FROM THE CEO.

KEVIN DENNIS CEO

I would like to be the first to welcome everybody to your new publication Krueger Connect.

Krueger Connect is different to the Kronicle which it replaces and will reach a much wider audience including customers, suppliers as well as all Krueger staff. This new vibrant and colourful format aligns itself perfectly with company branding and the image we portray to the marketplace, so we hope that you enjoy this first issue. If you have any feedback or wish to see specific features, please reach out to the editor.

Since the final issue of our previous publication, I have spent time at both Sydney and Brisbane, and it was fantastic to see the effort that has gone into updating and rebranding the facilities as well as meeting all the staff and the many new employees we have in the two branches and hear

IN THIS EDITION

• KVAN’s roll out for Linfox.

• Krueger nominated for Victorian Hall of Fame award.

• Krueger’s newest Investment is the cutting edge.

• 39 year veteran calls time on career.

positive stories of how we compare against working for our competitors. It was also encouraging to hear very positive feedback from some of our key customers regarding the fantastic level of customer service that we supply in both these locations – well done Team Sydney and Brisbane.

July saw us kick off the new financial year, it was the service teams in all locations that got off to a very strong start, but Laverton despite manpower shortages came out on top. It’s also nice to report that we are starting to build a strong pipeline of work in the service shops with premium customers.

We have completed our first full month of production with the new Laser Cutter, the statistics around efficiency compared to the old plasma and quality of product is quite remarkable and is already proving to be a very valuable addition. Finally, after a hiatus of almost two years it is good to see several dry vans being manufactured, this time in the factory, which is a first, and there are more to come.

1 22/23

QTR

EDITION 001

WELCOME TO KRUEGER CONNECT.

Krueger Connect is your quarterly magazine about all things Krueger Learn more about the business and activities through all parts of the Krueger Business. We hope you all enjoy the read.

Editor: James Tamanika (james_tamanika@krueger.com.au)

KRUEGER NOMINATED FOR VICTORIAN MANUFACTURING HALL OF FAME AWARDS.

KEVIN DENNIS CEO

As many of you know, Krueger Transport was nominated for the 2023 Victorian Manufacturing Hall of Fame, Manufacturer of the Year –Large Business.

Although we did not secure the award, the journey and recognition is truly rewarding for the company. Our celebration of 45 years in business, from its inception in John Krueger’s Werribee home driveway, to being nominated alongside esteemed brands like Boeing Aerostructures Australia and NCI Packaging is an achievement we all should proudly cherish. While the victory went to another deserving contender, our nomination remains a powerful acknowledgment of Krueger’s dedication to manufacturing excellence within the state. We are genuinely honoured to have been recognised for our consistent commitment to providing high-quality solutions to Australia’s transport and logistics industry.

At Krueger, we understand that success is measured not only in awards but also in the value we bring to our clients, partners, and the industry as a whole. This nomination is a reflection of our ongoing efforts and the unwavering passion we put into our work. On behalf of John, Grant, and the whole senior management team, I’d personally like to extend our heartfelt gratitude to everyone who has been a part of our journey and contributed to our success.

As we move forward, we are more determined than ever to continue our tradition of excellence and innovation, ensuring that Krueger Transport remains a driving force within the manufacturing landscape.

JOHN KRUEGER MANAGING DIRECTOR/FOUNDER

“It’s a great honour to be nominated, not just for me but my family and all the employees we have past and present.”

Left to Right: John Krueger (Founder) with Kevin Dennis (CEO), Terri Krueger & Grant Krueger (National Sales Director)

KVANS ROLLING OUT FOR LINFOX

GRANT KRUEGER NATIONAL SALES DIRECTOR

Krueger Transport Equipment has begun to roll out its latest line of KVans for long time client, Linfox.

These dry freight vans are expertly manufactured to accommodate various dedicated freight tasks, empowering fleets to invest in purpose-built technology and equipment that maximizes productivity and gains.

National Sales Director, Grant Krueger, highlights the company’s commitment to meeting diverse customer needs. “Our dry freight vans can be customised for dedicated freight tasks, allowing fleets to optimise their operations with specialized equipment,” Grant added. “For instance, our vans designed for

food distribution come with heavy-duty fulllength flooring and a reinforced threshold plate, ensuring seamless loading and unloading with forklifts and pallet trolleys.”

