Our Snout® system has been leading the charge in stormwater management for over 25 years. Designed to last, it captures pollutants at the source and reduces downstream pollution. For optimal performance, add the Bio-Skirt® and Turbo

Plate®.

storm drains. Pair it with the Bio-Skirt® for enhan

ter ced

Don’t let trash flow downstream. The Snout® stormwater treatment hood reduces floatables and sediment in ced oil capture and the Turbo Plate® to tame high-velocity flows and increase sediment removals. Together, they deliver effective trash capture, sediment control without overcomplicating maintenance.

Your job is demanding, but your pumps shouldn’t be. The Sulzer XFP with Contrablock Evo impeller is designed to maintain smooth operations with the clog-resistant performance you can rely on.

Whether you’re operating a plant, managing a facility, or overseeing upgrades, our pump helps you stay on track, stay compliant, and avoid unplanned downtime.

With full BABA compliance, it helps you meet today’s infrastructure requirements while giving you back what matters most, your quality time.

Learn more about Sulzer’s XFP go.sulzer.com/trusted-xfp

Devon Ducote, President, Clean Water Professionals of Louisiana

It is an honor to serve as President of the Clean Water Professionals of Louisiana.

Our mission – to support Louisiana’s dedicated water professionals through advocacy, education, and connection –is more than a professional calling; it’s a personal commitment to the health and future of our communities.

As a mother to a spirited three-year-old and a baby born this past March, I am

reminded daily of the importance of the work we do. Clean water is not just a resource – it’s a legacy we leave for the next generation. That perspective fuels my passion and deepens my resolve to support the professionals who make this work possible.

This year, we are focused on expanding professional development, empowering young professionals,

and connecting Louisiana Water Professionals. I encourage each of you to get involved – whether through mentorship, committee service, or simply sharing your knowledge and experience.

Thank you for your continued dedication to clean water and to one another. I look forward to all we will accomplish together in the year ahead.

“Our mission – to support Louisiana’s dedicated water professionals through advocacy, education, and connection – is more than a professional calling; it’s a personal commitment to the health and future of our communities.”

Scan here to learn more

No matter whether your products are liquid or solid, hot, cold, or corrosive – for decades, our radar technology has been setting the standards in level measurement for wastewater treatment. We deliver precise, reliable measured values exactly where they’re needed, resulting in more stable processes, greater safety, and maximum product quality. With our radar solutions, innovation knows no limits.

Everything is possible. With VEGA.

Chicago, Illinois | McCormick Place

Conference: Sept. 27 – Oct. 1, 2025

Exhibition: Sept. 29 – Oct. 1, 2025

WEFTEC.ORG

The Channel Monster® FLEX continues the Channel Monster legacy of high-flow capacity while capturing and shredding rags, rocks, wood, and other solids into small pieces to pass through pumps, pipes, and process equipment. The accumulation of waste debris poses significant challenges; we are committed to working hard 24/7 to enhance performance efficiency.

Devon Ducote serves as the current President for the Clean Water Professionals of Louisiana. She is currently an Environmental Specialist for Providence, an engineering and environmental consulting firm, since 2018. She holds a Bachelor of Science degree from Louisiana State University.

Brenda Faz-Cresie serves as the current President-Elect for the Clean Water Professionals of Louisiana. She is currently an Engineered Systems Regional Leader for Infiltrator Water Technologies, based out of Walker, Louisiana. In her position, Brenda assists designers, engineers and developers in designing effective wastewater treatment systems, from collection through treatment and final disposal. She has been in the wastewater industry for over 20 years, starting her career as an environmental scientist for a treatability laboratory where she evaluated waste streams and remediation techniques for operators and engineers throughout the South. Brenda’s involvement with CWPLa brings experience from working with multiple utilities and regulatory agencies throughout the US and Latin America, and she hopes to contribute to Louisiana’s evolving water quality efforts by expanding on local regulatory best practices, as well as providing education on new processes and technologies. She holds a Bachelor of Science degree in Environmental Science from Texas A&M University, a Masters of Science degree in Environmental Management from the University of Maryland University College, and is currently a PhD student at Louisiana State University. Brenda is a proud mother of two teenage daughters, Tori and Max, and has been happily married to her husband, Shane, for four years.

www.hawkinsinc.com

•Phosphorus removal

•Corrosion control

•Zebra mussel control

• Bioaugmentation, biological controls

•Settling aids

•Disinfection chemicals

•Dechlorination chemicals

• TSS (Total Suspended Solids) control

•Lagoon sludge reduction

•Dewatering polymers and so much more

•Antifoams

As water and wastewater challenges grow in scale and complexity, so does the need for smarter, more adaptable infrastructure. While centralized treatment systems have long been the standard for municipal wastewater management, advances in decentralized wastewater treatment are expanding possibilities for communities of all sizes. These systems are not just an alternative; they are increasingly becoming a strategic solution for addressing critical environmental, economic, and regulatory pressures.

