ARC80004 Fabrication & Creative Processes Kaitlyn

102110707 Project 1

McNaughton

Acknowledgement of Country

We respectfully acknowledge the Wurundjeri People of the Kulin Nation, who are the Traditional Owners of the land on which Swinburne’s Australian campuses are located in Mel bourne’s east and outer-east, and pay our respect to their Elders past, present and emerging.

We are honoured to recognise our connection to Wurundjeri Country, history, culture and spirituality through these locations, and strive to ensure that we operate in a manner that respects and honours the Elders and Ancestors of these lands.

We also respectfully acknowledge Swinburne’s Aboriginal and Torres Strait Islander staff, students, alumni, partners and visitors.

We also acknowledge and respect the Traditional Owners of lands across Australia, their Elders, Ancestors, cultures and heritage, and recognise the continuing sovereignties of all Aboriginal and Torres Strait Islander Nations.

Part 1 | Timber to Timber Connection

Joist to Bearers or Top Plates

The joist to bearer timber fixture method is commonly used in the floor of residen tial timber framed construction.

Joint group (J, JD rating) shall be based on the weakest of either member as design strength is controlled by shear or bearing of the bolt in both members. - AS 1684.2 2021 pg191

Scale 1:5 @ A4 ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Perspective Direction of load Compression Tension Uplift Capacity, kN Unseasoned Timber Seasoned Timber J2 J3 J4 JD4 JD5 JD6 16 14 10 10 7 5 Shear

Characterisitcs

In line with standards AS 1684.2 2021 & AS 1720.1-2010

Minimum Required Size of Washers for Structural Bolted Joints

Washer Size, mm Bolt Thickness Diameter Side Length

Effective Area for Bearing mm

Axial Design Capacity of Bolt N

M6 1.6 30 25 200 6400 M8 2.0 36 32 350 11700 M10 2.5 45 40 570 18600

Characteristic Capacity for Single Bolts Perpendicular to the Grain - Unseasoned Timber Bolt Diameter (D) Joint Group

Effect Timber Thickness mm M6 M8 J2 25 1310 1750 2190 38 2000 2660 3300 50 2630 3500 4380

Characteristic Capacity (Qkp), N M10 M12 75 3090 4750 6560 100 3090 4750 6540 150 3090 4750 6540 200 3090 4750 6540

