Shutdown SIS

Previous Screen

Product: WHEEL LOADER

Model: 962K WHEEL LOADER T6A

Configuration: 962K Wheel Loader T6A00001-UP (MACHINE) POWERED BY C7.1 Engine

Disassembly and Assembly

950K and 962K Wheel Loaders Machine Systems

Piston Pump (Implement) - Assemble

SMCS - 5070-016-II; 5070-016; 5070-016-FD; 5084-016-QP; 5084-016

Assembly Procedure

Table 1

Required Tools

Illustration 2

g02722269

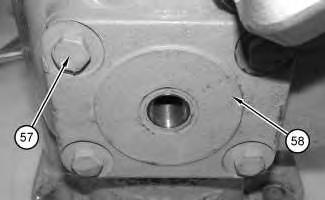

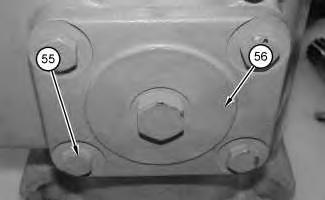

2. Install cover (56) and bolts (55) .

Illustration 3

g02722268

3. Install bearings (54) .

Illustration 2

g02722269

2. Install cover (56) and bolts (55) .

Illustration 3

g02722268

3. Install bearings (54) .

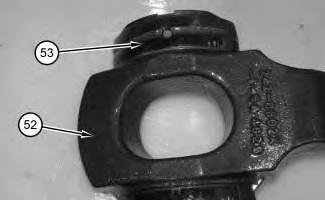

4. Install bearings (53) onto swashplate (52) .

5. Install swashplate (52) .

6. Raise the temperature of bearing (51) .

7. Install retaining ring (50) and bearing (51) onto shaft assembly (49) .

Illustration 4

g02722267

Illustration 5

g02722266

Illustration 6

g02722265

Illustration 4

g02722267

Illustration 5

g02722266

Illustration 6

g02722265

Illustration 7

g02722264

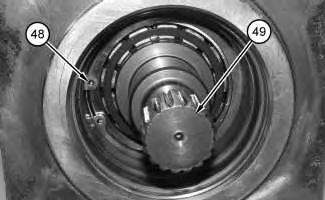

8. Install shaft assembly (49) .

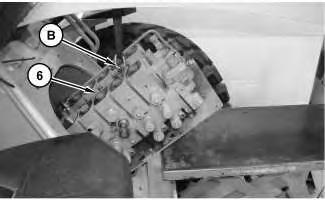

9. Use Tooling (B) in order to install retaining ring (48) .

Illustration 8

g02722263

10. Install lip seals (47) .

Illustration 9

g02722262

Illustration 7

g02722264

8. Install shaft assembly (49) .

9. Use Tooling (B) in order to install retaining ring (48) .

Illustration 8

g02722263

10. Install lip seals (47) .

Illustration 9

g02722262

11. Install O-ring seals (46) .

Illustration 10

g02722261

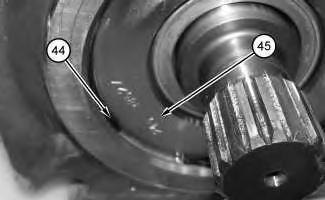

12. Install cover (45) and retaining ring (44) .

Illustration 11

g02722258

13. Install springs (42) into barrel (43) .

11. Install O-ring seals (46) .

Illustration 10

g02722261

12. Install cover (45) and retaining ring (44) .

Illustration 11

g02722258

13. Install springs (42) into barrel (43) .

Illustration 12 g02722254

14. Install retainer (41) .

Illustration 13 g02722252

15. Install bearing (40) .

Illustration 14 g02722250

16. Install pistons (38) into retainer (39) .

Illustration 15 g02722249

17. Install pistons (38) and retainer (39) into the barrel assembly.

Illustration 16 g02722248

18. Install barrel assembly (36), O-ring seal (35), and O-ring seal (37) .

Illustration 17 g02722245

19. Lower the temperature of bearing (34) .

Illustration 15 g02722249

17. Install pistons (38) and retainer (39) into the barrel assembly.

Illustration 16 g02722248

18. Install barrel assembly (36), O-ring seal (35), and O-ring seal (37) .

Illustration 17 g02722245

19. Lower the temperature of bearing (34) .

20. Install bearing (34) into the port block assembly .

21. Apply Tooling (D) to the back side of port plate (33) .

22. Install port plate (33) onto the port block assembly .

Improper assembly of parts that are spring loaded can cause bodily injury.

To prevent possible injury, follow the established assembly procedure and wear protective equipment.

