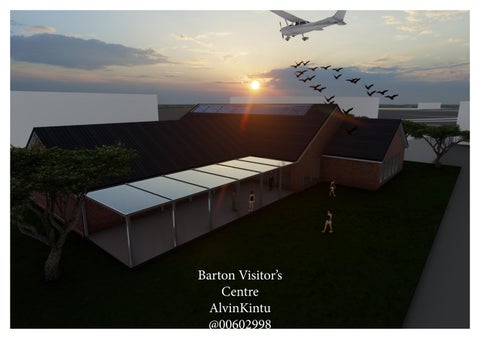

Barton Visitor’s Centre AlvinKintu

@00602998

CONTENTS Introduction Site Analysis Project Overview Details U-value table pg 2 pg 1 pg 4-5 pg 9-18 pg 20

TABLE OF

EYE VIEW

BARTON VISITOR’S CENTRE

Located Located along the M62 .

BARTON VISITOR’S CENTRE

Located Located along the M62 .

Project Brief

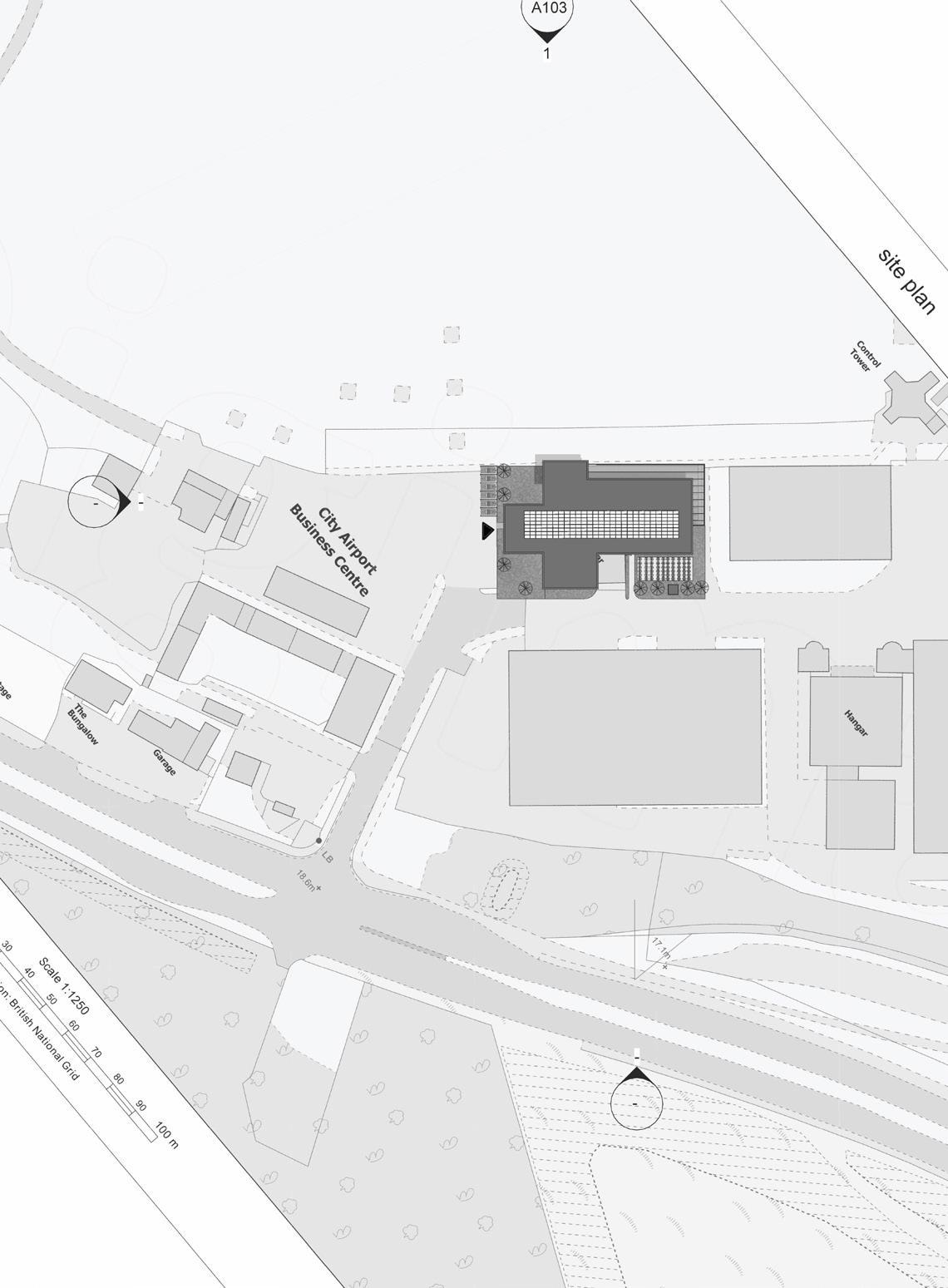

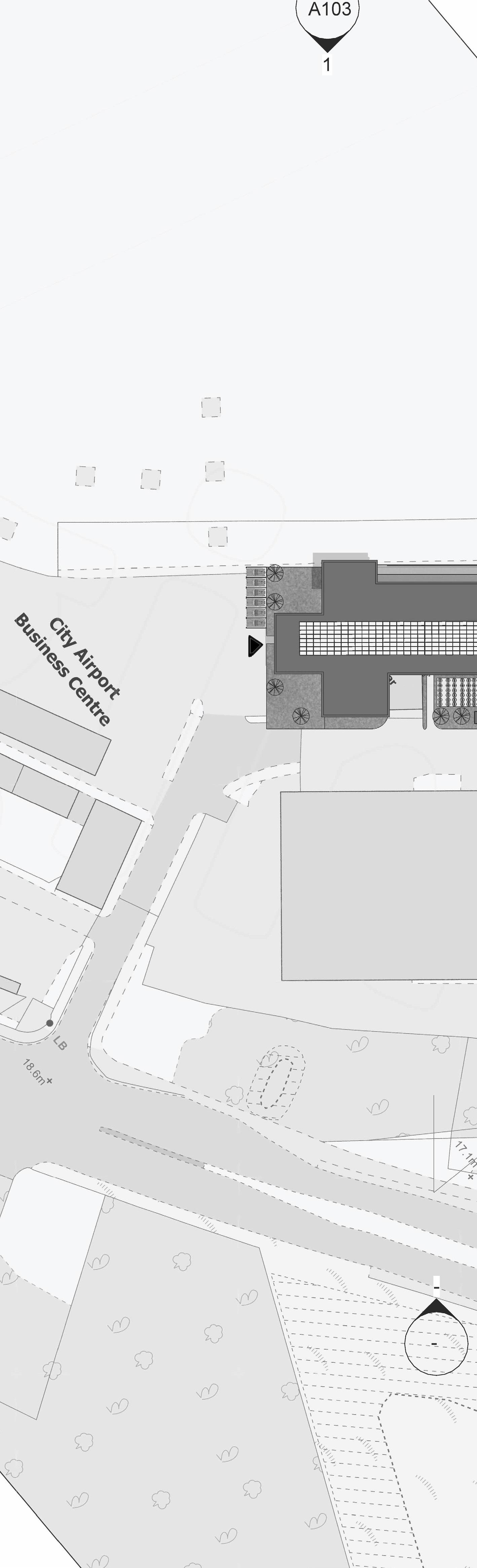

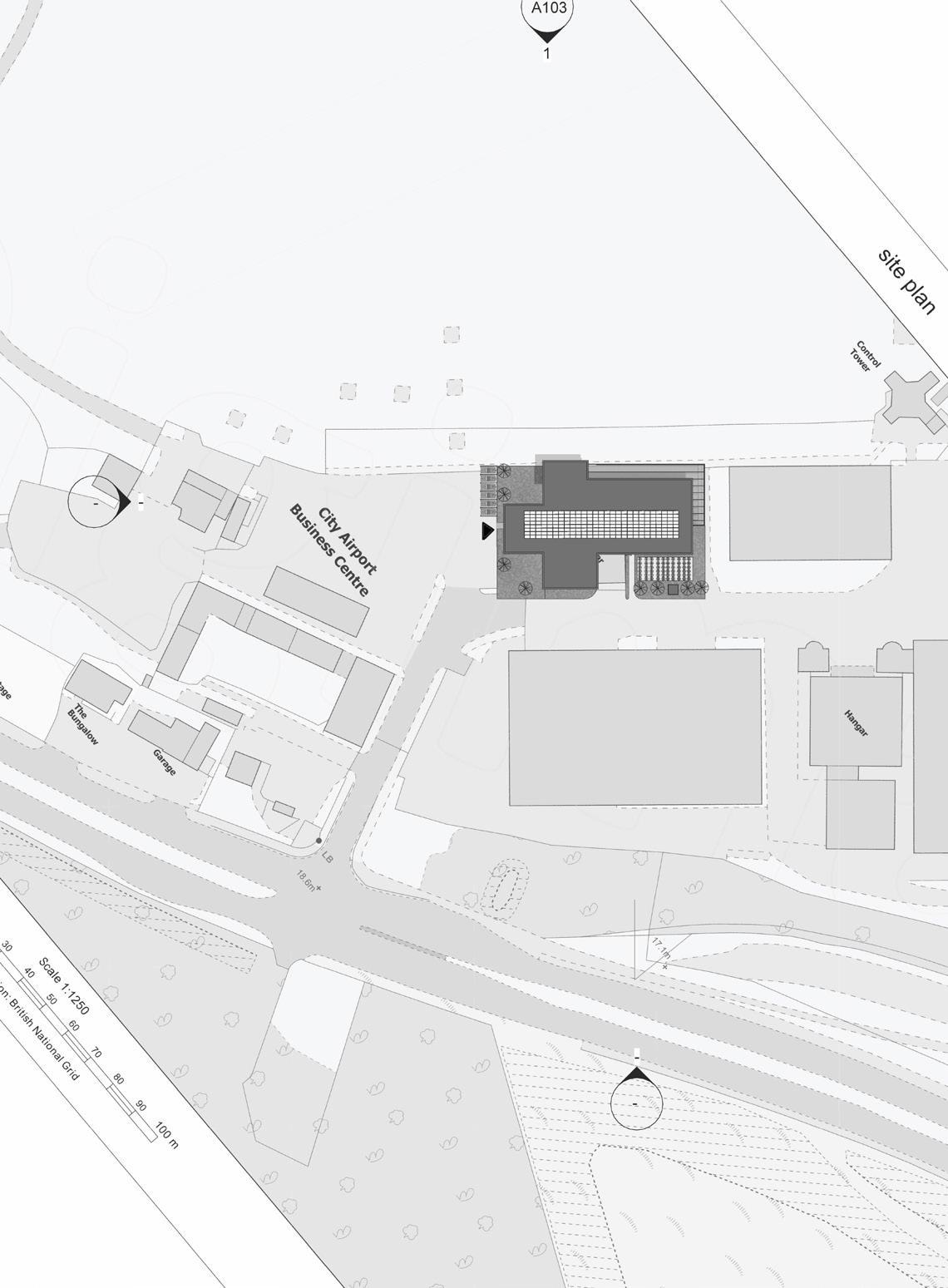

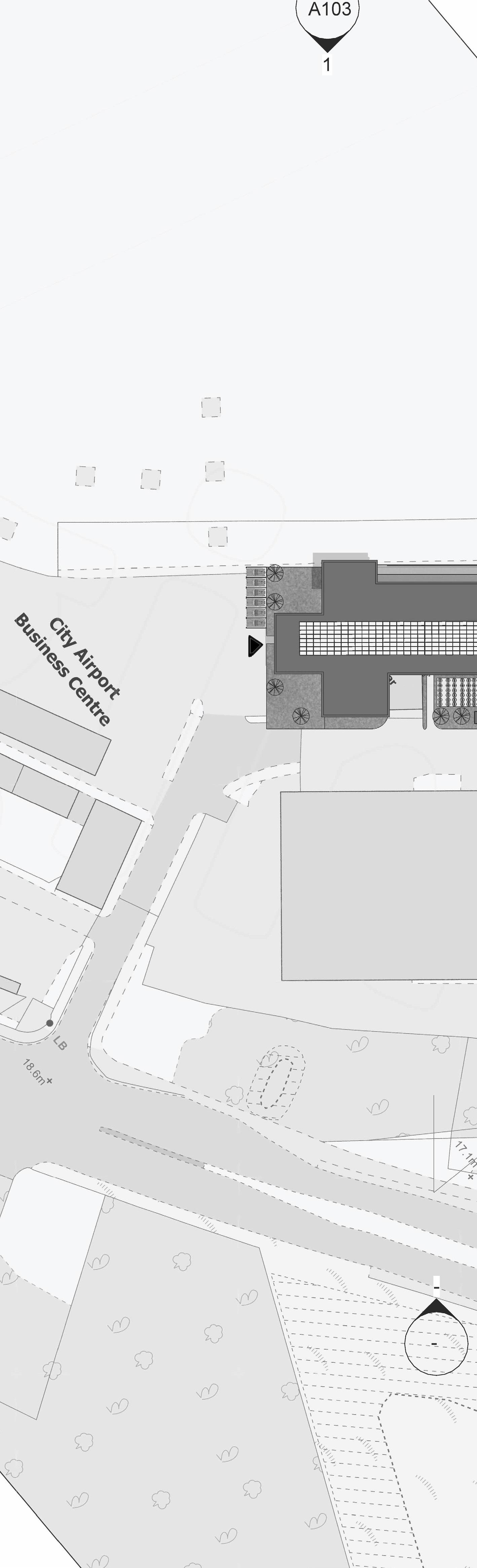

Located north east of the Observatory the Barton Visitor’s is located on what used to be part of chat moss and creates a link between port salford master plan, Off the Beaten Track Masterplan & the Cadished/Little Woolden Bird Hide Conservationist Facility.

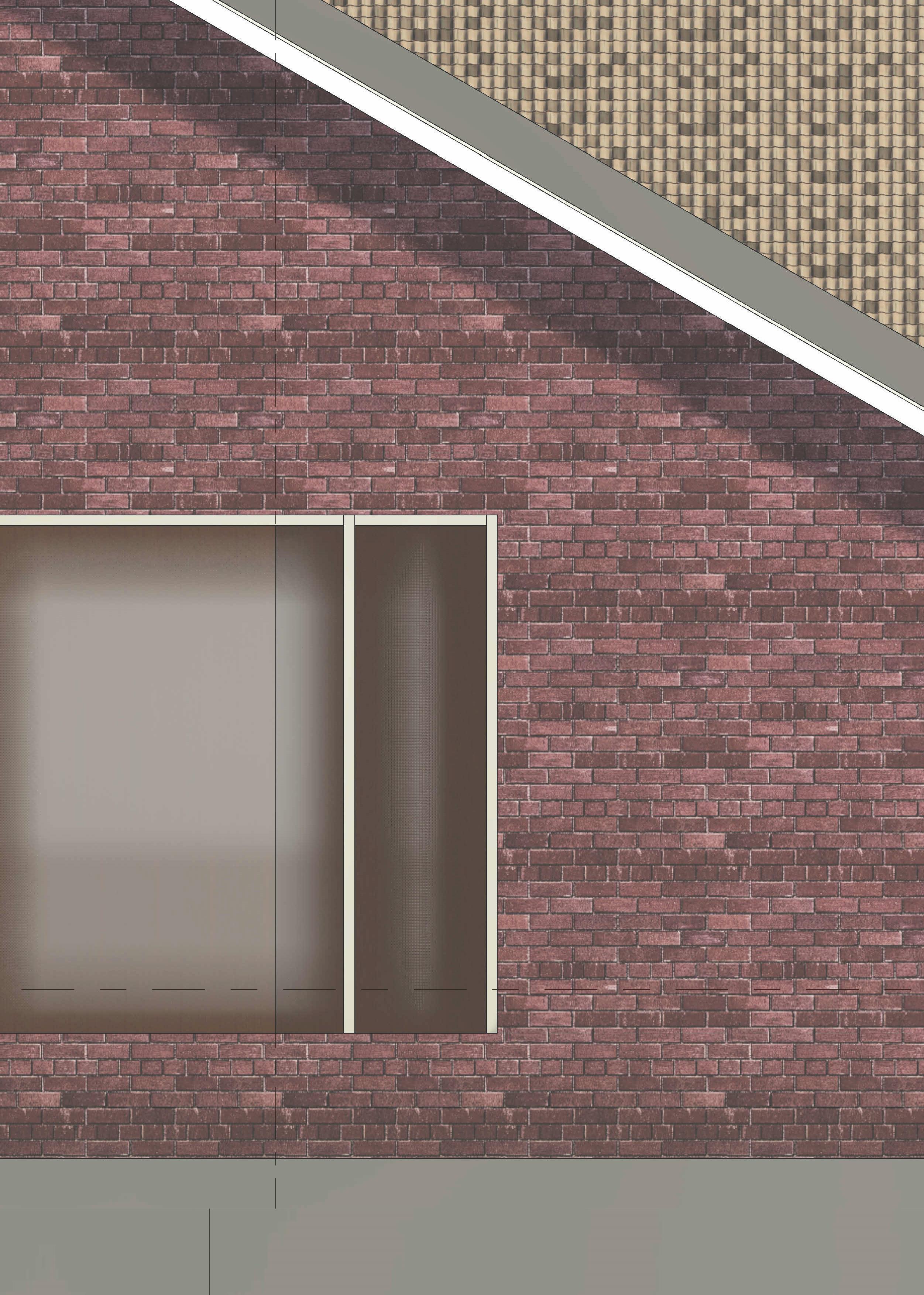

The Barton Visitor’s Centre provides a means to create a communal space for mainly plan spotters and individulas willing to become piolts whilst preseving site hertiage through materiality selection such as brick.