2360 3990 5250 7880 8730 8730 8730

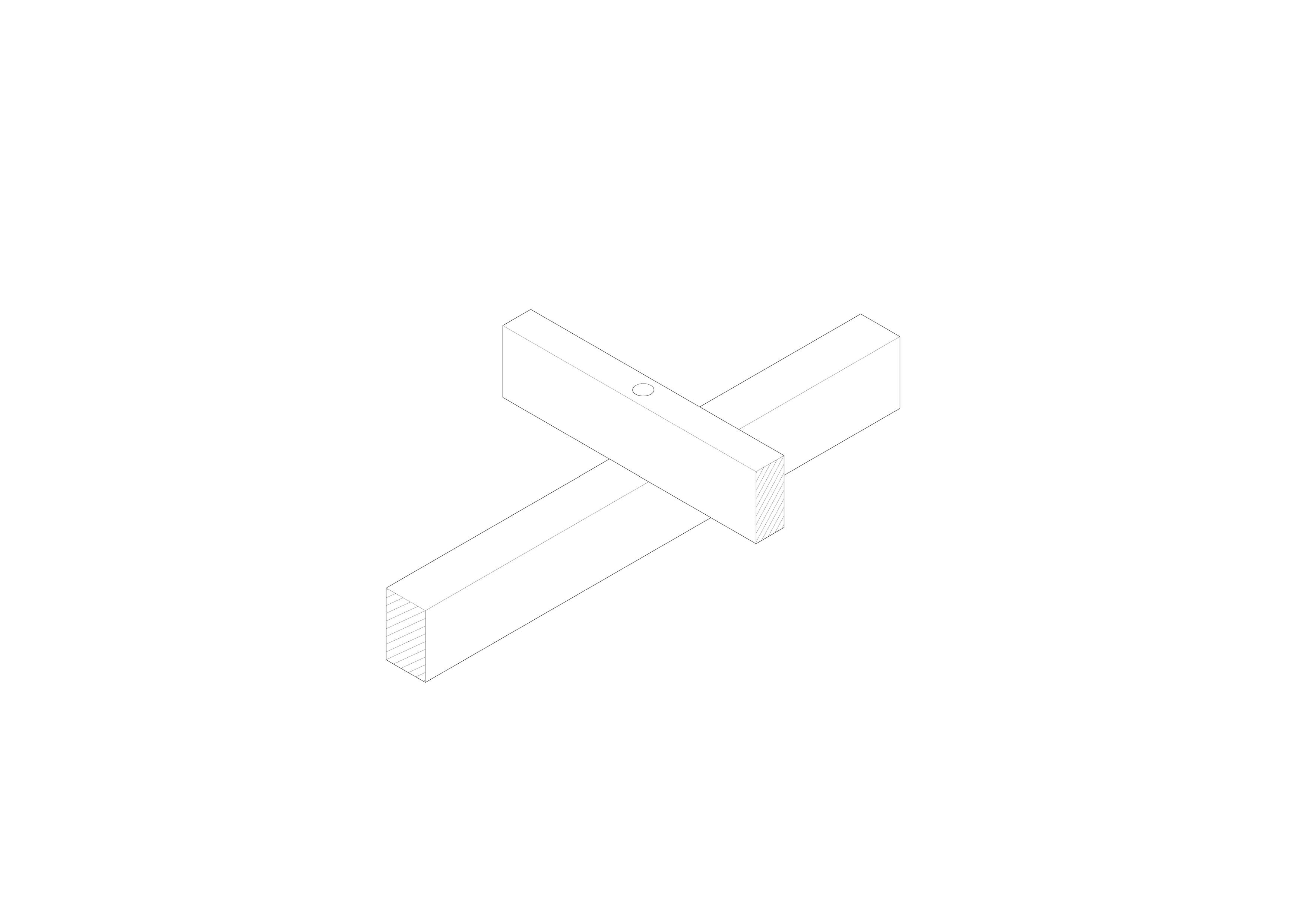

Exploded Axonometric

Scale 1:5 @ A4

M10 Cup-Head Bolt

Galvanised @ 10x240

Bearer

J2 Unseasoned Hardwood @ 63x100

Joist

J2 Unseasoned Hardwood @ 45x100

M10 Washer M10 Nut ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Scale 1:5 @ A4 Detail 1

Hole diameter @ 12 Detail 1

31.5

31.5

Scale 1:5 @ A4 Scale 1:5 @ A4

Scale 1:2 @ A4 300 300 10

45 550 550 22.5 22.5

Part 2 | Tolerances

Taiyuan Botanical Garden - The Tea House

The Tea House was constructed using a unique two way lattice structure. The lattice spans from three to nine layers throughout the design.

The blocks placed in between the beams have a larger space then needed to allow for imperfec tions in measurements. These imperfections are caused by timber warping over time, human error and changes in weather.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

The Joint Technique

Starting with Beams alligned in a single direction

Beams alligned in the opposite direction to create a lattice

Blocks added to in terlock the two lattices and replicated

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Arching Hall Japan

The Arching Hall was constructed using tim ber left over from furniture construction. The timber wasn’t pure enough so was disreguarded. This innovative timber method allows for large spans without columns.

The upright timbers act like clamps on the per perpendicular members which allow for slight tolerances in the timber.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

The Joint Technique

Starting with members alligned in a single direction

Members are then slid through the four upright timbers

Members are fixed us ing bolts to sandwich them between uprights

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Robot Workflow

Whilst the use of robots has many benefits it also has its challenges. In the workflow demonstrated in class a human-robot collab oration is essential.

A human needs to first design the project, then program and test the course the robot will need to take to build it. This can often be challenging and take a long time for there to be no errors or collisions. This also involves finding or designing a new attachment.

Humans must compile the materials in a way the robot can easily reach them and manu ally start and stop the program. They also need to supervise for the duration to stop the robot if any problems occur. The robot does not have sensors if collusions occur.

Robots have the ability to replicate builds at and accurate level with minimal errors.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

