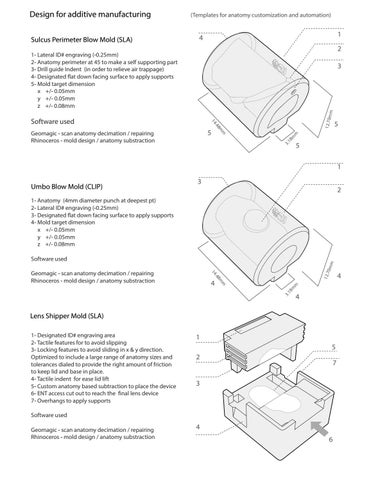

Design for additive manufacturing Sulcus Perimeter Blow Mold (SLA)

(Templates for anatomy customization and automation)

1

4

2

1- Lateral ID# engraving (-0.25mm) 2- Anatomy perimeter at 45 to make a self supporting part 3- Drill guide Indent (in order to relieve air trappage) 4- Designated flat down facing surface to apply supports 5- Mold target dimension x +/- 0.05mm y +/- 0.05mm z +/- 0.08mm

5

3.1

8m

m

m m

5

Geomagic - scan anatomy decimation / repairing Rhinoceros - mold design / anatomy substraction

.48

14

Software used

12.70 mm

3

5 1

Umbo Blow Mold (CLIP)

3

2

1- Anatomy (4mm diameter punch at deepest pt) 2- Lateral ID# engraving (-0.25mm) 3- Designated flat down facing surface to apply supports 4- Mold target dimension x +/- 0.05mm y +/- 0.05mm z +/- 0.08mm

3.1

8m

m

m

4

m

.48

12.7

14

Geomagic - scan anatomy decimation / repairing Rhinoceros - mold design / anatomy substraction

0mm

Software used

4

Lens Shipper Mold (SLA) 1- Designated ID# engraving area 2- Tactile features for to avoid slipping 3- Locking features to avoid sliding in x & y direction. Optimized to include a large range of anatomy sizes and tolerances dialed to provide the right amount of friction to keep lid and base in place. 4- Tactile indent for ease lid lift 5- Custom anatomy based subtraction to place the device 6- ENT access cut out to reach the final lens device 7- Overhangs to apply supports

1 5 2

7

3

Software used Geomagic - scan anatomy decimation / repairing Rhinoceros - mold design / anatomy substraction

4 6

4