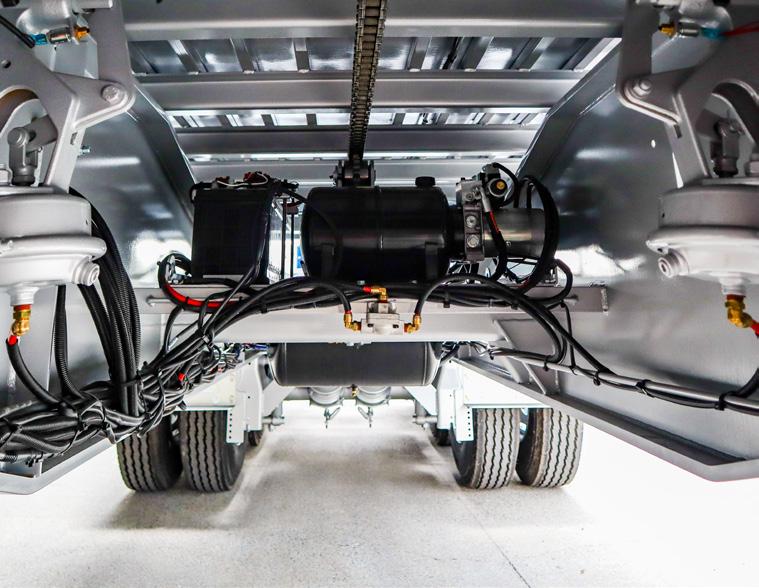

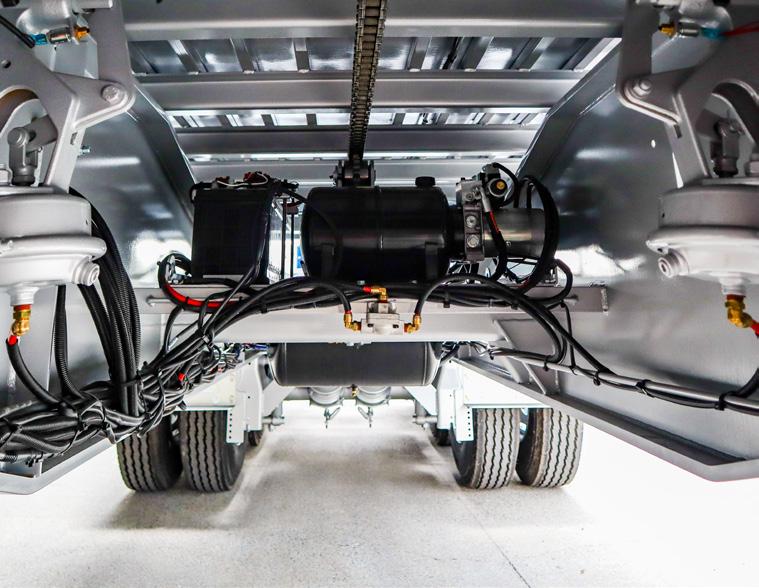

Combining Krueger’s renowned highperformance RFS suspension and their million-kilometre axle package, these KVan’s enhance line haul fleet requirements, emphasising reliability and long-term durability but also caters to the unique demands of Australia’s rigorous applications and everchallenging environments.

Krueger’s RFS is not only engineered for low tare weight and improved equipment longevity but also caters to the unique demands of Australia’s rigorous applications and

challenging environments.

Krueger’s ongoing vision for customised, purpose-built dry freight vans aligns perfectly with all their vast array of products with the evolving needs of customers and their fleets. Grant concludes. “Whether it’s food distribution, general cargo transport, or specialized loads, Krueger has the right solution.”

KRUEGER’S LATEST INVESTMENT IN CUTTING EDGE TECHNOLOGY.

STEVEN TEOFILO DIRECTOR OF ENGINEERING & SUPPLY CHAIN

STEVEN TEOFILO DIRECTOR OF ENGINEERING & SUPPLY CHAIN

To future proof its operations and continue to develop itself as an industry 4.0 manufacturer, Krueger Transport Equipment has recently installed and commissioned an HG Farley Laser Lab Marvel 12kW Fiber Laser cutting machine. The requirement for a laser cutting machine came about as its existing plasma cutting machine reached the end of its journey on Krueger’s manufacturing road map, and it was time to look to the latest technology in the steel cutting industry.

Naturally, this search took the company to the technology of laser cutting, and Krueger’s requirements were to take traditional laser cutting to the next level in terms of size and power of the machine. Such requirements would give Krueger uncompromised flexibility to be able to throw everything it needs at the new laser cutting machine in order to make best in class semi-trailers. The laser cutting machine ordered had 12kW

FOCUSING OUR LASER CUTTING SOLUTION.

DANIEL HUNT SENIOR PURCHASING OFFICER

of power with a 2.55m x 10m bed. After finalising the specifications of the laser, the company moved to the installation phase of the project where Krueger partnered up with industry leading local suppliers to ensure that the new facility was built to a class leading level.