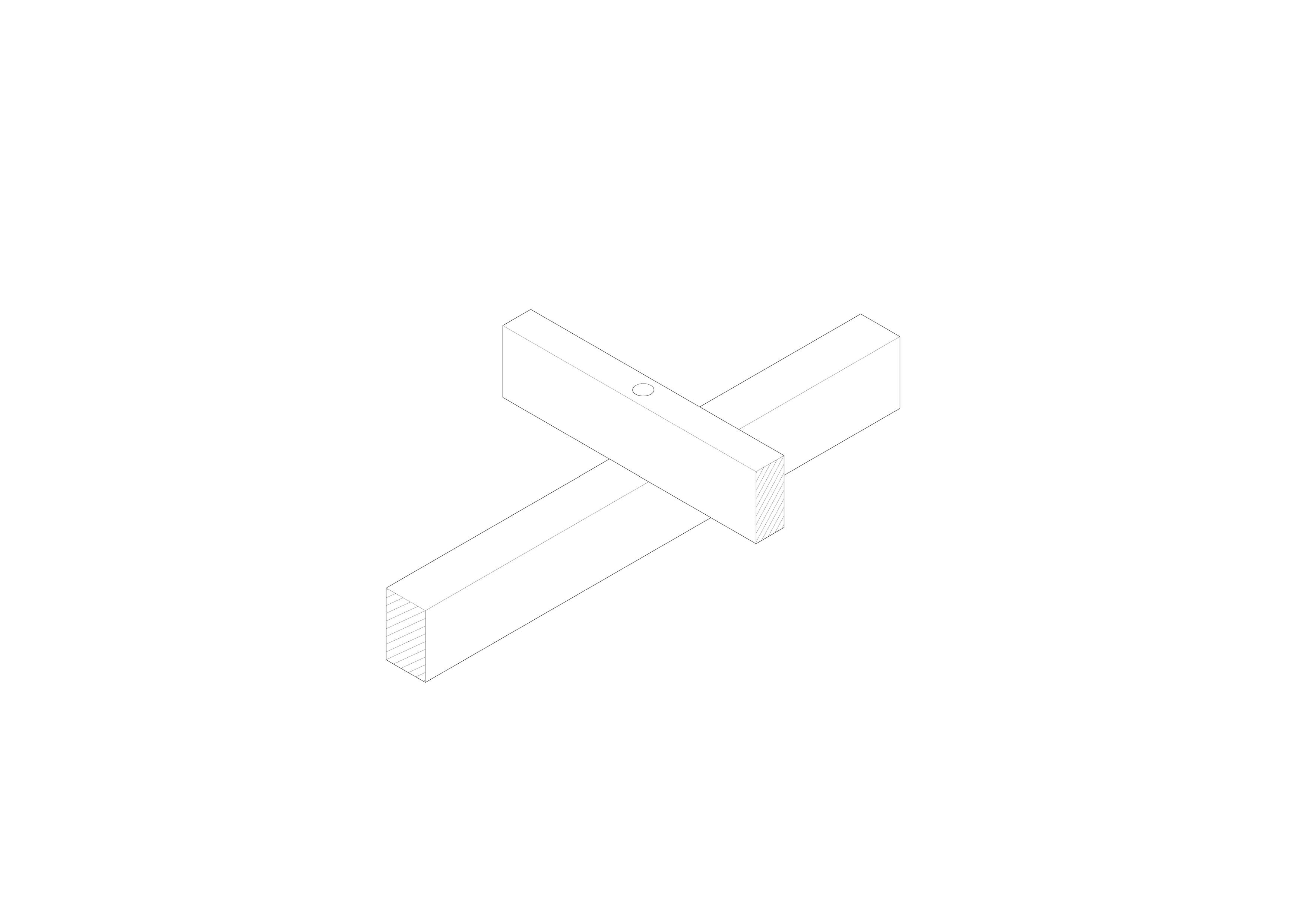

Part 3 | My Joint Technique

Joint Idea

The joint is designed to work with a hu man robot collaboration. The robot will use suction to place the members like in class. However, the timbers will be pre cut with a 20mm notch cut out to lock the members to gether. The human will then need to nail in two nails to complete the joint.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Joint

Wall

Exploded Axonometric

Scale 1:4 @ A4

Flat Head Nail Galvanised @ 50x2.8

Flat Head Nail Galvanised @ 50x2.8

Structural Pine @ 90x45

Structural Pine @ 90x45

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Top

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707 100 25

300

220 160 220

200 60

200 160

Elevation

Section 25 45

100 300

Scale 1:5 @ A4 Detail 1 Scale 1:5 @ A4 Scale 1:5 @ A4 Scale 1:2 @ A4

31.5 Nails spaced as per standard AS 1720.1 Detail 1

65 40 150 360 210 25

Physical 1:1 Model

The Process - Using the limited materials I could find in isolation

Measure 90x45mm structural pine & mark cut lines

Lightly sand and clean dirt off timber

Cut joint out at 20mm deep, make multiple cuts to help next step

Chisel and rasp out joint slowly down to 20mm deep

Clamp and hammer in two nails to strengthen the joint

Finished model

ARC80004 Fabrication & Creative Processes

McNaughton 102110707

Kaitlyn

Stacked Joint Scale 1:20 @ A4

This joint technique works well being stacked. Once the joints are chisled out they are quick and easy to assemble. As they practically lock into place without the need for fixing. This could work well with a robot/human collaboration, or just the robot if fixing wasn’t required.

Flat Head Nail

Galvanised @ 50x2.8

Flat Head Nail

Galvanised @ 50x2.8

Structural Pine @ 90x45

Structural Pine @ 90x45 Exploded Axonometric

Scale 1:5 @ A4

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Prototyping the Stacked Joint

Continuing on with the third layer of the joint worked very well and slotted to gether with ease. This joint works quick ly when constructed by hand. However, when considering a partnered workflow with a robot some issues could arrive. Most of these issues would be when it comes to fixing. Hammering nails in could cause the timber to move, so when the robot goes to add the next layer there could be a variance in placement.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Robot Workflow with Stacked Joint

If it was possible to use multiple robots the process would work much better. Ro bots or a CNC router could first create the cut out part of the joint. One robot can then place each timber into the de sired location whilst another uses a nail gun attachment to nail the fix the joint. This nail gun attachment will not cause the timbers to move as much as nailing with a hammer would.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