THE BIRD’S

Page 1

site Anaylsis Page 2

Page 3

Floor plan ( 1:200) Page 4

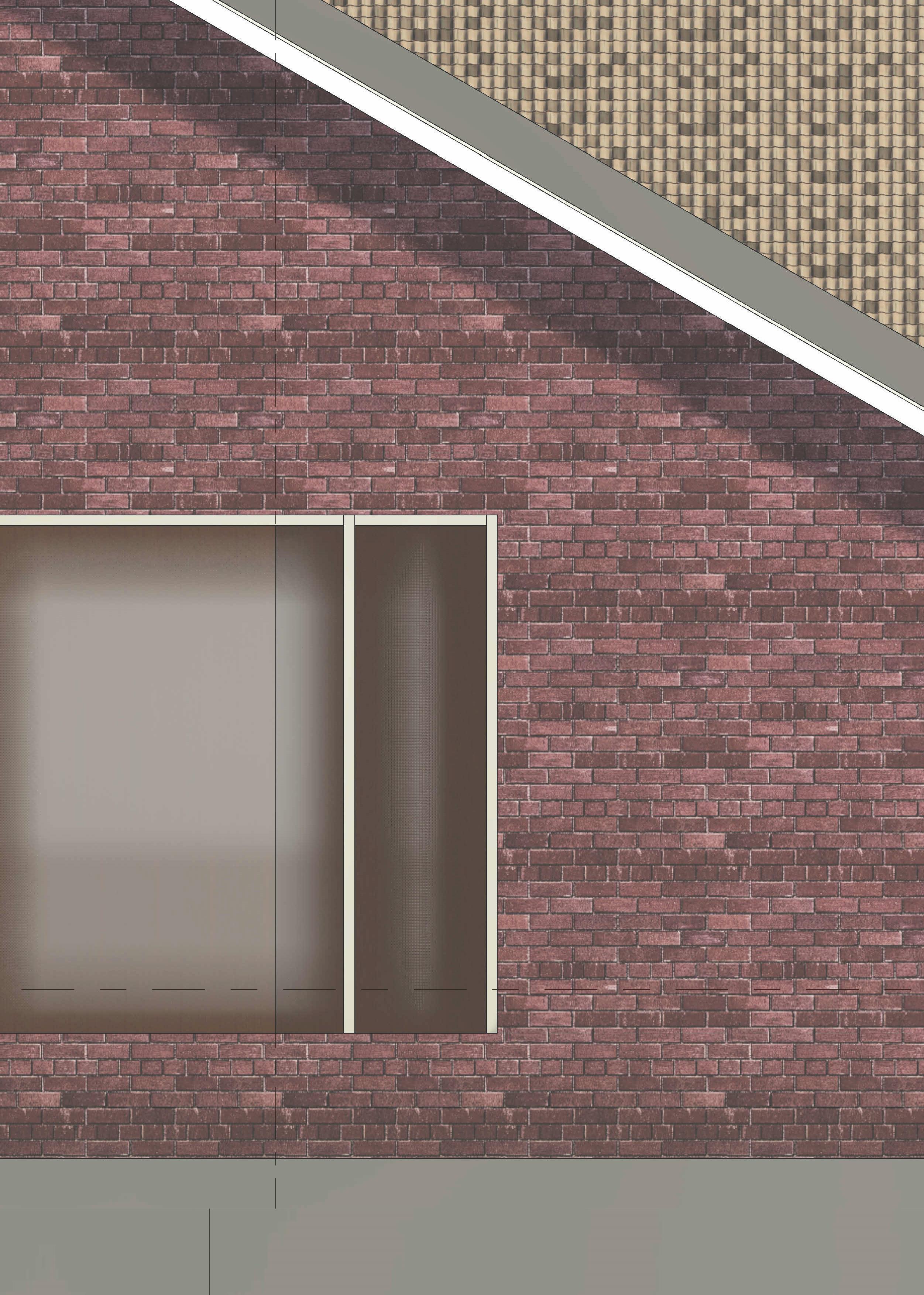

Elevations (1:200)

