Material Application Guide ELECTRICAL 2023/2024

Since 1996, Juxing has been the preferred partner to electrical installation equipment manufacturers in the supply of silver electrical contact and copper components. With our national recognized R&D team, we had helped our clients to better their products in pricing competitiveness and quality by utilizing the fruits of our R&D efforts to deliver contacts that are produced using the latest technology.

Contact Rivet

Composite Strip

Powder Metallurgy

Copper Assembly

1 Introduction

R&D and Manufacture

Relay

Electrical contacts are used in a wide variety of electrical relays that cater speci cally to different industrial and consumer products.

Household Relay

Household Appliances

Industrial Relay

Industrial Automation

Automobile Relay

Automobile

Power Relay

Smart Meter

HVDC Relay

EV Charging Station

2

Material Applications

Applications

Switches

Electrical switches are primarily used in buidlings as well as electrical tools in the form of contact rivet available in solid, bi-metal and tri-metal variation.

Wall Switch & Extension Socket

Building and Construction Electrical Drill & Tool

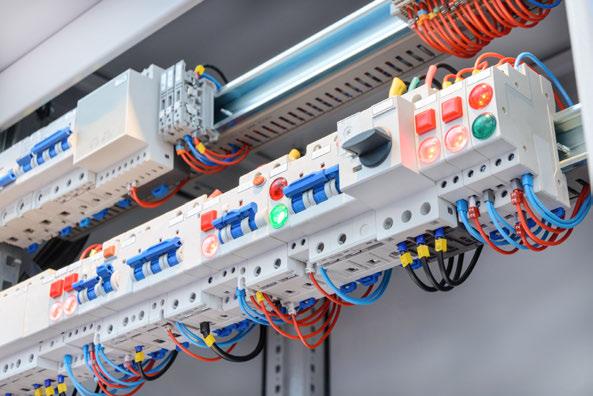

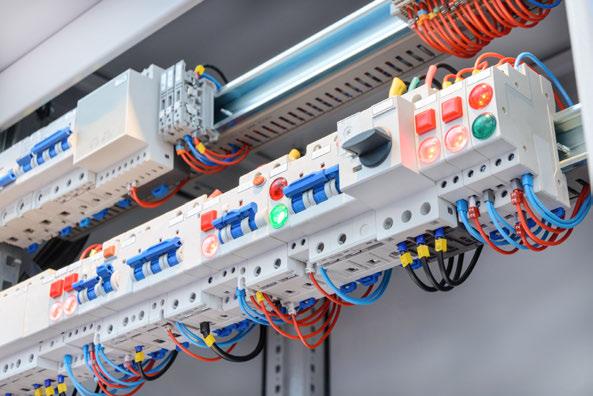

Breakers & Contactors

Circuit breakers and contactors utilize electrical contacts in the form of contact tips in different silver alloy composition.

3

Material Applications

Electrical Contactor Circuit Breaker Industrial Automation Electrical Distribution System Applications

Contact Materials

With over 50 different electrical contact material, the application of speci c material would be dependent on the electrical requirements and it’s nal product application.

Technical support encompass with over 20 years of experience are available to assist our clients on the material suitable to achieve enhanced product performance, cost reduction and trouble-shooting. Detail computerized analysis are also available on request.

4

Material Characteristics

Contact Materials

Silver Tin Oxide

Environmental friendly low voltage contact material with excellent welding resistance and arc erosion.

For: Relays, Contactors and

AgSnO2

Silver Tin Oxide

Indium Oxide

High hardness with good thermal stability and provides good resistance to fusion welding and arc erosion.

AgSnO2In2O3

For: Automotive Relays, General Purpose Relay, HVDC relays and Contactors.

Silver Nickel

Good anti-welding performance and arc erosion resistance under small to mid current ow. Excellent processing performance with stable contact resistance.

For: Relays, Switches, small to mid sized AC Contactors.

AgNi

Material Characteristics

5

Contact Materials

Silver Cadmium Oxide

Low contact resistance, high resistance to fusion welding and arc erosion.

Fine-Grain Silver

Good conductivity and low contact resistance. Improve material hardness, strength, welding resistance and arc erosion.

AgCdO

Silver Zinc Oxide

Environmental friendly material with short arcing time, strong impact resistance and good breaking performance. Possesses ideal arc erosion resistance under high breaking current.

Material Characteristics

6

For: Relays, Contactors and Switches

FAg

For: Micro Switches

AgZnO

For: Relays, Contactors & Circuit Breakers.

Contact Materials

Silver Graphite

Low contact resistance, excellent anti-welding performance, small temperture increase and self lubricating when used as sliding contact.

AgC

Silver Tungsten

Good electrical and thermal performance, high hardness, arc erosion resistance, strong welding resistance and less material transfer.

Silver Tungsten Carbide

Silver Tungsten Carbide Graphite*

Improve oxidation resistance of electrical contacts, stabilize electrical properties of electrical contact during current ow. *Good anti-welding and lubrication. Low contact resistance and hardness.

AgWC

Material Characteristics

7

For: Circuit Breakers and Heavy Industrial Relays

AgW

For: Circuit Breakers and Heavy Industrial Relays

For: Circuit Breakers and Heavy Industrial Relays

AgWCc

With a wide range of electrical contact in different silver alloy composition, it is crucial that the correct electrical contact material is being deploy correctly to insure the longevity and quality of the electrical equipment.

Listed below is a general recommendation on the electrical material to be used under different AC loads. The list is non-exhaustive and new electrical contact material can be developed on receipt on the full electrical requirement.

8

Application Guidelines

Material Guidelines

Light Load Switches and Relays for Electronics Switches and Relays for Automotive Light DC Load 1 - 250V 0.1 - 10 Amp Medium - High DC Load 6 - 48 V 10 - 150 Amp Medium AC Load 110 - 600 V 10 - 100 Amp High AC Load 220 - 1000 V 100 - 1000 Amp Ag, FAg AgNi (0.15) AgNi (10-30) Ag, FAg AgNi (0.15) AgNi (10-30) Material Guidelines Relays and Contactors for HVAC Control AgCdO (10-15) AgCdO (10-15) AgZnO (6-10) AgNi (10-30) AgSnO2 AgSnO2In2O3 (2-14) AgNi (10-30) Consumer Products & Wired Appliance Control Ag, FAg AgNi (0.15) AgNi (10-30) AgCdO (10-15) AgZnO (6-10) AgNi (10-30) AgSnO2 AgSnO2In2O3 (2-14) AgSnO2 AgSnO2In2O3 (2-14) Relays and Contactors for AC Switch and Industrial Control AgSnO2 AgSnO2In2O3 (2-14) AgNi (10-30) AgSnO2 AgSnO2In2O3 (2-14) AgZnO (6-10) Ag, FAg AgNi (0.15) AgNi (10-30) AgCdO (10-15) Domestic and Industrial MCCB and MCB AgC (3-5) AgNi (1--30) AgC (3-5) AgC (3-5) AgSnO2 AgSnO2In2O3 (2-14) AgNi (10-30) Application Guidelines 9

@juxingtec ©2023 Juxing Electrical Contact Technology Pte Ltd. All rights reserved. 124 Gelyang Lorong 23 #06-01 Arcsphere Singapore 388405 juxingtec.com +65-6746-9339 contact@juxingtec.com Juxing Electrical Contact Technology Pte Ltd Electrical Material Application Guide 2023/2024