Conquer your engineering and construction challenges with our design-build solutions

EXPLORE OUR SOLUTIONS

Conquer your engineering and construction challenges with our design-build solutions

EXPLORE OUR SOLUTIONS

At Garver, we know the future of water in Colorado goes beyond pipelines, treatment plants, and technology. It depends on emerging leaders like Wesley Lozano — dedicated professionals ready to meet the challenges facing utilities and communities across the state. By supporting the next generation, Garver is helping to protect and preserve this vital resource for years to come.

Wesley Lozano, PE | Water Project Manager

Rocky Mountain Water Magazine Group

The following volunteers support RMSAWWA and RMWEA with content collection, management, editing, and reviewing the magazine.

BLAIR CORNING bcorning@englewoodco.gov

ANDREW DUGAN andrew.dugan@waterwrites.co

KARI LARESE klarese@hrwater.org

RMSAWWA Communications Committee

KARI LARESE, Chair klarese@hrwater.org

ERIN RIDOLFO, eNewsletter Editor eridolfo@rmsawwa.org

RMWEA Communications Committee

ELIZABETH DEWAARD, Co-Chair edewaard@englewoodco.gov

JORI NELSON, Co-Chair jori.nelson@hdrinc.com

NATALIE COOK, eNewsletter Reviewer ncook@auroragov.org

ANDREW DUGAN, eNewsletter Reviewer andrew.dugan@waterwrites.co

ROCKY MOUNTAIN VIEW

From the RMWEA President 7

From the RMSAWWA Chair 11

COMMITTEE SPOTLIGHT

Strengthening the Backbone of Water Utilities 15

MANAGEMENT PIPELINE

The Case for Conferences: Growing Leadership Beyond the Office 18

HOT TOPICS

Fighting Freeze and Failures: A Tribal School’s Wastewater Crisis Meets a Cold Reality 39

SCIENCE, RESEARCH, AND TECHNOLOGY

Scaling Up Solutions: Building the Rocky Mountain Region’s Largest Ion Exchange Facility for PFAS 49 Enhancing Efficiency and Biological Nutrient Removal in Wastewater Treatment: Industry Lessons about Low DO Biological Nutrient Removal 53

South Platte Renew’s RNG Pipeline System Pays for Itself! 58

COMMITTEE CORNER

Building A Stronger Internal Culture: The Value of ERGs in Water 60

OPERATIONS

Tel: 866-985-9780 Fax: 866-985-9799 info@kelman.ca www.kelman.ca

Managing Editor: Mathias Leiendecker

Marketing Manager: Chad Morrison Design/Layout: Jackie Magat

Advertising Coordinator: Sabrina Simmonds

Thinking Big in a Small District: The Larry D. Moore Water Treatment Plant 44

MEMBER IN FOCUS

Share Your Experience With RMWEA and RMSAWWA 47

Five Years After the Cameron Peak Fire: Greeley’s Ongoing Recovery and Resilience 63

ADVERTISER PRODUCT &

69

Kristin Johansen, RMWEA President, Senior Project Manager, Stantec

Iam honored to introduce myself, Kristin Johansen, as the 2025-2026 Rocky Mountain Water Environment Association (RWMEA) President.

I would like to begin by expressing appreciation to Past President Clay Rahn for his leadership over the previous year. Clay and a dedicated group of volunteers stewarded important initiatives for our organization, and I’m excited to keep the momentum rolling!

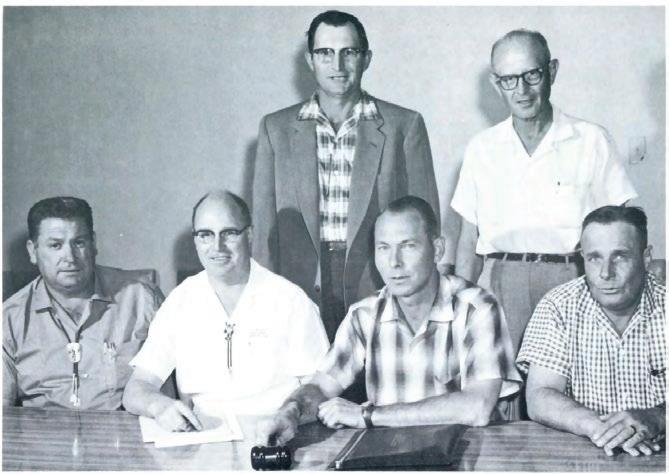

RMWEA has had several presidents from New Mexico since the organization was founded in 1936 (then known as the Rocky Mountain Sewage Works Association).

The first president from New Mexico was P.S. Fox in 1940 of Santa Fe, when the price of membership was only $3 (what a deal!). From 1936-1976, the organization saw presidents from Santa Fe, Lordsburg, Carlsbad, University Park, Los Alamos, and Roswell.

The New Mexico Operator School was founded in 1946. The same year, the annual conference was held in Santa Fe after Charles G Caldwell of the New Mexico Department of Public Health insisted that Santa Fe be considered along with

Cheyenne as a venue. The conference broke an attendance record with 30 attendees from New Mexico. My term began at the annual Rocky Mountain Water Conference held in Keystone, Colorado, where we celebrated a record of over 1500 attendees! I am humbled to follow the late Joseph Chwirka (Past President, 2001) as the second RMWEA President from New Mexico in the last 25 years.

As I embark on my term and busy myself digging into RMWEA history, I am reminiscent of my professional journey. All of us have a water story – the story of how we became involved in the water industry. I knew that I wanted to be a water engineer from an early age because I was fascinated by city planning and biology. I was intrigued by the aspects of the city and environment that are “out of sight, out of mind,” from sewer collection systems below grade to microscopic water bears (Tardigrades) that can survive for thousands of years in a desiccated state. I wanted every citizen to know where their water comes from and for global communities to have access to sanitation and clean, reliable water.

My first job was in 2005 with the Colorado Department of Public Health and Environment (CDPHE), where I conducted wastewater treatment plant inspections. Since then, I have served as a regulator,

As I embark on my term and busy myself digging into RMWEA history, I am reminiscent of my professional journey. All of us have a water story – the story of how we became involved in the water industry.

engineering consultant, contract operator, farmer, firefighter, research scientist, teacher, community engineer in Asia, and engineer for public municipalities. In 2016, I moved from Colorado to New Mexico to pursue my dream of qualifying for the Olympics in the marathon while working as a full-time engineer – I’m known as the “Correcamino” or Roadrunner for saving time by running to my project sites.

My journey has shown me that there are countless avenues to work in the water industry. Whether you have a CDL or an operator license or you’re interested in IT, maintenance, communications, chemistry, government affairs, engineering, industrial treatment, electronics, safety, or composting, there exists a niche and place for everyone to make not just a living, but an impact.

Within RMWEA, there are a plethora of ways to be involved. I started my involvement in RMWEA in 2011 as a member of the University of Colorado Boulder Student Chapter and participated in the Student Design Competition, where our team won the national competition at WEFTEC. I later joined the Young Professionals Committee, served as Biosolids Committee Chair, founded the New Mexico Professional Wastewater Operator (PWO) Seminar, and

am currently a member of the Innovative Water Technology, New Mexico RIO, and Government Affairs Committees. Through networking and knowledge sharing, RMWEA has empowered me to be curious, innovative, and to challenge myself in new roles to advance my career and those of others.

Our industry today faces a variety of challenges, but there is an opportunity to have nimble approaches to innovation –the theme of this publication issue.

In 1982, RMWEA President Bob Hegg wrote, “... Our industry is rapidly changing in the face of increasing financial austerity brought on by major government funding

cutbacks and increasing citizen concern about ever-increasing taxes and inflation. These concerns are often apparently in direct conflict with concerns of protecting our natural resources, especially water. This potential and often real conflict will require innovative and aggressive solutions if a successful balance is to be achieved.”

Despite the changing times, many of the challenges and the dedicated approach of our organization have not changed.

In the upcoming year, I aim to promote two main initiatives: 1) regional outreach and 2) workforce development.

1. Regional Outreach – The purpose of this goal is to extend and expand

our geographic outreach to outside of the Denver-metro area, Wyoming, and New Mexico. At our summer planning meeting held in Salida, Colorado, in July, we heard from guest speakers David Lady (Director of Public Works, Town of Salida) and Greg Felt (General Manager, Upper Arkansas Water Conservancy District) about the importance of collaboration and creative partnerships with other organizations to achieve broader outreach, tackle challenges, and offer mutual support.

2. Workforce Development – The top priority goal of the 5-Year Strategic Plan is workforce development, which aims to attract and retain the next generation of professionals to fill gaps created by retirees in the workforce. The objectives are to increase awareness of water sector careers among students, educators, and career transitioners and to support continuous learning, professional development, and mobility within the current water workforce. This includes developing a regional water career ambassador program, “Why work in water” campaign, enhancing the RMWEA job board, expanding mentorship programs, and continuing to deliver high-quality training events for our members.