4 | Karamba

Part

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707 490 810 1300 100 450 450 900 900 450 450 450

Timber Frame Scale 1:20 @ A4

D E F G

Top Plate Bottom Plate Common Stud Noggin Lintel Sill Trimmer Jack Stud

1 1 8 5 2 1 3

90 x 45 90 x 45 90 x 45 90 x 35 90 x 35 90 x 35 90 x 35

Schedule

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707 A B C D E G

Scale 1:40 @ A4

F A B C

# Name Amount Size Length Needed 4,050 4,050 21,600 2,250 1,800 900 1,990 Product Size # Cost Framing MGP10 Untreated Pine 90 x 45 90 x 35 30m 7m $203.40 $35.42

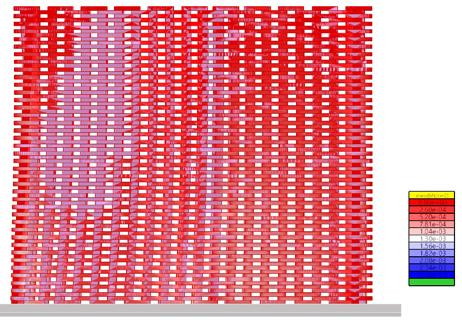

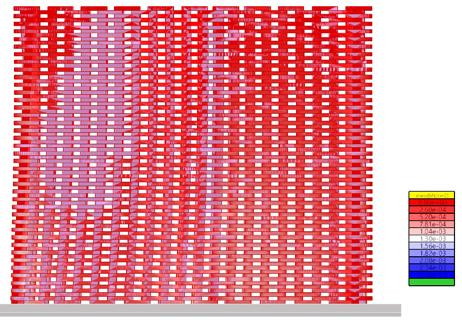

Karamba

Testing the frame

Support

Displacement Utilisation

Less then 1cm

Less then 16%

Load (1kn = 101.97kg)

Load (1kn = 101.97kg)

Support

Support Support

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Karamba

Interations - Exploring changes - Load 1kn = 101.97kg - Refer to previous legends

It appears that changing the distance of the studs had the biggest impact on displacement and utilisation. The iteration with closer studs has lower utilisation on the noggins especially.

Whilst this works better the difference is not substancial enough to justify the increase in price because of the extra timber needed.

Original Closer Studs

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Displacement 0.037cm Displacement 0.0052cm Bigger Window Lower Window Displacement 0.037cm Displacement 0.37cm

ARC80004 Fabrication & Creative Processes

Kaitlyn McNaughton, Manish Nupur Shah, Syed Farooq Ahmed

Kaitlyn McNaughton, Manish Nupur Shah, Syed Farooq Ahmed

Project 2

Part 1 | RoboDK ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

RobotDK Reflection

This was my first time using RoboDk, I found the interface relatively easy to use. I would be interested to try out my dance and drawing on a real robot in the workshop. This assignment was a great in troduction to the program and helped with the next simulation.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Design Intent

