Medical Applications Additive manufacturing has changed the way we typically see medical manufacturing. The ability to create parts, fixtures, and concepts in a matter of hours has changed the time scale of production. This enables companies to take a concept into production at a faster pace. An increasing number of medical device manufacturers have implemented 3d printing and other digital processes into their manufacturing

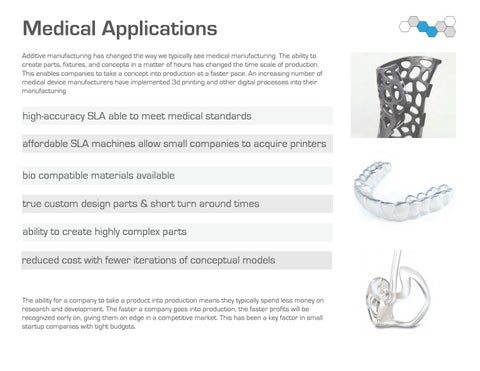

high-accuracy SLA able to meet medical standards affordable SLA machines allow small companies to acquire printers bio compatible materials available true custom design parts & short turn around times ability to create highly complex parts reduced cost with fewer iterations of conceptual models

The ability for a company to take a product into production means they typically spend less money on research and development. The faster a company goes into production, the faster profits will be recognized early on, giving them an edge in a competitive market. This has been a key factor in small startup companies with tight budgets.