If you are interested in volunteering for a workgroup or sharing ideas on either initiative, or if you want to get involved with RMWEA, please contact me at kjohansen. rmwea@gmail.com I’d love to hear from you! Thank you all for serving our members, industry, communities, and the environment. Cheers to the year ahead – as we say in New Mexico, “Agua es Vida, Water is Life!”

Kristin Johansen, PE, CWP is the 2025-2026 President of the Rocky Mountain Water Environment Association. She is a Senior Project Manager at Stantec. Kristin has a BS in Environmental Engineering from the University of Colorado Boulder and MS from Johns Hopkins University. She can be reached at kjohansen rmwea@gmail.com.

Building strong communities is at the heart of our endeavors. We’re proud to support the Engineers Without Borders - USA through the HDR Foundation.

Brett Pugh, RMSAWWA Chair, Project Manager, Burns & McDonnell

Greetings, water professionals! I am excited for the year ahead as your Chair for the Rocky Mountain Section of the AWWA. It is a privilege to serve the membership of our active and thriving Section. This column is an opportunity to introduce myself and discuss some of my goals for the year.

I moved to Colorado in 2018 with my wife and our three, now-teenage, sons. We promptly got our obligatory Subaru Outback and adopted another foster dog, which I understood at the time to be mandatory before being eligible for a Colorado driver’s license. I work as a consulting engineer with Burns & McDonnell in Englewood, CO, focused on water supply and treatment projects. I have been involved with AWWA since the late 1990s. Opportunities in the water industry have taken me across the USA, Canada and overseas. This is my second time as a Section Chair, with the first occurring in Atlantic Canada in 2013. The Atlantic Canada Water and Wastewater Association (yes, another ACWWA) is a multi-provincial, geographically diverse organization that acts as both a Section of AWWA and a Member Association of WEF. Many lessons from ACWWA can be applied to the Rocky Mountain Section. My involvement with the Rocky Mountain Section started in 2019 with the Rocky Mountain Water Conference (RMWC) technical program, and I became a Trustee in 2022. Working with Victor Sam, Andrea Song and Erin Ridolfo, we developed the first virtual RMWC due to restrictions related to COVID-19. Thankfully, we returned to

My leadership slogan for this year is “Get Involved, Bring a Friend.” This simple phrase captures two key elements of professional organizations: engagement of current members and growth through new members.

in-person conferences, where I stayed active with the technical program until this year.

I look forward to seeing where Michelle Young and Joe Tamburini take the technical program next year.

My leadership slogan for this year is “Get Involved, Bring a Friend.” This simple phrase captures two key elements of

professional organizations: engagement of current members and growth through new members. My experience is that active engagement drives deeper value and passion for our industry through meaningful connections with peers. The Section facilitates the creation of professional and business relationships,

which, in my opinion, leads to friendships that last for years. Please don’t wait until later in your career to get involved. Start now. The people you meet today will be valuable contacts as you both progress within your profession.

Examples of ways to get involved include participating in one of our 21 committees, attending a member appreciation event, helping plan the RMWC, writing an article for this publication or attending a treatment plant tour through the Water Treatment Committee. Visit our website rmsawwa.org to learn more. RMWC is the flagship event for the Section. This year brought a record number of people to Keystone, CO. It takes many hands to pull off that level of success. Where else can you rub shoulders with students, academics, laboratory professionals, operators, owners, suppliers and consulting engineers, all under one roof? I encourage you to reach out to the 2026 RMWC Co-Chairs, Natalia Hoogestejin or Jeff Berlin, to get involved.

Get involved in all three states. Our section faces challenges with our membership spread across population centers in the roughly 326,000 square miles and 8.6 million people combined between Wyoming, Colorado and New Mexico. The New Mexico Water Workshop is rebranding this year as

the New Mexico Water Summit to reflect its growth into a vibrant two-day conference, covering the diverse water issues in New Mexico. I was fortunate to attend this year as Chair-Elect, and I recommend you take the opportunity in 2026.

Wyoming is going strong with the constant support of Jason Palmer and Alexis Spray. The Western Slope is well represented by the growing Western Colorado Water and Wastewater Conference. The Action Now Committee continues its mission of delivering operations training to smaller communities. The Action Now and Supervisory Leadership Committees are both transitioning to new leadership. Do you have a special interest, knowledge or experience that may benefit the students of those two committees? Please reach out to Drake Dennert or Greg Stoncipher, respectively. Support Water For People (waterforpeople.org). It is a highly effective and impactful global non-profit addressing water supply and sanitation projects in Latin America, Asia and Africa, based in Denver, CO. Water For People’s origins are within AWWA. I first visited Denver in 2006 as part of a Water For People leadership workshop. It is another way to make a meaningful impact through Section participation.

Bring a Friend. Start attending events or continue what you are doing, but be sure you’re not alone. There is someone sitting next to you who could be more involved. Encourage your colleagues to get active in RMS and expand their business network or strengthen their technical acumen. We grow and are successful as a membership with new people. Did you know that RMS is considered a large section? We typically end up in the top six of the 43 total AWWA sections in terms of total membership. Many organizations offer financial support for professional membership dues. Take advantage of those employer benefits. Bringing a new person along helps you gain more benefits from the Section, too. Get new people excited to see the wide breadth of things we do in this industry.

Do you have a child in school? Several school districts have career-focused learning centers that offer courses in water for high school students. My children are in Littleton Public Schools, whose water courses were not offered in 2025/2026 due to low enrollment. Let’s take on that challenge as an industry and help make young people aware of water as a career choice. We can build pipelines for new people into the industry, as we expect many people to retire in the coming years. Water is not only a multi-faceted and diverse field, but it also offers purposeful work for those who safeguard safe and reliable drinking water for our communities.

In conclusion, I will finish with some goals for the year. I hope to sustain and grow our membership. Let’s broaden the collaboration across our committees and our sister organization Rocky Mountain Water Environment Association. We can build new relationships with secondary educational institutions. A personal goal is to improve our membership’s knowledge of the broad range of offerings of the Rocky Mountain Section and AWWA. We can get more young people involved so that they can learn and share the knowledge of those who are soon to retire. No matter what the involvement is, but sure to never be alone. Get Involved, Bring a Friend

You need equipment that works and works within the rules. Sulzer’s XFP submersible sewage pumps deliver clog-resistant performance and long-term reliability, all while meeting full Build America, Buy America (BABA) compliance.

That means peace of mind for your operations and access to funding your project relies on, without compromising performance.

We don’t just meet standards. We help you move forward with confidence.

Built here. Built to last. Built for you.

Learn more about Sulzer’s BABA go.sulzer.com/trusted-baba

Mark A. Thomas, Director of IT Operational Technology, Denver Water and Jason R. Taussig, Director of Emergency Management, Health, Safety and Security, Denver Water

From cyberattacks targeting utility infrastructure to extreme weather straining operations, water utilities are facing unprecedented risks. The Rocky Mountain Section’s Risk & Resilience Committee (R&R Committee) is stepping up to provide guidance, support, and actionable solutions. Co-chaired by industry veterans Mark Thomas and Jason Taussig, the committee brings together a team of approximately ten experts specializing in emergency management, occupational health, safety, and both physical and cybersecurity.

As we look ahead to 2026, the R&R Committee is sharpening its focus on three critical areas that impact every water utility:

• Cybersecurity

• Emergency Management

• Business Continuity

These pillars are essential for ensuring utilities can not only respond to crises but also maintain operations during and after disruptive events.

What sets this committee apart is its commitment to addressing these issues through the lens of small and mediumsized utilities. According to recent

The Rocky Mountain Section’s Risk & Resilience Committee (R&R Committee) is stepping up to provide guidance, support, and actionable solutions.

AWWA surveys and the lived experience of committee members, these utilities often operate with limited personnel and constrained budgets. This reality makes resilience planning both more challenging and more vital.

Throughout 2025, the committee has been hard at work developing content that is not only informative but also actionable. Their goal is to equip utility professionals with practical tools and insights that can be implemented regardless of size or resources. This content will be delivered through a variety of channels, including:

• Magazine articles

• Best practices documentation

• Conference presentations

• Workshops

Resilience isn’t optional; it’s essential. The R&R Committee is not just offering advice; they’re building a community of support and shared learning.

In addition, the committee is exploring ways to enhance its online presence, with the aim of hosting technical documentation and standards on a dedicated website. This digital hub would serve as a go-to resource for utilities seeking guidance on risk and resilience strategies. With a simple interface, finding documentation on standards from local and federal resources will be easier than navigating the source website.

One particularly new initiative is the committee’s plans to conduct site visits to small and medium-sized utilities. These visits will help the committee gain a deeper understanding of the unique challenges these small and medium-sized organizations face as to what a “bad day” looks like and to offer tailored advice to improve their

preparedness and response capabilities.

Starting with the next issue of this magazine, readers can look forward to a recurring column from the R&R Committee. Each article will delve deeper into the committee’s focus areas and offer at least three minimum actions or best practices that utilities can adopt. Over the course of the year, this series will build into a comprehensive, step-by-step guide for enhancing risk and resilience across the sector.