This article explores the current landscape of decentralized wastewater treatment, the mounting challenges faced by stakeholders, the practical solutions being implemented across the country, and where the industry is headed next.

One of the most powerful aspects of today’s decentralized wastewater treatment systems is flexibility. With an array of treatment technologies and design strategies now available, engineers and designers can select the “best fit” solution for a specific application.

Whether it’s a conventional septic design for a rural residential project or a complex, nutrient-reducing system with advanced online monitoring, decentralized systems can be tailored to serve specific needs. These systems can also produce highquality effluent, suitable for non-potable reuse such as irrigation, industrial processes, or aquifer recharge. Further, their smaller carbon footprint compared to centralized infrastructure means significantly reduced capital and operational costs.

Decentralized systems often require less physical infrastructure, less piping, pumping, and excavation, making them ideal for rural communities, suburban developments, commercial operations and areas where large-scale utilities aren’t viable, are at capacity, or need an upgrade. When partnered with decentralized

solutions, centralized systems and the communities they serve can gain relief from critical water and wastewater issues and the cost of replacement.

The water sector is under growing pressure. Engineers, system designers, technology developers, municipalities, contractors, and regulators are grappling with a range of challenges:

1. Cost of centralized infrastructure: Both initial capital investments and long-term operations and maintenance (O&M) costs are rising.

2. Aging Infrastructure: Much of the nation’s existing centralized infrastructure is outdated and in need of replacement or rehabilitation.

3. Performance and Reliability: Systems must maintain optimal performance over decades, even as demand fluctuates and regulations change.

4. Environmental Concerns: Saltwater intrusion, combined sewer overflows (CSOs), groundwater contamination, and nutrient loading are just a few of the issues threatening ecosystems and water supplies.

5. Utility Staffing: Many smaller municipalities or utility districts have limited staff, often without the resources to manage complex treatment systems.

6. Growth and Development: Communities must expand their treatment capacity as they grow, ideally without overhauling entire systems or incurring massive expenses.

Decentralized wastewater treatment offers a variety of benefits that help address these challenges head-on. For many communities, particularly rural and semi-urban areas, decentralized systems are not just a stopgap solution; they are an integral part of long-term sustainability.

Here’s why:

• Scalability: Systems can be sized and phased based on current and future demand, supporting growth without upfront overbuilding.

• Cost-Efficiency: Lower capital requirements and the potential for locally sourced materials and labor make these systems more affordable.

• Low O&M Burden: Many decentralized systems can operate with minimal oversight, and remote monitoring options are increasingly available to improve efficiency and reduce service visits.

• Environmental Stewardship: High-quality effluent enables beneficial reuse and reduces the risk of contamination. The smaller footprint also minimizes land disturbance.

• Tailored Design: Each system is engineered from collection through treatment and disposal based on site-specific conditions and performance goals.

These characteristics make decentralized wastewater treatment a viable strategy to help manage some of the most critical water issues facing municipalities and utilities.

To better understand the power and flexibility of decentralized wastewater treatment, let’s explore three project examples that address specific infrastructure or environmental challenges.

1. Highway Convenience Store High-Strength Wastewater (Pilot Gas Station)

The Challenge: A busy convenience store located off a major interstate in a rural area requires wastewater treatment. Too remote to connect to a centralized municipal system, the store presented additional challenges due to its 24/7 operation, high-volume traffic from oil and gas workers, and the presence of hot food and beverage service, resulting in high-strength wastewater and inconsistent flows.

The Solution: A decentralized system was designed to manage both hydraulic and organic loading effectively. The system included an oversized primary tank to improve solids settling after the grinder pump station and flow equalization to address peak periods and stabilize treatment. The design tailored the biological treatment based on organic load rather than flow alone. This approach ensured long-term performance, resilience, and reduced maintenance even with the store’s challenging wastewater profile.