Page 5

north elevation south elevation east elevation west elevation

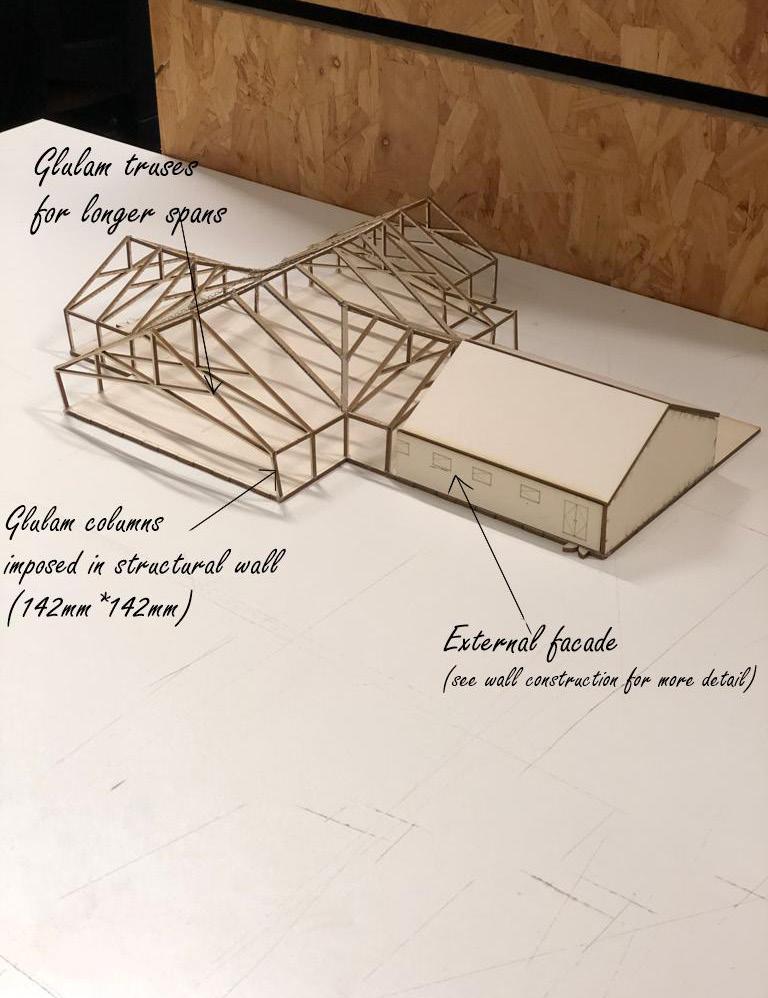

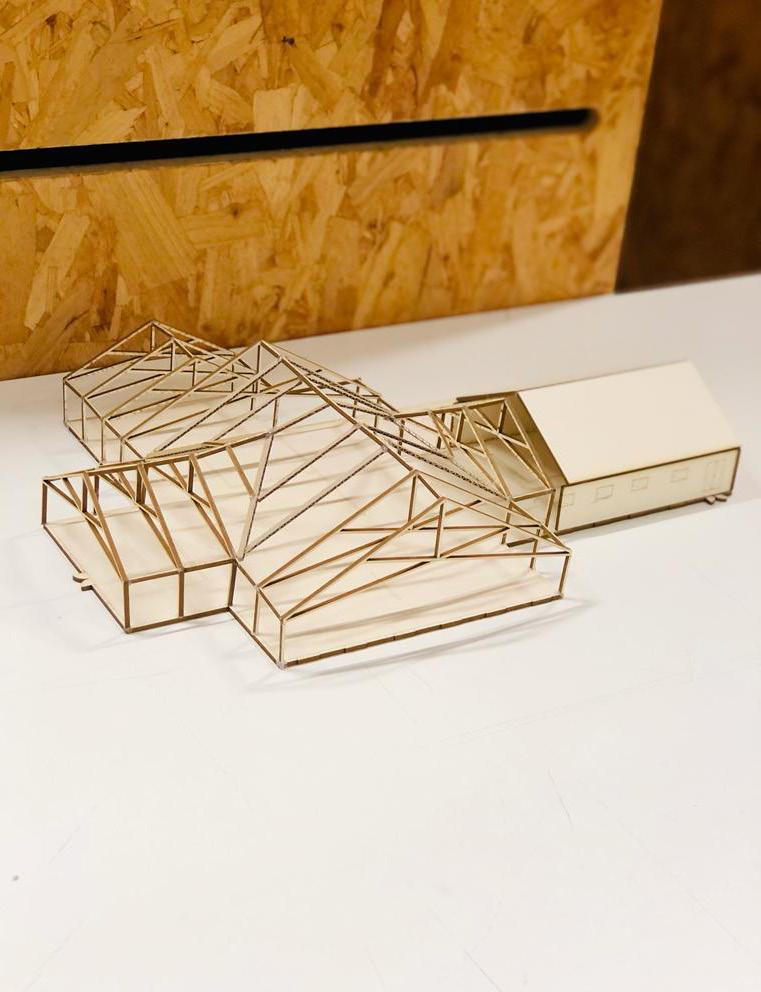

Structural frame construction (1:50) Page 6

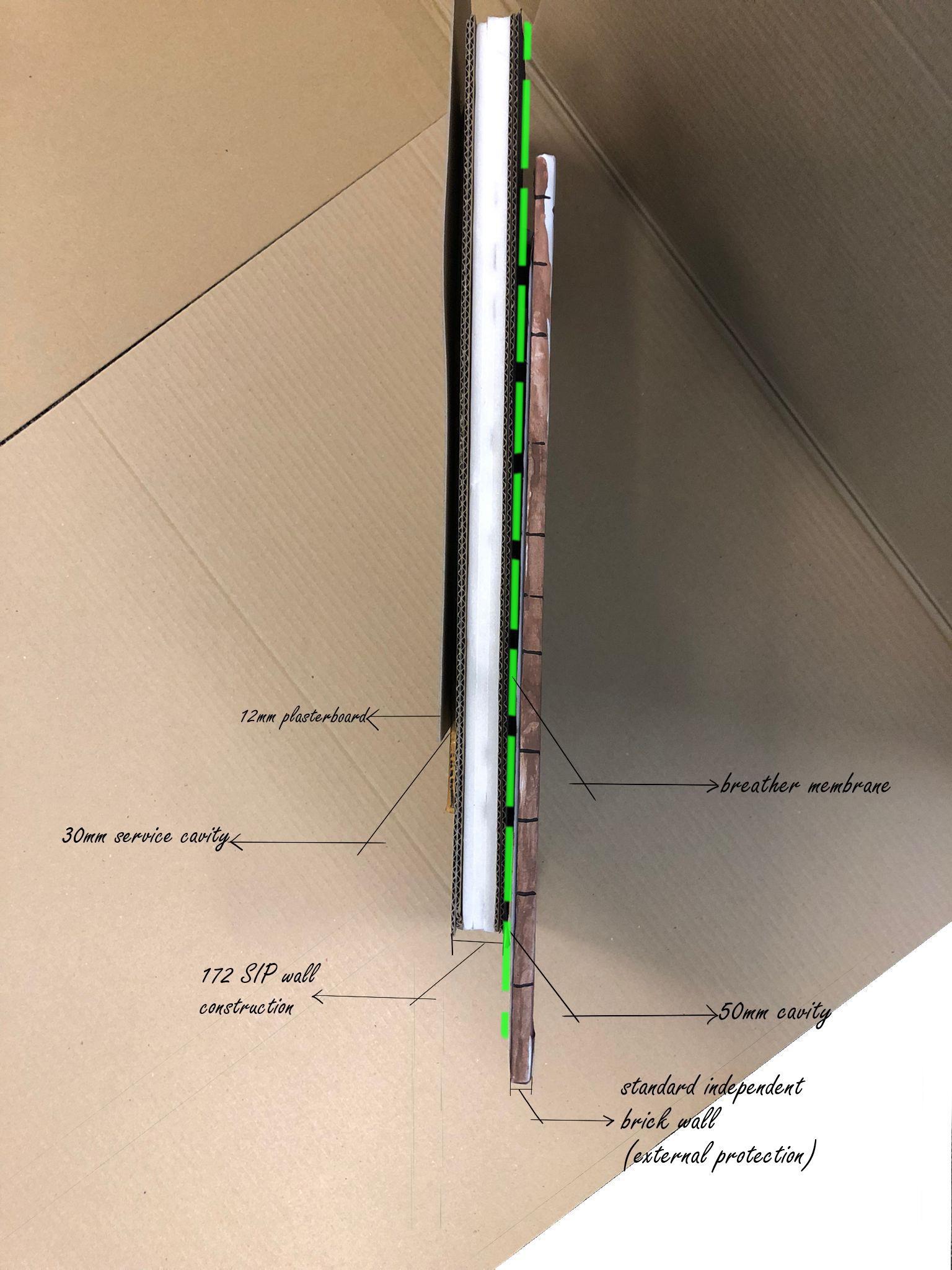

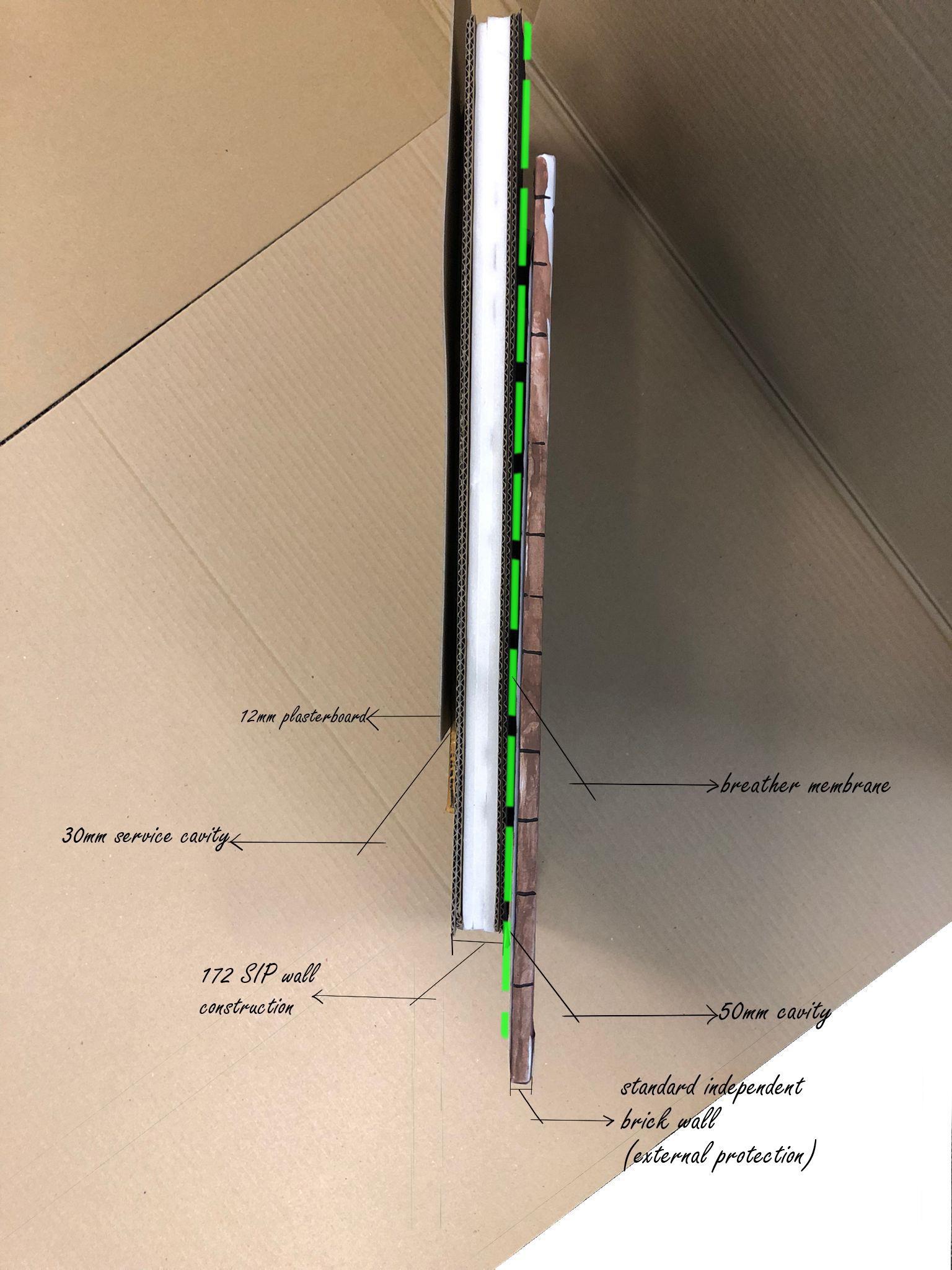