The committee also welcomes input and collaboration from the broader water utility community. If you have ideas for future content or firsthand stories from your own utility, the committee encourages you to reach out. They are always looking

for motivated, self-starting individuals who are passionate about strengthening the industry’s resilience. Email Mark and Jason at mark.thomas@denverwater.org and jason.taussig@denverwater.org.

Resilience isn’t optional; it’s essential. The R&R Committee is not just offering advice; they’re building a community of support and shared learning. Stay tuned, get involved, and let’s work together to ensure that every utility, regardless of size, is ready for whatever comes next.

Mark Thomas serves as the Director of IT Operational Technology at Denver Water, where he leads strategic and technical initiatives focused on cybersecurity, resilience, and the deployment and maintenance of critical infrastructure systems, including SCADA, Networking, Telecommunications, and Wireless Technologies. With over 20 years of experience in the water industry and over 30 years in telecommunications, networking and Information Technology management, Mark brings a deep understanding of operational technology systems and their role in utility performance and security. He holds a bachelor’s degree (BS) in information systems management and an MBA with a concentration in business strategy and strategic leadership.

Jason Taussig serves as the Director of EMHSS at Denver Water, where he leads strategic initiatives emphasizing the resilience of the systems and people of Denver Water. With over 20 years of experience in critical infrastructure industries, with the last eight years in the water industry, Jason brings a systems approach to solving complex challenges facing critical infrastructure.

Water utilities generate vast amounts of operational data daily, yet most organizations are not taking full advantage of these valuable information streams. Digital tools have the ability to strengthen your utility’s resilience and sustainability by reducing chemical usage, lowering energy consumption, maintaining water quality standards, and improving operational efficiency. Modernizing data management systems is the key first step to unlocking the value of your data. Carollo’s approach to digital water transformation provides a structured framework for utilities to leverage technology investments effectively, regardless of their current digital maturity.

Kacie Allard, Deputy Director, Business Solutions for South Platte Renew

Iam both delighted and fortunate to be writing this article from the Rocky Mountain Water Conference. This will not be a recap of the conference itself. Instead, I want to share why it’s essential for leaders, whether you’re managing a team, running a project, or guiding an entire organization, to make time for conferences.

Conferences can sometimes feel intimidating, but they also offer tremendous benefits, especially for leaders. Attending conferences provides professional development, expands your network, strengthens your personal brand, and builds a sense of community.

One of the most common reasons to attend a conference is for professional development. Every agenda is packed with technical sessions, panel discussions, and presentations on emerging challenges and innovative solutions. Attending these sessions helps refresh your professional knowledge.

For leaders, this allows you to gather insights you can bring back to your teams to improve an internal process, implement a technology that could solve a current organizational challenge, or learn what not to do by hearing about another utility’s trial-and-error approach.

Conferences provide an opportunity to step outside your daily routine and gain a broader perspective. They help you grow in ways that are harder to achieve by staying within your own organization.

Beyond the professional development, conferences are also about the people. The sessions are great, but the conversations over coffee, in the exhibit hall, or at the evening reception often prove just as valuable.

Building a strong network in the water industry pays off. Having other professionals to call when you hit a roadblock, to brainstorm solutions, or to share lessons

learned can be invaluable. Your network can also connect you with people who may be a perfect fit for an open position on your team. And if the time comes when you’re exploring a new opportunity yourself, those professional relationships often serve as the bridge to your next step.

For leaders, networking isn’t just about LinkedIn connections. It’s about building authentic relationships. These are the people who will challenge your thinking, share their expertise, and celebrate your wins. So, take the time to chat with that person sitting next to you in a session, or strike up a conversation with someone in line for coffee. You never know where it might lead.

The benefit that doesn’t always get enough attention is that conferences can do wonders for your personal brand.

Think of your personal brand as your professional reputation, the story people tell about you when you’re not in the room. Conferences allow you to shape that story in a positive way. Presenting on a panel, moderating a session, or even just asking thoughtful questions can position you as someone knowledgeable, engaged, and willing to contribute.

Your name and your organization may also appear in conference programs, signage, and digital materials, giving you visibility beyond the people you interact with directly. And don’t underestimate the power of association. When you’re seen in the same spaces as respected leaders and organizations, it naturally elevates your brand and helps you to build a reputation that goes beyond your résumé.

One of the most fulfilling aspects of conferences, especially local or regional ones, is the sense of community they create.

The Rocky Mountain Water Conference, for example, is a wonderful reminder of the strength of our industry. It’s not just

Conferences can sometimes feel intimidating, but they also offer tremendous benefits, especially for leaders. Attending conferences provides professional

development,

expands your network, strengthens your personal brand, and builds a sense of community.

about technical knowledge. It’s about people coming together to learn, teach, grow, and even have a little fun.

I get to reconnect with colleagues from my utility, catch up with friends from other organizations, and meet new faces who are just beginning their careers in water. The energy is contagious. You’re reminded that you are part of something bigger than yourself, contributing to an industry that impacts every single person, every single day. That sense of belonging and shared purpose is powerful.

Now, before I make conferences sound like the perfect experience, let me add a friendly disclaimer: they can also be overwhelming!

There are people everywhere. The schedule is packed. The conversations are constant. Even as an extrovert, I feel drained by the end of the day. I can only imagine how exhausting it can be for my introverted peers. If that’s you, permit yourself to take breaks. You don’t need to attend every single session or event. Step outside, recharge, and come back when you’re ready.

The other challenge is information overload. Conferences can feel like drinking from a fire hose. With so many sessions, it’s impossible to absorb everything. And here’s the secret: you’re not supposed to. Be strategic. Pick a handful of sessions that align with your goals or interests. Take away two or three key ideas you can implement, and don’t feel guilty about leaving the rest behind.

At the end of the day, conferences are more than just events on your calendar. They’re opportunities. They help you grow professionally, expand your network, strengthen your personal brand, and connect with a larger community.

For leaders, these benefits are significant. Conferences help you step out of the day-to-day, gain fresh perspectives, and build the relationships that will carry both you and your organization forward.

So, the next time a conference invite lands in your inbox, don’t brush it off. Say yes!

Kacie Allard is the Deputy Director –Business Solutions for South Platte Renew, Colorado’s third-largest wastewater treatment plant. She has 18 years of experience in municipal government, 11 of which have been in the water sector. Kacie is an expert communicator, change leader, novice gardener, and devoted wife and mother. She landed in the water sector by happenstance but has become passionate about serving the community and its stakeholders since then. Her enthusiasm for collaboration and team empowerment has allowed her to grow and encourage others in their personal and professional development.

his year’s Rocky Mountain Water Conference brought together more than 1,500 water and wastewater professionals from across the region, marking a record-breaking year for attendance! Set in the scenic mountain town of Keystone, Colorado, the conference delivered a dynamic blend of professional development, networking, and outdoor fun.

From the moment attendees arrived, the energy was high. Despite occasional light rain, the weather cooperated enough for participants to enjoy a wide variety of activities. Whether you joined the 5K Fun Run, Mountain Bike Ride, Golf Tournament, or took part in Meet & Greets, General and Technical Sessions, or explored the Exhibit Hall, there was something for everyone.

Congratulations to this year’s award recipients:

Celebrating Excellence in the Industry

Each year, the Rocky Mountain Water Conference also takes time to recognize individuals who have gone above and beyond in their contributions to the water and wastewater sectors. Their dedication and passion continue to inspire the broader water community and elevate the standards of our industry.

From the Conference Planning Committee:

“The conference planning committee works hard every year to put together an enjoyable, informative conference with a good balance of technical and social events to facilitate professional growth for attendees of all organizations and levels. It’s rewarding for conference planners to see our colleagues enjoying themselves, learning, reconnecting, and making new connections. Attending the Rocky Mountain Water Conference offers valuable opportunities for professional growth, networking, and staying current with industry trends. Participants gain insights into the latest technologies, regulatory updates, and best practices in water and wastewater management. The conference also fosters collaboration among engineers, scientists, utility professionals, and policymakers, helping to drive innovation and sustainable solutions in the region.”

Attendee Spotlight:

Alexis Beckman, Water Quality Analyst III, Highlands Ranch Water

A six-year member of AWWA and a fivetime attendee of the conference. Alexis loves attending the conference because it gives her a chance to earn education credits for the year while checking out innovations and learning about new

upcoming regulations. She likes attending presentations that are outside of the box for her normal routine. Her favorite presentation this year was about a small wetland pilot plant at a ski resort and an underground wastewater plant in Sweden. She says the conference is a great way to network with others in the same field and learn something new.

Patty Brubaker, Water Quality Treatment Plant Manager, Denver Water

A 22-year member of RMSAWWA who attends the conference every five years. Patty’s favorite aspect of the conference was the networking events, Shark Tank competition and many different technical sessions. She says the conference is a great place to meet and discuss ideas with peers in the industry.

normal workplace. He noted that lunches are a great time to network!

