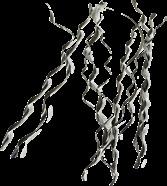

The Z-Carb HPR 7 Flute roughing end mills are the number one choice for achieving high material removal rates (MRR) on lower powered machines and unstable applications.

TOOL DIAMETERS

available in 6, 8, 10, 12 & 16mm

CUT LENGTHS

3xD and 4xD

CORNER RADIUS available as standard

AVAILABLE IN TWO OPTIMISED COATINGS (TX and TH) for superior performance

Coating

NEW STYLE CHIP BREAKER NOTCHES to reduce load and provide a more stable chip evacuation TX Coating

IDEAL FOR:

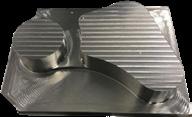

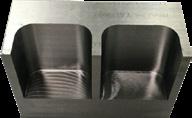

• High speed roughing (profiling, trochoidal, dynamic) machining of titanium, Inconel, stainless steels and steels

• Lower powered machines

• Components with lower clamping / workholding

Recommended for:

• High Temp Alloys

• Inconel

• Stainless Steels TX

Profiling Titanium

Tool size 16mm 3xD

Speed (rpm) 1790

Feed (mm/min) 1980

Surface speed 90

Fz 0.158

Ae 1.6 mm

Ap 30 mm

Recommended for:

• Titanium

• Carbon Steels

• Hardened Steels TH

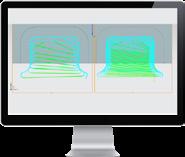

Standard endmill 2 Level 30% Ae Z-CARB 7 1 level 8% Ae

MRR 31.6 cm3 75.3 cm3

TIME 2:30 1:14

Single level milling strategy delivers over 50% cycle time reduction!

6,0 18,0 3xD 57,0 0.5

8,0 24,0 3xD 63,0 0.5

10,0 30,0 3xD 72,0 0.5

12,0 36,0 3xD 84,0 0.5

12,0 36,0 3xD 84,0 1,0

12,0 36,0 3xD 84,0 2,0

12,0 36,0 3xD 84,0 3,0

12,0 36,0 3xD 84,0 4,0

12,0 48,0 4xD 100,0 0.5

12,0 48,0 4xD 100,0 1,0

12,0 48,0 4xD 100,0 2,0

12,0 48,0 4xD 100,0 3,0

12,0 48,0 4xD 100,0 4,0

16,0 48,0 3xD 100,0 1,0

16,0 48,0 3xD 100,0 2,0

16,0 48,0 3xD 100,0 3,0

16,0 48,0 3xD 100,0 4,0

16,0 64,0 4xD 115,0 1,0

16,0 64,0 4xD 115,0 2,0

16,0 64,0 4xD 115,0 3,0

16,0 64,0 4xD 115,0 4,0

FS00101

FS00102

FS00103

FS00104

FS00105

FS00106

FS00107

FS00108

FS00109

FS00110

FS00111

FS00112

FS00113

FS00114

FS00115

FS00116

FS00117

FS00118

FS00119

FS00120

FS00121

FS00122

FS00123

FS00124

FS00125

FS00126

FS00127

FS00128

FS00129

FS00130

FS00131

FS00132

FS00133

FS00134

FS00135

FS00136

FS00137

FS00138

FS00139

FS00140

FS00141

FS00142

DIAMETER

= -0.010/ -0.050

= h 6 RE = +/-0.030

>10–25 DIAMETER

= -0.010/ -0.050 DCON = h 6 RE = +/-0.030

STEELS STAINLESS STEELS CAST IRON

Alloy Steel

4140, 4150, 4320, 5120, 5150, 8630, 86L20, 50100

Stainless Steel (PH) 13-8 PH,15- 5PH, 17-4 PH, Custom 450 < 325

Titanium Base Alloy Pure Titanium, Ti6Al4V, Ti6Al2Sn4Zr2Mo, Ti4Al4Mo2Sn0.5Si

High Temperature Alloy Hastelloy, Incoloy, Inconel, Rene, Waspalloy

Cutting data is based on a controlled radial engagement not to exceed the stated level. If the tool path used exceeds this then the data needs to be reduced accordingly. Recommend reduction in feedrate for 4xD tools of 25%. Maximum recommended engagement on the 4xD tools is 5%.