Wall Construction Build up (1:10) Page 7

Wall Construction Build up (1:10) Page 8

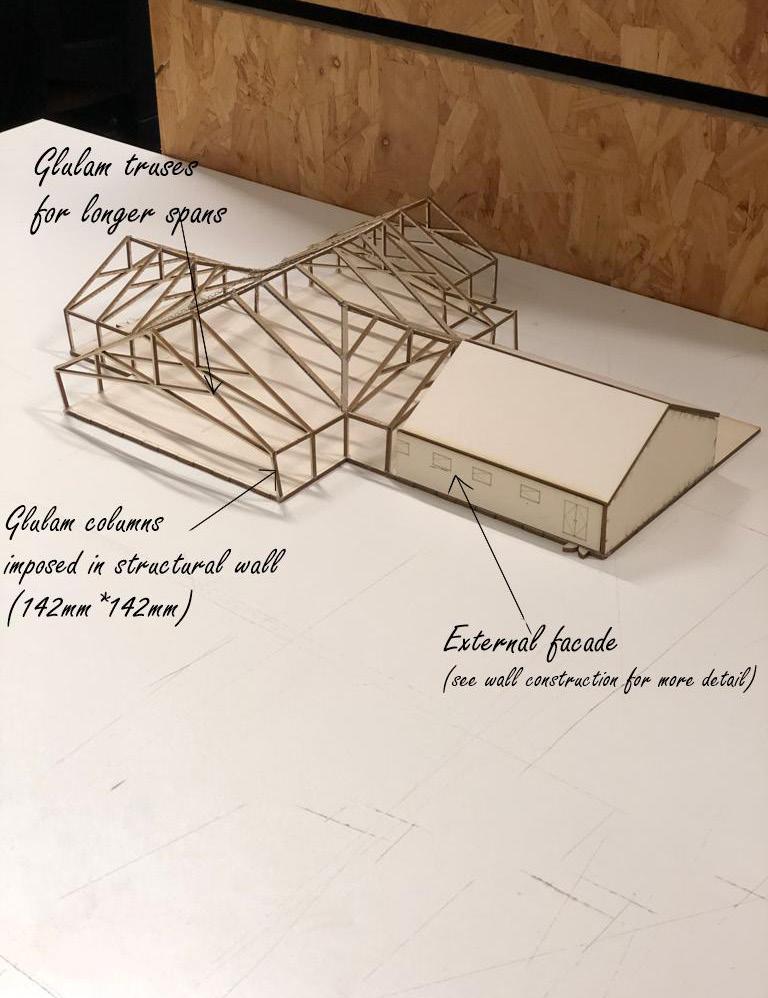

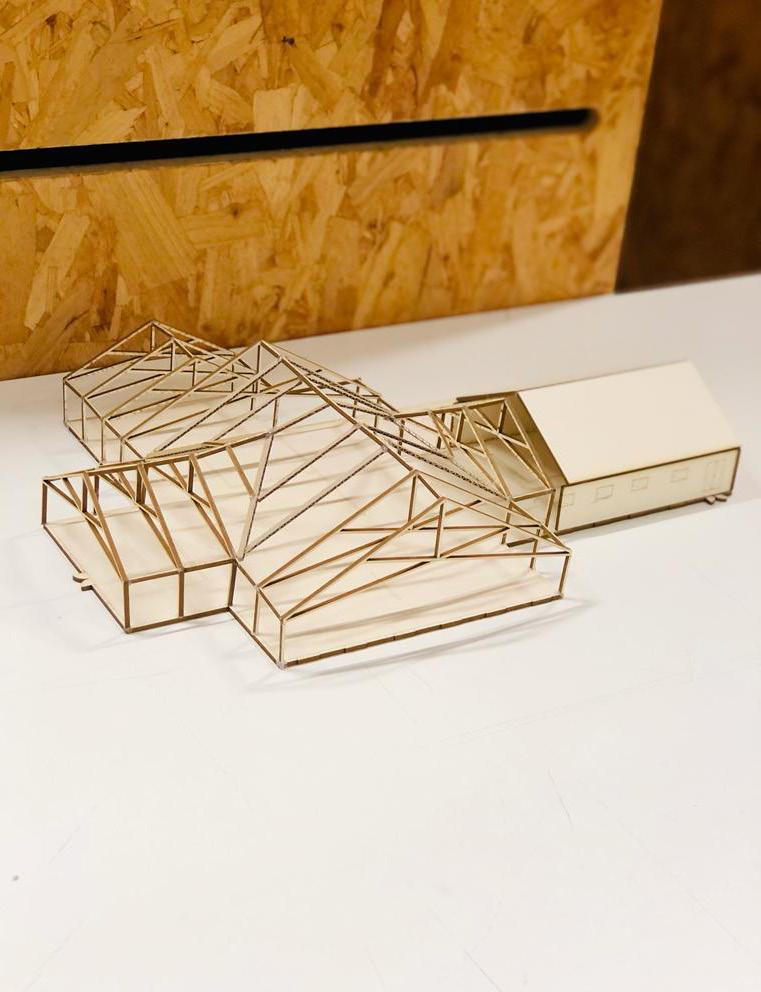

9m to 18m wide pitched roof with exposed glulam wolf truses and kingspan roof system made from Structural insulated panels topped by roof tiles.