A member of RMSAWWA for nearly two decades and a regular attendee of the conference. John attended the conference to listen to municipal and utilities share challenges, successes and in-progress updates as they continue to support the rapidly growing and shifting Rocky Mountain West. He says the conference is a place to learn new tricks – even “old dogs” like him! It is inspiring to see and feel the energy that water professionals bring to communities and industry, and that energy results in innovation. That innovation keeps him curious, eager and empowered to learn.

Davis,

Manager, Denver Water

A member of RMSAWWA for nearly two decades – and a conference attendee for that long as well. Fletcher attended the conference this year to share Denver Water’s story of fee setting and public outreach with the community. His favorite aspect of the conference is the opportunity to meet and have fun conversations with folks he wouldn’t usually meet in his

As the water sector continues to evolve, gatherings like the Rocky Mountain Water Conference play a vital role in fostering innovation, sustainability, and community. A heartfelt thank you goes out to all the attendees, presenters, volunteers, and organizers who made the 2025 conference a success.

We’re already looking forward to seeing you again next year in Keystone from August 30 to September 2!

Attendees: 1,507

Utilities/ Companies Represented:

Setting a new RMWC record!

Awards Presented: Participants in the 5K Fun Run:

Participants in the Golf Tournament:

Technical Sessions:

Participants in the Mountain Bike Ride:

Participants in the Corn Hole Tournament:

First Time Attendees:

Lauren Ris, Keynote Speaker, Colorado Water Conservation Board Director

For those of you who have tried to bake from scratch, you know the outcome depends not just on the ingredients but on how they are mixed. Too much of one thing, not enough of another, or adding them in the wrong order can ruin the whole batch. Colorado’s water community is a lot like that. We have all the essential ingredients – engineers, planners, attorneys, and innovators –but our success depends on how we work together. This is the conversation I was honored to have with the Rocky Mountain Water community as the keynote speaker at the annual Ro cky Mountain Water Conference

Colorado’s water story has always been a tension between geography and values. The plumbing has long been a challenge, balancing demand on the East Slope with the supply on the West. But today, the biggest challenge is not just moving water, but balancing competing values – from the agricultural heritage that feeds us to the recreational opportunities that define our quality of life. This is where the work of the Colorado Water Conservation Board (CWCB) becomes more than just policy; it becomes a practice in bringing people together.

Our role at the CWCB is unique. We don’t regulate or operate water projects. Instead, our influence comes from fostering collaboration and providing funding. We bring people to the table for tough conversations and provide the “carrot” of financial support through our Water Project Loan Program and Water Plan Grants. These are not abstract initiatives; they’re tangible investments in communities, livelihoods, and people.

It’s impossible to discuss Colorado’s water without addressing the future of the Colorado River. The last 20 years have been the driest on record, and we are living in a system that simply doesn’t add up. The outdated assumptions of abundant supply are gone, replaced by the reality of declining flows and increasing demand. While Colorado has consistently lived within our Compact apportionment, we understand that a new approach is needed –one driven by actual river conditions, not unsustainable downstream demand. The negotiations over new operating guidelines are critical, and we are hopeful for a solution that will secure this vital resource for the 40 million people, two countries, seven states, and 30 tribes who depend on it.

In the face of these challenges, Colorado is leaning into innovation, adaptation, and partnerships. This is the core of the Colorado Water Plan. The updated 2023 Plan is more than a document; it’s an invitation to collaborate. It provides a roadmap for resilience across four key action areas: Vibrant Communities, Robust Agriculture, Thriving Watersheds, and Resilient Planning. These are the lenses through which we act with intention and balance, with people and communities at the core of every action we take.

We’ve already seen significant progress. Through our Water Plan Grant Program, we’ve supported diverse projects that range from modernizing farm irrigation to restoring streams. Our progress report highlights how

we’re on track to achieve the 10-year plan by 2033. For example, our Growing Water Smart workshops bring water and land-use professionals together to integrate watersaving practices into community planning. We’ve also released a report detailing strategies to protect our irrigated agricultural lands, which are vital to our rural economies. In addition, our Wildfire Ready Watersheds Program proactively identifies vulnerable watersheds to protect water resources before fires occur.

The success of the Colorado Water Plan is a testament to the power of partnership.

• The Basin Roundtables are a cornerstone of our collaborative management, ensuring that local voices and solutions drive statewide priorities.

• The Interbasin Compact Committee brings those voices together for honest, balanced policy discussions.

• The Water Conditions Monitoring Committee combines local, state, and federal data to create a shared picture of our water supply, leading to shared preparedness.

• The Colorado Water Loss Initiative is a prime example of collective effort creating

results no single entity could achieve alone, with utilities coming together to audit systems and share best practices.

This collaboration needs fuel, and that’s where the CWCB’s funding programs come in. Our loan and grant programs turn good ideas into tangible projects on

Supplying water through the natural process of riverbank ltration, these wells consistently deliver water with low turbidity and stable quality, simplifying the treatment process and reducing long-term operating costs for Owners.

Want to know more, contact: Luca DeAngelis: luca.deangelis@gcinc.com

Matt Reed: matthew.reed@gcinc.com or call us at 614-888-6263

the ground. Last year alone, we awarded $36.7 million in Water Plan Grants, representing people coming together across sectors to solve real problems. We’ve even invested in regional grant managers to ensure that every community, no matter its size, has an accessible touchpoint for information and support. Another tool, the Technical Assistance for Federal Cost-Sharing (TAFC) Program, helps smaller entities compete for federal dollars, leveling the playing field so every community has a chance to bring its priorities forward. Colorado’s water challenges are immense, but I firmly believe our greatest asset is not just our rivers or our infrastructure; it’s our people. The engineers, operators, and utility leaders that attended the conference, the farmers, and the community members – you are the partnerships that connect us all. When we bring people together to share data, priorities, and funding, we can turn the challenges of drought and climate variability into opportunities for resilience. Thank you for being partners in building Colorado’s water future.

Lauren Ris is the Director of the Colorado Water Conservation Board.

As a water policy expert focused on water resilience, Ris’ priorities include continuing the momentum of the Colorado Water Plan and collaborating with partners across the state to find creative solutions to water challenges.

Ris holds a Bachelor’s in English and Environmental Science from Willamette University and a Master’s in Natural Resource Policy and Conservation Biology from the University of Michigan. She previously worked as a Committee and Policy Staff Fiscal Analyst for the Colorado Legislative Council, a Legislative Liaison for the Colorado Department of Natural Resources (DNR), Assistant Director for Water in the DNR, and the Deputy Director of the CWCB.

All wastewater treatment plants are not alike. That’s why plant designers prefer our Raptor® line of screening products, the innovative all-in-one units that screen, wash, convey and dewater screenings efficiently, capturing more fine solids and long fibers than other available screens. Raptor® products are adaptable to a wide range of configurations, giving you more choices for better performance in your unique application. They are preferred among plant operators for their simple operation, ease of use, and minimal maintenance. When performance counts, count on the industry leader for more than 90 years—Lakeside Equipment Corporation.

REPRESENTED LOCALLY BY:

Speak to one of our experts at 630.837.5640, email us at sales@lakeside-equipment.com or visit lakeside-equipment.com for more product information.

Derek Belka, Innovative Water Technology Committee, Wastewater Treatment Technologist, Garver

This year marked the sixth annual Innovative Water Technology (IWT) Committee Shark Tank event during the Rocky Mountain Water Conference. Competitors from academia, utilities, and consulting pitched their innovative solutions for tackling some of the water industry’s unique challenges in advanced treatment, emerging contaminants, and workforce development to a packed room of water professionals. The top pitch would take home a substantial $5,000 grand prize sponsored by Garver, HDR, Brown and Caldwell, and the IWT Committee to help advance their ideas into the real world.

Five contestants gave five-minute pitch presentations before being grilled by the panel of Sharks and members of the audience. This year’s shark panel included Derek Belka from Garver, Jamie Safulko from PCL Construction, Cadee Oakleaf from the City of Greeley, and Dmitriy Zinchenko from HDR. Although typically solitary creatures, the Sharks felt uneasy about their even numbers and recruited a surprise audience fifth judge, Ben Johnson from Copper Mountain Sanitation District.

Ben was attending his first Shark Tank event and thought he was there to serve as a spectator. Little did he know he would be helping determine the 2025 Shark Tank winner.

The first competitors were a team from Black and Veatch (Becca Chapa) and Jacobs Solutions (Dr. Dotti Ramey), who highlighted a major issue in the water workforce begging for a creative solution. It has been estimated that more than one third of the water operator workforce will be eligible for retirement over the next ten years, while recruitment and retention of new operators have remained major issues for many utilities. The competitors proposed that we solve this problem by tapping into the nearly 200,000 veterans returning to civilian life annually through targeted outreach and engagement with veteran groups supported by Shark Tank funds. Their Mission Hydro Heroes solution was win-win-win-win for the water sector that is in critical need of future operators.