To compliment the new laser cutting machine’s size and power, it also has the flexibility of cutting with Nitrogen, Oxygen and Compressed Air. To supply the machine with these critical gases, Krueger partnered with Coregas to design a new compound to house the Nitrogen and Oxygen storage tanks. Krueger also worked very closely with Hitachi Global Air Power to install a pair of oil free scroll compressors, which would supply very clean compressed air, from almost silent compressors which are located inside the new laser cutting factory. (continue over page)

We have successfully integrated the SureScope Ultimate 4K into our manufacturing process. This cutting-edge digital microscope, developed by Suba Engineering, has proven to be an invaluable asset in our efforts to enhance accuracy, streamline operations, and set new standards for excellence.

“As we continue to future proof our business, we have commissioned a 12kW laser to cut our plate requirements.” shares Daniel Hunt, Senior Purchasing Officer. “The laser is a high-speed high-precision instrument that requires periodic calibration. We needed a partner that understood magnification and could supply an easy-to-use and feature-rich solution that could operate in our factory environment and is fast and more accurate than the human eye. As an Australian business with an existing presence in Victorian manufacturing, Suba Engineering was a natural fit to provide our requirements.”

The introduction of the SureScope Ultimate 4K has enabled Krueger’s Laser Cutting arm to take a significant leap forward. “With its exceptional magnification, high-resolution imaging, and userfriendly software, we are equipped to calibrate our laser cutter with unparalleled accuracy. This integration aligns seamlessly with our commitment to delivering top-quality products and elevating our position as industry leaders” concluded Hunt.

Matheus Oliveira, Product Design and Support Engineer at Suba Engineering, emphasises the significance of the SubaScope Ultimate 4K in this integration: “Suba Engineering is the Australian lead solutions supplier to the Surface Mount Industry & Wire Processing manufacturing technology, for over 40 years. Our advanced digital microscope, the SubaScope Ultimate 4K, stands as a testament to our commitment to excellence. It is an Australian digital auto-focusing microscope with a zoom capability of up to 380x (with the additional 2.0x lens), delivered in incredible 4K picture quality @ 60 FPS. The microscope’s integrated measurement software provides a powerful yet intuitive interface allowing for real-time adjustments and immediate feedback. From its crystal-clear imaging to its seamless software integration, our SubaScope Ultimate 4K is the best tool to ensure a fast & meticulous calibration of your Laser Cutter for flawless machine performance. Our vision = YOUR ADVANTAGE.”

We extend our gratitude to the teams at Suba Engineering for their innovative solutions and partnership. Together, we are shaping the future of manufacturing at Krueger Transport Equipment.

Click on the icon above to see our latest video on the Krueger Laser Odyssey

With the new laser cutting machine up and running, ongoing calibrations of the cutting nozzle are required to ensure the machine is running to optimum specifications to suit the job on hand. To perform such calibrations quickly and with a high degree of accuracy, the team sought expert input from Suba Engineering who is a leading expert in the field of industrial microscopes. With a SureScope Ultimate 4K in place, the team can not only perform accurate nozzle calibrations in short time but can also perform careful examinations of the laser cut quality, arising from the need to adjust the laser cutting machine parameters due to different materials and gases used in the cutting process.

Finally, to take full advantage of the laser cutting machine’s advanced cutting technology, Krueger has begun using the Metalix suite of CAM software with the support of the local supplier Punchtech who specialise in solutions for the sheet metal industry. The goal of seeking local support from Punchtech was to not only develop highly efficient nests to maximise raw material usage, but to exploit all the advanced features of the software and the laser cutting machine to get the most from them in terms of capability, handling high volumes of work, and optimising for best-in-class quality.

With Krueger Transport Equipment’s latest piece of industrial technology in place, our customers will continue to experience our ongoing pursuit for best-in-class manufacturing excellence, as our trailers are built faster and with a new level of precision that will set a benchmark for the industry.

Engineering oversees design and programming of all parts required for new trailers.

To ensure required parts are cut, engineering is accountable to raise purchase requisitions to procurement department, and by having this laser, this process and communication has never been easier.

Furthermore, by having this laser in house, we can swiftly cut parts which in the past were considered long lead time items, be in control and have these delivered to our factory just in time, consequently preserving our valuable factory floor space.

Tony Hafoka (HC Farley) walks a tour though the laser facility with Kevin Dennis (CEO) & Steven Teofilo (Director Supply Chain & Engineering)

ADIS SELMIC MANAGER - ENGINEERING

Tony Hafoka (HC Farley) walks a tour though the laser facility with Kevin Dennis (CEO) & Steven Teofilo (Director Supply Chain & Engineering)

ADIS SELMIC MANAGER - ENGINEERING

MANUFACTURING SET FOR A BIG PUSH TO END 2023 AND BEYOND.