Estimated U value =0.16

3m high loadbearing wall with Structural insulated panels and external brick work finish and internal plasterboard finish excluding paint.

Estimated U value =0.16

Concrete raft foundation spread out through the structure with a concrete floor screed with material obtained from Green bloc.uk lower environmental negative impact.

Estimated U value= 0.22

Elevation & Section (1:20) SECTION B-B

Page 9

SECTION B-B

Why SIPs and glulam and Brick?

Structural insulated panels as main structural componet.

• The use of non flamed materialsresults into very limited contribution to fire that may lead to fire spread and little no smaoke production.

• The use of oriented strand boards in SIPs render them highly resistant to water.

• 142mm of adeqaute insulation results into little to no heat loss gain within the structure.

Glulam

• Light in nature and strong under compression from external forces.

• Highly resistant to fire (burn off rate 0.7mm/min) most espically with the addition of fire protective finishes such as Zeroflame Fire Retardant Paint hence waterproffing it as well.

Brick

• The availablity of locally sourced bricks onsite helps reduce the cost of material purchase as well as enables structural itergration into site context with existing buildings.

Elevation & Section (1:20)

Page 10

Section (1:20) Site Context Page 11

Elevation &

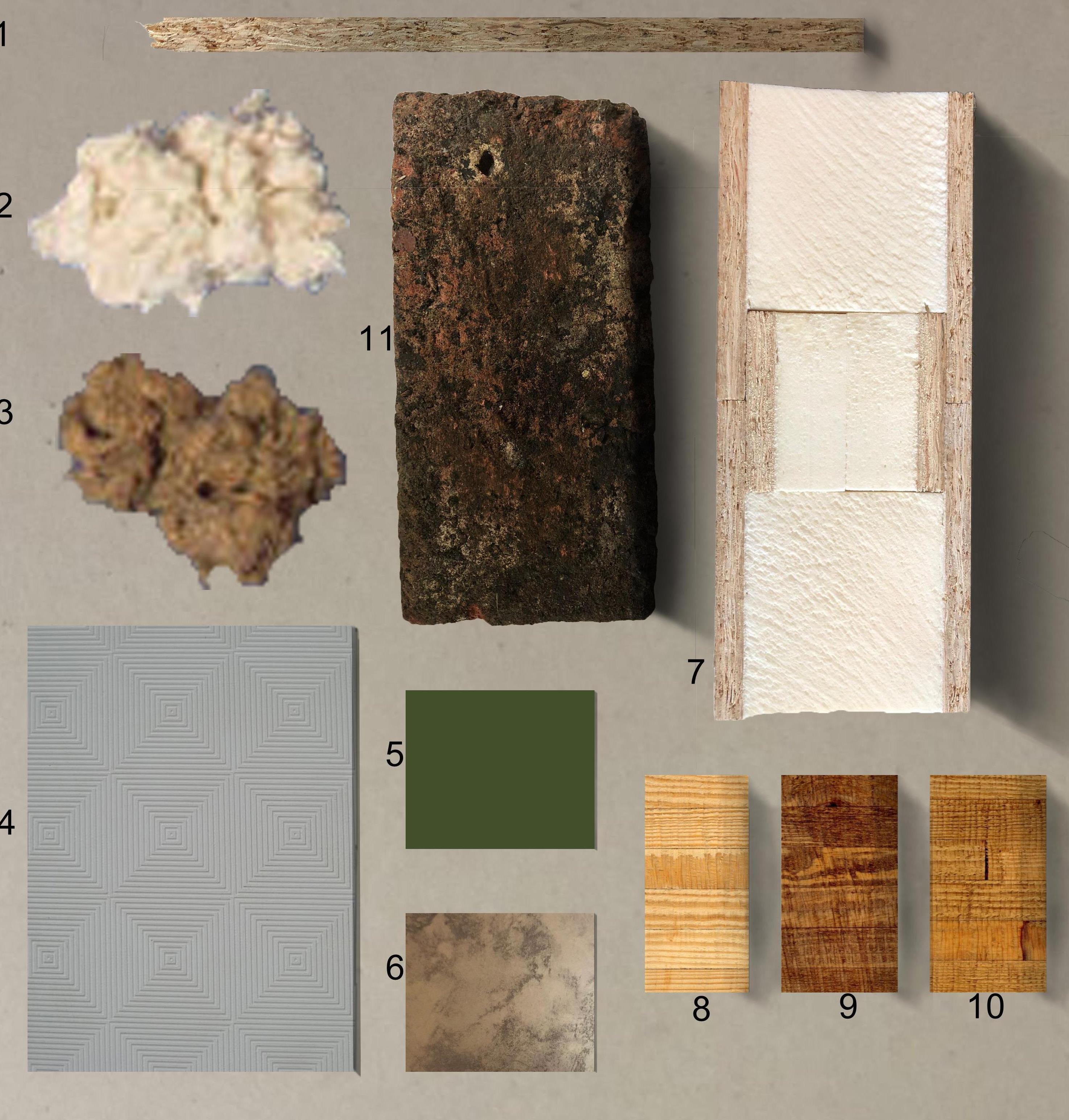

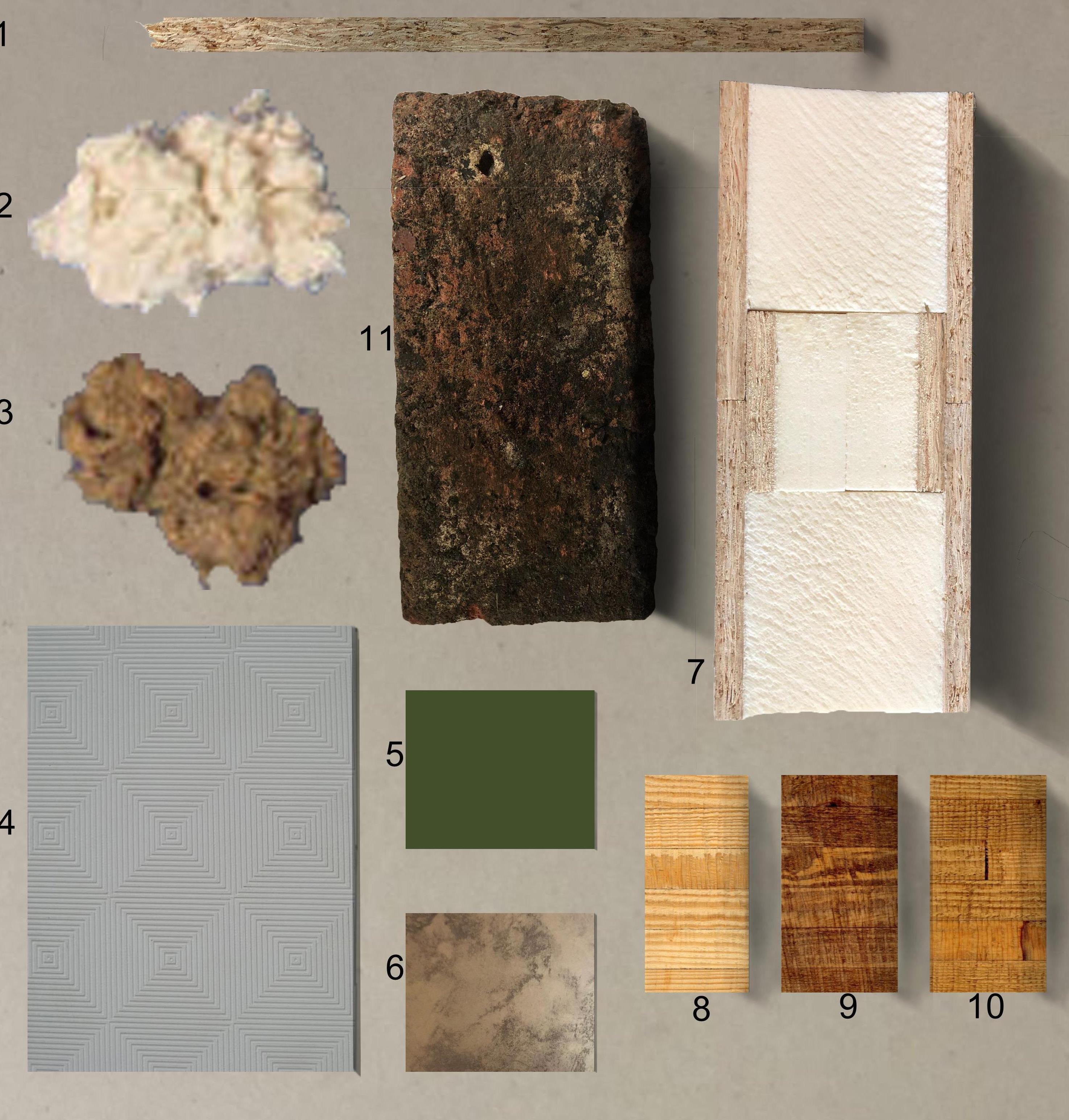

Onsite Material Page 12

Material Samples for Wall Build Up

1- Oriented strand board enclosing Structural insulated panels (Kingspan).