Next up was PhD candidate Fuwad Ahmed from New Mexico State University whose work on low-cost coatings for electrodialysis (ED) membranes has the potential to reshape

the industry by improving membrane selectivity and durability and affordability of treatment. Applied to reverse osmosis concentrate streams, coated ED membranes help further concentrate monovalent ions for on-site generation of acids and bases in zero liquid discharge systems. Fuwad proposed using the Shark Tank winnings to scale-up and make improvements to their membrane coating methodology so that recoating can be performed in-place, reducing the maintenance burden in practice. This technology could play a pivotal role in the feasibility of potable reuse and in-land brackish groundwater desalination where membrane concentrate stream disposals options are limited.

The third competitor was Vanessa Maybruck, a PhD candidate at the University of Colorado at Boulder, pitching SeweRx – a free, open-source, web-based R Shiny app for predicting pharmaceutical concentrations in water resource recovery facility (WRRF) influent. SeweRx leverages publicly available datasets on prescriptions, physicochemical properties,

reactions, use, and toxicity for more than 200 commonly prescribed pharmaceuticals. As direct potable reuse becomes more common, understanding and quantifying the pharmaceuticals loading to WRRFs is essential to the planning, design and optimization of systems that have a direct impact on public health. Vanessa proposed using the Shark Tank winnings for the cost of web hosting and field sampling to validate SeweRx’s current model-based approach. SeweRx is poised to become a powerful tool for engineers and operators to estimate pharmaceutical WRRF loads without costly sampling and analyses, especially in small communities.

Metro Water Recovery’s Brian Marron was the Shark Tank’s fourth competitor, presenting his solution to an imprecise approach to magnesium chloride dose determination for struvite precipitation at the Robert W. Hite WRRF’s MagPrex™ facility. Brian’s novel approach provided online dilution and filtration of high-strength (> 300 mg-P/L) and high-solids streams (~ 2.3% solids) using readily available components to facilitate the use of an online phosphate analyzer for automated, feedback control of magnesium chloride dosing, potentially saving Metro tens of thousands annually. Brian requested funding to construct and test additional improvements to the system, which can be deployed as a solution to measuring critical dosing control parameters (e.g., NH4) in any high-strength and/or high-solids treatment stream.

The competition was rounded out by Sarang Gosavi, a graduate student at the University of Colorado at Boulder and co-founder of SynForce, a start-up trying to bring his novel Thermo-PhotoCatalysis system to market. The pitch claimed that the system uses heat and light to degrade a wide spectrum of PFAS species and requested funds to further refine the prototype and execute a pilot study with the City of Boulder. This lowcost, emission-free technology reduces energy consumption and could be a game changer as PFAS treatment becomes more common in water and wastewater facilities throughout the United States.

While the Sharks were deliberating, Caleb Vannice (South Platte Renew) provided an update on last year’s winning idea: the Facility Asset Renewal Marketplace (FARM).

The FARM is an online marketplace for our members to buy and sell surplus equipment and supplies that may be beneficial to other utilities. The FARM is up and running and can be accessed via the RMWEA’s website under the membership tab. Utilities are encouraged to offer up surplus equipment and supplies to help each other redistribute assets and reduce waste.

All the competitors were enthusiastic and passionate about their work and how their ideas could drive innovation in the water industry. It was difficult for the judges to choose the top presentation from such a strong group of enthusiastic presenters sharing impactful ideas across the water industry. Ultimately, the Mission Hydro Heroes project presented by Becca Chapa and Dr. Dotti Ramey took home the $5,000 grand prize. These funds will be

used to begin developing a clear pathway for recruiting our veterans into the water workforce. The best place to learn more about the Mission Hydro Heroes pitch will be at the IWT Annual Innovation Seminar on February 5, 2026.

Do you have an innovative idea that you think could help the industry, but need some seed money to get it going? Or maybe you want to be a Shark in 2026? The Call for Abstracts for 2026 will go out in the spring, or you can reach out to IWT chairs Carolyn Coffey (coffeycl@bv.com) or Anna Scopp (ascopp@hazenandsawyer.com) for additional information.

Derek Belka is a member of the Innovative Water Technology Committee and is a Wastewater Treatment Technologist at Garver. This article was supported by the other Sharks.

The accumulation of waste debris poses a significant challenge. JWC has established itself as a leader in providing reliable, highperformance municipal wastewater equipment solutions for both solids removal and reduction, effectively tackling waste debris.

5K Fun Run/Walk and Happy Hour

Meet & Greet

Team “Corn Blaster” consisting of Evan Person of Castle Pines Metropolitan Districted teamed with Angus Campbell of Matrix Design Group won the final round against Team “Funbags” consisting of Cody Henry and Louis Morris representing the City of Brighton.

At Johnston Pump, reliability isn’t a feature, it’s our foundation. Since 1907, we’ve delivered rugged, high-performance pumps that keep systems running smoothly and customers worry-free.

We understand what’s at stake, which is why every Johnston pump is engineered for durability, backed by expert support, and available as Build America, Buy America compliant so you can move forward with confidence and compliance from day one.

Learn more about Johnston Pump trusted-johnston

Reduces O&M Costs & Capital Expenses

Very Low Life Cycle Cost

Helps Protect the Environment

Prevents Corrosion

Rapid Trenchless Installation

As a result of the impervious nature of the SpectraShield Liner System, infiltration and ex-filtration is eliminated in structures. Operating and maintenance expenses are reduced, plant capacity is preserved, and plant expansion requirements may be delayed or eliminated.

As a result of the long life and competitive installation cost, the life cycle cost for the SpectraShield Liner System is very low. In many cases the ROI is under 24 months.

Groundwater entering the system is reduced, allowing more to percolate to the aquifer. Reduced pumping requirements reduce energy use reducing the carbon footprint. SSOs (Sewer System Overflows) are reduced as infiltration is reduced.

The Spectrashield Liner System provides a protective barrier that prevents H2S and moisture from reaching the surface of the structure.

The SpectraShield Liner System can be installed in a typical 7 foot deep manhole in about an hour without any excavation. The manhole may be returned to service immediately upon completion of the installation. An average sized pump station or wet well application takes about 2 days from start to finish. The pump station or wet well may be returned to service immediately upon completion of the installation.

Flexibility

Long Life

Versatile Experience

Cost competitive

The multi-layer SpectraShield Liner System is flexible, allowing it to handle the stresses associated with structure settling, traffic loading, and freeze thaw cycles.

The SpectraShield Liner System has a design life of 100 years and comes with a 10 year manufacturer warranty. The first structures lined in 1993 are still in place, and in good condition.

The SpectraShield Liner System may be used in a variety of structures, such as; manholes, lift stations, wetwells, large diameter pipes, box culverts, headworks, grit chambers, weirs, and package WWTPs.

Since 1993, in-house applicators, and trained certified licensees, have applied the SpectraShield Liner System in over 121,000 structures. Over 12 million square feet of the SpectraShield Liner System have been applied.

The SpectraShield Liner System installation cost is very competitive with all other liners and coatings.

Most see a mountain lake. We see a resource worth protecting.

Suzan Chin-Taylor, MSc

In the rugged heart of Wyoming’s Wind River Indian Reservation, St. Stephens Indian Mission faced a quietly growing crisis. Its lagoon-based wastewater treatment system – shared with the adjacent federally operated St. Stephens Indian School –wasn’t just failing, it was frozen, overloaded with sludge, emitting persistent odors, and threatening the health and operations of the mission and the school it supported. Now, the story is one of resilience, innovation, and unexpected renewal.

The St. Stephens Indian Mission is home to a small rural community and sits just outside Riverton in Arapahoe, Wyoming. While modest in population, its grounds serve a dual purpose: not only for its own operations but also as the wastewater treatment site for the St. Stephens Indian School, a federal K-12 institution serving roughly 300 students.

The lagoon system had been patched over the years. “They did put some new plastic liners in around 15 years ago,” said Father Andrew “Drew” Duncan of the Mission. “They dug out some of the sludge then, but not in the finishing pond. The system was very old.”

Even with those updates, the treatment system remained vulnerable. The original surface aerators were failing frequently. “They were constantly freezing, clogging, and stopping,” said Father Drew. The failures weren’t just inconvenient – they were serious. Odors from the lagoon regularly drifted to nearby homes, including Father Drew’s own residence just 100 yards away.

With no background in wastewater operations, Father Drew had taken on the role of operator out of necessity.

He had newly arrived and was trying to learn on the fly. “I was taking courses to be the operator, but I didn’t know how to fix any of it,” he recalled. “We were constantly calling in repair people.” That’s when fate –and a trade show – intervened.

At a Wyoming Rural Water Association operator training school, Father Drew encountered a booth for Titus Wastewater Solutions. Lewis Titus, founder of the Casper-based company, was manning it. “I told him, ‘I’ve got a system that doesn’t work at all,’” said Father Drew.

Titus made the 150-mile trip to Arapahoe and confirmed the problem. The lagoons were shallow, heavily loaded with sludge, and operating with

ineffective, outdated aeration equipment. A solution was devised, but the real challenge would be securing funding.

Because the school is a federally operated institution and the mission is a church-affiliated nonprofit, the wastewater system fell into a bureaucratic gray zone. While the Bureau of Indian Education (BIE) technically supported school infrastructure, accessing funding took months – often years.