DAVID GRANT HEAD OF MANUFACTURING

DAVID GRANT HEAD OF MANUFACTURING

The manufacturing plant is alive with activity as we seamlessly process incoming orders, a result of the collaborative efforts between our sales team and our dedicated customer base. Our factory teams are diligently engaged in producing a diverse range of Krueger trailers, spanning from the renowned Kurtainers to the industry-leading Skels and the growing demands of dry and cold chain transportation with our KVan and Freezer B Double and Line haul sets.

Responding to the market’s increased emphasis on maximising freight capacity, Krueger is delivering notable solutions. Among these are the impressive Drop Deck 36 pallet B double sets and the expansive A-double Skel combo, capable of accommodating two 48-foot containers with ease. These robust solutions address the critical need for transporting palletised cargo across long distances during projected road and rail disruptions.

Innovation remains a driving force as we introduce the newly designed 14.6-meter Ratchet Mezz Drop Decks, showcasing our advanced Rachet Mezz-deck system. Anticipating a positive response, this innovation is poised to make a lasting impact on our customers, both in the present and the foreseeable future.

Lastly, our Dry Van team is in the final stages of completing the last batch of 6 new KVans for Linfox, each exceeding expectations and poised to

create a remarkable impression. Looking ahead, our strategic roadmap for further development is already underway, featuring intriguing plans that are currently in progress.

With these orders and commitments, our order bank is very healthy and as our goals for the manufacturing goals year on year continue to grow, we have continually met these goals successfully over the past 3+ years. With the guidance of our management team and customer loyalty to the Krueger product, these figures are poised to ascend even higher. Recent months have demonstrated our ability to meet and surpass these expectations, and the trend is expected to continue in the upcoming months.

As we continue to push boundaries and exceed expectations, rest assured that we are not resting on our laurels. Our team is actively working behind the scenes on new and exciting developments that will further enhance our manufacturing output for the upcoming year, 2023/24.

Let’s continue to work together and continue to make our mark in the industry.

BETTERING OUR AFTERSALES SERVICE.

Todays ever-evolving landscape of the transportation industry, where innovation and technology take centre stage, the critical link between new trailers and after-sales service cannot be overstated. Michael George, an industry veteran with over 30 years of experience and currently serving as the Service Manager for Victoria, sheds light on the importance of bridging this gap and the value it brings to both manufacturers and customers.

“Very interesting,” says George, when asked about his thoughts on the symbiotic relationship between new trailers and after-sales service. “In my 30 plus years in the industry, I’m always learning more, and seeing the manufacturing process and techniques have definitely opened my eyes and will help us to better how we service our product better for the customer.”

This insightful perspective shared by Head of Manufacturing, David Grant, who ran the National Service division for 10 years prior to taking his current role. Grant highlights the need for a seamless integration between the production phase and the post-sales support offered to customers. “As the industry continues to produce new cutting-edge designs, materials, and technologies into trailer manufacturing, it becomes imperative to ensure that the end-users are well-equipped to handle, maintain, and maximize the potential of these advancements.” says Grant. “Krueger is no different and being able to share the knowledge and know how the service teams can benefit from knowing what we do at a manufacturing level helps us to maintain high standards across the business.”

George’s emphasis on having his team learn and adapt is also high on his agenda for making his workshop better. “We have just taken on 2 new apprentices and have exposed them to the manufacturing side of the business in their first few weeks to help build their knowledge banks. We also have all the team scheduled for regular visits to the manufacturing side as we want our service professionals to evolve their expertise to keep up to speed, especially with our own equipment.

Krueger’s perspective on bridging the gap between new trailers and after-sales service shines a spotlight on the transformative impact this integration can have on improving process and particularly customer satisfaction. Kevin Dennis, CEO, added “A robust after-sales service framework will contribute to a manufacturer’s reputation and long-term success. When customers experience consistent, effective support, brand loyalty is fostered. Satisfied customers are more likely to recommend the brand to others and make repeat purchases in the future, thereby driving growth and market share.”

Above: David Grant shows Michael George (top) and his new apprentices, Emmileigh & Jack (bottom) through the factory to gain an understanding of the manufacturing process.

Above: David Grant shows Michael George (top) and his new apprentices, Emmileigh & Jack (bottom) through the factory to gain an understanding of the manufacturing process.

RESETTING OUR VALUES INTERNALLY & EXTERNALLY.

KAREN MORGAN GENERAL MANAGER - PEOPLE & SAFETY

Adaptability and innovation are paramount for any company’s success. Companies must continually reassess their core values to ensure they remain aligned with the current environment. At Krueger, we recognise the need for this evolution and are committed to resetting our values to reflect the changes in today’s industry.