23. Install port block assembly (32) and bolts (31) .

Illustration 18 g02722244 Illustration 19 g02722243Improper assembly of parts that are spring loaded can cause bodily injury.

To prevent possible injury, follow the established assembly procedure and wear protective equipment.

Illustration 20

g02722232

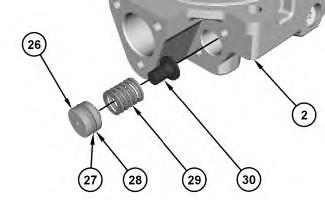

24. Install guide (30), spring (29), backup ring (27), O-ring seal (28), and plug (26) into pump control head (2) .

Illustration 21

g02722228

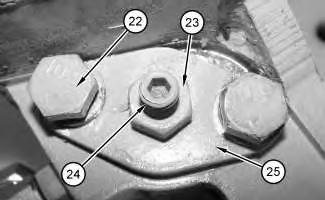

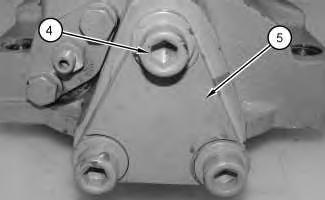

25. Install cover (25), bolts (22), adjustment screw (24), and locknut (23) .

Illustration 20

g02722232

24. Install guide (30), spring (29), backup ring (27), O-ring seal (28), and plug (26) into pump control head (2) .

Illustration 21

g02722228

25. Install cover (25), bolts (22), adjustment screw (24), and locknut (23) .

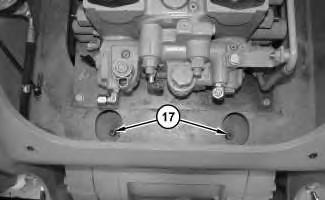

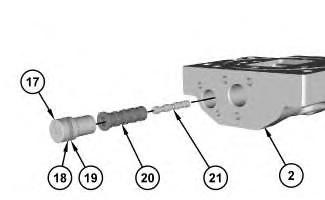

26. Install backup ring (18), O-ring seal (19), onto piston (17) .

27. Install spool (21), sleeve (20), and piston (17) into pump control head (2) .

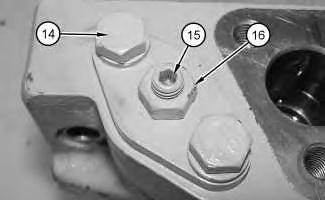

28. Install the cover, bolts (14), adjustment screw (15), and locknut (16) .

Illustration 22

g02722205

Illustration 23

g01145877

Illustration 24

g01145875

Illustration 22

g02722205

Illustration 23

g01145877

Illustration 24

g01145875

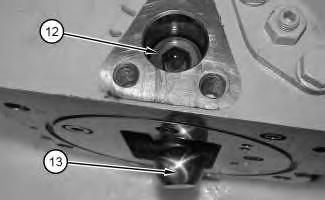

29. Apply Tooling (C) to the threads of piston (12) .

30. Install piston (12) and ball (13). Tighten piston (12) to a torque of 350 ± 30 N·m (258 ± 22 lb ft).

Note: Do not use an impact wrench in order to install piston (12) .

Note: Allow Tooling (C) to dry for 4 hours at room temperature.

31. Install the O-ring seal, the backup ring, and piston (11) .

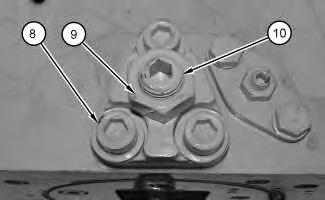

32. Install the cover, bolts (8), adjustment screw (10), and locknut (9) .

Illustration 25 g01145874 Illustration 26 g01145873

Illustration 27 g01145872

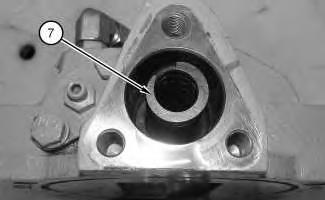

33. Install spring (7) .

Illustration 28 g01145871

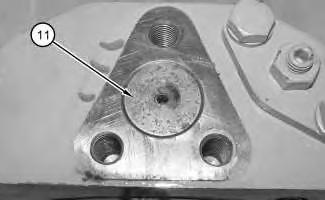

34. Install O-ring seal (6) and the backup ring.

Illustration 29 g01145870

Illustration 27 g01145872

33. Install spring (7) .

Illustration 28 g01145871

34. Install O-ring seal (6) and the backup ring.

Illustration 29 g01145870

Improper assembly of parts that are spring loaded can cause bodily injury.