“I badgered the BIE all summer,” said Titus. “Meanwhile, the lagoons started freezing. In November, Father Drew called me and said, ‘There’s already two inches of ice. If this freezes solid, we’ll have to shut down the school.’”

That winter would turn out to be the coldest on record in the region.

Titus eventually secured emergency authorization. But by the time his team arrived, the lagoon was buried under 15 inches of snow, and the surface ice was nearly a foot thick. With temperatures plunging into the single digits, the crew couldn’t even get close without a frontend loader clearing the road.

Breaking the ice was another matter. A thousand-pound iron weight bounced off the frozen surface. Even an 18-inch auger only managed a small hole. Eventually, the team resorted to using the aerators themselves – each weighing nearly 3,000 pounds – as battering rams to widen the opening.

Somehow, the units withstood the abuse. Once installed, they faced another challenge: sludge. “They were sitting right on top of it,” Titus explained. “We got them running, and they ate their way through it.”

As temperatures dropped further, to as low as -44°F, the equipment remained operational, preventing the lagoons from freezing solid. Three months of 0 to minus 44-degree temperatures were the true test. A power outage, which shut down the blower, was the only real challenge. This went several days before maintenance personnel discovered the shutdown. The aerator’s air pipe was frozen solid. Titus’s team resorted to creative solutions to restart the aerators. They heated propylene glycol antifreeze on a stove inside the mission, poured it

into insulated coolers, and hand-delivered it down air pipes, melting the ice plug that was preventing air flow to the aerator diffuser. The system ran uninterrupted for the rest of that brutal winter.

What started as a desperate intervention has proven durable and transformative. The aerators, still running three years later, have never broken down.

“To my knowledge, there’s not been a single stoppage,” said Father Drew. “They never froze up, even when it hit -44.”

After installation, the federal school assumed operational oversight of the system. Odor issues, once a constant concern, vanished entirely. “There’s not been any odor since. And that was a big change,” said Father Drew. “My house is just 100 yards away. I used to smell it constantly. Now, nothing.”

This change hasn’t gone unnoticed by the local community. The lagoons sit just 30 yards from the Wind River, a popular fishing and swimming spot. “The tribal members come and fish right next to it again. The area has really opened back up for recreation,” said Father Drew. “It’s very pleasant now.”

Photos taken by Father Drew show children swimming in the river next to the treatment site, something unimaginable during the years when the lagoon’s odor and condition made it uninviting.

–AND A DISAPPEARING CITATION

An unexpected side benefit of the installation has been the disappearance of a persistent duckweed problem. “There used to be times when the ponds were completely covered with duckweed,” said Father Drew. “And when I first got here, we actually got an EPA citation for it.”

Duckweed overgrowth is often a sign of low oxygen and poor water quality. Since the aerators went in, the plant has not returned. “I’m not a scientist,” Father Drew said, “but it hasn’t come back, and we haven’t had any citations since either.”

While it’s difficult to definitively prove causation, the timing and conditions suggest a strong correlation. Installing the aerators during extreme cold likely disrupted the duckweed’s life cycle. By the time spring arrived, the elevated dissolved oxygen and improved circulation may have prevented regrowth.

“There may be more to this than we expected,” said Titus, “it’s definitely worth looking deeper.”

LESSONS FROM A QUIET SUCCESS

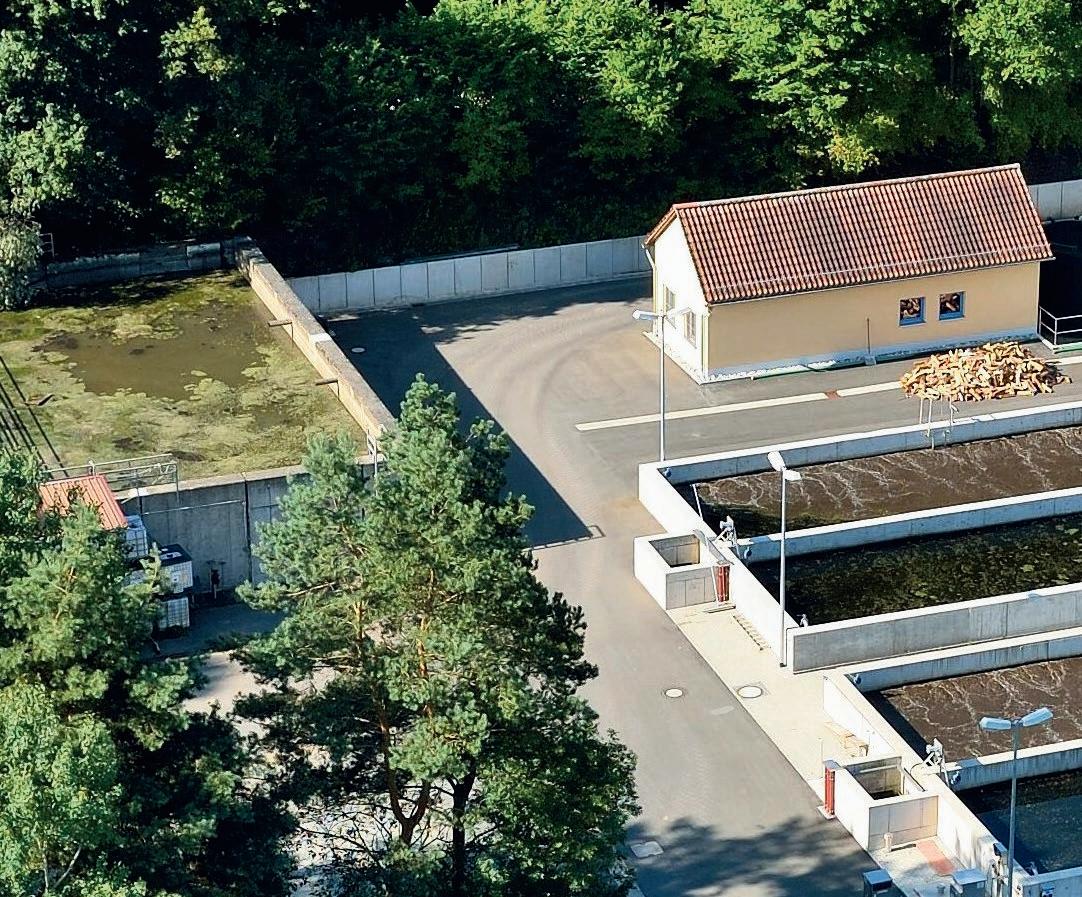

St. Stephen permanent structure pond in summer.

a side-draw intake and a durable, selfcontained design that reduces volatile solids significantly, while protecting the lagoon liner. Its floating platform allows it to function even in high-sludge environments, and it can oxygenate water at impressive distances.

installed that can automatically restart the aerators if they shut down.

And yet, even running at half speed, the system has proved itself.

“I went out the summer after installation and tested dissolved oxygen levels all around the lagoon,” said Titus. “Top, bottom,

RECLAIMING A COMMUNITY ASSET

environmental and spiritual. The lagoon is no longer a problem to manage, but a

“I can’t say enough about how much better things have been,” he said. “No odor. No breakdowns. The kids swim near there now. It’s gone from being something we dreaded to something that just works.”

And perhaps most tellingly, the wastewater system, once the site of frequent complaints and emergency repairs, is now something few people even notice. “That’s the best compliment of all,” said Father Drew. “It does its job, quietly.”

Suzan Chin-Taylor, MSc is an international entrepreneur, author, course creator, podcast host and speaker who helps manufacturers, contractors, and service providers in the wastewater, stormwater and water sectors stand out, tell their story and drive demand.

CDPHE STR Comprehensive Tank

Inspections with Certified Dive Team or ROV

In service tank cleanings with proprietary cleaning system (faster cleaning times)

Summary or full inspection reports, authored by AMPP CIP or PE

Passive CP Installation per AMPP

RPO1906-96

Common Tank Repairs

Active Tank Mixing sales and installation

Underwater Ultrasonic Thickness

Readings

Tank rehabilitation cost estimates

2024 ENR INTERMOUNTAIN CONTRACTOR OF THE

At Haskell, we know water is more than a utility—it’s essential to life, public health, economic development and long-term environmental resilience. Since our founding in 1965, we’ve focused on delivering infrastructure, strengthening communities and sustaining future generations.

Mike Marcum, Roxborough Water & Sanitation District General Manager

What does $35 million buy in the world of water treatment?

For the Roxborough Water & Sanitation District (RWSD), the answer is a future-focused, technologically advanced facility that rivals those of much larger utilities.

Although RWSD is classified as a small utility by federal standards, serving approximately 4,000 customers today with a planned build-out of 4,428 service accounts, it has never thought small when it comes to delivering safe, reliable water.

Roxborough sits at the foot of the Front Range of the Rocky Mountains, nestled near Roxborough State Park, with its towering sandstone ridge being the community’s natural trademark. With a population of nearly 15,000 residents, Roxborough is an unincorporated community in Douglas County.

The district’s Larry D. Moore Water Treatment Plant, which came online in 2017, represents a new era of innovation, efficiency, and quality for its customers in the foothills southwest of Denver.