RESPECT: Fostering Collaboration

Respect has always been a fundamental value at Krueger. We believe in treating every individual with dignity and fairness, valuing diversity, and promoting a harmonious workplace. In today’s industry, collaboration has taken on new significance. We understand that success often hinges on our ability to work seamlessly with partners, suppliers, and customers from around the world. Our commitment to respect means not only valuing our team members but also our broader community and stakeholders.

INTEGRITY: Transparency in Action

Integrity has always been the backbone of the Krueger business. As the business world becomes increasingly interconnected and information flows more freely, maintaining transparency and ethical conduct is essential. At Krueger, we are resetting our commitment to integrity by heightening this practice on which the company was founded. This means not only following our regulated business practices, but also adhering to the highest moral standards and codes set by our board, our management team and our founder, John Krueger. We believe that ethical business practices are not just good for our company but also for society as a whole and embrace this with leadership and responsibility.

PASSION: Driving Innovation

Passion fuels innovation, and in today’s industry, innovation is the lifeblood of progress. John Krueger built Krueger with engineering innovation and a desire to do better. This continues today and to the future as double down on this value by encouraging and supporting a culture of innovation. We understand that staying competitive means embracing change, challenging our older ways, and pushing the boundaries of what’s possible for our company in greater scope. Our passion for innovation will drive us to find new solutions and opportunities in an ever-evolving marketplace.

STRENGTH: Resilience in Adversity

Strength is not just about physical prowess; it’s about resilience in the face of adversity. The business world can be unpredictable and recent history can attest to that. Krueger is resetting its commitment to strength by ensuring our company is adaptable and resilient. We are future proofing the business by investing in the skills and resources necessary to navigate uncertainty confidently. Our strength lies in our ability to overcome challenges, learn from setbacks, and emerge stronger

In resetting our values, we are not abandoning our roots but fortifying them; they are and always have been the guiding principles that has steered us through the ever-changing currents of the industry to date. Our commitment to Respect, Integrity, Passion, and Strength remains steadfast, but how we express these values will evolve to meet the demands of today’s business world and we invite all our employees, partners, and suppliers to join us on this journey as we continue to build a better, more adaptable, and more ethical business for tomorrow.

OUR 39 YEAR VETERAN CALLS TIME ON A FANTASTIC CAREER AT KRUEGER.

CHRISTINE SAMUEL HR CO-ORDINATOR

Kevin Anderson’s 39-year career at Krueger is a testament to dedication, skill, and an unwavering commitment to excellence in his work. Throughout his nearly four-decade journey with the company, Kevin remained a steadfast and valued member of the finishing department, where he honed his craft to become a legend in his own right. His unparalleled ability to plumb in trailers is the stuff of legends within the organization.

Shayne Beri, Supervisor - Finishing, recalls working with Kevin over the years. “I’ve been here for over 20 years on and off, and in that time, I’ve never seen a harder worker than Kev.” “To the day he hung up the overalls, he was still as active as he was in his prime years.”

Kevin’s journey at Krueger began in 1984 when he walked through the company’s doors as a fresh-faced, eager worker ready to make his mark. Over the years, he not only made his mark but left an indelible impression on the entire organization. His role in the finishing department may not have been in the spotlight, but his contributions were nothing short of extraordinary.

What truly set Kevin apart was his unparalleled skill in plumbing in trailers. This crucial step involved connecting all the intricate hydraulic, pneumatic, brake and electrical systems, ensuring they functioned flawlessly. Many considered it a challenging part of the finishing process, but for Kevin, it was a labour of love.

What made Kevin’s contributions even more remarkable was his unassuming demeanour. “He was never one to boast about his abilities or seek recognition but would clock on every day to do the job… for 39 years.” adds Shayne. Given the nickname “Kevi-Leaks”, after his self-proclaimed knowledge of all things in conversation Shayne recalls the more sarcastic and fun side of Kevin’s personality, “He’d know everything about anything and the boys in the department would never believe him, but he had a knack for getting us to all listen to that nonsense anyway.”

When Kevin finally decided to retire after 39 years of dedicated service, the company and his colleagues celebrated his remarkable career. He had become a legend at Krueger, not for seeking the spotlight, but for quietly and consistently being the best at what he did.

John Krueger, Founder of Krueger Transport, concluded “In our 45 years of business, it’s a testament to the company to have so many employees who have been here 20 and 30 years. In the world of manufacturing, where precision and expertise are paramount, Kevin Anderson’s 39-year journey at Krueger stands as a testament to the value of skill, experience, and unwavering dedication to the job and company. He is a true legend in the finishing department, leaving behind a legacy that we hope to continue to inspire generations of workers at Krueger in the future.”