2

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Part

|

The Concept

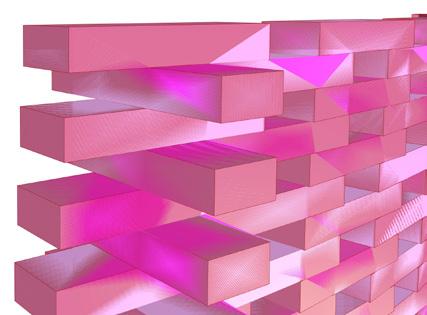

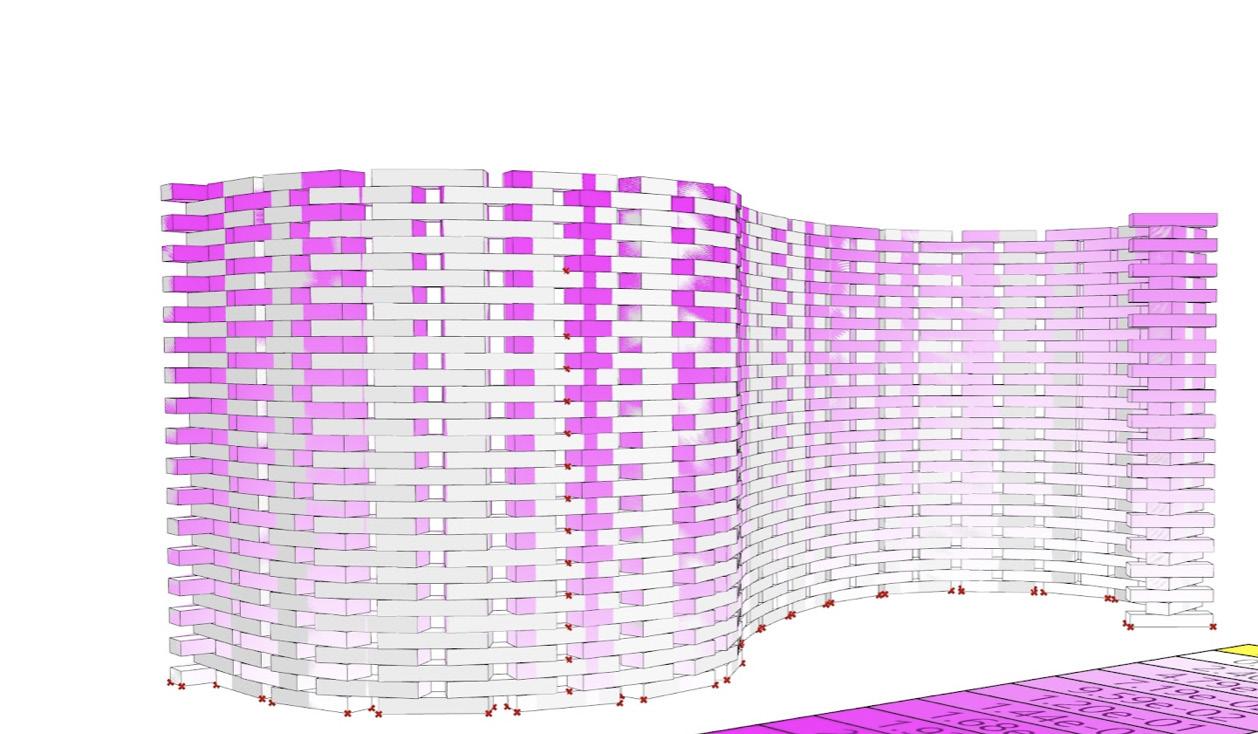

Swinburne has many study spaces that allow for flexible study options. However, when these spaces are used for private or group study some separation is needed. We would like to create a wall that allows for flex ible study separation.

ARC80004 Fabrication & Creative Processes

102110707

Kaitlyn

McNaughton

Group Study Individual Study

The Concept

If we can create a joint method that moves then the wall will be able to be manipulated. This will be very useful to change the space from group to private.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

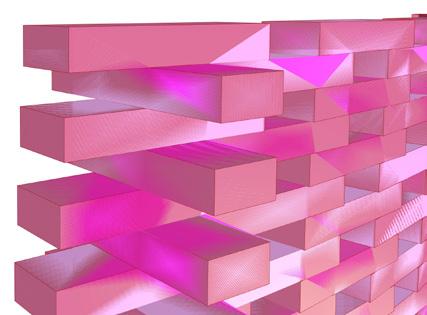

Iterations

Through an iterative process we be came aware that the joints couldn’t move unless they are vertically in-line with each other. This cre ates a very neat vertical wall. We also had the challenge of the edge bricks basially floating in mid air. To stop this from happening we rotated the end brick on every sec ond layer.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Scale 1:10 @ A4

45 MM BY 90 MM TIMBER MEMBER

25 MM DIAMETER TIMBER DOWEL 25.5 MM DIAMETER HOLE IN THE MEMBERS FOR DOWEL

25.5 MM DIAMETER HOLE IN THE MEMBERS FOR DOWEL

45 MM BY 90 MM TIMBER MEMBER 25 MM DIAMETER TIMBER DOWEL

45 MM BY 90 MM TIMBER MEMBER

25.5 MM DIA HOLE IN THE MEMBERS FOR TIMBER DOWEL

STEP 1 STEP 2 STEP 3 Connection Method

ARC80004 Fabrication & Creative Processes

Syed

Kaitlyn, Manisha,

Connection Method Scale Below

25 MM DIA WOODEN DOWEL 45 MM BY 90 MM TIMBER MEMBER

25.5 MM DIA HOLE IN THE MEMBERS FOR DOWEL

45.0 45.0 45 MM BY 90 MM TIMBER MEMBER

ELEVATION, 1:5 @ A 4

25.5 MM DIA HOLE IN THE MEMBERS FOR DOWEL

90.0 PLAN, 1:5 @ A 4

ARC80004 Fabrication &

Creative Processes Kaitlyn, Manisha, Syed

Part

| Material Properties

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

3

What material qualities are needed?

AMDC Level 3 is an extremely open area which allows for noise to easily carry through the space. Ideally a material with noise absorption qualities would be ideal.

AMDC Level 3

ARC80004 Fabrication & Creative Processes

102110707

Kaitlyn McNaughton

Absorb

Reflect

Noise Canceling Materials

Whilst timber is the most sustainable and structur ally appropriate material for the wall it is not necessarily good at absorbing noise. To make tim ber have more absorption you can apply texture or notches to the surfaces.

ARC80004 Fabrication & Creative Processes

102110707

Kaitlyn McNaughton

Single Brick

Timber Type & Measurements

Sticking with a standard size 90x45 which is used as timber studs in residential builds, gives the opportunity to reuse timber from demolished proj ects instead of buying new.