ECOPOD treatment system designed to treat 45,000 GPD of domestic wastewater being generated by the Town of Section, AL.

The Challenge: A small city with limited infrastructure funding needed to replace an aging lagoon system that no longer met regulatory discharge standards. The city required a costeffective, scalable system with low O&M needs and the potential for future capacity expansion.

The operations building houses the controls center for the entire treatment system, from treatment to disposal, and allows the managing utility to easily maneuver the function and operation of the complete system.

The Solution: Engineers proposed a fixed film treatment system designed to meet stringent effluent criteria suitable for subsurface drip disposal that could be installed in locally sourced concrete tanks to lower construction costs. The system operates in modular trains, providing O&M flexibility and is sized with ample sludge storage capacity, minimizing maintenance activities. The design allows for

easy expandability, enabling the city to go from 30,000 GPD capacity to 45,000 GPD capacity, to 90,000 GPD capacity in a matter of 10 years. This approach helped the city meet regulatory requirements, manage growth affordably, and minimize staff burden.

The Challenge: South Alabama Utilities (SAU) needed capacity for community growth to handle the build-out of nearly 4,000 new homes – as well as schools, apartments, and business parks.

Phase I and Phase II of SAU’s West Mobile wastewater treatment facility include 36 Advan Tex AX100 textile treatment units. Two additional phases of similar size are planned.

The Solution: SAU worked with developers to install more than 60 miles of Orenco Effluent Sewer lines, which now serve 47 subdivisions and commercial properties. Filtered wastewater is sent to approximately 150 AdvanTex® textile treatment units at 14 different treatment facilities.

The road ahead for the water and wastewater industry is paved with both promise and complexity. Emerging contaminants such as PFAS, pharmaceuticals, and microplastics are raising the bar for treatment technologies. Simultaneously, climate change is intensifying weather patterns, stressing infrastructure with both drought and flood events.

Decentralized wastewater treatment systems will continue to remain effective in protecting public health and the environment through advancements in five key areas:

1. Technology: As regulations evolve, so must treatment technologies. Innovations in treatment technologies as well as monitoring devices will be essential.

2. Data-Driven Operations: Integrating real-time data, predictive maintenance, and AI-based control systems can drive performance and reduce operating costs.

3. Public-Private Partnerships: Collaboration between municipalities, engineers, manufacturers, and regulators is key to funding and deploying effective systems.

4. Flexible, Modular Designs: Solutions that can grow with a community or scale back in times of need will provide longterm value.

5. Focus on Resilience and Sustainability: Systems must withstand changing climate conditions, protect source water, and operate with minimal environmental footprint.

Decentralized wastewater treatment is not just a technical approach; it’s a mindset. It’s about building a smarter, more responsive infrastructure that supports communities, preserves the environment, and prepares us for future challenges. Whether it’s serving a rural school, a booming suburb, or a critical piece of industry, these systems are already proving their worth. As an industry, our mission is to continue evolving, adapting, and delivering the solutions needed to ensure safe, reliable, and sustainable water systems for all.

Source: The Water Environment Federation

By Gary Hunter, PE, Black and Veatch, Yian Sun, PhD, Hazen and Sawyer and Jenny Reina, Jacobs

PFAS have been classified by the U.S. Environmental Protection Agency (U.S. EPA) as emerging contaminants on the national landscape.