Congratulations on your retirement Kevin and thank you for your dedication and hard work over the years. May you enjoy your freedom and unlimited weekends to work on the boat.

Kevin presented with his 39 year certificate with Finishing Department Supervisors Shayne Beri & Adrian Short.

Above: Looking sharp back in 2000 there Kev. Below: The St Albans team that Kevin was apart of.

Kevin presented with his 39 year certificate with Finishing Department Supervisors Shayne Beri & Adrian Short.

Above: Looking sharp back in 2000 there Kev. Below: The St Albans team that Kevin was apart of.

MILESTONE: 1000 DAYS LDI AFTER RESTRUCTURING WORK SAFE PRACTICES IN SERVICE DEPARTMENT.

BRETT TWEEDLY

WARRANTY , COSTINGS & QA SUPERVISOR

Reaching a remarkable milestone of 1000 days without a lost time injury is a testament to the commitment of safety in the workplace at Krueger. This achievement showcases the dedication of Krueger and its workforce towards creating a safe environment where employees can thrive without the burden of injury or incident impeding their productivity

Surpassing this milestone reflects a focus on preventative measures, continuous training, implementation and understanding safety procedures and investment in workplace equipment and facilities. It is a reminder that fostering a culture of safety is not an isolated effort, but a collective responsibility that grows through every employee at Krueger This accomplishment underscores the potential for long-term success when safety is integral in the core values of Krueger.

Celebrating 1000 days without a lost time injury is not merely a number, but a reflection of the efforts of all employees to not only safeguard their own well-being but the co-workers around them.

It sets a benchmark for others to emulate at every level of our business, emphasizing that safety is a journey with no finish line, where each day without injury or incident is worth celebrating.

NEW FACES TO KRUEGER.

We extend a warm and hearty welcome to all our new recruits, including 3 new apprentices and our first female team member in the service department, as they join the Krueger Family across our diverse areas of service, manufacturing, and administration.

Your fresh perspectives, skills, and enthusiasm are invaluable assets that will help us continue to grow and thrive as a company. We look forward to working together and achieving great success as a team.

New Service Department (VIC) Apprentices Emmaleigh Young & Jack Shadbolt

Our new Financial Controler, Michael Degtiarev, with Accounts Officers, Angela Reweti & Marina Moore.

Joining our NSW Service teams is Timmothy Myles..

Celebrating in style with the team from Smokin’ Barrys.

New Service Department (VIC) Apprentices Emmaleigh Young & Jack Shadbolt

Our new Financial Controler, Michael Degtiarev, with Accounts Officers, Angela Reweti & Marina Moore.

Joining our NSW Service teams is Timmothy Myles..

Celebrating in style with the team from Smokin’ Barrys.

STRENGTHENING PARTNERSHIPS: ATR’S COLLABORATIVE JOURNEY WITH CENTRAL TRUCK TRANSPORT.

DAVID RAFFAELE MANAGER - ATR HIRE

In the dynamic industry that is transport, the wisdom gained from experience often shapes our approach and understanding. Earlier in my career, a senior manager shared an enlightening perspective on the essence of any successful enterprise. While I initially thought most important part of the business was in the product itself, I was corrected with a resounding truth: “It’s the customer!”

Today as the Manager of ATR, I am always aware of the unwavering commitment our clients, particularly owner-operators, invest in their daily operations. Managing every- changing, ever-shifting freight demands can be a tricky task, and with new trailers being such a sort after asset with long wait times, the hire trade has benefited, even smaller more boutique services like ATR.

Our role at ATR is more than the provision of rental equipment; we are enablers of solutions that empower our clients to navigate the complexities of the transportation sector. It is a point of pride for us to contribute to these solutions by ensuring that our services are reliable, prompt, and tailored to their specific requirements where we can.

Central Truck Transport’s rise in the industry serves as a testament to our collaborative efforts. Providing Ayhan Bascar, Director, and his team with dependable and adaptable rental trailers is not just about equipment; it’s about being a part of his expansion, successes, and journey.

“When I first started out, I had a truck but needed a trailer. David and ATR were there to start me off and get me going.” Now 5 years on, the trend has continued. “Every time I bought a new truck, I’d hire a trailer till we could get our own.” Ayhan now uses ATR as a major part of

his business ensuring he always has a truck and trailer, whether its part of their fleet or an ATR rental, on hand to help a customer at moment’s notice. “We always like to have 2 setups on standby in case we need to act fast. ATR has helped us be more efficient for our customers, and their customer service keeps us coming back. In the past where we have used other companies; we’ve felt like a number.” Ayhan concludes, “ATR & Krueger has always been a partner to our business and will be as we keep growing.”