Pine studs can easily be textured on the sides to help absorb noise. In areas that arent loud it can be left plain. Other noise absorbing mate rials could also be applied to the surface but these would significantly increase the budget.

45 90 300

ARC80004 Fabrication & Creative Processes Kaitlyn, Manisha

Materials & Cost

A B

A B Timber Block Wooden Dowel 90 x 45 90 x 45 578 576

# Name Amount Size Length Needed 173.4m 28.9m

Product Size # Cost

Framing MGP10 Timber Dowel 90 x 45 25mm 174 29 $1175.60 $367.20

Schedule

ARC80004 Fabrication & Creative Processes Kaitlyn, Manisha

Modelling

Connection Construction Process

Step 2 Drill holes for dowels to insert into Insert dowels and place next layer ARC80004 Fabrication & Creative Processes Kaitlyn, Manisha, Syed

the

Step 1

Part

| Structural Analysis

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

3

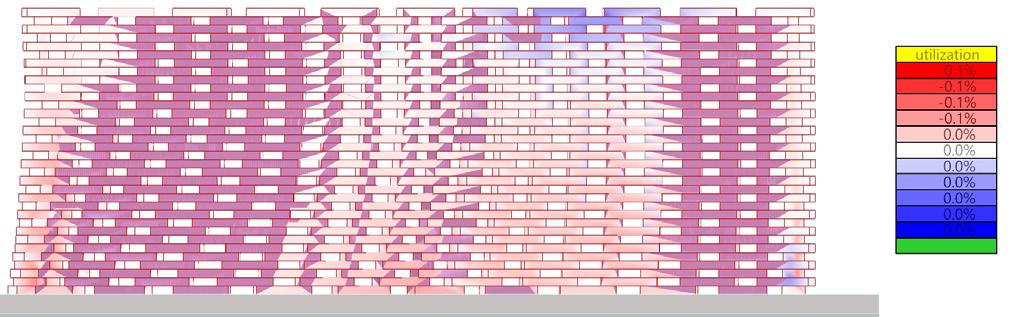

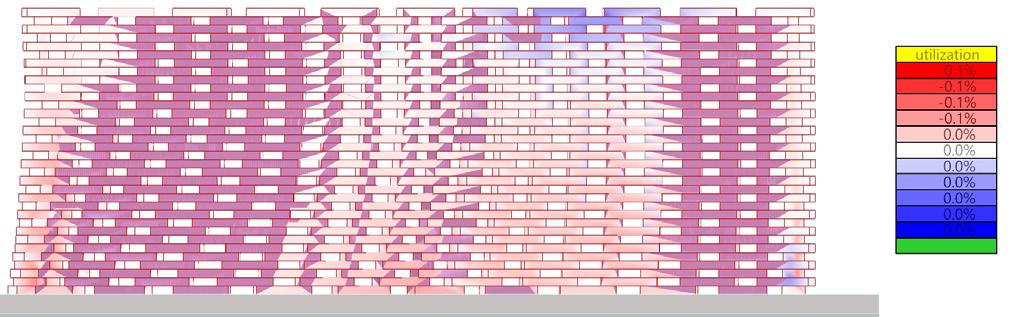

Displacement

Utilization Stress

Minimal displacement variation at the edges of wall when deformation percentage changes from 0 to 5

Minimal utilization variation when deforma tion percentage changes from 0 to 5

All results are considering support at the base and gravity as load

Minimal equivalent stress variation when de formation percentage changes from 0 to 5

ARC80004 Fabrication & Creative Processes Kaitlyn, Manisha

D0 D1 D5

Iteration 1 - Wall Height 560mm

Iteration 2 - Wall Height: 1550mm

When compared with wall of height 560 mm to almost double the height the displacement value, utilization and equiva lent stress increased.

In this case as well a minimal variation was noticed in the results while changing the deformation percentage from 0 to 100.

Displacement Utilization Stress

Minimal displacement variation at the edges of wall when deformation percentage changes from 0 to 5

Minimal utilization variation when deforma tion percentage changes from 0 to 5

All results are considering support at the base and gravity as load

Minimal equivalent stress variation when de formation percentage changes from 0 to 5

D0 D1 D5 ARC80004 Fabrication & Creative Processes

Kaitlyn, Manisha

Iteration 3 - Wall Height: 3200mm

When compared with wall of height 560 mm and 1550 mm to a wall height of almost a room size the value for displacement, utilization and equivalent stress changed drastical ly.

In this case a little variation was noticed in the results while changing the deformation percentage from 0 to 100.