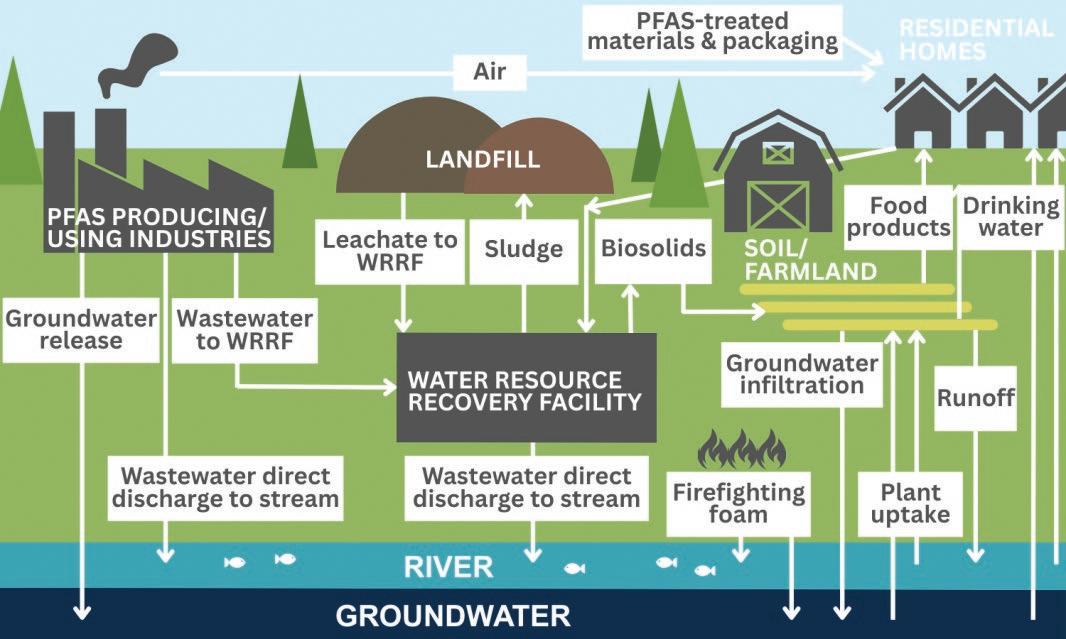

Per- and polyfluoroalkyl substances (PFAS) are a large family of manmade chemicals that are persistent in the environment (see Figure 1). PFAS have been classified by the U.S. Environmental Protection Agency (U.S. EPA) as emerging contaminants on the national landscape. For many years, PFAS have been utilized in a wide range of industrial applications and consumer products, including carpeting, waterproof clothing, upholstery, food packaging, personal care items, firefighting foams, electronics, and metal plating (Gallon et al., 2018; O’Connor et al., 2022; Rehman et al., 2023). These substances continue to be in use today. PFAS have been detected at varied levels in both the environment and the blood samples of the general U.S. population (Fenton et al., 2021). Water resource recovery facilities (WRRFs) receive PFAS primarily from industrial and domestic discharges to the collection system.

Conventional WRRF treatment systems do not effectively remove PFAS from wastewater. Hydrophilic short-chain

Adapted from Michigan Department of Environment, Great Lakes, and Energy (2019)

PFAS typically pass through conventional WRRFs to effluent discharges to surface water, marine ecosystems, and groundwater (Shah et al., 2020).

Meanwhile, long-chain PFAS tend to partition onto particulates because of

their hydrophobicity and, consequently, can accumulate in wastewater residual biosolids (Jiang et al., 2023; Zenobio et al., 2023). It should be noted that although long chain PFAS tend to adsorb to solid surfaces, they are also highly soluble

and can remain in the treated WRRF discharge. In addition, PFAS mass can be higher in effluent discharges relative to the mass in biosolids because treated municipal effluent is characterized by high volume and low solids makeup.

Utility staff, including operators, laboratory personnel, and management, face the challenge of implementing source reduction strategies that require the implementation of new sampling and analytical procedures. Becoming familiar with potential new regulations, proper sampling procedures, and analytical techniques will allow utilities to be proactive and an integral part of addressing the PFAS challenge.

PFAS regulations are very dynamic, with no federal regulations in place for treated wastewater effluents at the time of the preparation of this factsheet.

As shown in Figure 2, the U.S. EPA set a schedule in their PFAS Strategic Roadmap for federal regulatory activity in 2024 and 2025. The roadmap includes plans to leverage National Pollutant Discharge Elimination System permitting to obtain more data through PFAS monitoring.

PFOA and PFOS were declared hazardous substances under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) on July 8, 2024 (U.S. EPA, 2024).

According to CERCLA, the reporting threshold for PFOA or PFOS is the release of greater than 1 pound per 24 hours. Table 1 presents a simple example of the concentrations in either treated effluent or biosolids that could result in an exceedance of the reporting threshold. This ruling does not designate WRRF residuals as hazardous waste and does not require specific treatment or disposal of those residuals.

CERCLA designation allows contaminated sites to identify potentially responsible parties and seek litigation for PFAS contamination.

Clarifications on utility challenges from the ruling are summarized below:

• Public comments to the U.S. EPA on a final ruling on PFAS emissions have raised concerns about a potential

Table 1. PFOS/PFOA Concentrations in Effluent and Solids Needed to Exceed CERCLA Reporting Threshold

deviation from the ‘polluter pays’ principle, possible third-party litigation, and compliance costs.