2- Mineral wool insulation type A.

3- Mineral wool insulation type B.

4- Gypsum plasterboard .

5- Wall paint finish option A.

6- Wall paint finish option B.

7- Structural insulated panels by Kingspan with Rigid insulation.

8- Glulam sample unpolished.

9- Glulam sample polished and coated with protective layer.

10- Glulam sample polihed.

11- Used brick sourced from site.

Page 13

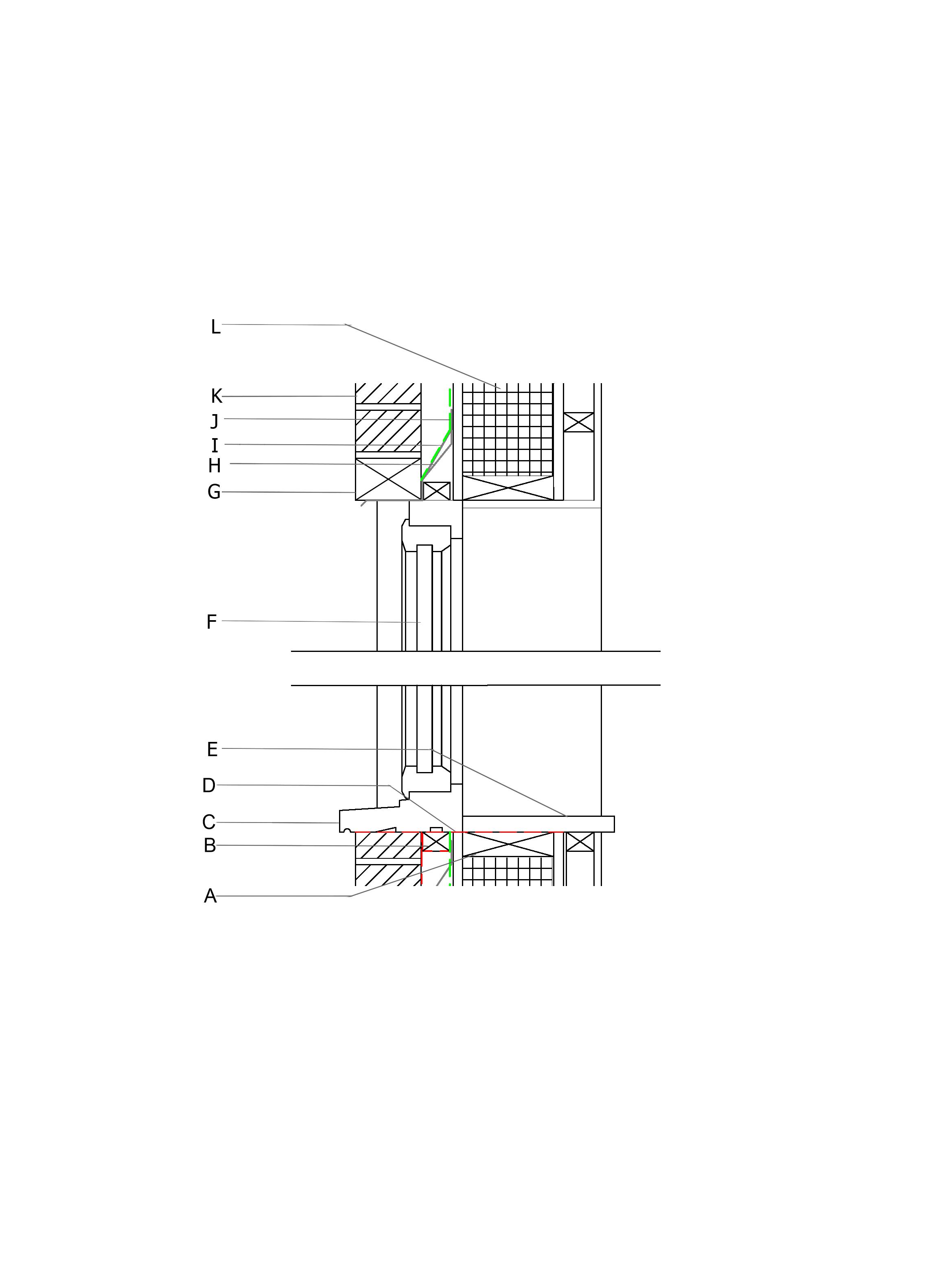

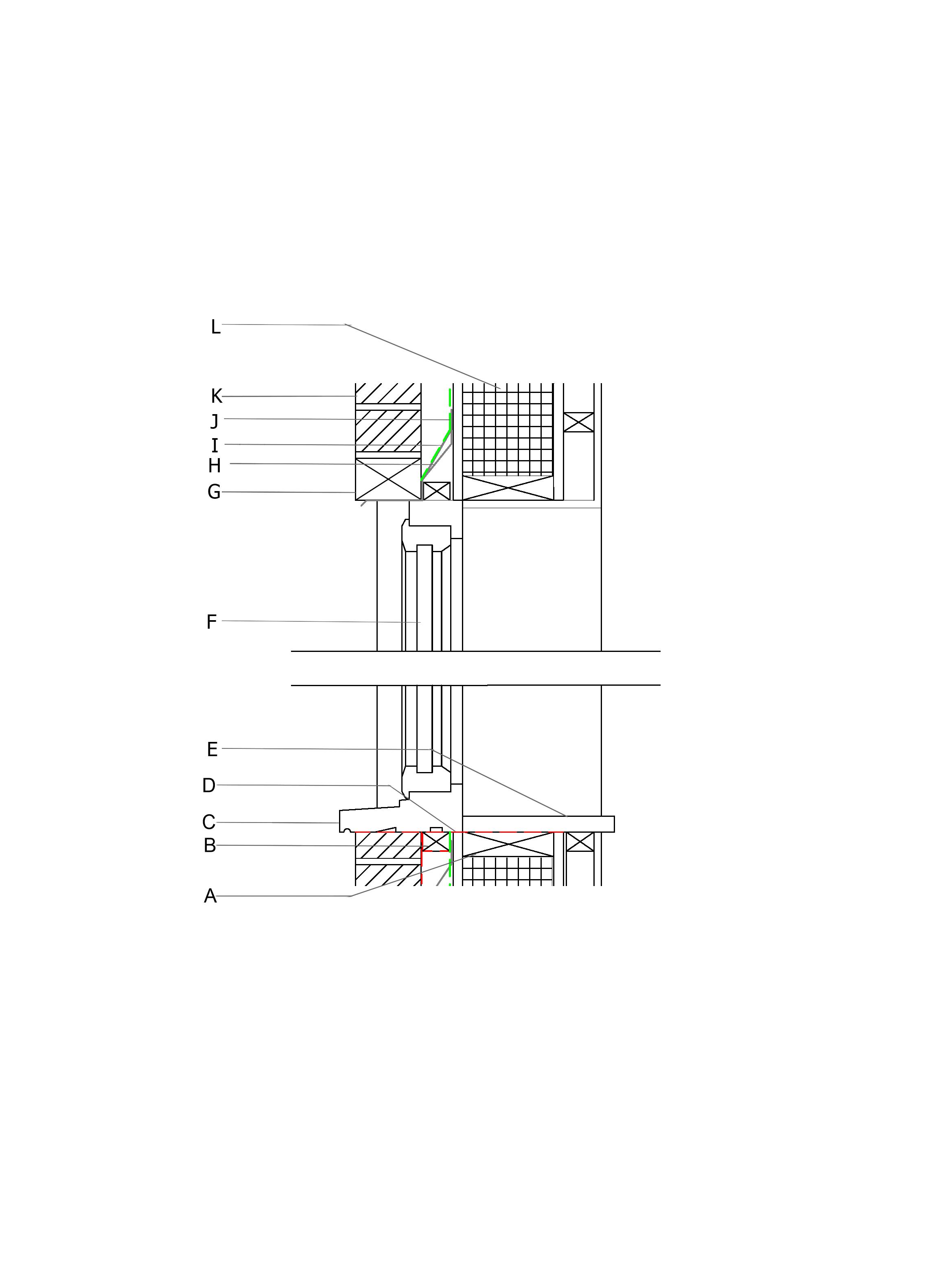

A- 38mm*140mm endplate.

B- 50mm*50mm cavity closer.

C- Window sill.

D- Insulated dump proof membrane (DPM).

E- Window board.

F- Doubled glazing wth argon gas.

G- Air break.

H- Proprietary steel lintel.

I- Proprietary cavity tray fixed as per manufacturer.

J- Breather membrane lapped over proprietary cavity tray.

K- External brick finish.

L- 172mm SIP panel.