Central Truck Transports business, many of our customers look to us to be a part of the solution through reliable, fast service. As I previously stated, our cliental make minor miracles happen daily. As a greater business, Krueger commits to the goal to see our clients win and grow their business. Whilst the core offering is making trailers to their fleet, it’s our other business units like spare parts, service and rental trailers that form a larger part of what we offer at Krueger in supplementing and aiding their growth.

Left to Right: David Raffaele (ATR Manager) and Ayhan Bascar (Director Central Truck Transport)

A DISTURBING TREND: RISING SEMI-TRAILER THEFTS.

SHANE MYERS STATE MANAGER - NSW/QLD

In recent times, the transportation industry has been facing a concerning surge in semi-trailer thefts, posing a significant challenge to both truck owners and manufacturers. Among those who are actively combatting this issue is Krueger National Service & Krueger National Spare Parts.

Semi-trailers serve as the backbone of the logistics and transportation sector, facilitating the movement of goods across vast distances. However, the industry has recently witnessed a disturbing trend - an increase in thefts targeting these valuable assets. One such incident involved a near-new Freighter semitrailer which fell victim to theft, resulting in the loss of rear guards, taillights, and even a toolbox. This unfortunate event underscores the urgency of finding effective measures to deter theft and safeguard these critical components.

Recognising the need for enhanced security measures, both Krueger National Service & National Spare Parts Departments has collaborated with suppliers to introduce innovative changes that protect truck owners’ investments and maintain the integrity of their vehicles. One remarkable solution they have introduced is the use of anti-theft shear nuts to secure rear jumbo taillights. These specially designed nuts are engineered to resist tampering and unauthorised removal, providing an added layer of protection for valuable trailer components.

As thefts targeting semi-trailers continue to rise, the transportation industry faces a pressing challenge that requires innovative solutions. As we continue to learn more on the events of such tragic scenarios, our collaboration with suppliers and their innovation we continue to remain proactive in safeguarding assets against the growing threat of theft.

A COST-EFFECTIVE AND RELIABLE CHOICE FOR NEW & OLD TRAILERS.

Over the past 6 months, we’ve had a lot to say about RFS by Krueger. In celebrating its 25th year in the market we have had articles written and even made it part of our major attraction at the Brisbane Truck show. As the “downturn” of the economy increases we’ve witnessed a significant surge in the number of aging trailers looking for a reliable and costeffective suspension system upgrades or replacements. Many trailer operators are searching for an alternative to expensive alternate brands, and they’re finding their solution right here at Krueger. Krueger’s RFS suspension system has emerged as a popular choice, offering a blend of affordability, reliability, and readily available parts across our service centre locations in Melbourne, Sydney, and Brisbane and through our network of resellers Nationwide.

One of the key concerns when considering a suspension upgrade is reliability. Trailer operators need to know that their investment will stand the test of time. Krueger understands this, and that’s why we offer a solid warranty on our RFS suspension system. This warranty provides peace of mind to our customers, assuring them that they are investing in a reliable and long-lasting solution.

When it comes to maintenance and repair, availability of spare parts is paramount. Our Parts & Service centres locations in Melbourne, Sydney, and Brisbane are strategically positioned to provide easy access to Krueger’s RFS suspension parts. We understand that minimizing downtime is crucial for trailer operators, and our extensive parts inventory ensures that you can quickly get back on the road.

As a National Parts business, whilst being owned by Krueger, we still offer like-for-like replacements and stock one of the largest range of Genuine Hendrickson parts instore and quick easy access to BPW and other competitor’s parts close to our main warehouse location in Derrimut Victoria. This allows us to offer operators the option on what they need and if need be, we can remove and fit new or replacement product within one of our National Service Centres.

Our National Service Centres locations are equipped to handle suspension system replacements across all brand models and makes of trailer and suspension, so you don’t have to worry about the hassle of finding a separate service provider. We offer a complete package: from supplying the parts to removing the old suspension and expertly fitting suspension system in its place.

Krueger’s RFS suspension system has quickly become a talking point of many trailer fleet and owner operators seeking a reliable, cost-effective, and readily available solution to upgrade their aging trailers. With a strong warranty, readily accessible parts, and complete service solutions, Krueger is committed to keeping your trailers on the road, ensuring both your peace of mind and your bottom line. Don’t let your aging trailers hold you back – contact our Spare Parts locations and ask about making the switch to Krueger’s RFS suspension and experience the difference for yourself.

BEN RAUDINO NATIONAL SPARE PARTS MANAGER

LOVE MY KRUEGER.

TRAIANON TRANSPORT.