• The sector is exploring legislative remedies that reflect wastewater utilities’ role as PFAS receivers, including exemptions for permitted releases. Potential changes to CERCLA may be forthcoming.

• State-level strategies aim to reduce PFAS in the environment by restricting or banning these substances in firefighting foams, textiles, and cosmetics, thereby reducing PFAS burdens on WRRFs. However, these reductions vary significantly from state to state, and their impacts will take time.

Understanding the needs of each utility is crucial for designing studies investigating PFAS within WRRFs and effectively communicating results. For regulatory compliance, detailed data on PFAS concentrations in the final product (i.e., biosolids and reclaimed water) are essential. Research and development should focus on understanding the fate and mass balance of PFAS, seasonal variations, and PFAS destruction efficiency, as well as standard methods for capturing broader range of chemicals like PFAS precursors (PFAS that degrade to one or more other PFAS including perfluoroalkyl acids PFAAs) and organofluorides. Tailoring information

to address specific concerns can help in decision-making for effective management of PFAS in WRRFs.

LIMITATIONS OF PFAS MEASUREMENTS

Over the past decade, extensive research has been conducted on the fate and transformation of PFAS in WRRFs, focusing on consumer confidence and regulatory requirements. However, uncertainties remain in PFAS characterization because of the presence of precursors like fluorotelomers and perfluorinated sulfonamides in manufacturing and wastewater, which can undergo transformation during treatment processes to perfluoroalkyl acids (PFAAs), making it challenging to estimate PFAS mass balance or understand treatment process impacts. Accurate measurement of PFAS in gaseous samples, such as air emissions

or off-gassing from treatment, is challenging due to the complexities of sampling and analysis. Therefore, it is difficult to develop WRRF PFAS mass balances or understand treatment process impacts.

WRRF operators may be responsible for sampling liquid or solid materials for PFAS at, or discharged to, their facilities. Proper sampling guidance is crucial for reliable analysis. To minimize PFAS contamination during sampling, attention must be given to clean sampling equipment; sample storage methods; field documentation; and decontamination methods; as well as the use of specific types of clothing, food, beverages, or personal care products. Sample collection methods should be reviewed to ensure collection of representative samples. The Michigan PFAS Action Response Team

USEPA 533 Determination of PFAS by Isotope Dilution Anion Exchange SPE and LC/MS/MS (2019)

USEPA 537.1 Determination of Selected PFAS by SPE and LC/LM/MS (2018/2020)

USEPA SW-846 Method 8327 PFAS Using External Standard Calibraiton and MRM LC/MS/MS (2019)

USEPA 1633 Analysis of PFAS in Aqueous, Solid, Biosolids, and Tissue Samples by LC-MS/MS (2024)

created the PFAS Sampling Guidance, which contains technical information on sampling a variety of media.

Targeted analyses are analytical methods and standards used to identify and quantify known and identifiable PFAS (analytes) for regulatory compliance. Targeted analyses typically use liquid chromatography-tandem mass spectrometry (LC-MS/MS) to detect and quantify these specific analytes. Table 2 lists approved U.S. EPA methods used for targeted PFAS.

A variety of precursors may ultimately transform into target PFAAs suggesting a ‘generation’ of PFAS. An estimate of these precursors is captured using the total oxidizable precursors assay, which uses a strong oxidative reaction to transform precursors primarily into PFAAs in the target list of analytes.

Surface Water, Wastewater

Groundwater, Surface Water, Wastewater, Soil, Biosolids, Sediment, Landfill Leachate, Fish Tissue

USEPA 1621 Determination of AOF in Aqueous Matrices by CIC (2024) Surface Water, Wastewater Organofluorines

USEPA Draft

OTM-45 Measurement of Selected PFAS from Stationary Sources (2021)

USEPA Draft

OTM-50 Sampling and Analysis of Volatile Fluorinated Compounds from Stationary Sources Using Passivated Stainless-Steel Canisters (2024)

Semi-Volatile and Particulate-Bound Analytes Monitoring (Draft)

Targeted and Non-Targeted Volatile Analytes Monitoring (Draft)

Abbreviations: AOF = adsorbable organic fluorine; CIC = combustion ion chromatography; LC = liquid chromatography; MRM = multiple reaction monitoring; MS = mass spectrometry; SPE = solid-phase

Table 2. U.S. EPA Analytical Methods

Regardless of the analytical method used, it is important to understand the results reported by laboratories, specifically any ‘U’ or ‘J’ flagged values. A ‘U’ or ‘J’ flag does not mean the sample had the concentration value reported, but rather that the analyte was detected below the limit of quantitation. Therefore, the number should be considered an estimate below the reporting limit.