Displacement Utilization Stress

Minimal displacement variation at the edges of wall when deformation percentage changes from 0 to 5

Minimal utilization variation when deforma tion percentage changes from 0 to 5

All results are considering support at the base and gravity as load

Minimal equivalent stress variation when de formation percentage changes from 0 to 5

ARC80004 Fabrication & Creative Processes

D0 D1 D5

Kaitlyn, Manisha

Iteration 4 - Wall Height: 1550mm Width: 150mm

Displacement Utilization Stress

Minimal displacement variation at the edges of wall when deformation percentage changes from 0 to 5

Minimal utilization variation when deforma tion percentage changes from 0 to 5

All results are considering support at the base and gravity as load

Minimal equivalent stress variation when de formation percentage changes from 0 to 5

ARC80004 Fabrication & Creative Processes

D0 D1 D5

Kaitlyn, Manisha

Iteration 5 - Wall Height: 1550mm Width: 300mm

D0 D1 D5

Displacement Utilization Stress

Displacement variation at the edges of wall when deformation percentage changes from 0 to 5

Utilization variation when deformation per centage changes from 0 to 5

All results are considering support at the base and gravity as load

Equivalent stress variation when deformation percentage changes from 0 to 5

Kaitlyn, Manisha ARC80004 Fabrication & Creative Processes

Iteration 6 - Wall Height: 1550mm Width: 500mm

D0 D1 D5

Displacement Utilization Stress

Visible displacement variation at the edges of wall when deformation percentage changes from 0 to 5

Visible utilization variation when deforma tion percentage changes from 0 to 5

All results are considering support at the base and gravity as load

Visible equivalent stress variation when de formation percentage changes from 0 to 5

ARC80004 Fabrication & Creative Processes Kaitlyn, Manisha

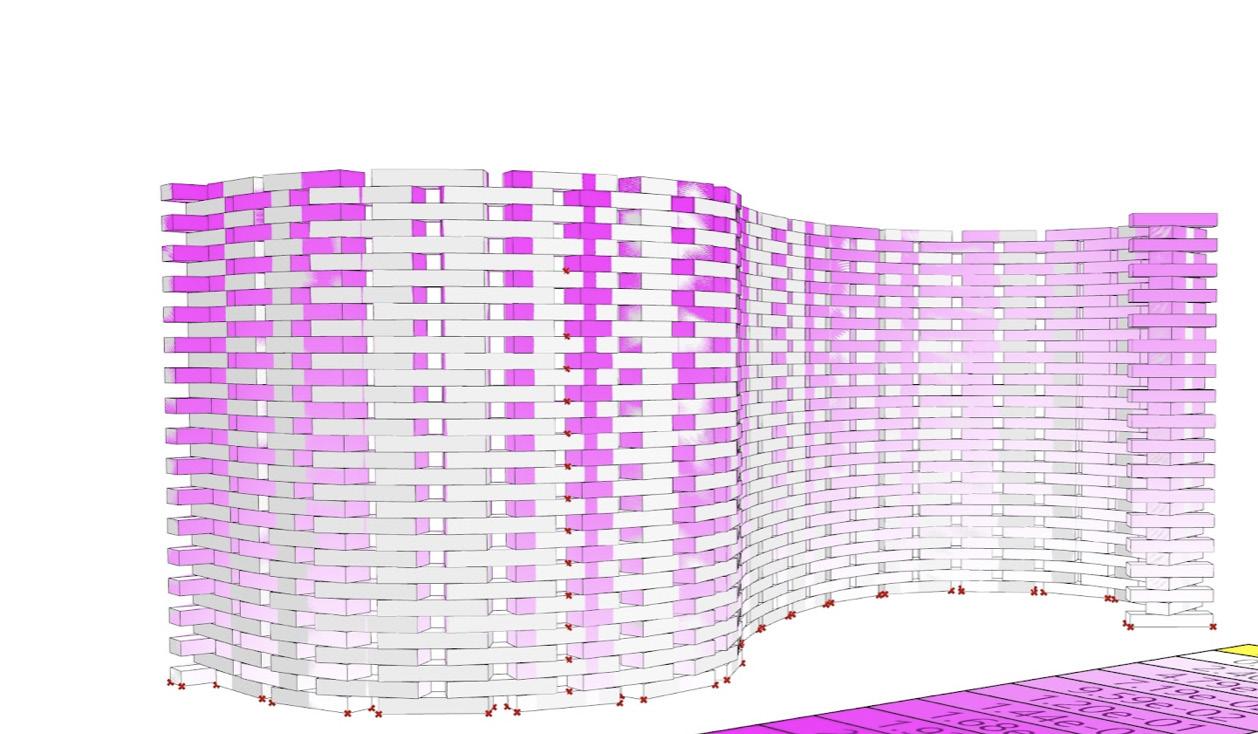

Horizontal Loads

Testing Horizontal Loads on the Wall

Because our wall is movable it will need to withstand horizontal forces when it is moved. We applied a 1,2 and 3 kg force to the sides of the wall to see how it would handle being moved.

1. 2. 3.