Window deatils (1:5) Page 14

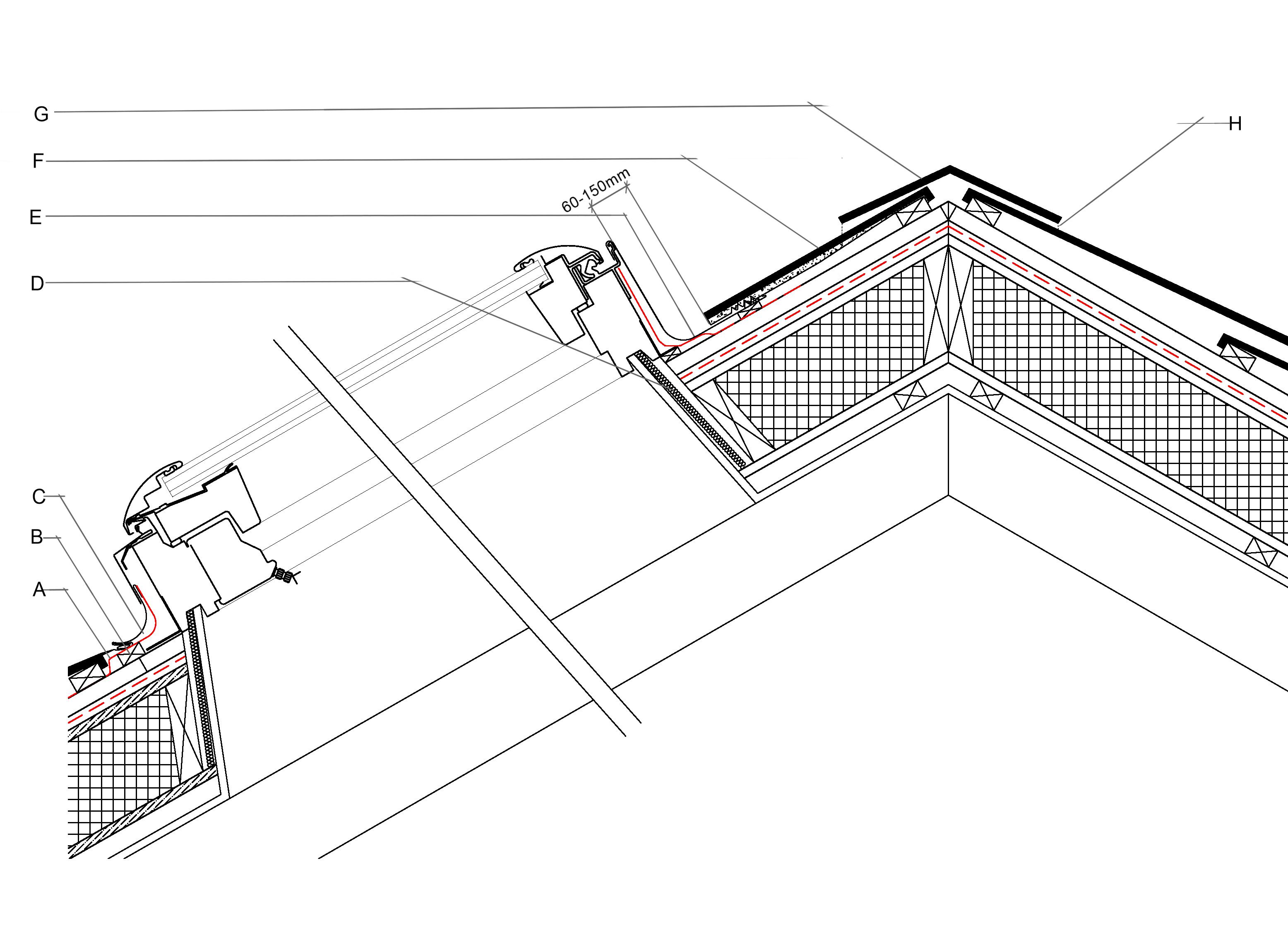

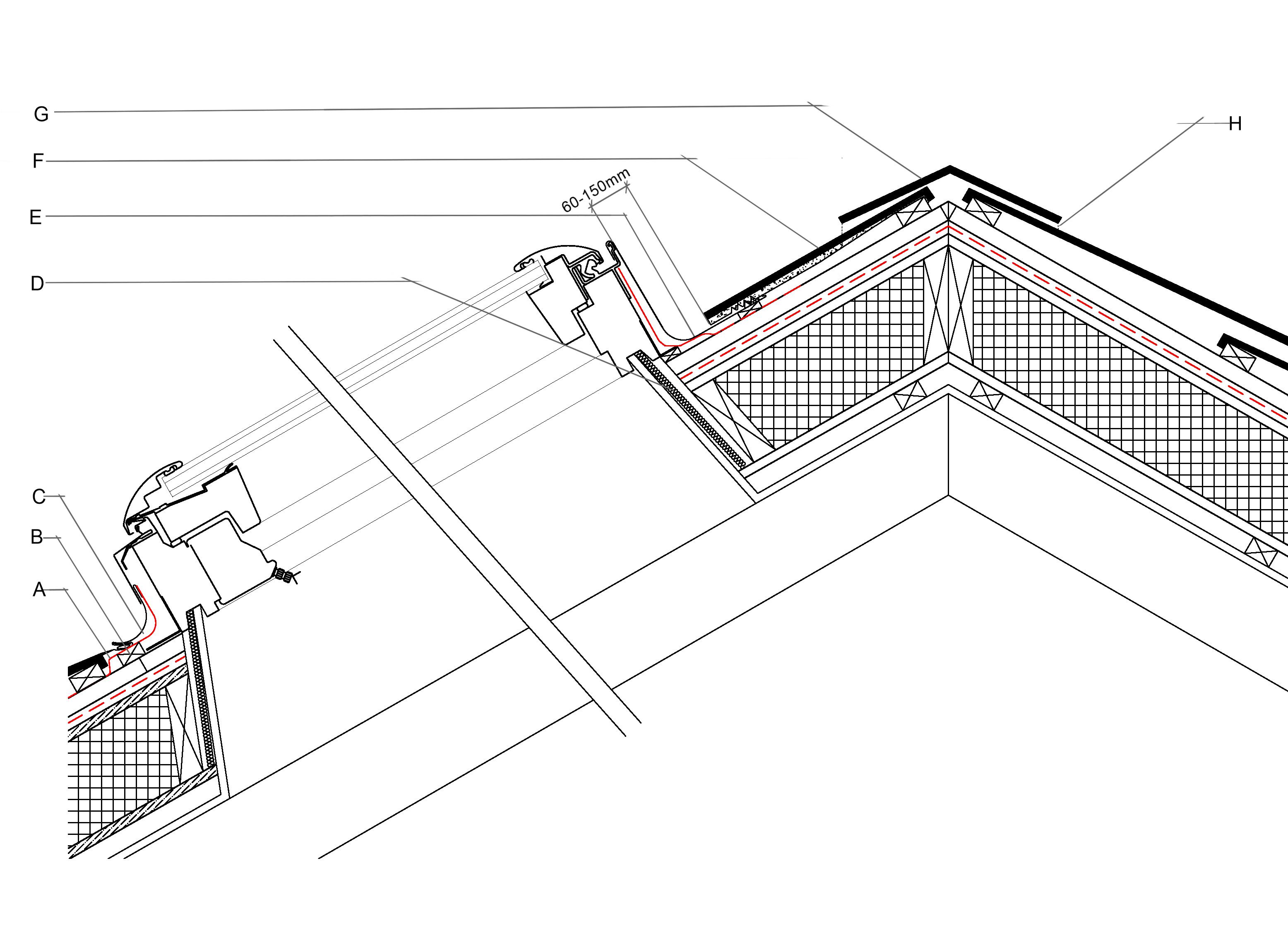

A- Underlayment [as per manufacturer’s specifications].

B- Support barten under Velux EKW window sill.

C-Velux Ekw sill flashing onto roof tile.

D- 15mm Rockwool insulation wrapped around skylight window.

E- Velux roof gutter above window head.

F- Modified roof tile [as specified by structural engineer].

G-Roof tile ridge.

H- Vented roof ridge cavity.

Skylight deatil (1:5) Page 15

A- Reused brick finish sourced from site 102mm thick.

B-Breather membrane placed on extrnal finish of SIP(Structural Insulated Panel).

C- 15mm Kingspan OSB board(Oriented Strand Board).

D-142mm rigid insulation.

E- 15mm kingspan OSB board(Oriented Strand Board).

F-30mm*30mm horizontal bartens in service void.

G-12.5mm plasterboard finish covering service void.

SIP wall deatils (1:5) Page 16

172mm

A- Cavity Closure/barier.

B- Treated wood to support soffit.

C- Treated wood soffit.

D- 142mm eaves underlay gutter skirt.

E- Soffit cavity vent.

F- Drainage gutter.

G- Proprietary ventilator between counuter batterns.

H-15mm OSB board(Oriented Strand Board)

I- 142mm rigid insualtion.

J- 15mm OSB board(Oriented Strand Board).

K- Roof breather membrane below counter batterns.

L- 25mm counter batterns.

M- 25mm roof tile surrport bartterns at 400mm apart.

N- Roof tiles.