Laboratories follow various quality control measures to ensure the validity of reported data. Measures usually identified for PFAS analysis include the following:

• Laboratory control standard (LCS): Matrix aliquot carried through the extraction process with accompanying samples, receiving the same treatment as samples, including the addition of surrogates/internal standards – except for native, non-isotopically labeled PFAS at a known concentration.

• Field blank (FB): Prepared in the laboratory by placing an aliquot of PFAS-free water reagent water in a sample container and treating it as a sample in all respects, including exposure to sampling site conditions, shipping, storage, preservation and all analytical procedures.

• Method blank (MB): Similar to a LCS but without native PFAS; used to confirm the absence of contamination from equipment or reagents during sample collection and analysis.

• Instrument blank (IB): A blank solvent analysis that was not extracted; used to evaluate the cleanliness of the instrument.

• Matrix spike/matrix spike duplicate (MS/MSD): Prepared like native field samples but spiked with native nonisotopically labeled PFAS; used to compare instrument response.

• Initial calibration verification (ICV): Used to ensure accuracy after a PFAS quantification; tolerances are method dependent but typically fall within +/- 30% of the known value of the standard.

Understanding the occurrence and composition of PFAS within a WRRF and its accompanying collection system is a crucial step of PFAS management. It allows utility staff to compare system PFAS to state thresholds, identify potential upstream discharges, and develop suitable PFAS management strategies.

Source control can play an important role in reducing or diverting PFAS loads from WRRFs by targeting certain industries discharging wastewater containing PFAS. The U.S. EPA’s PFAS Strategic Roadmap (2021) outlined a plan to require pretreatment programs to include source control and best management practices to protect WRRF discharges and biosolid applications.

The U.S. EPA is also developing effluent guidelines for manufacturing PFAS and PFAS requirements for metal finishing industrial users. As PFAS monitoring data becomes available,

utilities can develop pretreatment programs with industrial users.

States have provided grants and funding for implementing best management practices for industrial users to develop strategies to reduce PFAS. The State of Michigan launched the Industrial Pretreatment Program (IPP) PFAS initiative to reduce PFAS sources discharging to WRRFs. Michigan has developed a Frequently Asked Questions (FAQ) document for IPP PFAS source reduction focusing on pollutant minimization plans, equipment/ tank change outs, product replacement, and pretreatment to remove PFAS before discharge.

PFAS management may require that utilities explore methods to reduce PFAS from process streams, such as in residuals or scum, if unacceptable levels are found after source control measures have been implemented. New technologies or innovative applications of existing technologies are crucial for treating waste streams to reduce PFAS concerns.

MECHANISM AND MATRIX

TYPE OF INSTALLATION

Full-scale

Pilot-scale

On development

Separation for Liquids

• GAC/PAC

• Ion exchange

• High-pressure membrane

• Foam fractionation

• Specialty adsorbents

• Electrochemical oxidation

• Regenerable adsorbents

• Specialty adsorbents

Several separation technologies (Table 3) have been applied to remove PFAS from wastewater and concentrate them into a low flow and manageable waste stream for further treatment. Advanced thermal processes – like pyrolysis, gasification, supercritical water oxidation, and hydrothermal liquefaction –can be used to remove PFAS from biosolids and concentrated streams, but their fate, including removal/separation, transformation, and destruction, through these processes remain an active area of research.

• Removal means PFAS is no longer present in the original phase. Technology studies mostly report ‘removal’ but might use other words like ‘destruction.’

• Transformation/degradation describes when a parent compound becomes a transformation product.

• Mineralization occurs when the carbon-fluorine bond breaks, leaving no PFAS. This destruction can only be confirmed through measurement of inorganic fluoride resulting from the destroyed PFAS.

Based on challenges associated with distinguishing among different types of transformation products, it can be difficult to understand the relative importance of removal, transformation, and destruction in advanced thermal processes.