To prevent possible injury, follow the established assembly procedure and wear protective equipment.

g01145869

Illustration 31

End By: Install the pump.

g01145867

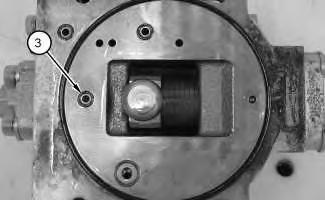

35. Install cover (5) and bolts (4) . Illustration 30 36. Install O-ring seals (3) . 37. Install head (2) and bolts (1) .Shutdown SIS

Previous Screen

Product: WHEEL LOADER

Model: 962K WHEEL LOADER T6A

Configuration: 962K Wheel Loader T6A00001-UP (MACHINE) POWERED BY C7.1 Engine

Disassembly and Assembly

950K and 962K Wheel Loaders Machine Systems

Electrohydraulic Control - Remove and Install

SMCS - 5702-010

Removal Procedure Table 1

Required Tools

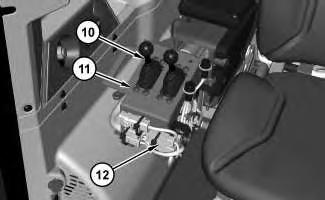

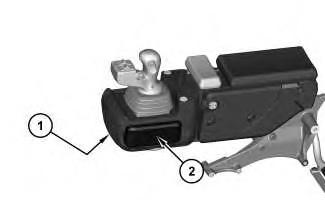

Illustration 2

g02486722

2. Remove plate (2).

Illustration 3

g02486738

3. Loosen knob (4) and remove arm rest (3).

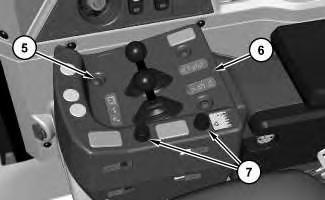

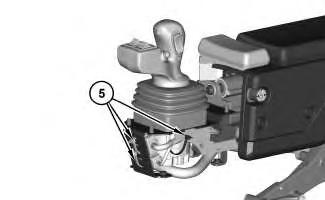

Illustration 4

g02486756

4. Remove screws (5) and (6). Disconnect harness assemblies from switch assemblies (7).

Illustration 2

g02486722

2. Remove plate (2).

Illustration 3

g02486738

3. Loosen knob (4) and remove arm rest (3).

Illustration 4

g02486756

4. Remove screws (5) and (6). Disconnect harness assemblies from switch assemblies (7).

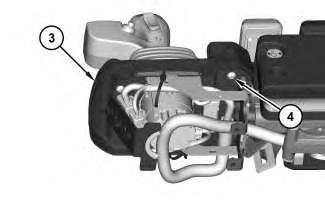

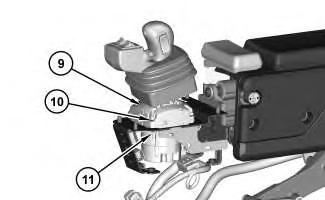

Illustration 5

g02487117

5. Remove screws (8) and cover (9).

Illustration 6 g02487136

6. Disconnect harness assemblies (12). Remove screws (11) and electrohydraulic controls (10).

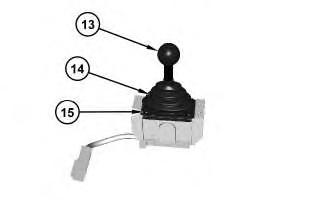

Illustration 7 g02487617

7. Remove knob (13), screws (15), and boot (14).

Illustration 5

g02487117

5. Remove screws (8) and cover (9).

Illustration 6 g02487136

6. Disconnect harness assemblies (12). Remove screws (11) and electrohydraulic controls (10).

Illustration 7 g02487617

7. Remove knob (13), screws (15), and boot (14).

Illustration 1

g02620276

Illustration 1

g02620276

Illustration 5

g02627777

7. Remove bracket assemblies (9) from frame assembly (10). Reposition tube assemblies (5) out of the way. Repeat for the opposite side.

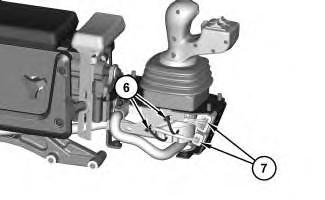

Illustration 6

g02627519

8. Disconnect tube assemblies (11) and hose assemblies (12) .

Illustration 7

g02628759

Illustration 5

g02627777

7. Remove bracket assemblies (9) from frame assembly (10). Reposition tube assemblies (5) out of the way. Repeat for the opposite side.

Illustration 6

g02627519

8. Disconnect tube assemblies (11) and hose assemblies (12) .

Illustration 7

g02628759