Our goal was to build a water treatment facility that meets the technical and financial needs of both Roxborough and

our wholesale customer utility, while at the same time delivering high water quality and saving our customers millions of dollars.

The facility carries the name of former RWSD General Manager Larry D. Moore, who spent nearly 30 years with the district and was instrumental in securing a permanent raw-water supply for the community. That legacy of foresight is reflected in the plant’s design; not only does it meet the district’s current needs, but it also positions RWSD for future growth, long-term water security, and continued regulatory compliance.

With an initial treatment capacity of six million gallons per day (mgd) and an ultimate build-out capacity of eight mgd, the plant was intentionally designed with dual treatment trains. This unique design allows RWSD to treat two separate raw water sources simultaneously, an essential capability since the district also treats water provided by Dominion Water & Sanitation District.

At the heart of the treatment process is Veolia’s ACTIFLO® pretreatment system, which uses microsand as a ballast to dramatically speed up the settling process. The system can remove more than 99% of turbidity, discoloration, iron, and other

contaminants even in winter, when raw water temperatures often drop to just 1–2 degrees Celsius.

Actiflo gives us a very small footprint with huge results. Instead of detention times measured in hours, we’re talking about minutes. It’s highly efficient, saves space, and ultimately saved about 30% on the total installed cost of the facility.

The system also plays a critical role in reducing disinfection byproducts. By removing 60% of organic carbon at the pretreatment stage, Actiflo lowers the potential for trihalomethanes and haloacetic acids to form later in the distribution system. This has led to an 80% reduction in disinfection byproducts compared to RWSD’s previous plant.

The Larry D. Moore plant utilizes a multi-barrier treatment approach from pretreatment through final disinfection. Our processes include:

• Conventional Dual-Media Filtration –After Actiflo, water passes through dualmedia filters composed of 30 inches of anthracite and 18 inches of sand. These filters provide a finishing polish, capturing any remaining particulate matter before disinfection.

• UV Disinfection – RWSD made history as the first utility in Colorado to achieve 100% primary disinfection credits from the Colorado Department of Public Health and Environment (CDPHE) using ultraviolet light. UV treatment inactivates bacteria, viruses, and protozoa –including chlorine-resistant pathogens like Giardia and Cryptosporidium. Because UV doesn’t add chemicals, it preserves the natural taste and odor of the water while reducing reliance on chlorine.

• Chloramination – While UV provides primary disinfection, the district still must maintain a disinfectant residual in the distribution system. For this, RWSD uses chloramines. Chlorimines form when sodium hypochlorite, generated on-site, is combined with aqueous ammonia. Chloramines are more stable than free chlorine, last longer in the system, and generate fewer byproducts. The combination of UV and chloramines gives us the best of both worlds – pathogen protection and stable water quality all the way to the customer’s tap.

RWSD has also embraced a state-ofthe-art GIS system, ESRI Arc Map. Key capabilities include 3D visualization of facilities, real-time asset performance tracking, mobile access for field crews, integration with other systems, and advanced spatial analysis for water quality and environmental impact assessment

For a small district with a lean staff, such digital tools are invaluable. It lets us run a highly sophisticated facility without requiring the resources of a big-city utility. The plant itself is only part of RWSD’s investment story. Recognizing that clean water must travel through an equally reliable distribution system, the district has undertaken a comprehensive program to modernize its infrastructure.

We continue to update our system –every pump station is brand new. That allows us to focus on the stuff in the ground.

RWSD’s system is divided into 12 pressure zones to manage the steep terrain of its service area. By carefully managing pressure to stay at or below 130 psi, the

district reduces the risk of main breaks and prolongs the life of its assets.

On the wastewater side, RWSD is proactively addressing aging clay sewer lines through structural cured-in-place pipe (CIPP) lining. Each year, the district rehabilitates between 15,000 and 20,000 feet of pipe. This trenchless technology uses a steam-cured liner to reinforce the existing pipe without excavation – reducing costs, minimizing disruption, and extending asset life.

Since the Larry D. Moore Plant came online, the results have been striking:

• Total organic carbon removal has increased to roughly 60%.

• Disinfection byproducts in the distribution system have dropped by 80%, from around 80 parts per billion (ppb) at the old plant to just 17 ppb today.

• The district’s water has earned recognition in regional taste competitions, including second place in the Rocky Mountain Section AWWA contest.

RWSD has also demonstrated the economic value of regional collaboration. By designing the plant to serve Dominion Water & Sanitation District’s phased growth, both utilities avoided duplicative infrastructure and shared significant cost savings.

At RWSD, we have built a culture of continuous improvement. We view the Larry D. Moore Plant not as a finished product, but as a platform for continuous innovation. Current optimization efforts are focused on improving manganese removal –a challenge for many Colorado utilities. The plant’s flexible design ensures it can adapt to future water quality concerns and regulatory requirements.

We’re proud to have an innovative, flexible, and cost-effective facility that will take us into the next century. It’s proof that even small to mid-size districts can build big when it comes to protecting public health and delivering great-tasting water.

In the world of water treatment, size does not always dictate capability. Roxborough Water & Sanitation District may serve fewer than 15,000 residents, but its investment in advanced treatment, digital tools, and infrastructure renewal places it among the leaders in Colorado’s water sector.

By combining Actiflo pretreatment, dual-media filtration, UV disinfection, and chloramination, RWSD has built a process train that maximizes efficiency while safeguarding water quality. Paired with system-wide upgrades – from brandnew pump stations to trenchless sewer rehabilitation – the district has created a truly comprehensive approach to water and wastewater service.

Ultimately, the Larry D. Moore Water Treatment Plant is more than a facility; it is a symbol of RWSD’s philosophy: that small to mid-size utilities can and should think big when it comes to protecting public health, serving their customers, and preparing for the future.

Mike Marcum has been an integral part of Roxborough Water & Sanitation District operations since 2001.

Starting as an entrylevel operator, he soon worked his way up to become the Operator of Responsible Charge and eventually the Director of Operations. In October 2023, he was promoted to the position of General Manager.

During his tenure, Mike played an operational role in the development of the Larry D. Moore Water Treatment Plant and the Wastewater Regionalization Project. His academic achievements include graduating with honors through Phi Theta Kappa with an Associate Degree in Water Quality Management. He holds Class A water and wastewater certifications, as well as Class 4 collections and distribution certifications. Additionally, he successfully completed multiple years of the Special District Associations’ Leadership Program.

When he’s not working, Mike enjoys spending time with his wife, Melisa, and their two children, Skylar and Ian. Together, they like to travel and go on camping expeditions with their two rescue dogs, Monster and Yogi.

y experience with RMWEA spans many years. I first joined as a member of the Government Affairs Committee, then the Water For People Committee, and finally the Innovative Water Technology (IWT) Committee, where I now serve as a steering committee member and treasurer. Throughout this journey, I have met incredible people, developed lasting friendships, and shared many laughs. Serving on an RMWEA committee offers

• Lagoon & Digester Cleaning

• Transportation & Land Application

• Biosolids Management

•

excellent opportunities to learn new skills, take on leadership roles, expand your network and knowledge, and have a lot of fun.

What I love most about being on the IWT Committee is the chance to share knowledge and educate our peers about new and exciting developments in the water sector. We have a fantastic team that collaborates to create insightful content and conversations through topical seminars and tours. My favorite memories have been at our in-person events, most notably Shark Tank at the Rocky Mountain Water Conference.

Want to share your experience volunteering with RMWEA and RMSAWWA? Scan the QR code and send us your testimonial today! You’ll be featured in our newsletter and Rocky Mountain Water!

What I love most about being on the IWT Committee is the chance to share knowledge and educate our peers about new and exciting developments in the water sector.

Biochemical Oxygen Demand

Total Suspended Solids

Ammonia-Nitrogen

Nitrate and Nitrite Nitrogen

Kjeldahl-Nitrogen (TKN)

E-Coli, Total Coliform

Metals by ICP-MS and ICP-OES

SOC/VOC

Biosolids-503 Regs/Fecal Coliform

NPDES Requirements

DMRQA Study Participant

Organic Contaminants (SOC/VOC)

DBP (THM/HAA, TOC/ALK)

Inorganic Contaminants (Metals)

Nitrate and Nitrite Nitrogen

Copper and Lead

Total Coliform

Fluoride

Metals by ICP-MS and ICP-OES

Compliance Auto-Ship Bottle Program

VISITONEOFOURCONVENIENTLOCATIONS FOR MODERNDAYTECHNOLOGYAND OLD-FASHIONED SERVICE!

Commerce Cit y Laboratory 10411 Heinz Way Commerce City, CO 80640

Lakewood S ervice Cent er

610 Garrison St. Unit E Lakewood, CO 80215 303.659.2313 www.coloradolab.com info@coloradolab.com

Contact us

Drew Howland, Public Affairs Coordinator, South Adams County Water & Sanitation District

In 2018, South Adams County Water and Sanitation District (SACWSD) discovered per- and polyfluoroalkyl substances (PFAS) in its alluvial groundwater wells.