Mineralization or Removal for Concentrate

• Incineration

• Pyrolysis/gasification

• Supercritical water oxidation

• Hydrothermal alkaline treatment

• Electro-oxidation

• Non-thermal plasma

• Advanced Re/Ox

Mineralization or Removal for Solids

• Incineration

• Pyrolysis/gasification

• Supercritical water oxidation

• Hydrothermal liquefaction

• Mechanochemical treatment

Fenton, S. E., Ducatman, A., Boobis, A., DeWitt, J. C., Lau, C., Ng, C., Smith, J. S., & Roberts, S. M. (2021). Per‐ and polyfluoroalkyl substance toxicity and human health review: Current state of knowledge and strategies for informing future research. Enviro Toxic and Chemistry, 40(3), 606–630.

Gallen, C., Eaglesham, G., Drage, D., Nguyen, T. H., & Mueller, J. F. (2018). A mass estimate of perfluoroalkyl substance (PFAS) release from Australian wastewater treatment plants. Chemosphere, 208, 975–983.

Jiang, L., Yao, J., Ren, G., Sheng, N., Guo, Y., Dai, J., & Pan, Y. (2023). Comprehensive profiles of per- and polyfluoroalkyl substances in Chinese and African municipal wastewater treatment plants: New implications for removal efficiency. Science of The Total Environment, 857, 159638.

Michigan Department of Environment, Great Lakes, and Energy. (2019). IPP PFAS initiative. https://www.michigan.gov/egle/about/organization/water-resources/industrialpretreatment/pfas-initiative

O’Connor, J., Bolan, N. S., Kumar, M., Nitai, A. S., Ahmed, M. B., Bolan, S. S., Vithanage, M., Rinklebe, J., Mukhopadhyay, R., Srivastava, P., Sarkar, B., Bhatnagar, A., Wang, H., Siddique, K. H. M., & Kirkham, M. B. (2022). Distribution, transformation and remediation of poly- and per-fluoroalkyl substances (PFAS) in wastewater sources. Process Safety and Environmental Protection, 164, 91–108.

Rehman, A. U., Crimi, M., & Andreescu, S. (2023). Current and emerging analytical techniques for the determination of PFAS in environmental samples. Trends in Environmental Analytical Chemistry, 37, e00198.

Shah, A. I., Din Dar, M. U., Bhat, R. A., Singh, J. P., Singh, K., & Bhat, S. A. (2020). Prospectives and challenges of wastewater treatment technologies to combat contaminants of emerging concerns. Ecological Engineering, 152, 105882.

U.S. Environmental Protection Agency. (2021, October). PFAS strategic roadmap: EPA’s commitments to action 2021 – 2024.

U.S. Environmental Protection Agency. (2024, May 8.) Designation of perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS) as CERCLA hazardous substances. Federal Register 40 CFR Part 302.

Zenobio, J. E., Salawu, O. A., Han, Z., & Adeleye, A. S. (2022). Adsorption of per- and polyfluoroalkyl substances (PFAS) to containers. Journal of Hazardous Materials Advances, 7, 100130.

This article is originally from www.accesswater.org/?id=-10116781&fromsearch=true#iosfirsthighlight, and is freely available online.

SEPTEMBER 27 –OCTOBER 1, 2025

CWPLa is looking for articles for future issues of The Pelican. We want to highlight people, projects, and facilities in the State of Louisiana. Please get in touch with Mathias Leiendecker at mathias@kelman.ca or Andrew Alleman at andrew.alleman@waggonereng.com for more information or to submit your article for consideration. Thank you so much for your contribution to The Pelican!

The Pelican is made possible by the companies below who convey their important messages on our pages. We thank them for their support of the CWPLa and its publication and encourage you to contact them when making your purchasing decisions. To make it easier to contact these companies, we have included the page number of their advertisement, their phone number, and, where applicable, their website.

• Fully Programmable Sampling

• 7" Color Touchscreen

• High-Impact, Acrylic/ABS Enclosure

• Heavy Duty, Piston Vacuum Pump

• Modular Refrigeration

The WAVE™ by Emerald Coast Manufacturing is an electronically controlled, heavy duty vacuum wastewater sampler capable of fully programmable composite sampling with a high level of accuracy.

The WAVE’s powerful vacuum system generates stronger purges that remove contamination and can draw samples from greater distances than other samplers on the market, up to 200 Feet.

The WAVE’s integrated touch screen and userfriendly interface provide for straightforward control of sample volume, time and temperature, and the high impact acrylic/ABS body make this all-climate unit able to withstand even the harshest outdoor environments.