Roof detail (1:5) Page 17

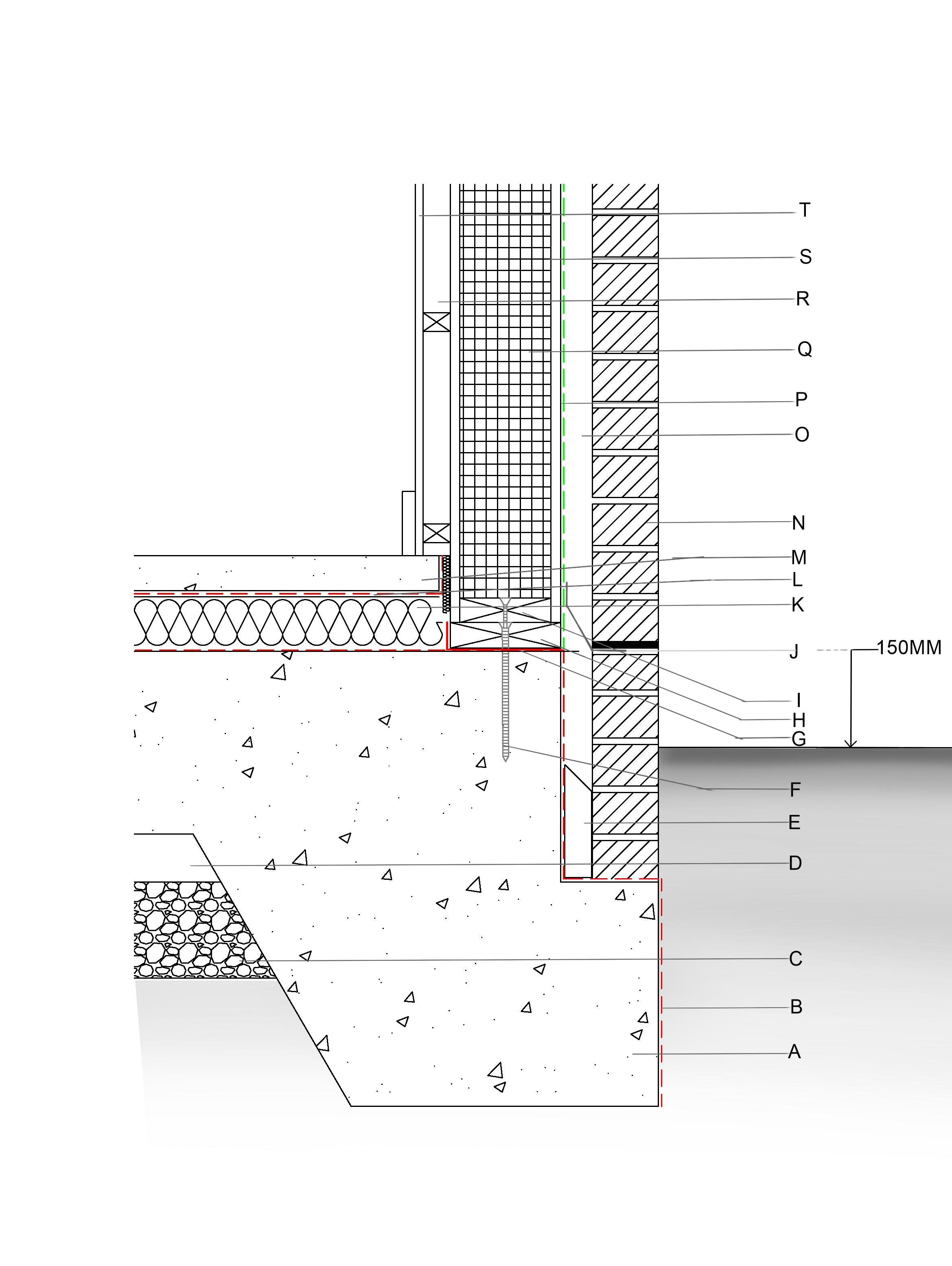

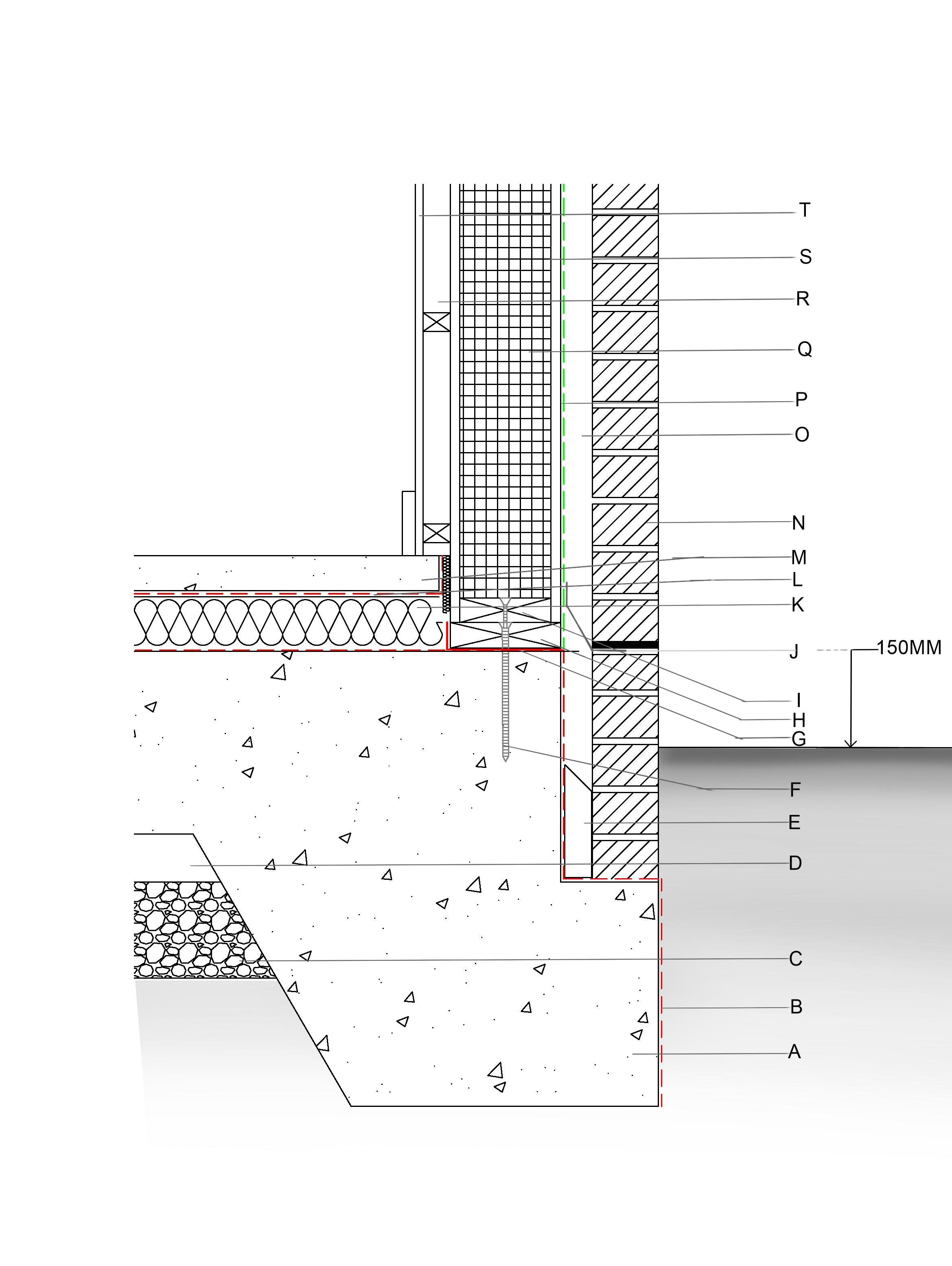

A- Concrete foundation slab.

B- Dump proof course (DPM).

C- 150mm compacted gravel layer [to be assessed on site by structural engineer].

D- 75mm compacted sand layer [to be assessed on site by structural engineer].

E- Cavity fill 225mm below top foundation slab.

F- 0.48mm*225mm nail as per manufacturer.

G- 5mm shim across full width of base as per manufacturer with DPC wrapped over DPM.

I- 38mm*140mm bottom plate.

H- 40mm*140mm soleplate.

J- Stainless steel wall ties with air break above.

K- 100mm floor insulation.

L- dump proof membrane.

M- 50mm floor screed and finish layer over seperating membrane.

N- 160mm recycled brick finish.

O- 50mm wall cavity.

P- Breather membrane.

Q- 15mm OSB board.

R- 30mm service cavity.

S- 142mm rigid internal insulation.

T- 12mm internal wall finish plasterboard.

Foundation detail (1:5) Page 18

Page 19

U

values

Material Thickness (m) Conductivity (λ) Resistance (R) Material Thickness (m) Conductivity (λ) Resistance (R) surface reistance 0.06 surface reistance 0.04

External finish (Brick) 0.1025 1 0.1025 Roof tiles 0.0085 0.7106 0.011961722 Air Cavity 0.05 0.17 0.294117647 Counter battens 0.025 0.16 0.15625 Breather membrane 1 0 breather membrane 0.691 0

Oriented strand board 0.015 0.13 0.115384615 Oriented strand board 0.015 0.13 0.115384615 Rigid insulation 0.142 0.027 5.259259259 Rigid insulation 0.142 0.027 5.259259259 Oriented strand board 0.015 0.13 0.115384615 Oriented strand board 0.014 0.13 0.107692308

Internal finish (british gypsum) 0.012 0.19 0.063157895 Air cavity 0.03 0.17 0.176470588 internal resistance 0.04 internal resistance 0.1 sum 6.049804032 Internal finish (british gypsum) 0.012 0.19 0.063157895 0.16529461 sum 5.990176388 0.166939992

WALL FLOOR

Material Thickness (m) Conductivity (λ) Resistance (R)

Floor cement screed finish 0.0545 0.38 0.143421053 DPM 0.00038 0.691 0.000549928 Mineral wool Insulation 0.1 0.038 2.631578947 DPC 0.00038 0.039 0.00974359 Concrete Foundation slab (aerated slab) 0.2801282 0.16 1.75080125 sum 4.536094767 0.220453948

ROOF U value (w/ ����2 − ���� ) U value (w/ ����2 ���� ) U value (w/ ����2 ���� )

estimates)

Page 20