The District responded by isolating the most contaminated wells and purchasing more treated drinking water from Denver Water to blend supplies. This approach provided time to evaluate treatment options while continuing to serve customers.

SACWSD’s main treatment process for the removal of volatile organic compounds (VOC), granular activated carbon (GAC), is another important part of the response to managing elevated PFAS levels in the raw water supply. GAC adsorbs PFAS molecules

onto porous carbon media and has been effective at reducing long-chain PFAS compounds such as PFOA and PFOS. With this process, the District has been able to maintain non-detect levels of PFAS in its finished water in the short term.

The District operates 18 contactors, each containing 20,000 pounds of GAC, for VOC removal. In order to manage the elevated PFAS levels, SACWSD began running the 18 contactors in a lead-lag configuration. As a result, this limited SACWSD’s ability to fully utilize the 13.5 million gallons per day capacity of the facility by 50%. To maintain removal efficiency, GAC beds have had to be changed out much more frequently than in the past. This accelerated maintenance schedule, as well as limited treatment capacity, is expensive and not a cost-effective treatment solution.

SACWSD also invested in its Water Quality Laboratory, becoming the first utility in Colorado with in-house PFAS testing capabilities. This step has given the District important advantages:

• Faster Response Times: Results are available more quickly than waiting for outside laboratory analyses.

• Cost Efficiency: In-house testing reduces reliance on third-party services.

• Data-Driven Decisions: Staff can track PFAS trends across wells, optimize treatment performance, and make informed operational adjustments.

Recognizing the limits of GAC and thirdparty water purchases, SACWSD broke

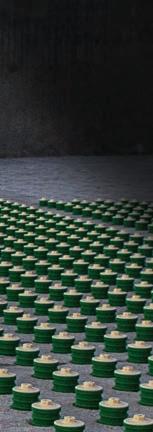

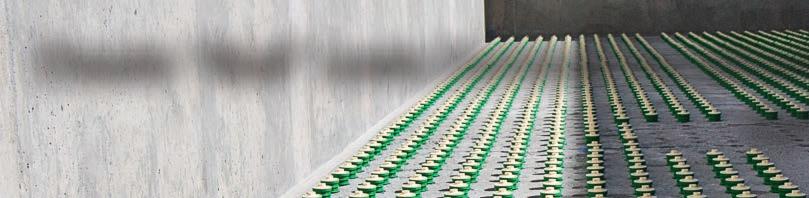

ground in 2024 on the Klein Enhancement Project, an $80 million ion exchange treatment facility that will be the largest of its kind in the Rocky Mountain region. The facility is designed and being constructed to remove PFAS from its treated drinking water and to meet adopted PFAS regulations for PFOA and PFOS, and to ensure a continued reliable supply of highquality drinking water to serve the District’s existing and growing service area.

Design began in 2021 with Brown and Caldwell, followed by community

engagement, permitting, and funding. PCL Construction was selected in 2023 as the construction manager at risk, and completion is expected in late 2026. Nearly $61 million in federal funding from the Bipartisan Infrastructure Law will cover most of the cost, with the remainder financed through a low-interest state drinking water revolving fund loan via the Colorado Water Resources and Power Development Authority.

“The District is committed to continuing to provide our residents with drinking

water that exceeds state and federal drinking water regulations,” said District Manager Abel Moreno. “Commerce City is a disadvantaged community that has been heavily impacted by a number of environmental challenges through no fault of its residents, and the financial burden of this project should not fall on our ratepayers. Places like Commerce City are exactly the kinds of communities that should benefit from that funding identified for emerging contaminants.”

The Klein Enhancement Project has remained on track through strategic construction practices. The project team implemented early work packages and earthwork optimization, including early procurement of materials and an optimized site plan, to maintain schedule and control costs.

In addition, the project has successfully navigated federal funding requirements, including compliance with Build America, Buy America (BABA) provisions and DavisBacon prevailing wage standards. Careful planning and coordination ensured these requirements were met without delaying construction progress.

The District is proud of the steps it has taken to plan ahead, engage the community, and adapt to new regulations while continuing to provide high-quality drinking water.

Drew Howland is the Public Affairs Coordinator at South Adams County Water & Sanitation District, where he leads community outreach, digital communications, and public relations efforts. He is also actively involved with the RMSAWWA Communications Committee. You can reach him at dhowland@sacwsd.org

Enhanced Bio-P Activity Biomass minimizes demand for chemical phosphorus precipitation

Small Tankage Reliably improved settling performance due to densified biomass significantly reduces overall system volume

Post-denite Capability Typically up to 50% of the nitrogen removal occurs in the sludge blanket of the settling compartments and therefore this post-denitrification approach is highly suitable fo r low BOD/N ratios in the feed

Low Fine Particles Sequenced settling of the sludge blanket forms a floc-filter which reliably removes fines, producing an effluent low in suspended solids suitable for water reuse

Simple O & M No mechanical equipment within the aeration tank and the settlers while blower air is utilized for RAS-recycle and mixing resulting in low maintenance requirements

The BIOCOS® activated sludge process is operated at a constant water level during the whole process cycle, and therefore represents a hybrid technology (Biological Combined System) comprising features of continuous flow and SBR systems.

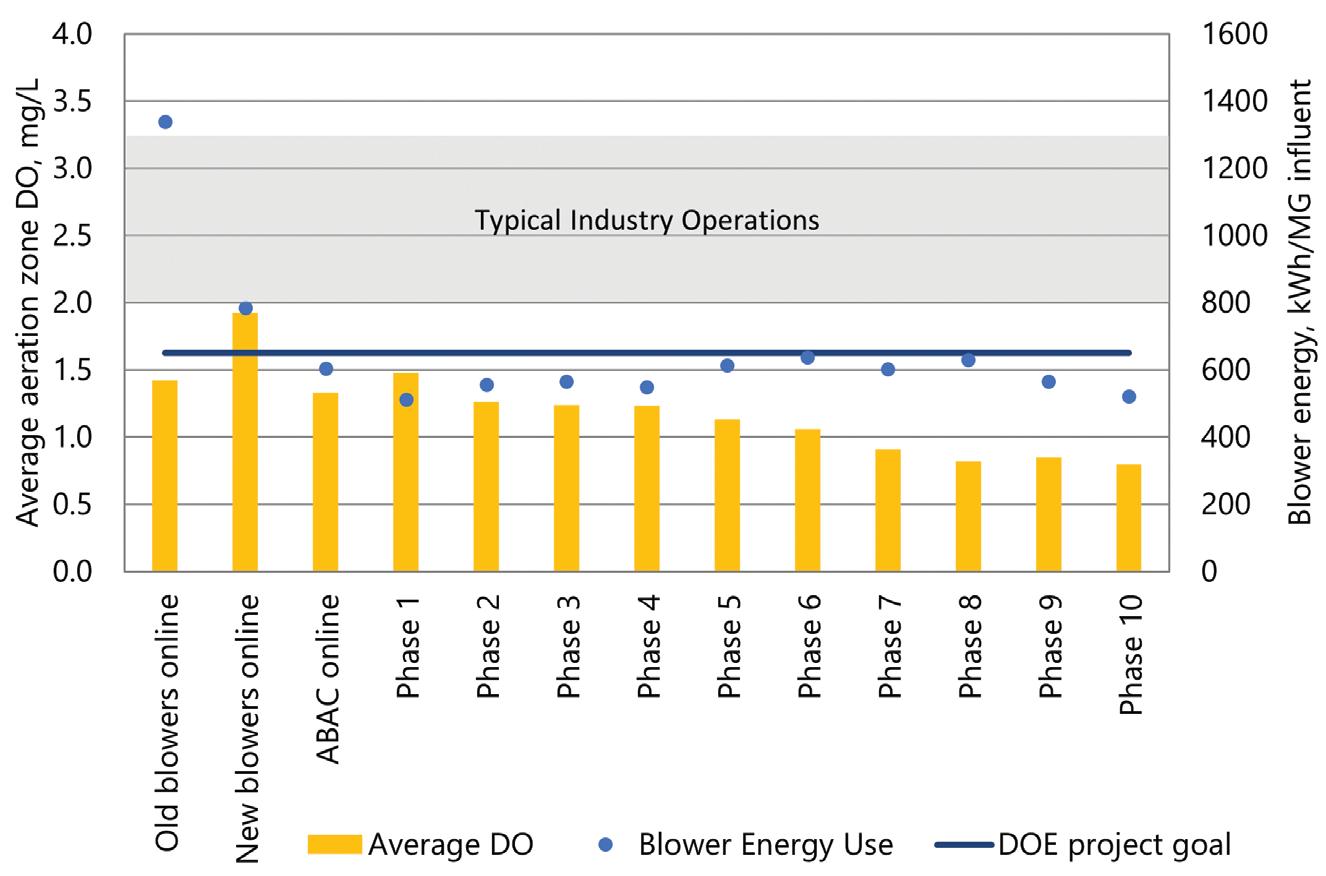

Low Space Demand Common-wall construction allows for a compact footprint with the reduced need for external piping runs and recycle pumpstation