JAMES TAMANIKA CREATIVE LEAD - MARKETING

With so many companies now involved in the transport landscape, few companies manage to carve out a legacy, but Traianon’s Transport stands as a shining example of such a triumph. The journey of Traianon’s Transport dates to 1978 when Arthur, the patriarch of the family, founded the business. What began as a modest family venture has evolved into a thriving enterprise over the years. Brothers Anthony and Peter, having cut their teeth working alongside their father since they were old enough to operate a vehicle, took the reins a decade ago after Arthur’s unfortunate accident and have done their father proud in its growth over this time.

In a candid moment, Anthony acknowledges the unceasing pace of their operations: “Always something going on.” Throughout its history, Traianon’s Transport has been a stalwart presence along the eastern seaboard of Australia and in Adelaide. Their scope of work encompasses a wide range of general freight services, catering to diverse clients through various partnerships.

The heart of Traianon’s Transport lies in its fleet. Of the 27 trailers owned, 17 Krueger trailers take centre stage with a further 6 in the order bank for delivery over the next 12 months. These trailers have earned a special place in the hearts of the team, as evidenced by the enthusiastic endorsement of one team member: “F%&king love them,” as succinctly put. “We bought our first Krueger’s in 1998 and where immediately impressed. The Krueger trailers are known for their durability and innovation, that in turn becomes Traianon’s commitment to excellence in servicing our customers.” Says Anthony.

Using all of Krueger’s business units, Anthony puts it blatantly, “Nothing seems to be a problem! I get a high level of customer service and whether it’s Grant, or Ben or Phil, they always make time to help me with my problems.” A highlight of this service was Traianon’s 2009 built Krueger Drop Deck Mezz that was given to the service department to refurbish. “This trailer had done it all and was pretty beaten and bruised from its continued use. The guys took away this old workhorse and brought me back what was an as- new refurbishment that you’d never know that it was nearly 20 years old.” Adds Anthony.

“The level of service we receive for Krueger’s means our business can keep doing what it does best, and we know they always have our backs when we need them.”

Left to Right: Peter & Anthony Traianon

KRUEGER’S READY

TO ROLL OUT

PERSONAL RELATIONSHIPS ARE THE KEY TO GOOD BUSINESS.”

LINDSAY FOX AC

At Krueger Transport, we pride ourselves on being a family owned and operated business and, like Linfox, started from humble beginnings to the business we are today. Over the past 20 years we have been proud to support Linfox Logistics as we continue to manufacture quality products for Australia’s leading Transport & Logistics company.

We value this personal relationship today, and into the future. www.krueger.com.au

“

STEVEN TEOFILO DIRECTOR OF ENGINEERING & SUPPLY CHAIN

STEVEN TEOFILO DIRECTOR OF ENGINEERING & SUPPLY CHAIN

Tony Hafoka (HC Farley) walks a tour though the laser facility with Kevin Dennis (CEO) & Steven Teofilo (Director Supply Chain & Engineering)

ADIS SELMIC MANAGER - ENGINEERING

Tony Hafoka (HC Farley) walks a tour though the laser facility with Kevin Dennis (CEO) & Steven Teofilo (Director Supply Chain & Engineering)

ADIS SELMIC MANAGER - ENGINEERING

DAVID GRANT HEAD OF MANUFACTURING

DAVID GRANT HEAD OF MANUFACTURING

Above: David Grant shows Michael George (top) and his new apprentices, Emmileigh & Jack (bottom) through the factory to gain an understanding of the manufacturing process.

Above: David Grant shows Michael George (top) and his new apprentices, Emmileigh & Jack (bottom) through the factory to gain an understanding of the manufacturing process.

Kevin presented with his 39 year certificate with Finishing Department Supervisors Shayne Beri & Adrian Short.

Above: Looking sharp back in 2000 there Kev. Below: The St Albans team that Kevin was apart of.

Kevin presented with his 39 year certificate with Finishing Department Supervisors Shayne Beri & Adrian Short.

Above: Looking sharp back in 2000 there Kev. Below: The St Albans team that Kevin was apart of.

New Service Department (VIC) Apprentices Emmaleigh Young & Jack Shadbolt

Our new Financial Controler, Michael Degtiarev, with Accounts Officers, Angela Reweti & Marina Moore.

Joining our NSW Service teams is Timmothy Myles..

Celebrating in style with the team from Smokin’ Barrys.

New Service Department (VIC) Apprentices Emmaleigh Young & Jack Shadbolt

Our new Financial Controler, Michael Degtiarev, with Accounts Officers, Angela Reweti & Marina Moore.

Joining our NSW Service teams is Timmothy Myles..

Celebrating in style with the team from Smokin’ Barrys.