Fabrication Strategy

4

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Part

|

90 x 35 MM TIMBER BRICK, 300 MM LENGTH,18 IN NUMBER ALONG THE LENGTH GAP BETWEEN TWO TIMBER BRICKS 1485.0 3670.6 SIDE ELEVATION 1:10 @ A3 1000mm 800mm 600mm 400mm 200mm 200mm 1485.0 90 35 MM TIMBER BRICK, 300 MM LENGTH,18 IN NUMBER ALONG THE LENGTH FRONT ELEVATION 1:10 @ A3 1000mm 800mm 600mm 400mm 200mm 200mm Our Wall 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 90 x 35 MM TIMBER BRICK, 300 MM LENGTH 18 IN NUMBER ALONG THE LENGTH 90.0 300.0 1300 3604.9 PLAN 1:10 @ A3 1000mm 800mm 600mm 400mm 200mm 200mm ARC80004 Fabrication & Creative Processes Kaitlyn, Manisha, Syed

1485.0 6 8 10 11 12 13 14 15 16 17 18 KEY PLAN - N.T.S SECTION AA' 1:10 @ A3 0 1000mm 800mm 600mm 400mm 200mm 200mm 90 x 35 MM TIMBER BRICK, 300 MM LENGTH,18 IN NUMBER ALONG THE LENGTH Our Wall ARC80004 Fabrication & Creative Processes Kaitlyn, Manisha, Syed

Picking Station Concept

The picking station is a simple de sign that requires little assembly. Simply laser cut each layer and the bricks are cut at the same time. Once the robot finishes a layer it can suction off the empty frame to reveal a fresh layer. In a more collaborative approach the layers can be removed by hand.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Picking Station

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

1:5 Scale @ A4 145mm 60mm Suction Space Layer Stabilisers Plywood Block 30x10 5mm Thick Plywood

Robot Simulation

Scaling the Wall

When scaling the wall down for the robot simulation, wooden dowels are no longer a viable connection meth od. The material is too thin. Instead glue works best.

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Our Wall ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Our Wall ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Our Wall ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Our Wall ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

Our Wall ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

References Project 1

2010. AS 1720.1-2010. Timber Structures Part 1: Design Methods. [online] Australian Stan dard. Available at: <https://subscriptions-techstreet-com.ezproxy.lib.swin.edu.au/prod ucts/826387> [Accessed 6 August 2022].

2021. AS 1684.2 2021. Residential Timber Framed Construction Part 2: Non cyclonic areas. [online] Standard Australia. Available at: <https://subscriptions-techstreet-com.ezproxy. lib.swin.edu.au/products/826386> [Accessed 6 August 2022].

2022. termiSPAN LVL 11 H2 100x63 Bearer. [online] Canterbury Timber & Building Supplies. Available at: <https://canterburytimbers.com.au/buy/termispan-lvl-11-h2-100x63-bearer/> [Accessed 6 August 2022].

Bunnings Warehouse. 2022. Zenith M10 x 240mm Hot Dipped Galvanised Cup Head Bolts And Nuts - 12 Pack. [online] Available at: <https://www.bunnings.com.au/zenith-m10-x-240mm-hotdipped-galvanised-cup-head-bolts-and-nuts-12-pack_p2260512?store=6247&gclid=Cj0KCQjwxb2X BhDBARIsAOjDZ37dPACkxacxH9WnrdSqN7P82iENreBDgU2lJ1hozmjpqiPutT8H6PIaArjHEALw_wcB&gclsrc=aw. ds> [Accessed 6 August 2022].

ArchDaily. 2022. Archery Hall & Boxing Club / FT Architects. [online] Available at: <https://www.archdaily.com/444857/timber-structure-archery-hall-and-boxing-club-ft-archi tects> [Accessed 10 August 2022].

StructureCraft Builders. 2022. Taiyuan Botanical Garden - The Tea House. [online] Available at: <https://structurecraft.com/projects/taiyuan-botanical-garden-restaurant> [Accessed 10 August 2022].

ARC80004 Fabrication & Creative Processes Kaitlyn McNaughton 102110707

References Project 2

2010. AS 1720.1-2010. Timber Structures Part 1: Design Methods. [online] Australian Stan dard. Available at: <https://subscriptions-techstreet-com.ezproxy.lib.swin.edu.au/prod ucts/826387> [Accessed 6 August 2022].

2021. AS 1684.2 2021. Residential Timber Framed Construction Part 2: Non cyclonic areas. [online] Standard Australia. Available at: <https://subscriptions-techstreet-com.ezproxy. lib.swin.edu.au/products/826386> [Accessed 6 August 2022].

2021. Swinburne University AMDC. [image] Available at: <https://www.idea-awards.com. au/2015/swinburne-university-advanced-manufacturing-and-design-centre-2/> [Accessed 19 Oc tober 2022].

Mele, T.V. (2014) Funicular Funnel Shell Workshop at Ilek, Stuttgart, Germany, 2014, Block Research Group. Available at: https://block.arch.ethz.ch/brg/teaching/funicular-fun nel-shell-workshop-ilek (Accessed: October 23, 2022).

ARC80004 Fabrication & Creative Processes

Kaitlyn McNaughton 102110707